Patents

Literature

349results about How to "Change quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

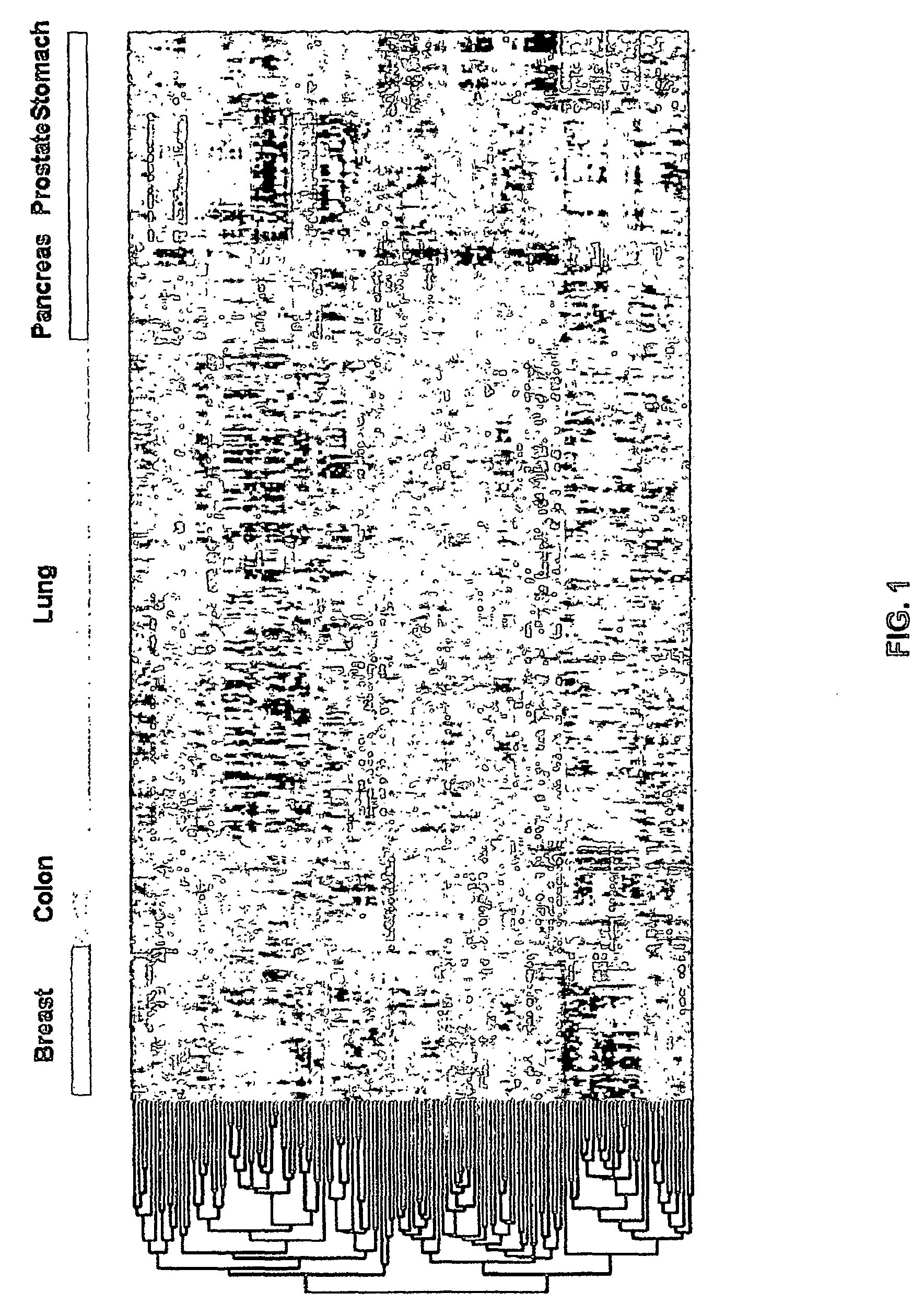

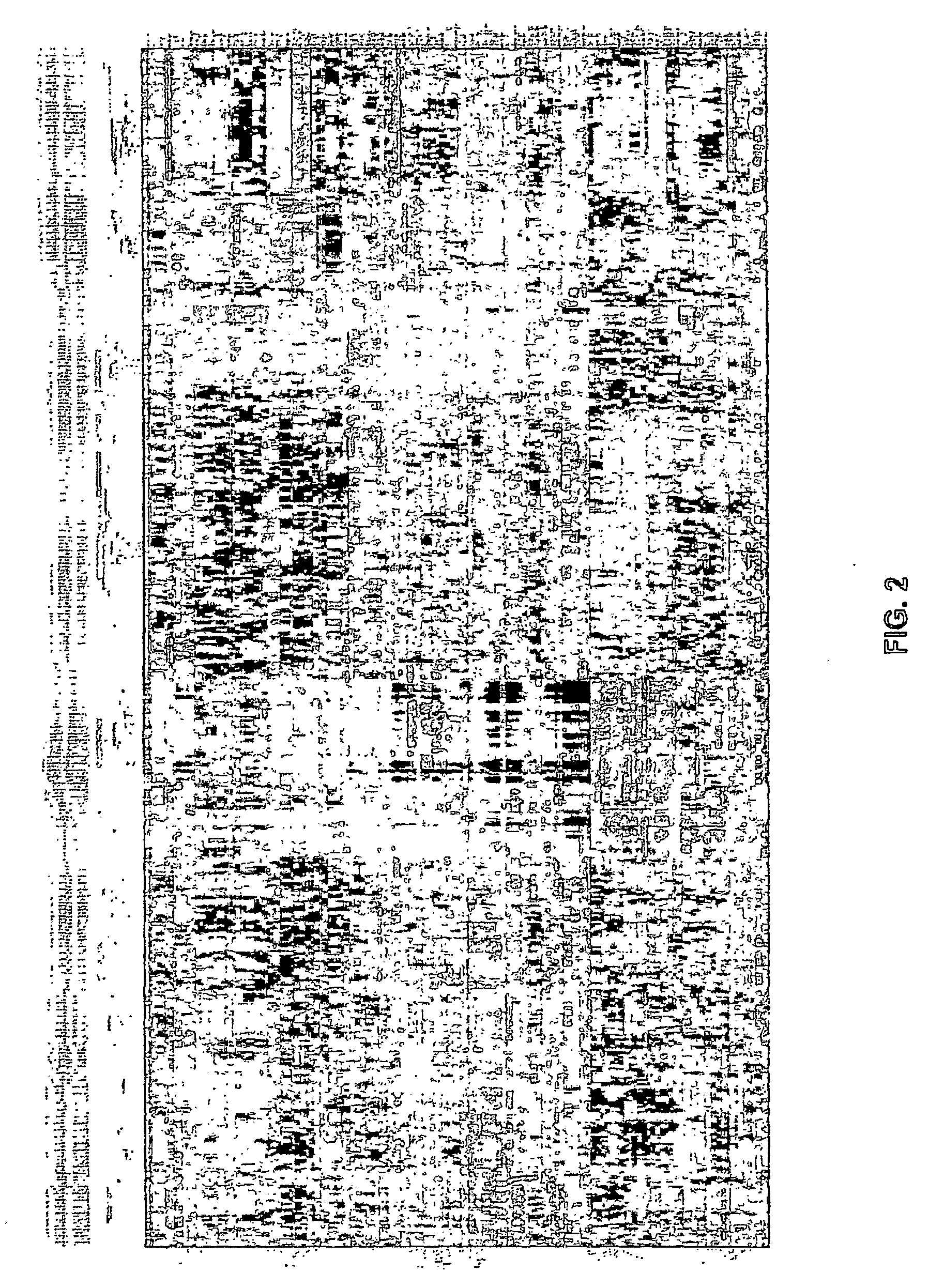

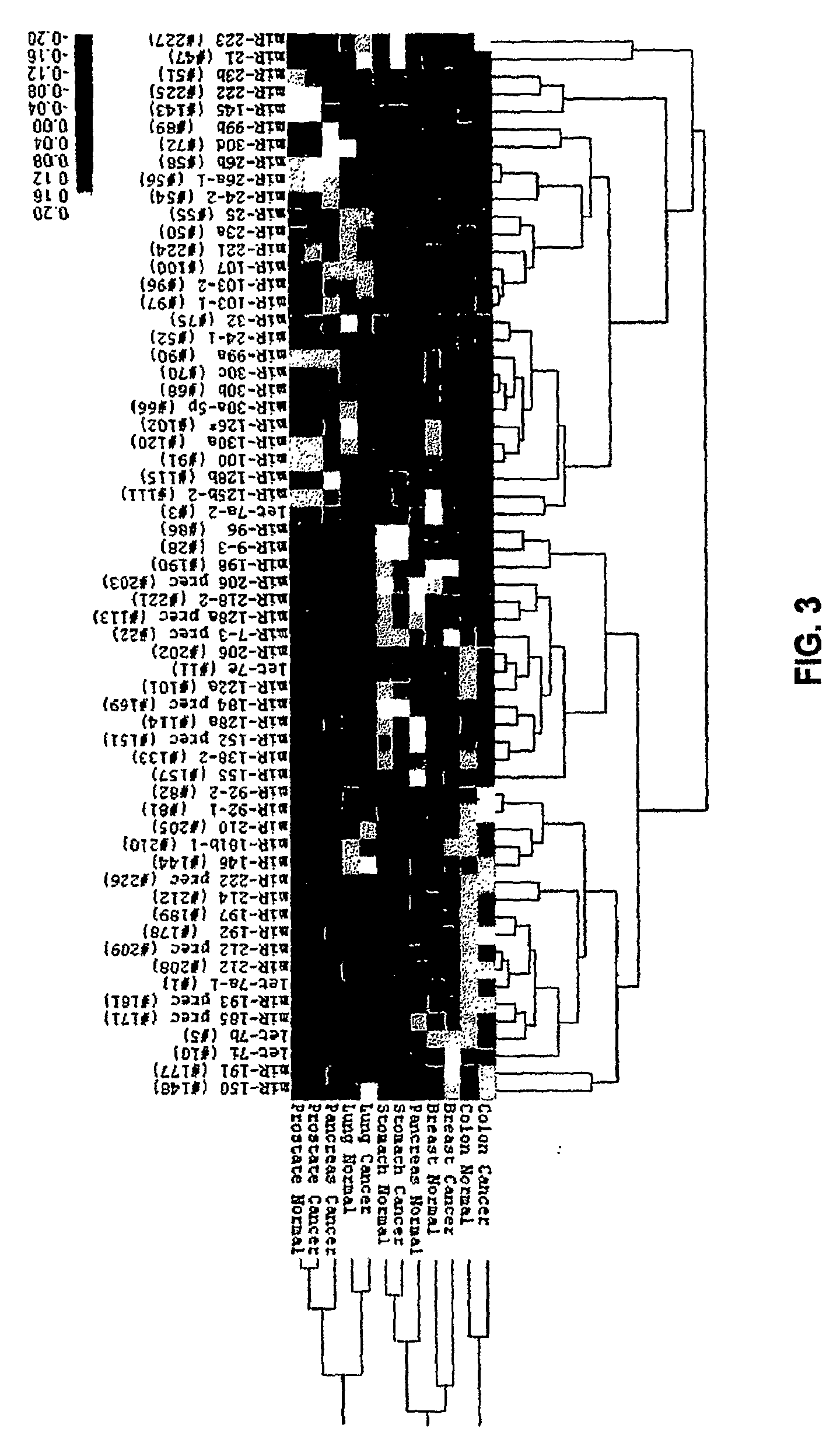

MicroRna-Based Methods and Compositions for the Diagnosis, Prognosis and Treatment of Solid Cancers

ActiveUS20080306006A1Inhibiting tumorigenesisPrevent proliferationOrganic active ingredientsPeptide/protein ingredientsMicroRNASolid cancer

The present invention provides novel methods and compositions for the diagnosis and treatment of solid cancers. The invention also provide methods of identifying inhibitors of tumorigenesis.

Owner:THE OHIO STATE UNIV RES FOUND

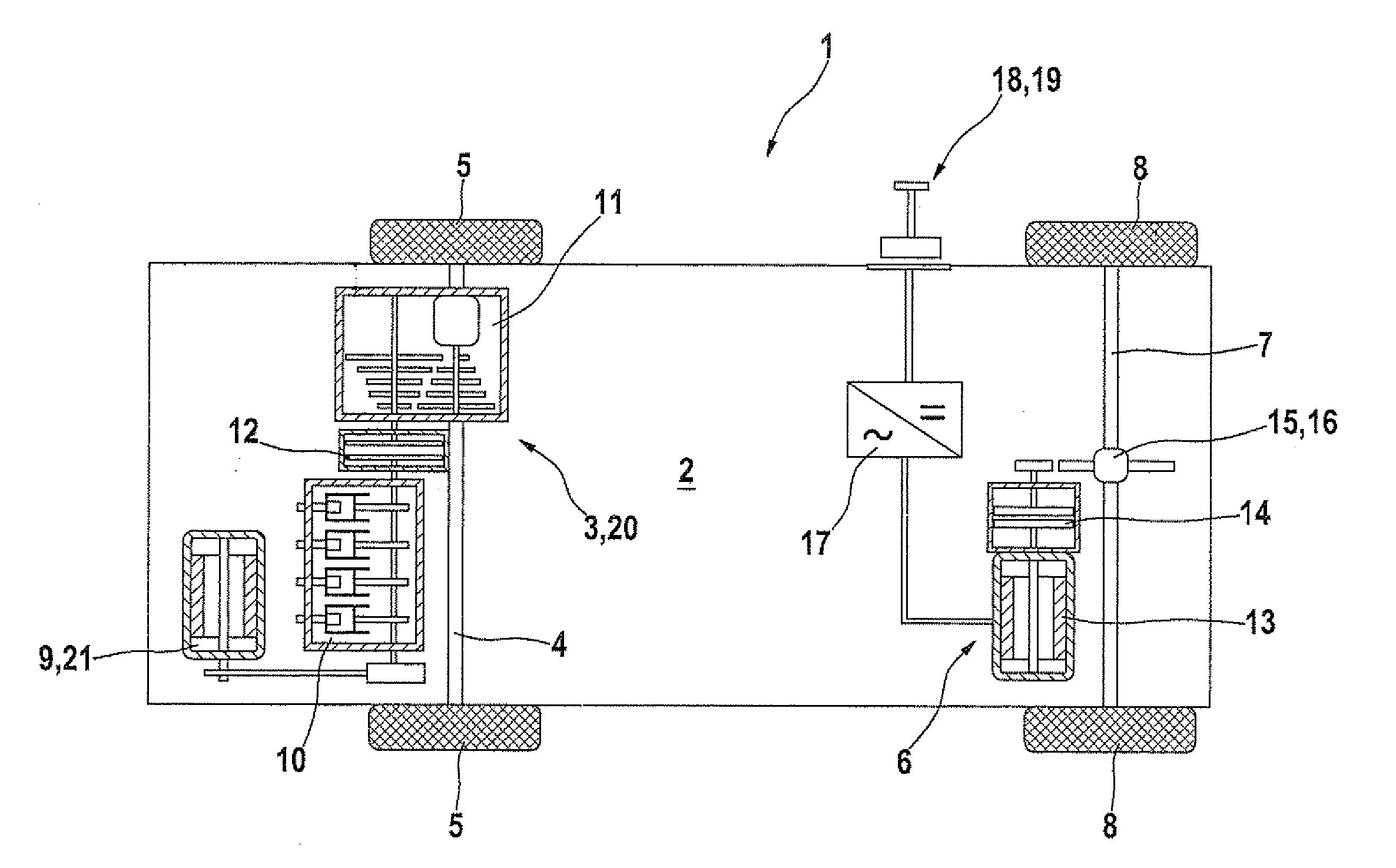

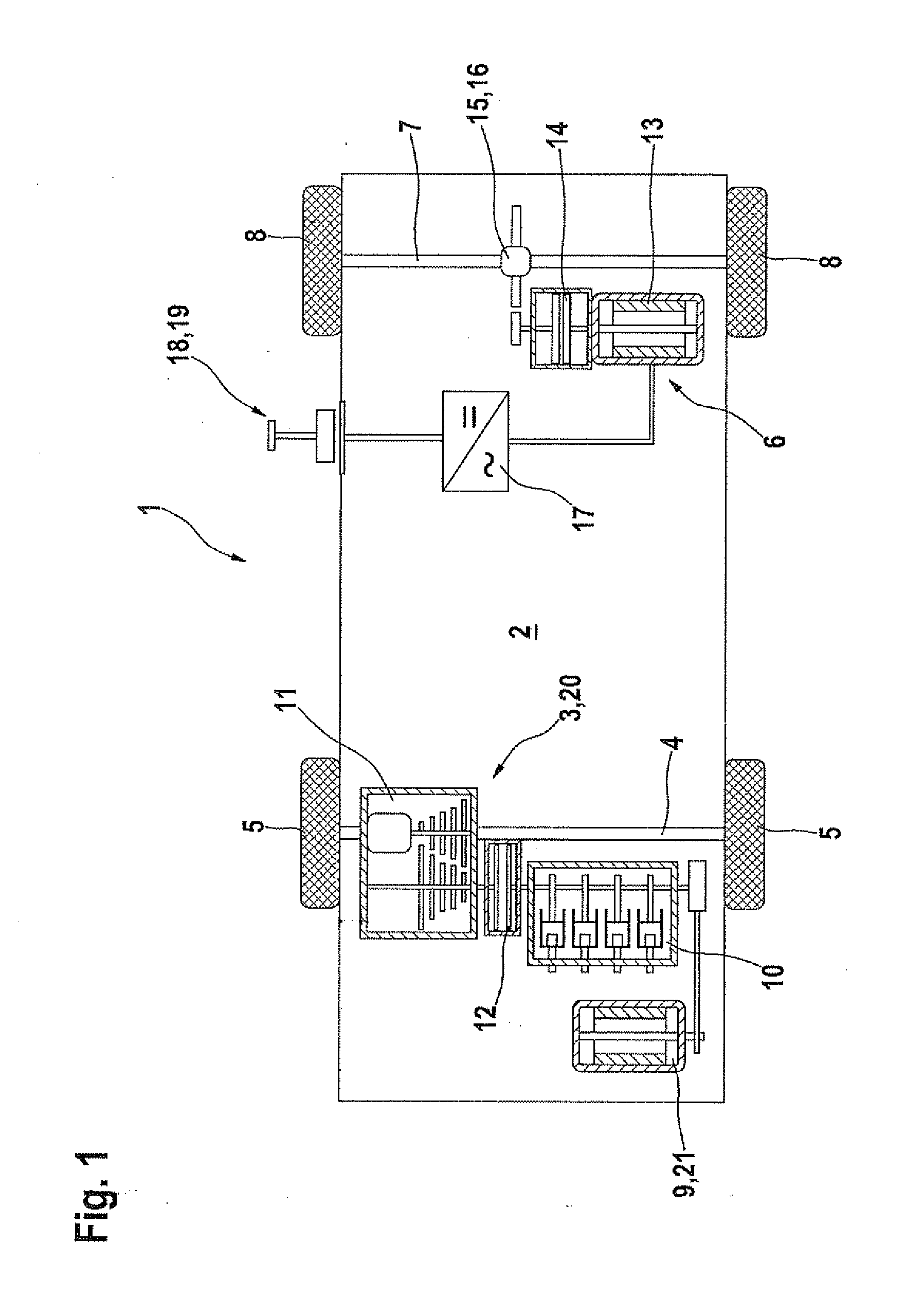

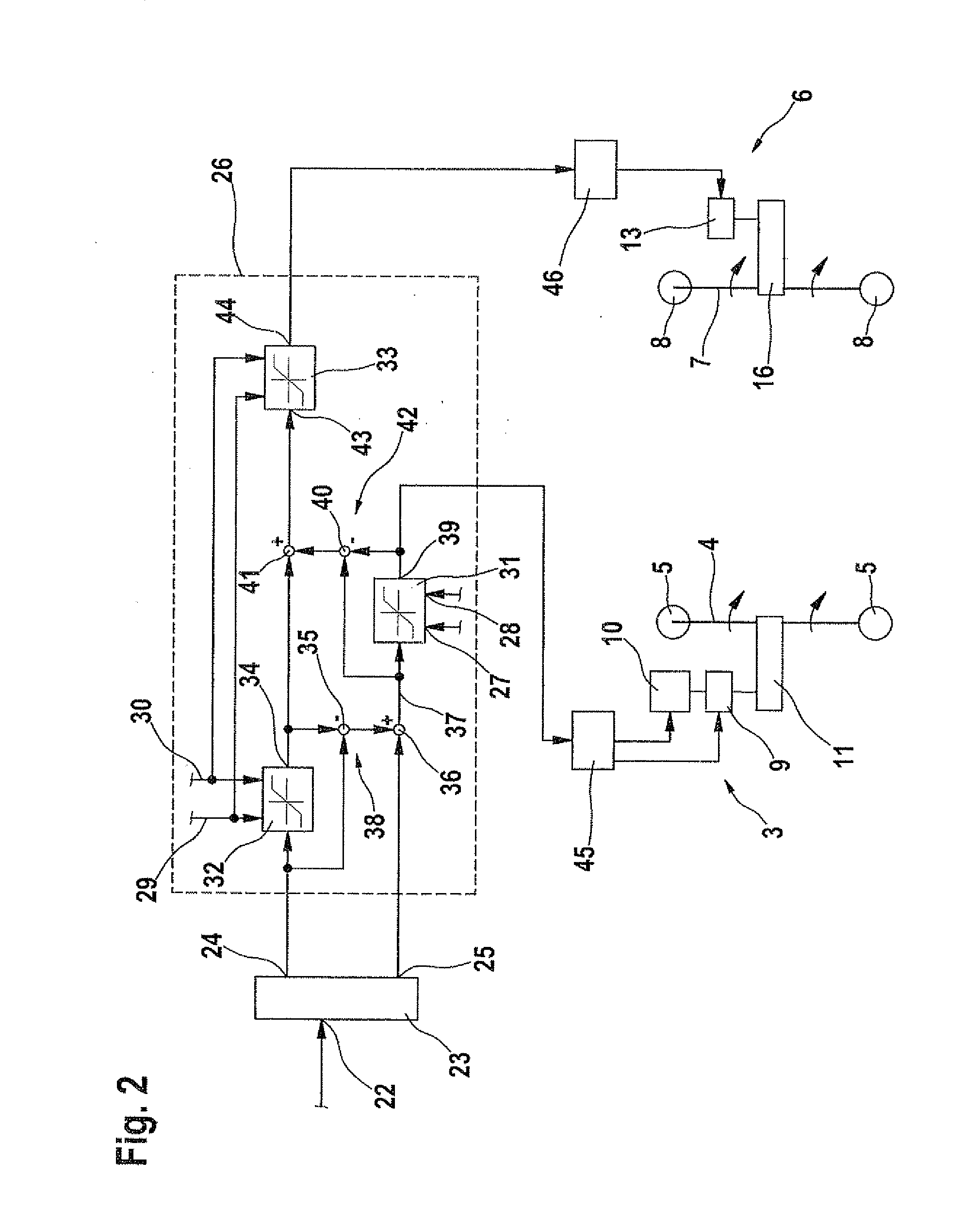

Method for operating a drive of a motor vehicle, as well as a drive device and an electronic control unit

InactiveUS20110276207A1Unsafe operating conditionChange quantityDigital data processing detailsElectric propulsion mountingLoop controlClosed loop

A method is described for operating a drive of a motor vehicle that has at least two shafts, each able to be driven by a shaft drive device, a total drive torque of the motor vehicle corresponding generally to the sum of the shaft torques applied to the shafts. In this context, it is provided that a quantity and / or a change in the quantity of one of the shaft torques is / are taken into account in the open-loop and / or closed-loop control of the remaining shaft torques. A drive device of a motor vehicle as well as an electronic control unit are also described.

Owner:ROBERT BOSCH GMBH

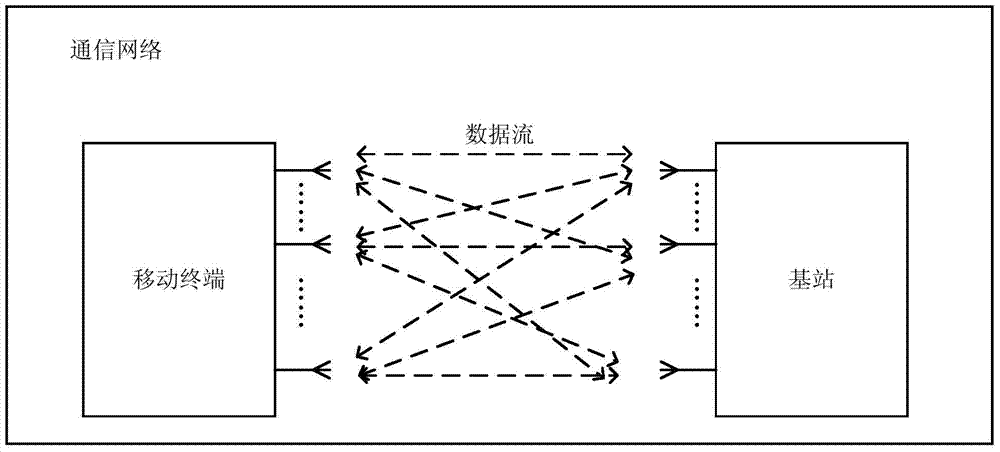

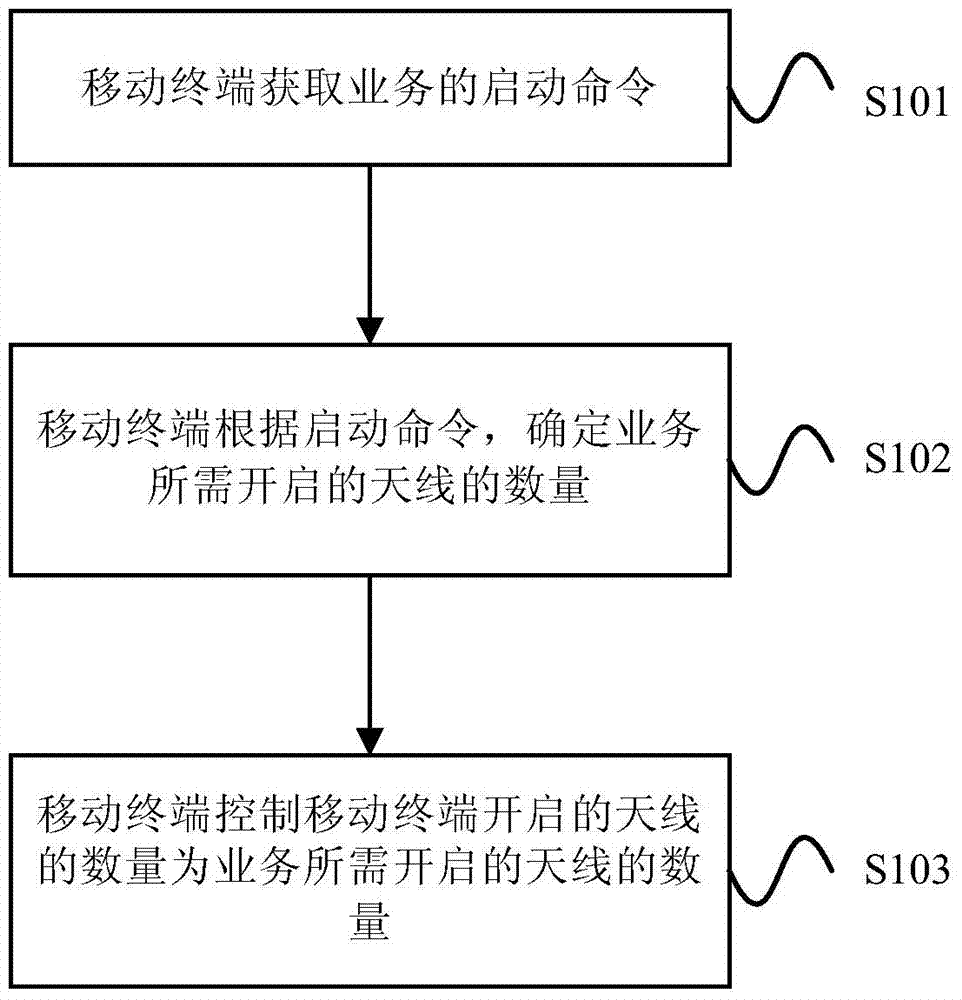

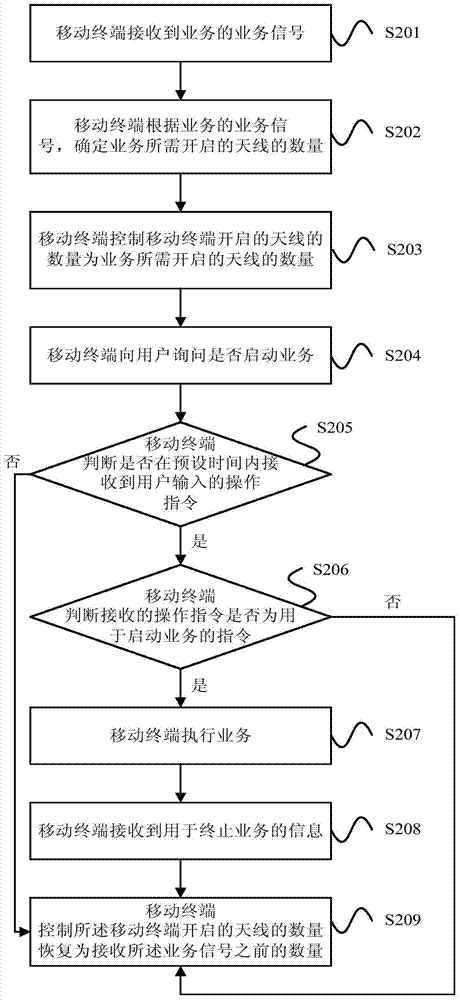

Mobile terminal and antenna control method thereof

ActiveCN104219377AAffect performanceChange quantityPower managementSpatial transmit diversityEmbedded systemEnergy loss

An embodiment of the invention provides a mobile terminal and an antenna control method thereof. The mobile terminal can determine the number of antennas to be started according to specific application scenes such as operations to be executed and perceptive information of the environment, so that the number of the antennas of the mobile terminal to be shut or started is reasonably controlled, energy loss is avoided and performance of the mobile terminal is affected.

