Patents

Literature

31results about How to "Adjust reaction speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron and steel surface sensitizing and blackening agent and relevant blackening process

InactiveCN1453394AComposition is stableImprove adhesionMetallic material coating processesMetallurgySodium citrate

The iron and steel surface sensitizing and blackening agent includes sensitizing agent and normal temperature blackening liquid. Its formula is as follows: the sensitizing agent consists of CuSO4.5H2O, NiSO4.7H2O, sodium citrate, tartaric acid, amido sulfonic acid and water, and has pH value of 2-4; and the normal temperature blackening liquid consists of sodium sulfide, ethanol and water, and has pH value of 8-10. The blackening process includes the main steps of: pre-treatment of iron and steel parts, soaking the pre-treated iron and steel parts in the sensitizing agent liquid for 2-6 to sensitize, and soaking the sensitized and washed iron and steel parts in the normal temperature blackening liquid for 3-5 min to form black film.

Owner:LIUZHOU OVM MASCH CO LTD

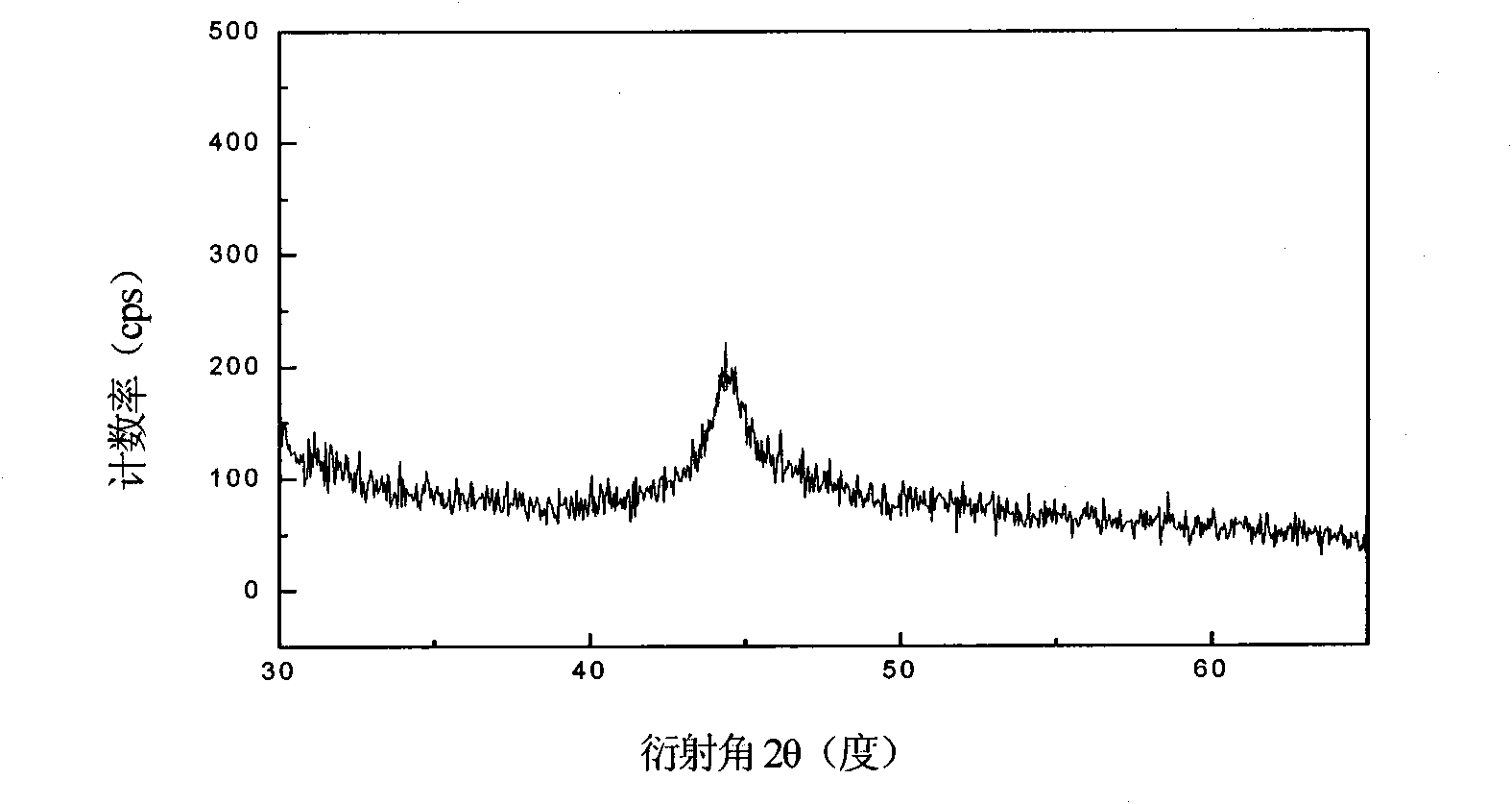

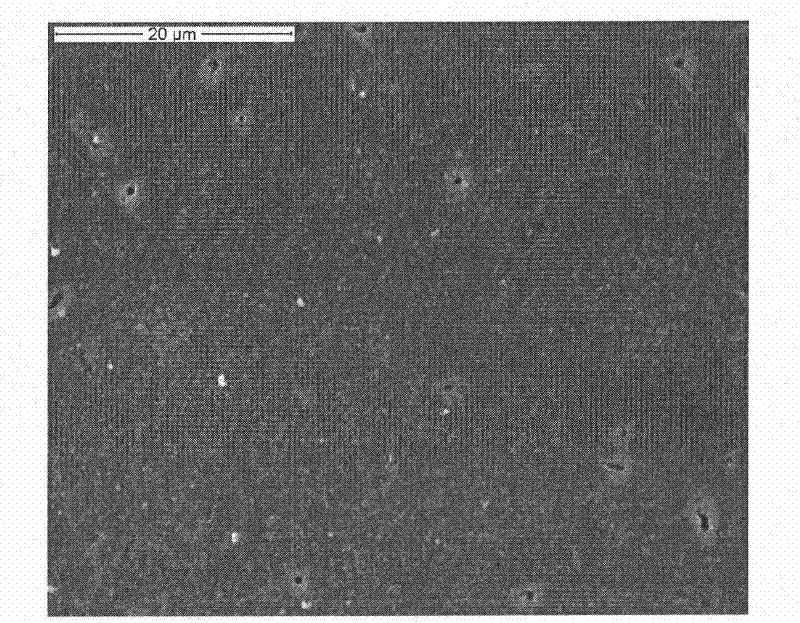

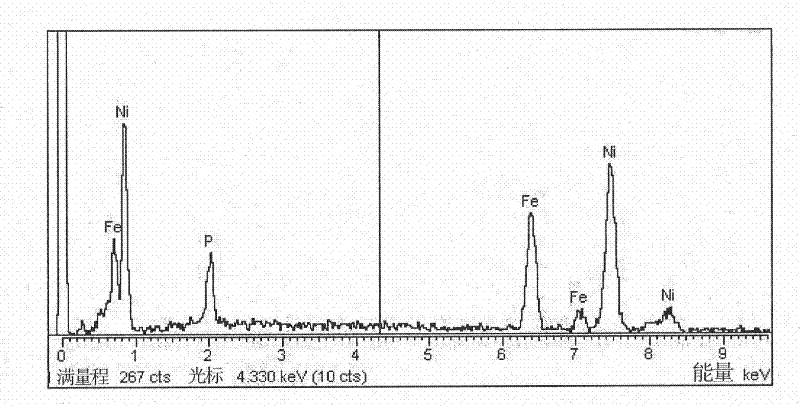

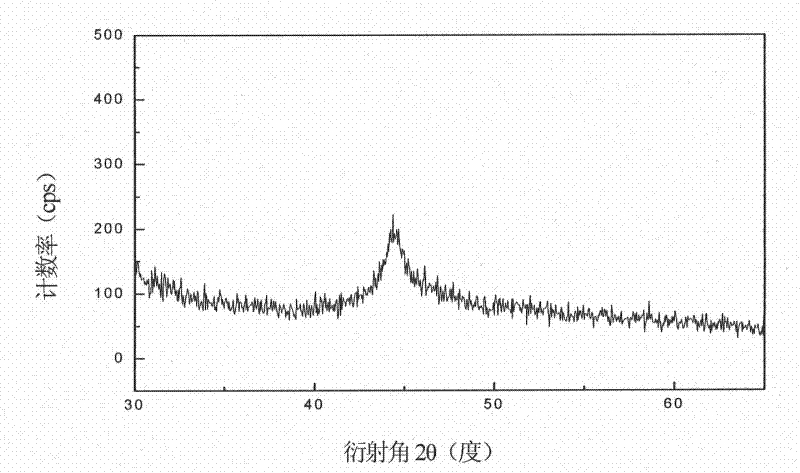

Method for preparing iron-nickel-phosphorus chemical plating

InactiveCN101906624AHigh in ironAdjust reaction speedLiquid/solution decomposition chemical coatingChemical platingSodium potassium tartrate tetrahydrate

