Iron and steel surface sensitizing and blackening agent and relevant blackening process

A technology of steel surface and process method, applied in the direction of metal material coating process, etc., can solve the problems of low corrosion resistance, toxic blackening liquid, insufficiently stable surface film adhesion, etc., and achieve stable film composition and adhesion. Good, fast film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A normal temperature iron and steel surface sensitizing blackening agent, comprising a sensitizing liquid and a normal temperature blackening liquid, the formulas are as follows:

[0039] ① Sensitizing solution:

[0040] CuSO 4 ·5H 2 O: 4~10g / l NiSO 4 ·7H 2 O: 1~5g / l

[0041] Sodium citrate: 4~10g / l Tartaric acid: 4~10g / l

[0042] Sulfamic acid: 4~10g / l H 2 O: margin

[0043] pH=2~4

[0044] ②Normal temperature blackening liquid:

[0045] Sodium sulfide: 40~100g / l Ethanol: 20~50ml / l

[0046] H 2 O: margin

[0047] pH=8~10

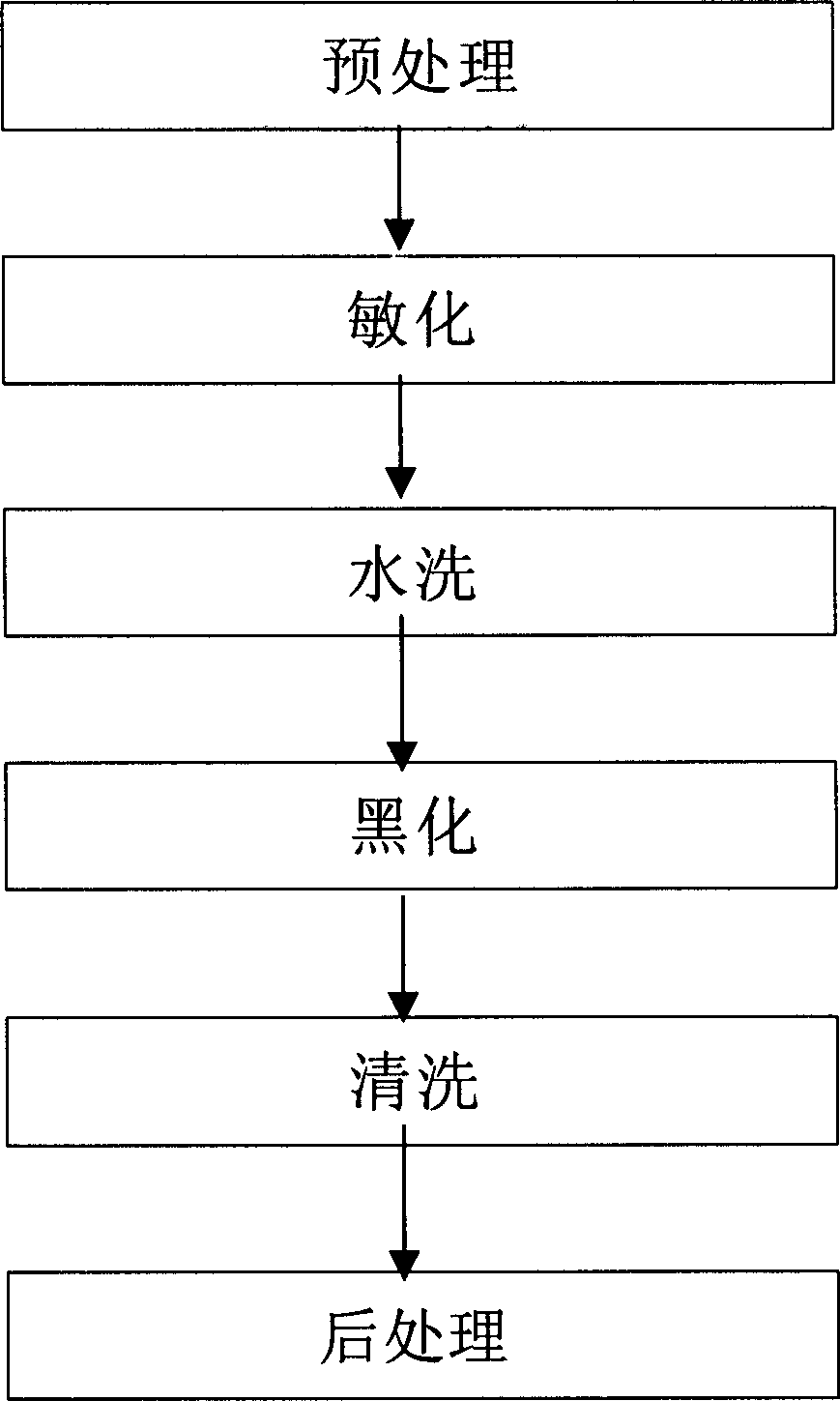

[0048] A process method for using the above-mentioned normal temperature iron and steel surface sensitizing blackening agent for iron and steel surface blackening, which is characterized in that it includes the following processes:

[0049] ①Pretreatment: degreasing, pickling and rinsing the surface of steel parts;

[0050] ② Sensitization: immerse the pretreated steel piece in the sensitizing solution of the normal tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com