Owner:HUAWEI TECH CO LTD

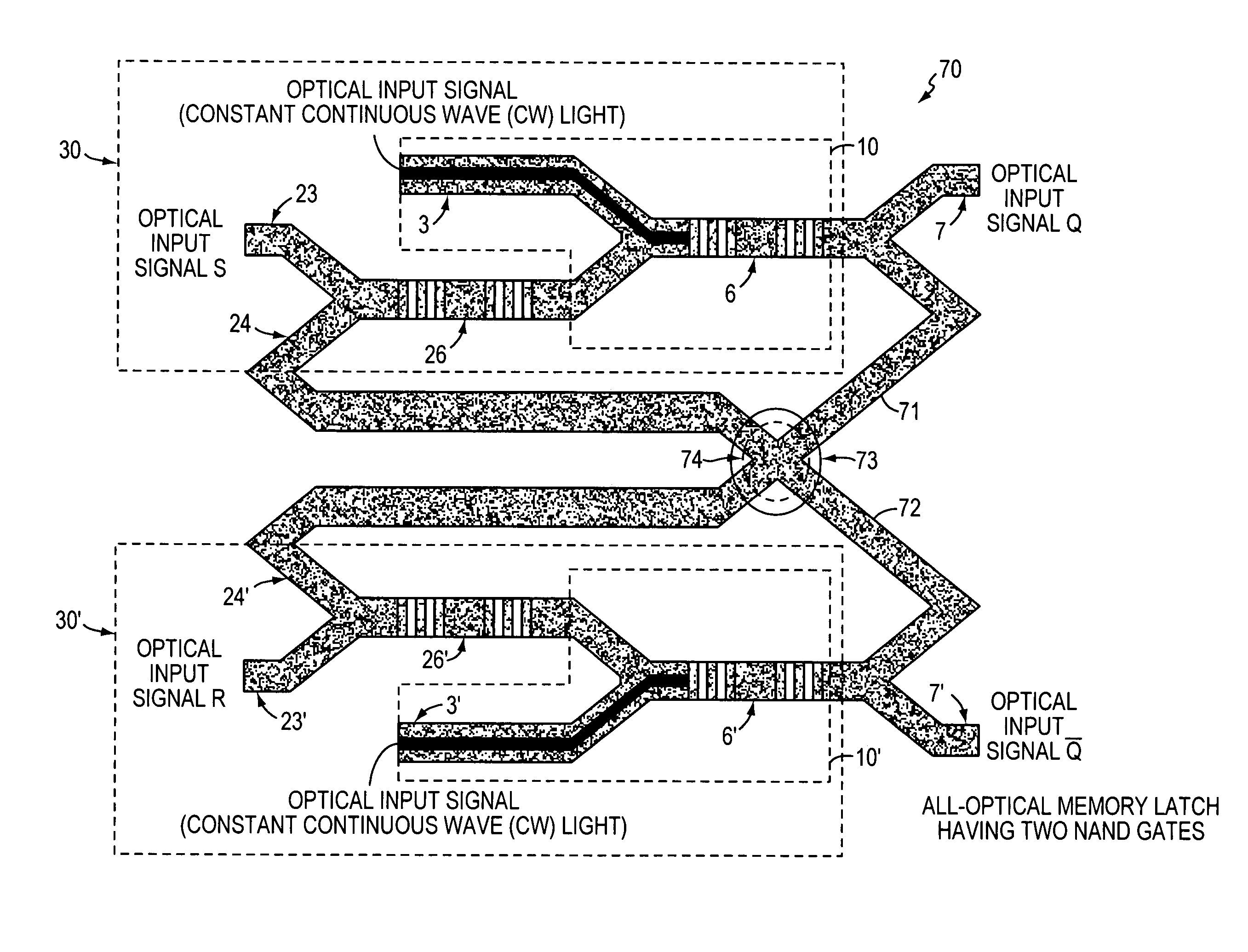

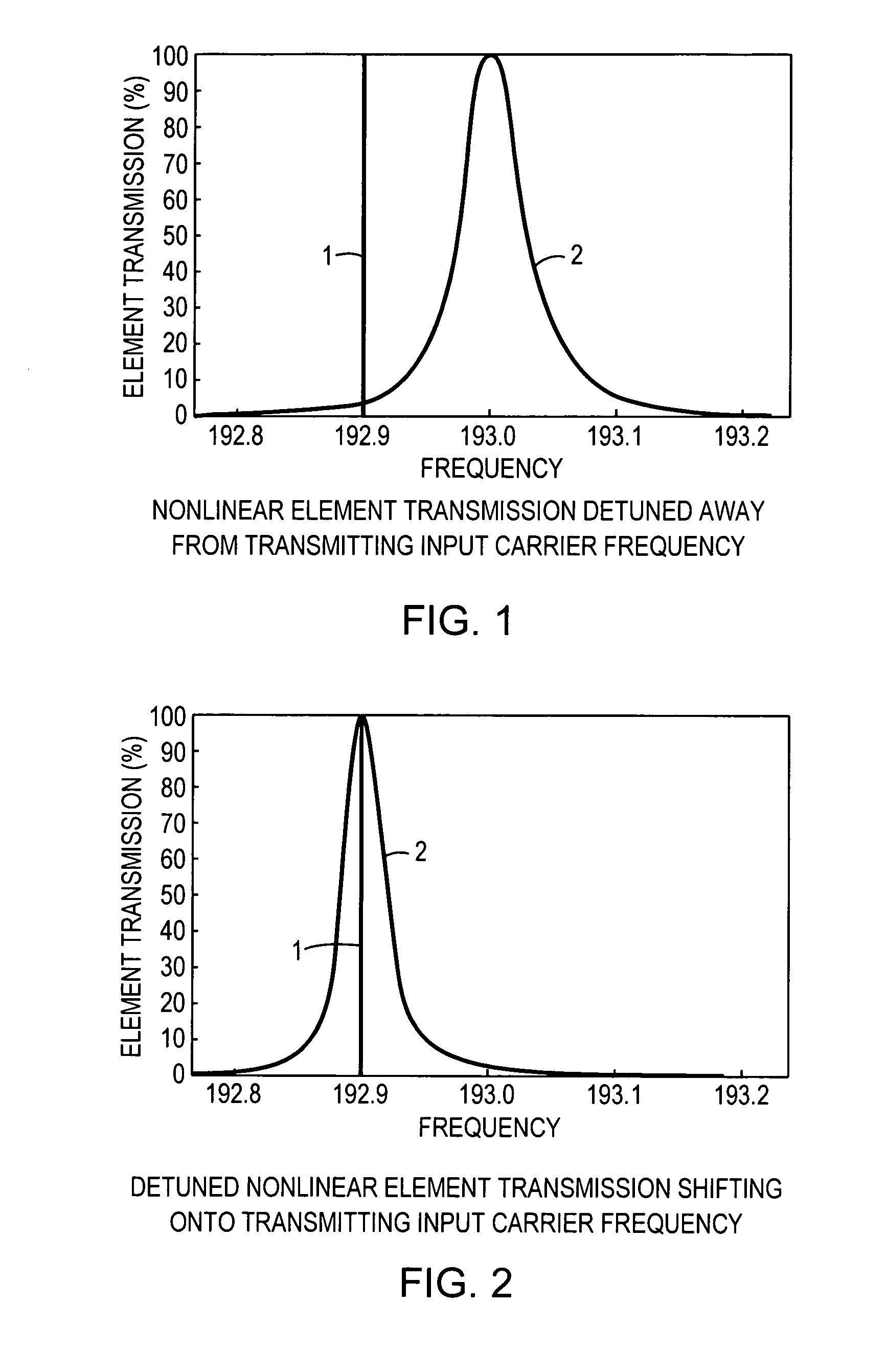

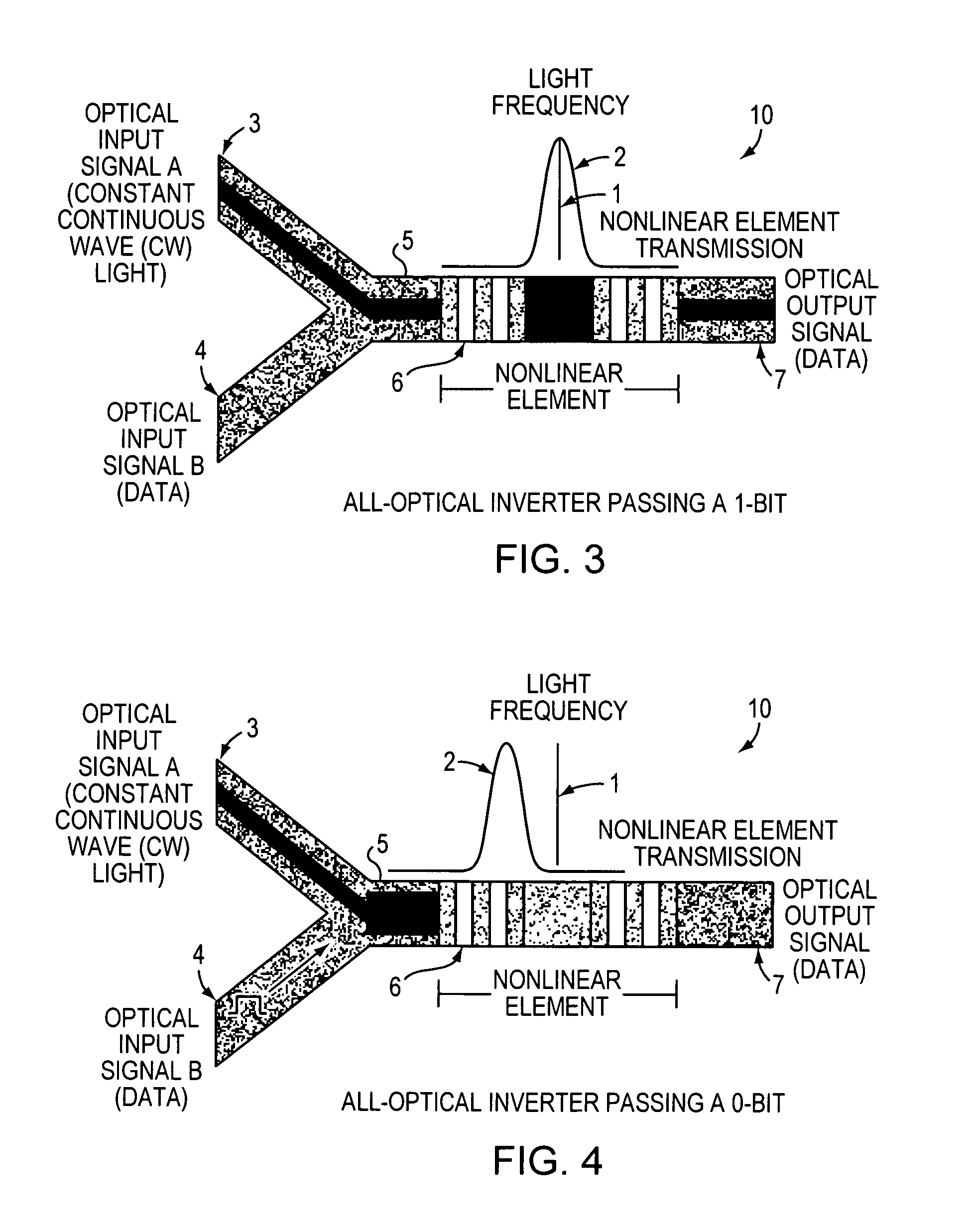

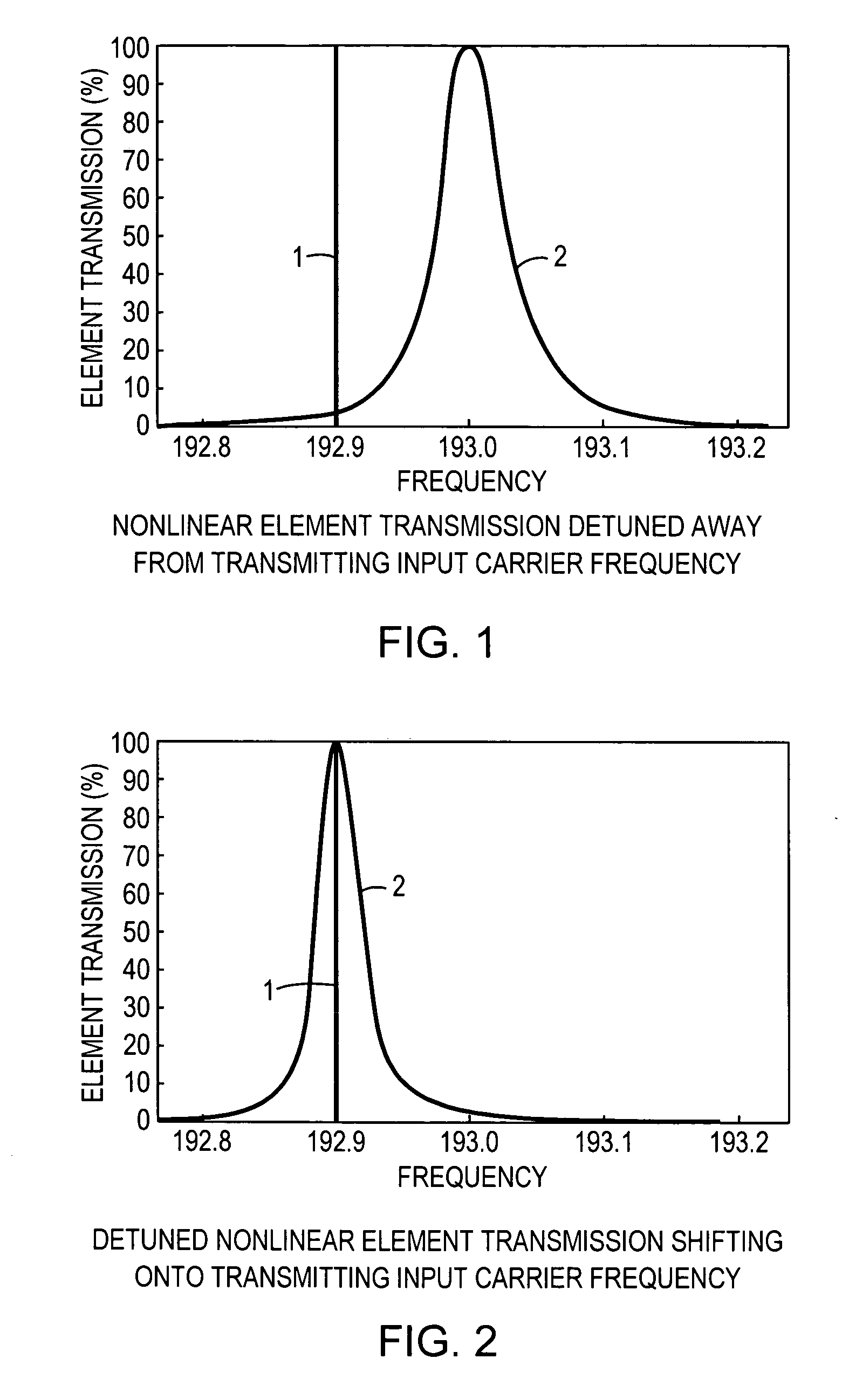

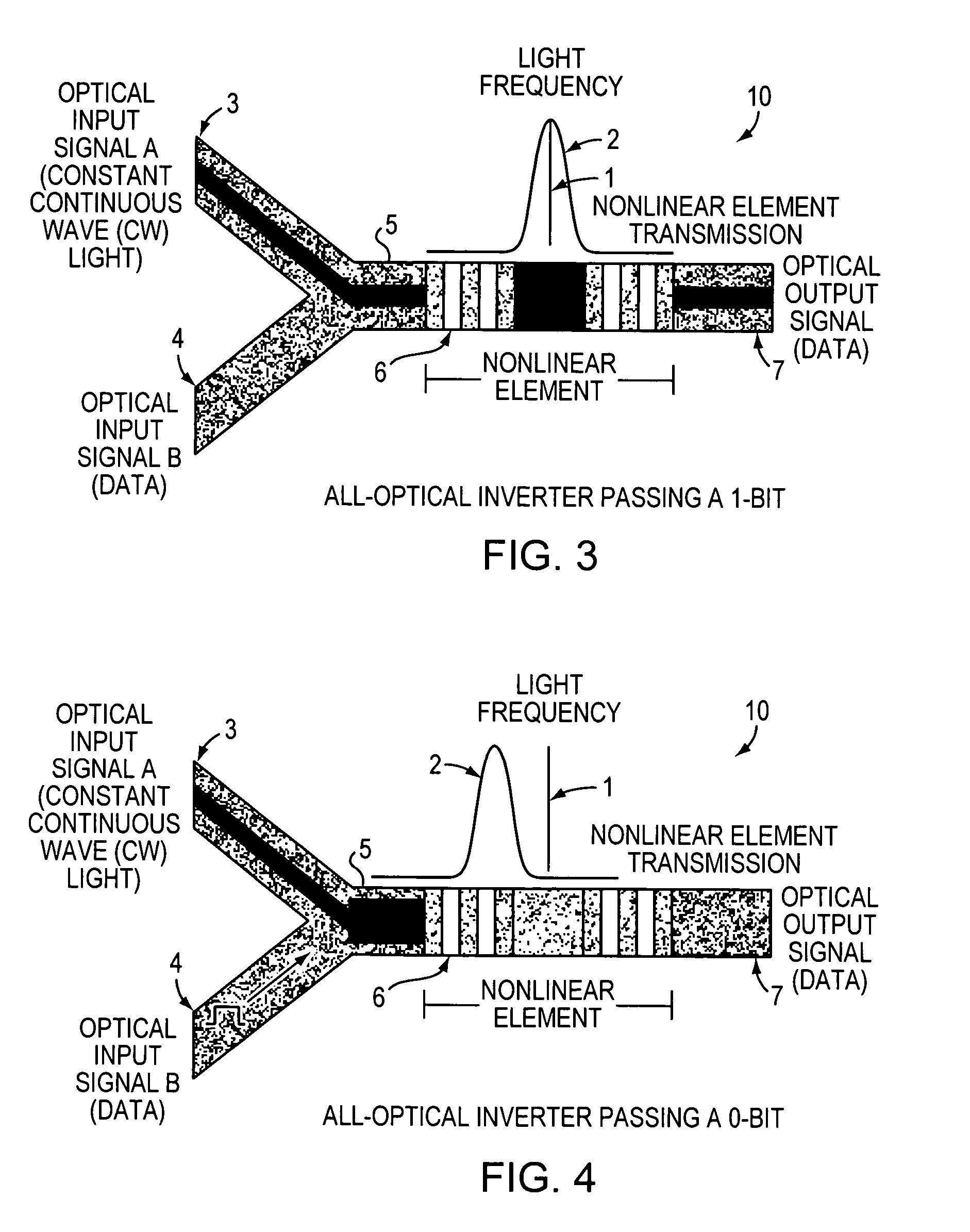

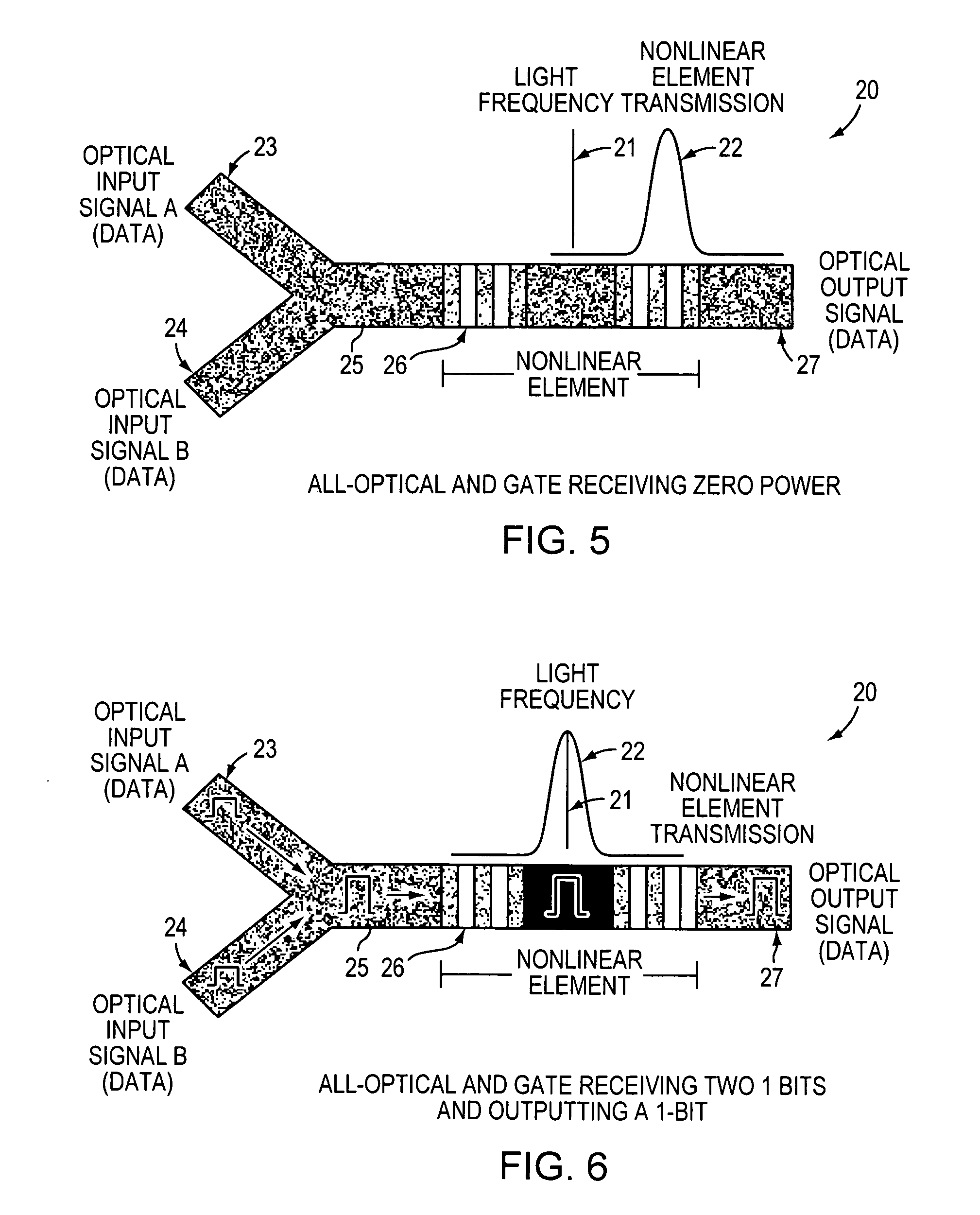

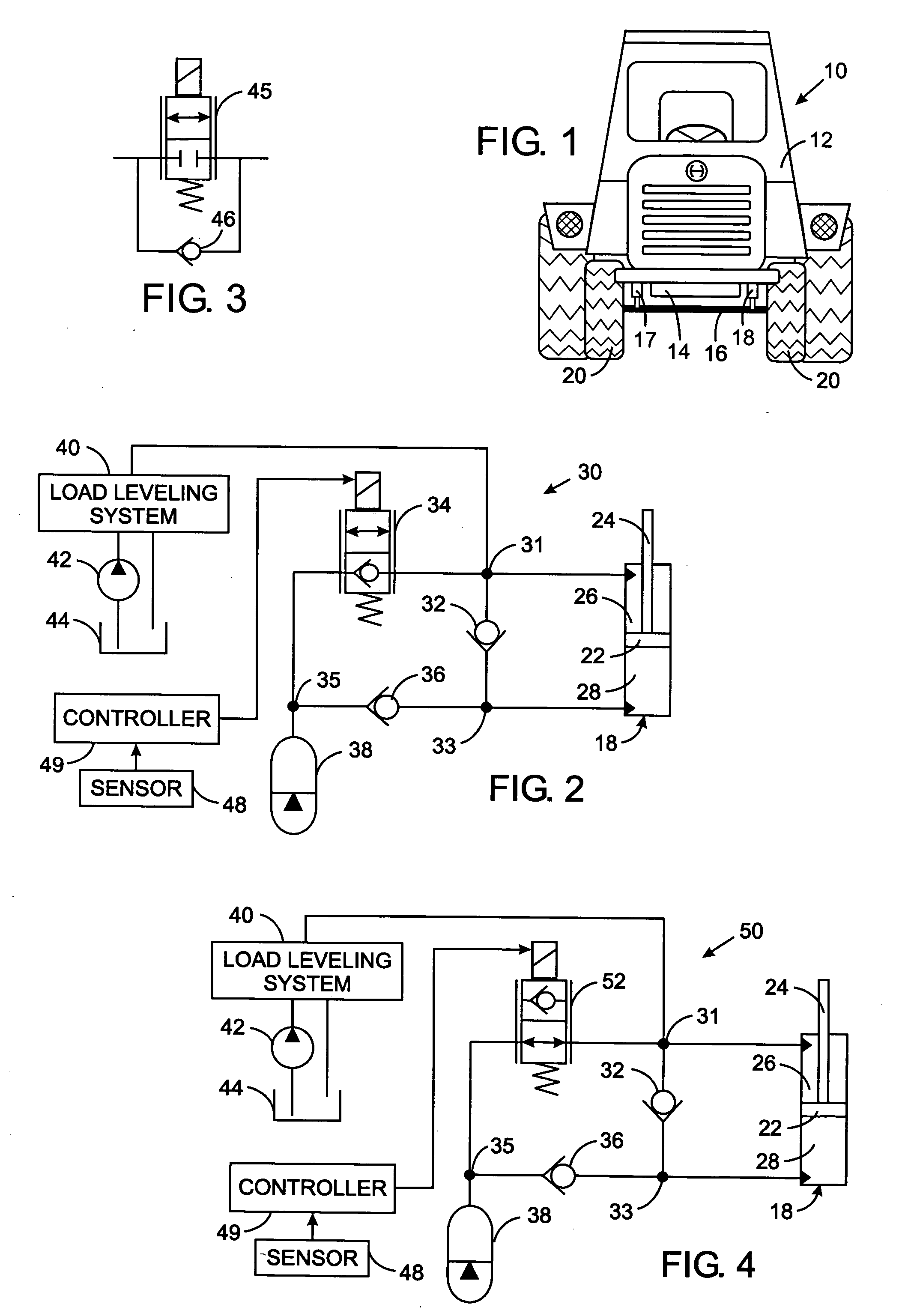

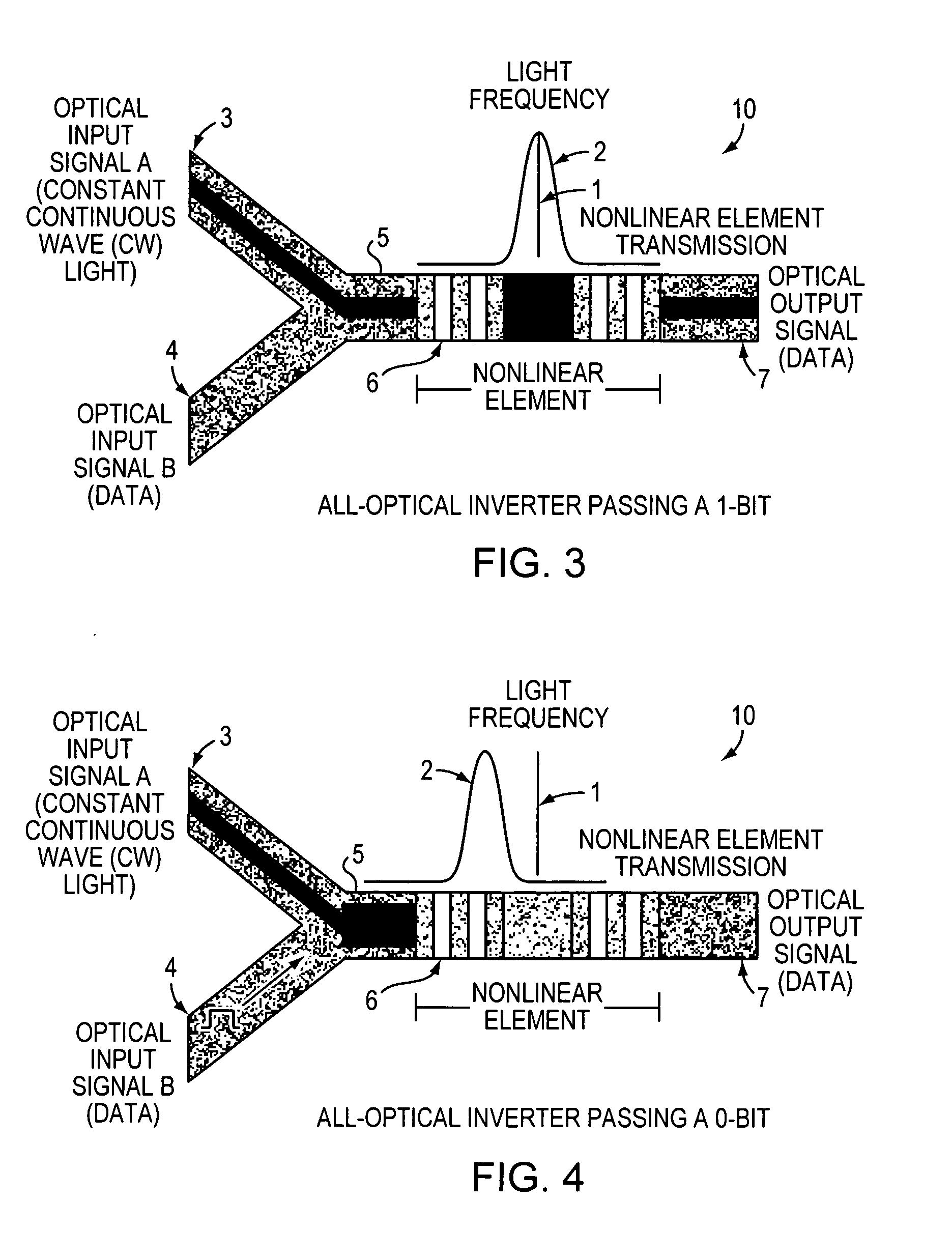

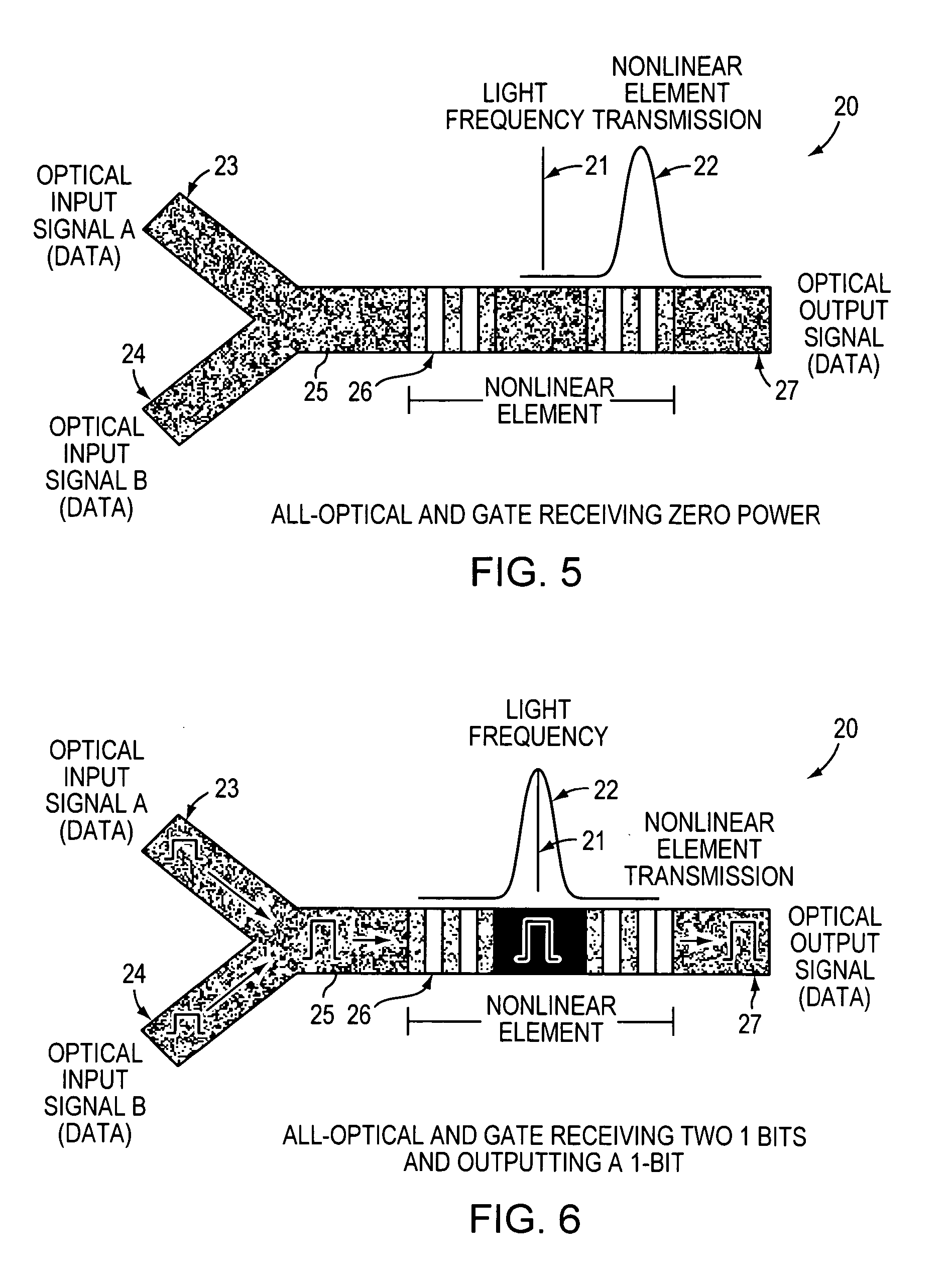

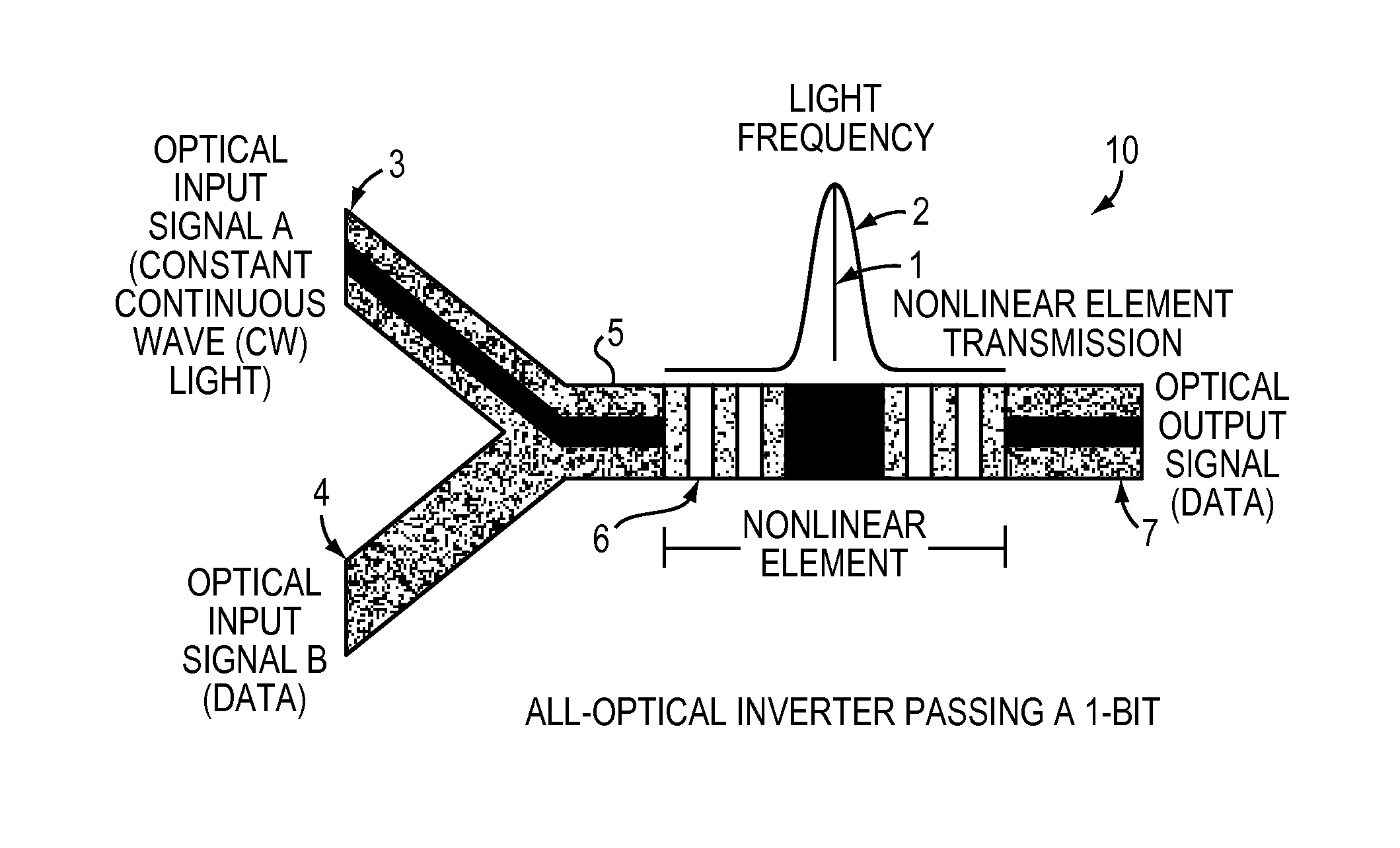

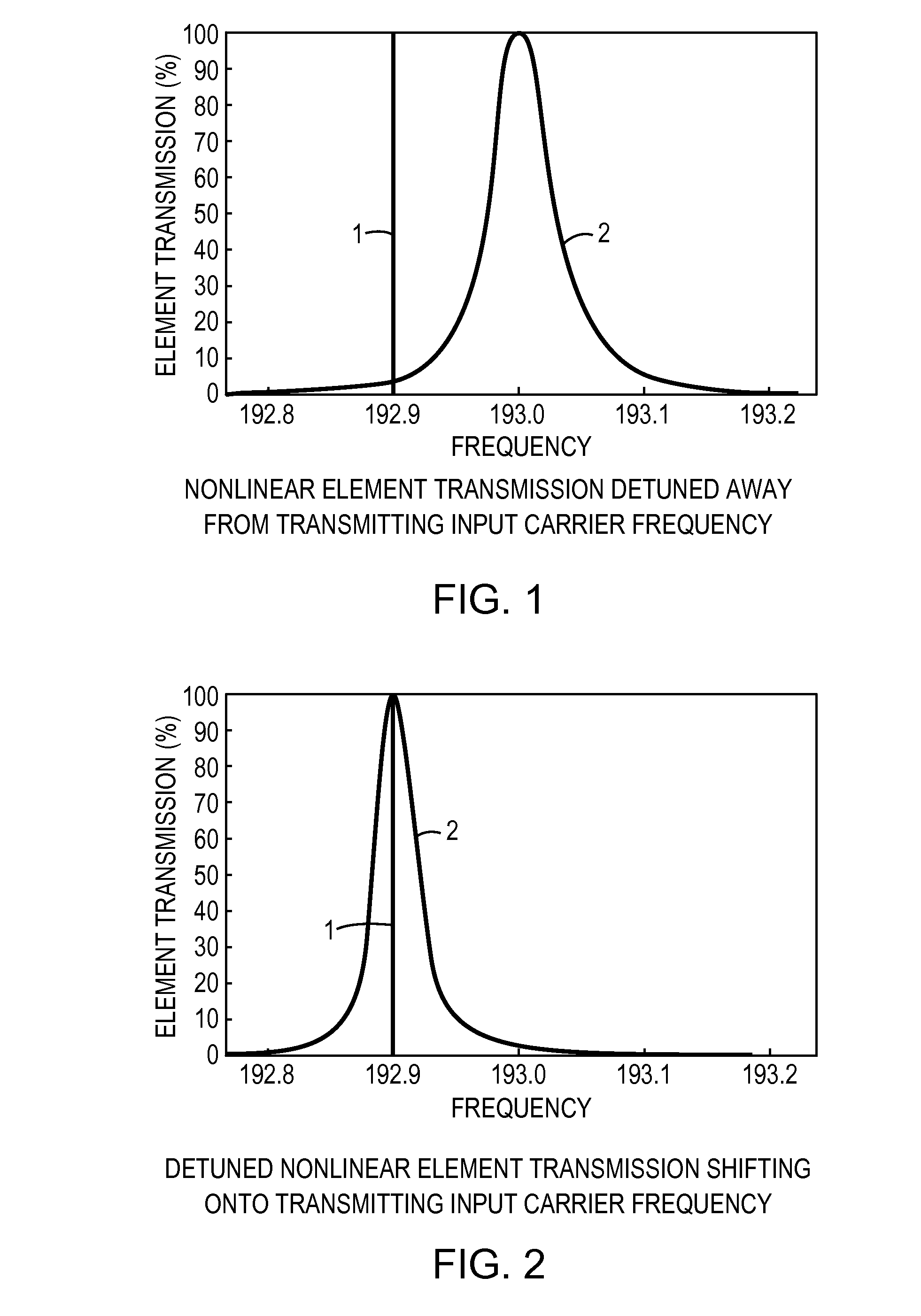

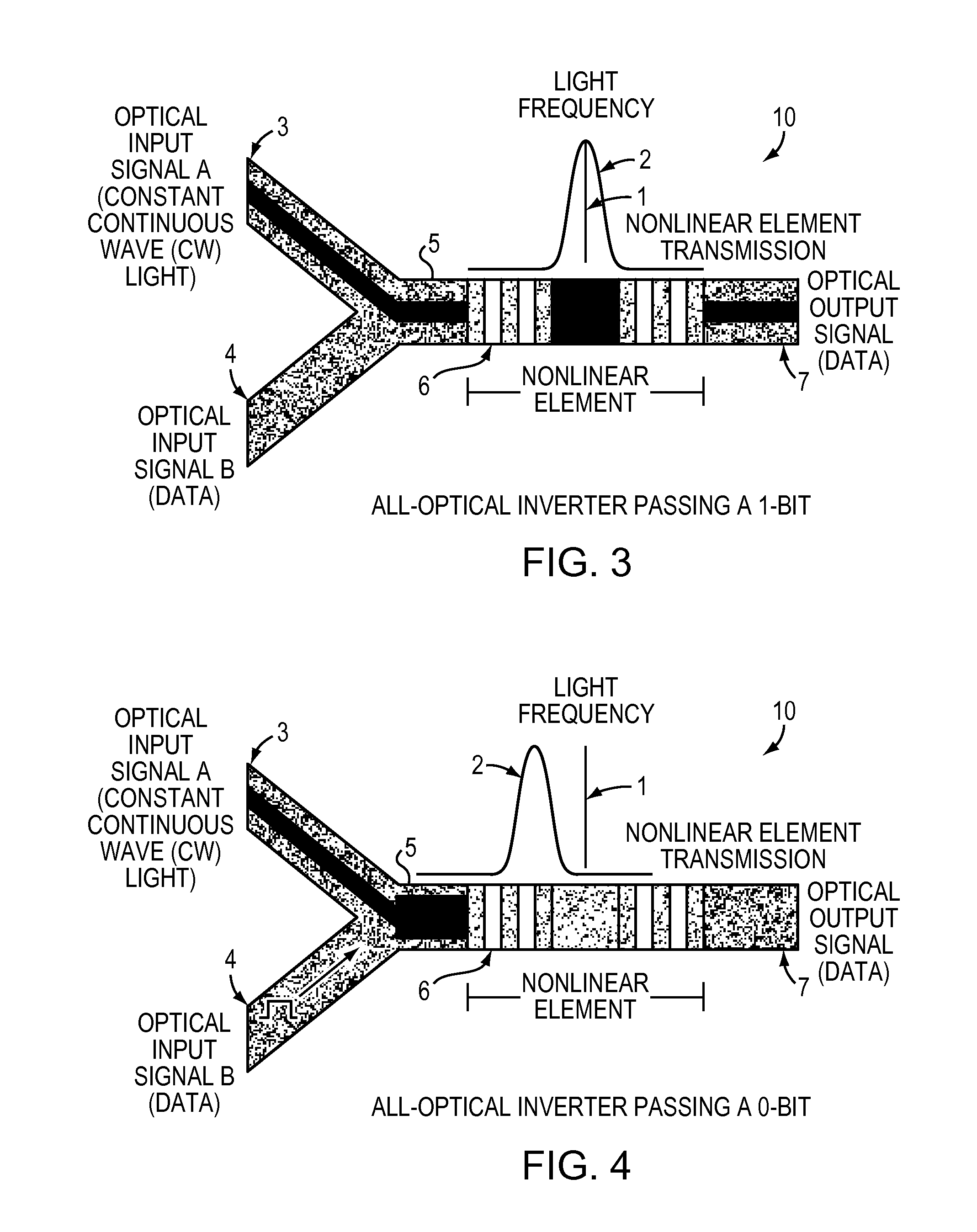

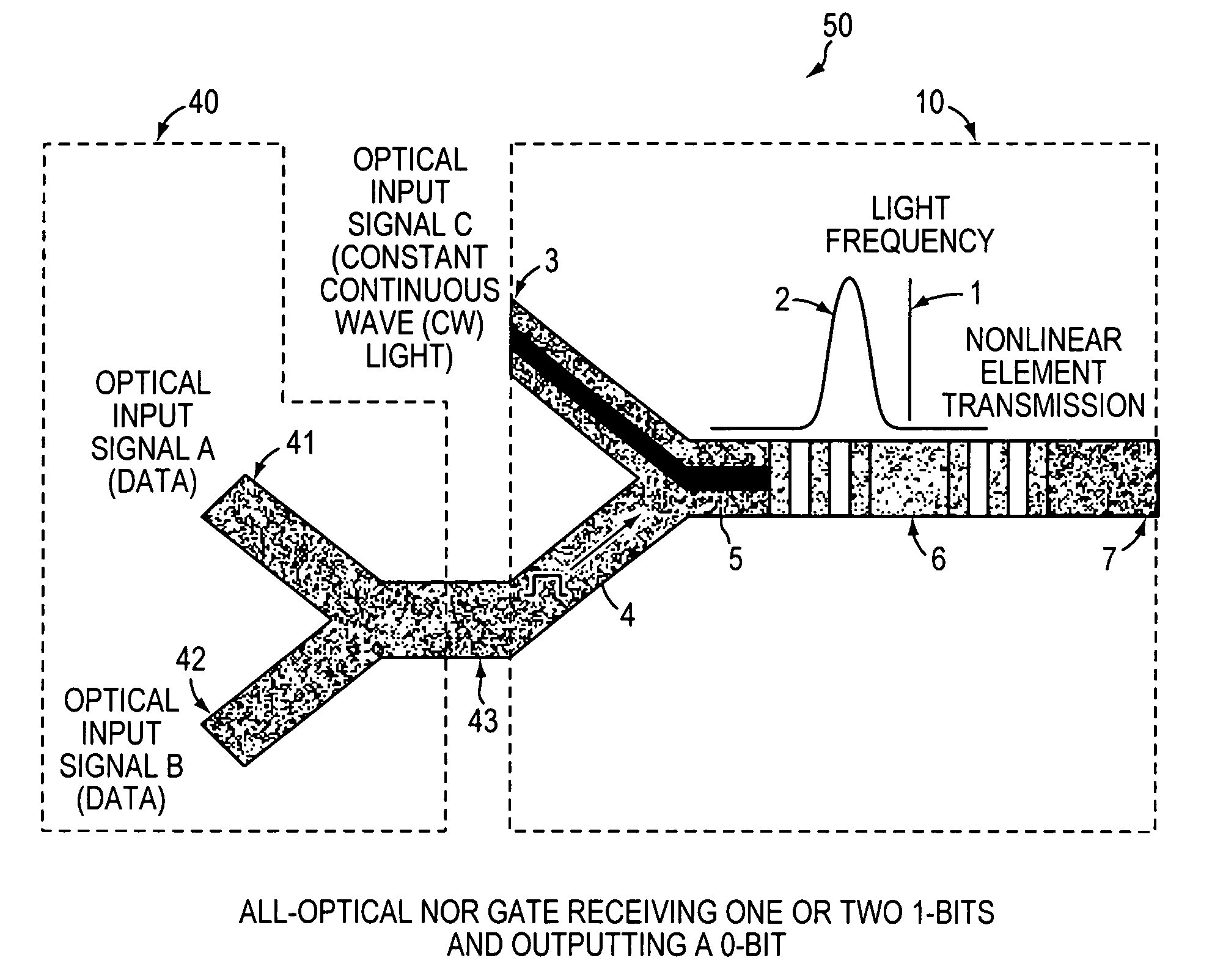

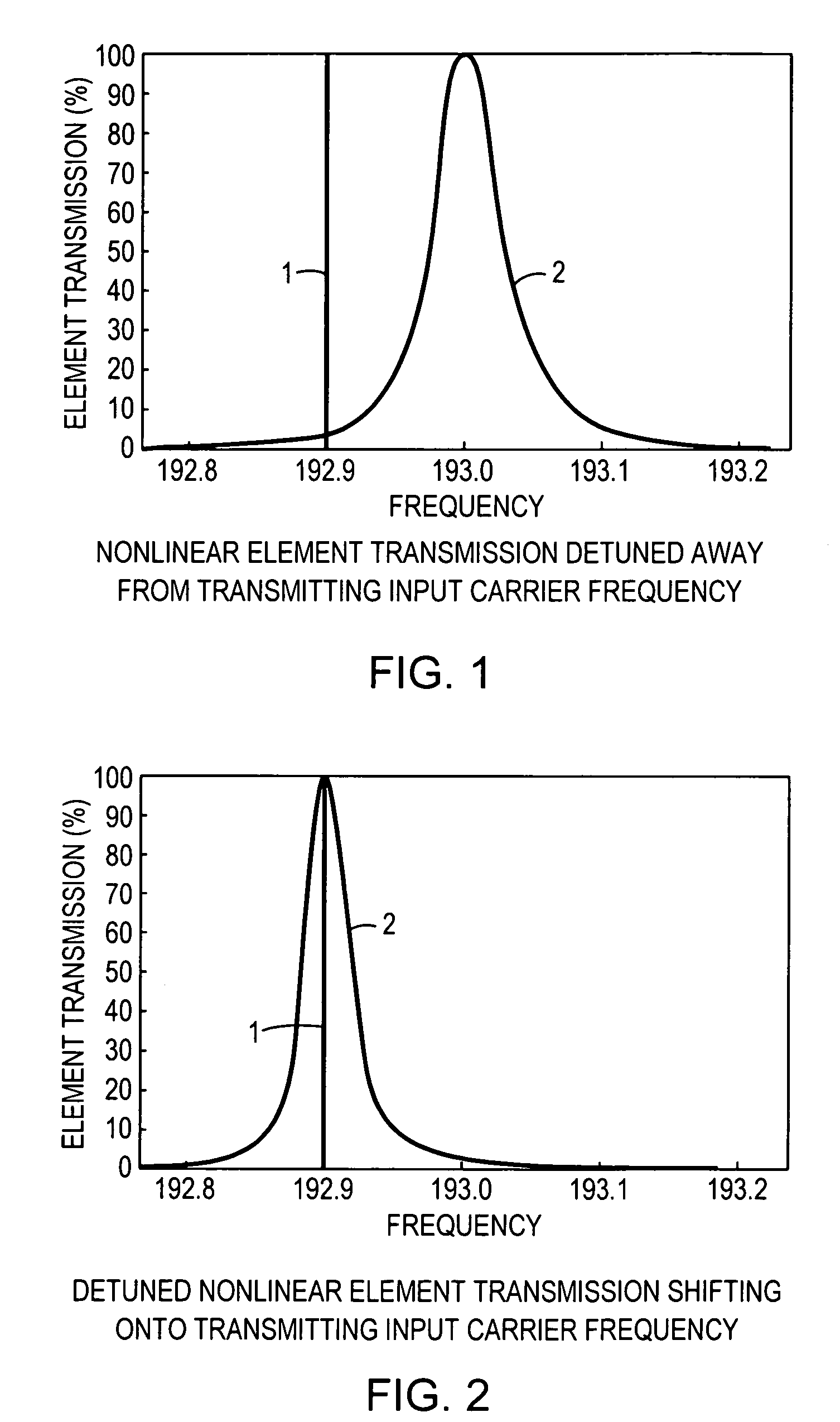

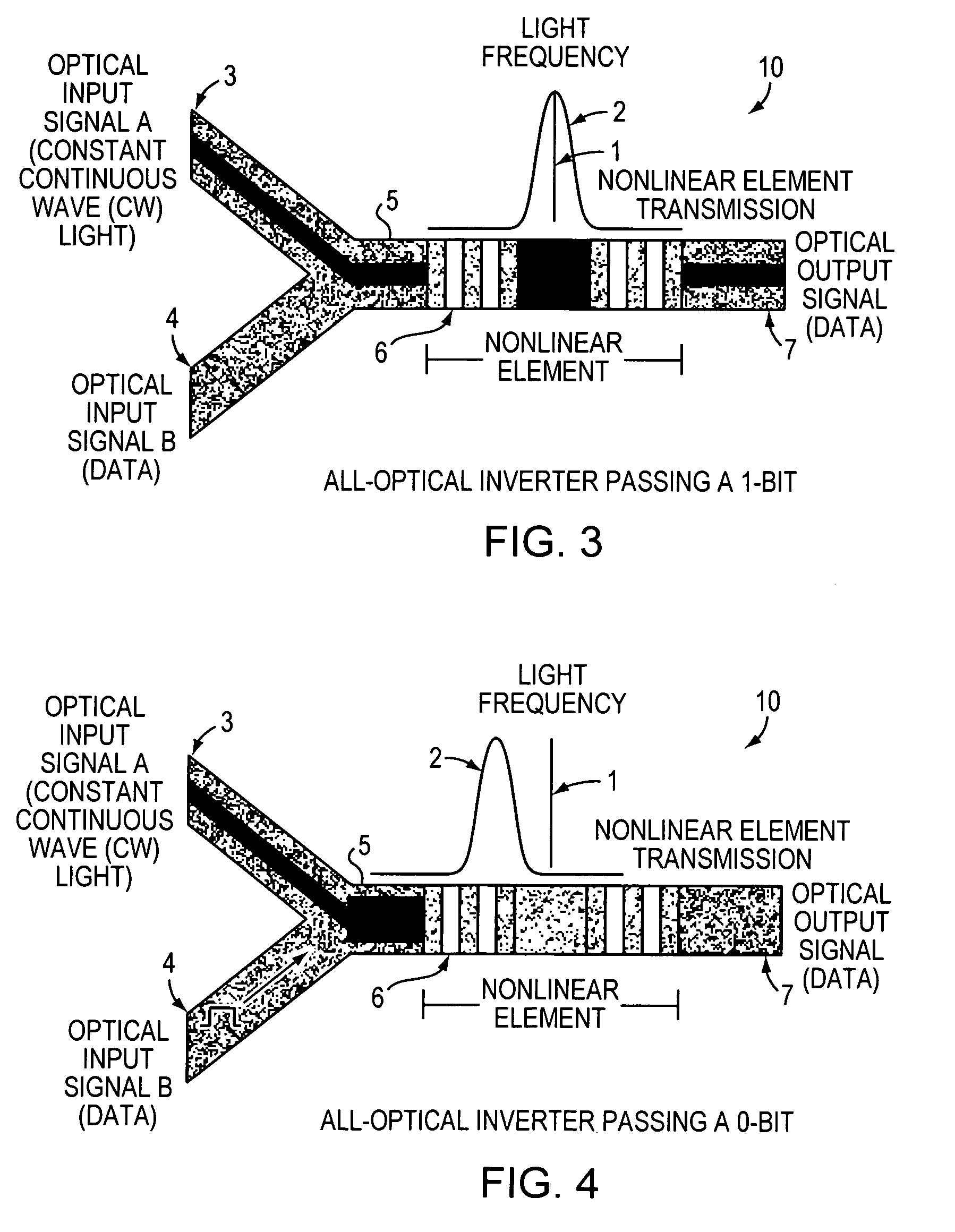

All-optical logic gates using nonlinear elements-claim set VI

InactiveUS7263262B1Change quantityPrecise arrangementCoupling light guidesOptical bistable devicesNonlinear elementLogic gate

An all-optical logic gates comprises a nonlinear element such as an optical resonator configured to receive optical input signals, at least one of which is amplitude-modulated to include data. The nonlinear element is configured in relation to the carrier frequency of the optical input signals to perform a logic operation based on the resonant frequency of the nonlinear element in relation to the carrier frequency. Based on the optical input signals, the nonlinear element generates an optical output signal having a binary logic level. A combining medium can be used to combine the optical input signals for discrimination by the nonlinear element to generate the optical output signal. Various embodiments include all-optical AND, NOT, NAND, NOR, OR, XOR, and XNOR gates and memory latch.

Owner:COVEY JOHN

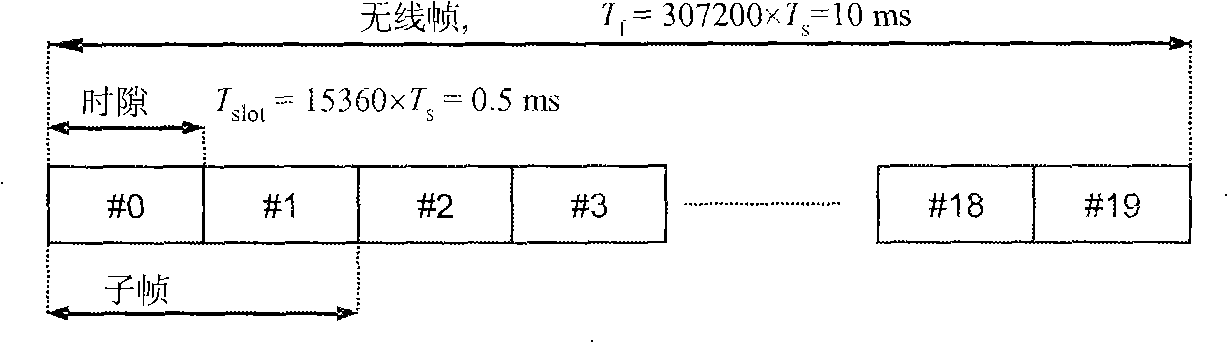

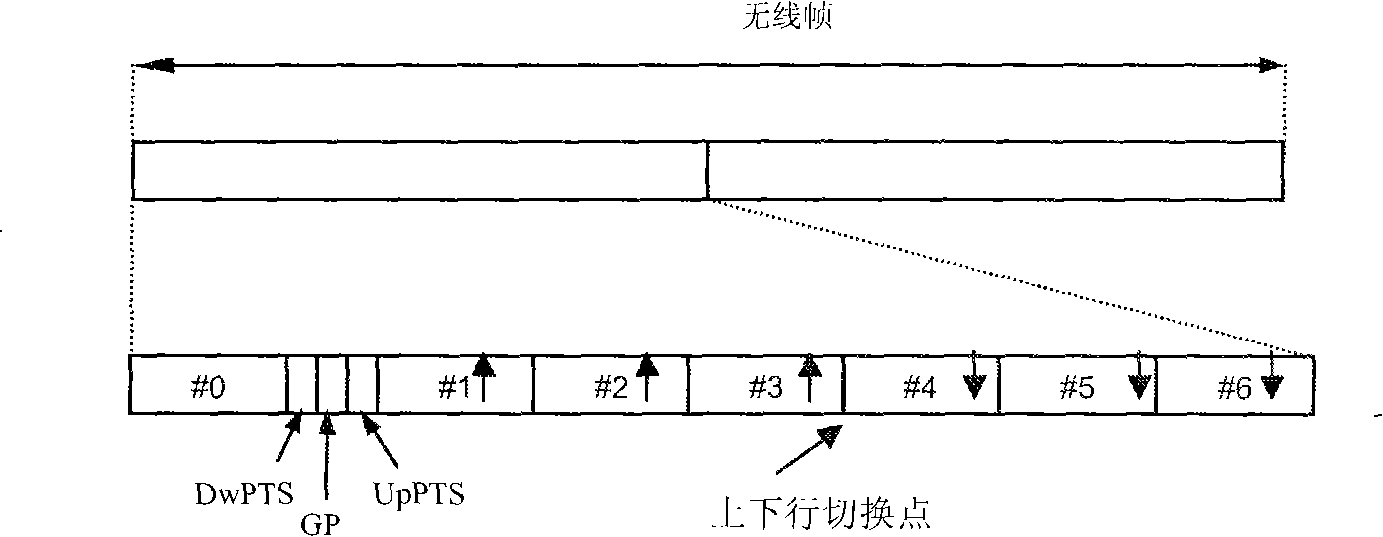

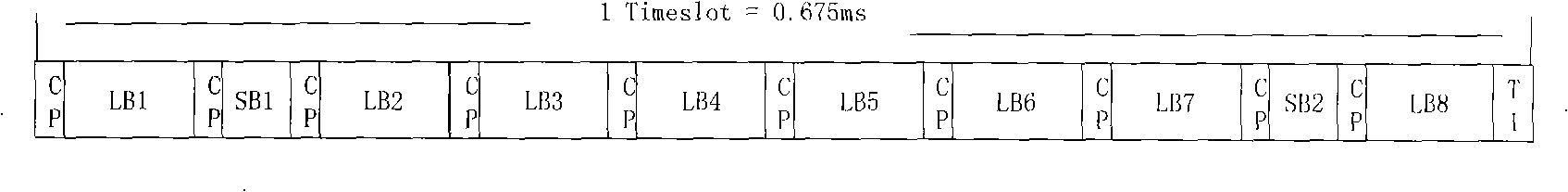

TDD OFDMA system ascending control signaling transmission method and device

ActiveCN101272175AChange quantityFlexible configurationSignal allocationTime-division multiplexTime domainControl signal

The invention relates to a method for transmitting uplink control signaling of a time-division duplexing orthogonal frequency-division multi-access system and a device, which is a proposed specific technical scheme of separately transmitting the non-data correlation control signaling for long-term evolution time-division duplexing (LTE TDD). A control signaling processing unit reserves a frequency band for an uplink control channel according to the total amount of the uplink control signaling, and configures the reserved frequency band at two sides of