Patents

Literature

255results about How to "Change composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

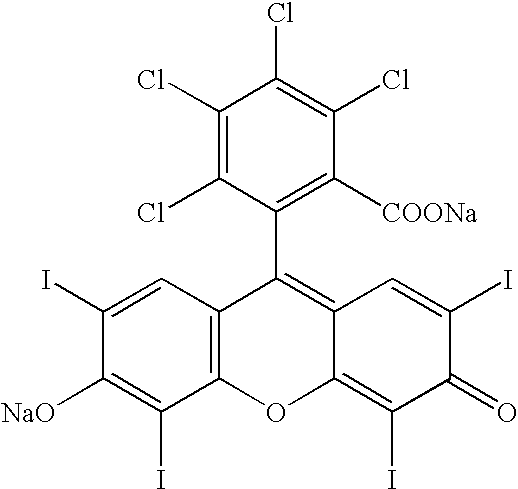

Color changing skin sealant with co-acid trigger

InactiveUS20080060550A1Change compositionGroup 4/14 element organic compoundsSurgical adhesivesBiomedical engineeringSealant

Skin sealants are applied over skin preps to seal the skin and hold any remaining bacteria in place prior to incisions. It is desirable for the person applying the sealant to know where the sealant has been applied. It is also desirable to be able so see through the sealant to observe the skin to detect any possible infection. A skin sealant is provided that has a pH indicator and co-additive acid that react soon after mixing, rendering the skin prep colorless.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Freeze-dried scent compound and a method of preparation

InactiveUS20060263326A1Facilitate chemical reactionsChange compositionBiocideCosmetic preparationsFlavorFreeze dry

A freeze-dried scent compound comprises at least one carrier material and at least one active ingredient. The selected carrier material and active ingredient are combined and freeze-dried. The scent compound may be a granular or powdered product. The active ingredient may be at least one of an animal product, a food product, a natural fragrance product or a synthetic fragrance product. The scent compound is freeze-dried which enhances the stability and potency of the scent compound. The scent compound is not significantly affected by environmental conditions and does not significantly evaporate, freeze or absorb into the ground. The scent compound may be used as an attractant, a repellent or an air fragrance material.

Owner:WEISER GRP

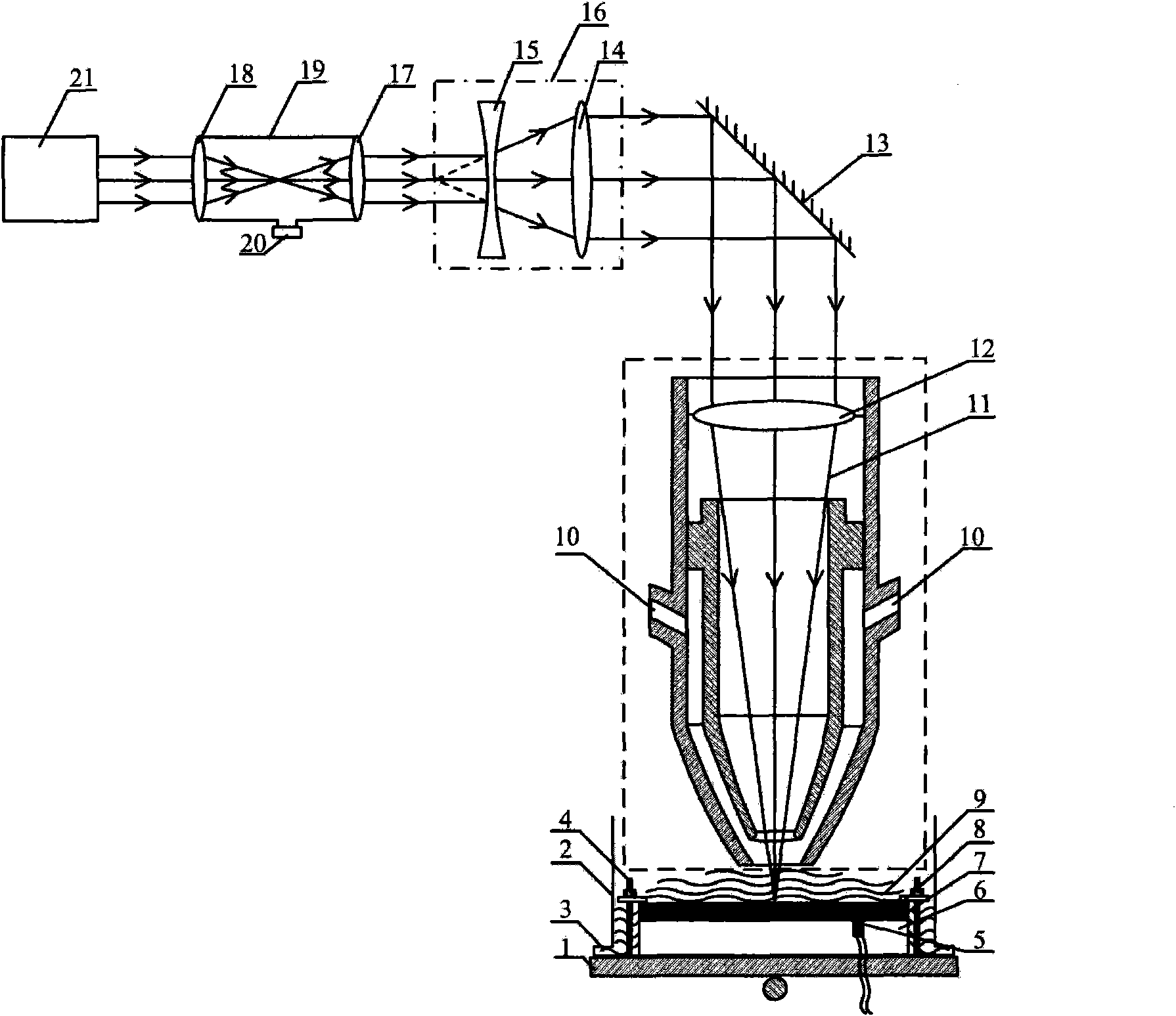

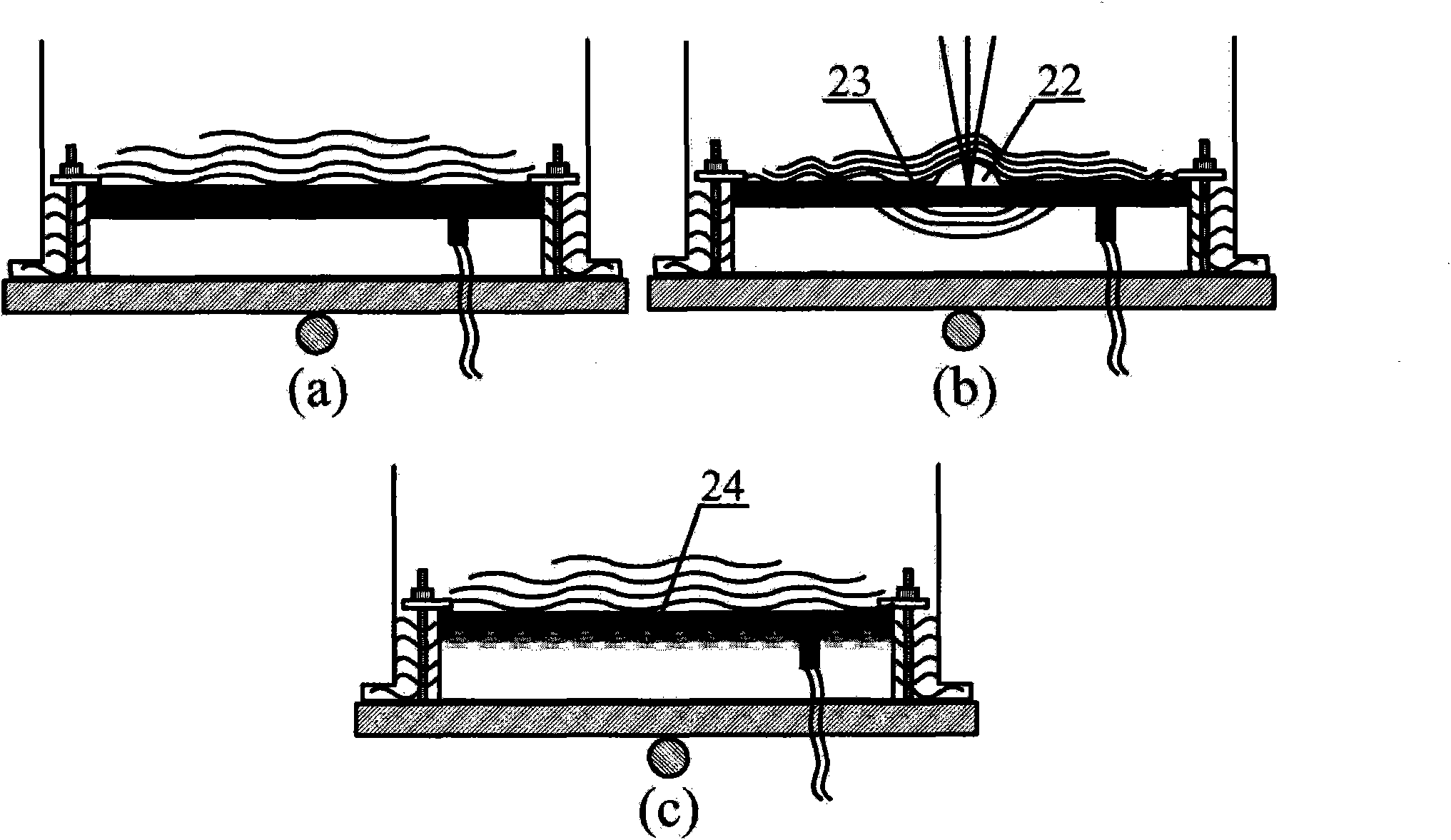

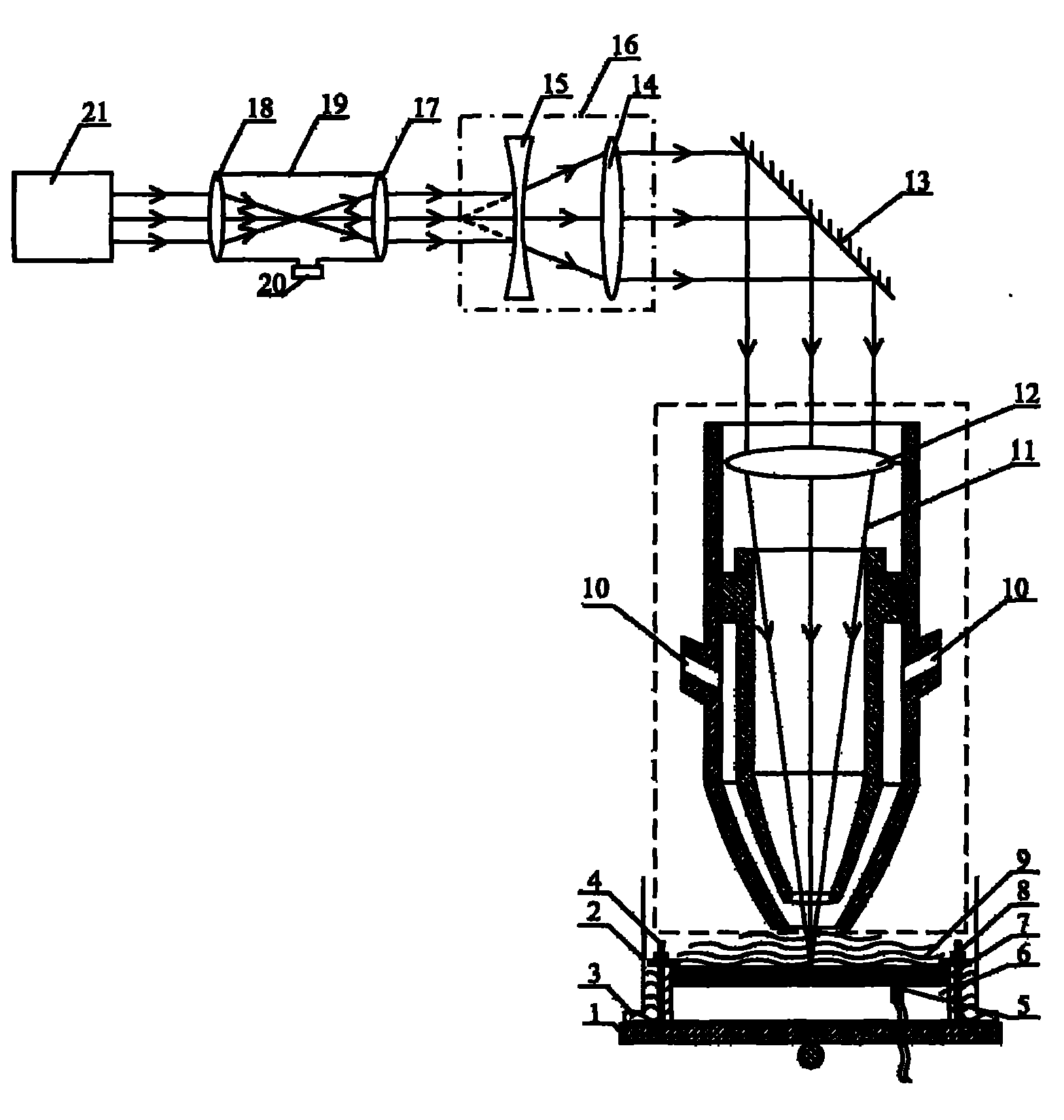

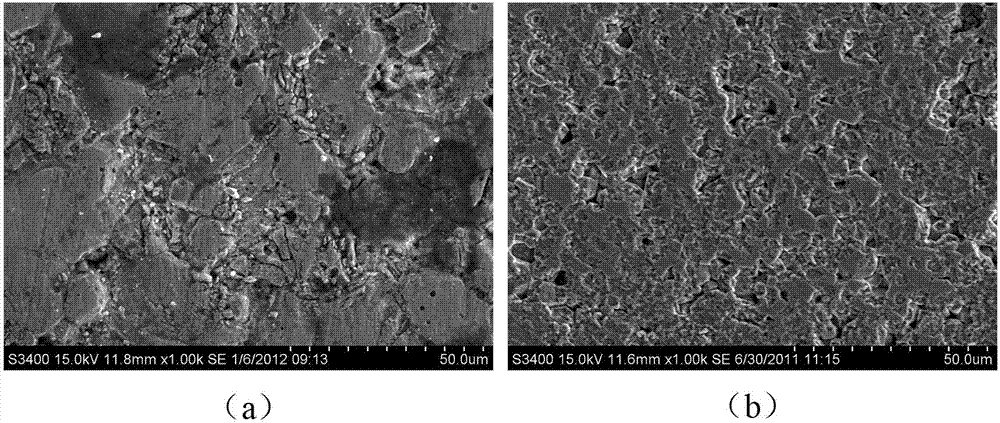

Nano coating preparation method and device based on ultrafast ultrahigh pressure photodynamics effect

InactiveCN101787528AChange compositionChange organizationMetallic material coating processesLaser beamsMechanical property

The invention discloses nano coating method and device based on ultrafast ultrahigh pressure photodynamics effect, belonging to the technical field of material surface. The invention is characterized by embedding or cold welding nanometer metal powder, nanometer nonmetal powder or compound nanometer powder which are precoated on the surface of a metal matrix in the surface layer of the metal matrix by means of laser induction mechanics effect, forming a thick nanometer particle strengthening layer or a coating layer which is called as a nano coating on the surface of the metal matrix, wherein the metal matrix is impacted and strengthened by laser. The device comprises a three-dimensional hexad working platform, a water tank, a clamp, a thermocouple, a coaxial synchronous water sender, a laser beam focusing system, a 45-degree fully-reflecting mirror, a laser beam optimizing system and a nanosecond laser. By the invention, the obtained surface nano coating has firm interface joint with the matrix and the mechanical property on the surface of the metal matrix is remarkably improved. The invention has simple technical process and lower cost, and is easy to realize automation and suitable for large-scale batch production.

Owner:JIANGSU UNIV

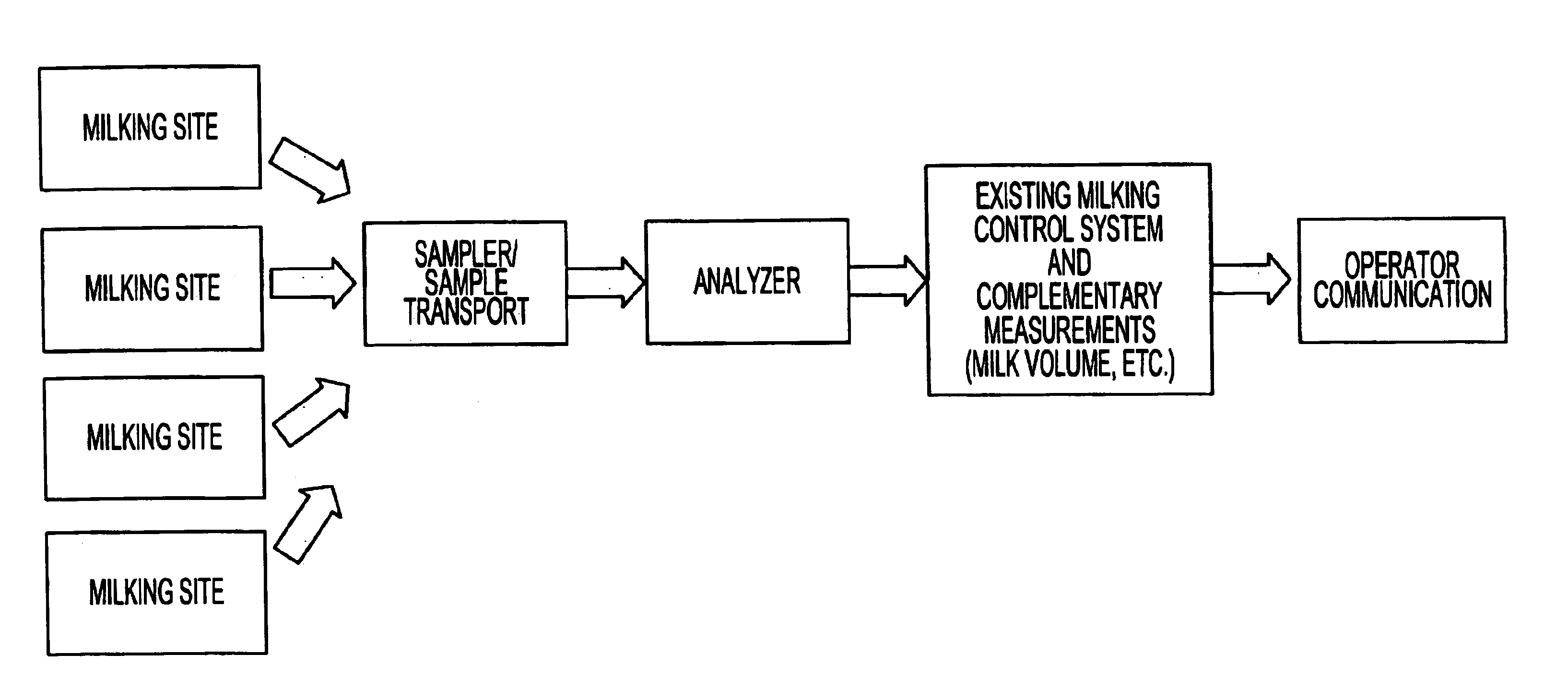

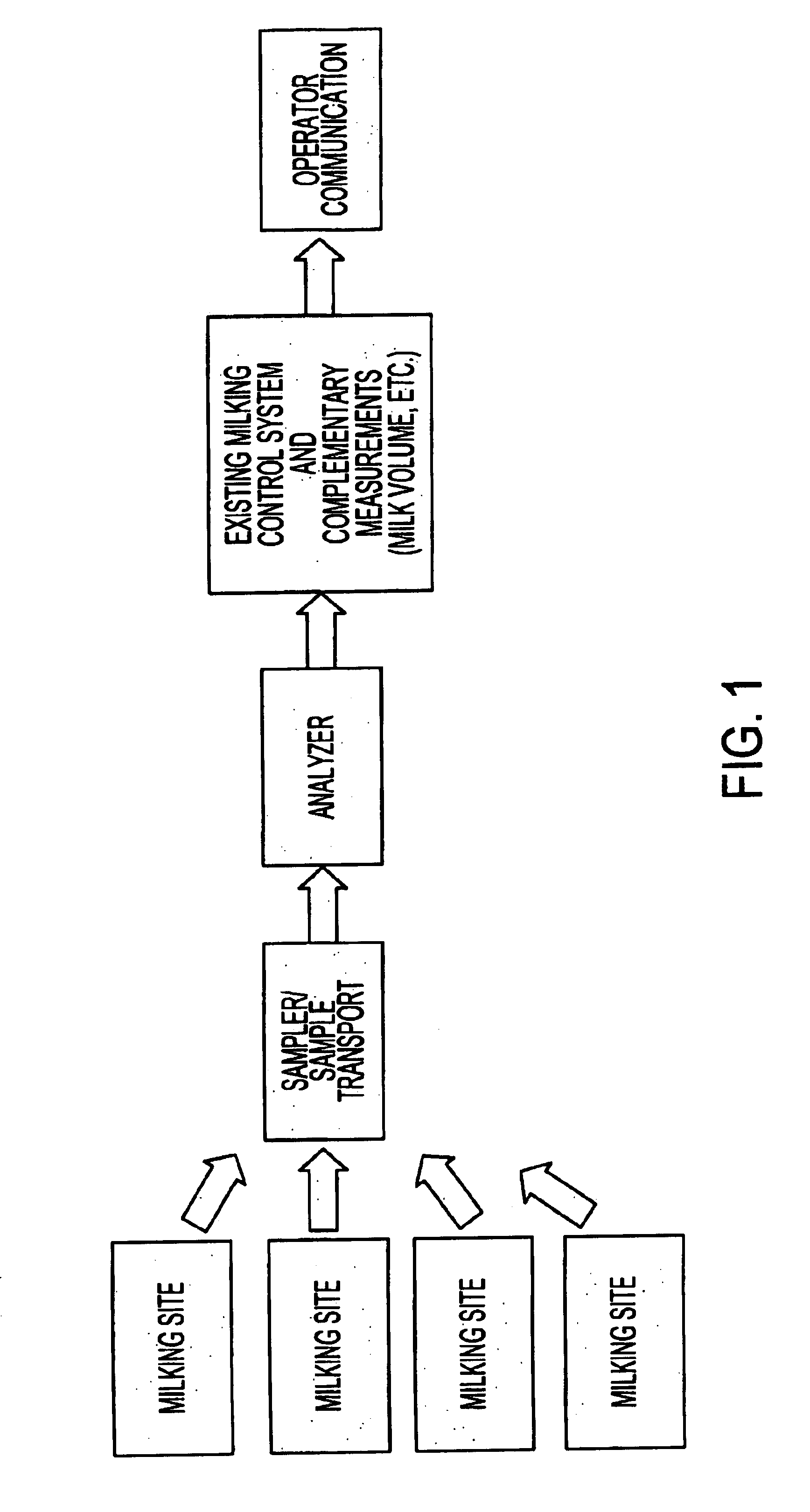

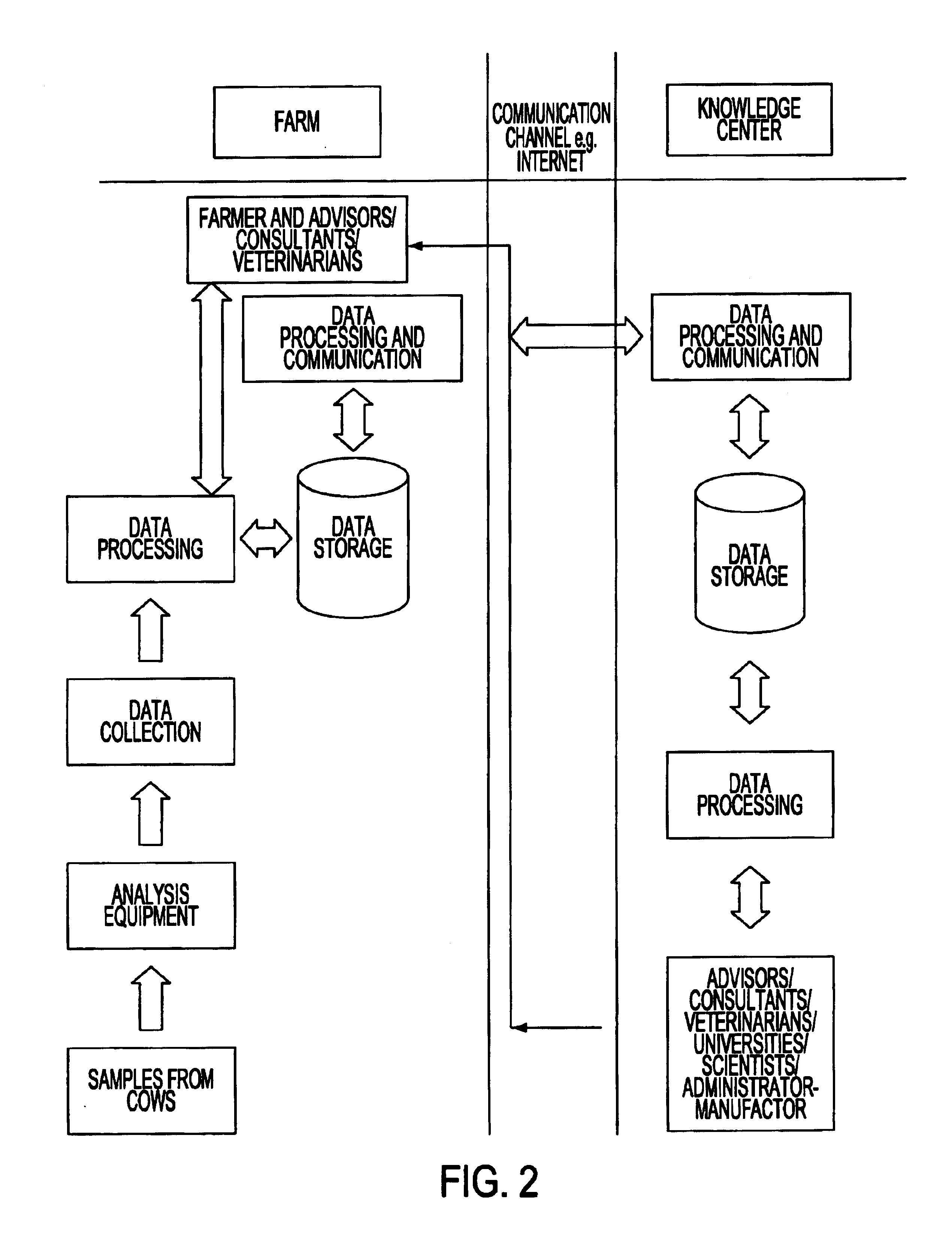

System for optimizing the production performance of a milk producing animal herd

InactiveUS6814025B2Increase productivityIncrease profitabilitySamplingCathetersLactate dehydrogenaseAgricultural science