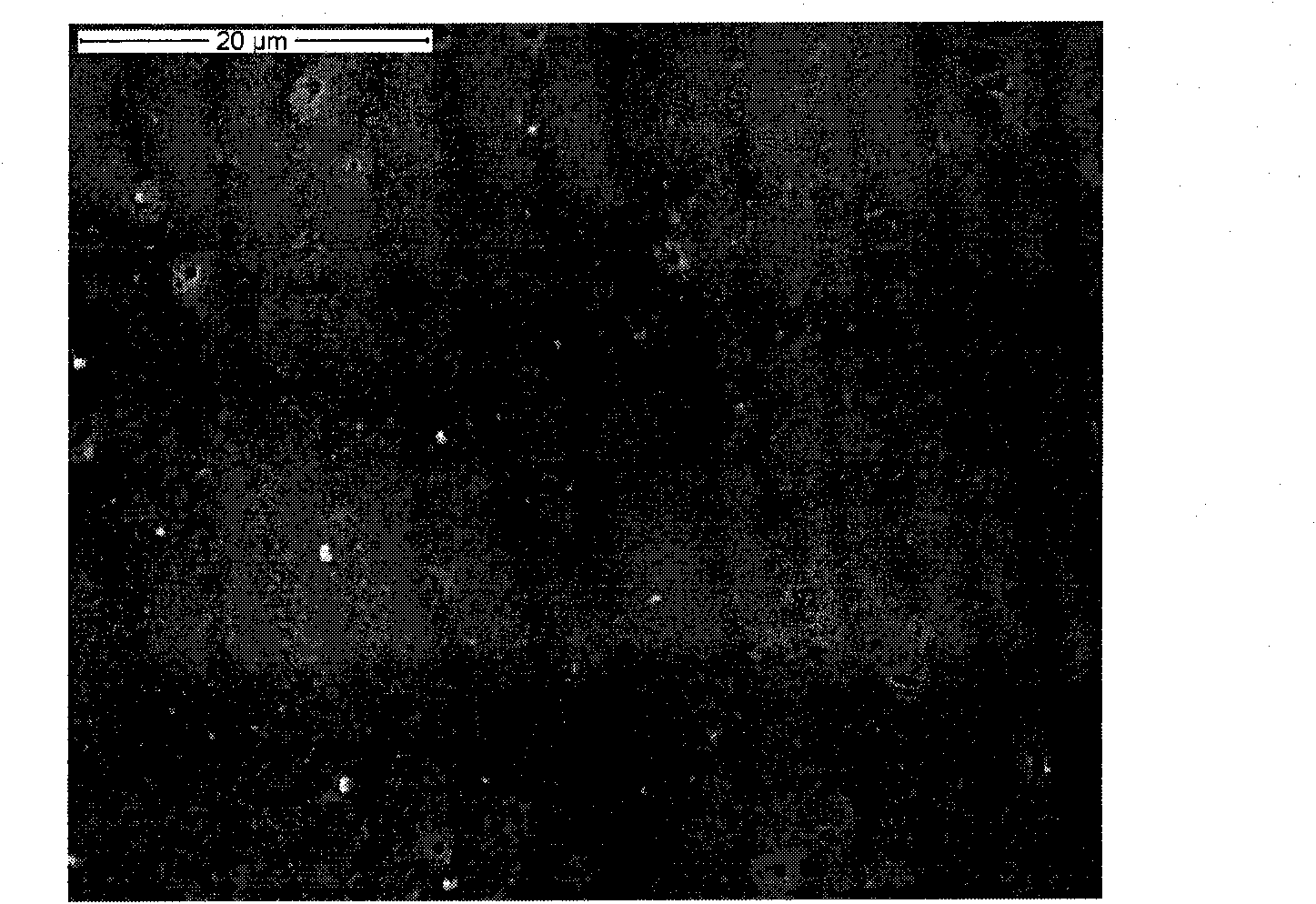

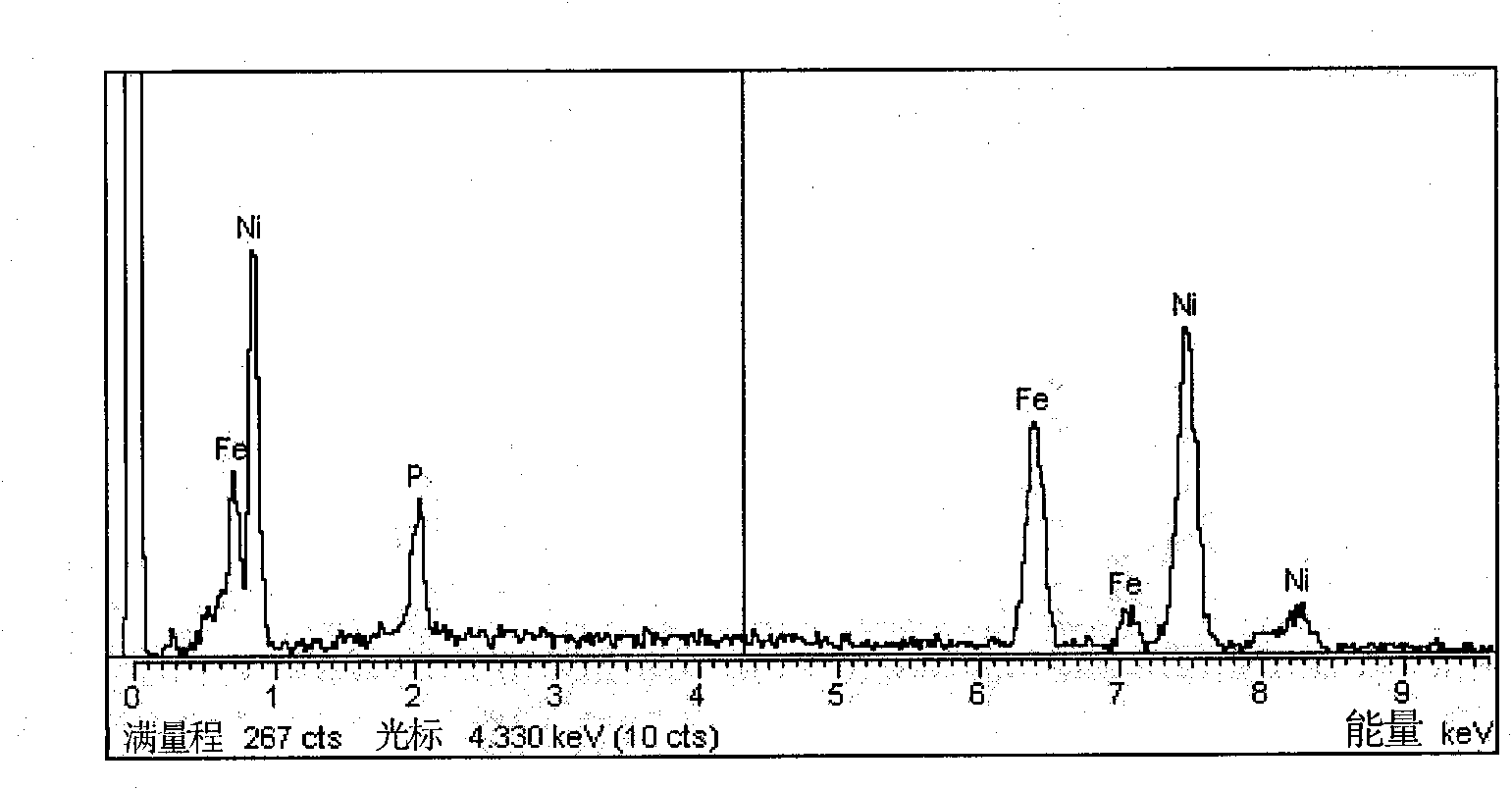

The invention belongs to the technical field of chemical deposition, in particular to a new method for preparing an iron-nickel-phosphorus chemical plating. The plating can be widely used in (micro) electronic industry and space navigation and general projects. In the method, a compound complex system consisting of sodium potassium tartrate tetrahydrate, trisodium citrate, two organic mixed additives having N(CH2COOH)2 groups and ammonia water is used for controlling Fe<2+> and Ni<2+> concentrations, reducing the reduction speed of nickel and improving the reduction speed of iron so as to improve the iron content of the plating; the compound complex system can be complexed with impurity ions to improve the containable metal impurity ion concentration of the solution. The method is particularly suitable for preparing high-iron content iron-nickel-phosphorus chemical plating on silicon chips or copper surfaces. The plating on a silicon chip surface comprises 0 to 50 percent (controllable) of iron atoms, 2 to 18 percent of phosphorus atoms and the balance of nickel; and the plating on a copper surface contains 0 to 90 percent (controllable) of iron atoms, 2 to 16 percent of phosphorus atoms and the balance of nickel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

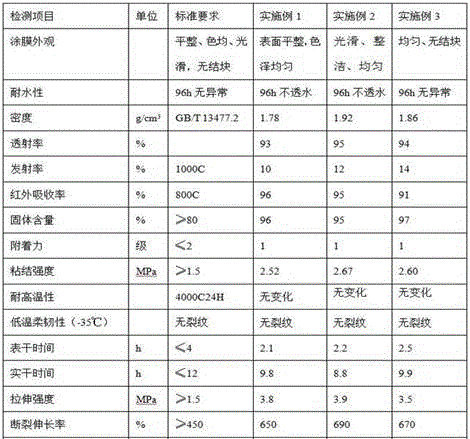

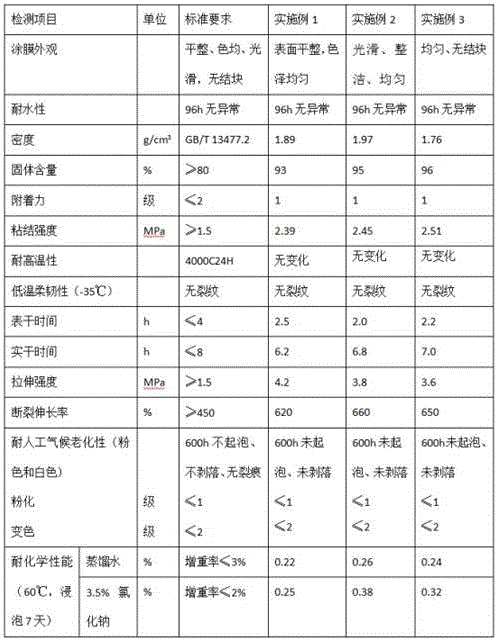

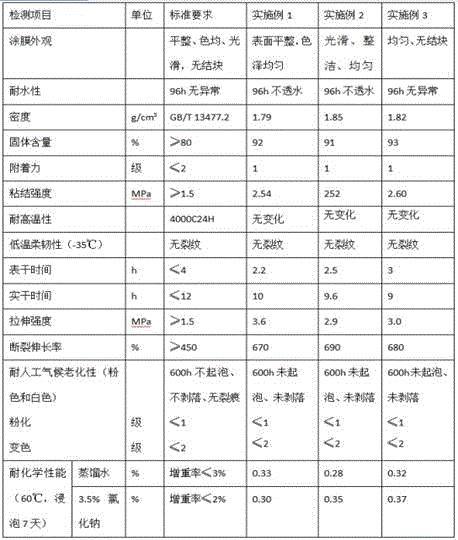

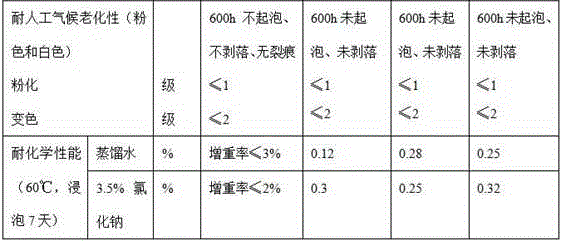

Color modified waterproof coating

InactiveCN106433458AShorten drying timeGood extensibilityProtein coatingsMulticolor effect coatingsWeather resistanceThermal insulation

The invention discloses a color modified waterproof coating which is prepared by the following steps: grinding pigment and filler into powder by a ball milling way; sequentially adding the powder together with a film forming agent, a solvent and an auxiliary into a plastic tank; stirring for 8-10min till uniform mixing; stirring for 25-28min at a speed of 1,500rpm for full dispersion; adding a film forming agent and dispersing at a high speed for 3-5min to obtain a disperse system; adding a sodium hydroxide solution and adjusting the pH value to 7.5-8.5; and mixing uniformly to obtain the waterproof coating. In the invention, the film forming agent is modified to serve as an important raw material for preparing the coating disclosed by the invention, the tensile strength and film hardness are remarkably improved, and the prepared coating has good weather resistance and waterproof property under an indoor condition and has the effects of high-temperature resistance, thermal insulation and decoration; and the preparation process is simple.