the frequency domain occupied by the uplink time slot so as to ensure that the uplink control signaling of a terminal UE is transmitted at the position of the reserved frequency band and on the bandwidth and provides a plurality of schemes for reserving the frequency band position and bandwidth. The transmitting uplink control signaling is transmitted in each reserved uplink control channel in the mode of frequency hopping in the sub-frame. Each terminal UE or a group of UEs corresponds to an FH sequence and a plurality of pilot frequency schemes are provided. In the method, the reserved frequency band is configured aiming at the system working bandwidth and positions of uplink and downlink switching points. The method is characterized by low implementation complexity and also sufficient utilization of resources, the transmission is carried out in the mode of frequency hopping in the sub-frame and the time domain and frequency domain diversity can be simultaneously utilized.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Grinding roller manufacturing/remanufacturing abrasion-resistant material and preparation method thereof

InactiveCN106238709AWide adjustment of hardnessWidth adjustment toughnessFurnace typesWelding/cutting media/materialsCouplingBoron containing

The invention discloses a grinding roller manufacturing / remanufacturing abrasion-resistant material and a preparation method thereof. A grinding roller is formed by a core roller body, a substrate abrasion-resistant layer, a transition layer and a roller face abrasion-resistant shape layer in a coupling mode. A core material is provided with the highly-abrasion-resistant modified boron-containing high-chromium cast iron substrate abrasion-resistant layer through casting and compounding. The substrate abrasion-resistant layer comprises, by mass, 1.75%-3.0% of C, 12.0%-18.0% of Cr, 0.2%-2.0% of B, 0.4%-0.8% of Mn, 0.4%-1.2% of Si, 0.30%-0.80% of Ni, 0.02%-0.04% of Mg, 0.03%-0.05% of Ce, 0.05%-0.10% of Ti, 0.006%-0.015% of N, 0-0.04% of S, 0-0.04% of P, and the balance Fe. Then surfacing of materials of the roller face abrasion-resistant shape layer is conducted on the surface of the transition layer. The roller face abrasion-resistant shape layer is formed by flux-cored wires through surfacing. The flux-cored wires comprises, by mass, 2.3%-3.5% of C, 14.0%-26.0% of Cr, 1.5%-2.0% of Ni, 0.8%-2.0% of Nb, 1.3%-2.0% of Mo, 1.2%-2.3% of Si, 1.0%-1.7% of Ti, 0.3%-1.0% of V, 0.2%-1.5% of B, 0-<0.007% of S, 0-0. 015% of P, and the balance Fe.

