Preparation method of flavor base material containing abundant umami peptide

A umami peptide and base material technology, which is applied in the field of deep processing of vegetable protein, can solve problems such as increased energy consumption, insufficient umami taste, and complicated processes, so as to improve the degree of enzymatic hydrolysis, increase the sensitivity of enzymatic hydrolysis, and improve the process operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

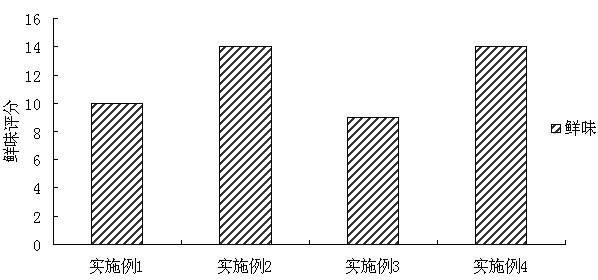

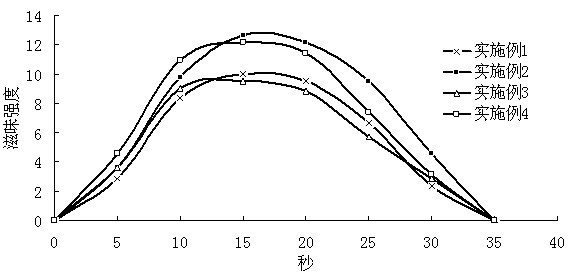

Examples

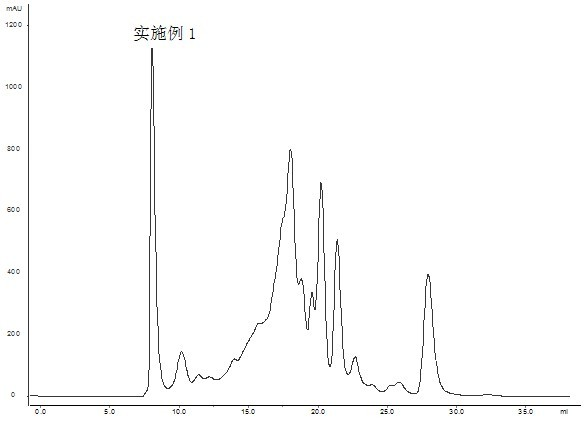

Embodiment 1

[0019] (1) Pretreatment of raw materials: crush the peanut meal into 20-mesh peanut meal powder, mix it with water at a ratio of 1:7, heat it at 100°C for 30 minutes, take it out and let it cool to room temperature; pass it through a colloid mill to obtain peanuts meal slurry;

[0020] (2) Hydrolysis of peanut meal: Use 1mol / L sodium hydroxide to adjust the pH value of the peanut meal slurry to pH8.0, add alkaline protease (Alcalase 2.4L) at 1.2% of the mass of the substrate (peanut meal), and proceed at 55°C For the enzymatic hydrolysis reaction, the degree of hydrolysis was controlled to 6% by pH-Stat method to obtain an enzymatic hydrolysis solution.

[0021] (3) Enzyme inactivation with enzymatic hydrolysis solution: heat at 85°C for 30 minutes to inactivate the enzyme and terminate the enzymatic hydrolysis reaction.

[0022] (4) Separation: centrifuge the enzymatic hydrolyzate treated with inactivation at 8000×g for 20 min, and the obtained supernatant is peanut enzymati...

Embodiment 2

[0026] (1) Pretreatment of raw materials: crush the peanut meal into 20-mesh peanut meal powder, mix it with water at a ratio of 1:7, heat it at 100°C for 30 minutes, take it out and let it cool to room temperature; pass it through a colloid mill to obtain peanuts meal slurry;

[0027] (2) Hydrolysis of peanut meal: Use 1mol / L sodium hydroxide to adjust the pH value of the peanut meal slurry to pH8.0, add alkaline protease (Alcalase 2.4L) at 1.2% of the substrate mass, and add at 6.0‰ of the substrate mass Monomer amino acid mixture (weight ratio methionine: taurine 1:0.4) was subjected to enzymolysis reaction at 55°C, and the degree of hydrolysis was controlled to 6% by pH-Stat method to obtain an enzymolysis solution.

[0028] (3) Enzyme inactivation with enzymatic hydrolysis solution: heat at 85°C for 30 minutes to inactivate the enzyme and terminate the enzymatic hydrolysis reaction.

[0029] (4) Separation: centrifuge the enzymatic hydrolyzate treated with inactivating e...

Embodiment 3

[0031] (1) Pretreatment of raw materials: Mix gluten powder with water at a ratio of 1:8, heat at 100°C for 30 minutes, take it out and let it cool to room temperature; pass through colloid mill to obtain gluten powder slurry;

[0032] (2) Hydrolysis of gluten: use sodium hydroxide to adjust the pH of gluten protein solution to 7.0, add papain (Papain) according to 1.5% of the substrate mass, carry out enzymatic hydrolysis reaction at 50°C, and use pH-Stat method to control hydrolysis degree to 10%, to obtain the enzymatic solution.

[0033] (3) Enzyme inactivation with enzymatic hydrolysis solution: heat at 85°C for 30 minutes to inactivate the enzyme and terminate the enzymatic hydrolysis reaction.

[0034] (4) Separation: centrifuge the enzymatic hydrolyzate treated with inactivation at 8000×g for 20 min, and the obtained supernatant is gluten enzymatic hydrolyzate. The protein recovery rate, peptide content, amino acid composition in the peptide, sensory evaluation and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com