Owner:南宁马瑞娜装饰工程有限公司

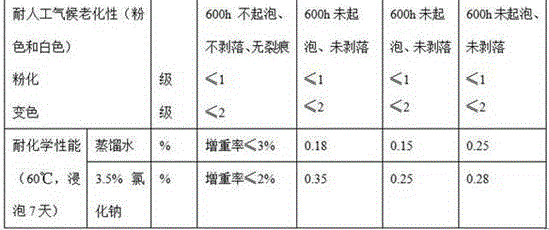

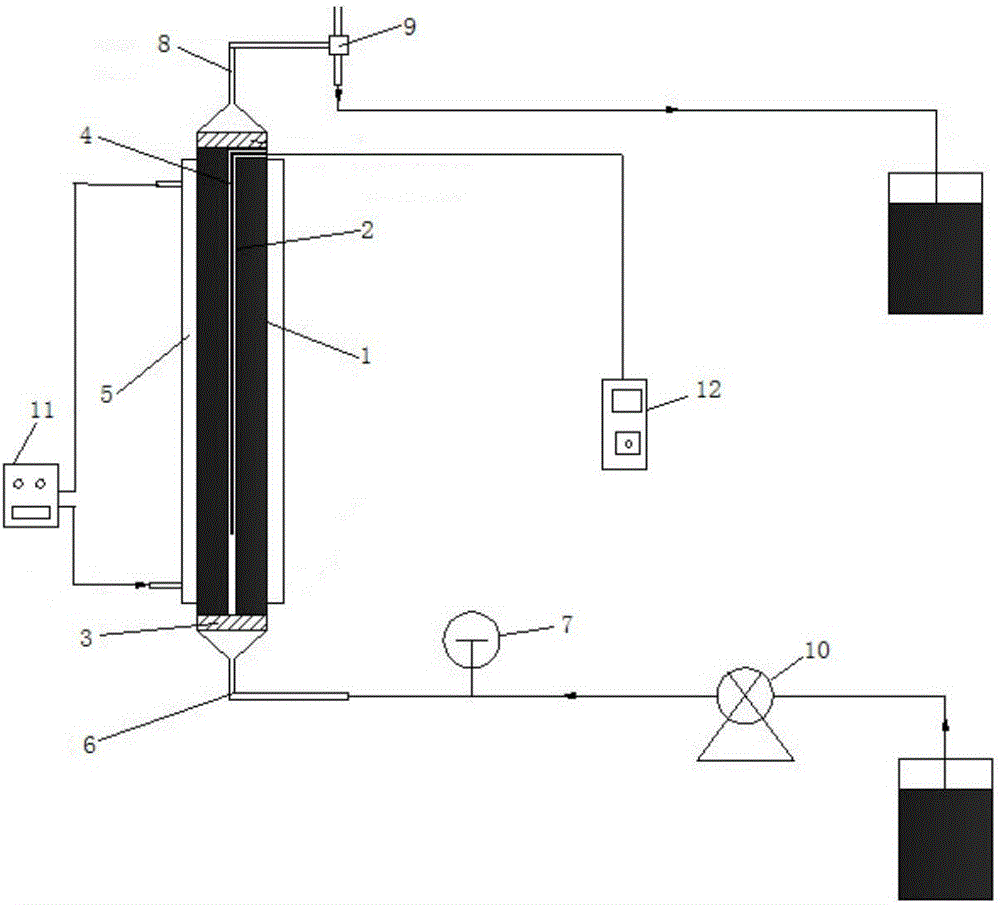

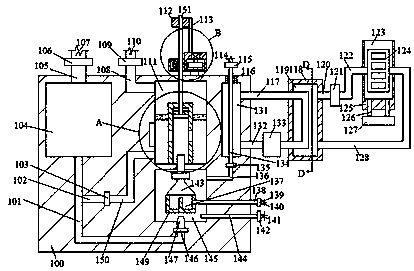

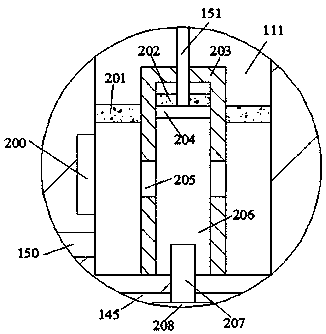

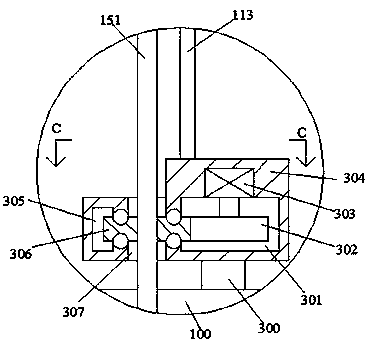

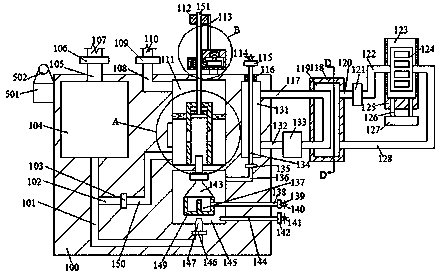

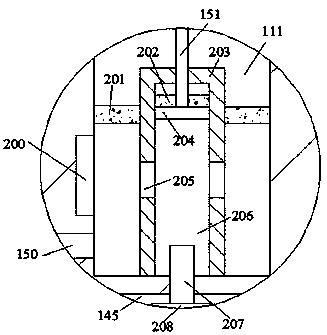

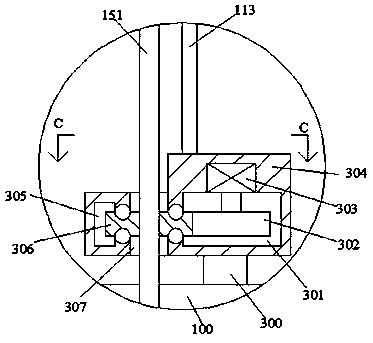

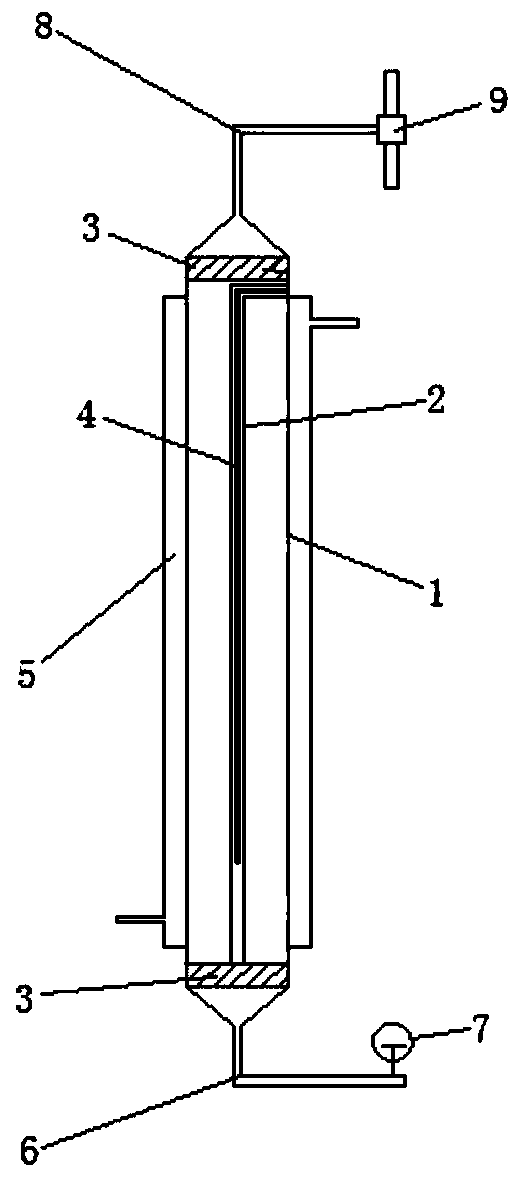

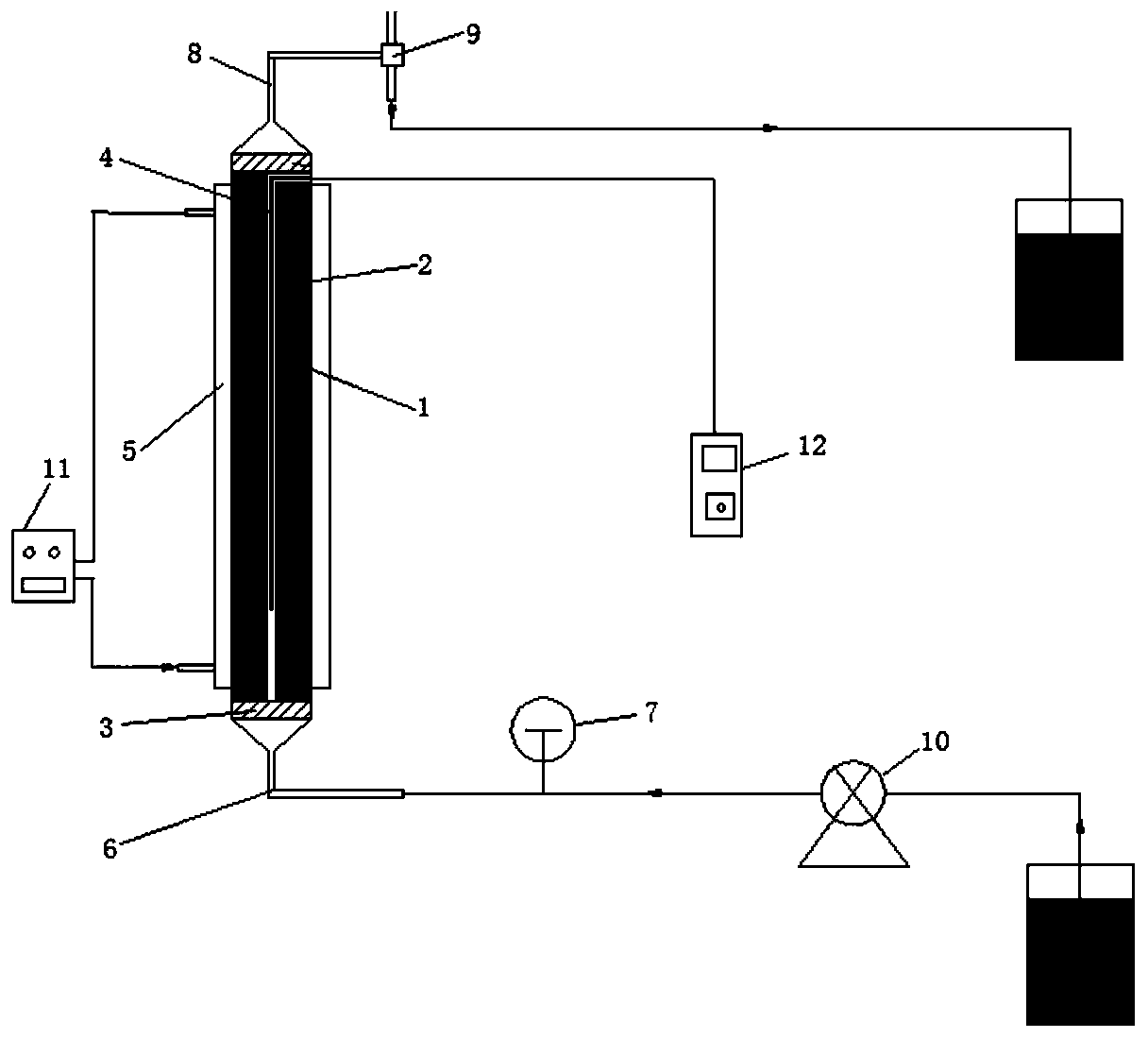

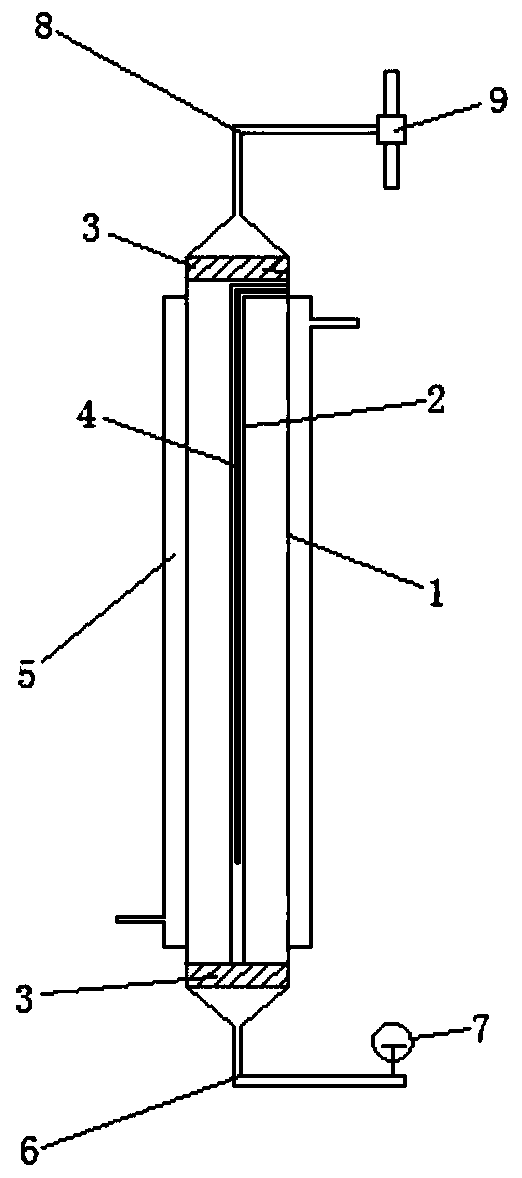

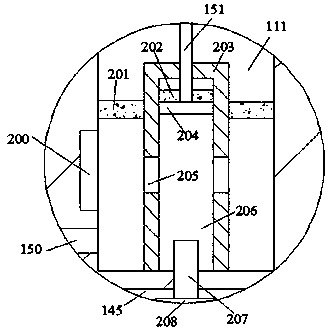

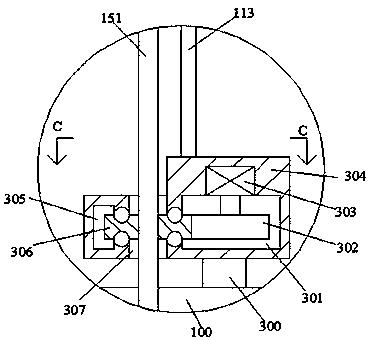

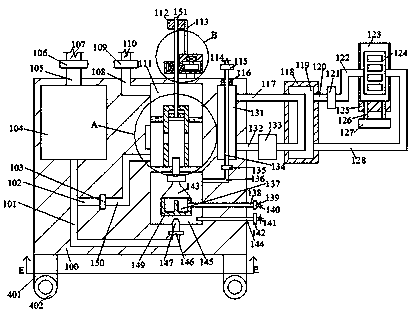

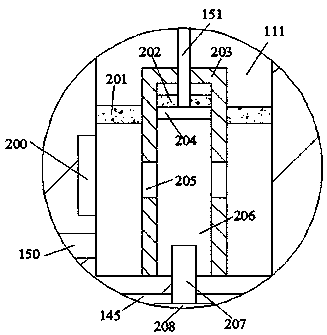

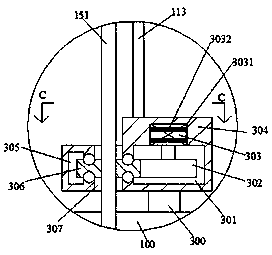

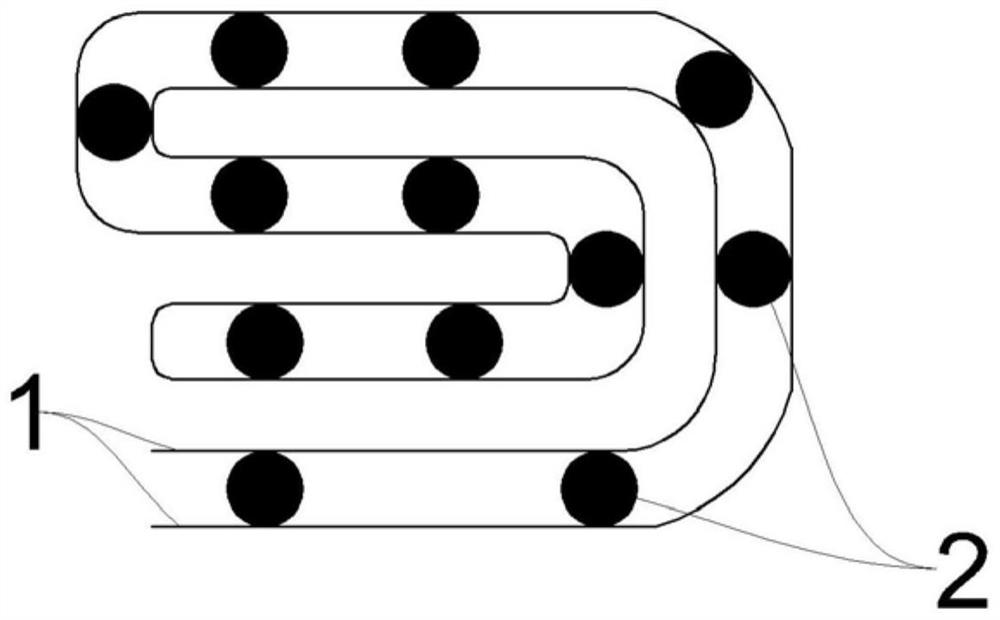

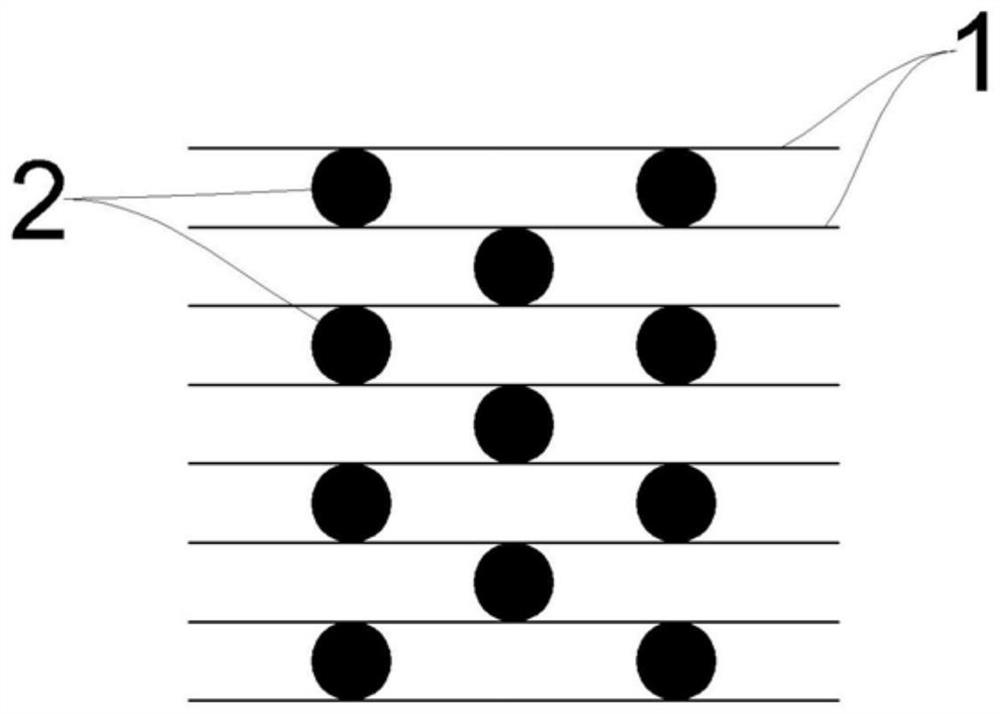

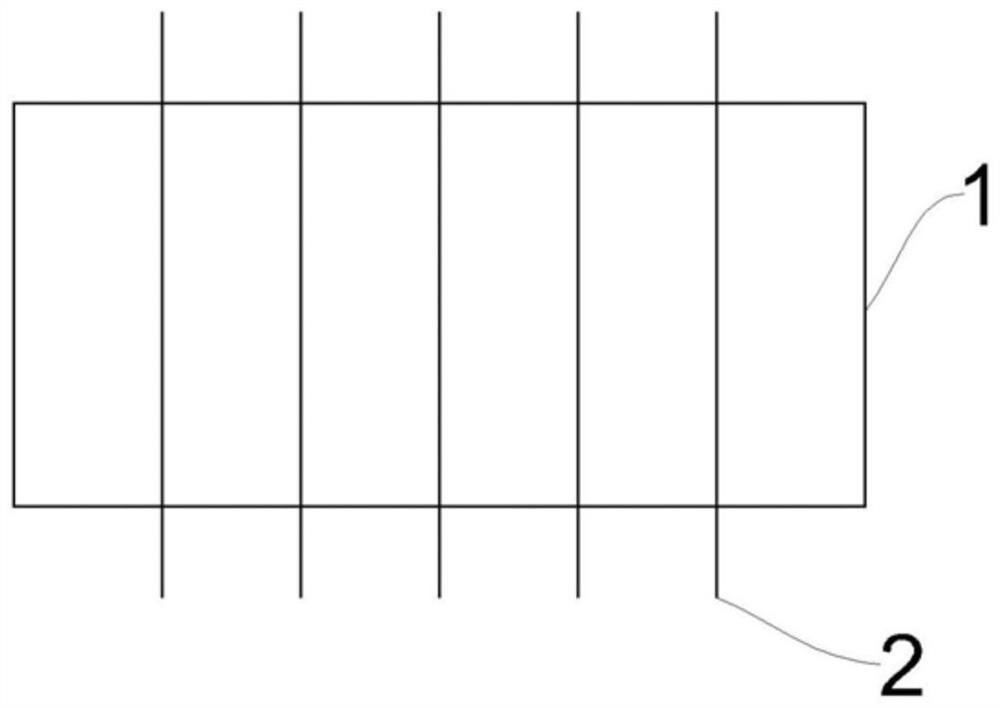

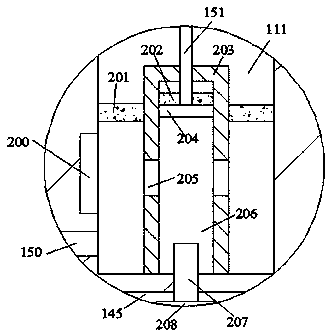

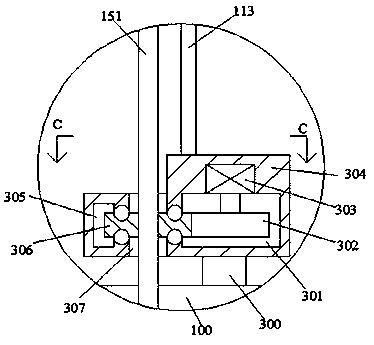

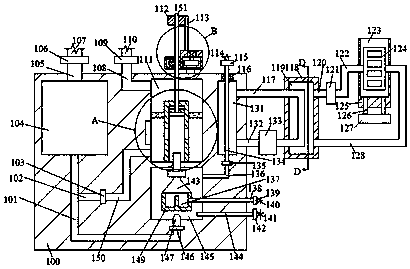

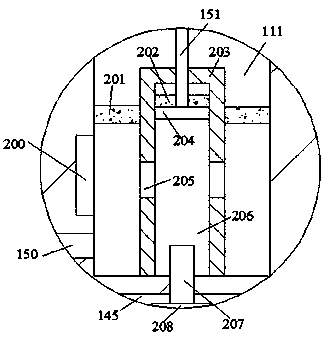

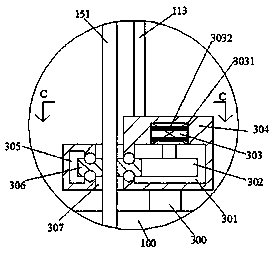

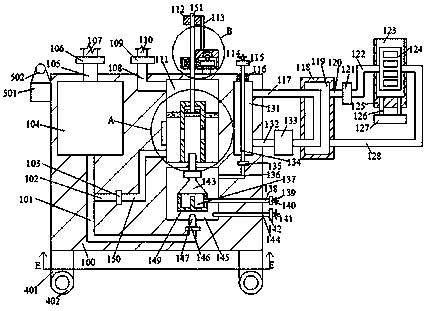

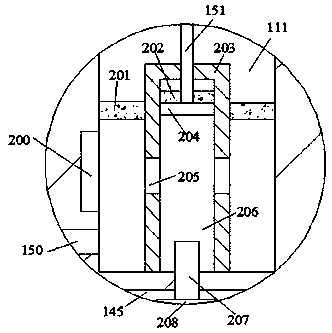

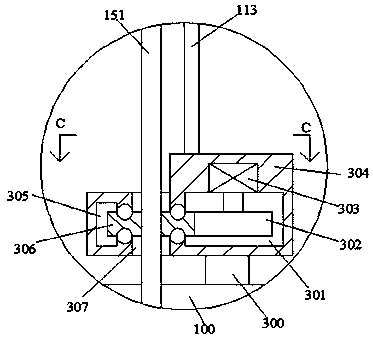

Catalytic device for preparing U(IV) solution

ActiveCN106311092AFully contactedLarge adjustment flexibilityChemical/physical processesMaterials scienceReaction conditions

The invention discloses a catalytic device for preparing a U(IV) solution. The device comprises an outer pipe, an inner pipe, a jacket, sintered stainless steel plates, a feeding hole and a discharging hole, wherein an annular structure is formed by the inner pipe in the outer pipe; the sintered stainless steel plates are arranged at the upper and lower ends of the outer pipe; the jacket is arranged on the exterior of the outer pipe; the feeding hole is formed in the bottom of the sintered stainless steel plate at the lower end; the discharging hole is formed in the top of the sintered stainless steel plate at the upper end. The catalytic device for preparing the U(IV) solution provided by the invention has the advantages of simple structure, mild catalytic reaction condition, easily controlled process, safety, reliability, easiness in continuous production and capability of continuously running in long period.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