Owner:镇江富华轧辊有限公司

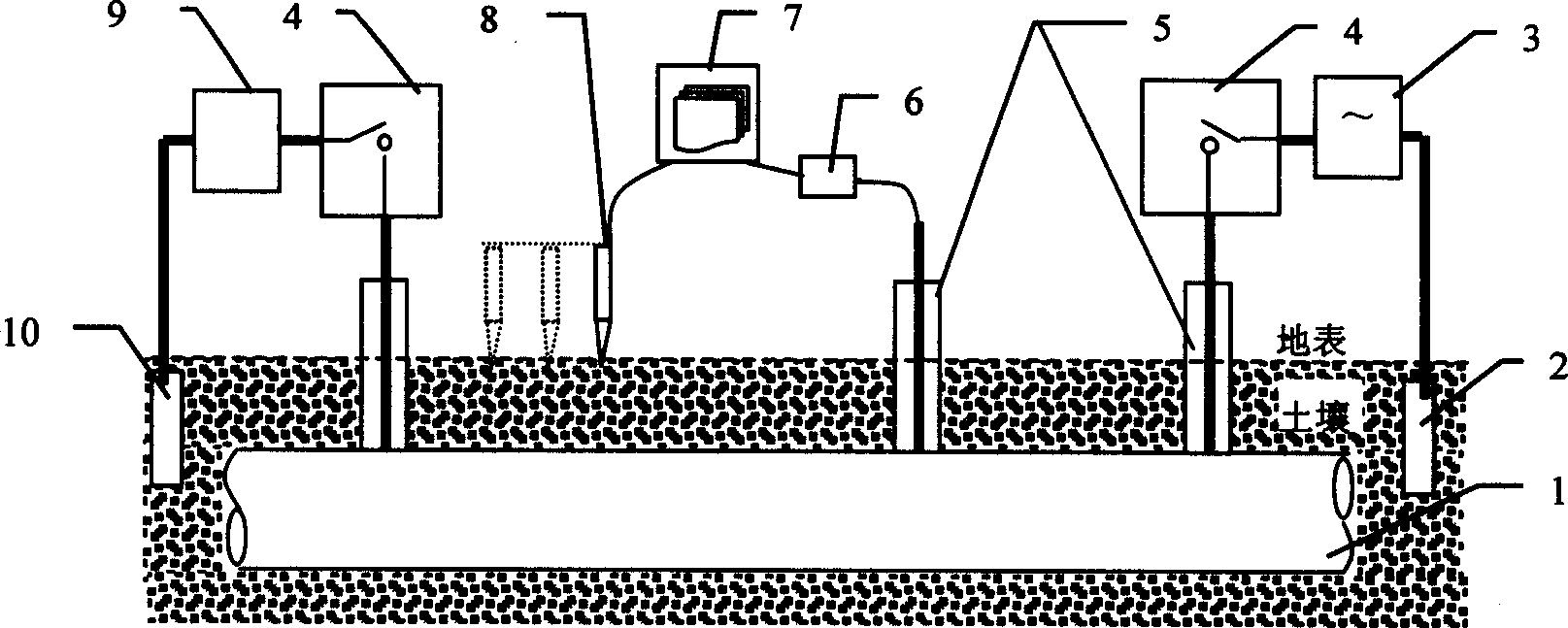

Comprehensively measuring method and device for electric potentials of pipe earth and ground surface for cathodic pipeline pretection

InactiveCN1456879AImprove detection efficiencyEliminate measurement effectsWeather/light/corrosion resistanceMaterial resistanceMicrocomputerData acquisition

The method uses at least each reference electrode to carry out measurement for pipe located position potential and for ground surface potential separately at the same time and instant interruption current method or additional applied eciting current signal method is applied to eliminate IP drop in the measuring course. The testing data collected by recorder is analysed by the microcomputer to confirm the true pipe located position potential and ground surface potential. The device to realize the method consists of reference electrode set, data collector recording device, signal generating device, current interrupt appliance, distance measurer and microcomputer analysis system, of which the signal generating device, current interrupt appliance and data collection recording device are set in synchronization with GPS.

Owner:TIANJIN UNIV

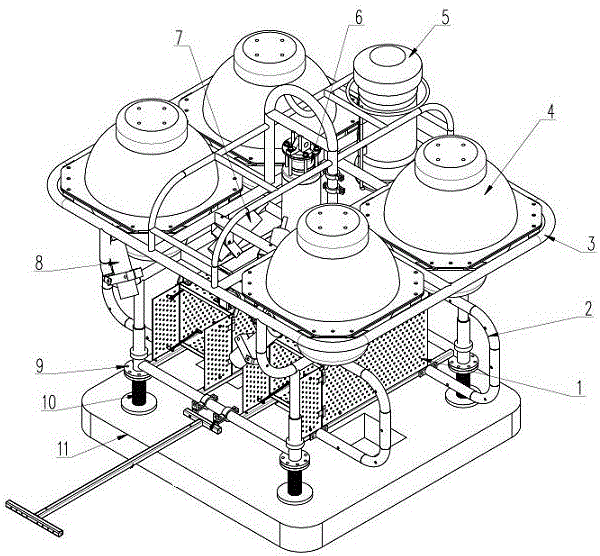

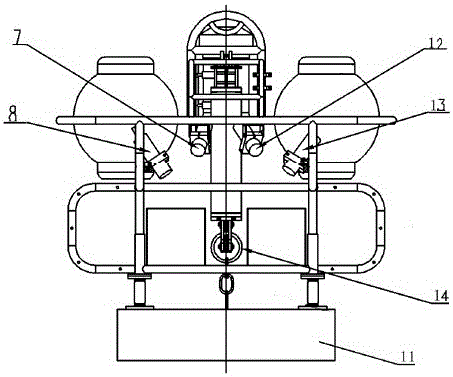

Long-term observing and biology trapping device for deep sea environment

InactiveCN105716663AAvoid biological escapeIncrease success rateMeasurement devicesFishingTechnical supportEngineering

The invention discloses a long-term observing and biology trapping device for a deep sea environment.The device comprises a buoyancy device.The device is characterized in that a rack connected with the buoyancy device is included, the rack is provided with glass power supply bins which are internally provided with power supplies and low-power dissipation power supply managing circuits in a packaged mode, biology trappers, a deep sea image observing instrument, a deep sea environment parameter measuring instrument and an acoustic releaser, and the acoustic releaser is connected with a bearing block.The device is suitable for full deep sea environment observation and entrapment of large deep-sea near-bottom fishes with the high action capacity, supplies technical support to deep sea scientific research and has the advantages of being suitable for deep-sea long-term observation, increasing the trapping sampling success rate and avoiding the phenomenon that a carrying instrument is damaged due to the fact that the instant shock is too big when the device lands under the sea.

Owner:SECOND INST OF OCEANOGRAPHY MNR

All-optical logic gates using nonlinear elements-claim set I

InactiveUS20070189703A1Change quantityPrecise arrangementNanoopticsOptical light guidesLinear elementLogic gate

An all-optical logic gates comprises a nonlinear element such as an optical resonator configured to receive optical input signals, at least one of which is amplitude-modulated to include data. The nonlinear element is configured in relation to the carrier frequency of the optical input signals to perform a logic operation based on the resonant frequency of the nonlinear element in relation to the carrier frequency. Based on the optical input signals, the nonlinear element generates an optical output signal having a binary logic level. A combining medium can be used to combine the optical input signals for discrimination by the nonlinear element to generate the optical output signal. Various embodiments include all-optical AND, NOT, NAND, NOR, OR, XOR, and XNOR gates and memory latch.

Owner:COVEYTECH LLC

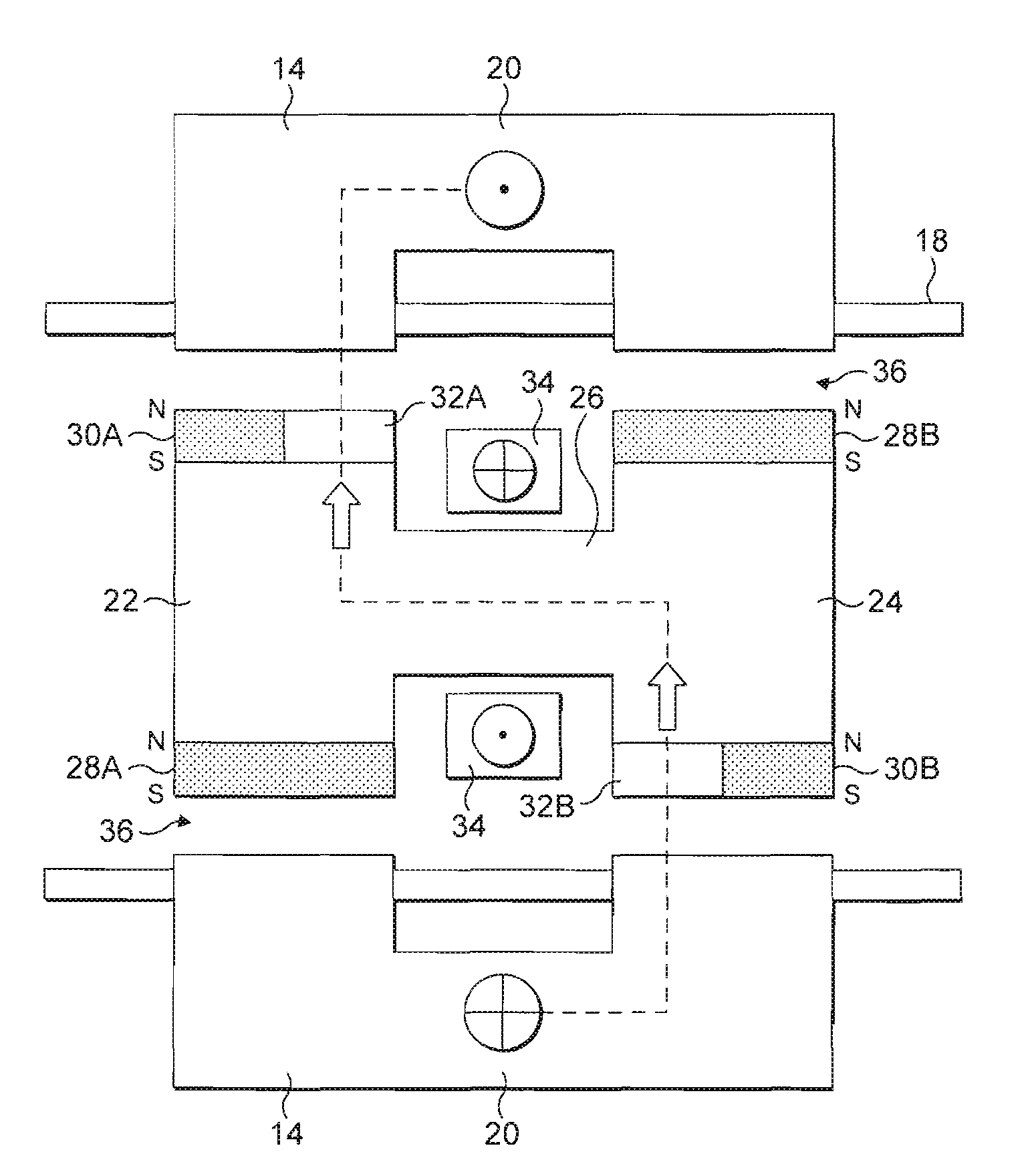

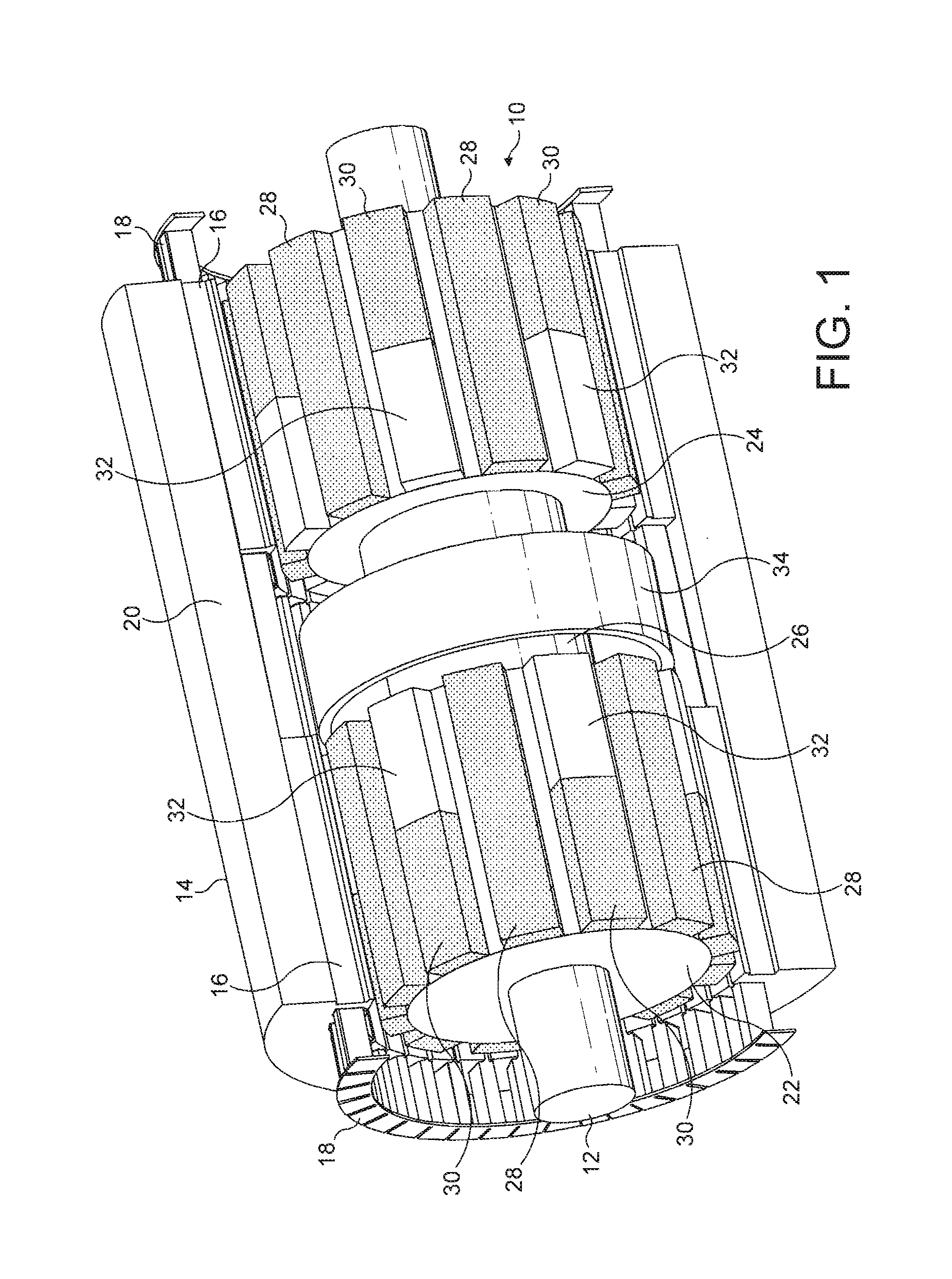

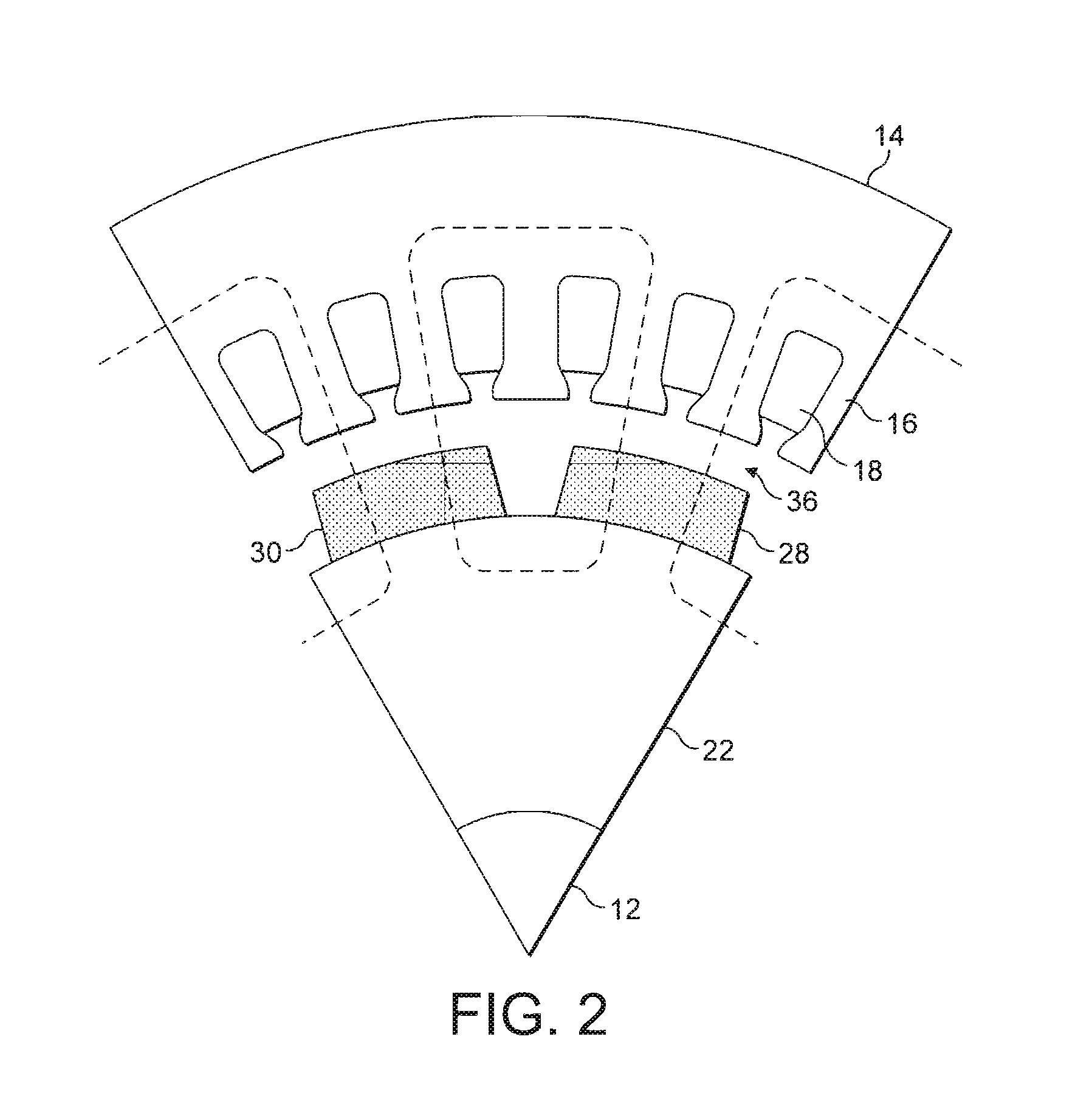

Rotating electrical machine

ActiveUS20100013340A1Change quantitySmall sizeSynchronous generatorsWindingsElectric machineMagnetic flux

A rotating electrical machine is disclosed, the machine comprising a stator 14, 52 and a rotor 10, 50 arranged to rotate inside the stator. The rotor comprises a plurality of permanent magnets 28, 30, 54 arranged to produce a radial magnetic flux in an airgap between the rotor and the stator. The machine also comprises a stationary excitation coil 34, 46, 66. The rotor comprises a plurality of low reluctance elements 32, 58. A current through the stationary excitation coil causes a magnetic flux to be established in a magnetic flux path which passes into the rotor through a first low reluctance element and out of the rotor through a second low reluctance element, which magnetic flux combines with the radial magnetic flux produced by the permanent magnets in the airgap. This arrangement can allow control of the field within a permanent magnet radial flux machine.

Owner:CUMMINS GENERATOR TECH LTD

Delivery of a substance to a pre-determined site

InactiveUS20050272677A1Reduce tensionReduce harmGenetic material ingredientsPharmaceutical non-active ingredientsDelivery vehicleAerospace engineering

The invention is directed to delivery vehicles for delivering a substance of interest to a predetermined site. The delivery vehicle includes a substance and means for inducing availability of at least one compartment of the delivery vehicle toward the exterior, thus, allowing access of the substance to the exterior of the delivery vehicle at the predetermined site. The invention is further directed to uses of the delivery vehicle and methods for preparing the delivery vehicle.

Owner:APPLIED NANOSYST

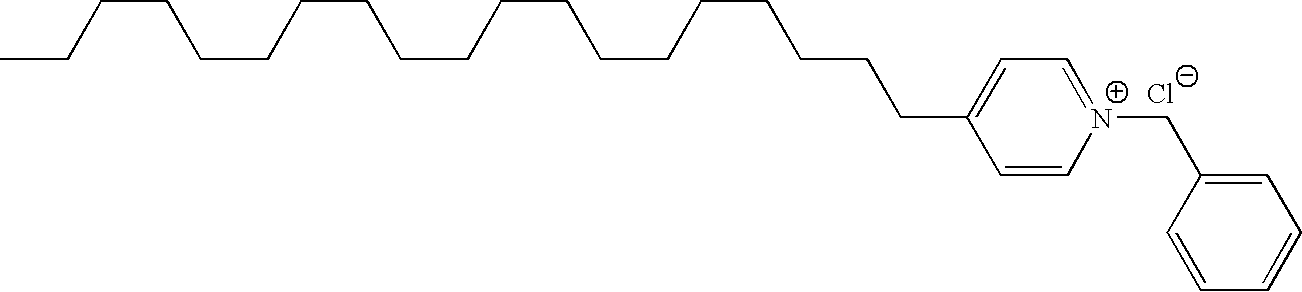

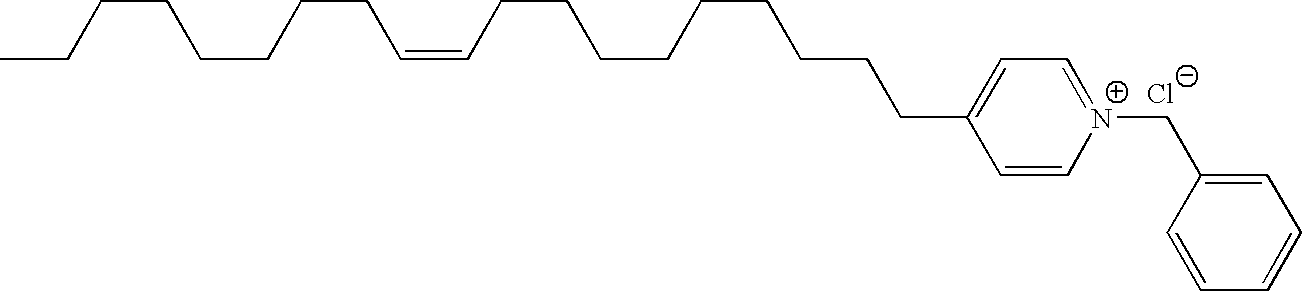

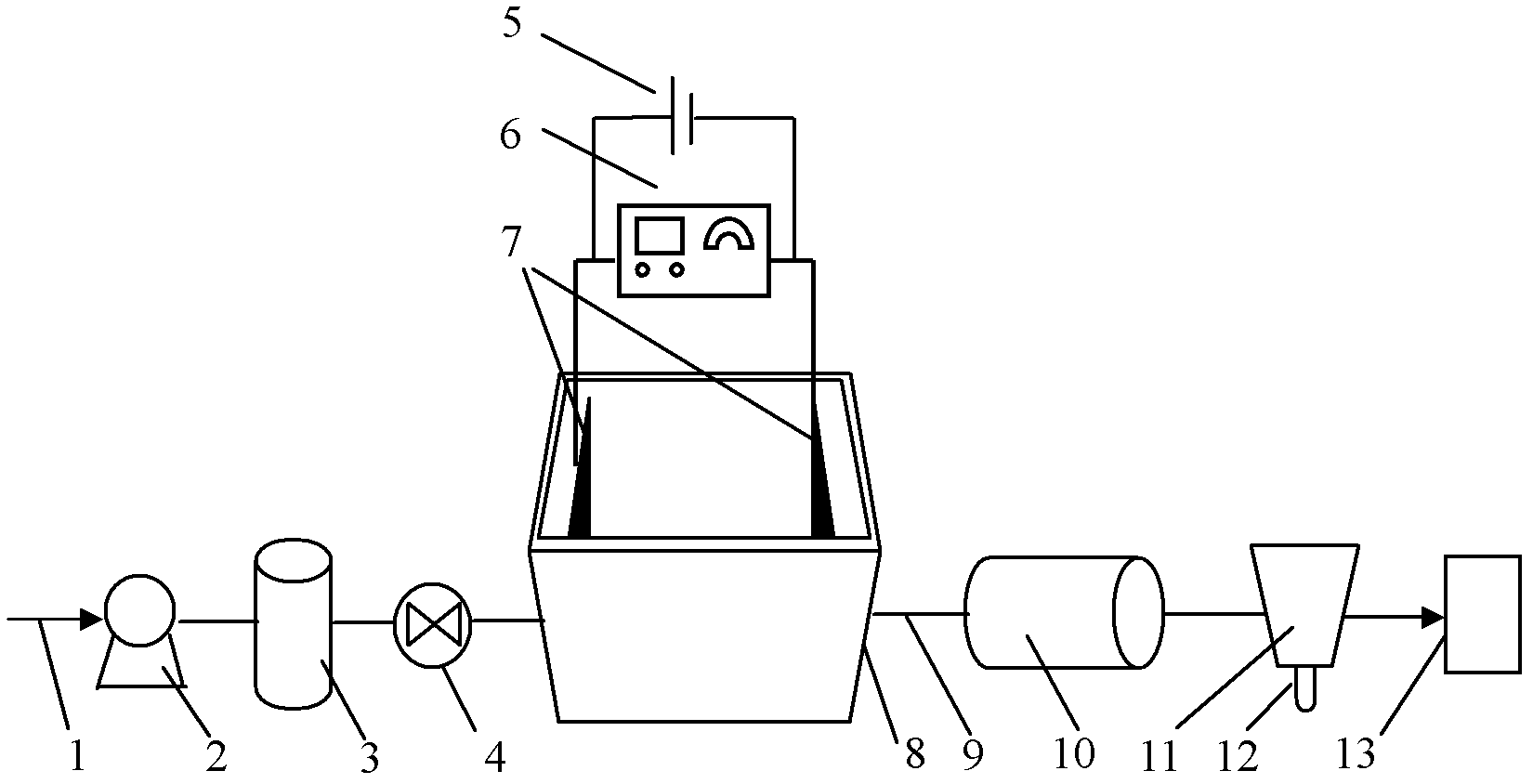

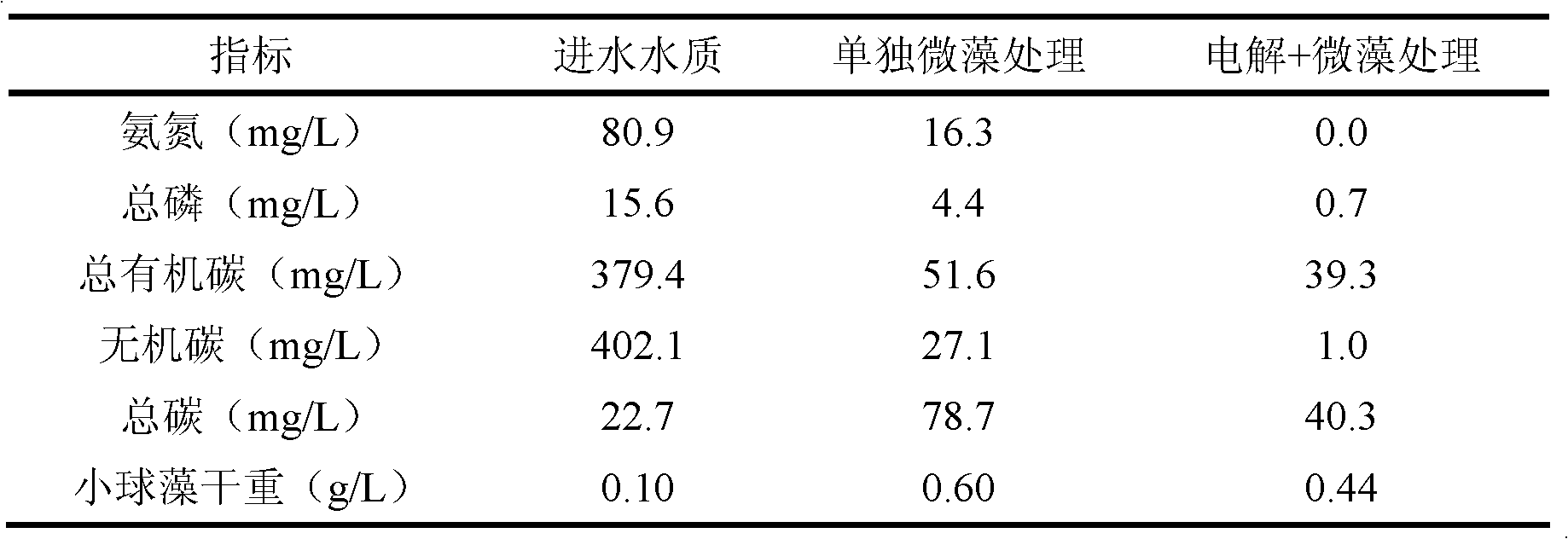

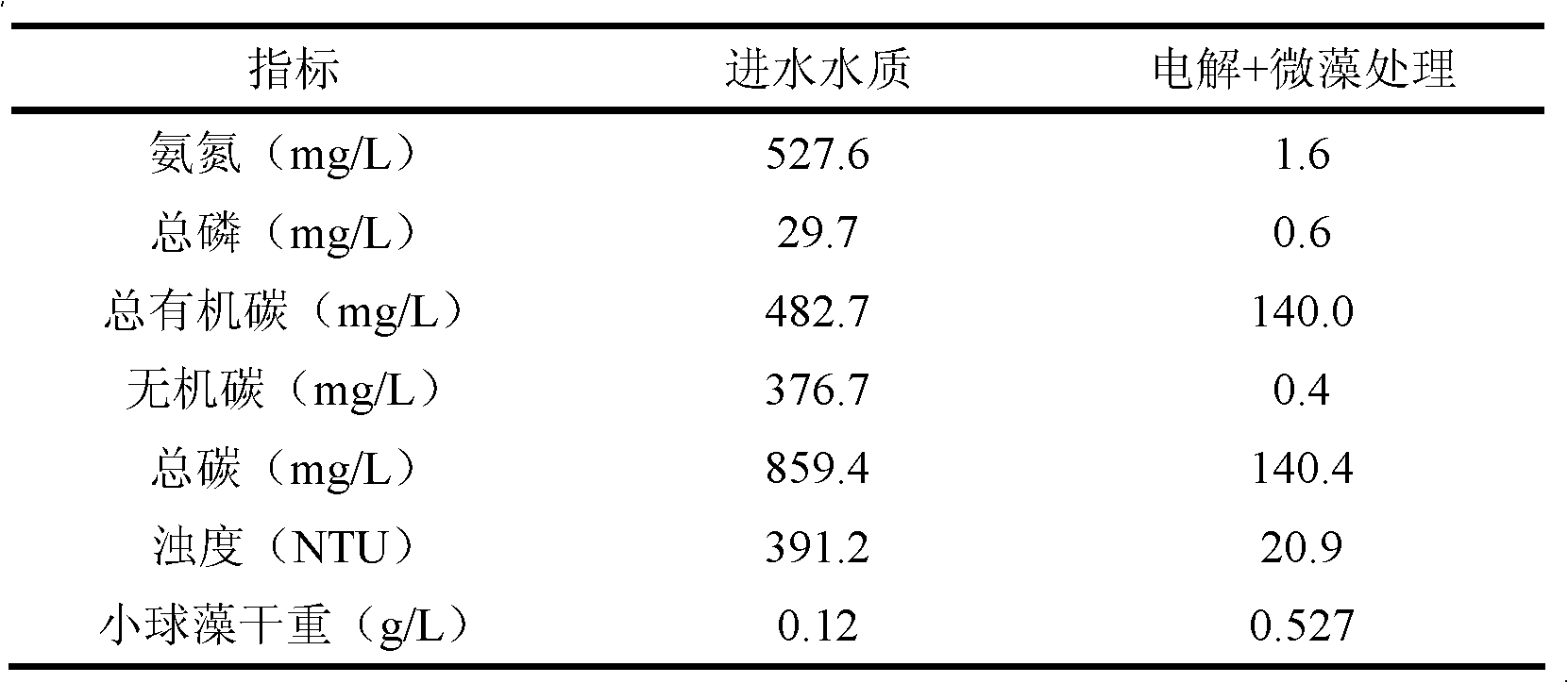

High-concentration sewage treatment method

InactiveCN102642987AImprove biodegradabilityReduce the concentration of pollutantsEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationHydrogen

The invention discloses a high-concentration sewage treatment method. The method includes the steps: firstly, using an electrochemical oxidation method for pretreatment of sewage to obtain pretreated sewage; and secondly, adjusting the pH (potential of hydrogen) value of the pretreated sewage to range from 7.0 to 9.0, inoculating microalgae into the sewage, and subjecting the sewage to microalgaebiological treatment so as to purify the sewage, wherein the microalgae biological treatment operating conditions include: the temperature ranges from 25 DEG C to 30 DEG C, the light dark period is 12:12, the illumination intensity ranges from 40001ux to 60001ux, and the steps include aerating or mechanically stirring and continuously culturing for ten to twenty days. By the high-concentration sewage treatment method, sewage treatment cost is reduced, pollutant removal efficiency is improved. Further, the high-concentration sewage treatment method is wide in sewage treatment range, free of secondary pollution and flexible and controllable in operation mode, and environment-enhancing energy is realized.