Owner:LATTEC

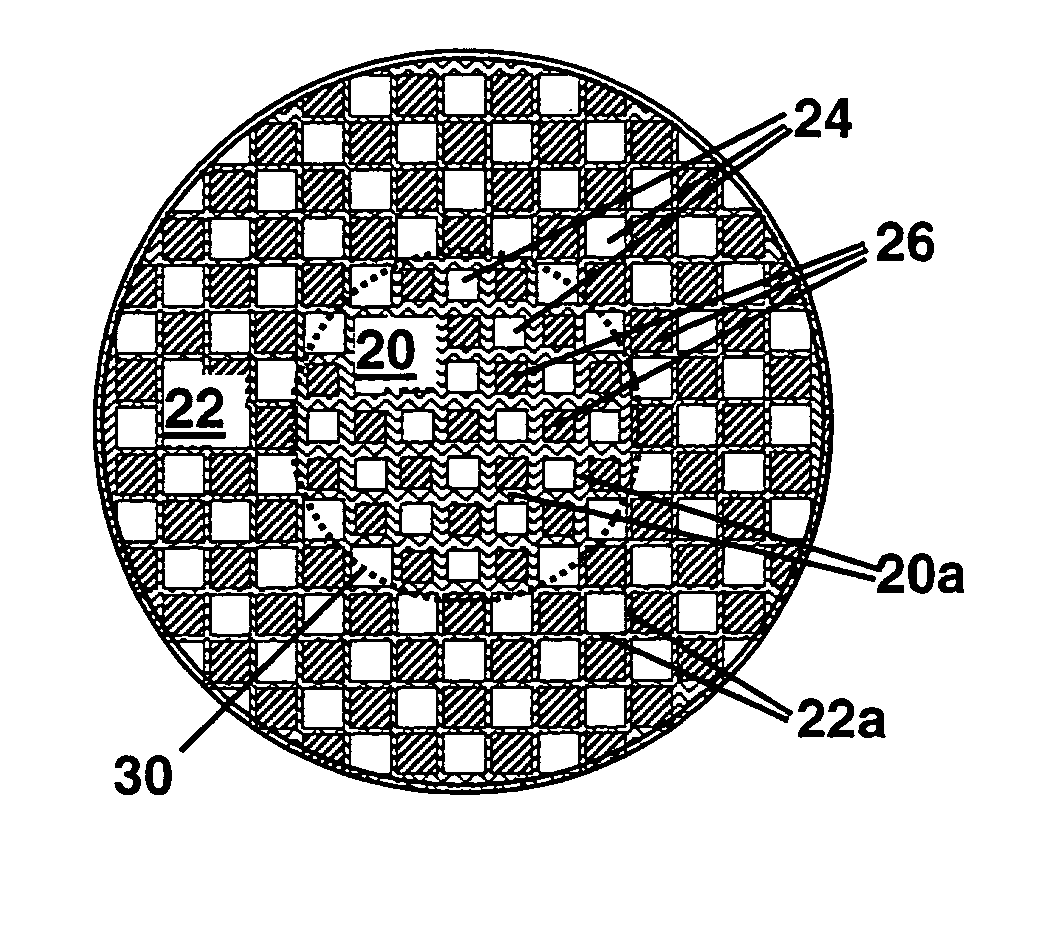

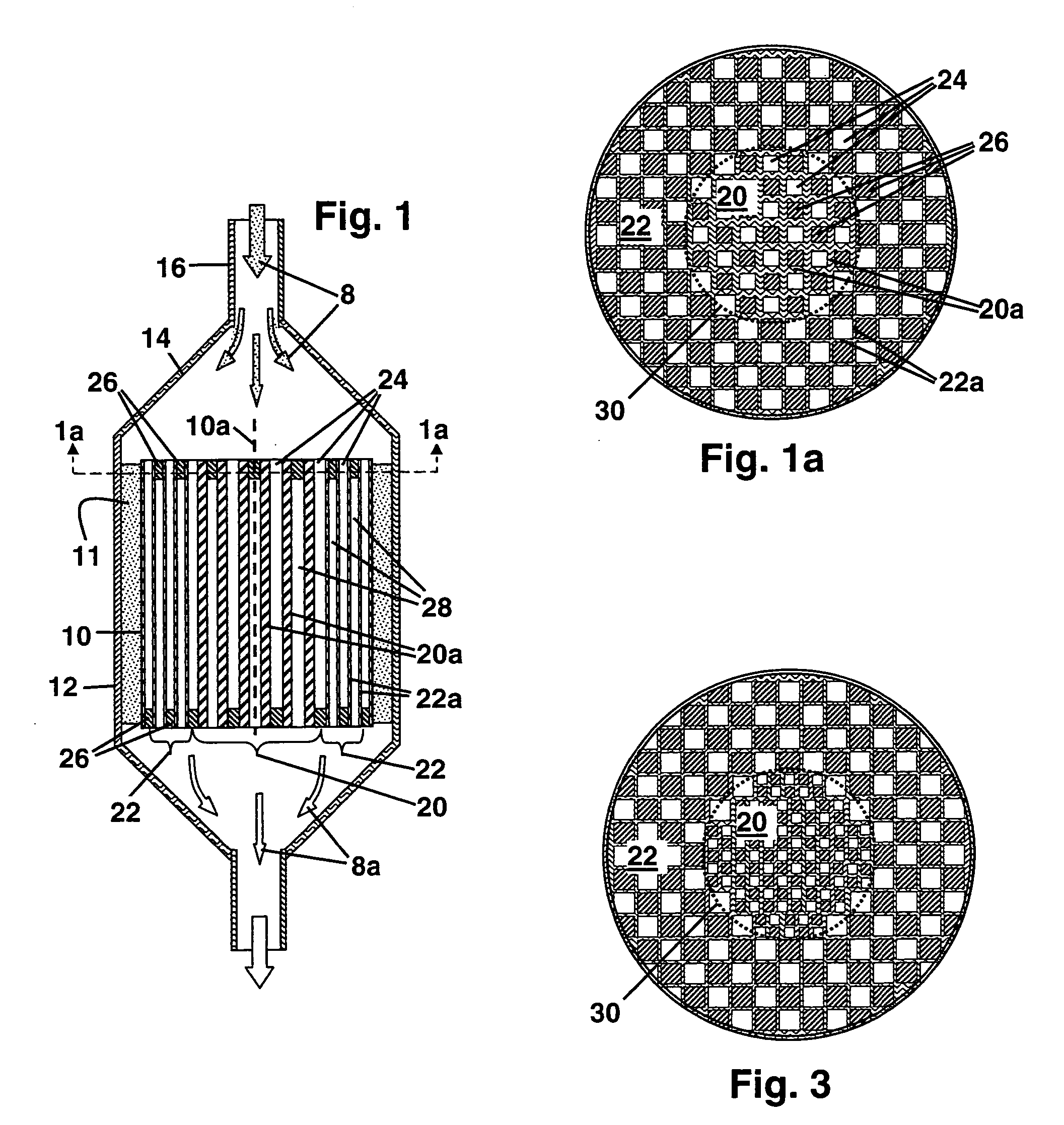

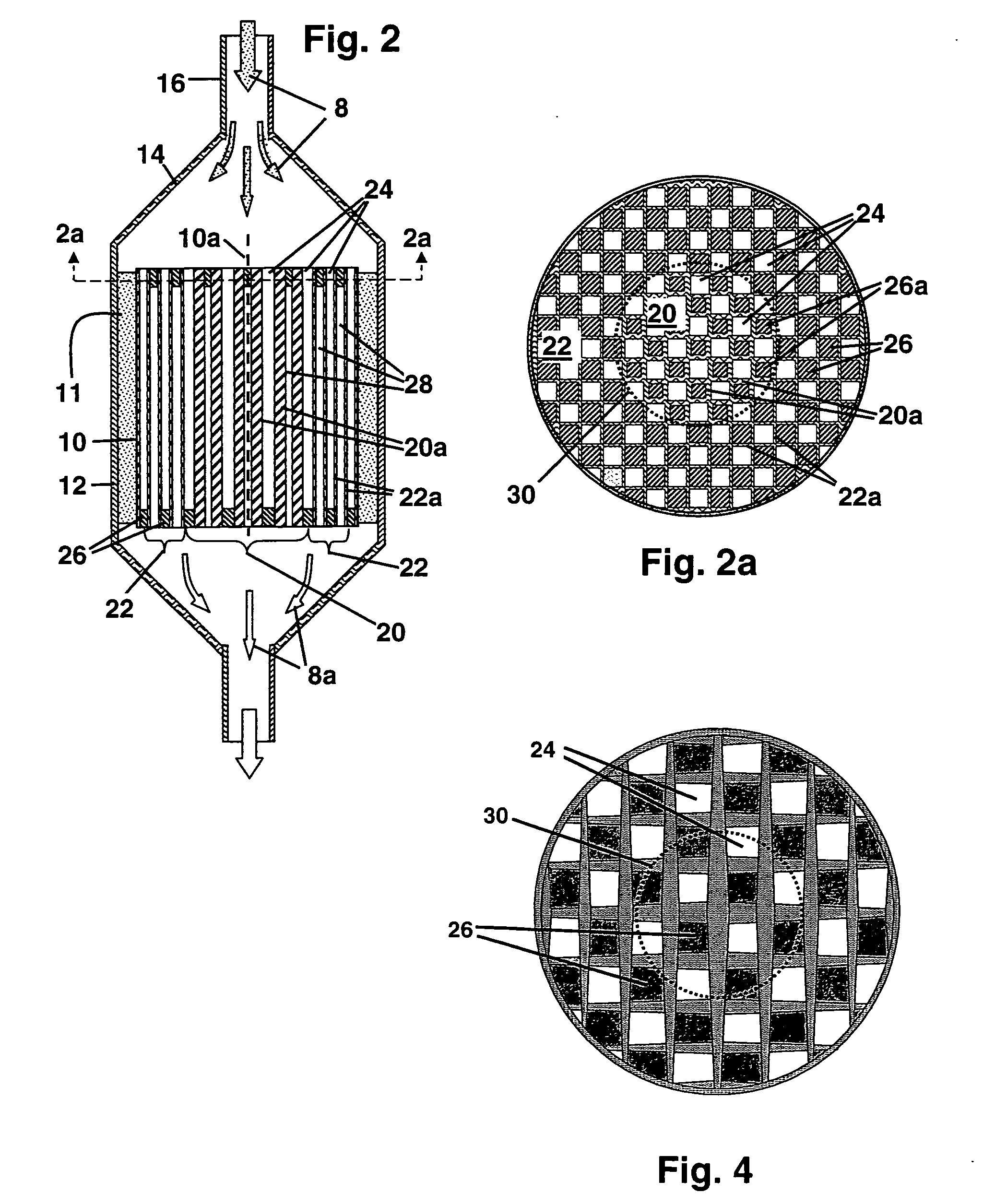

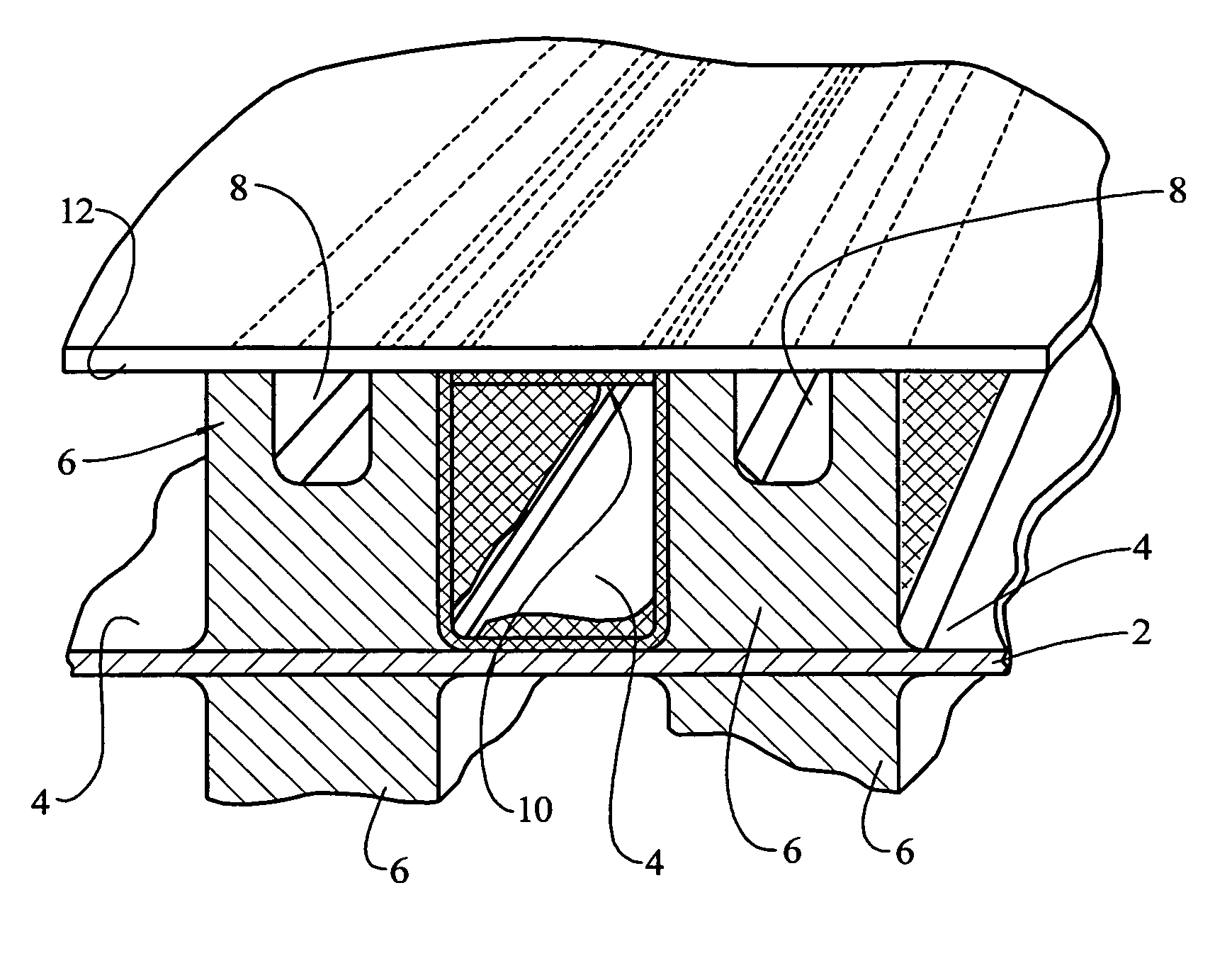

Diesel engine exhaust filters

ActiveUS20050235622A1Speed up the processResist damageCombination devicesGas treatmentFiltrationEngineering