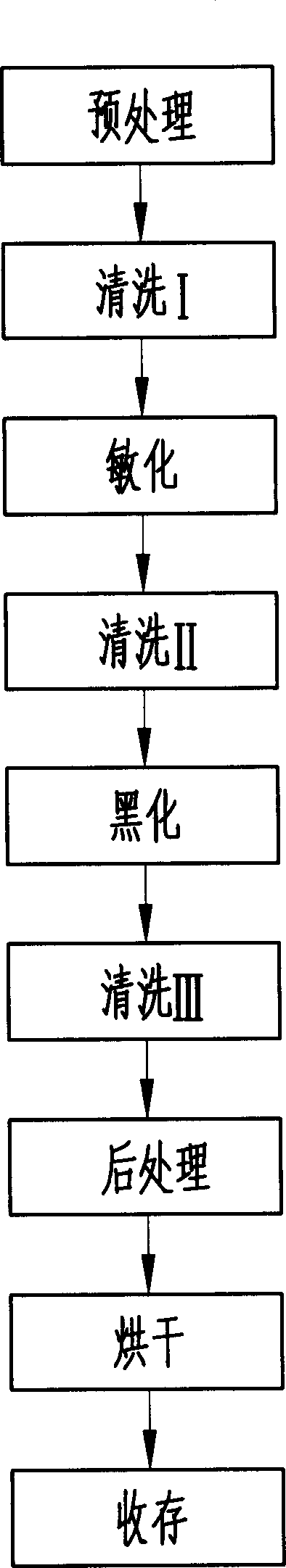

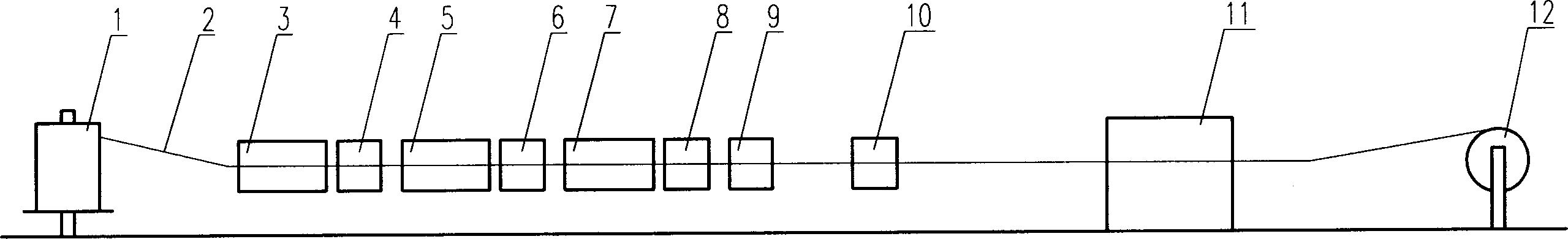

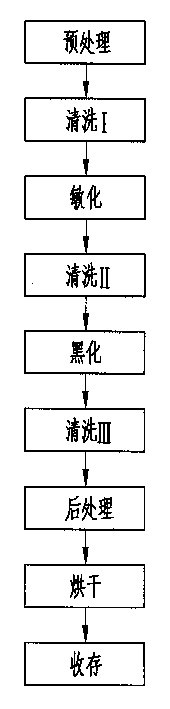

Anticorrosion prestressed bars and its manufacture

InactiveCN1407133ARich sourcesShorten the production cycleCeramic shaping apparatusMetallic material coating processesCooking & bakingPre stress

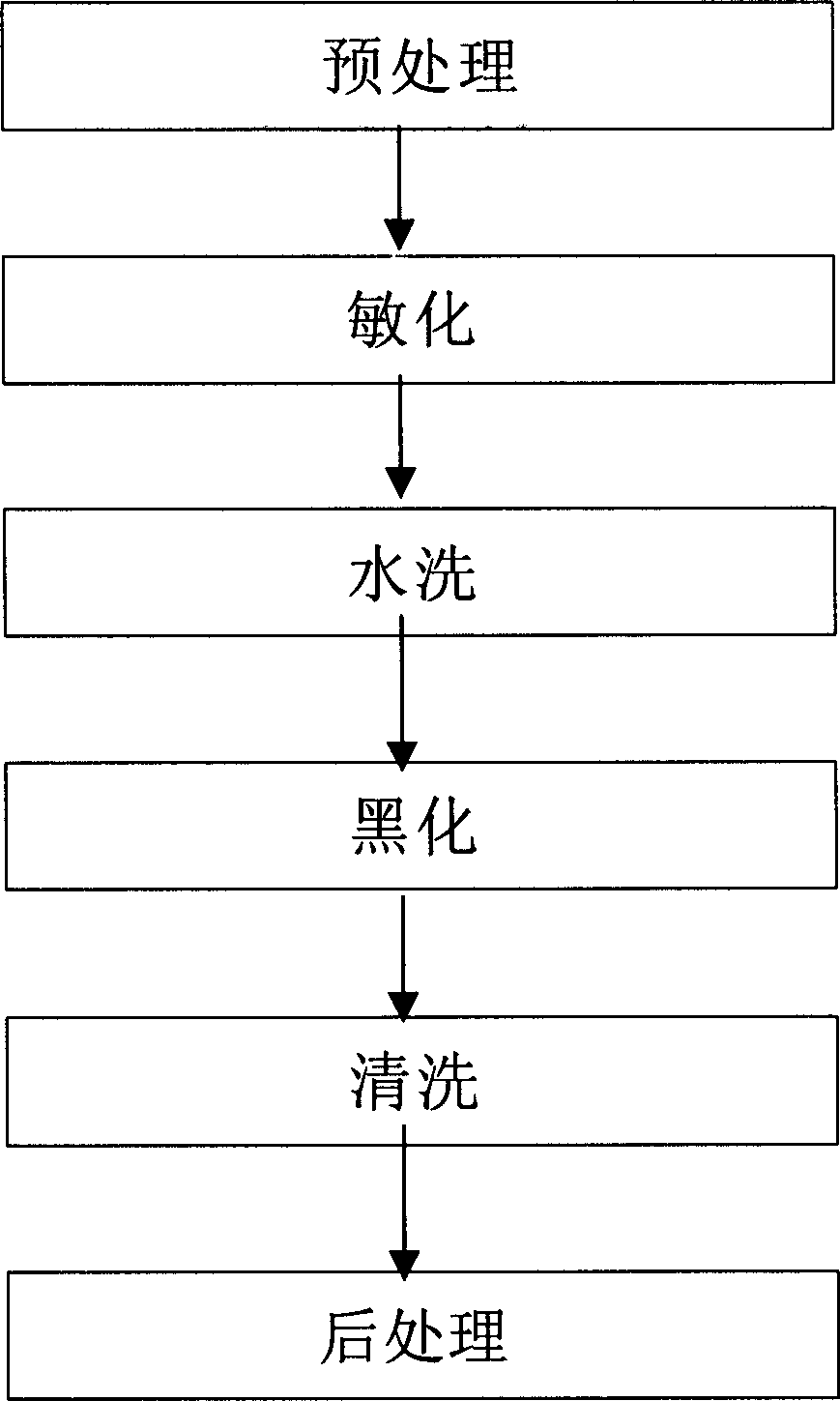

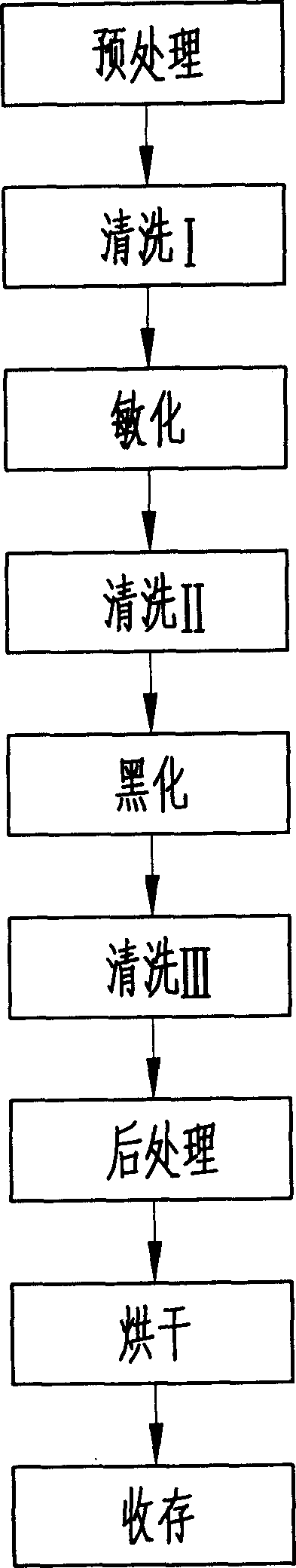

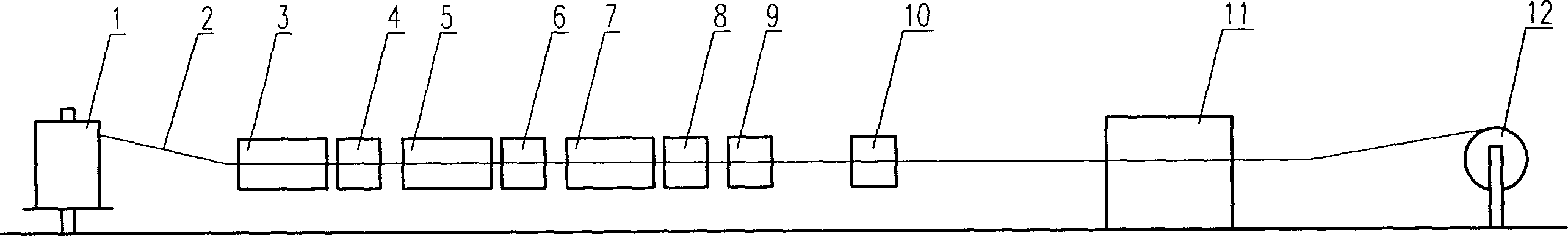

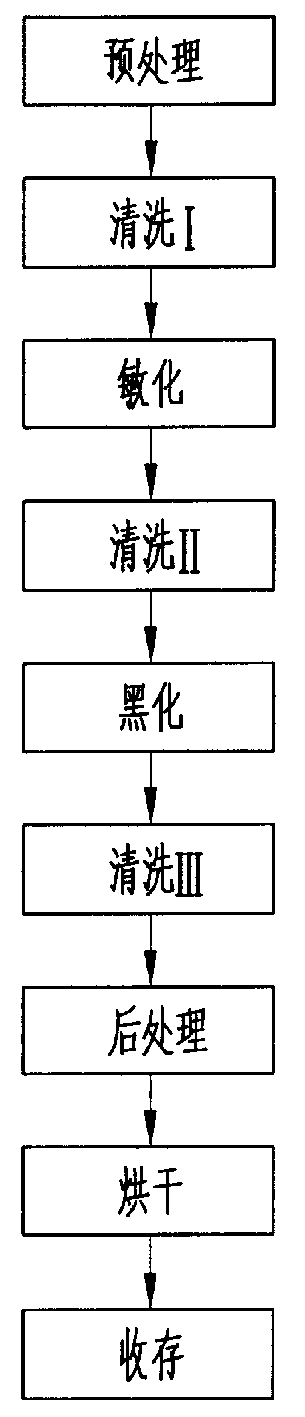

An anticorrosion prestressed steel bar is prepared from the ordinary steel bar through pretreating, washing, sensitizing, washing, blackening, washing, posttreating and baking. Its advantages are high anticorrosion performance, low cost, high adhesion of film layer, and no poison, odour and irritative smell of its discharged substance.

Owner:LIUZHOU OVM MASCH CO LTD

Anti-corrosion weather-proof waterproof paint

InactiveCN106497417AShorten drying timeGood extensibilityFireproof paintsAnti-corrosive paintsWeather resistanceFilm-forming agent

The invention discloses anti-corrosion weather-proof waterproof paint which is prepared from the following raw materials in parts by weight: 70 to 90 parts of film forming agent, 30 to 50 parts of solvent, 15 to 25 parts of coalescing agent, 10 to 20 parts of pigment filler and 10 to 30 parts of auxiliaries. A preparation method of the anti-corrosion weather-proof waterproof paint comprises the steps: grinding the pigment filler into powder in a ball milling mode; sequentially adding the pigment filler powder, the film forming agent, the solvent and the auxiliaries into a plastic tank; stirring for 8 to 10min until the materials are evenly mixed; stirring for 25 to 28min in a rotation speed of 1500r / min to fully disperse the materials; then adding the coalescing agent to disperse for 3 to 5min in a high speed to obtain a dispersion system; adding sodium hydroxide solution to adjust the pH value to 7.0 to 8.0; evenly mixing to obtain the anti-corrosion weather-proof waterproof paint. The tensile strength and the film hardness of the modified film forming agent are obviously improved, the paint which is prepared from the film forming agent matched with other ingredients has good weather resistance and waterproofness in the outdoor condition, also has the obvious effects of corrosion resistance and high temperature resistance and is simple in preparation process.