Owner:CHINA AGRI UNIV

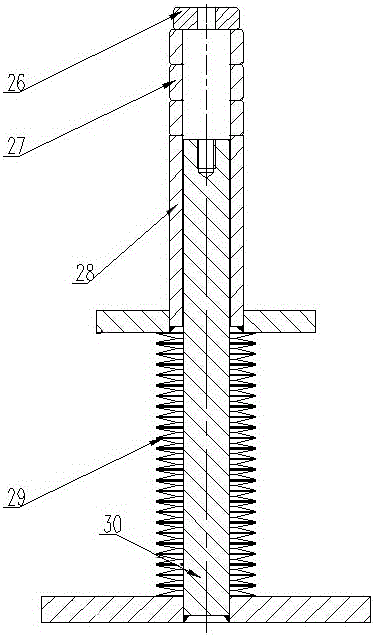

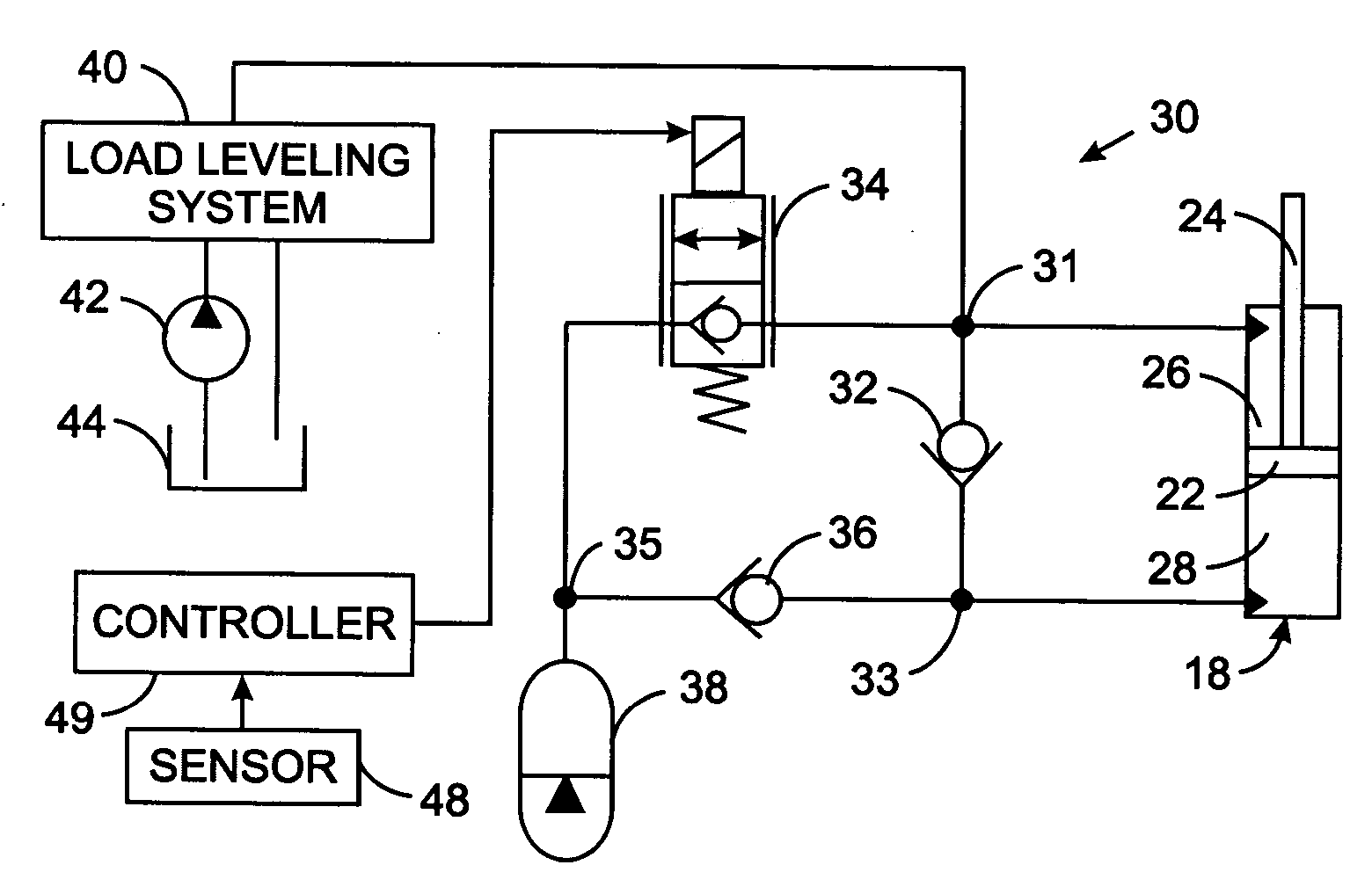

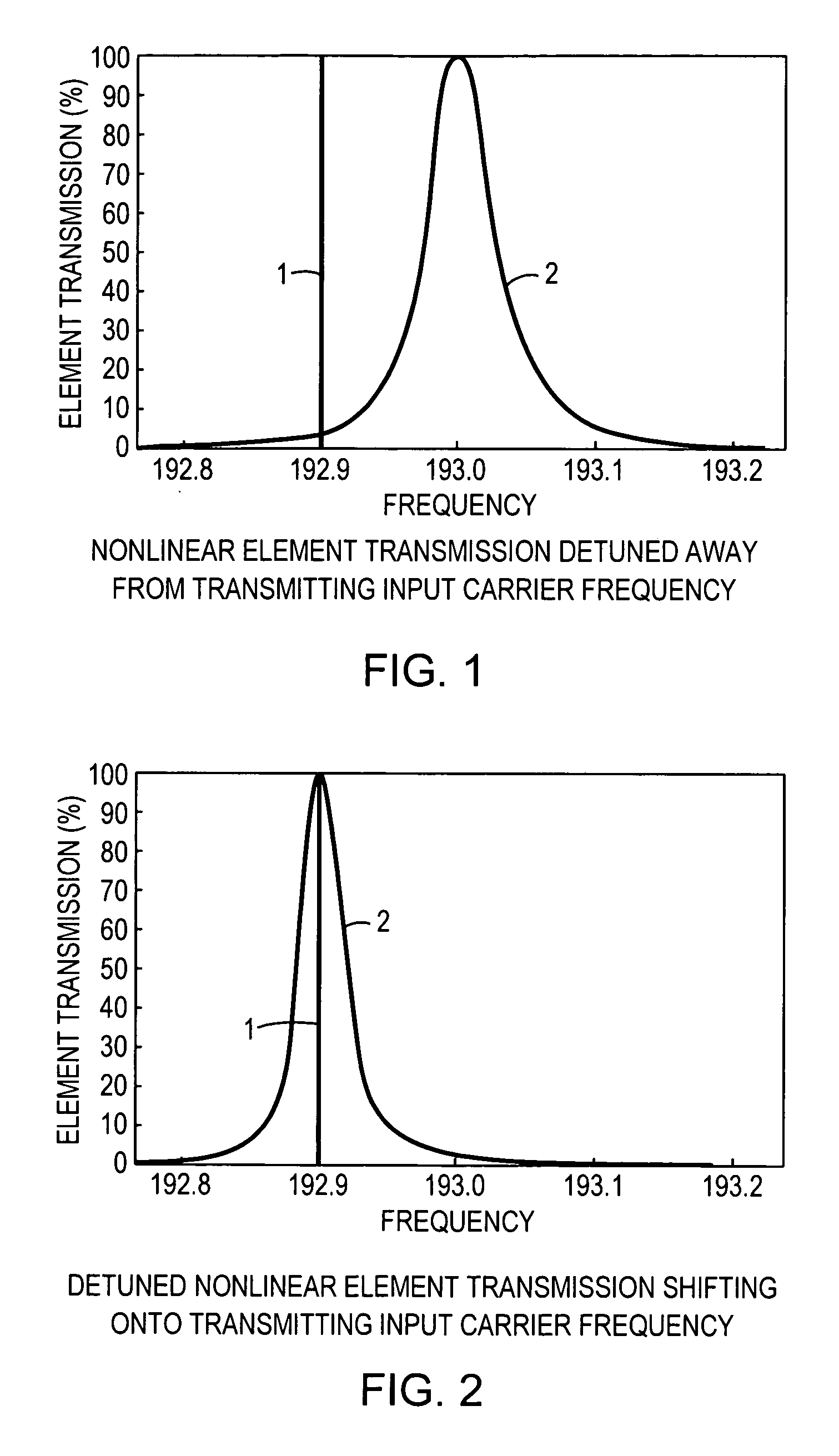

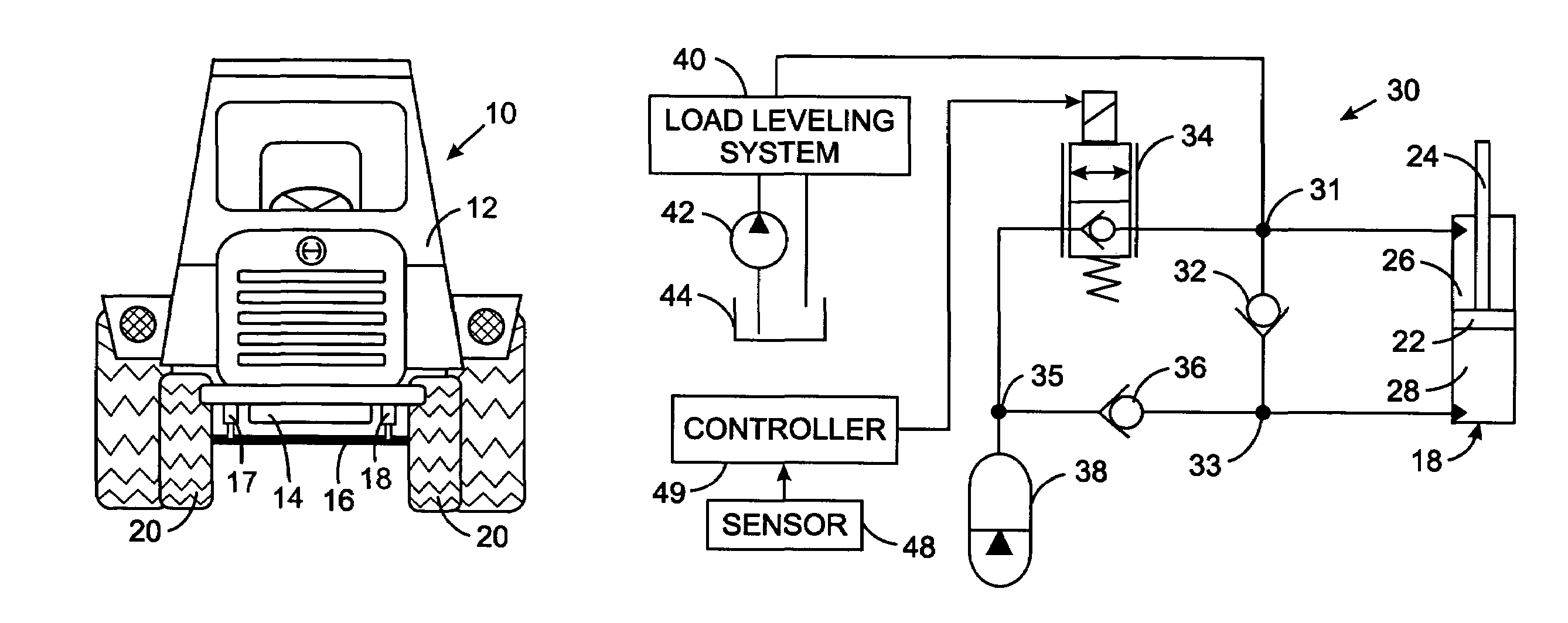

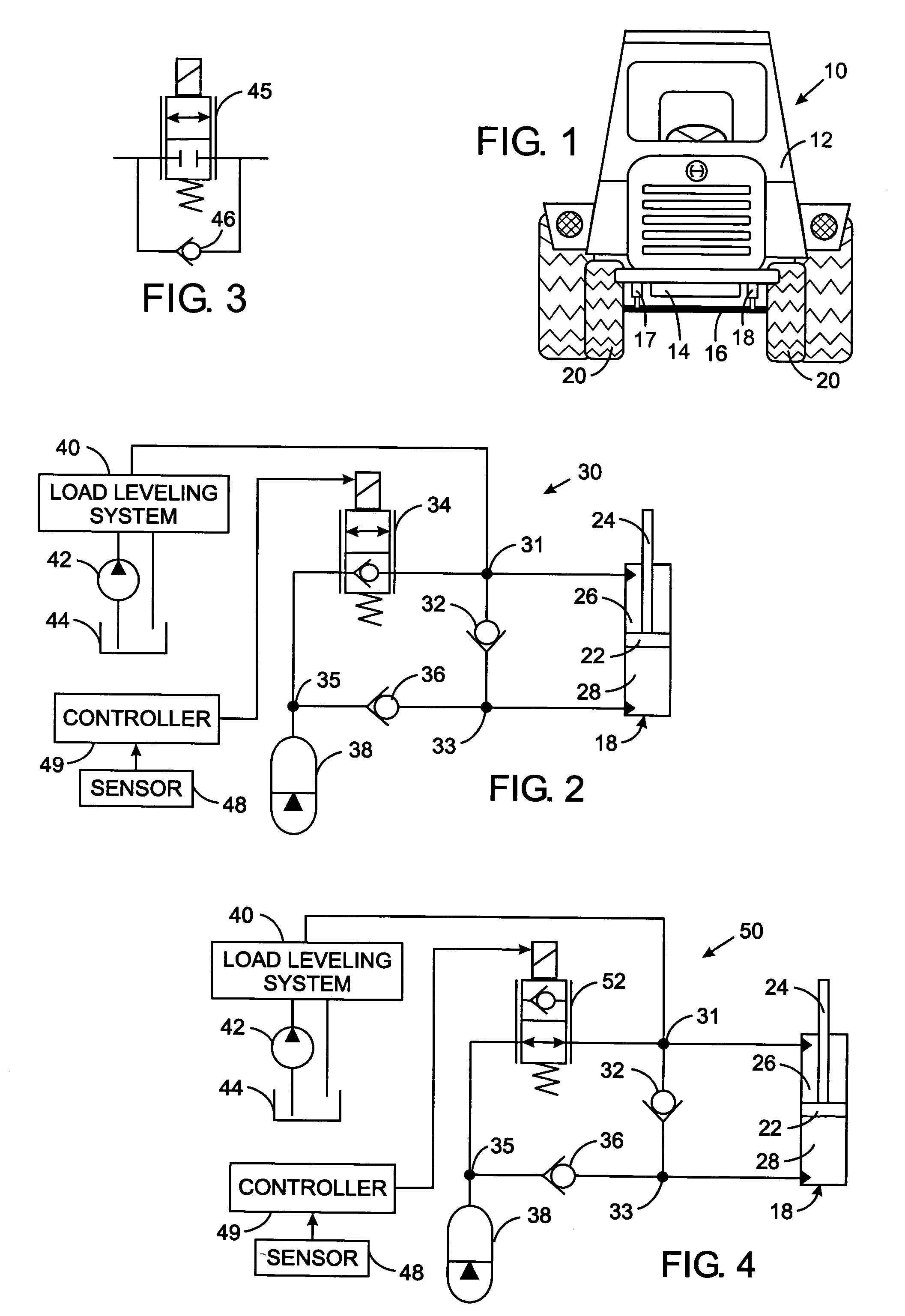

Hydraulic suspension with a lock-out mechanism for an off-highway vehicle

InactiveUS20050252699A1Change quantityVehicle fittings for liftingVehicle cleaning apparatusHydraulic cylinderVehicle frame

A vehicle has an axle connected to a frame by at least one hydraulic cylinder with two chambers separated by a piston. A hydraulic circuit controls flow of fluid between two cylinder chambers and between the chambers and an accumulator to dampen motion of the frame relative to the axle. The hydraulic circuit includes a control valve and a pair of check valves arranged so that the single control valve is able to lock-out the cylinder to emulate a rigid connection of the frame to the axle, as needed.

Owner:HUSCO INT INC

All-optical logic gates using nonlinear elements-claim set II

InactiveUS20070189705A1Change quantityPrecise arrangementNanoopticsOptical light guidesLinear elementLogic gate

An all-optical logic gates comprises a nonlinear element such as an optical resonator configured to receive optical input signals, at least one of which is amplitude-modulated to include data. The nonlinear element is configured in relation to the carrier frequency of the optical input signals to perform a logic operation based on the resonant frequency of the nonlinear element in relation to the carrier frequency. Based on the optical input signals, the nonlinear element generates an optical output signal having a binary logic level. A combining medium can be used to combine the optical input signals for discrimination by the nonlinear element to generate the optical output signal. Various embodiments include all-optical AND, NOT, NAND, NOR, OR, XOR, and XNOR gates and memory latch.

Owner:COVEY JOHN

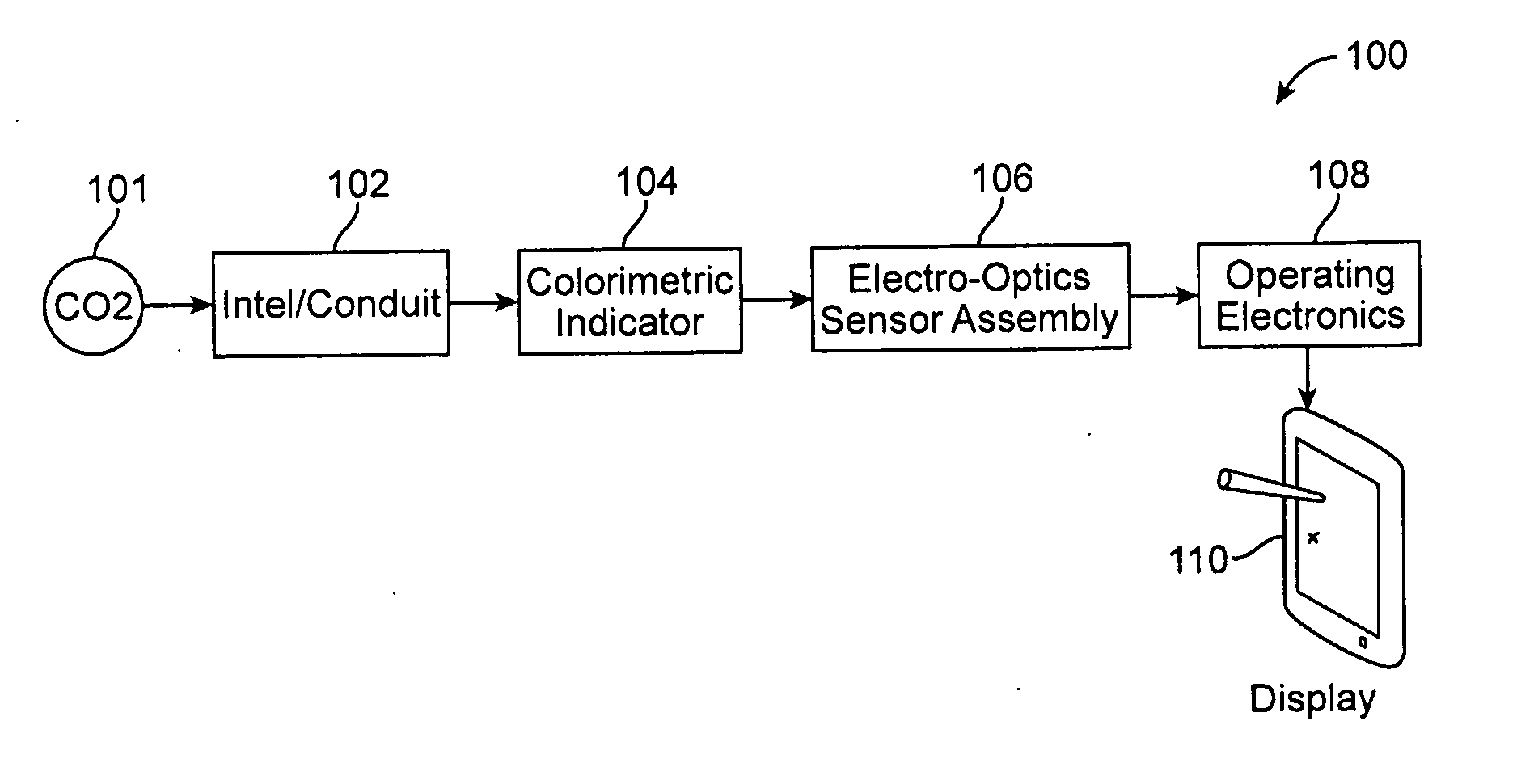

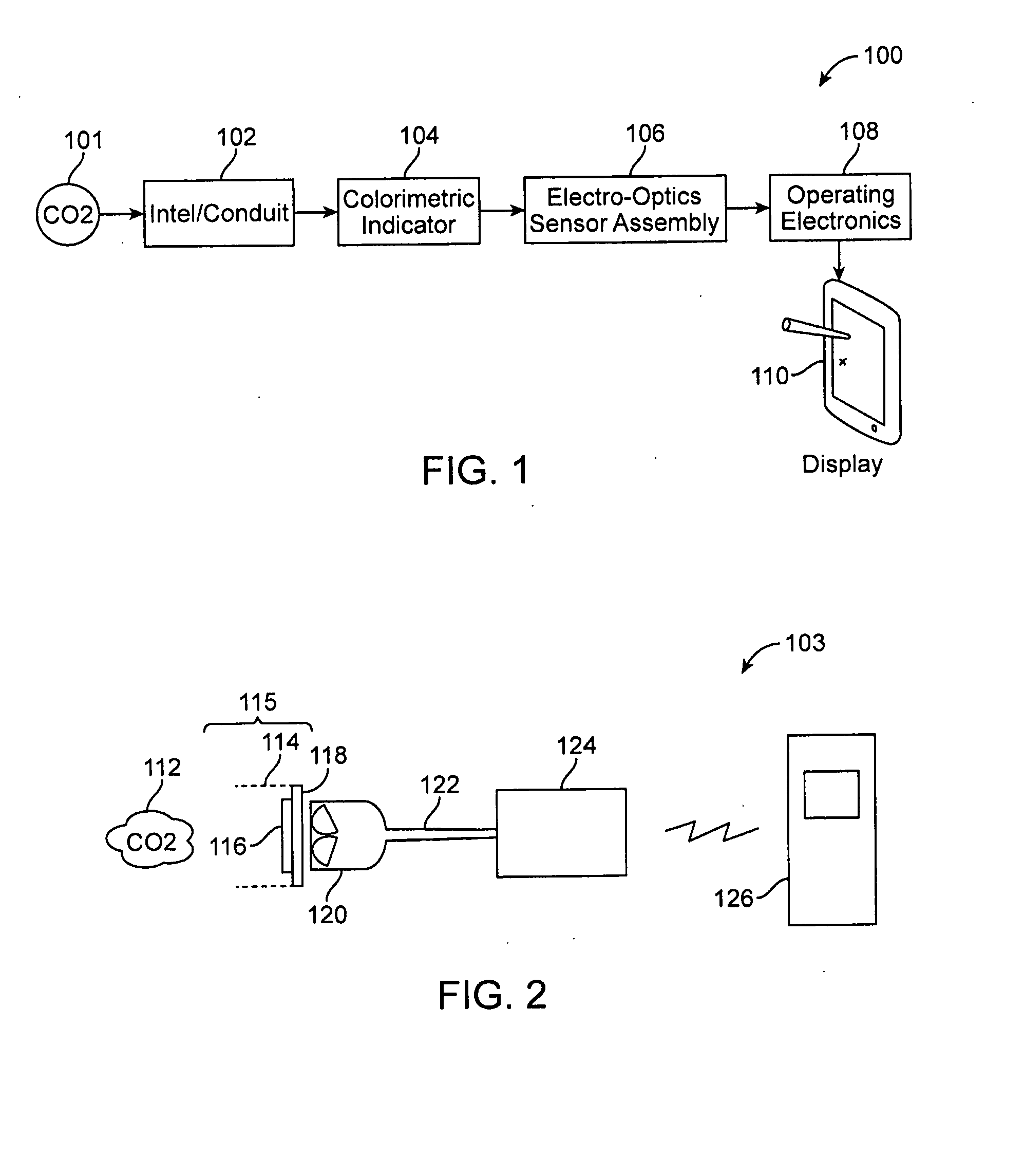

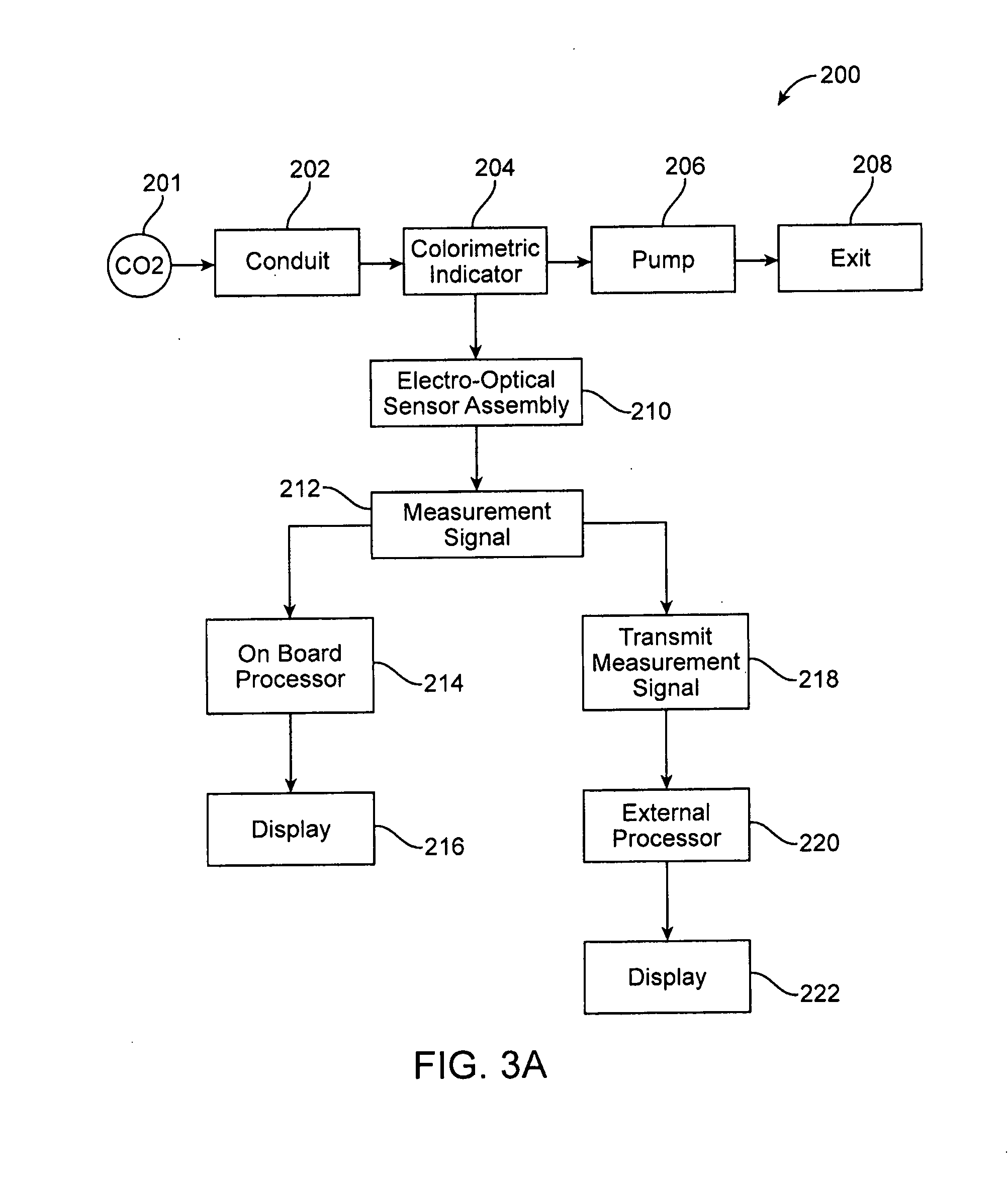

Methods and systems for quantitative colorimetric capnometry

ActiveUS20160245830A1Change quantityPhysical therapies and activitiesMechanical/radiation/invasive therapiesElectricityElectro-optical sensor

Quantitative colorimetric carbon dioxide detection and measurement systems are disclosed. The systems can include a gas conduit, a colorimetric indicator adapted to exhibit a color change in response to exposure to carbon dioxide gas, a temperature controller operatively coupled to the colorimetric indicator and configured to control the temperature of the colorimetric indicator, an electro-optical sensor assembly including a light source or sources adapted to transmit light to the colorimetric indicator, and a photodiode or photodiodes configured to detect light reflected from the colorimetric indicator and to generate a measurement signal, and a processor in communication with the electro-optical sensor assembly. The processor can be configured to receive the measurement signal generated by the electro-optical sensor assembly and to compute a concentration of carbon dioxide based on the measurement signal. Methods for using the systems are also disclosed including providing a breathing therapy to a patient or user.

Owner:FREESPIRA INC

All-optical logic gates using nonlinear elements - claim set vi

InactiveUS20070248124A1Change quantityPrecise arrangementLaser using scattering effectsCoupling light guidesLogic gateNonlinear element

An all-optical logic gates comprises a nonlinear element such as an optical resonator configured to receive optical input signals, at least one of which is amplitude-modulated to include data. The nonlinear element is configured in relation to the carrier frequency of the optical input signals to perform a logic operation based on the resonant frequency of the nonlinear element in relation to the carrier frequency. Based on the optical input signals, the nonlinear element generates an optical output signal having a binary logic level. A combining medium can be used to combine the optical input signals for discrimination by the nonlinear element to generate the optical output signal. Various embodiments include all-optical AND, NOT, NAND, NOR, OR, XOR, and XNOR gates and memory latch.