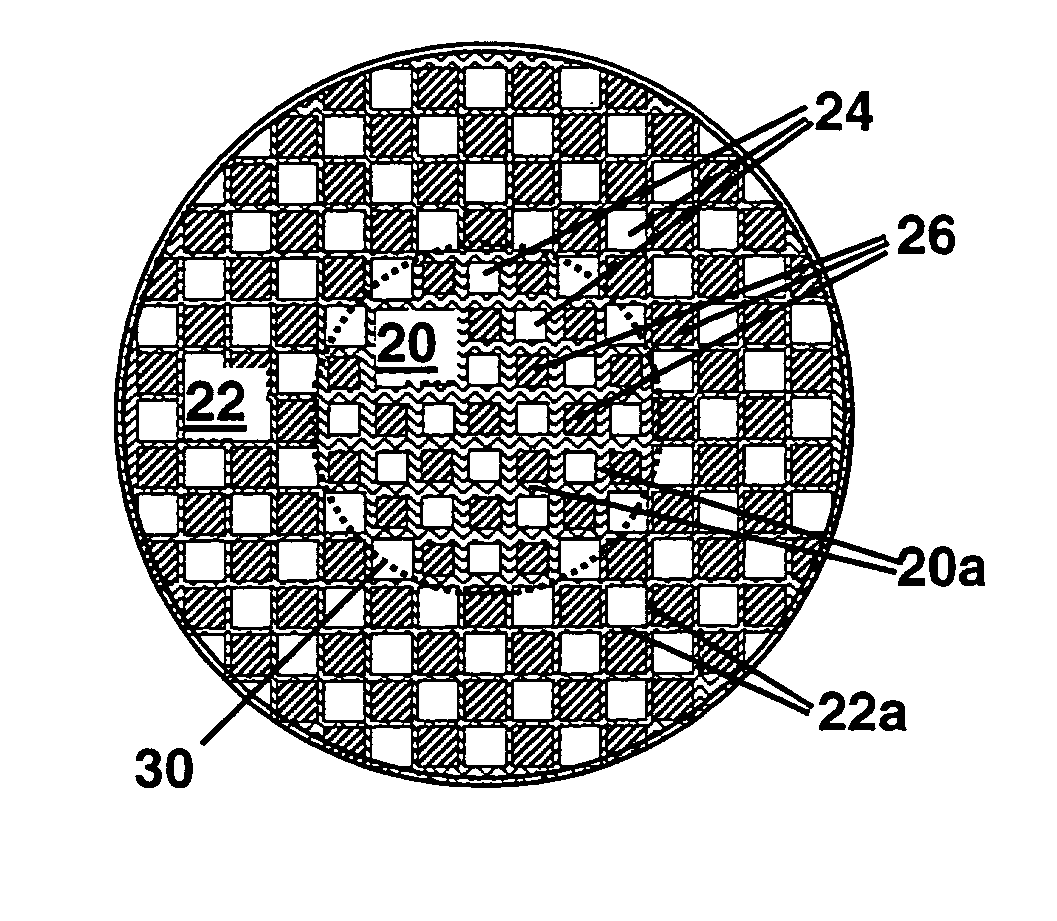

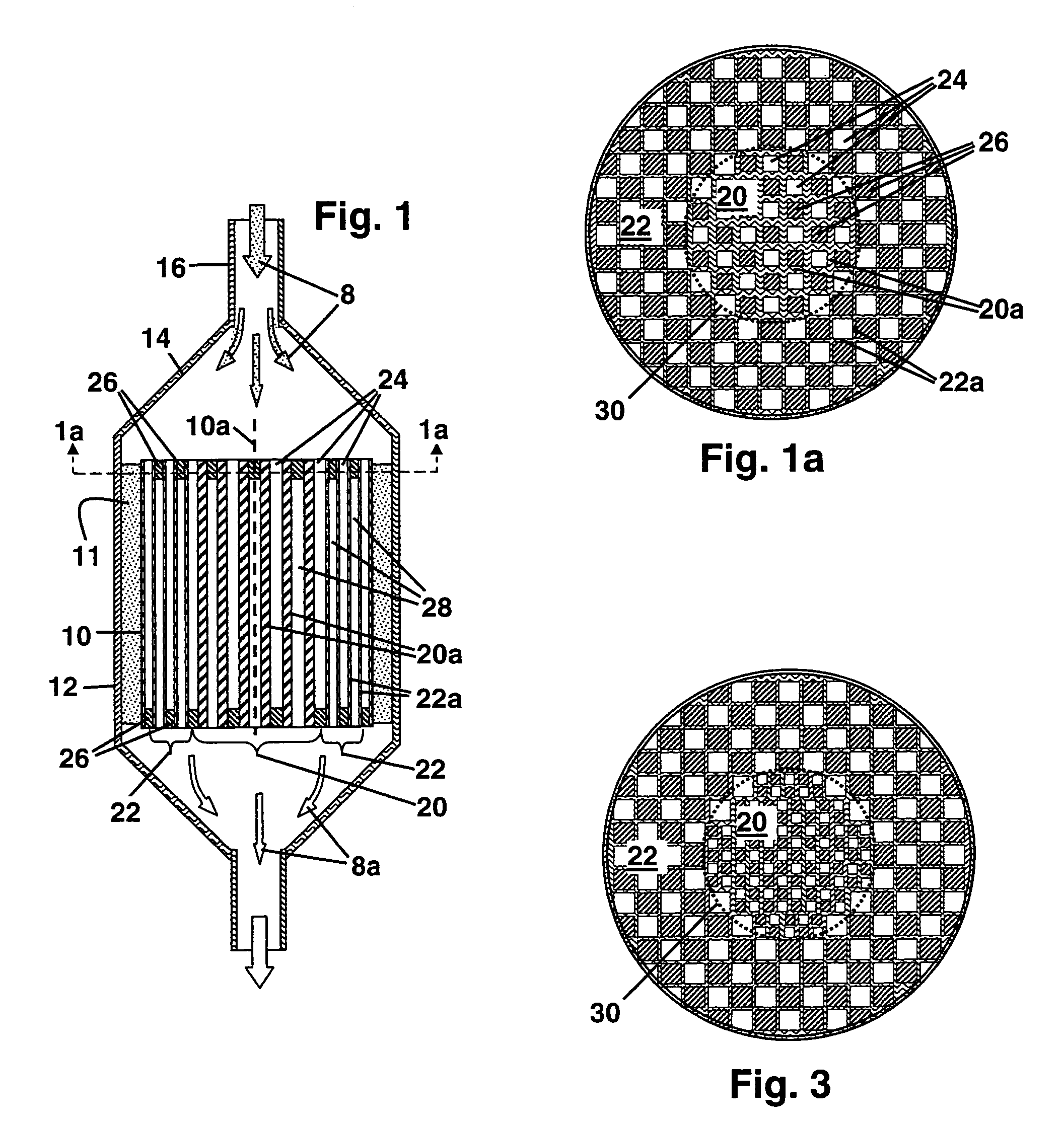

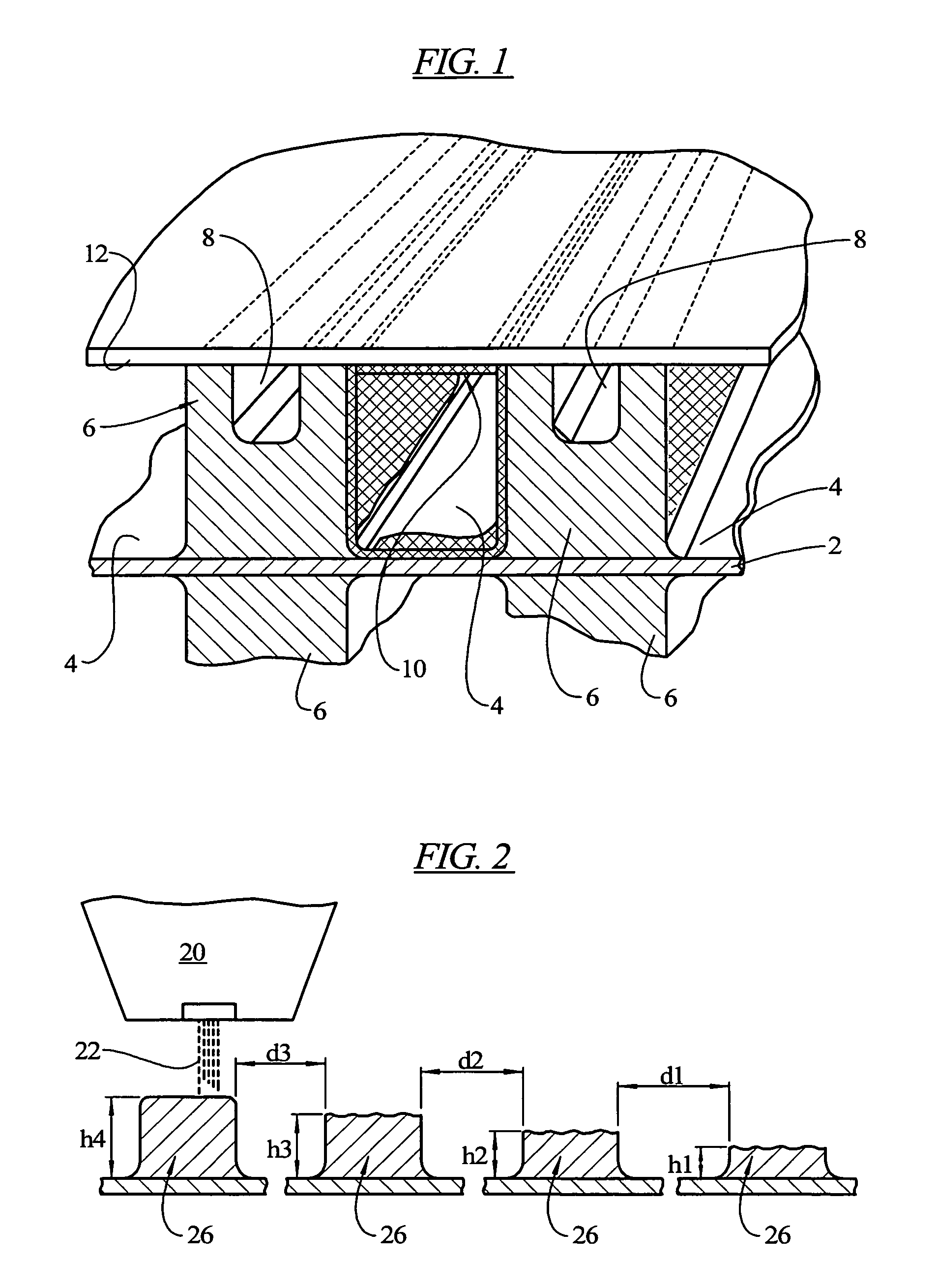

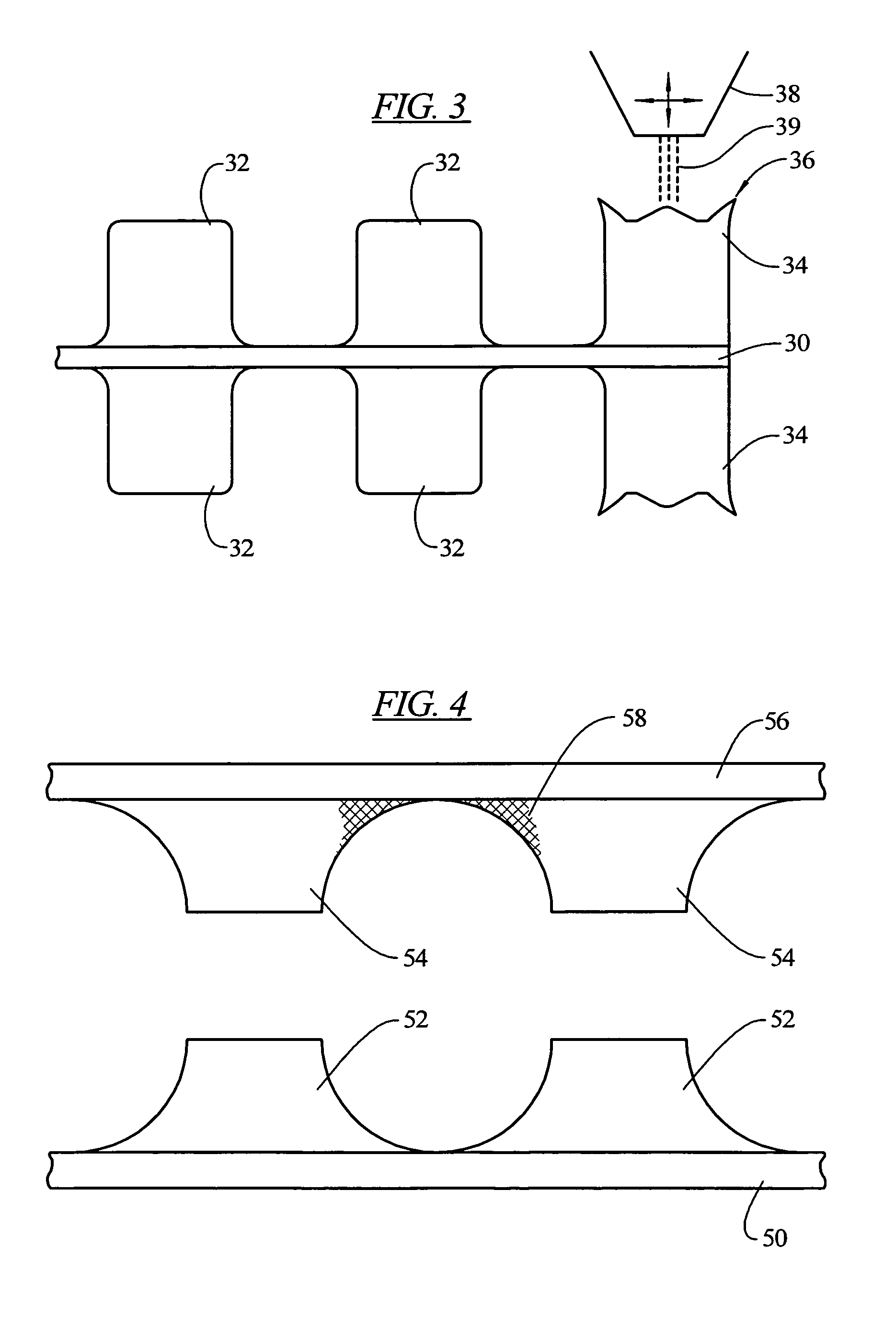

Diesel engine exhaust filtration systems, and ceramic honeycomb wall flow exhaust filters for such systems, wherein the filters comprise axially centralized filter sections having a higher heat capacity and / or a higher gas flow resistance than peripheral filter sections disposed radially outwardly thereof, the filters thereby exhibiting increased resistance to thermal damage from filter regeneration over-heating.

Owner:CORNING INC

Diesel engine exhaust filters

ActiveUS7238217B2Resist damageSpeed up the processCombination devicesGas treatmentDieselingMechanical engineering

Diesel engine exhaust filtration systems, and ceramic honeycomb wall flow exhaust filters for such systems, wherein the filters comprise axially centralized filter sections having a higher heat capacity and / or a higher gas flow resistance than peripheral filter sections disposed radially outwardly thereof, the filters thereby exhibiting increased resistance to thermal damage from filter regeneration over-heating.

Owner:CORNING INC

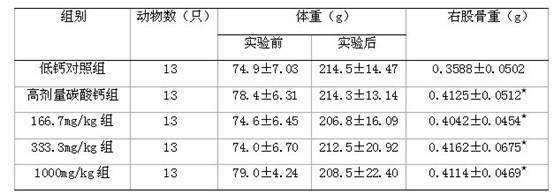

Composition for reducing bone loss and preparation method thereof

The invention discloses a composition for reducing bone loss and a preparation method thereof. The composition is prepared from a calcium compound, marine fishbone collagen oligopeptide powder, glucosamine hydrochloride, casein phosphopeptides, natural vitamin E, vitamin C, vitamin K1, vitamin B12, vitamin D3 and dietary fiber. As proved by animal and human body tests, the composition has the effects of increasing bone density, enhancing bone intensity, reducing bone loss, delaying aging and enhancing the immunity, and can be taken by the middle-aged and old as a health-care food for a long time. The preparation method is scientific and reasonable, and is suitable for industrial production.

Owner:石药集团中诺药业(泰州)有限公司

Magnesium oxysulfate cement and preparation method thereof

The invention relates to magnesium oxysulfate cement which comprises the following raw materials in parts by weight: 100 parts of magnesium oxide, 0 to 300 parts of filling material, 0.05 to 5 parts of additive, 10 to 200 parts of waste industrial sulfuric acid and 0 to 100 parts of water. By directly replacing magnesium sulfate with the waste industrial sulfuric acid as one raw material of the magnesium oxysulfate cement, reasonably proportioning the raw materials and adding proper amount of the additive, the magnesium oxysulfate cement which is high in mechanical strength, good in water resistance, difficult to crack and nonhygroscopic is obtained. Therefore, the production cost of the magnesium oxysulfate cement is lowered; and the environmental pollution is reduced. The magnesium oxysulfate cement is good in environmental-friendly, social and economic benefits.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Al-C fireproof material for continuous casting and its production method

A fireproof material containing aluminum and carbon for continuous casting. Taking aluminum oxide and carbon as the main components, it includes 0.5í½5.0úÑ boron nitride and 1.0í½5.0úÑ carborumdum by weight. The preparation method thereof comprises mixing white alundum, graphite, zirconium mullite, carborundum, industrial silicon ,2.0úÑ??.0úÑ solid phenol resin and 5úÑí½15úÑ liquid phenol resinby weight, and moulding at equal static pressure of 120í½150Mpa for 10-20 min, the moulded semi-product is dried and burned at 1280í½1350degree C for 60-70 hours. The product is suitable for columns of sagger, downspouts, with good heat-shock stability and resistibility of erosion.

Owner:山东淄川特种耐火材料有限公司

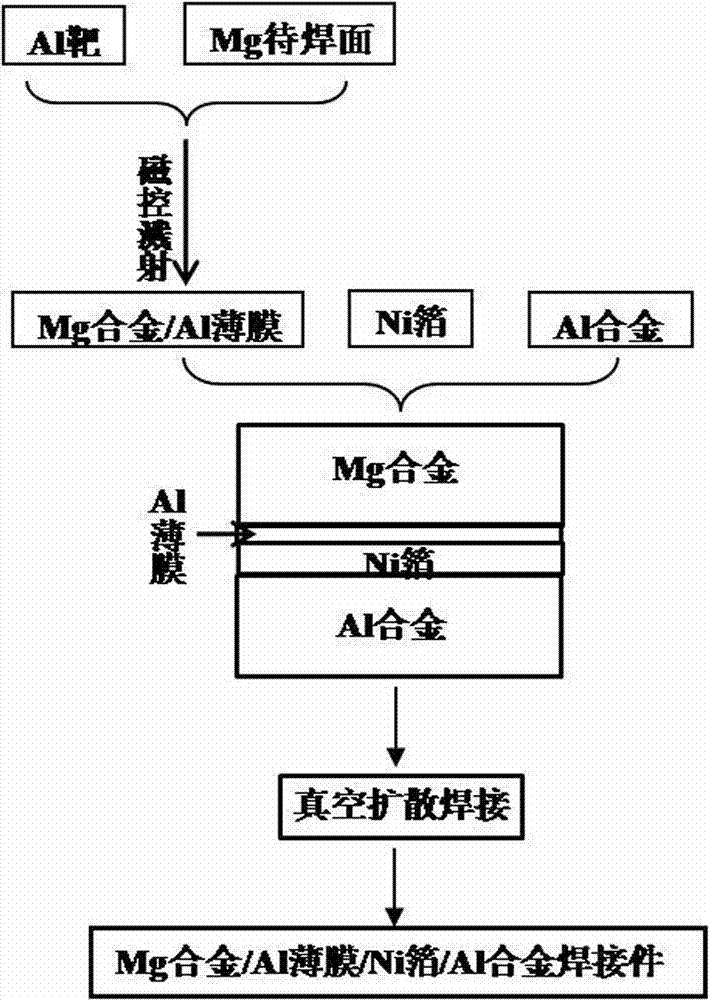

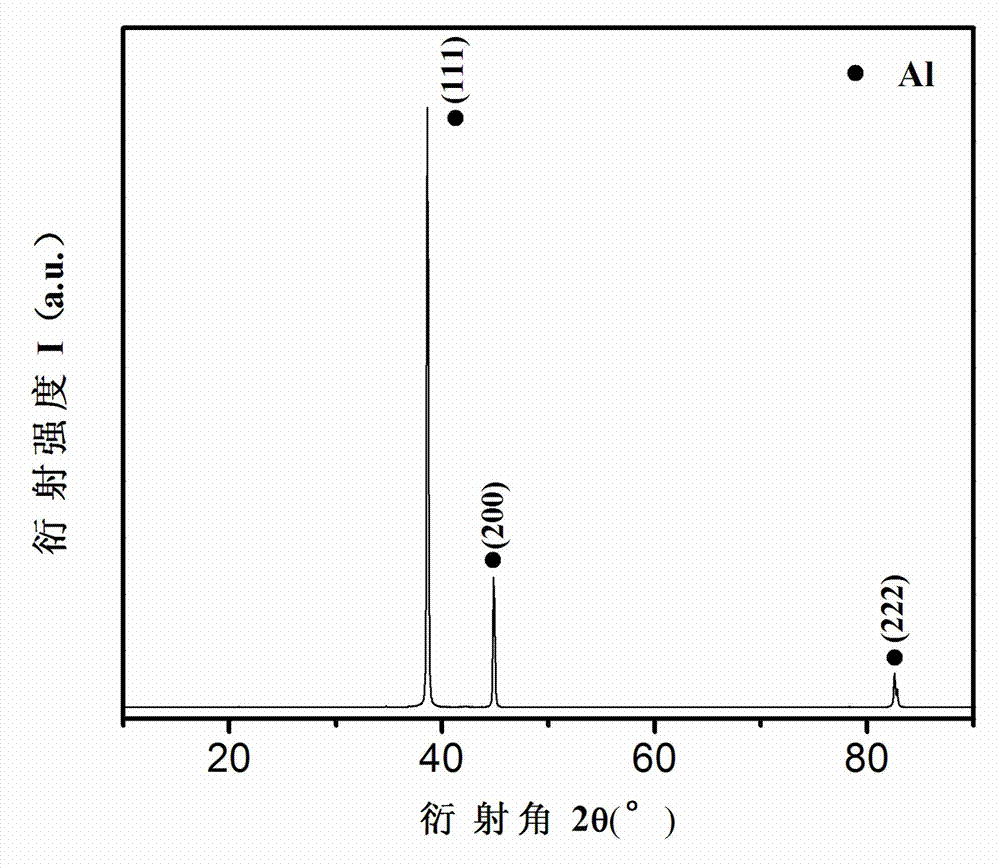

Spreading welding method of magnesium alloy and aluminum alloy containing composite middle layer

InactiveCN102861986AAchieve high-strength weldingSimple processNon-electric welding apparatusPhase compositionShear strength

The invention relates to a low temperature high intensity welding method of magnesium alloy and aluminum alloy containing a composite middle layer. The method includes utilizing an aluminum film and a nickel foil to serve as a composite middle layer. The aluminum film is precipitated on the face of magnesium alloy to be welded by magnetron sputtering. The method further includes adopting vacuum spreading welding with the welding temperature as 400-460 DEG C, keeping the temperature for 10-120min and enabling the welding pressure to be 0.1-3MPa. The method has the advantage of utilizing a composite middle layer of the aluminum film and the nickel foil to achieve spreading welding of the magnesium alloy and the aluminum alloy. Addition of the aluminum film layer and the nickel foil changes magnesium / aluminum interface phase composition and microstructure, and avoids generation of compounds between high-hardness fragile magnesium and aluminum at the interface. The shearing strength reaches 26MPa, and the magnetron sputtering aluminum coated film on the face of the magnesium alloy to be welded improves inoxidizability of the face of the oxydic magnesium alloy to be welded and improves structure and performance of products between Mg and Ni. The method is suitable for reliable welding of magnesium alloy and aluminum alloy in different kinds, and is simple in process, high in parallel accuracy and small in welding piece transformation.