Owner:南宁马瑞娜装饰工程有限公司

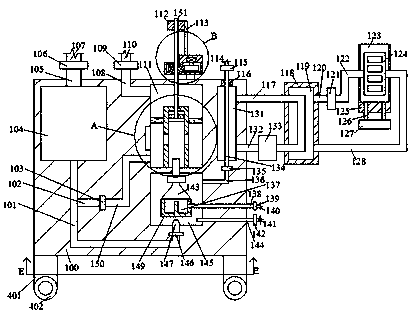

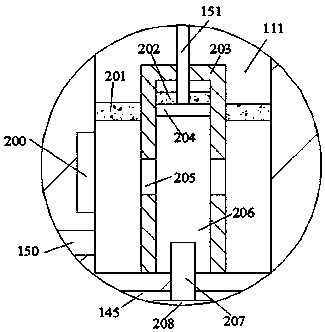

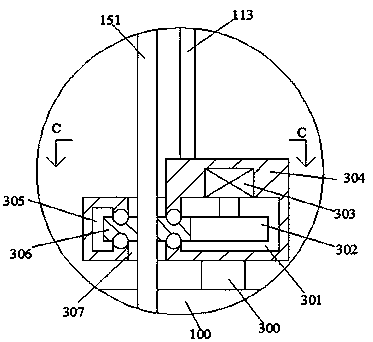

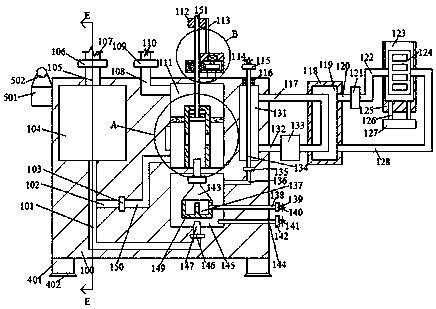

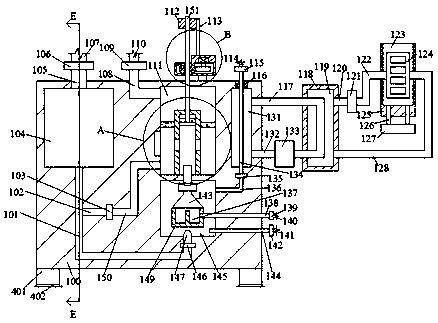

Metal manufacturing device for electronic components

The invention discloses a metal manufacturing device for electronic components. The metal manufacturing device for the electronic components comprises a machine body A, wherein support leg pillars arefixedly arranged on the periphery of the bottom surface of the machine body A; walking rollers are arranged on the support leg pillars; a generating chamber is arranged in the machine body A; a through pipe A outwards extending to the outer part is arranged in a left end wall of the generating chamber in a communicating way; a valve component A is arranged on the upper end surface of the throughpipe in a communicating way; a through pipe B is arranged on the upper end surface of the valve component A in a communicating way; a heating pipe is fixedly arranged in a left end wall of the generating chamber; a screen is fixedly arranged between the left end wall and a right end wall of the generating chamber; and a diffusion chamber is fixedly arranged in the screen and is fixed to a lower end wall of the generating chamber. The metal manufacturing device for the electronic components provided by the invention is simple in structure, convenient to use, beneficial to effectively reducing the manufacturing cost of metal parts for the electronic components, high in hydrogen preparation efficiency, adjustable in speed, capable of realizing heat recovery, low in energy consumption, simpleto operate, and time and labor saving.

Owner:广州常佰机械设计有限公司

Fluororubber-containing modified waterproof coating

InactiveCN107118629APrevent precipitationGood film forming effectCoatingsEnvironmental resistanceEnvironmentally friendly

The invention discloses a fluororubber-containing modified waterproof coating which is prepared from the following components in percentage by weight: 35-45 percent of fluororubber, 25-35 percent of a film forming agent, 2-5 percent of a natural surfactant, 10-15 percent of a high temperature improving agent, 10-15 percent of a filler, 6-9 percent of a flame retardant and 1-4 percent of a pH regulator. The invention also discloses a preparation method of the waterproof coating. The preparation method comprises the following steps: adding the fluororubber, the film forming agent, the natural surfactant and the flame retardant in a sealed reaction kettle, continuously adding the filler for reaction for 1-3h under the condition with the temperature being 80-100 DEG C, cooling to 40-50 DEG C, adding the pH regulator, and carrying out continuous reaction to obtain the fluororubber-containing modified waterproof coating. As for the fluororubber-containing modified waterproof coating, by using the fluororubber, the formation of the waterproof coating is promoted, the adhesion performance of the waterproof coating to an interface is improved, the waterproof effect is better, and the waterproof coating is safe and environmentally friendly to use and cannot bring negative effects.

Owner:阎玉珍

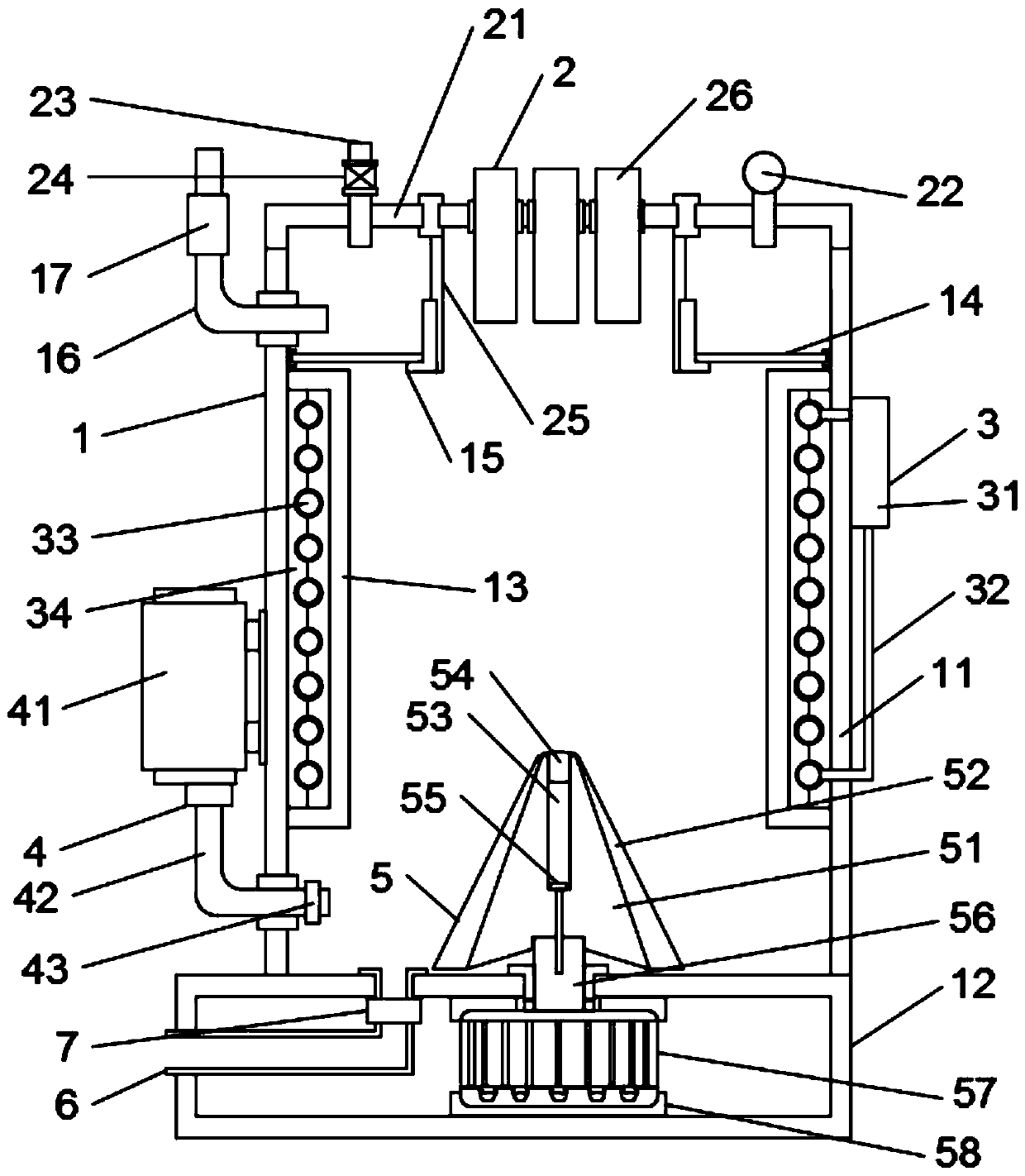

Coal gas hydrogen production equipment

InactiveCN108163808AIncrease flexibilitySimple equipment structureHydrogen productionElectric heatingHydrogen production

The invention discloses coal gas hydrogen production equipment which comprises a box body A, wherein the box body A is fixedly arranged on the ground, a reaction cavity is arranged in the box body A,a pipeline A which extends out of external space is arranged in a left end wall of the reaction cavity in a communication mode, a valve A is arranged on an upper end face of the pipeline A in a communication mode, a pipeline B is arranged on an upper end face of the valve A in a communication mode, an electric heating wire is fixedly arranged in the left end wall of the reaction cavity, a filter screen is fixedly arranged between the left end wall and a right end wall of the reaction cavity, an emitting box is fixedly arranged in the filter screen, and the emitting box is fixed with a lower end wall of the reaction cavity. The equipment disclosed by the invention has the advantages of simple structure and convenience in use; the equipment utilizes high-temperature steam generated by coal gas combustion to achieve the purpose of generating hydrogen from coal gas and the high-temperature steam; furthermore, a controllable reaction speed structure is utilized to achieve reaction speed adjustment; furthermore, liquid-state water and a heat transfer medium are utilized in a reaction process to achieve the purpose of recycling redundant heat; thus, equipment reliability is improved.

Owner:佛山腾谱工业设计有限公司

Flexible coal gas hydrogen production device

InactiveCN108439335AIncrease flexibilityEasy maintenanceHydrogenChemical industryCombustionLiquid water

The invention discloses a flexible coal gas hydrogen production device, which comprises a tank A fixed on the ground. The tank A is provided with a reaction chamber, and the left end wall of the reaction chamber is connected with a pipe A extending outwardly to form an outer space, the upper end surface of the pipe A is connected with a valve A, the upper end surface of the valve A is connected with a pipe B, an electric heating wire is fixedly arranged in the left end wall of the reaction chamber, a filter net is fixed fixedly arranged between the left and right end walls of the reaction chamber, a distributing box is fixedly arranged in the filter net, and the distributing box is fixedly connected with the lower end wall of the reaction chamber. The flexible coal gas hydrogen productiondevice is simple in structure and convenient in use, the flexible coal gas hydrogen production device uses coal gas combustion to generate high temperature steam to realize production of hydrogen fromcoal gas and high-temperature steam, the reaction speed is adjusted by a structure that can control the reaction speed, excess heat is recovered by using of liquid water and a heat transfer medium during the reaction, and the reliability of the device is improved.

Owner:佛山腾谱工业设计有限公司

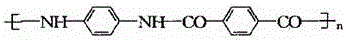

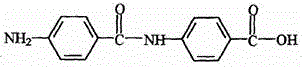

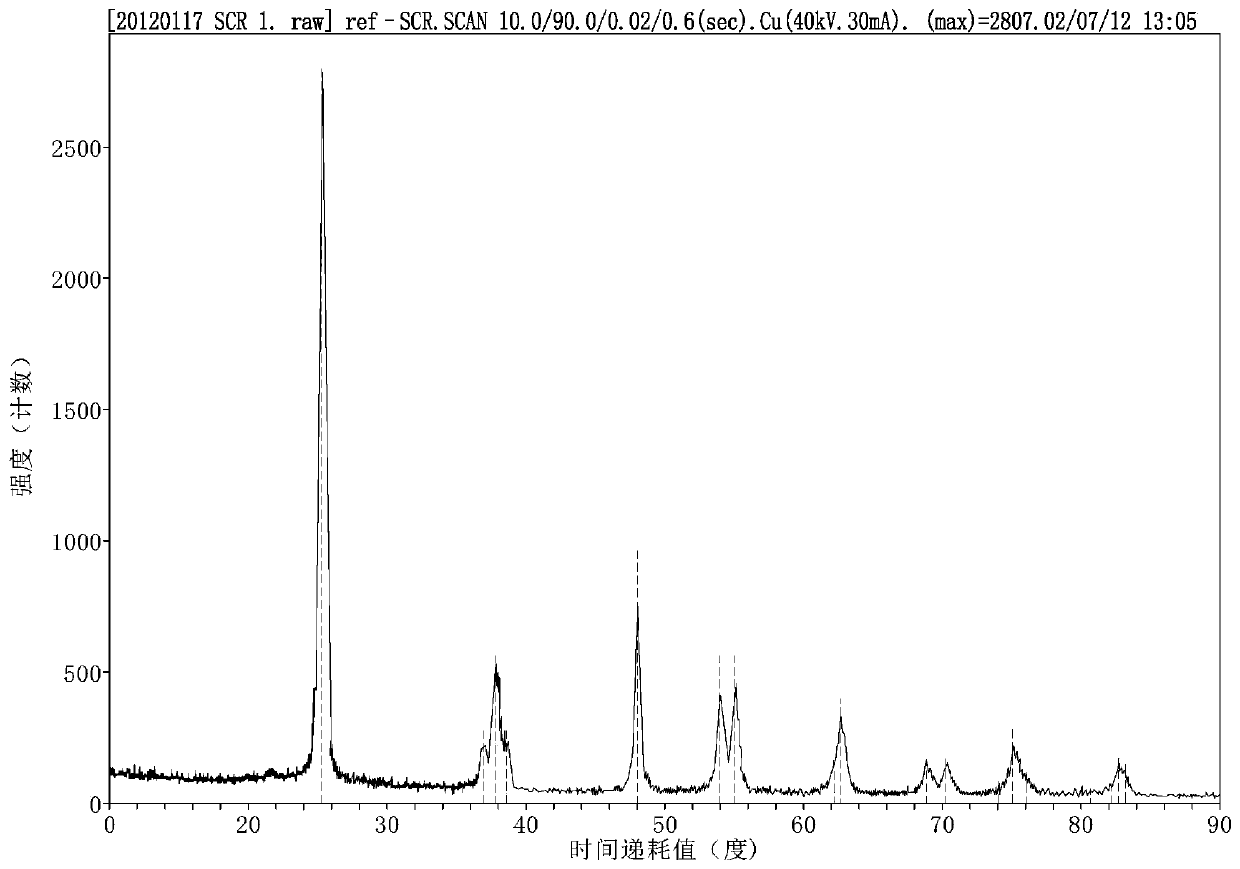

Anti-ultraviolet agent and preparation method of high-performance anti-ultraviolet fabric