Owner:COVEY JOHN

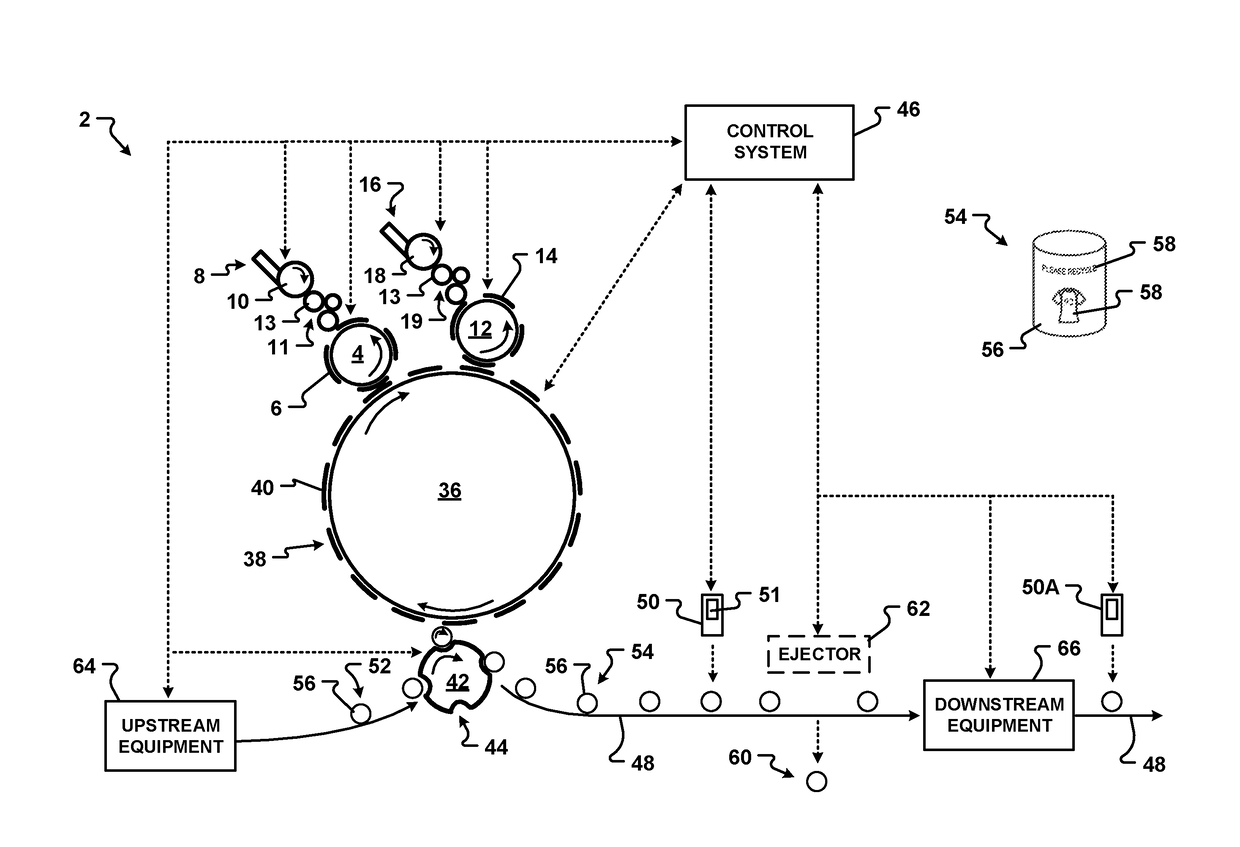

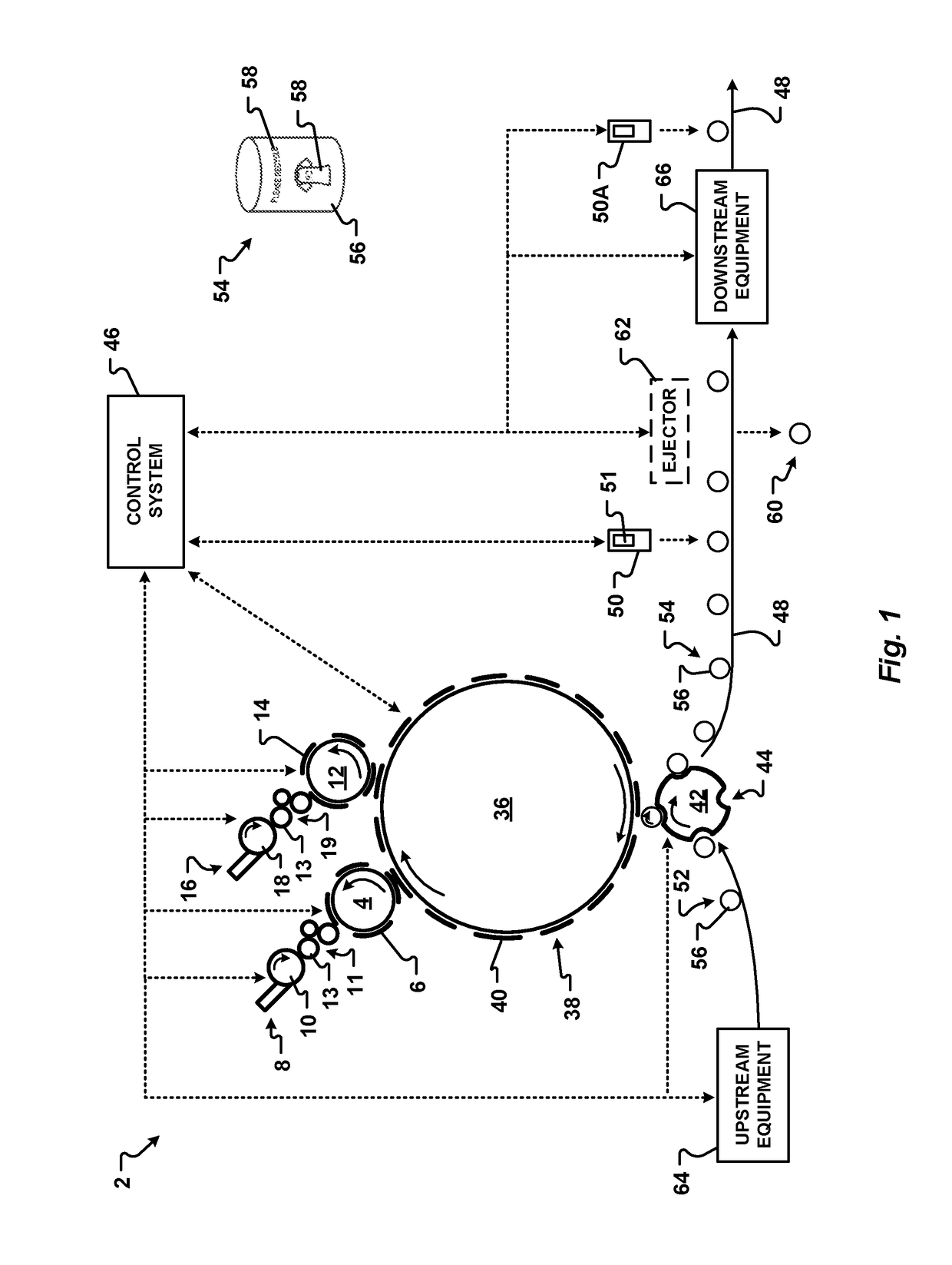

System and method for monitoring and adjusting a decorator for containers

ActiveUS20180201011A1Cost-effective and fast and reliableChange quantityTransfer printingOther printing apparatusControl systemEngineering

An apparatus and methods of monitoring and adjusting a decorator for metallic containers are provided. More specifically, the present invention relates to apparatus and methods used to provide a decoration on a predetermined portion of a metallic container body. The decorator includes a sensor that senses decorations on metallic containers. A control system receives information related to the sensed decorations from the sensor and then determines if the decorations at least meet predetermined color, density, thickness, orientation, and consistency targets. The control system can optionally automatically adjust elements of the decorator to correct a deficient decoration. In one embodiment, the control system can automatically send a signal to the decorator to adjust the color, density, orientation, positioning, and consistency of decorations transferred to the metallic containers. In another embodiment, the control system can send a signal to adjust a position of an inking assembly, an ink roller, a ductor roller a plate cylinder, a printing plate, a blanket cylinder, and a transfer blanket of the decorator.

Owner:BALL CORP

Hydraulic suspension with a lock-out mechanism for an off-highway vehicle

InactiveUS7377523B2Change quantityVehicle fittings for liftingVehicle cleaning apparatusHydraulic cylinderHydraulic circuit

A vehicle has an axle connected to a frame by at least one hydraulic cylinder with two chambers separated by a piston. A hydraulic circuit controls flow of fluid between two cylinder chambers and between the chambers and an accumulator to dampen motion of the frame relative to the axle. The hydraulic circuit includes a control valve and a pair of check valves arranged so that the single control valve is able to lock-out the cylinder to emulate a rigid connection of the frame to the axle, as needed.

Owner:HUSCO INT INC

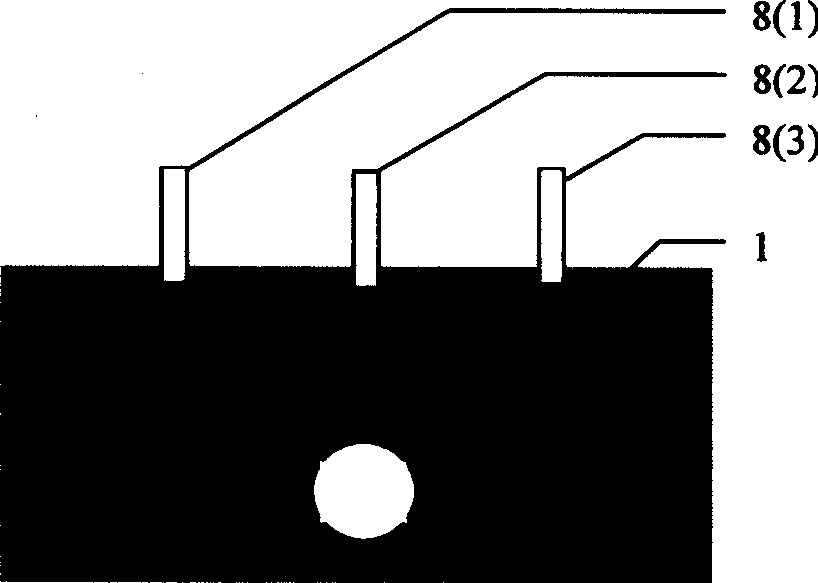

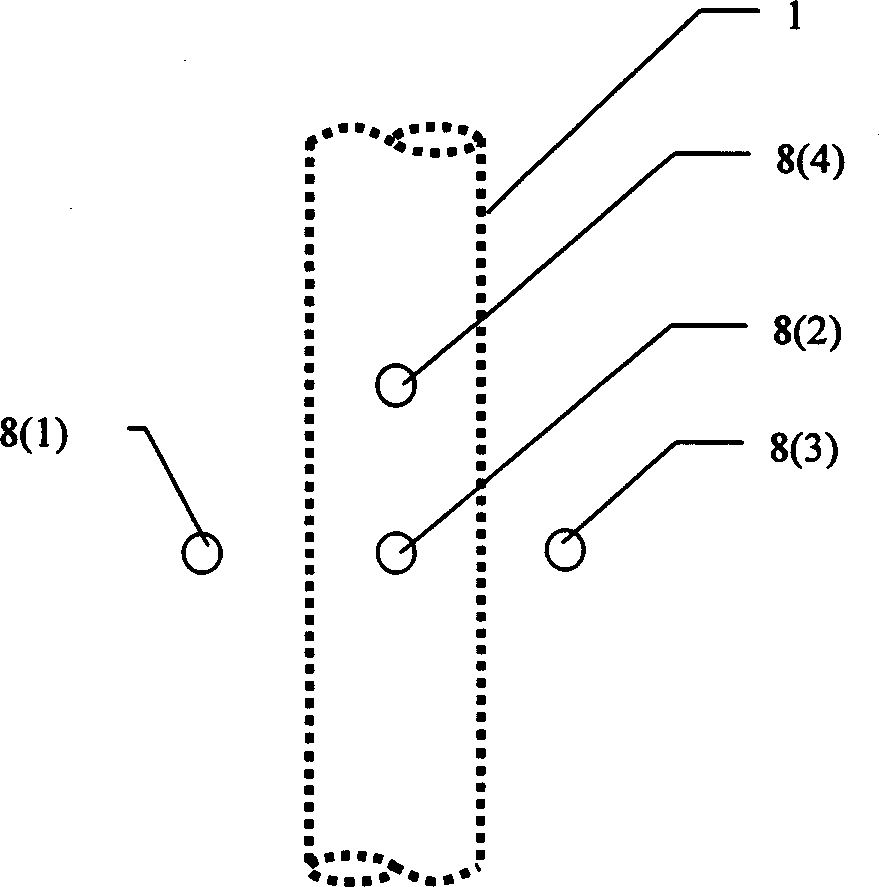

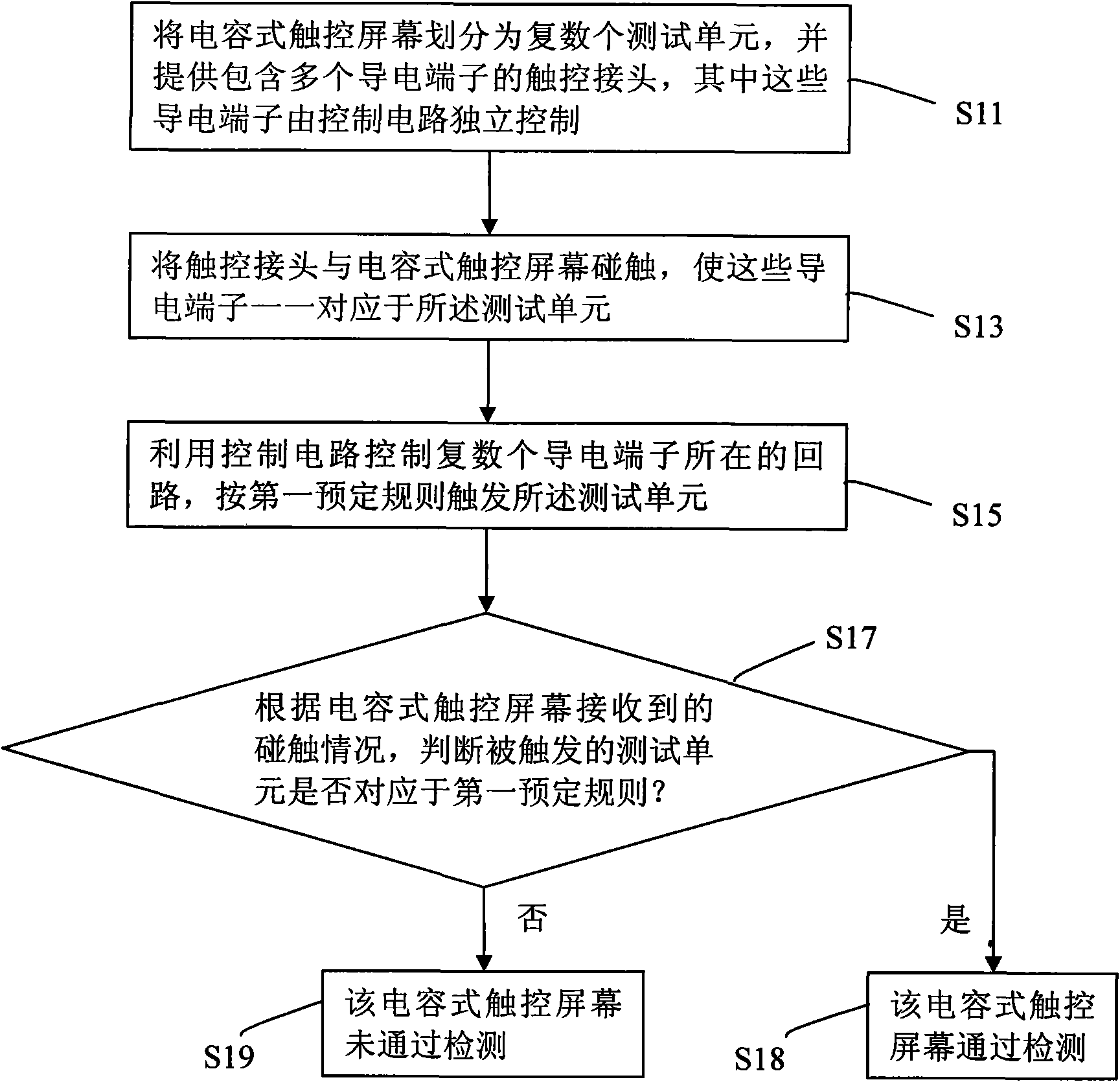

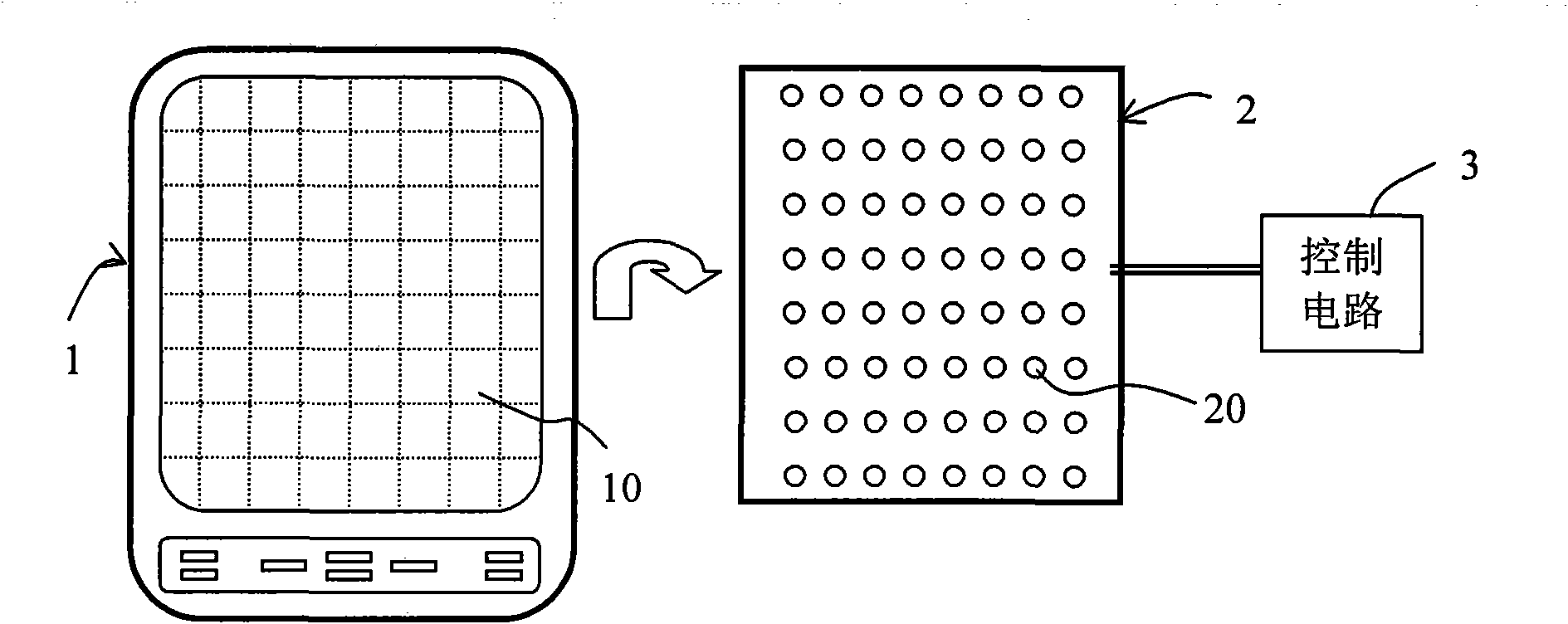

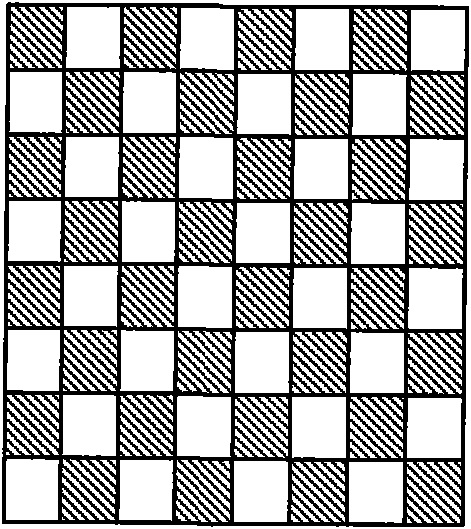

Detection method and system of capacitance-type touch screen

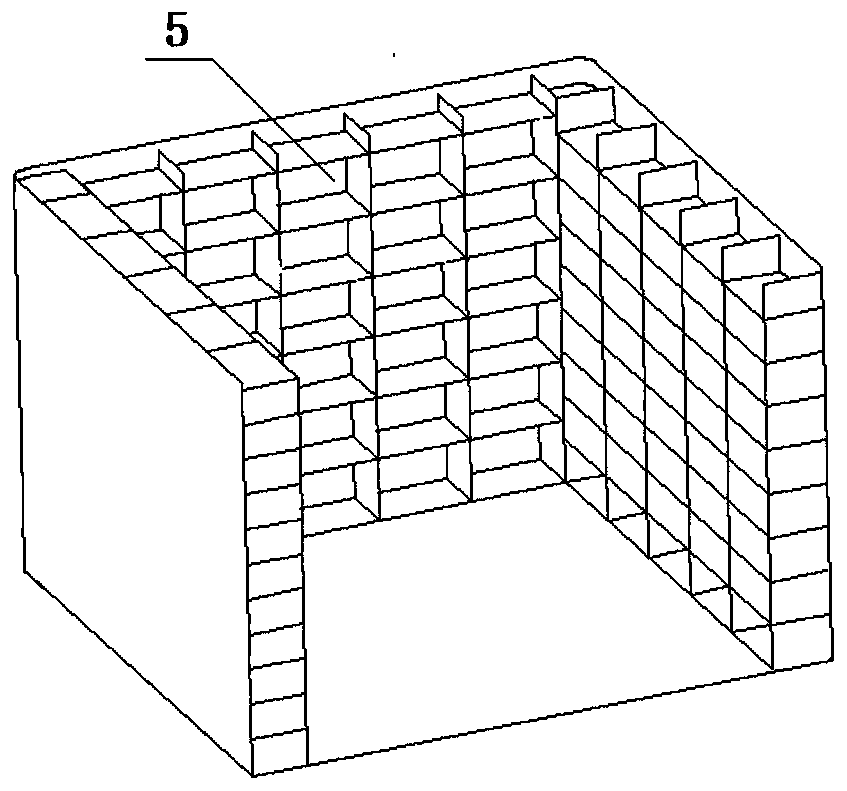

The invention provides a detection method and system of a capacitance-type touch screen. The detection method comprises the following steps of: dividing the capacitance-type touch screen into a plurality of test units, and providing a touch joint comprising a plurality of conductive terminals; then enabling the touch joint to be in contact with the capacitance-type touch screen; then controlling a loop with the plurality of conductive terminals by utilizing a control circuit; triggering the test units according to predetermined rules; and finally judging whether the triggered test units correspond to the predetermined rules or not according to touch conditions received by the capacitance-type touch screen so as to confirm whether the capacitance-type touch screen passes detection or not. The detection method and system provided by the invention can be used for fast finding the defect of touch ineffectiveness caused by assembly, simplifying the test process and increasing the test speed.

Owner:QISDA SUZHOU +1

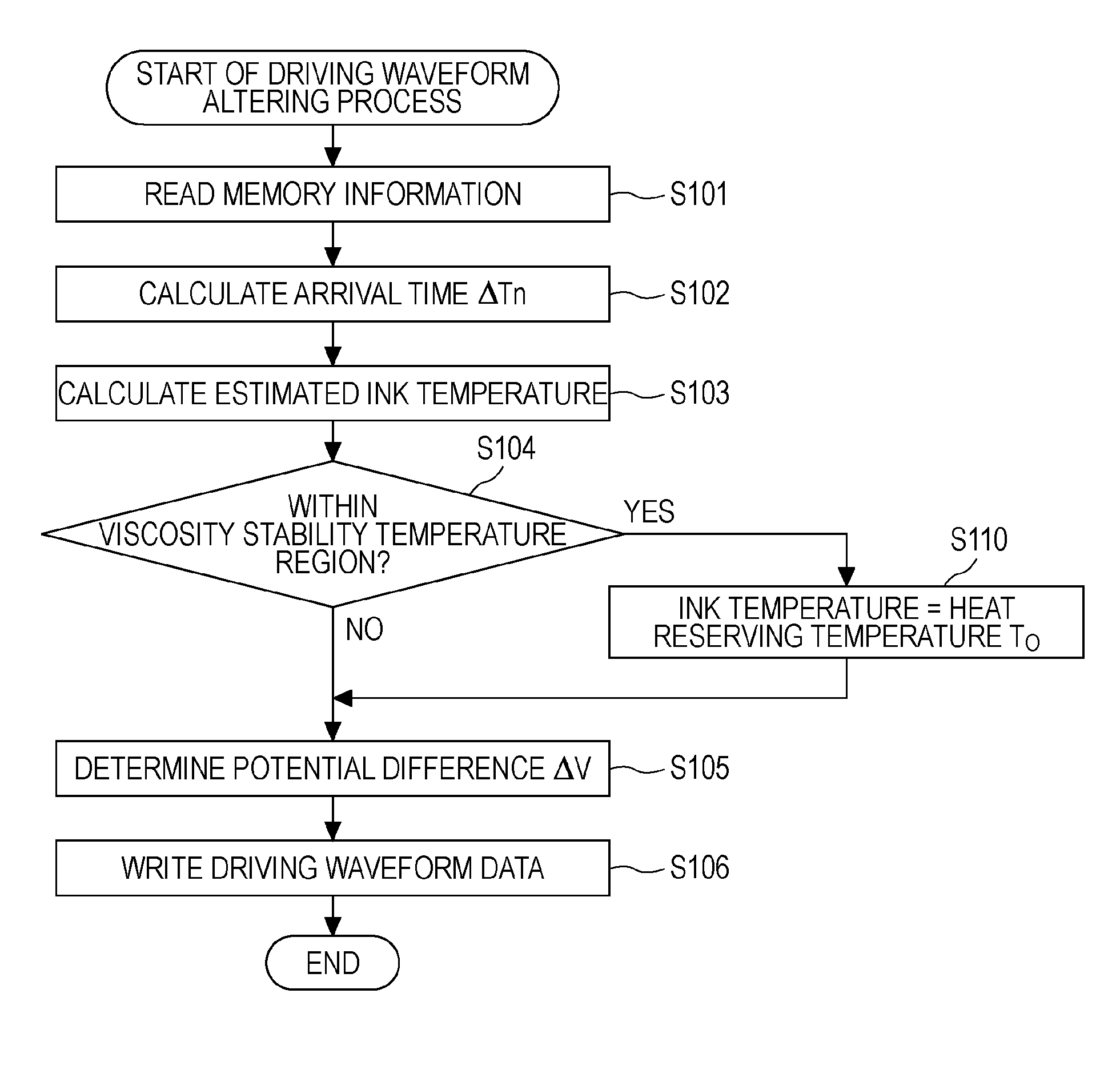

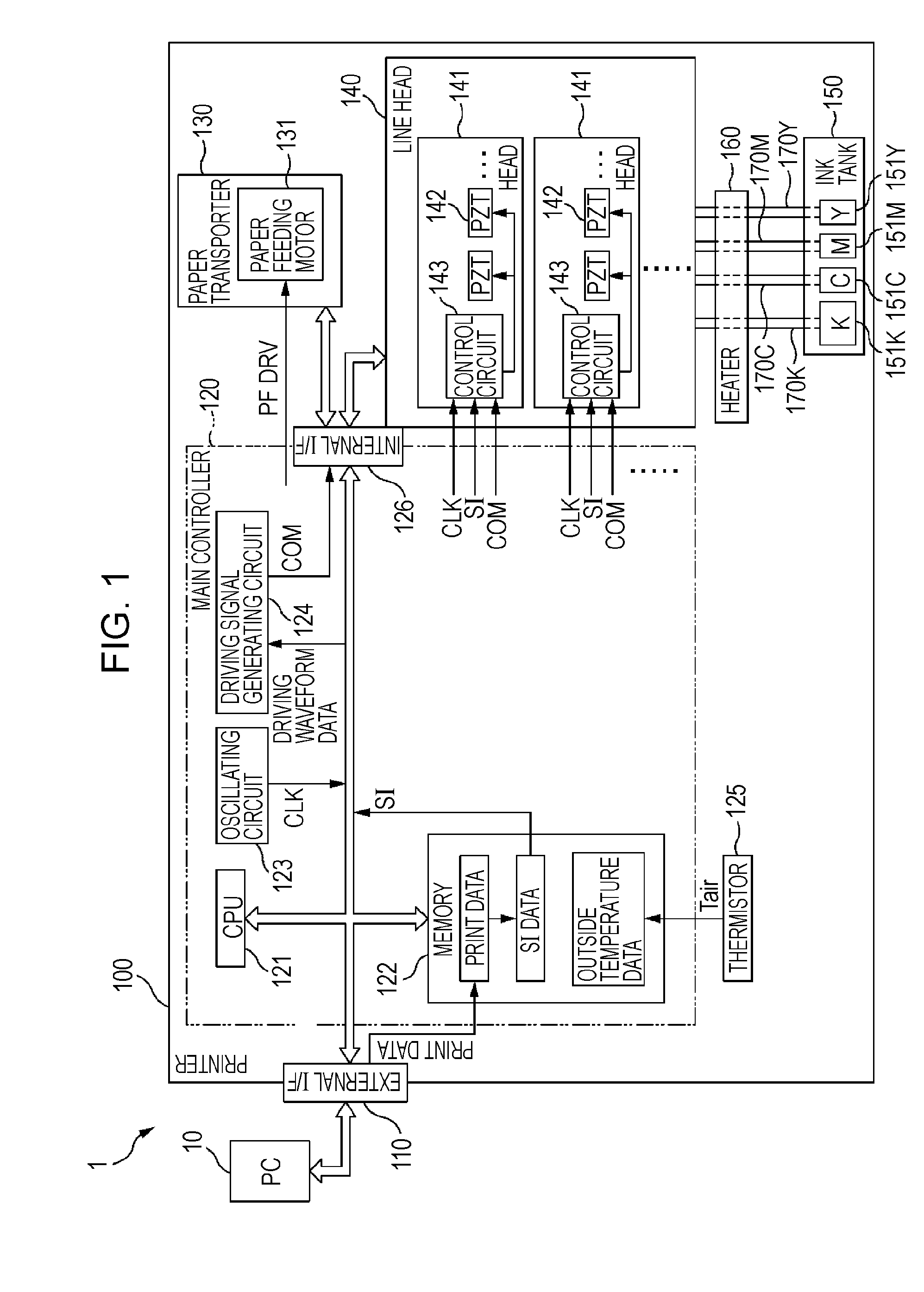

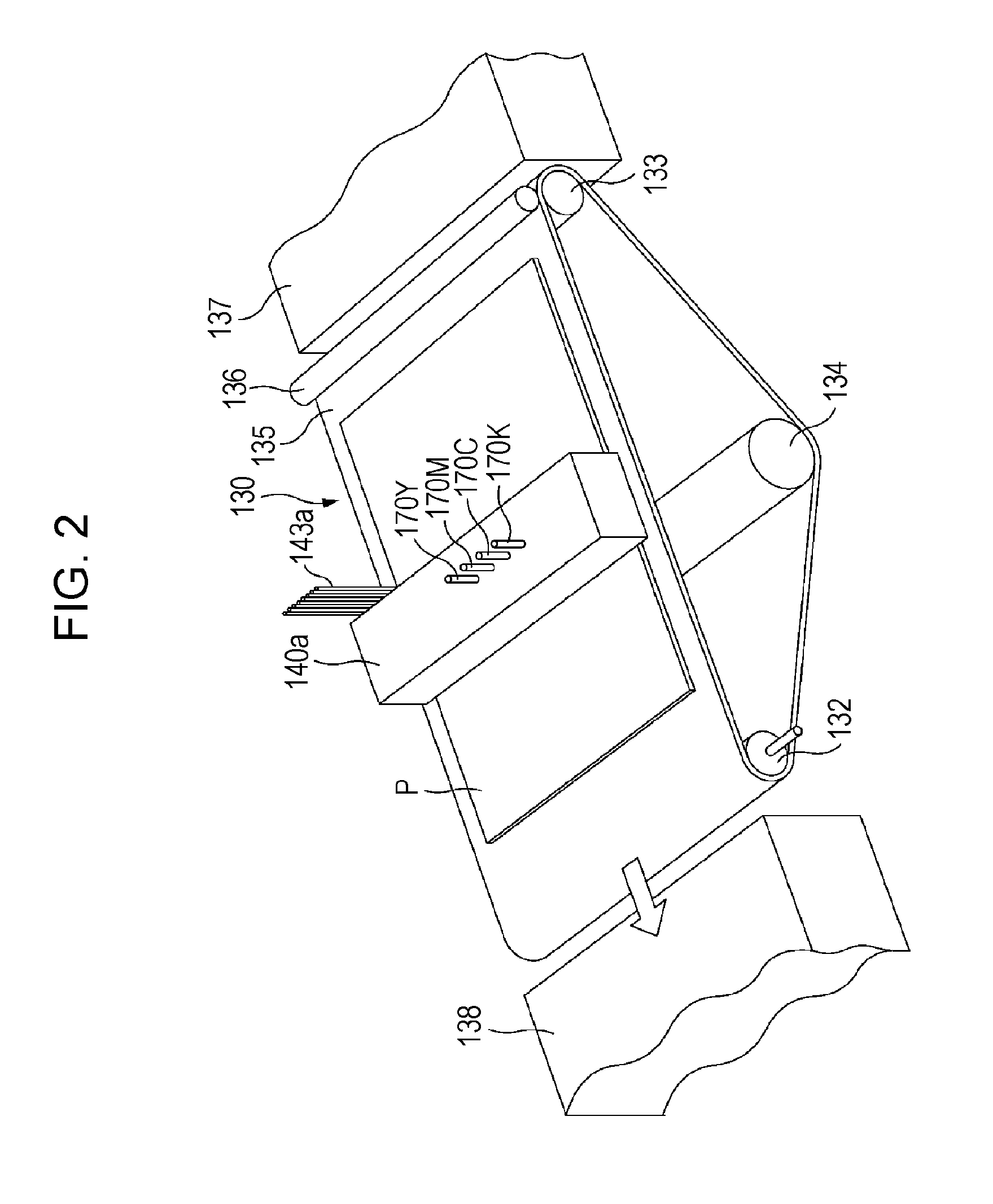

Liquid discharging apparatus, liquid discharging method, and program

A liquid discharging apparatus includes a head that is driven in response to a driving signal to discharge liquid, a controller that drives the head by generating the driving signal, an adjustment unit that adjusts the temperature of the liquid, and a supply path that supplies the head with the liquid having the temperature adjusted by the adjustment unit. The controller alters the driving signal in accordance with a flow amount of the liquid, which flows in the supply path.