Owner:WUHAN UNIV OF TECH

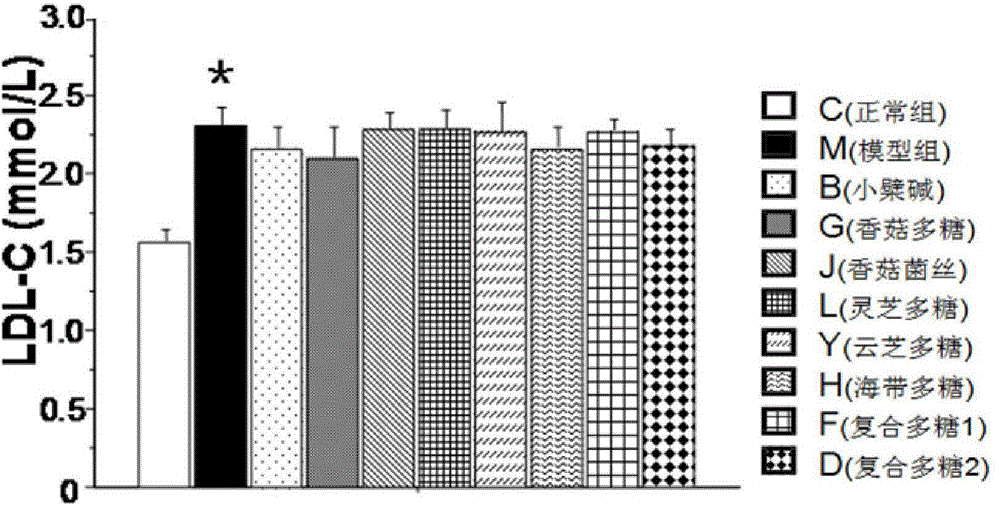

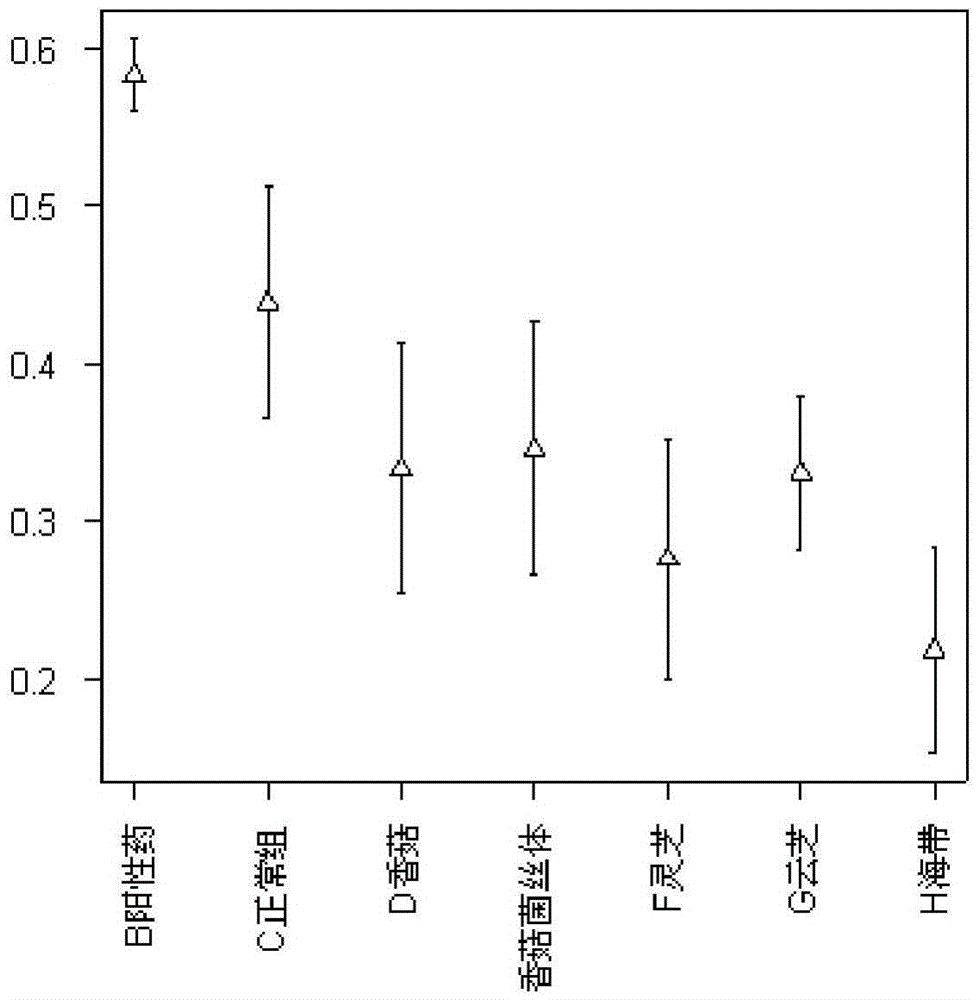

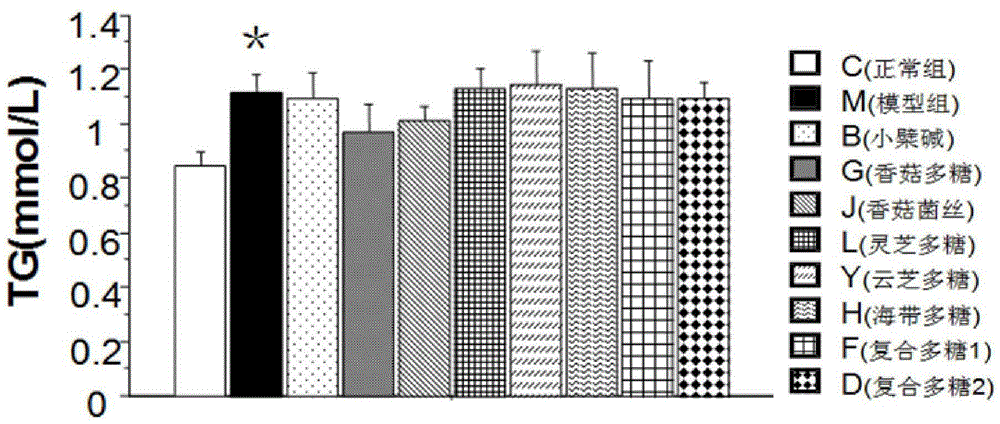

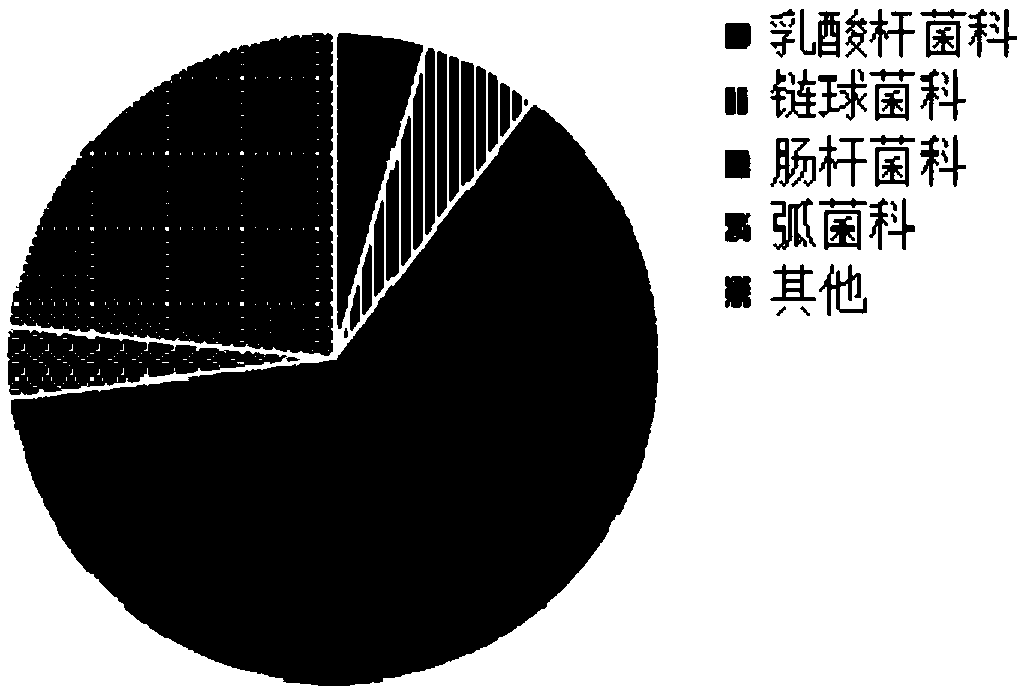

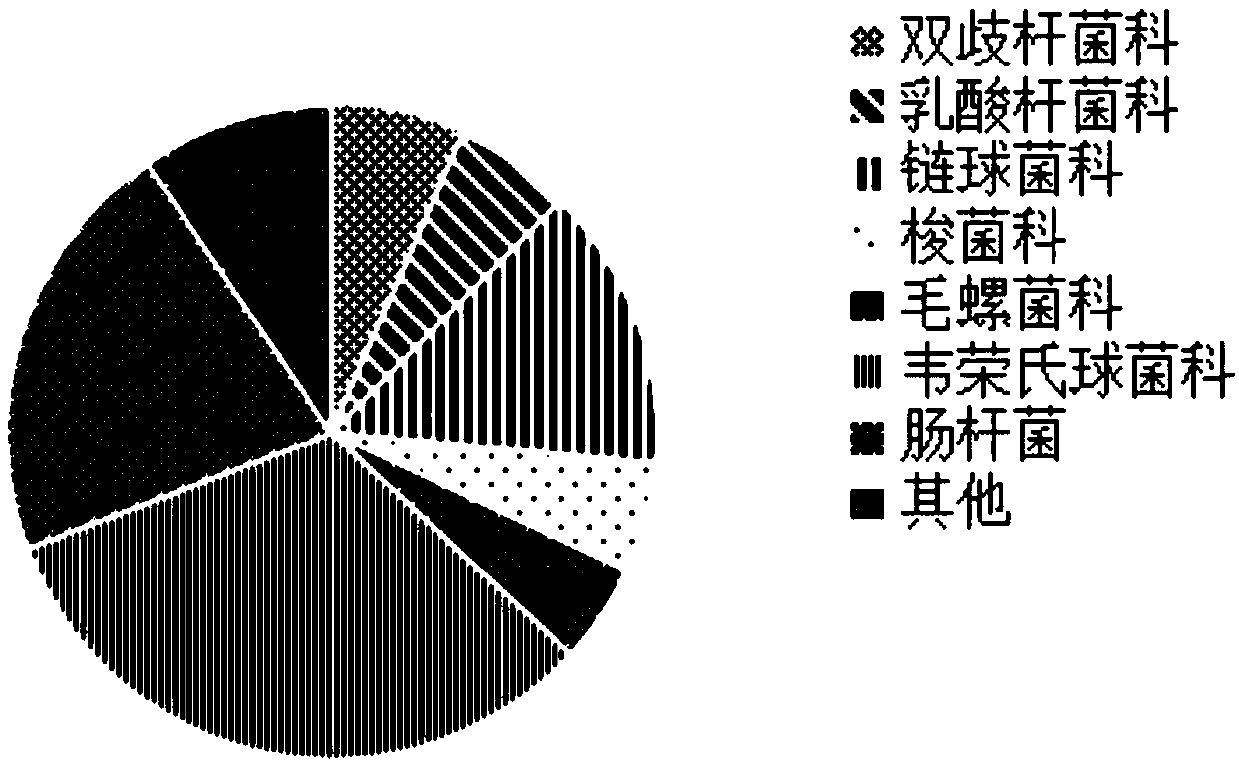

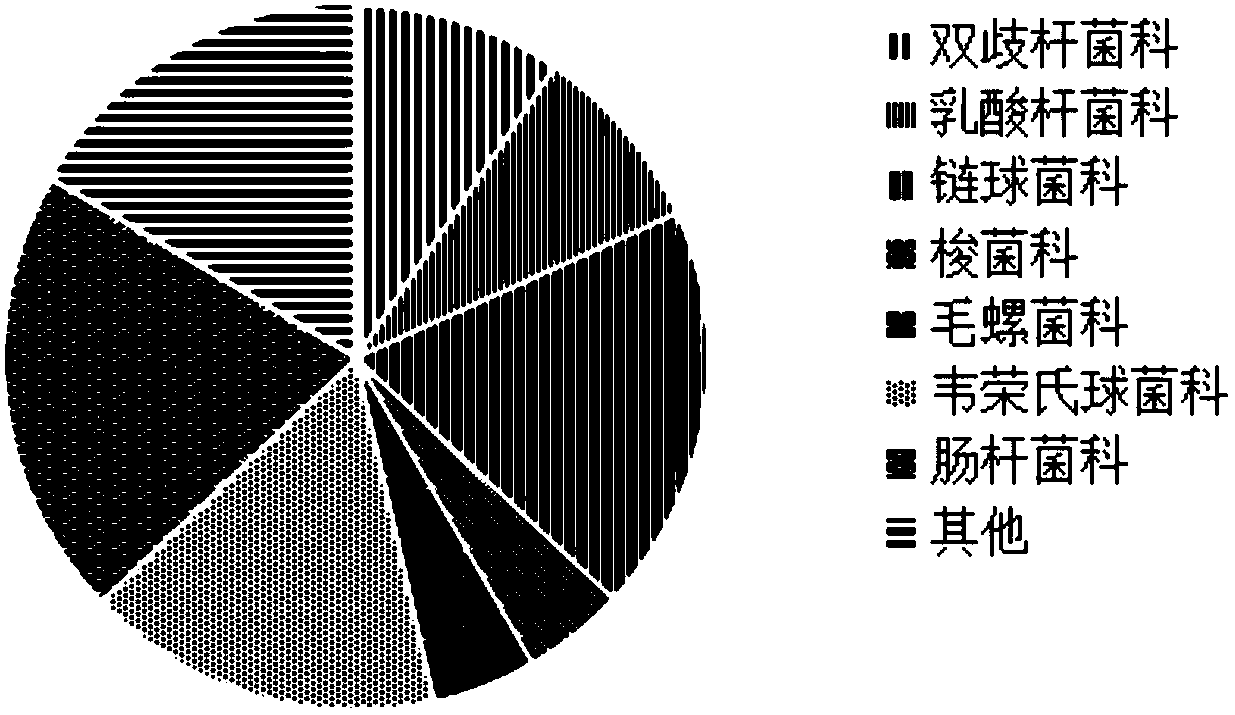

Application of lentinan in preparing medicine, healthcare product and food in treating or preventing disease caused by enteric flora disturbance

InactiveCN104546889AChange compositionReduce contentOrganic active ingredientsMetabolism disorderDiseaseDiabetes model

The invention provides application of lentinan in preparing medicines, healthcare products and food in treating or preventing diseases caused by enteric flora disturbance. The applicant of the invention adopts high-fat feed to induce a mouse obesity type-II diabetes model to observe the influence of polysaccharide in traditional Chinese medicines on lipid metabolism of mice through enteric florae, and by adopting the lentinan, enteric flora disturbance caused by diet can be adjusted, constitution of enteric florae can be remarkably improved, and the unbalance enteric florae in bodies can be recovered, so that the blood fat and the blood sugar indexes of obesity caused by enteric flora disturbance caused by diet can be adjusted, the content of triglyceride in blood plasma can be remarkably reduced, and the content of cholesterol, low density lipoprotein and free fatty acid can be reduced.

Owner:INFINITUS (CHINA) CO LTD

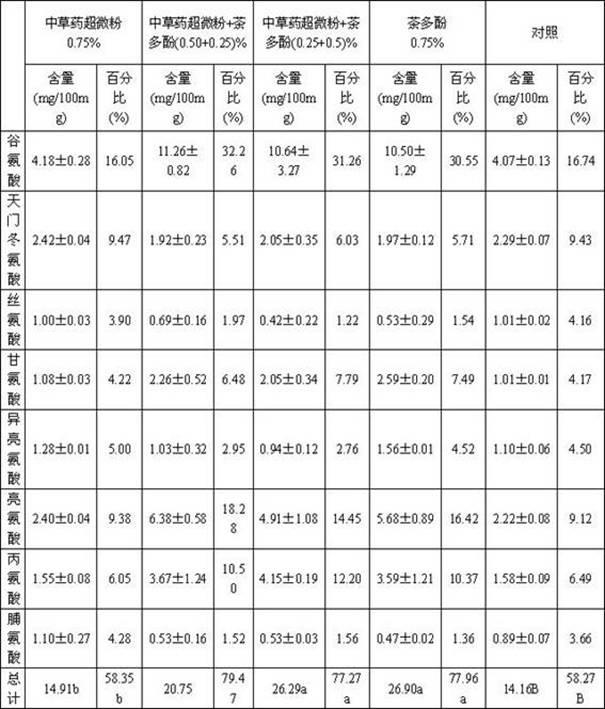

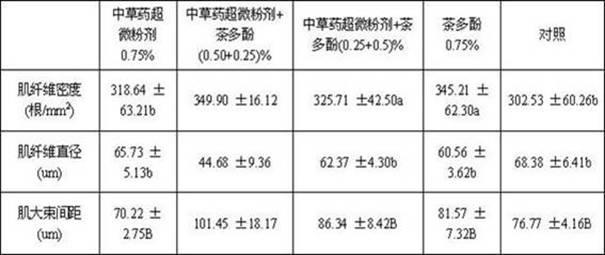

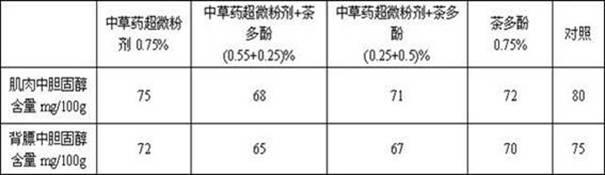

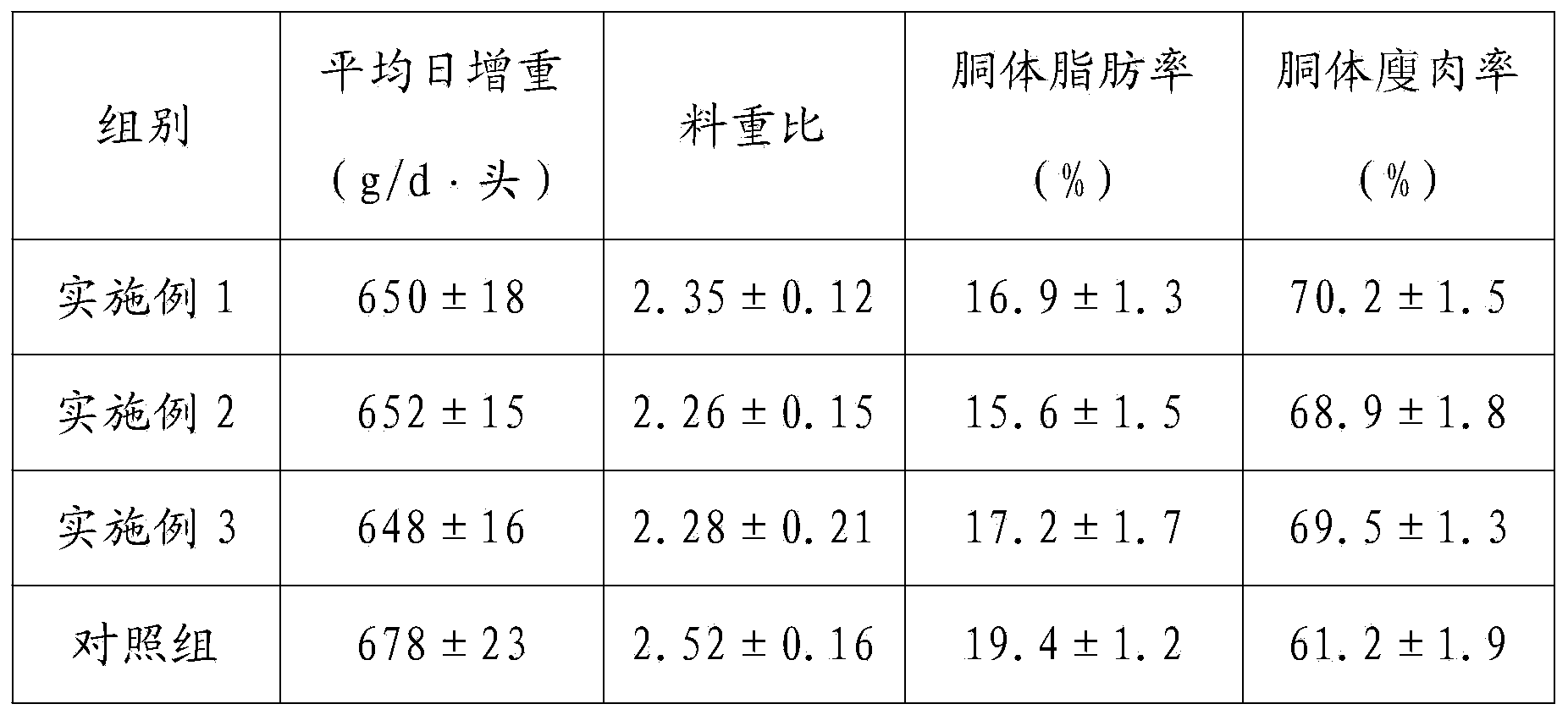

Compound feed additive for improving pork quality

InactiveCN102178122AHigh in fatImprove flesh colorFood processingAnimal feeding stuffPhosphodiesteraseMedicinal herbs

The invention relates to the technical field of feed additives for livestock, and particularly relates to a compound feed additive for improving pork quality. The compound feed additive is prepared by mixing Chinese medicinal herb superfine powder with tea polyphenols, wherein the weight ratio of the Chinese medicinal herb superfine powder to the tea polyphenols is 2:1, the applied additive accounts for 0.75% of the total weight of the feed, and the Chinese medicinal herb superfine powder is 200-mesh superfine powder which is prepared by mixing the following Chinese medicinal herbs in parts by weight: 3 parts of astragalus root, 3 parts of bighead atractylodes rhizome, 2 parts of amomum fruit, 2 parts of dried tangerine peel, 2 parts of anisum fruit, 1 part of wrinkled gianthyssop herb, 2parts of rhizoma kaempferiae, 2 parts of cortex cinnamomi, 1 part of pine needle and 1 part of licorice root. The effective ingredients of the Chinese medicinal herbs and the tea polyphenols in tea leaves both can inhibit the activity of phosphodiesterase in cells, thereby increasing the cyclic adenosine monophosphate content of pig cells; and under the action of the cyclic adenosine monophosphate, the energy, fat and proteins in pigs are redistributed and are finally represented by the improvement of pork quality.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY SCI SHANXI ACAD OF AGRI SCI SAAS

