Detection method and system of capacitance-type touch screen

A capacitive touch and detection method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as single point failure to sense, bad, touch function failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

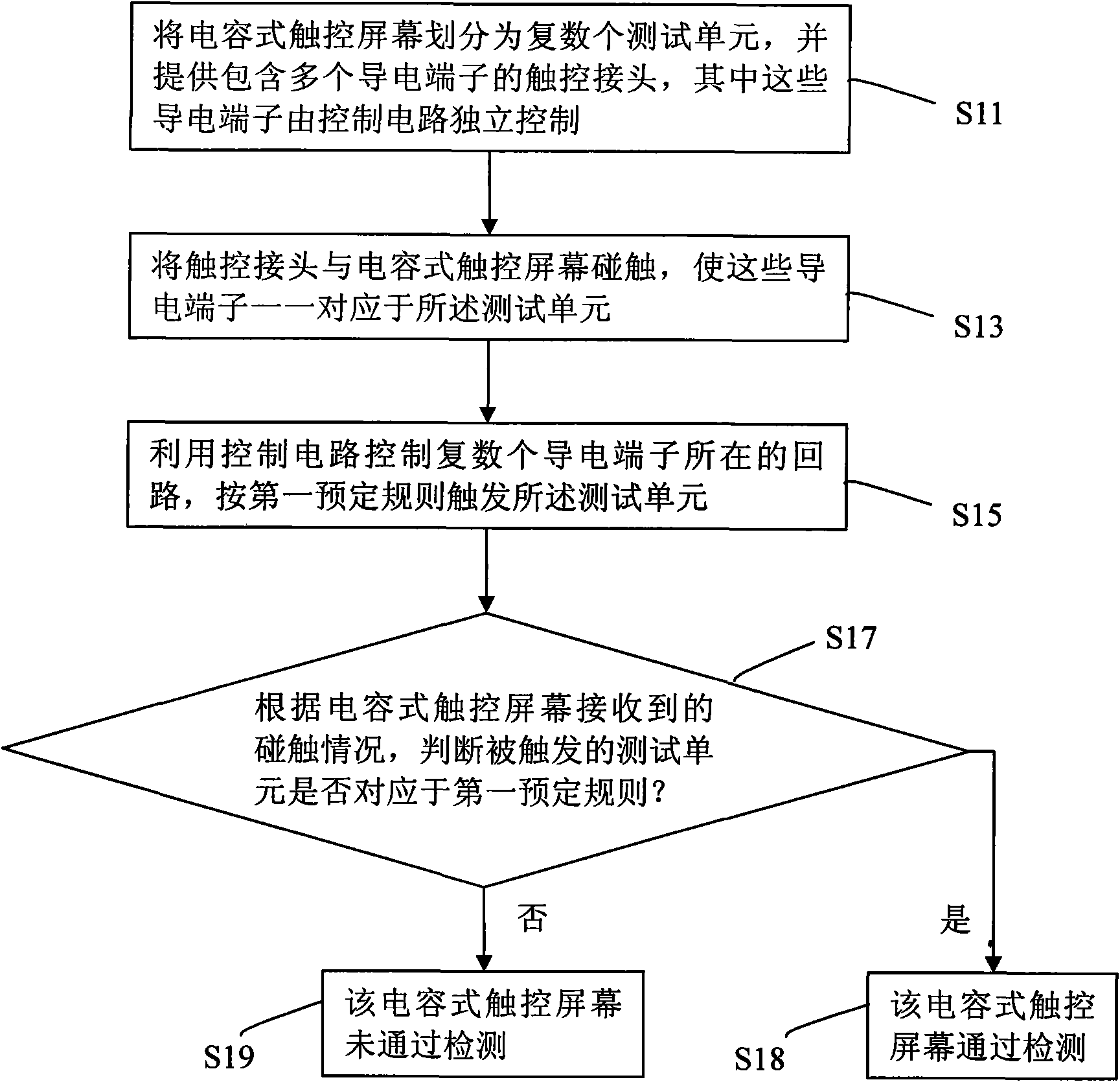

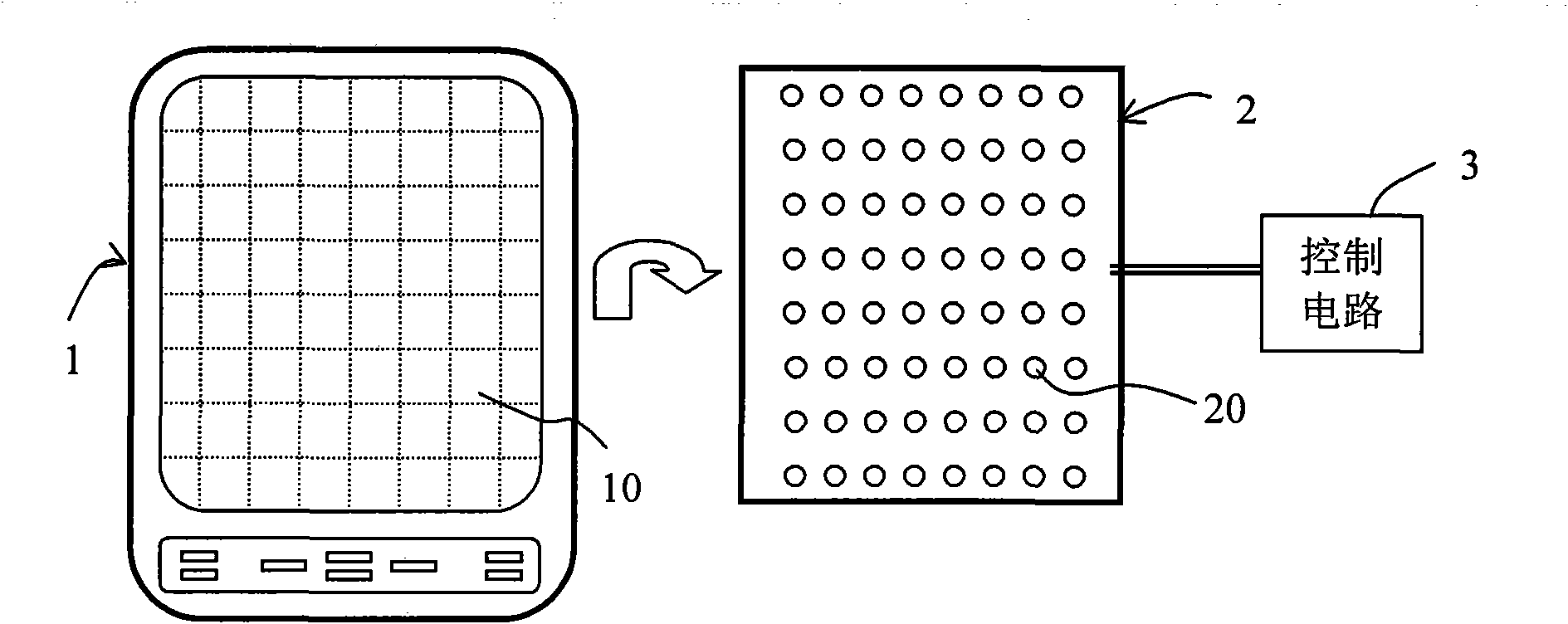

[0023] Please refer to figure 1 and figure 2 , figure 1 is a flowchart of a detection method for a capacitive touch screen according to an embodiment of the present invention, figure 2 It is a schematic diagram of a detection method for a capacitive touch screen according to an embodiment of the present invention.

[0024] A detection method for a capacitive touch screen provided by an embodiment of the present invention includes the following steps.

[0025] S11 , divide the capacitive touch screen 1 into a plurality of test units 10 , and provide a touch connector 2 including a plurality of conductive terminals 20 , wherein the conductive terminals 20 are independently controlled by the control circuit 3 . In one embodiment, the number and distribution of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com