Owner:SEIKO EPSON CORP

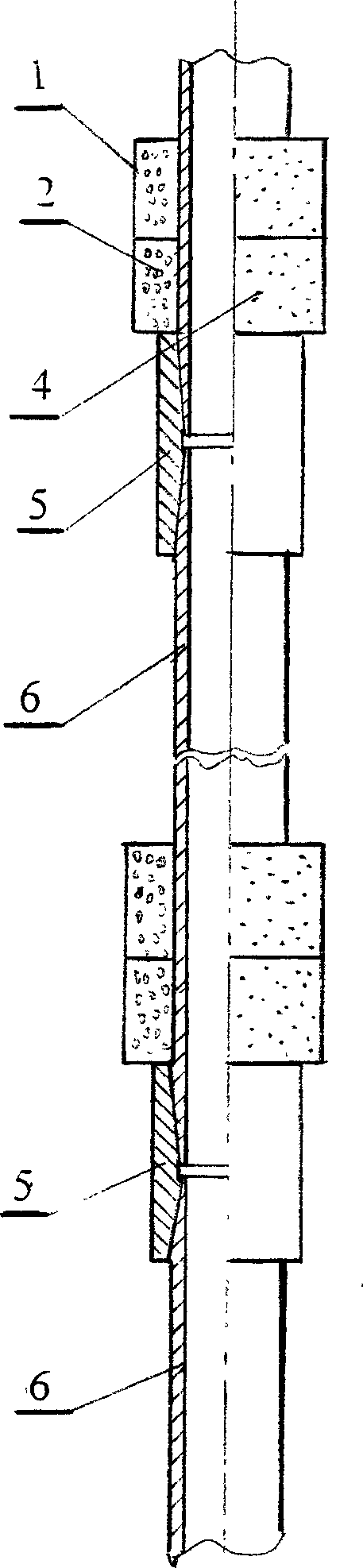

Formula, preparation method of solid corrosion inhibitor and its using method

The invention relates to a high temperature resistant solid corrosion inhibitor manufacturing and using method used in oil pipe and casing pipe. Its raw material preparation weight ratios are as follows: some dibasic acid 20-35%, diethylene triamine 5-15%, chloroacetic acid 5-15%, and sodium dodecyl benzene sulfonate, hexamethenyl tetramine, HPMA, poly epoxy succinic acid, epoxy resin, polyamide resins etc. The manufacturing method includes composing intermediate, preparing solid inhibitor, solidifying, forming, cooling to gain solid inhibitor finished product.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

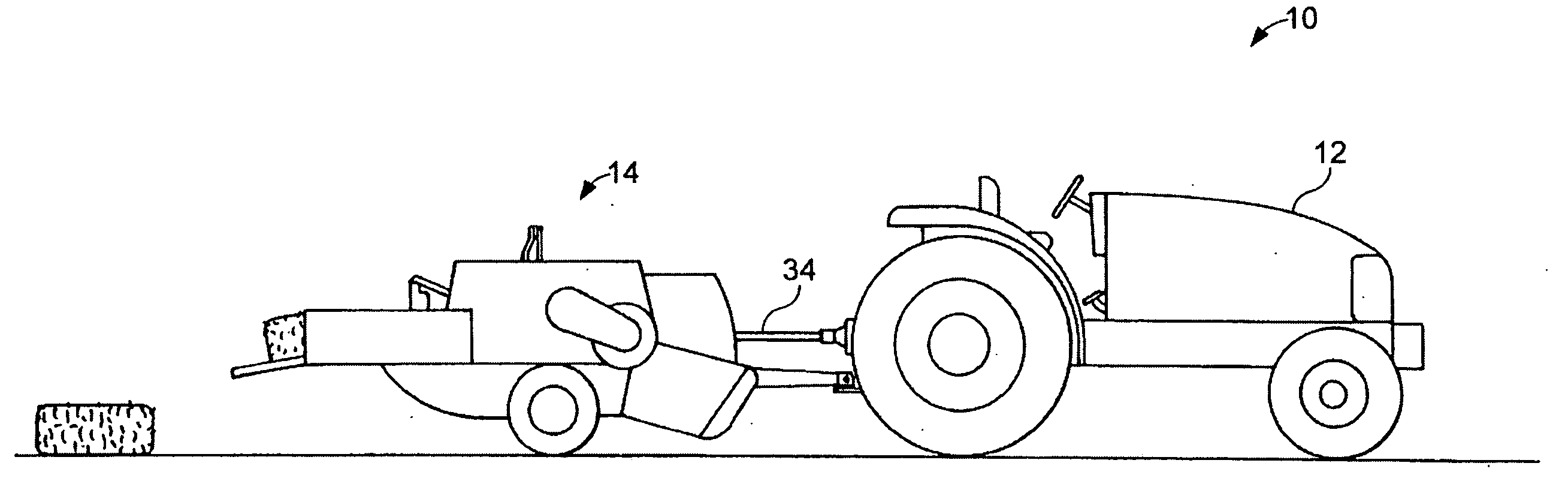

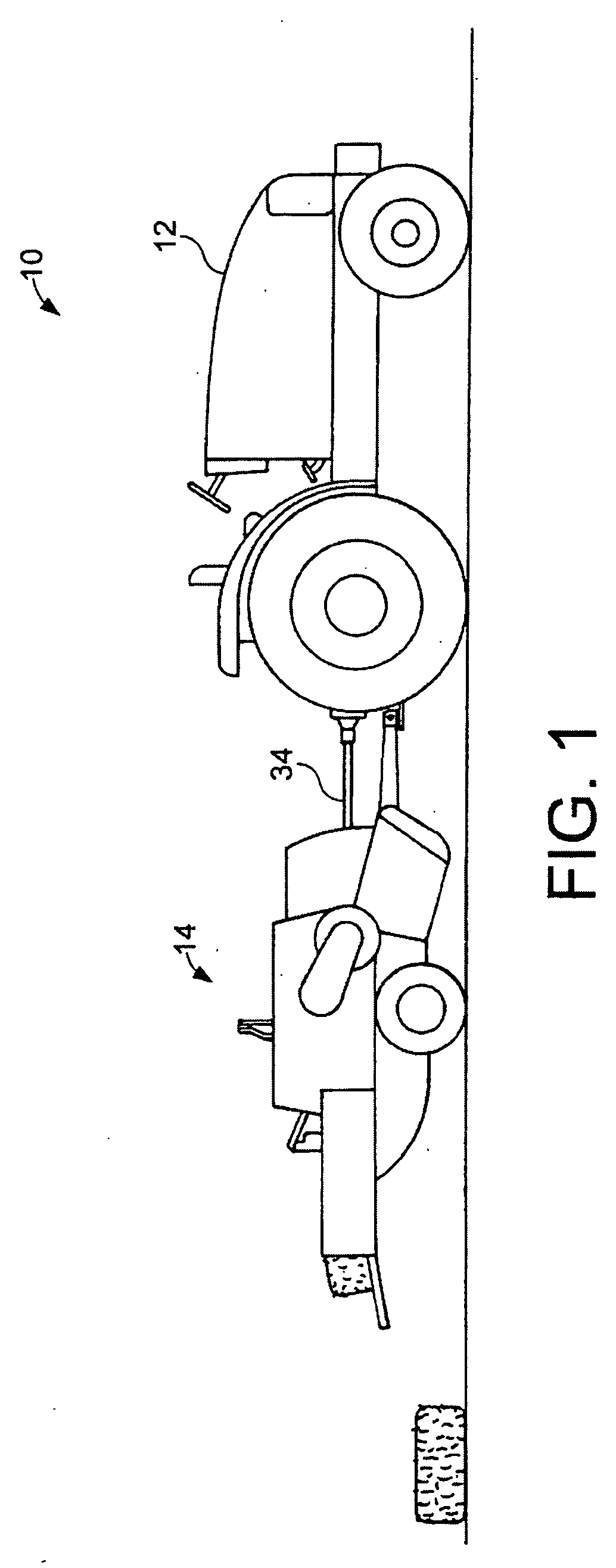

Tractor And Baler Interaction System

An agricultural power control system including a moving element, a power source, a signal generating element and a torque modifying device. The moving element is configured to engage a quantity of crop material in a cyclical manner. The power source conveys power to the moving element. The signal generating element is configured to provide a signal relating to an anticipated quantity of crop material prior to the moving element engaging the quantity of crop material. The torque modifying device is configured to cause the power source to alter an amount of torque delivered to the moving element dependent upon the signal.

Owner:DEERE & CO

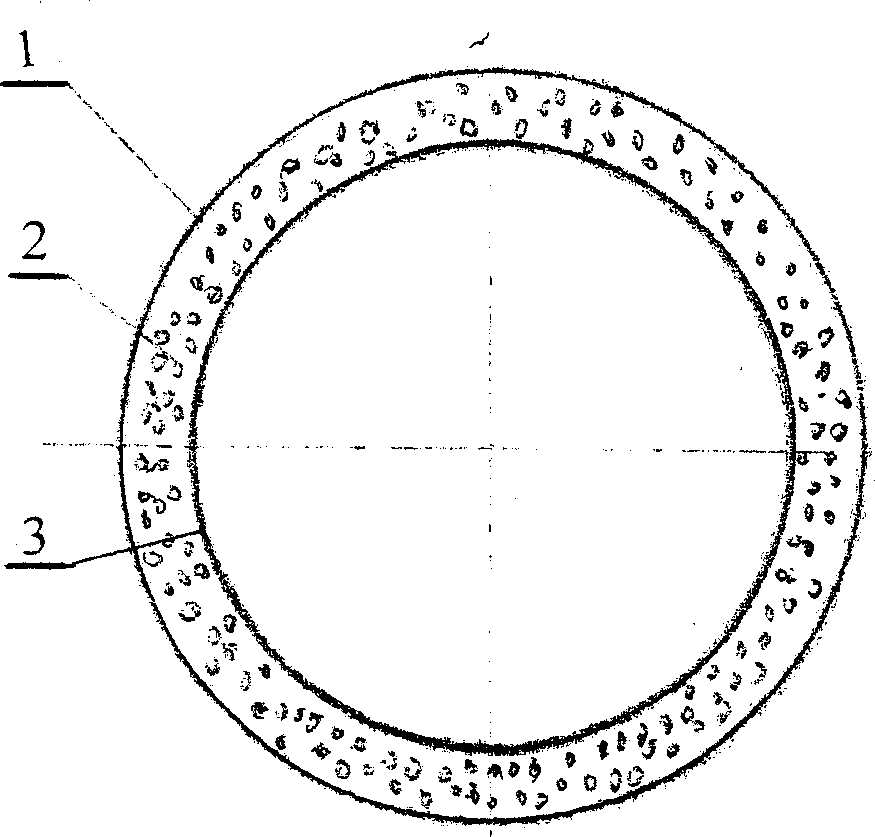

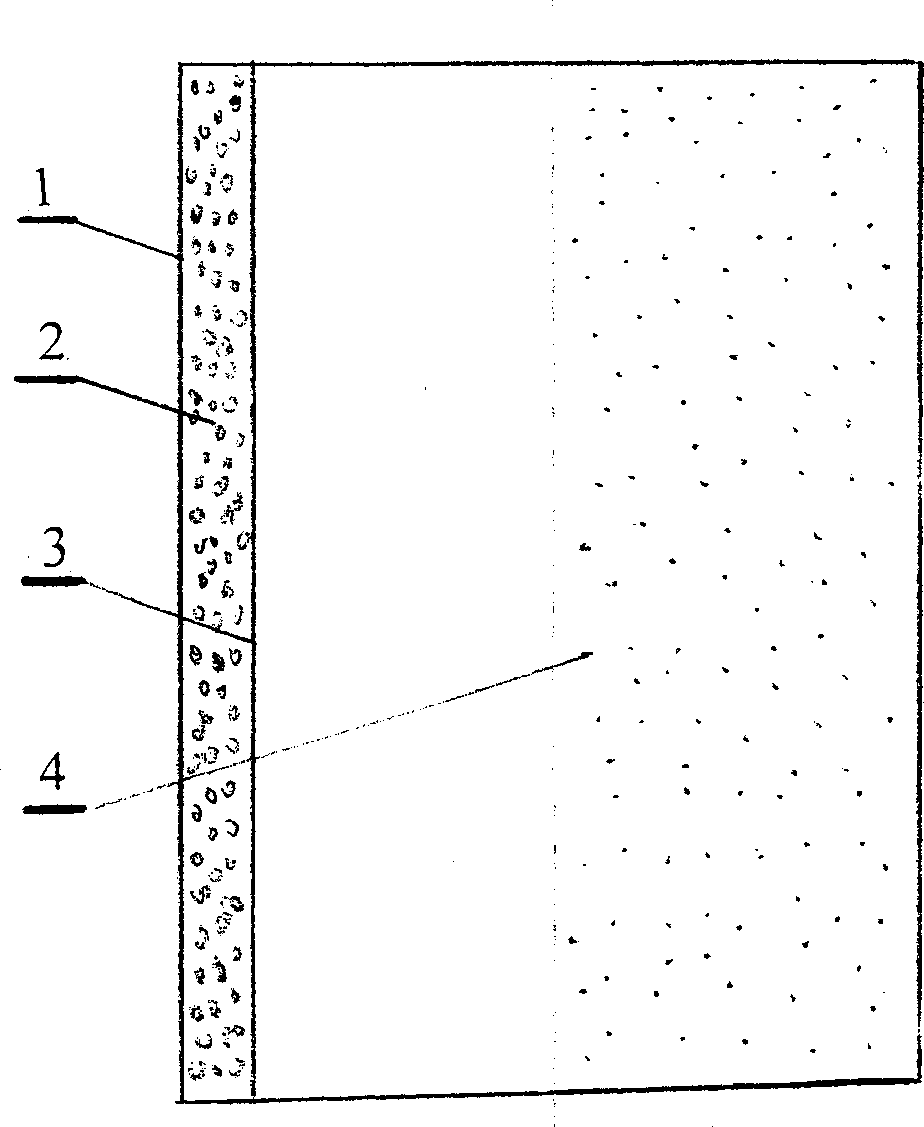

Spheroidizing pearlite and production method thereof

The invention relates to a nodulizing pearlite and a production method thereof and relates to the technical field of metallurgical technique. The production method comprises the following steps: 10 to 91.7 percent of scrap steel, 0 to 53.3 percent of scrap returns, 0 to 75 percent of pig iron, 0 to 3.87 percent of recarburizing agent, 0 to 1.53 percent of ferrosilicon and 0.2 to 0.67 percent of ferromanganese are thrown into a medium frequency induction furnace with acid lining; after being molten, the obtained mixture is poured in a ladle with 1.4 to 1.6 percent of rare earth ferrosilicomagnesium alloy and part of inoculant; then the remaining inoculant is added again; and the pearlite QT700-2 is formed after spheroidization. The invention does not use pig iron or uses little pig iron, but uses large amount of scrap steel and scrap returns so as to save the cost of raw materials; synthetic cast iron using a recarburizing method for adjusting the carbon content and a smelting method thereof contain 3.7 to 3.9 percent of C, precipitates large amount of graphite, have small dimension of sphere diameter, increase roundness and can reduce the hole area and reduce the area of shrinkage porosity, thus leading the casting product to be more compact.

Owner:徐宏亮

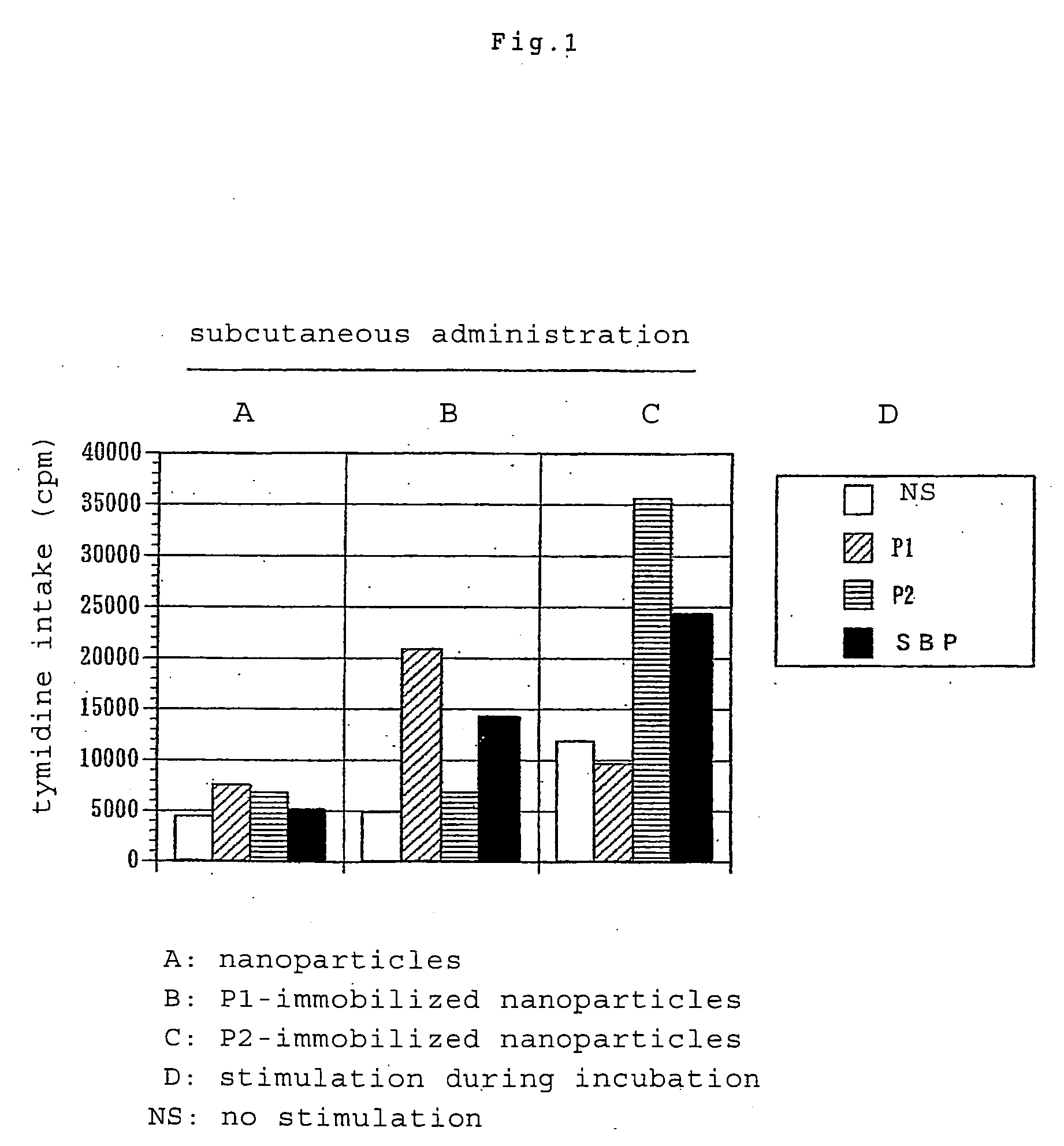

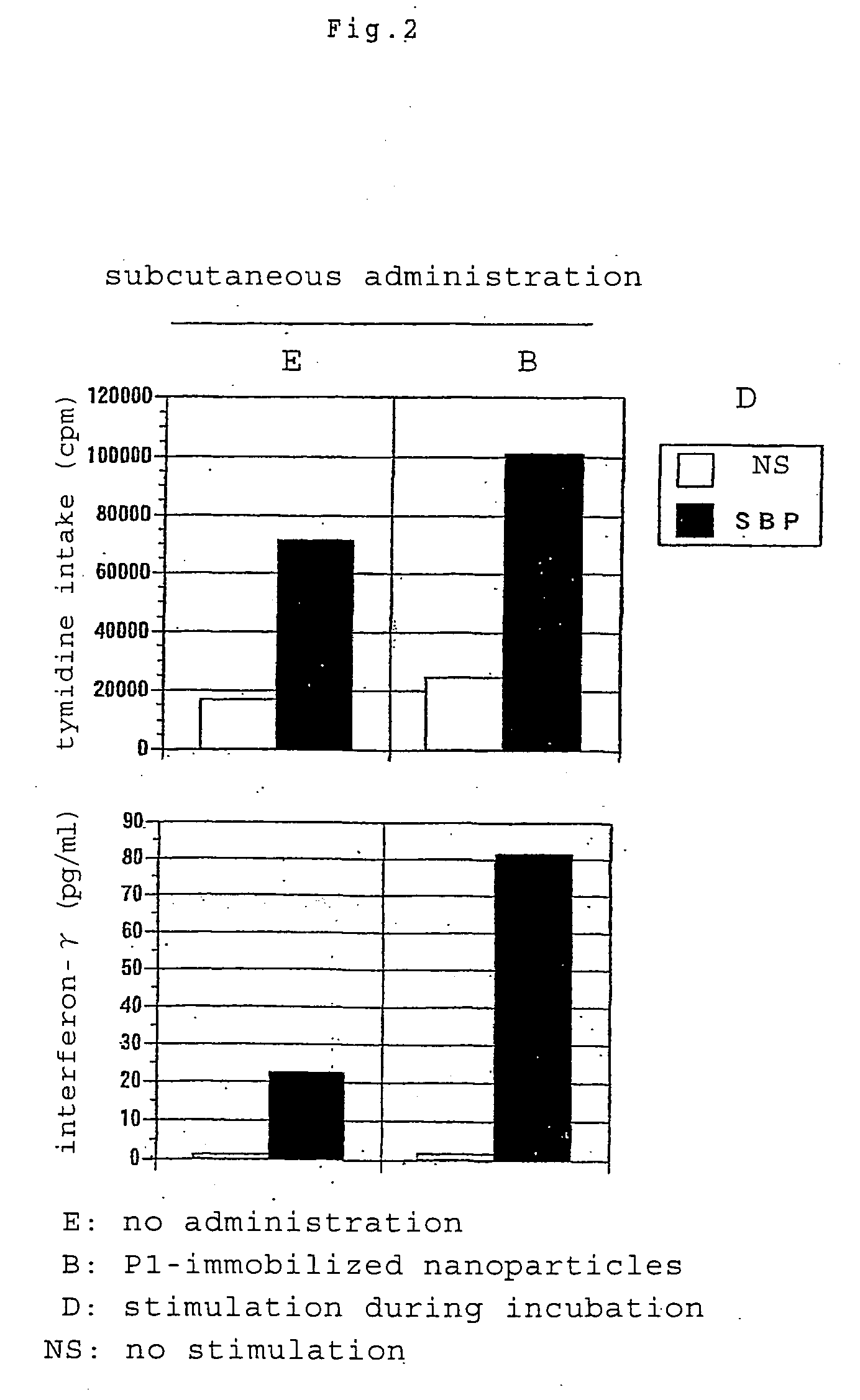

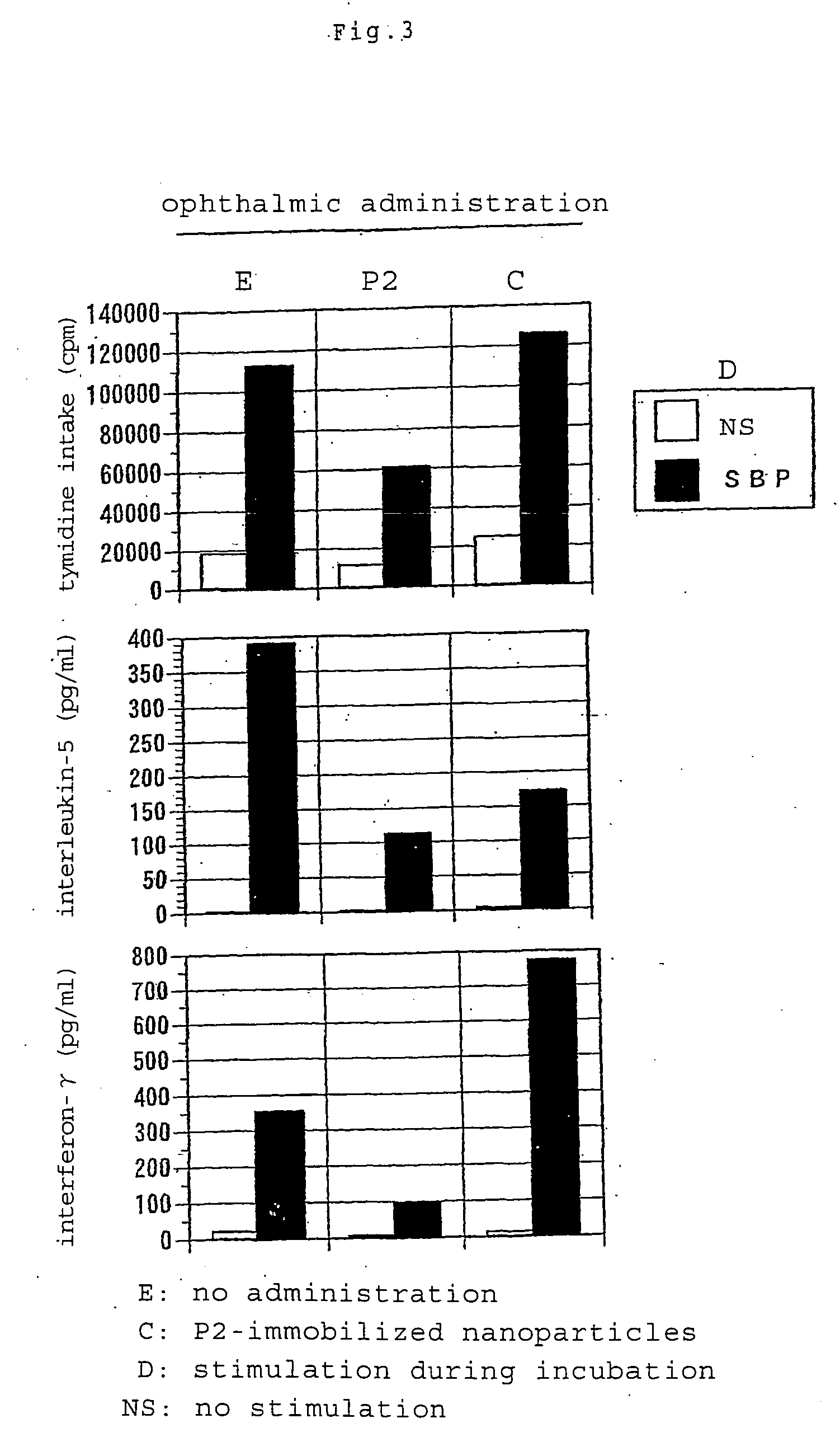

Biodegradable nanoparticle having t-cell recognizable epitope peptide immobilized thereon or encapsulated therein

InactiveUS20090156480A1Increase surface areaChange quantityPowder deliveryPeptide/protein ingredientsEpitopeDisease

A biodegradable nanoparticle having a T cell recognizable epitope peptide immobilized thereon or encapsulated therein of the present invention is usable as a safe and effective immunotherapeutic agent, and is useful as an immunotherapeutic agent for treating, for example, pollinosis, year-round nasal allergic disease and seasonal nasal allergic disease.