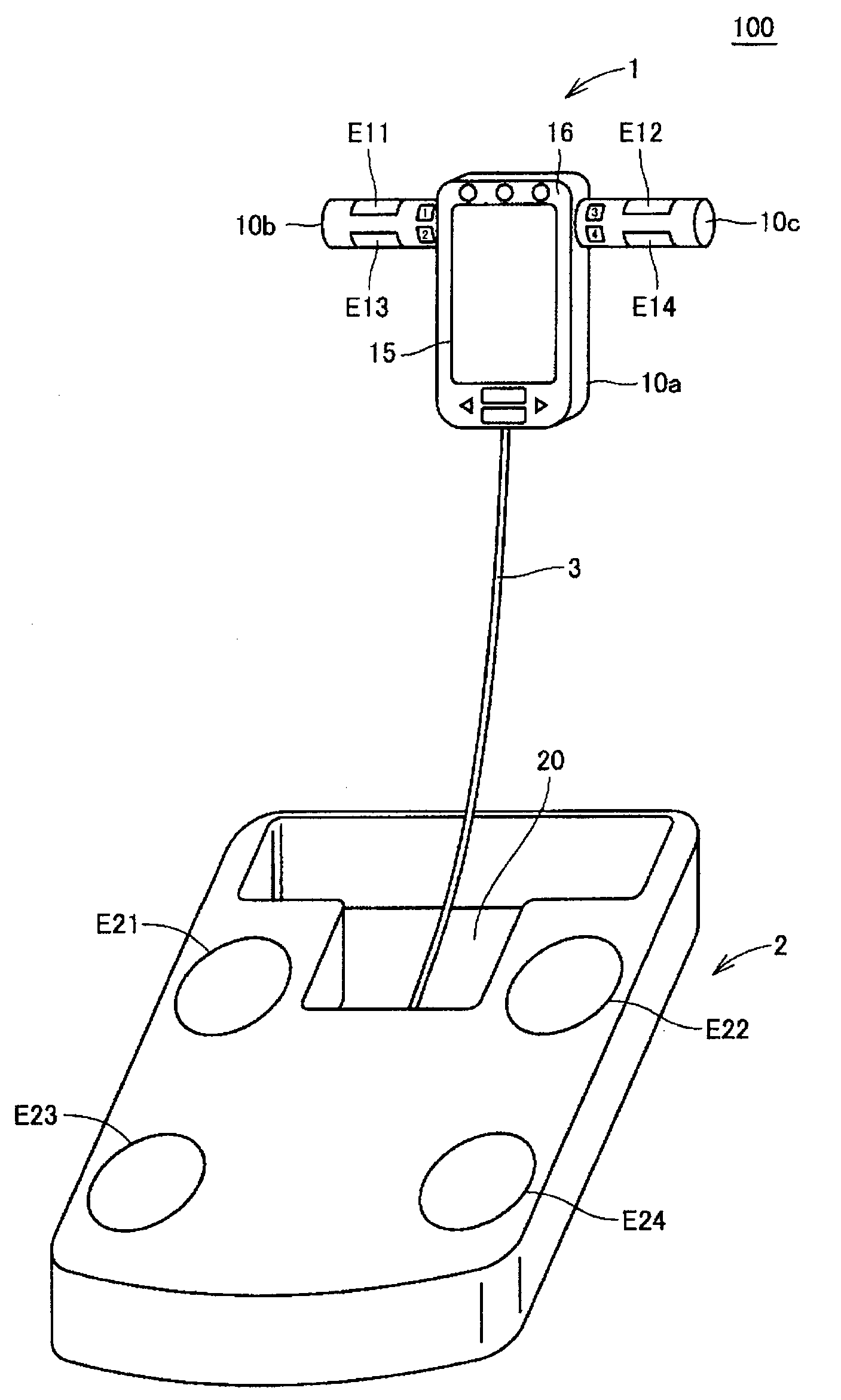

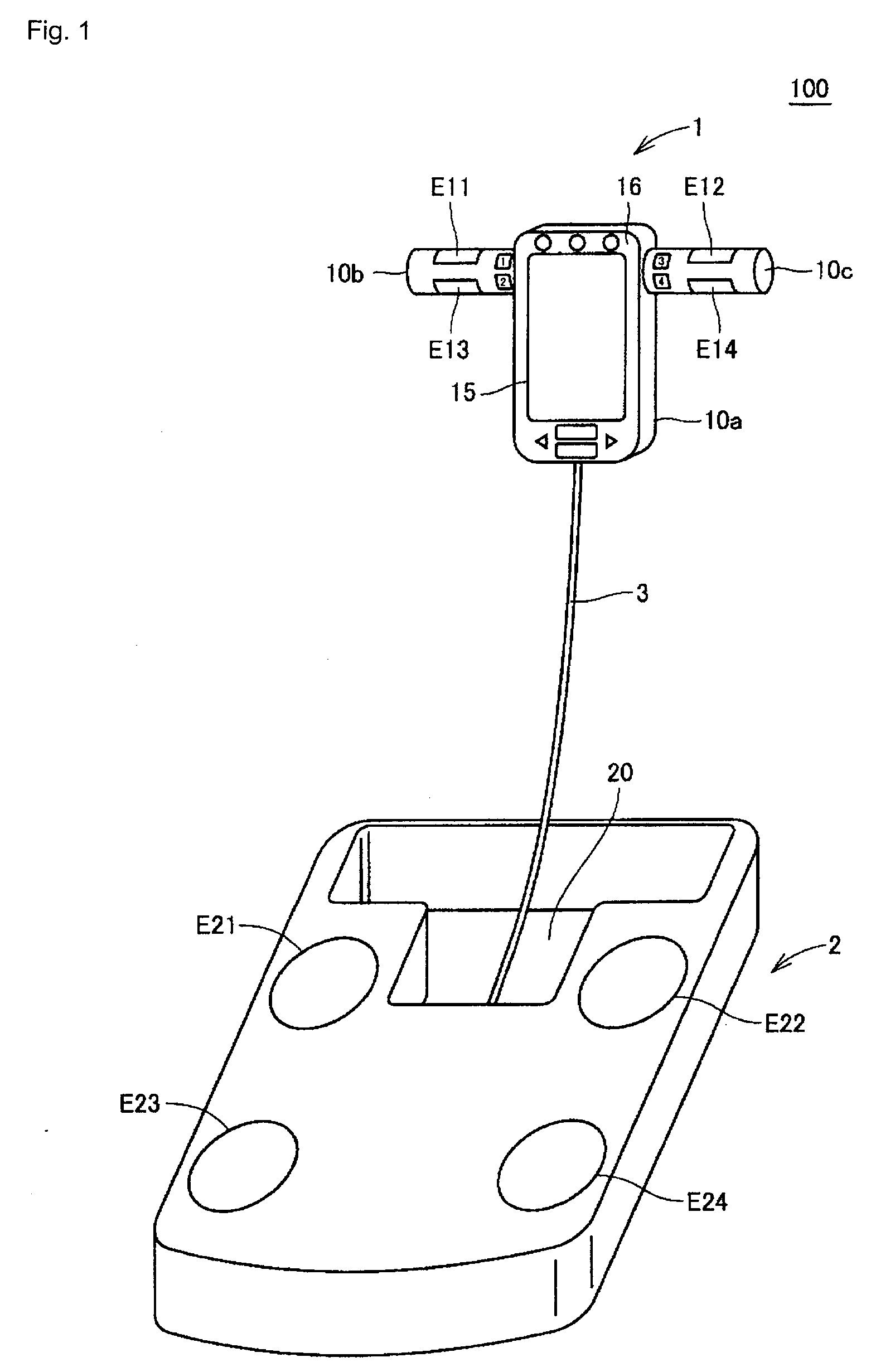

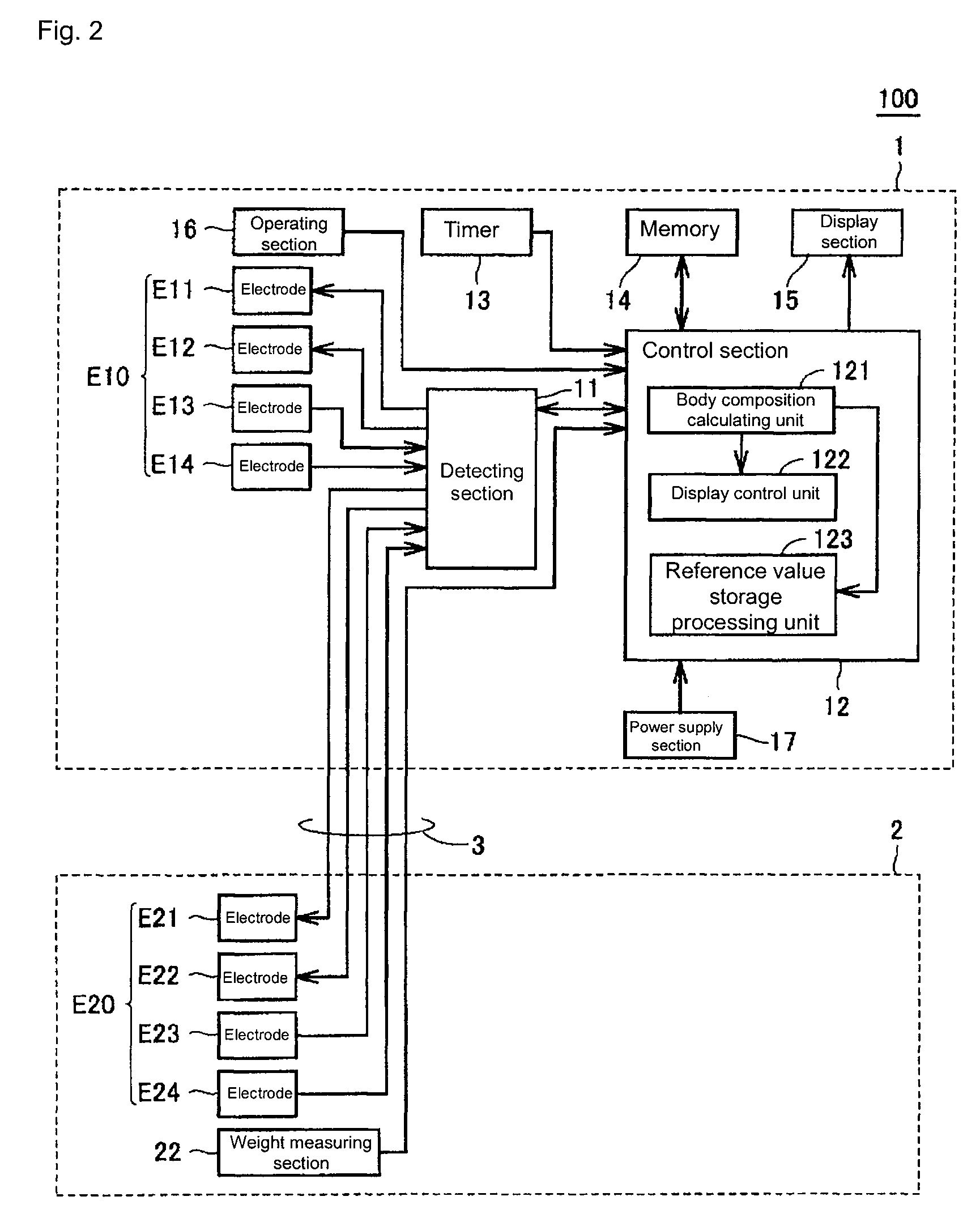

Body composition measuring instrument for recognizing changes in body composition

ActiveUS20090204018A1Easy to identifyEasy to understandPerson identificationWeighing apparatus for materials with special property/formBody composition measureMeasuring instrument

A body composition measuring instrument includes a body composition calculating unit for calculating a body composition of a user by using a plurality of electrodes, a reference value storage region for storing information of a reference value related to the past body composition of the user, a display control unit for performing a control to display a position (BR1) of the body composition for this time calculated by the body composition calculating unit and a line (62) being a position of a reference value on a predetermined graph (G1 to G4), and a display section (15) for performing a display corresponding to an output from the display control unit.

Owner:OMRON HEALTHCARE CO LTD

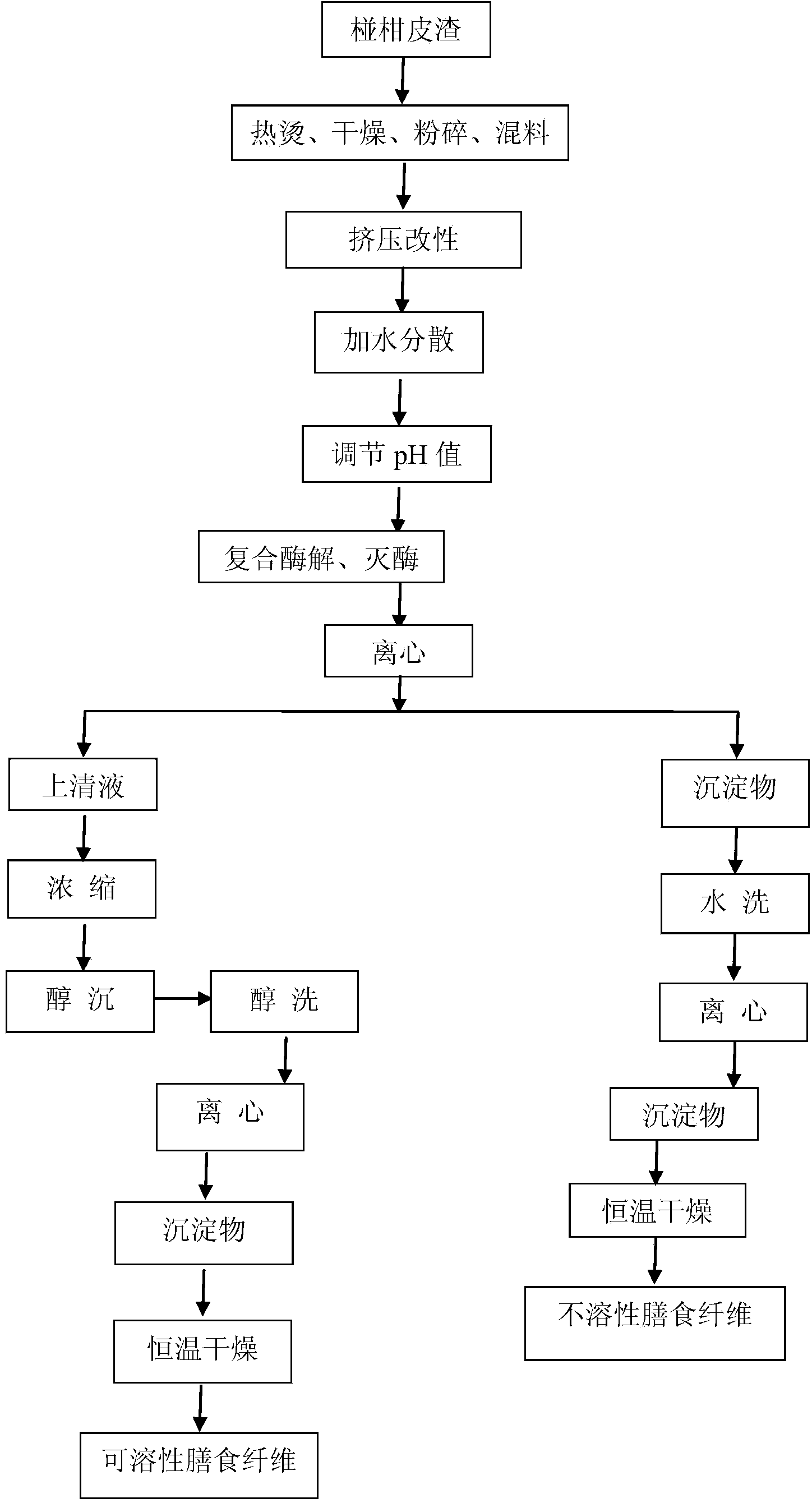

Method for extracting ponkan dietary fibers through extrusion modification and enzymolysis coupling

ActiveCN103976371AHigh extraction rateChange compositionFood ingredient functionsFood preparationAlcoholCentrifugation

The invention belongs to the technical field of deep processing methods of subsidiary agricultural products, and particularly relates to a method for extracting extracting ponkan dietary fibers through extrusion modification and enzymolysis coupling. The method comprises the steps of by taking ponkan hide trimmings as raw material, carrying out hot ironing, drying, grinding, mixing and extrusion modification, adding water for dispersion, adjusting the pH, adding compound enzyme for enzymolysis, carrying out enzyme deactivation and centrifugation to obtain filtrate and precipitate, carrying out concentration, alcohol precipitation, alcohol washing, centrifugation and drying on the filtrate to obtain water-soluble dietary fibers, and carrying water washing, centrifugation and drying on the precipitate to obtain insoluble dietary fibers. According to the method for extracting extracting ponkan dietary fibers through extrusion modification and enzymolysis coupling, the content of the dietary fibers in the ponkan hide trimmings is improved, the functionality of the ponkan hide trimmings is strengthened, meanwhile, a new path is provided for the comprehensive utilization of the ponkan by-products, the deep processing of the subsidiary agricultural products is realized and the resource waste is decreased.

Owner:CHINA AGRI UNIV

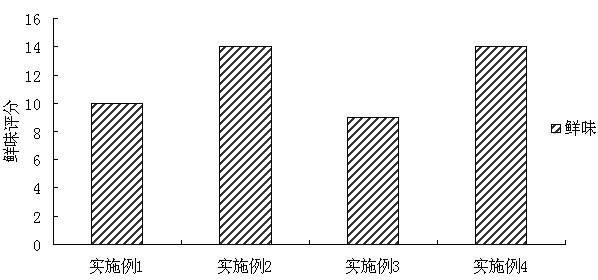

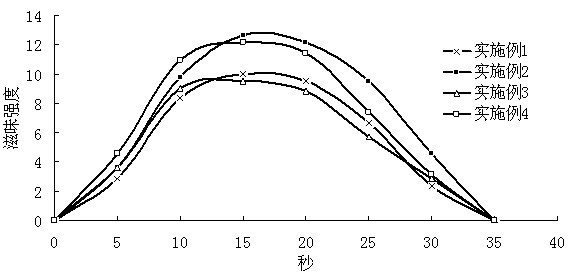

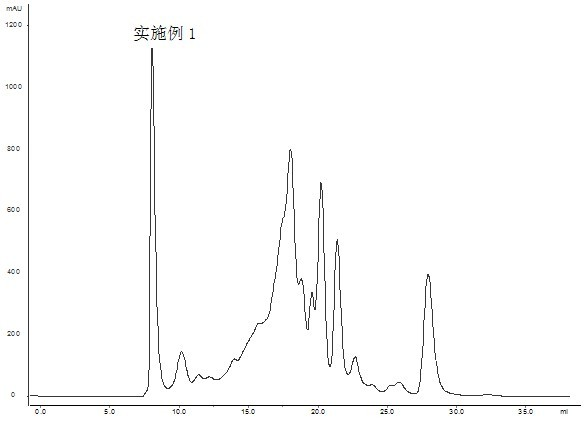

Preparation method of flavor base material containing abundant umami peptide

The invention relates to a preparation method of a flavor base material containing abundant umami peptide. The preparation method comprises the following steps: firstly evenly mixing vegetable protein with distilled water, and then heating the obtained mixed solution at the temperature of 100-121 DEG C for 15-30 minutes; adjusting the corresponding pH value and temperature range, and then adding a proper amount of protease and monomer amino acid; and hydrolyzing until the hydrolysis degree reaches 6%-12%, heating to 85-95 DEG C, keeping the temperature for 15-30 minutes, and filtering to obtain peanut meal hydrolysis supernate. In the preparation method, after the raw materials are pretreated, tasty amino acid in the obtained vegetable protein enzymolysis liquid is reversely regulated and controlled through the monomer amino acid to finally obtain the flavor base material containing the abundant umami peptide, thus the method is applicable to large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

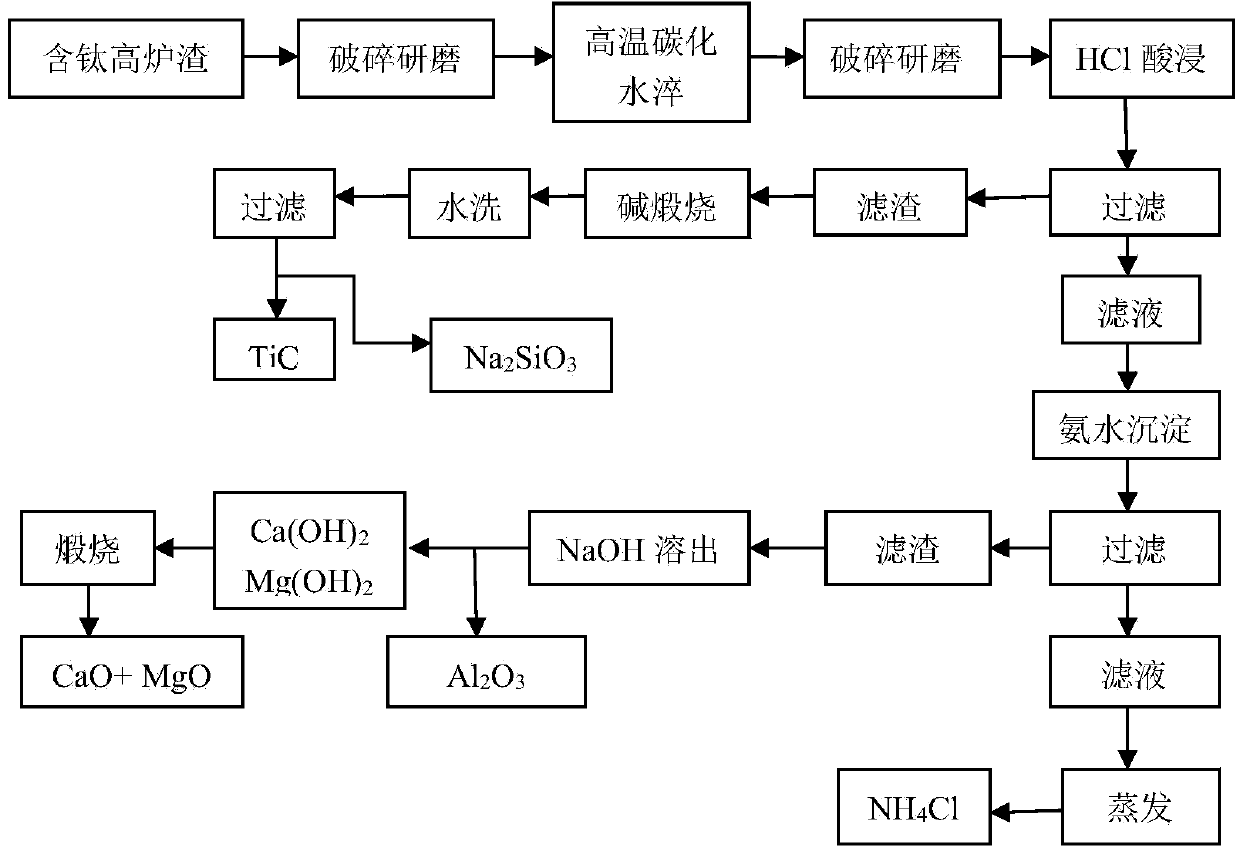

Method for extracting titanium from titanium-containing blast furnace slag by aluminothermy

InactiveCN103966455AHigh recycling rate of resourcesEfficient recyclingProcess efficiency improvementSlagTube furnace

The invention provides a method for extracting titanium from titanium-containing blast furnace slag, and belongs to the fields of metallurgy and chemistry. The method comprises the steps of preprocessing, mixing materials, reducing by the carbothermy, cooling with water, pickling, and roasting with alkali. The method specifically comprises the following steps: crushing and grinding titanium-containing blast furnace slag into 180+ / -10 meshes; mixing slag and carbon powder based on a certain mass ratio; heating an electric tube furnace to reach a given temperature under the argon protective atmosphere; feeding the mixed material into an alumina crucible; transferring into the electric tube furnace under a high temperature; maintaining the temperature for a certain time; taking out under a high temperature; cooling with water; filtering the slag subjected to HCl pickling and carbonizing, and separating filter residue and filtrate; processing the filter residue through NaOH (or Na2CO3) by roasting with alkali after pickling in order to generate Na2SiO3 through an Si-containing component in the filter residue; washing with water and filtering to separate Na2SiO3 and TiC to obtain TiC filter residue; and drying the filter residue to obtain relatively pure TiC. The method is simple in process, stable in process parameters, and effectively realizes separating and enriching extracting of titanium and other elements in the blast furnace slag.

Owner:UNIV OF SCI & TECH BEIJING

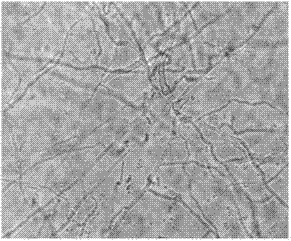

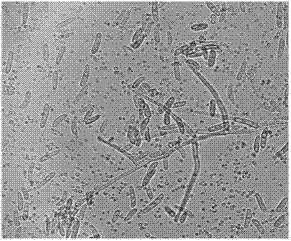

Technology for processing indissolvable and nondegradable organic waste gas by integrated composite organisms

InactiveCN102961962AChange compositionRaise the ratioDispersed particle separationAir quality improvementFilm resistanceLow speed

The invention relates to a technology for processing indissolvable and nondegradable organic waste gas by integrated composite organisms, and the technology is applicable to the purification of low-density, indissolvable and nondegradable organic waste gas. A high-density low-speed air suction way and a domestication way of low flow-rate circuiting liquid are adopted; and during the domestication process, a fungus-bacteria composite organism system with pseudomonas as a dominant bacterium is constructed by use of a pH changing way. A composite organism tower combines two microorganisms of fungus and bacteria, and the diversity of microorganisms can be effectively applicable to the requirements of various indissolvable and nondegradable organics on different bacteria; system resistance is reduced by the introduction of a fungus system; water film resistance is reduced effectively and the mass transfer process of the organic waste gas is accelerated by means of low circuiting flow-rate; an integrated type technological structure is adopted to the fungus and the bacteria, so the processing technology is simplified and the investment cost and operating cost are reduced. The system is high in efficiency of removing the indissolvable and nondegradable organic waste gas and load, and has an extensive applicability.

Owner:CHINA UNIV OF MINING & TECH

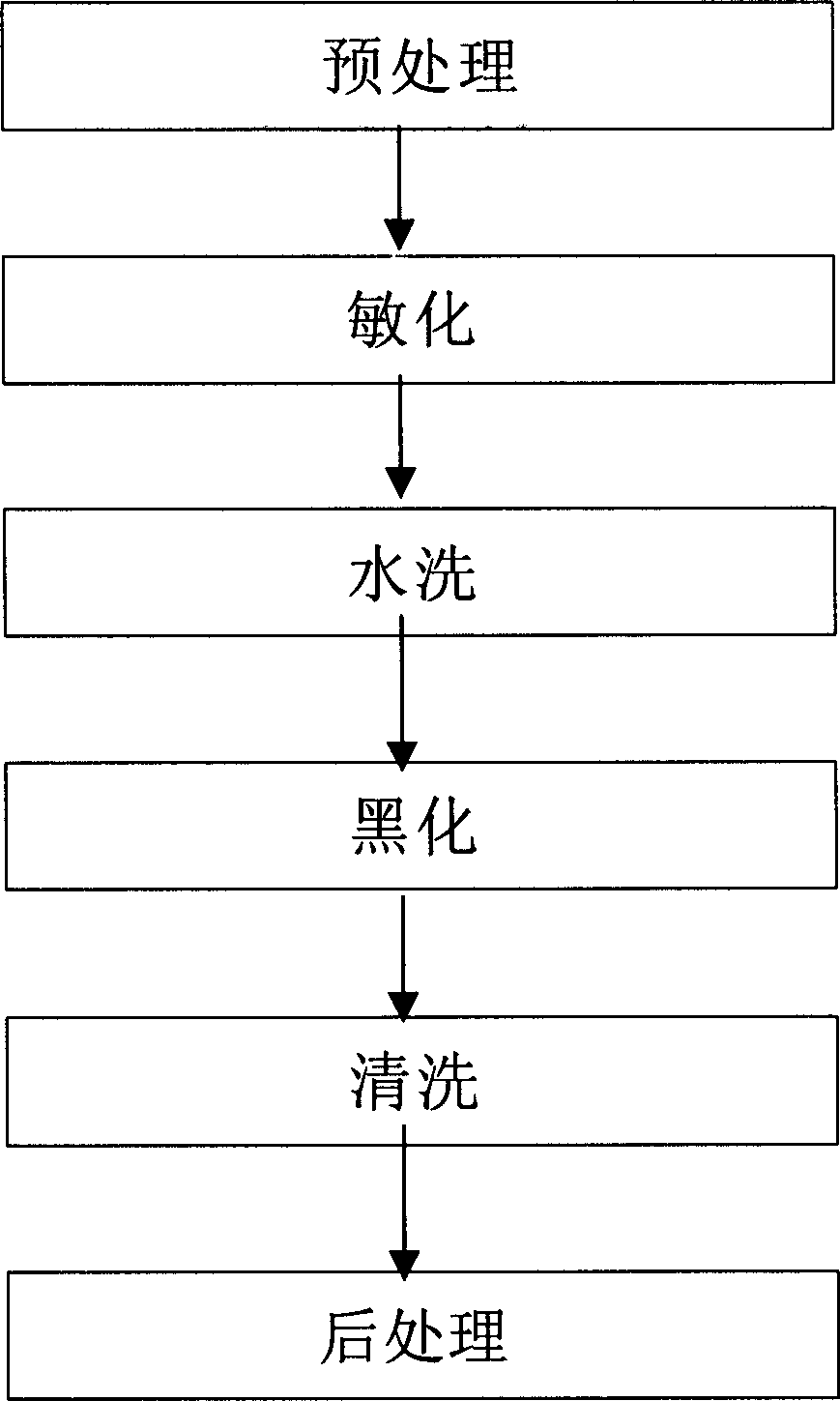

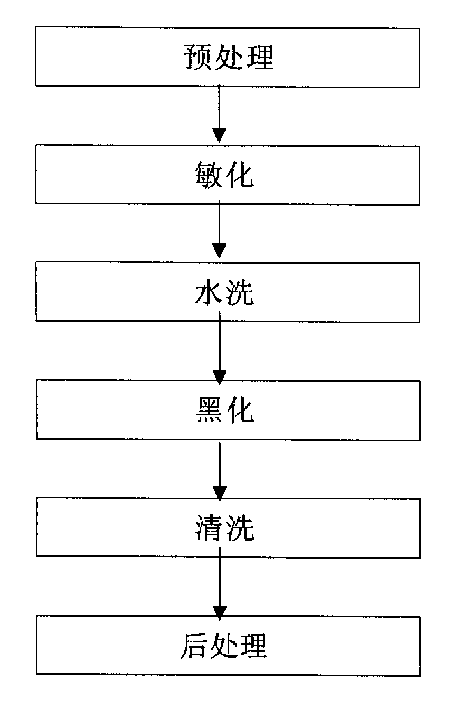

Iron and steel surface sensitizing and blackening agent and relevant blackening process

InactiveCN1453394AComposition is stableImprove adhesionMetallic material coating processesMetallurgySodium citrate

The iron and steel surface sensitizing and blackening agent includes sensitizing agent and normal temperature blackening liquid. Its formula is as follows: the sensitizing agent consists of CuSO4.5H2O, NiSO4.7H2O, sodium citrate, tartaric acid, amido sulfonic acid and water, and has pH value of 2-4; and the normal temperature blackening liquid consists of sodium sulfide, ethanol and water, and has pH value of 8-10. The blackening process includes the main steps of: pre-treatment of iron and steel parts, soaking the pre-treated iron and steel parts in the sensitizing agent liquid for 2-6 to sensitize, and soaking the sensitized and washed iron and steel parts in the normal temperature blackening liquid for 3-5 min to form black film.