InactiveCN107523987AGood chemical stabilityImprove thermal stabilityPhysical treatmentBiochemical fibre treatmentTitanium oxideAramid

The invention discloses an anti-ultraviolet agent and a preparation method of a high-performance anti-ultraviolet fabric, and belongs to the technical field of aramid fiber application. The anti-ultraviolet agent is prepared from, by weight, 4-6 parts of zinc oxide, 4-6 parts of titanium oxide, and 1-2 parts of graphite. The preparation method of the high-performance anti-ultraviolet fabric includes steps of 1), modifying the anti-ultraviolet agent; 2), coating; 3), post-treatment. By adopting the technical scheme, the aramid fiber 1414 resistance is increased, the aramid fiber 1414 product stability is improved, and the product sales volume is promoted.

Owner:BLUESTAR CHENGDU NEW MATERIALS

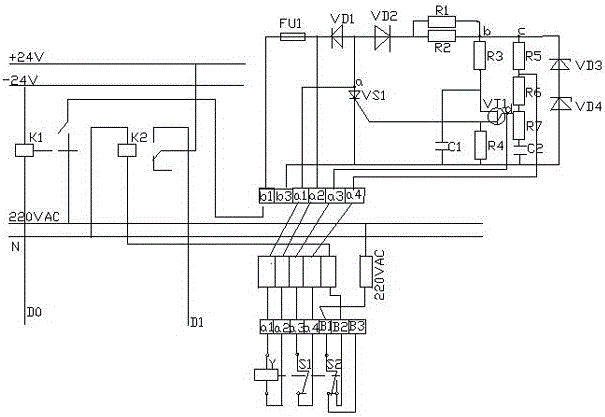

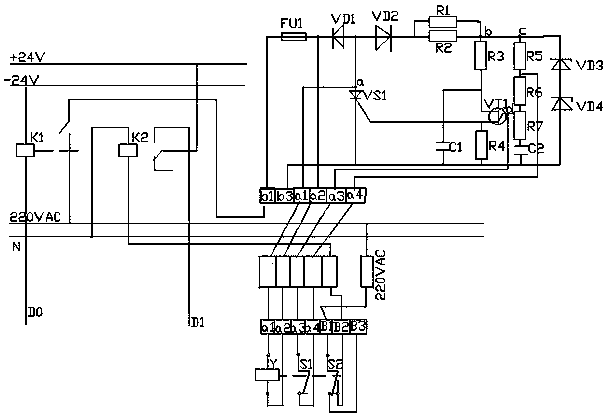

Automatic electromagnetic valve adjusting circuit and method thereof

ActiveCN106594359APrevent excessive reverse current from burning the coilBurn out preventionOperating means/releasing devices for valvesPotentiometerElectricity

The invention relates to an automatic electromagnetic valve adjusting circuit and a method thereof. The automatic electromagnetic valve adjusting circuit comprises a coil K1 connected with a fuse FU1. The fuse FU1 is connected with a coil Y and a thyristor VS1. After a rectifier diode VD2 is connected with a resistor R1 and a resistor R2, the rectifier diode VD2 is connected with a resistor R3, a resistor R4 and a voltage stabilizing diode VD3. An audion VT1 is connected with the resistor R3 and connected with a capacitor C1 in parallel. A control loop of an electromagnetic valve is connected with a base electrode of the audion VT1 through a resistor R5 via a contact S1 and connected with a potentiometer R7. The potentiometer R7 is connected with the resistor R5, a resistor R6 and a capacitor C2 in series. One path of the audion VT1 is connected with the resistor R4, and the other path of the audion VT1 is connected with a trigger circuit of the thyristor VS1. A contact S2 is connected with 220VAC current and an electromagnetic valve Y. A coil K2 is connected with a controller B2 and a power source null line, and the coil K2 is connected with a +24V power source. The control loop of the circuit is completely separated from the power source and control of the electromagnetic valve, the situation that in the electromagnetic valve operation process, interference is caused to the controller due to overcurrent or reverse signals is avoided, and damage of the electromagnetic valve due to the sudden power getting or power losing is prevented.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

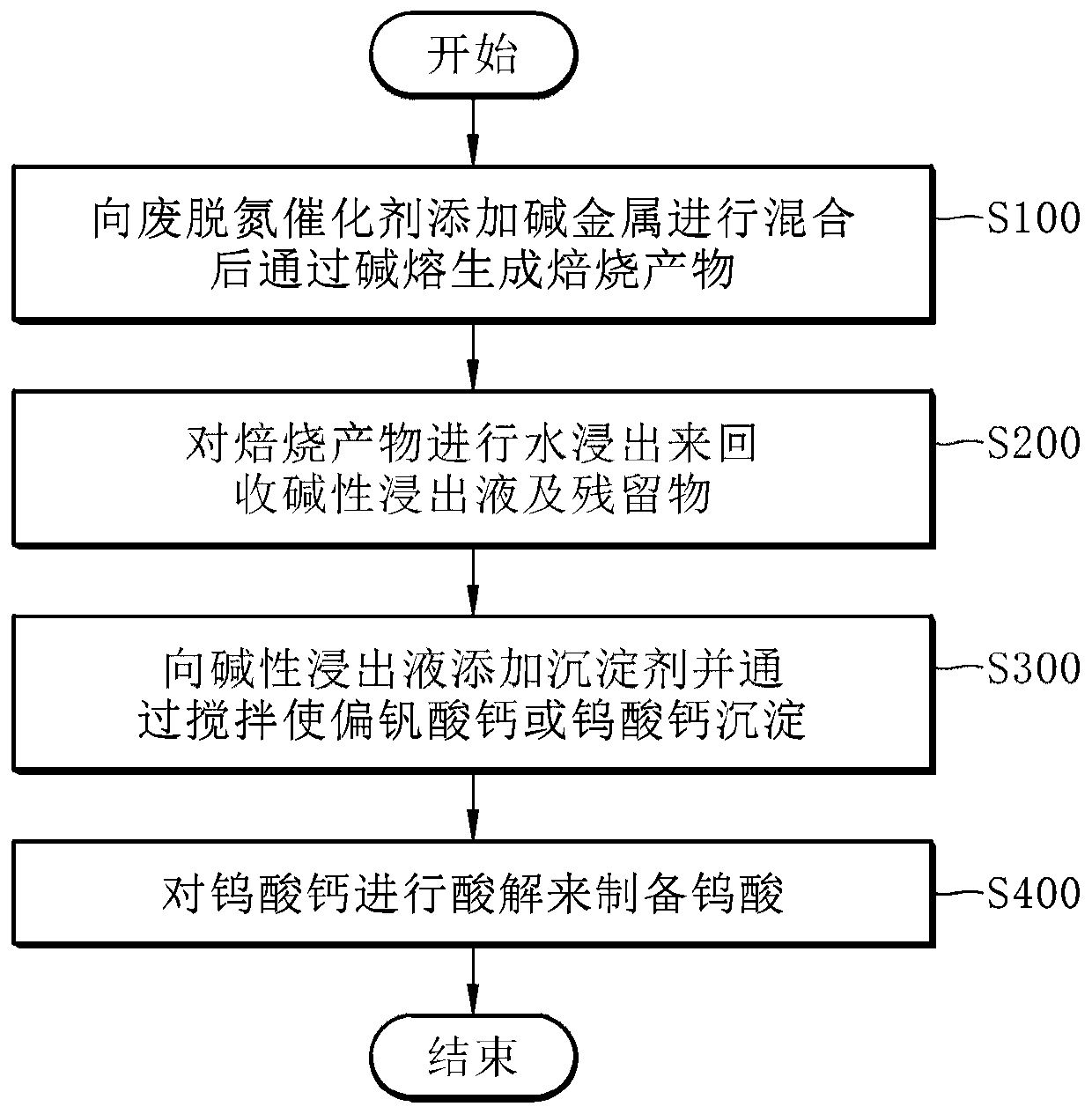

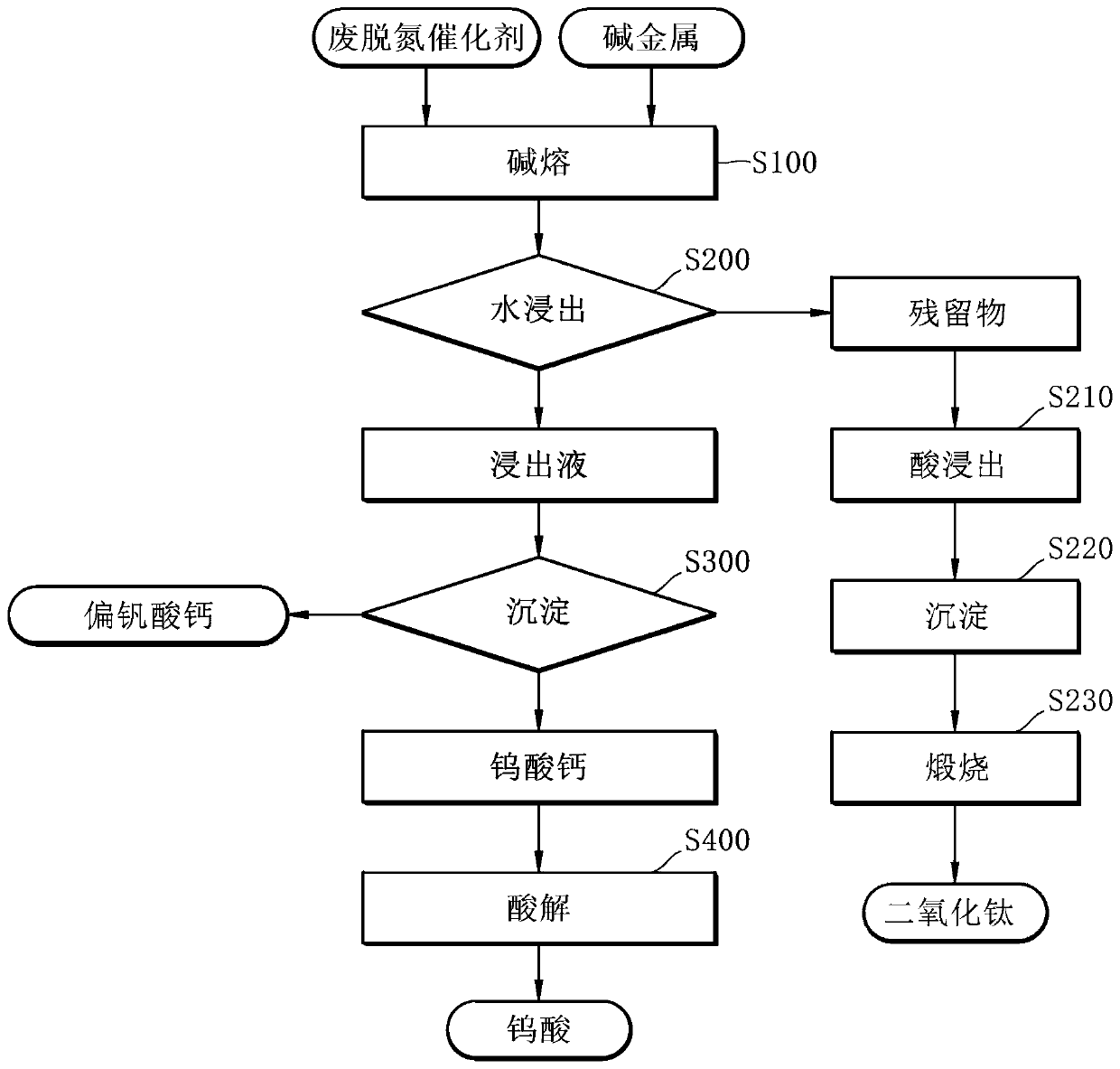

Method for selective recovery of valuable metal from waste denitrification catalyst through alkali fusion