Owner:TAIHO PHARMA CO LTD

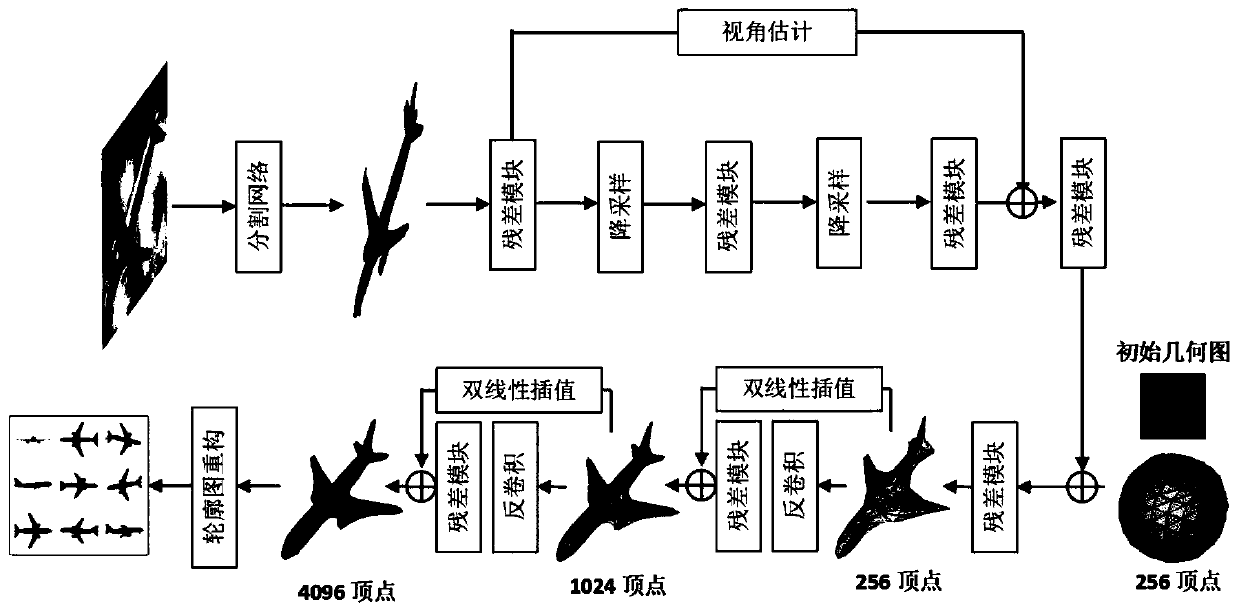

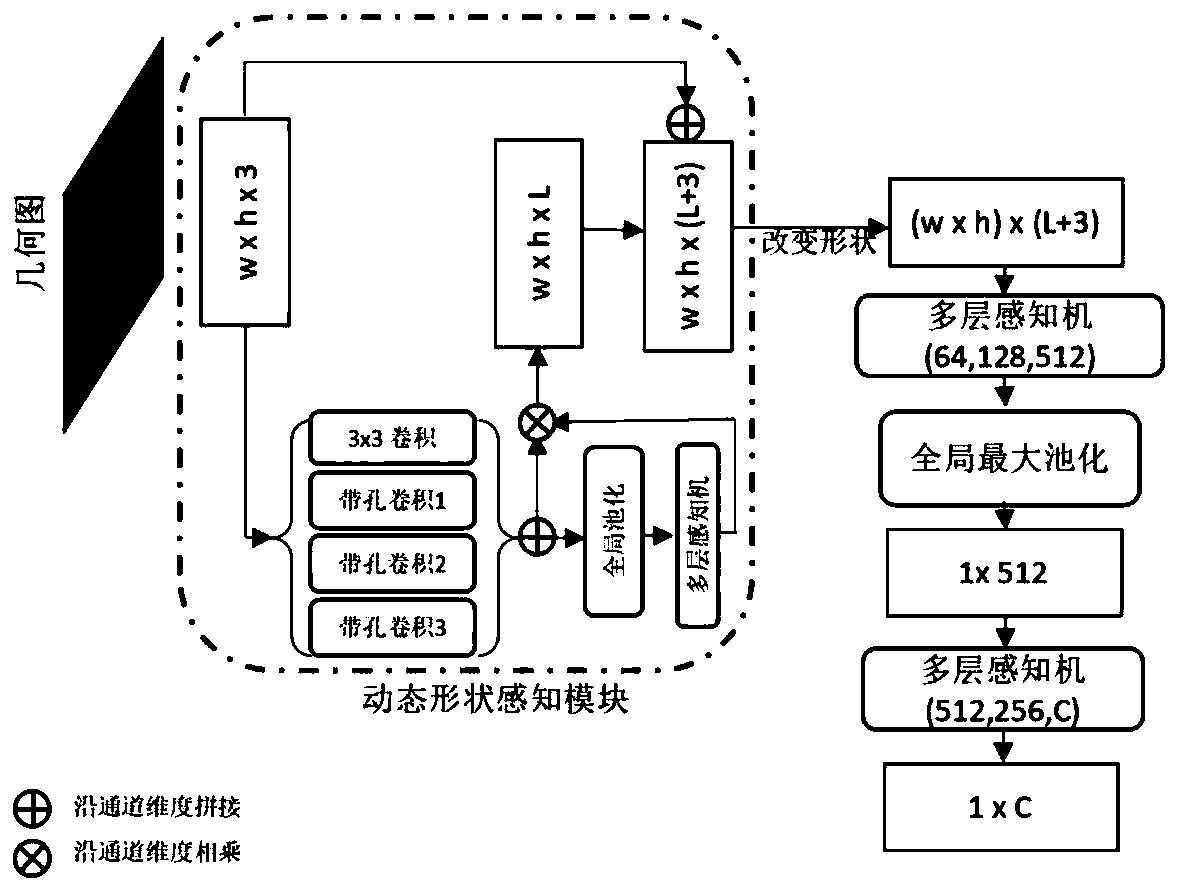

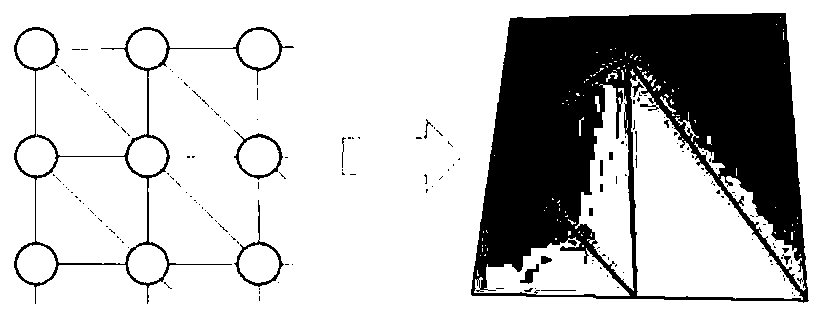

Three-dimensional grid model generation method and device based on single image

The invention discloses a three-dimensional grid model reconstruction method and device based on a single image, and the single image can be a contour map of a natural image or an object, and a three-dimensional model consistent with the shape of the single image is completely automatically generated according to the single image provided by a user. The method comprises the steps of semantic segmentation, foreground extraction, shape feature extraction, view angle prediction, three-dimensional model training and point cloud packaging of surface grids so as to reconstruct and generate a three-dimensional grid model. According to the method, the three-dimensional model design time can be greatly shortened, so that the target model can be obtained only by fine trimming on the basis of the generated three-dimensional model when the three-dimensional model is designed.

Owner:PEKING UNIV

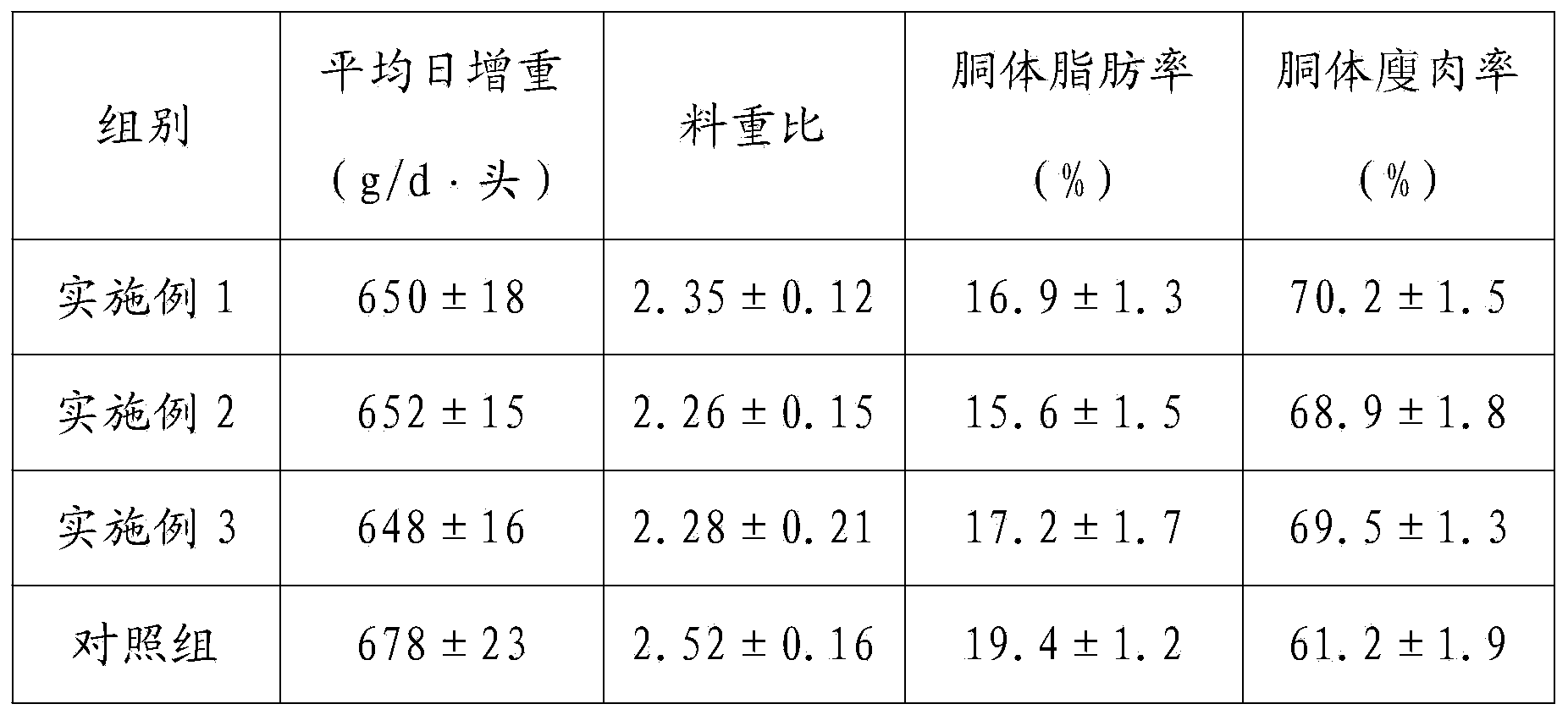

Feed additive capable of increasing meat factor of pork pigs and improving meat quality

The invention discloses a feed additive capable of increasing the meat factor of pork pigs and improving the meat quality, belonging to the technical field of feed additives. The feed additive comprises pure Chinese herbal medicine powder, lentinan, compound probiotics, a complex enzyme preparation, L-carnitine, beta-carotene, gamma-linolenic oil, vitamin E, vitamin C, ferric sulfate, magnesium sulfate, sodium selenite and carriers, wherein the carriers include rice hull powder, a mixture of rice chaff and husk and kaolin. According to the feed additive, the problem that the meat quality is reduced due to pig feed additives is effectively solved, the anti-stress capacity of the pigs is improved, pig diseases are well prevented and treated, the physique of the pork pigs is improved, and the high-quality pork can be produced; furthermore, the distribution of ketone fat and protein is improved, so that the meat factor of the pork pigs is improved.

Owner:GUANGXI UNIV

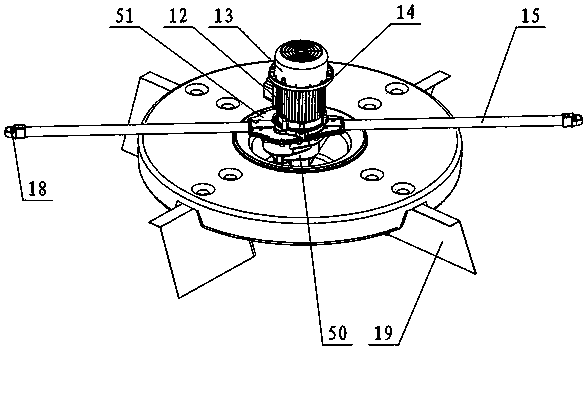

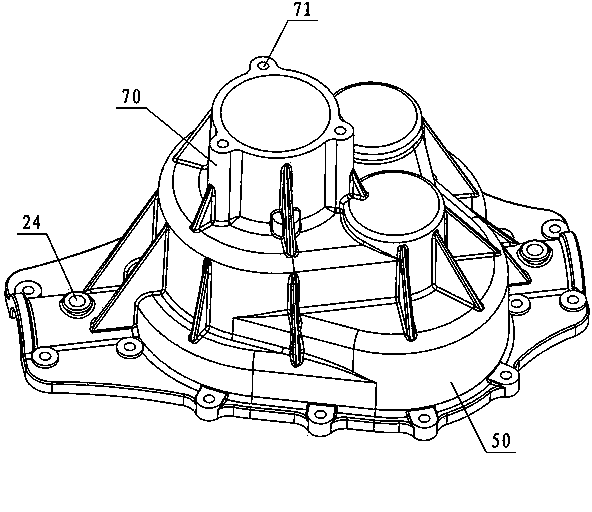

Swelling machine and manufacturing method of swelling machine floating body

ActiveCN103563829AChange powerImprove diffusion abilityPisciculture and aquariaGear wheelElectric machinery

The invention relates to a swelling machine and a manufacturing method of a swelling machine floating body. The swelling machine mainly comprises a motor, a reduction gearbox, a floating body, blades and a fixing rod, wherein the floating body is a hollow shell body, mounting spaces for mounting the blades are arranged on the circumference of the lower part of the floating body, and the blades are arranged in the mounting spaces; the middle part of the upper part of the floating body is sunken, an upper shell and a lower shell of the sunken part are integrated, and the sunken part is provided with a connection space matched with an output shaft; the reduction gearbox is mainly consists of a box body, a reduction gear, a bearing and the output shaft; the fixing rod is arranged on the reduction gearbox, a sealing chamber is arranged at the lower end of the reduction gearbox, the output shaft downwards extends out of the sealing chamber to drive the floating body to rotate together with the blades, and the motor and the reduction gearbox are fixed by the fixing rod to float on the water surface without rotation.

Owner:ZHEJIANG FORDY MACHINERY

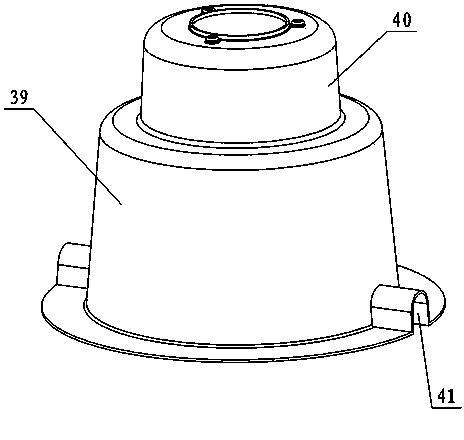

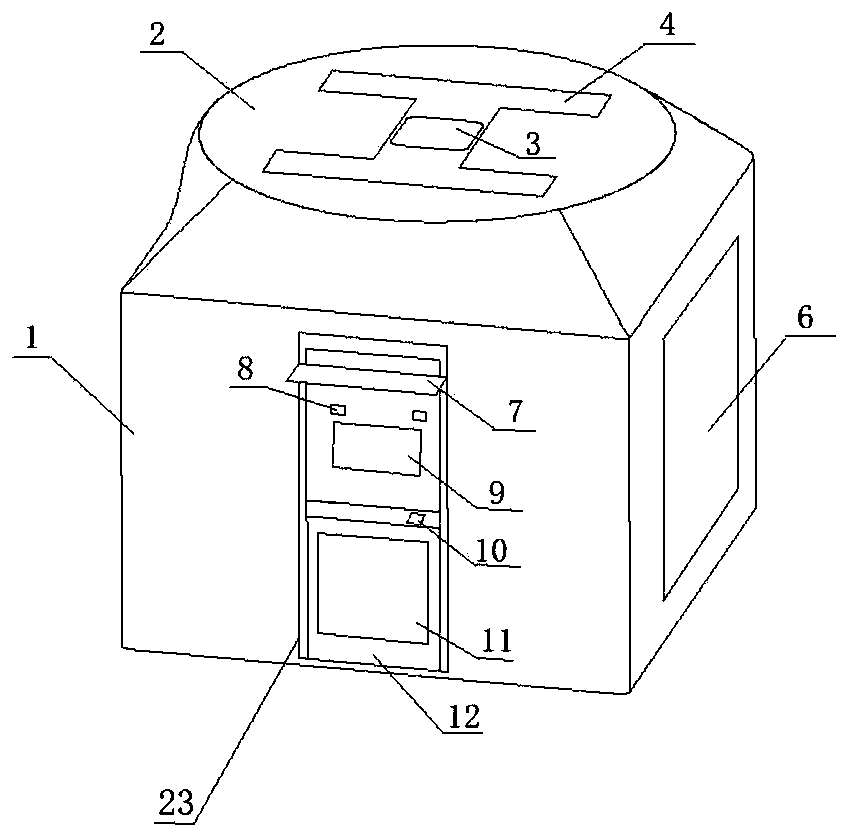

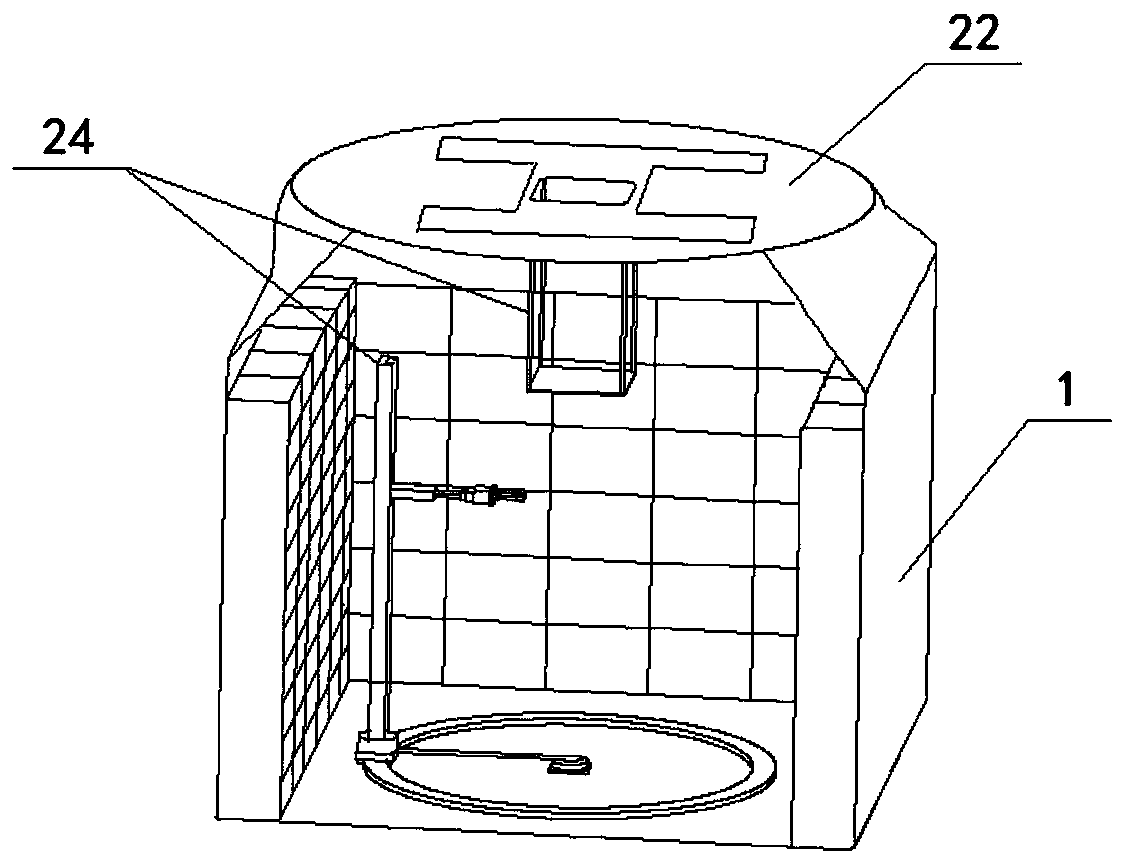

Freely combined type unmanned aerial vehicle intelligent express delivery cabinet

PendingCN109805724ALarge apron areaA large amountKitchen equipmentDomestic articlesDrive motorEngineering

The invention provides a freely combined type unmanned aerial vehicle intelligent express delivery cabinet. An unmanned aerial vehicle receiving platform is positioned on the upper surface of a cabinet body. Article storage compartments are arranged on the internal surface of the cabinet body. A package distribution mechanism is clamped on a track on a bottom plate in the cabinet body. A driving motor is mounted in the central positi9on of the track and drives a driving arm to move on the track. Packages are released to a tray through a delivery opening; a scanner is positioned at the center of the tray to scan the overall dimension of the package and feed back information to a control box; and the control box distributes the corresponding article storage compartments. After sensing package information, infrared detectors in the article storage compartments transmit signals to the control box and send express delivery success short messages to users. The freely combined type unmanned aerial vehicle intelligent express delivery cabinet, provided by the invention, has the advantages that the express delivery cabinets are freely combined according to the number of the express packagesin an area and the floor area; multiple unmanned aerial vehicles simultaneously land by increasing the number of express delivery cabinets; and the freely combined type unmanned aerial vehicle intelligent express delivery cabinet is suitable for the unmanned aerial vehicle delivery groups to deliver the packages.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

All-optical logic gates using nonlinear elements-claim set V

InactiveUS7409131B2Change quantityPrecise arrangementCoupling light guidesLogic circuits using opto-electronic devicesLogic gateNonlinear element

An all-optical logic gates comprises a nonlinear element such as an optical resonator configured to receive optical input signals, at least one of which is amplitude-modulated to include data. The nonlinear element is configured in relation to the carrier frequency of the optical input signals to perform a logic operation based on the resonant frequency of the nonlinear element in relation to the carrier frequency. Based on the optical input signals, the nonlinear element generates an optical output signal having a binary logic level. A combining medium can be used to combine the optical input signals for discrimination by the nonlinear element to generate the optical output signal. Various embodiments include all-optical AND, NOT, NAND, NOR, OR, XOR, and XNOR gates and memory latch.

Owner:COVEY JOHN

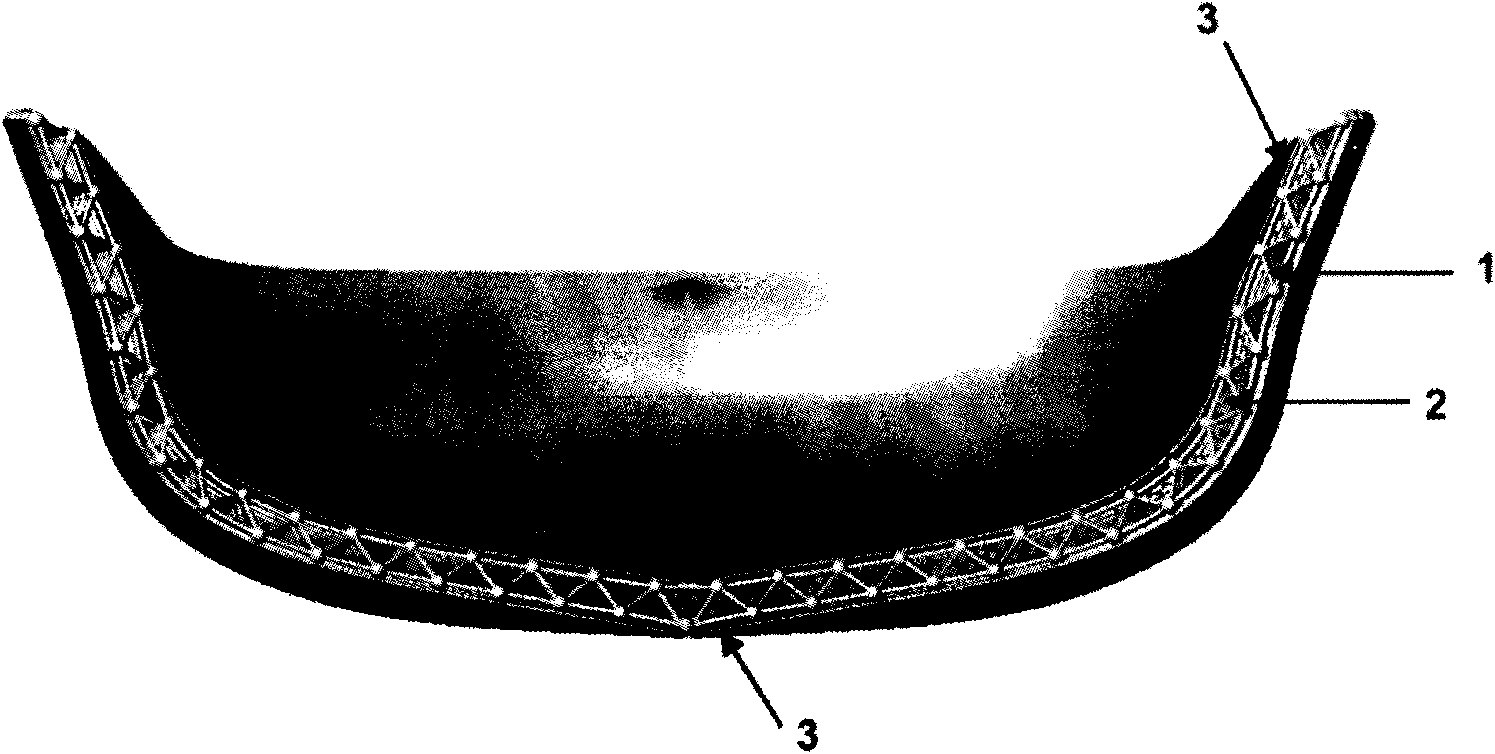

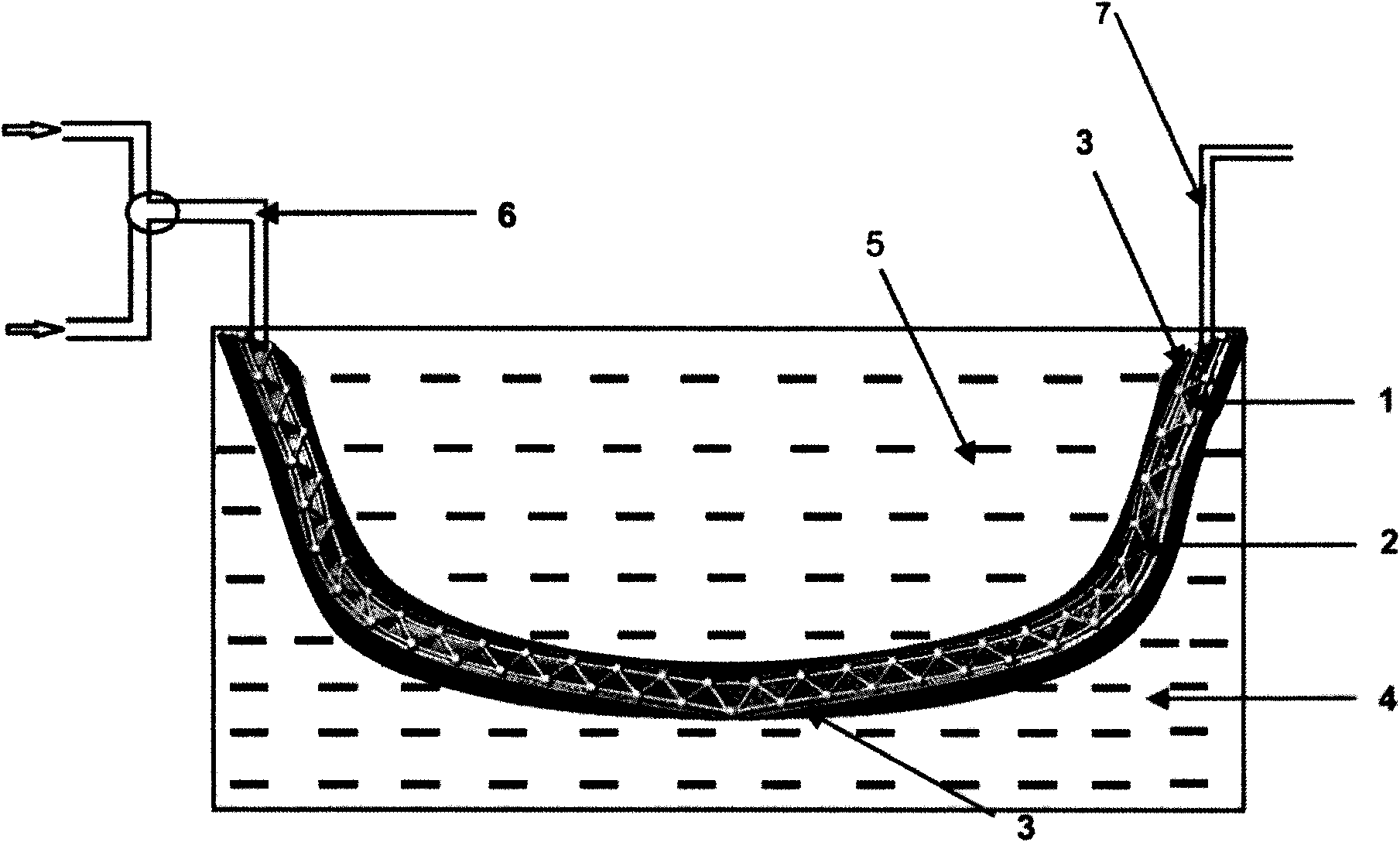

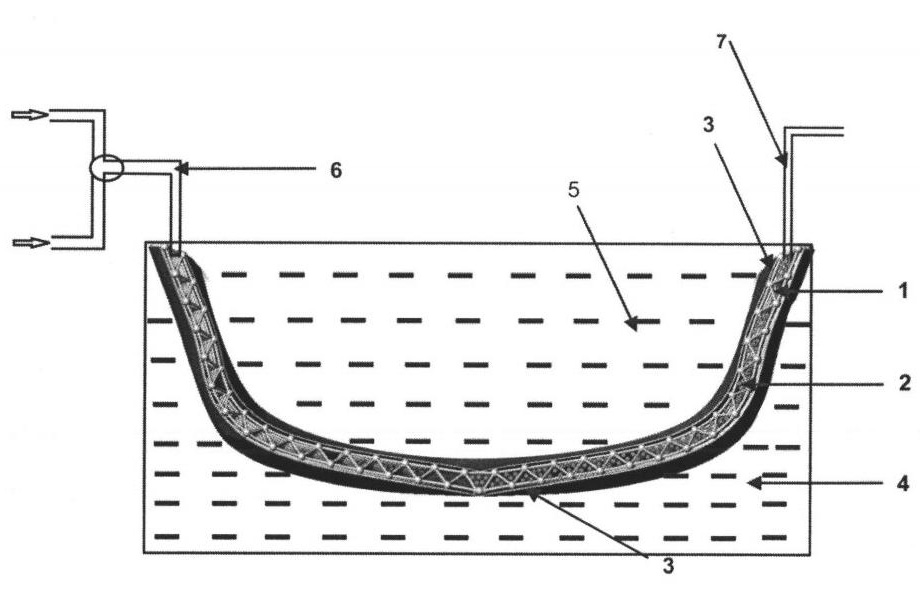

Truss framework composite material product, and flowing medium forming mould and forming method thereof

The invention discloses a truss framework composite material product, and a flowing medium forming mould and a forming method thereof. The truss framework composite material product consists of a framework reinforcing material, a skin material and a filling material, wherein the framework reinforcing material is formed by fixedly connecting rods and has the profile of the product; the skin material is attached to nodes of the framework reinforcing material, which serve as an outer profile; the filling material is embedded between the rods of the framework reinforcing material in the skin material; the flowing medium forming mould of the truss framework composite material product comprises a container, a cavity, a potting device and a flowing medium; and the forming method of the truss framework composite material product comprises the steps of potting the filling material into the cavity and curing the filling material to obtain the product. In the invention, the step of manufacturingthe mould cavity is saved, so that the manufacturing cost can be greatly reduced and the reinforcement function of the framework material can be fully exerted. The size of the product can be very large and is not limited to the conventional machining equipment, the length and the number of the rods of the reinforcing material are changed, and the skin material and the reinforcing material can very easily form the new cavity, so that the upgrading speed of the product is increased.

Owner:QINGDAO UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com