Owner:LIUZHOU OVM MASCH CO LTD

Breast milk oligosaccharide composition for improving intestinal flora abundance and fecal odor of infants and application thereof

The invention provides a breast milk oligosaccharide composition for improving intestinal flora abundance and fecal odor of infants and application thereof. The breast milk oligosaccharide compositioncomprises 2'-fucosyllactose and / or 3'-fucosyllactose, and galactooligosaccharides. The invention also provides application of the breast milk oligosaccharide composition in improving intestinal floraabundance and fecal odor of infants. The invention also provides infant formula milk powder containing the breast milk oligosaccharide composition. The composition according to the invention has a plurality of breast milk oligosaccharides in different ratios, can increase the abundance of actinomycetes and firmicutes in intestinal microflora of infants, increase the number of bifidobacteria and lactic acid bacteria of infants and change the composition of intestinal flora, and can reduce the pH value of intestines and the contents of indole and skatole, reduce the contents of indole and skatole in infant feces, improve the character of infant feces, and reduce the concentration of peculiar smell compounds.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Feed additive capable of increasing meat factor of pork pigs and improving meat quality

The invention discloses a feed additive capable of increasing the meat factor of pork pigs and improving the meat quality, belonging to the technical field of feed additives. The feed additive comprises pure Chinese herbal medicine powder, lentinan, compound probiotics, a complex enzyme preparation, L-carnitine, beta-carotene, gamma-linolenic oil, vitamin E, vitamin C, ferric sulfate, magnesium sulfate, sodium selenite and carriers, wherein the carriers include rice hull powder, a mixture of rice chaff and husk and kaolin. According to the feed additive, the problem that the meat quality is reduced due to pig feed additives is effectively solved, the anti-stress capacity of the pigs is improved, pig diseases are well prevented and treated, the physique of the pork pigs is improved, and the high-quality pork can be produced; furthermore, the distribution of ketone fat and protein is improved, so that the meat factor of the pork pigs is improved.

Owner:GUANGXI UNIV

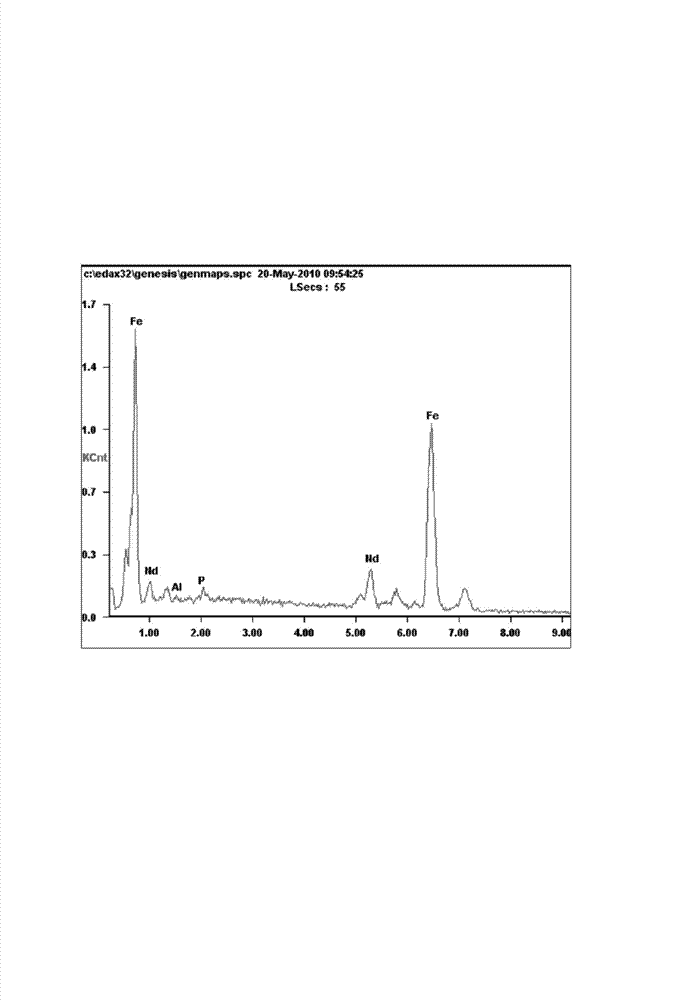

Method for improving corrosion resistance of phosphate coating on surface of neodymium-iron-boron permanent magnet

InactiveCN102965655AImprove corrosion resistanceSimple processMetallic material coating processesPhosphateElectroplating

The invention belongs to the neodymium-iron-boron material surface electroplating field and mainly relates to a method for improving the corrosion resistance of a phosphate coating on the surface of a neodymium-iron-boron permanent magnet, wherein basic oil removal and rust removal through acid washing are performed before phosphorization and drying is performed after phosphorization; a desired surface for phosphorization is obtained by means of controllable acid washing solution; the conventional process of performing surface adjustment after acid washing is omitted; the problem of low corrosion resistance of the existing neodymium-iron-boron phosphate coating and the problem that the conventional process still needs chromic acid passivating treatment after phosphorization in order to improve the corrosion resistance of the phosphate coating are solved; and the obtained film is even and compact in surface and thereby protects the neodymium-iron-boron substrate. The preparation method is simple in process flow, convenient to operate and friendly to the environment.

Owner:SHENYANG POLYTECHNIC UNIV

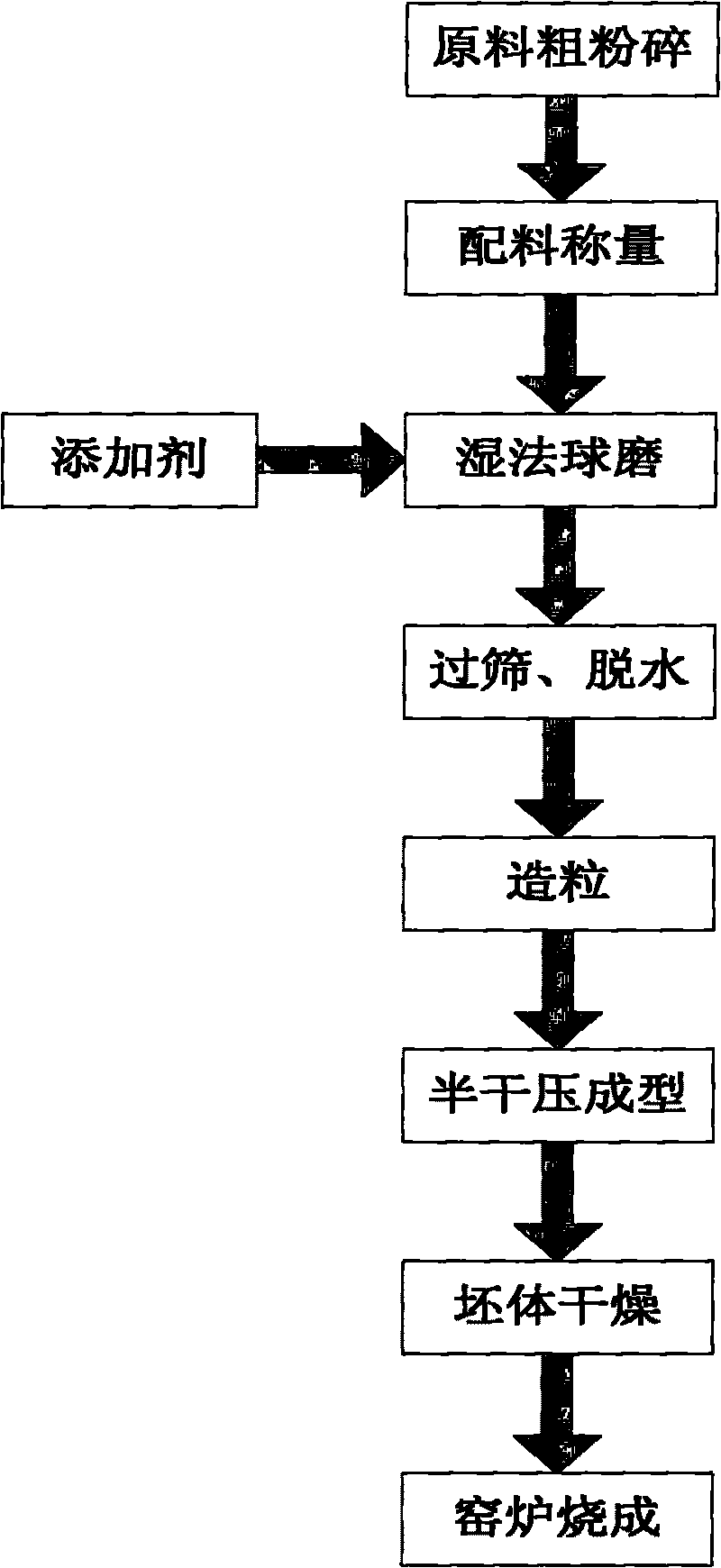

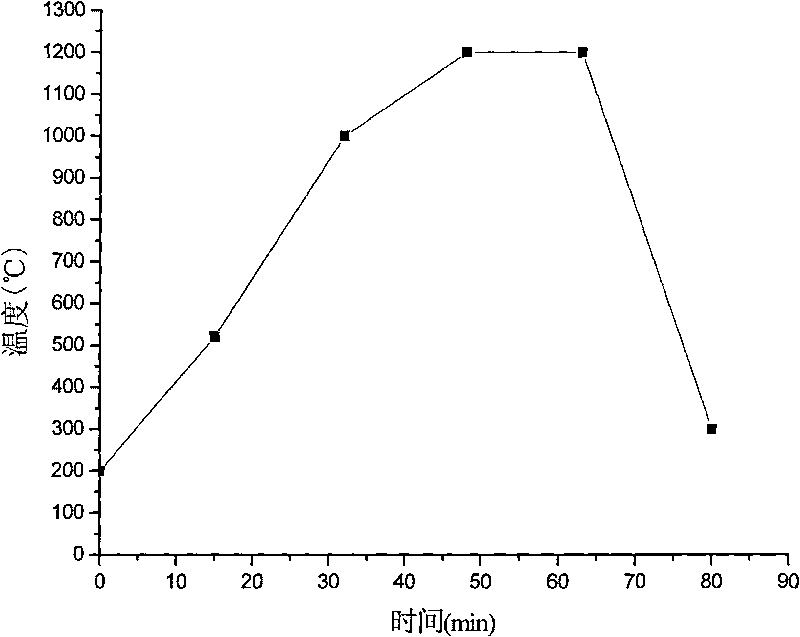

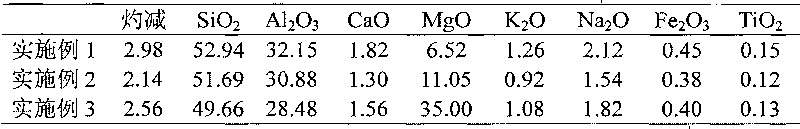

Method for firing porous filtering ceramic tiles with ceramic polishing scrap

InactiveCN101709001AIncrease contentIncrease the number ofSolid waste disposalCeramicwareCordieriteMaterials processing

The invention discloses a method for firing porous filtering ceramic tiles with ceramics polishing scrap. The method is implemented through raw materials processing, powder preparation, pressing molding, sintering and other processes performed on 50 to 70 percent of building ceramics polishing scrap mixed with 18 to 22 percent of calcined alumina, 0 to 10 percent of fired talc and 28 to 35 percent of light magnesium oxide. The porous filtering ceramic tiles prepared by the method not only have the function of protecting and purifying environment, but also have high modulus of rupture and good filtration performance. The method can effectively solve the problem of dealing with the building ceramics polishing scrap, can save natural ceramic raw materials, is simple in technological process of utilizing the ceramics polishing scrap to fire cordierite porous filtering ceramic tiles and low in cost, and has good application prospects in the fields of liquid pollution treatment, precise filtration and the like.

Owner:SOUTH CHINA UNIV OF TECH

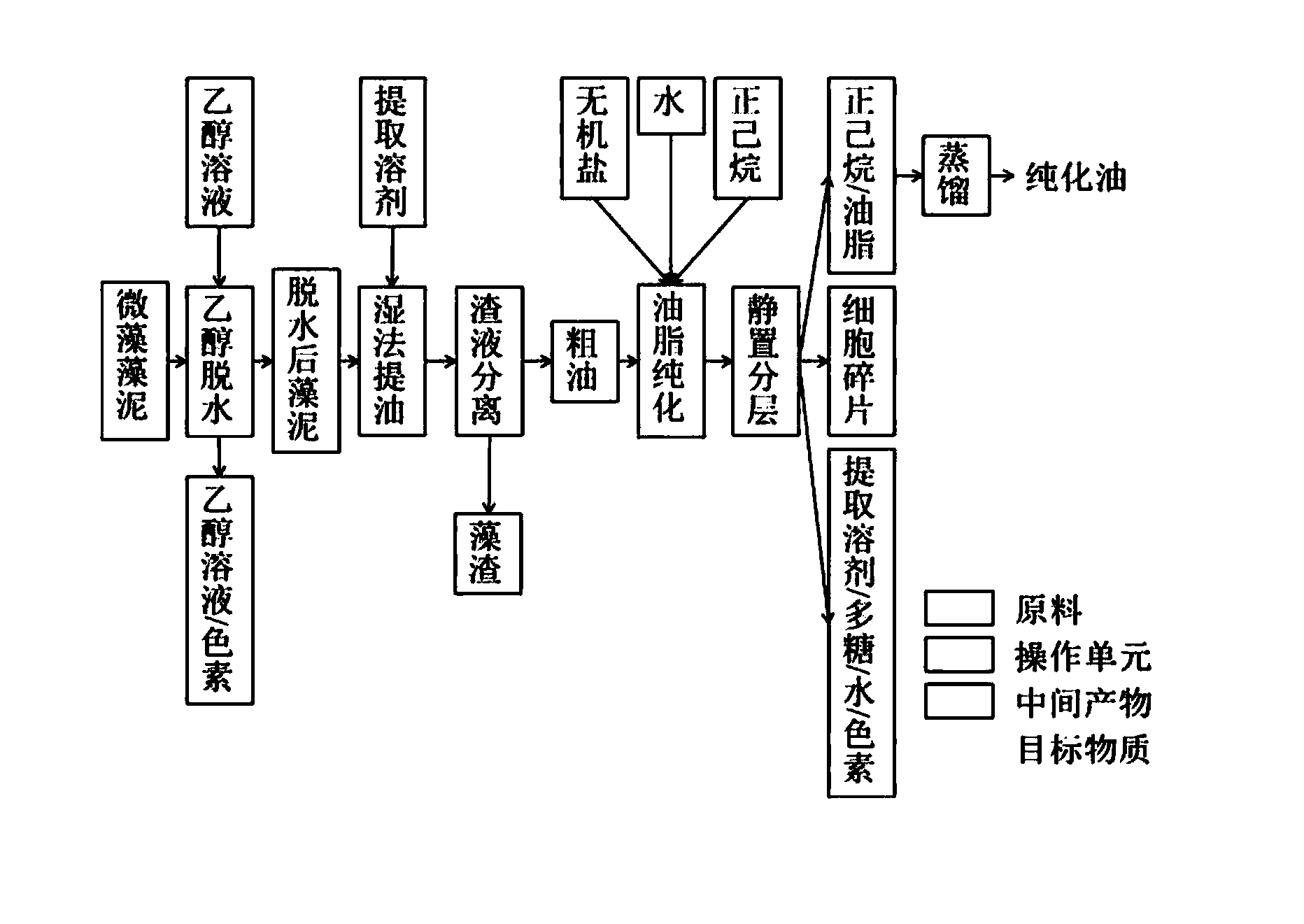

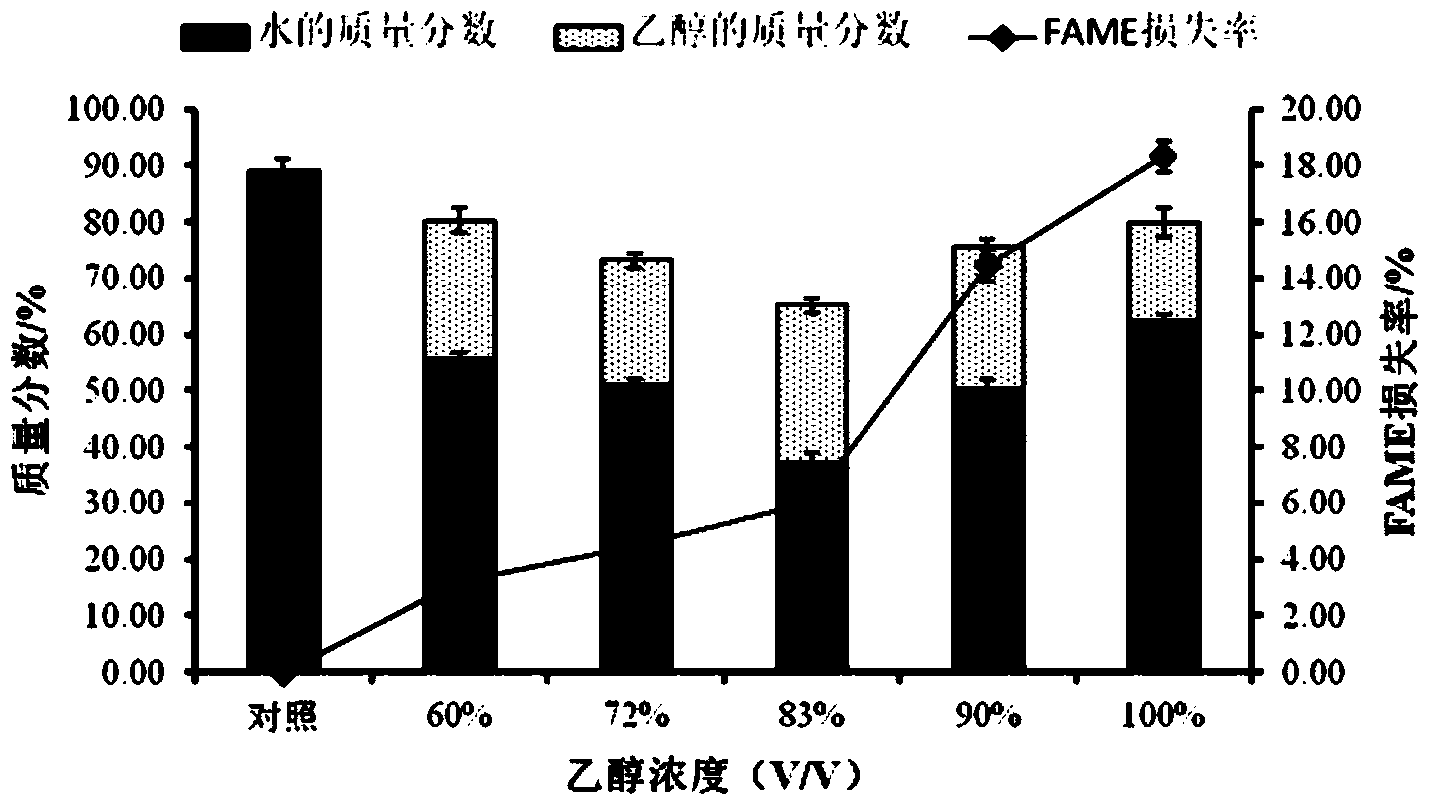

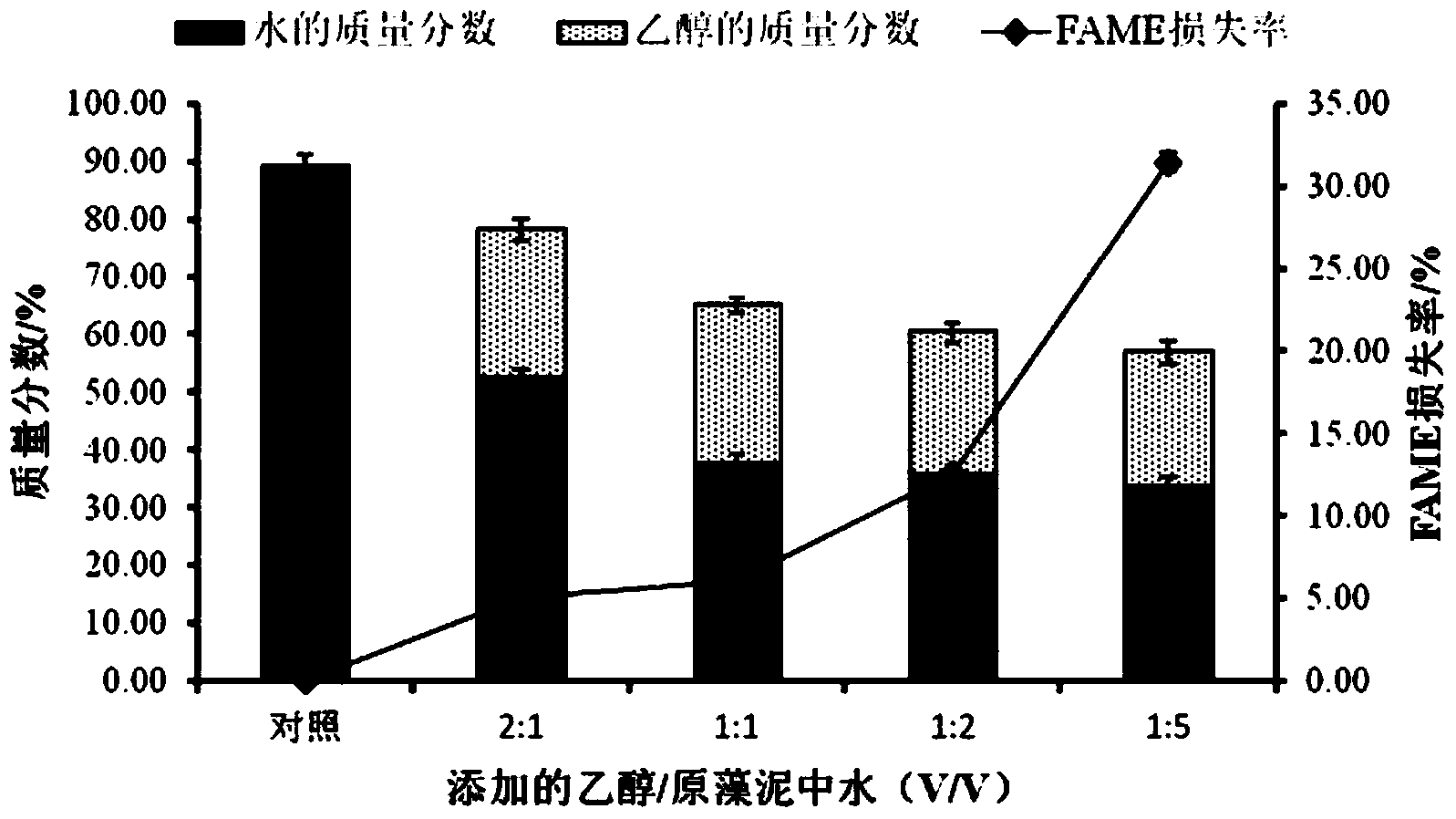

Method for wet extraction of purified microalgae oil

InactiveCN104059773AReduce energy consumptionReduce the impact of the extraction rateFatty-oils/fats refiningFatty-oils/fats productionOil and greaseDesolvation

The invention provides a method for wet extraction of purified microalgae oil. The method comprises the following steps: (1) adding an ethanol solution into ooze of collected microalgae, quickly stirring the mixture uniformly, carrying out centrifugation, and collecting sediments to obtain dehydrated algae ooze; (2) adding non-toxic or slightly-toxic organic solvent of a water solution of the organic solvent into the dehydrated algae ooze obtained in the step (1), carrying out cell disruption on the algae ooze, and extracting coarse oil in the microalgae; (3) carrying out centrifugation, collecting the coarse oil obtained in the step (2), adding water and inorganic salt into the coarse oil, stirring the mixture uniformly to form a coarse oil-water solution, adding n-hexane into the coarse oil-water solution, carrying out standing layering or centrifugal layering after uniform mixing to form three layers which are the upper solution layer, the middle solid matter layer and the lower solution layer, and collecting the solution on the upper layer; (4) carrying out desolvation on the solution on the upper layer to obtain the microalgae oil. According to the method for wet extraction of the purified microalgae oil, the yield of esterified grease is high, operation is easy, and energy consumption is low.

Owner:SOUTH CHINA UNIV OF TECH

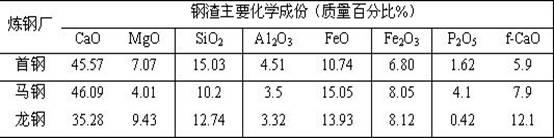

Method for modifying high-temperature steel slag by using compound materials of tailings

ActiveCN102605113AChange compositionChange physical stateIncreasing energy efficiencyCalcium in biologySteelmaking

The invention relates to method for modifying steel slag, in particular to a method for modifying high-temperature steel slag discharged in the final steelmaking stage by using a large amount of mining tailings with low cost, comprising the following steps: mixing 15-30 parts by weight of high alumina silicate tailings, 60-80 parts by weight of high calcium silicate tailings and 5-15 parts by weight of calcium carbonate tailings to obtain compound materials of the tailings; granulating to prepare agglomerated blocks of 3-5cm; adding the compound materials of the tailings into steel slag pot or disc by batches according to the proportion of (70-80%):(20-30%) of the discharged steel slag and the compound materials of the tailings; carrying out steel slag splashing for furnace maintenance, wherein the left steel slag is not poured into the steel slag pot or disc for modifying the steel slag; preserving the temperature of the steel slag at 1,200-1,400 DEG C for 30-60min; quenching by using water, applying heat or covering by heat when the temperature is below 1,200-1,400 DEG C; breaking; and carrying out magnetic separation. Due to the adoption of the method, the separation effect of the steel slag can be improved significantly, the grindability of the separated steel slag can be improved, the total recovery rate of the scrap steel can be up to 95-100%, the components of the separated steel slag are controllable and have high activity, and the separated steel slag contain less than 1.5% by weight of the free calcium oxide, has the grinding work index of 14-17kw.h / t and can replace the portland cement clinker.

Owner:迁安金隅首钢环保科技有限公司

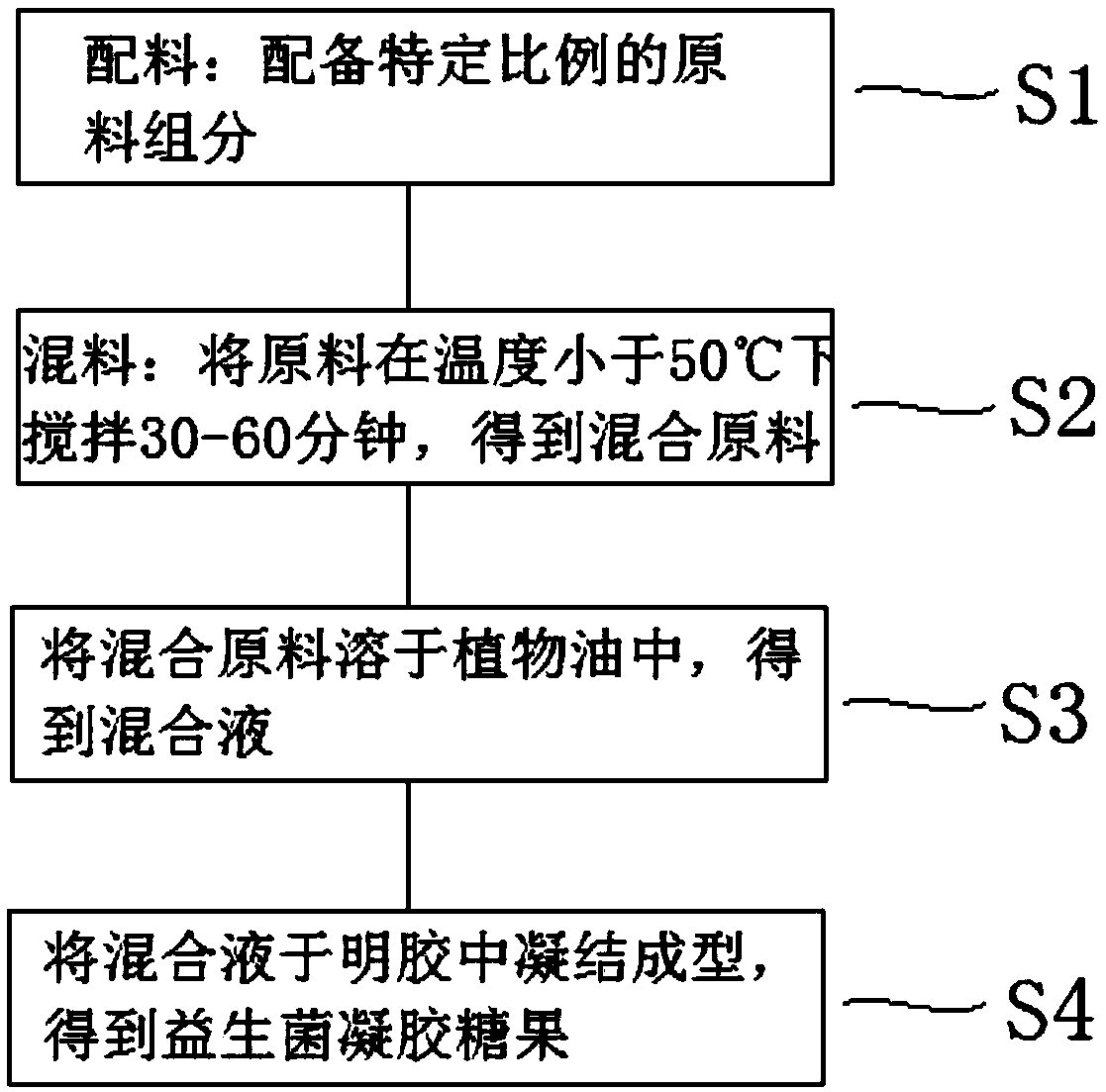

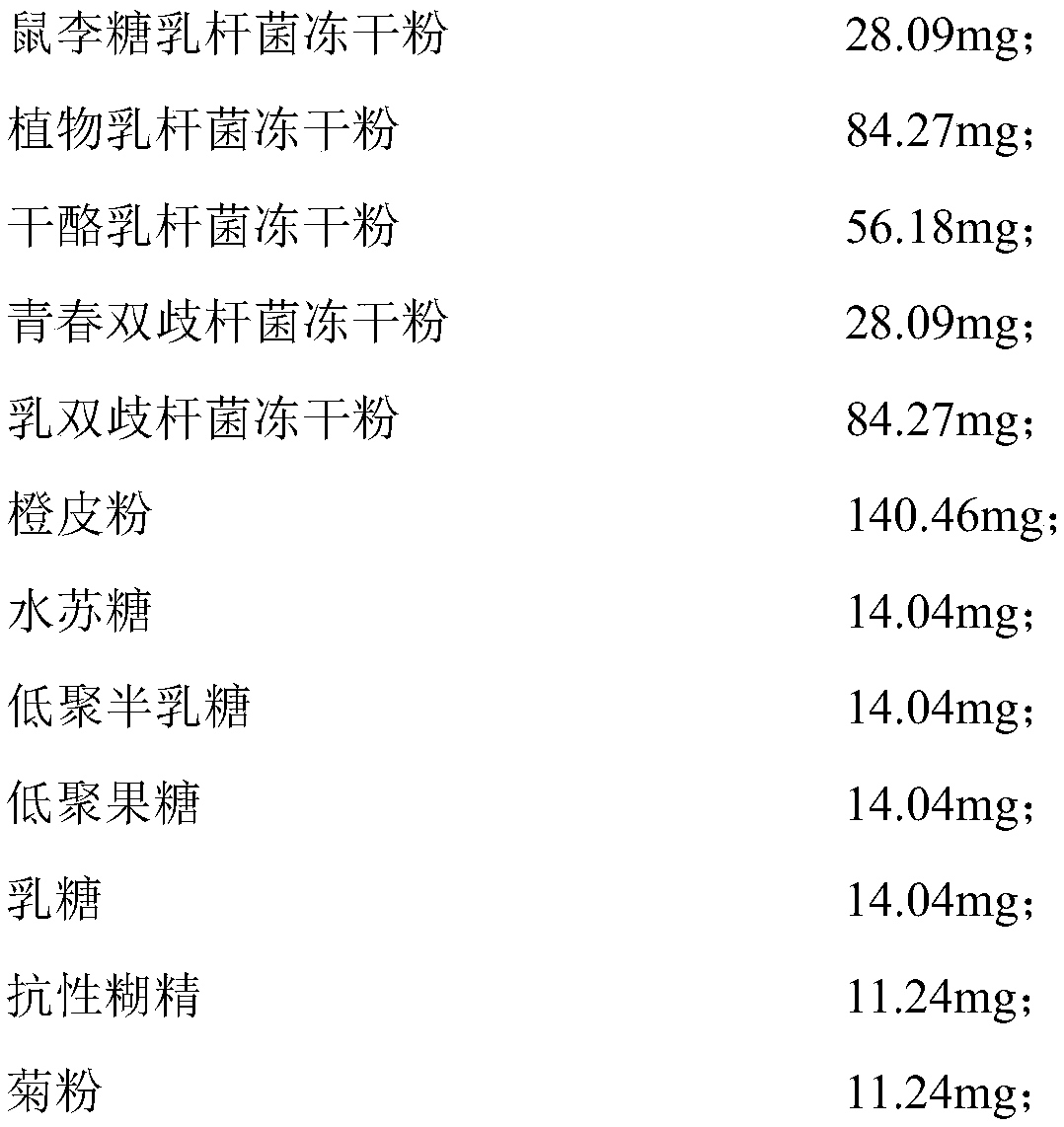

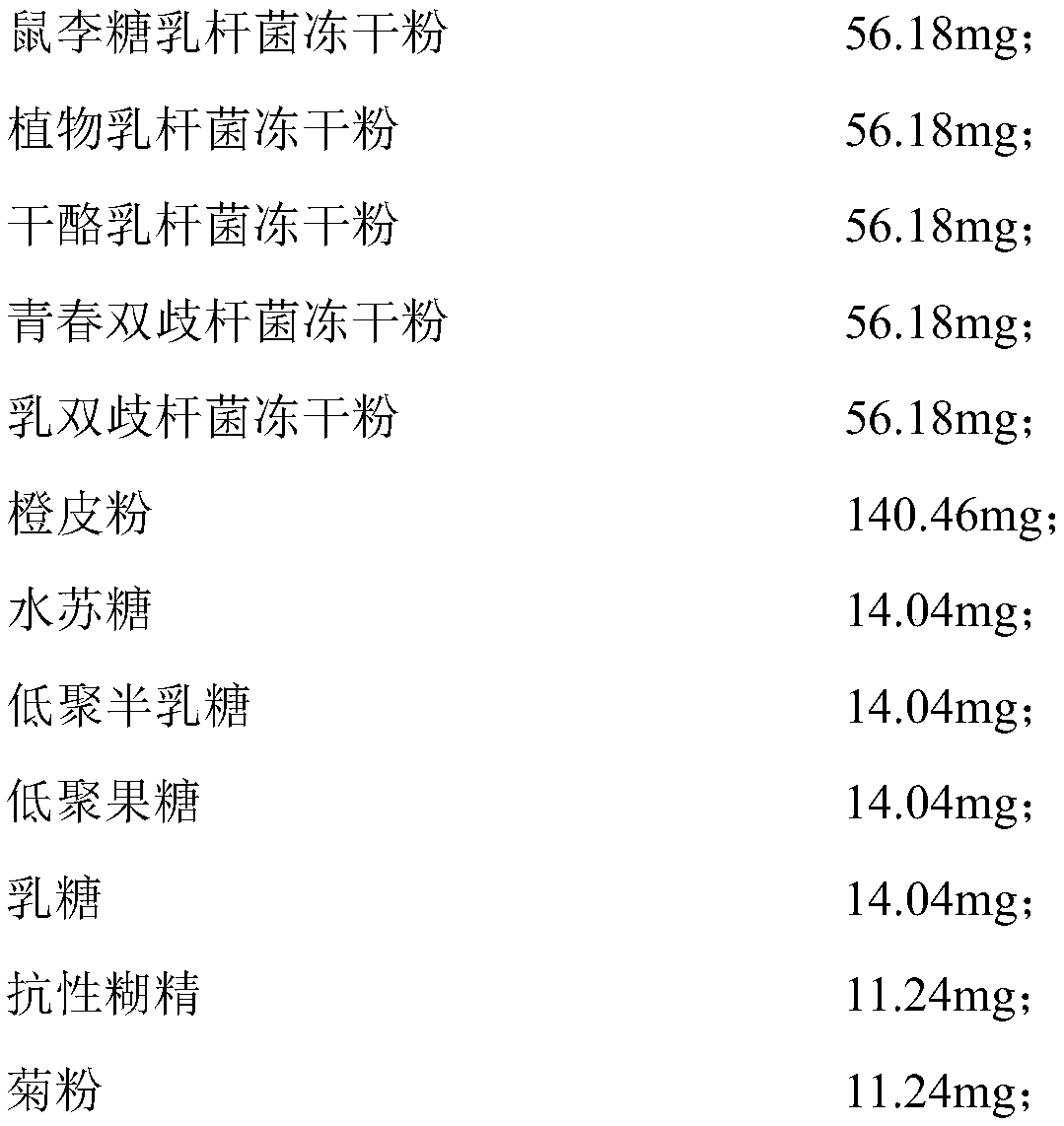

Antidiarrheal probiotic gel candy and preparation method thereof

The invention discloses an antidiarrheal probiotic gel candy. The antidiarrheal probiotic gel candy is prepared from the following raw material components in parts by mass: 100 parts of probiotic freeze-dried powder compound, 1-100 parts of plant dried powder or extract, 1-30 parts of functional oligosaccharide, 1-10 parts of lactose and 1-10 parts of water soluble dietary fibers, wherein the probiotic freeze-dried powder compound comprises at least lactobacillus plantarum freeze-dried powder and bifidobacterium lactis freeze-dried powder. The invention further discloses a preparation method of the antidiarrheal probiotic gel candy. According to the antidiarrheal probiotic gel candy and the preparation method thereof, the prepared antidiarrheal probiotic gel candy is safe and does not havetoxic or side effects, not only is carrying convenient so that taking can be more comfortable and easier, but also the raw materials are in scientific cooperation, through long-term taking, components of enteric microorganisms can be changed, intestinal flora are balanced, and intestinal health is improved, so that the effects of preventing and curing diarrhea are achieved.

Owner:GUANGDONG YANLING LIFE TECH CO LTD

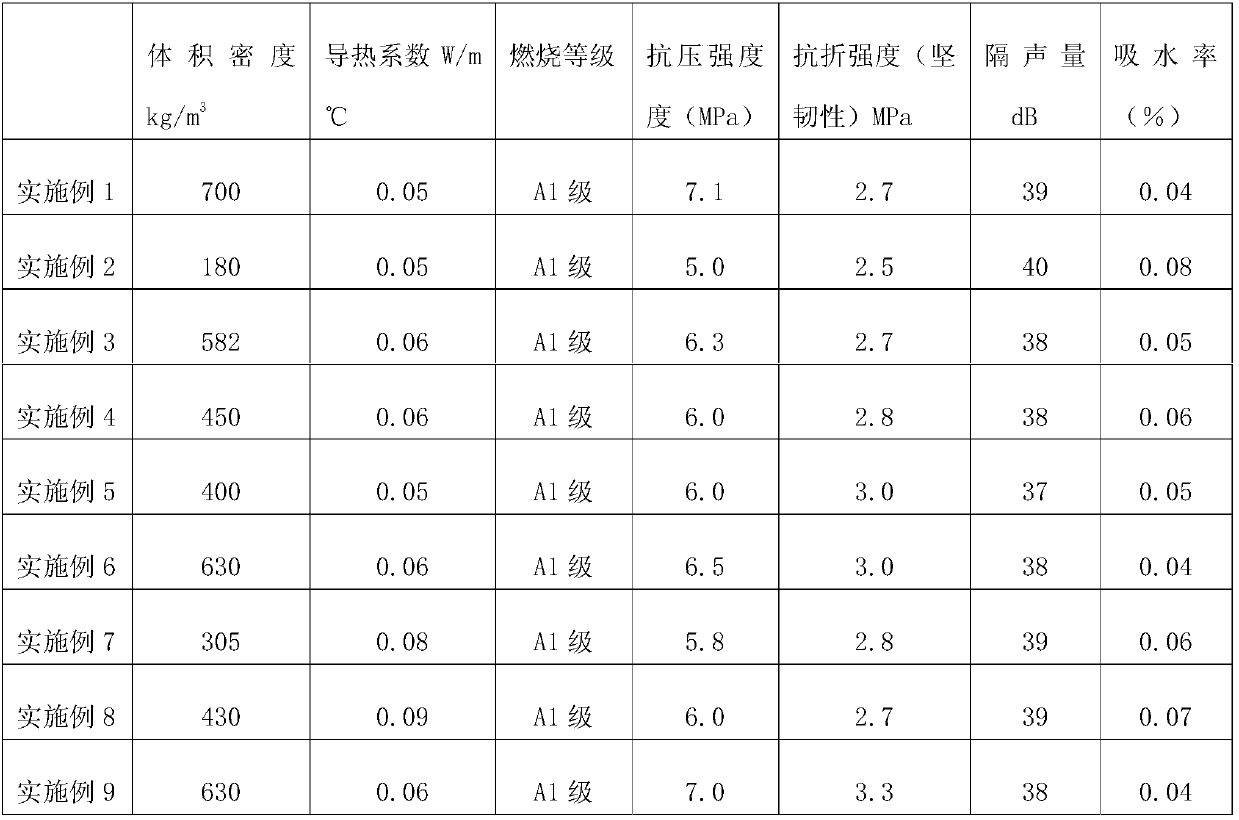

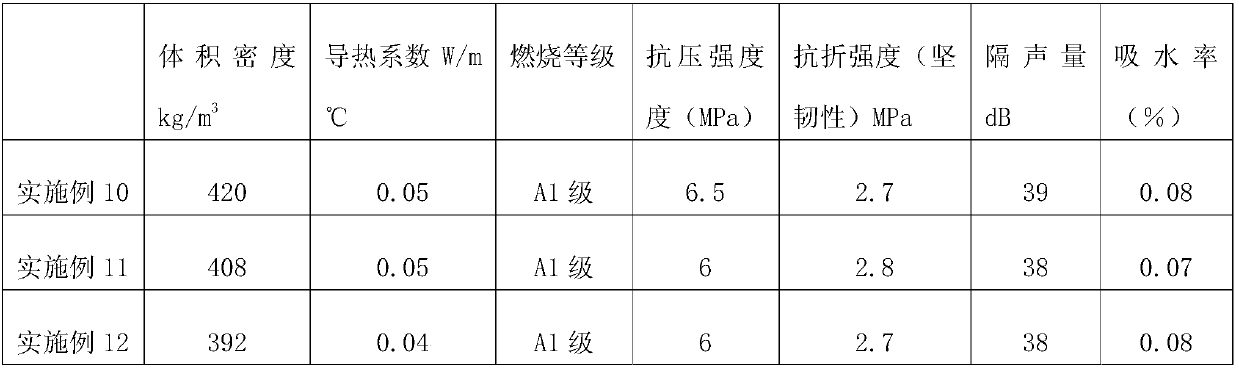

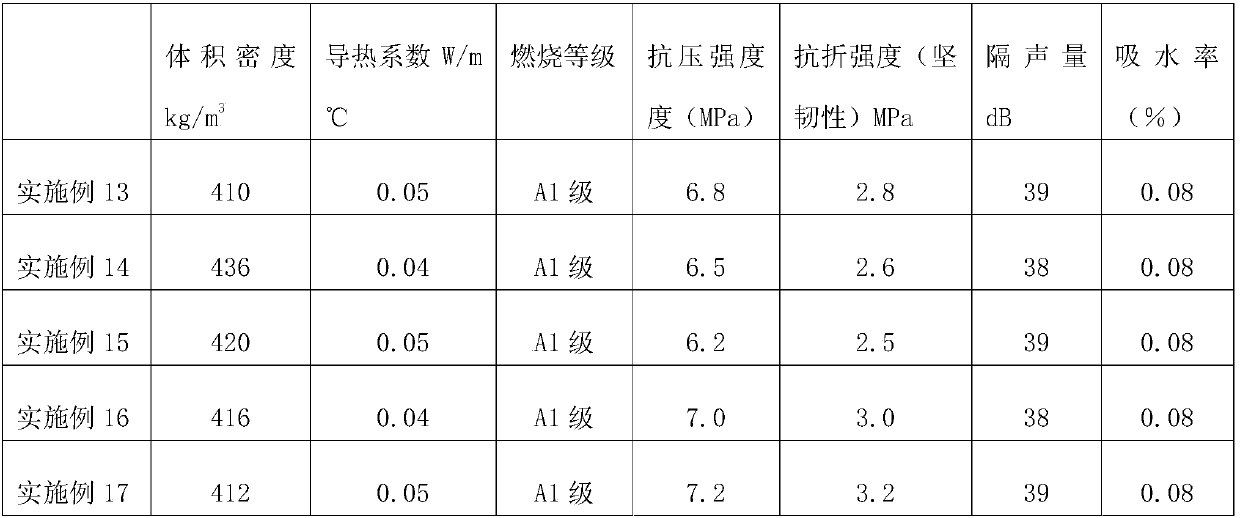

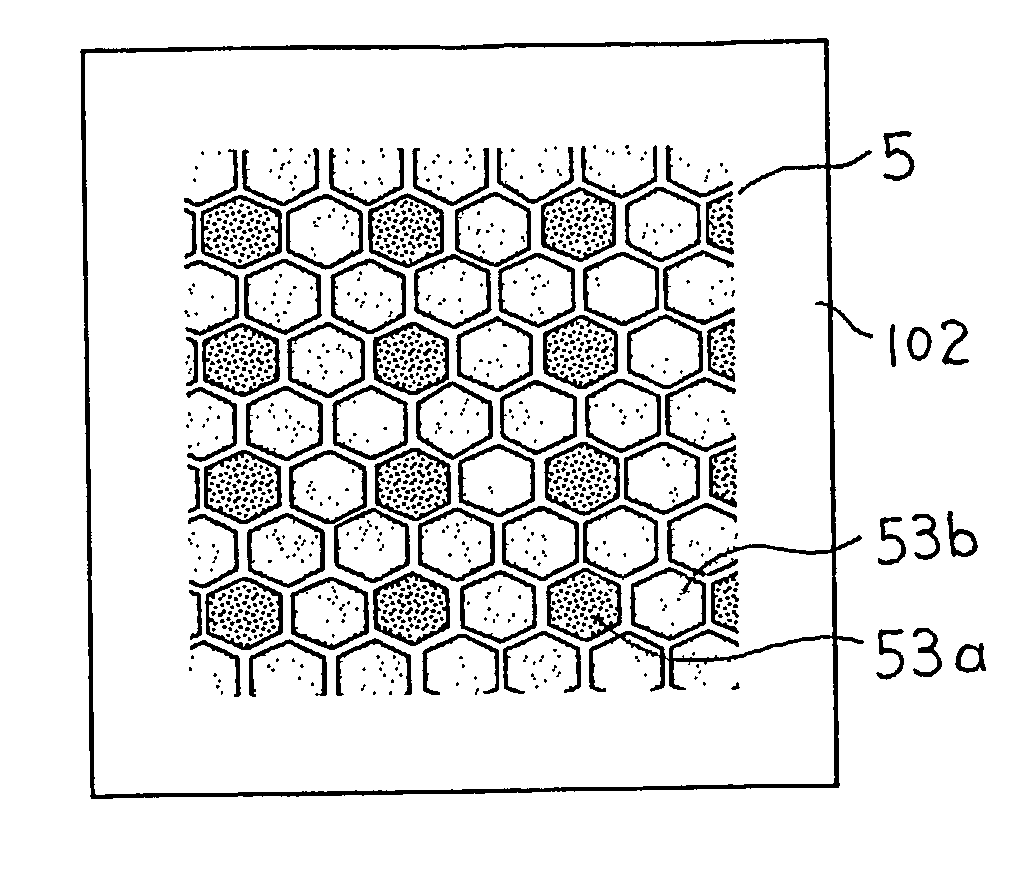

Foaming ceramic heat-insulating wallboard based on graphene and preparation method thereof

InactiveCN107602106AImprove fire insulation and weather resistanceImprove fire performanceCeramicwarePore distributionEnvironmental resistance

The invention provides a graphene-based foamed ceramic insulation wallboard, which is made of the following components: potassium sodium feldspar, ceramic waste residue, graphene, vermiculite, high-temperature co-solvent, expanded graphite, zirconia, clay, stable agent and debonding agent. Using potassium sodium feldspar and ceramic waste slag as the base material, adding graphene and vermiculite to make the board more lightweight, high-strength, thermal insulation, and improve the performance of the board such as fire resistance, insulation and weather resistance, using expanded graphite as a foaming agent, using high temperature The foaming process can better control the density, pore distribution and pore size of the board, achieve better heat preservation and light weight effects, and make a board with remarkable anti-aging, corrosion resistance, heat insulation, sound insulation, waterproof and impervious, fireproof and fireproof. , lightweight, high-strength, non-cracking, green and environmental protection and other comprehensive performance in one foam lightweight wallboard.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

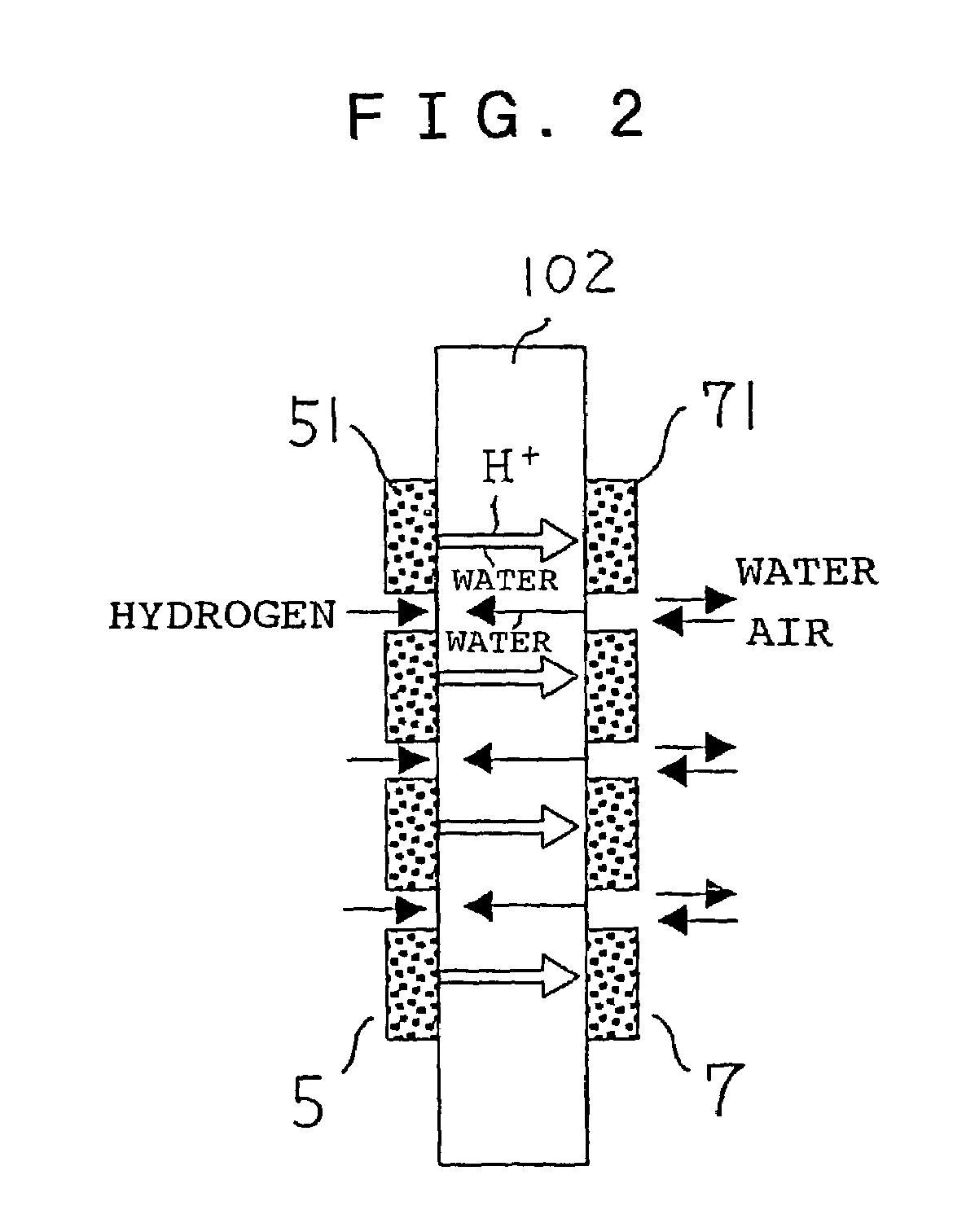

Fuel cell

InactiveUS7141328B2Improve reliabilityChange in composition of fuelActive material electrodesSolid electrolyte fuel cellsFuel cellsAlloy catalyst

A fuel cell includes an electrolyte membrane, an anode on one surface of the electrolyte membrane and having an anode catalyst layer that is supplied with fuel and contains a platinum-ruthenium alloy catalyst, and a cathode on the other surface of the electrolyte membrane and having an cathode catalyst layer that is supplied with air and contains a platinum catalyst. The anode catalyst layer and the cathode catalyst layer include divided catalyst segments, and gaps between the divided catalyst segments that are adjacent to each other.

Owner:MITSUBISHI ELECTRIC CORP

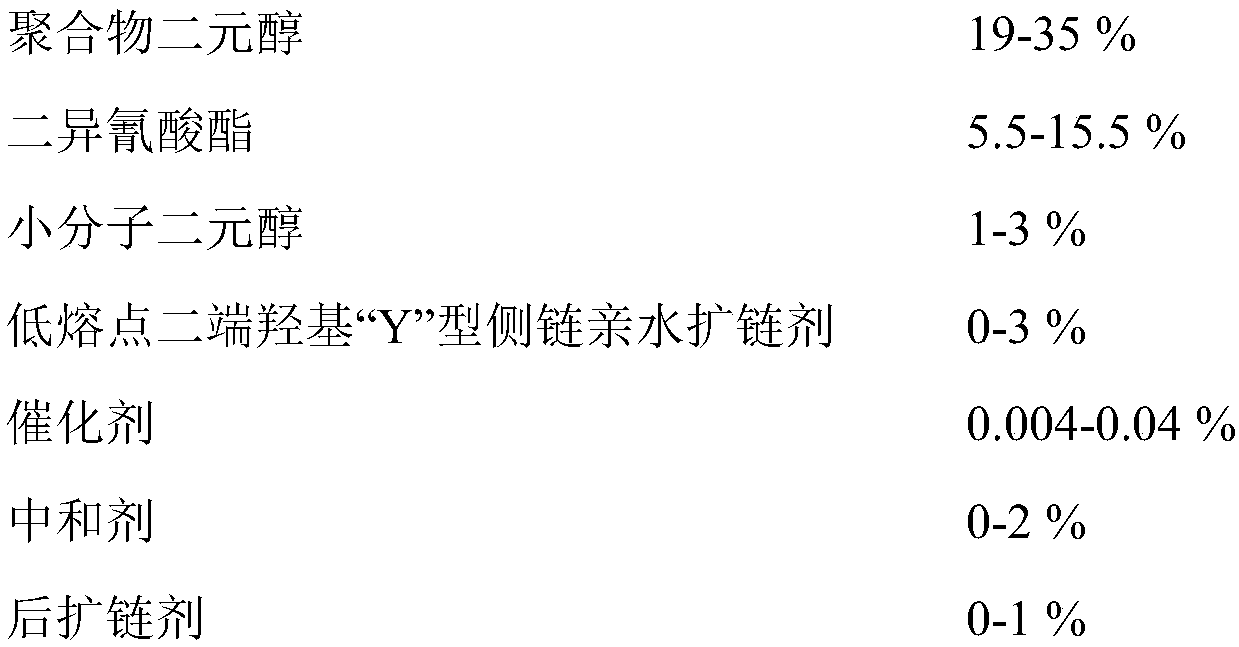

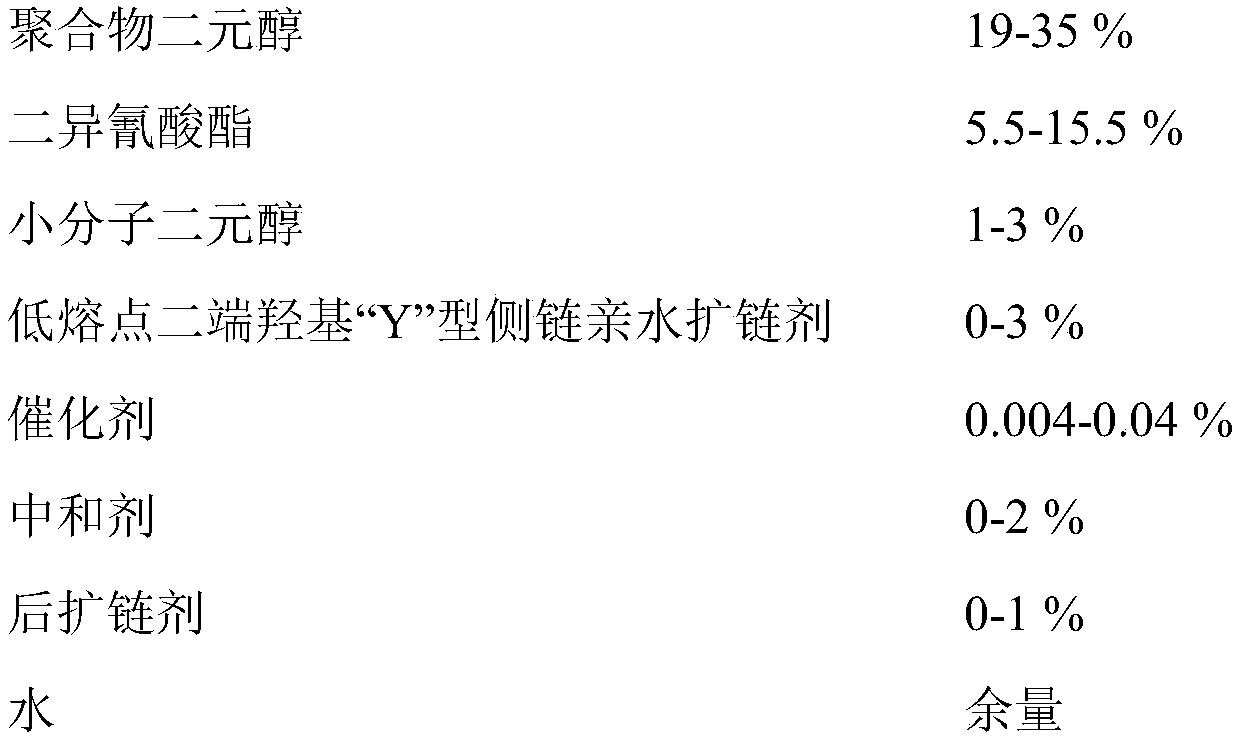

Continuous solvent-free aqueous polyurethane dispersion of sulfonate, and preparation method thereof

InactiveCN107903377ARealize pure green environmental protection requirementsOvercoming the disadvantages of demandingPolyesterPolymer science

The invention discloses a continuous solvent-free aqueous polyurethane dispersion of sulfonate, and a preparation method thereof. The preparation method comprises the following steps: (1) preheating polymer diol, diisocyanate, small-molecular diol, a low-melting point hydroxy-diterminated "Y"-type side chain hydrophilic chain extender and a catalyst, conveying the preheated materials into a twin-screw reactor, and carrying out a reaction to obtain a polyurethane melt, wherein the polymer diol is one or more of sulfonate-containing diol, polyether diol, polyester diol and polycarbonate diol; (2) injecting the polyurethane melt into a shear pump, injecting water or water containing a neutralizing agent into the shear pump, and carrying out shear dispersing; and (3) carrying out cooling and pressure reduction, adding a post-chain extender if needed, and carrying out a stirring reaction to obtain the solvent-free aqueous polyurethane dispersion. The disadvantage of harsh raw material requirements of existing twin-screw preparation technologies of the aqueous polyurethane dispersion and traditional acetone prepolymer aqueous technologies is overcome in the invention.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD

Methods for manufacturing electrochemical cell parts comprising material deposition processes

InactiveUS20070243315A1Change compositionExpensive and costly to machinePhysical/chemical process catalystsCell electrodesMulti materialDeposition process

The present invention relates to the resultant products, the method and apparatus to produce electrochemical cell parts using a material deposition process or processes and specially developed inks appropriate to the specific application requirements at each location on the bipolar plate and can include the gas diffusion layer and the specific deposition of the catalyst and the seals.

Owner:AMERICAN GFM

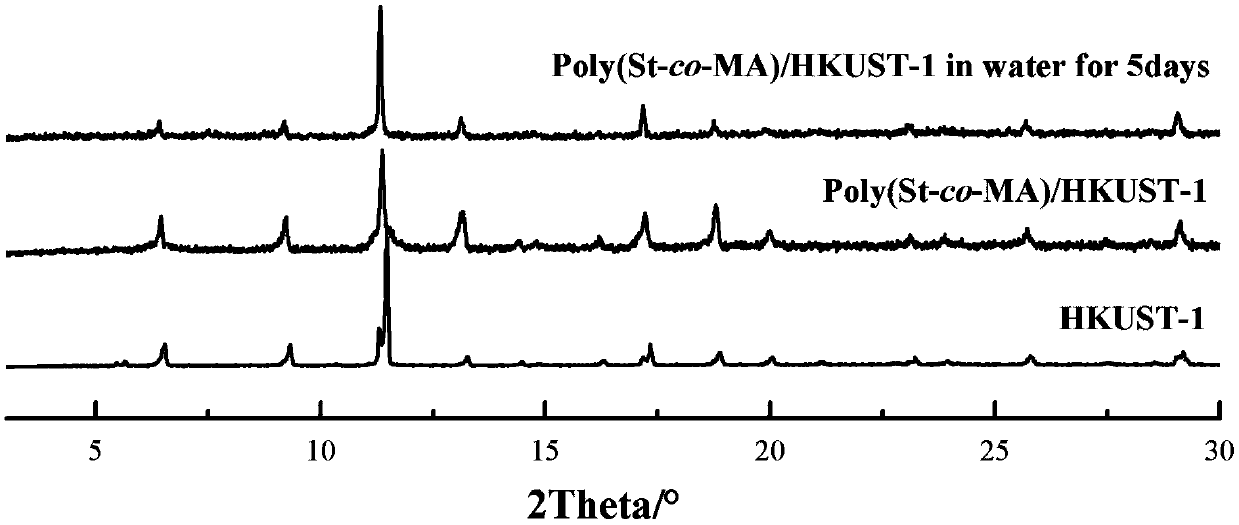

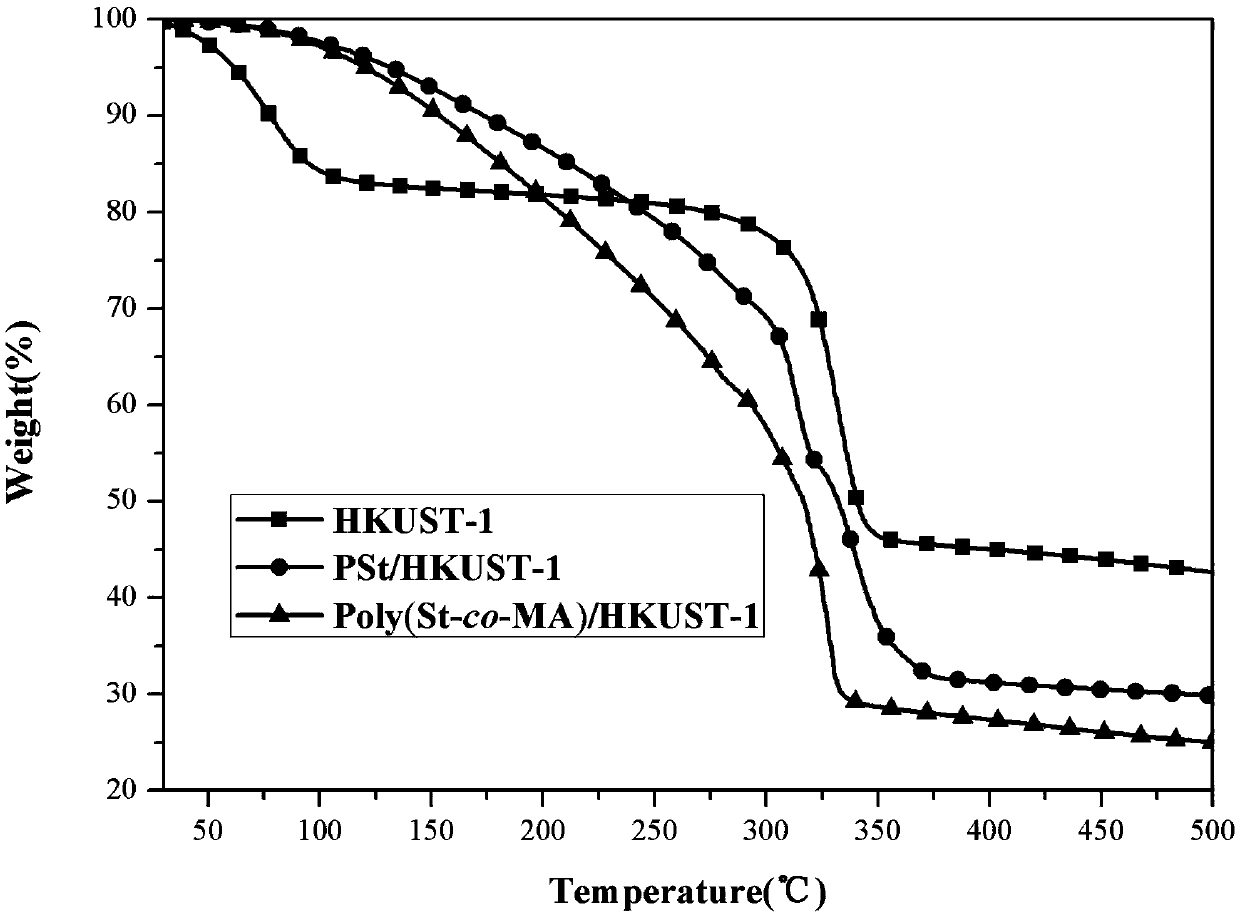

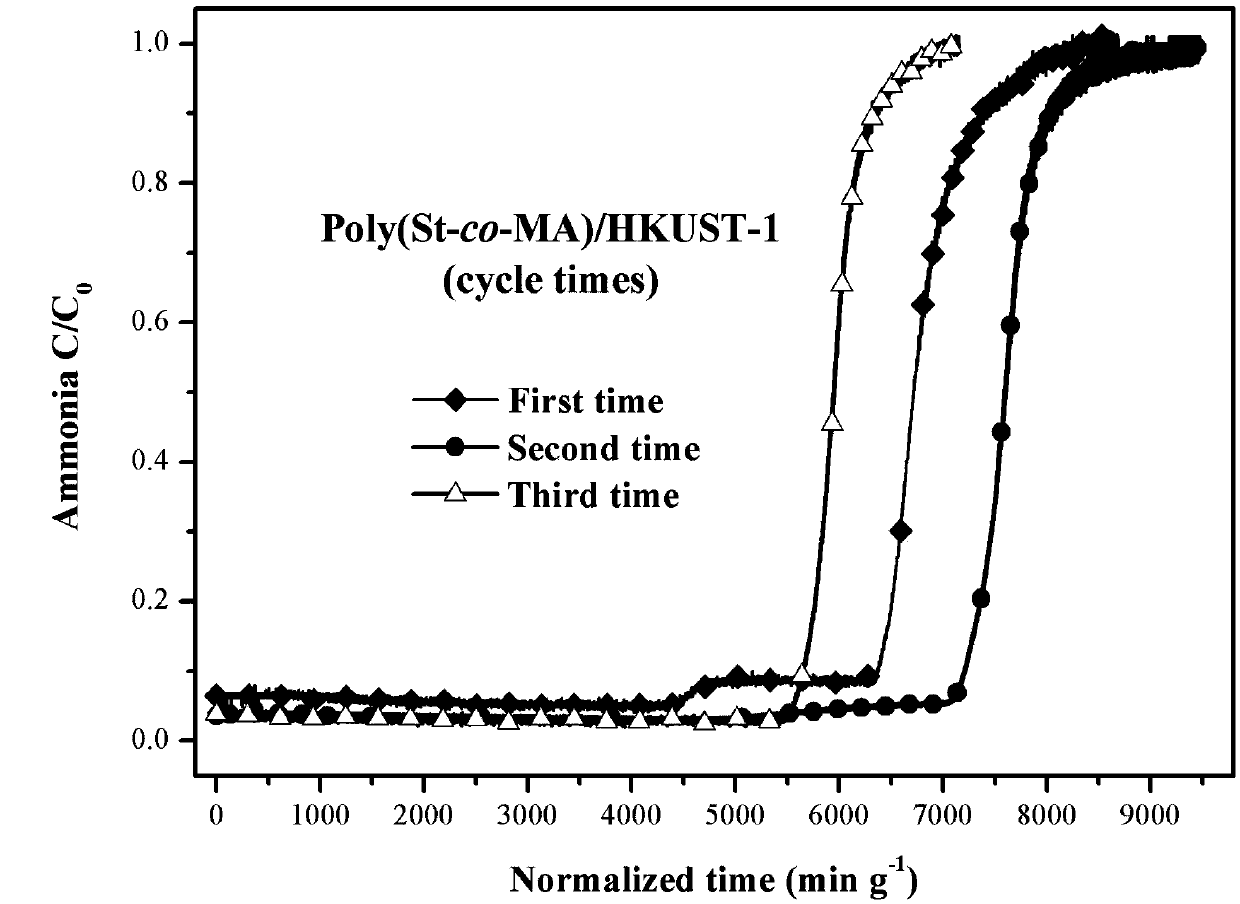

Modification method for effectively improving MOFs water stability and ammonia gas adsorption performance

ActiveCN110467707AReduce porosityImprove water stabilityGas treatmentOther chemical processesPorous compositeAmmonia adsorption

The invention discloses a modification method for effectively improving MOFs water stability, and belongs to the technical field of organic-inorganic porous composite materials. The method concretelyrelates to the use of a metal organic skeletal material MOFs as an inorganic phase and the use of a high specific surface and an internal pore structure of the MOFs. Monomers of an organic phase, suchas styrene, methacrylic acid and other olefin monomers, are introduced into the pore structure of the MOFs, and the monomers are induced to undergo free radical copolymerization in pores of a metal organic framework, thereby modifying a skeleton of the MOFs and improving the water stability. The free radical copolymerization is simple in reaction conditions and easy in implement. When the methodis applied to post-synthesis modification of the MOFs, the structure is not destroyed, and the water stability of the MOFs is improved. The MOFs has the absorption performance of ammonia, can be regenerated at high temperature to a certain extent, and can ensure the stability of a composite material in ammonia adsorption penetration.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com