PendingCN110945151AAdjust reaction speedIncrease the efficiency of the recycling processProcess efficiency improvementPtru catalystReaction rate

The present invention provides a method for selective recovery of a valuable metal from a waste denitrification catalyst through alkali fusion, the method comprising the steps of: (a) adding an alkalimetal to a waste denitrification catalyst, followed by mixing and alkali fusion, to generate a calcination product; (b) subjecting the calcination product to water-leaching to recover an alkali leachate and a residue; (c) adding a precipitator to the alkali leachate, followed by stirring, to recover calcium metavanadate (Ca(VO3)2) or calcium tungstate (CaWO4) through precipitation; and (d) subjecting the recovered calcium tungstate to acid decomposition to prepare tungstic acid. Therefore, vanadium and tungsten can be recovered at high efficiency by a method in which a precipitator is added to a leachate, which is obtained by adding an excess amount of an alkali metal to a waste denitrification catalyst and carrying out calcination and water-leaching, and then a reaction rate is controlled.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

High-viscosity environment-friendly waterproof coating

InactiveCN106497180AImproves water resistance and wet rub resistanceImproves elongation and flex resistanceFireproof paintsSolventAmmonium hydroxide

The invention discloses a high-viscosity environment-friendly waterproof coating. The high-viscosity environment-friendly waterproof coating is prepared from the following raw materials in parts by weight: 80 to 100 parts of film-forming agent, 40 to 50 parts of solvent, 10 to 15 parts of film-forming additives, 15 to 25 parts of pigment filler, and 15 to 30 parts of additives. A preparation method comprises the following steps: successively adding the film-forming agent, the solvent and the additives into a plastic tank, stirring for 8 to 10 minutes until all materials are uniformly mixed, stirring for 25 to 28 minutes at a rotation speed of 1500 r / min, sufficiently dispersing the materials, then adding the film-forming additives, dispersing for 3 to 5 minutes at high speed to obtain a dispersion system, adding a mixed solvent of acetone and ethyl acetate in a mass ratio of 1 to 1 to adjust the viscosity, finally adding an ammonium hydroxide solution to adjust a pH value to be 7.5 to 8.5, and uniformly mixing, thus obtaining the high-viscosity environment-friendly waterproof coating. The film-forming agent is modified to be used as an important raw material of the coating provided by the invention, so that the tensile strength, the coating film hardness and the viscosity are remarkably improved, and the prepared coating is not only good in weather and water resistance in outdoor conditions, but also remarkable in anticorrosion and high-temperature-resistant effects, and is non-toxic and pollution-free.

Owner:南宁马瑞娜装饰工程有限公司

Activator applied to carbon dioxide fracturing device

InactiveCN109053346AAdjust reaction speedImprove performancePressure gas generationOXALIC ACID DIHYDRATEAdditive ingredient

The invention discloses an activator applied to a carbon dioxide fracturing device. The activator is prepared from the following ingredients in parts by weight: 30 to 60 grams of potassium perchlorate, 10 to 18 grams of salicylic acid, 7 to 18 grams of ammonium oxalate, 6 to 12 grams of sodium fluoride, 6 to 12 grams of charcoal powder, 3 to 6 grams of oxalic acid, 4.5 to 7 grams of superfine aluminum powder and 5 to 7 grams of superfine magnesium powder. The activator has stable performance, cannot be lighted or detonated by open fire in air, can prevent impact, can prevent combustion or explosion caused by collision or high-altitude falling and has safety and reliability; the activator can be efficiently utilized in a fracturing pipe through liquid carbon dioxide even ambient pressure; in addition, a formula can be adjusted according to need within the above range, so that the reaction speed of the activator can be adjusted.

Owner:湖北照东机械有限公司

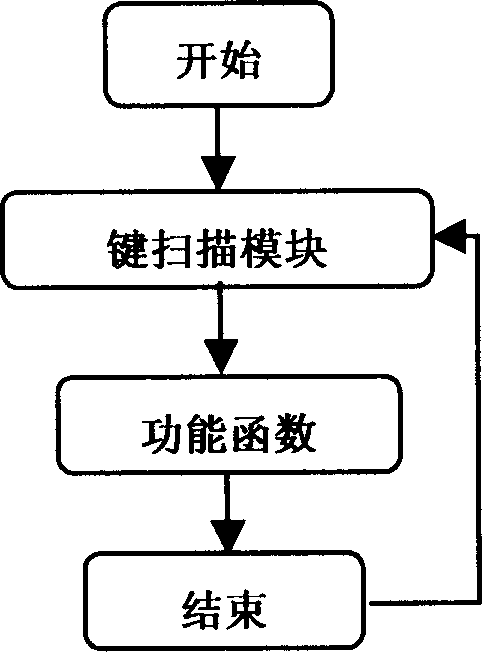

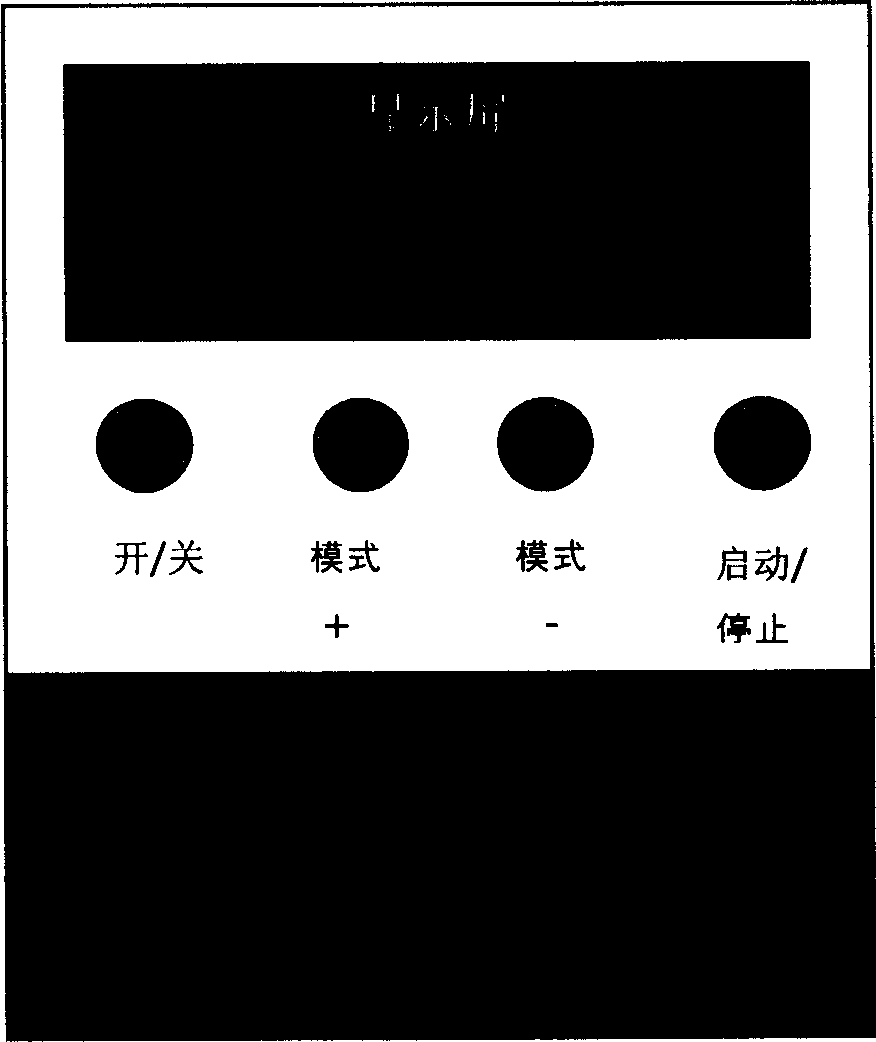

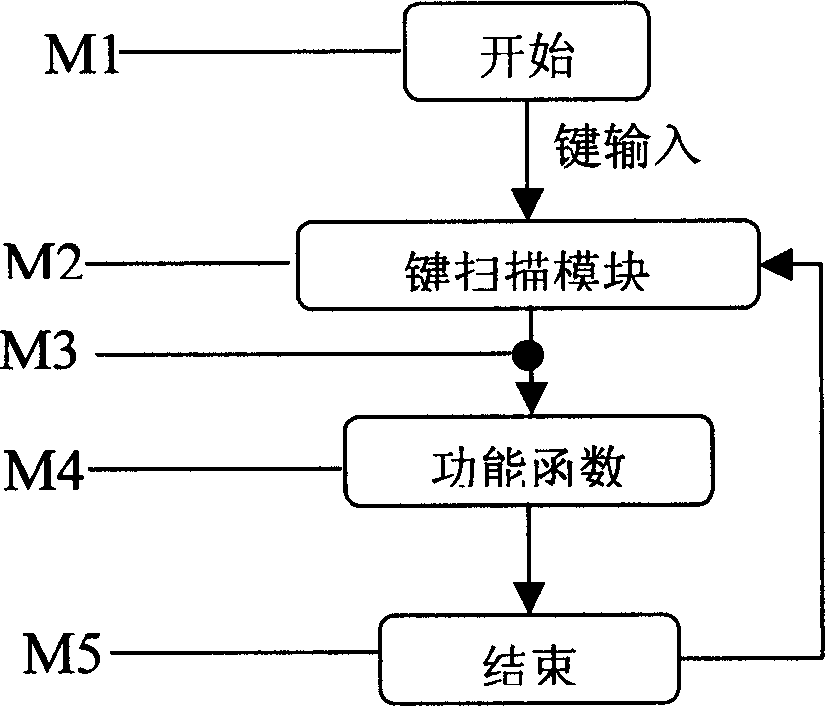

Anti-interference control method for key input of household electrical appliance

InactiveCN1632727AAdjust reaction speedGuaranteed to workInput/output processes for data processingUser needsHabit

This invention discloses an anti-interference control method of household appliance input, which comprises key input phase, key scanning module phase, anti-interference control module phase, function phase and key process close phase. This invention can clearly distinguish the key input and noise interference, which does not trigger when there is interference and triggers when there is real input. Furthermore, the user also adjusts the reaction speed of the key according to user needs and habits.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

A catalytic device for preparing u(iv) solution

ActiveCN106311092BFully contactedLarge adjustment flexibilityChemical/physical processesStructural engineeringMaterials science

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Improved high-efficiency and low-consumption catalytic material and combustion device

InactiveCN108488778AEasy maintenanceEasy to installHydrogenRecuperative heat exchangersCombustionHydrogen

The invention discloses an improved high-efficiency and low-consumption catalytic material and combustion device. The improved high-efficiency and low-consumption catalytic material and combustion device comprises a shell body A, wherein four support legs with the same dimensions are arranged on the four corners of the bottom surface of the shell body A; a suction disc used for being sucked onto the ground is fixedly arranged on the bottom surface of each support leg; a hollow cavity is formed in the shell body A; a pipe fitting A stretching outwards to the outside is arranged in the left endwall of the hollow cavity in a connection manner; a valve body A is arranged on the upper end surface of the pipe fitting A in a connection manner; a pipe fitting B is arranged on the upper end surface of the valve body A in a connection manner; a resistance wire is fixedly arranged in the left end wall of the hollow cavity; a filter is fixedly arranged between the left end wall and the right endwall of the hollow cavity; a dispersion box is fixedly arranged in the filter; and the dispersion box is fixed to the lower end wall of the hollow cavity. The device disclosed by the invention is simple in structure, convenient to use, high in hydrogen preparation efficiency, and adjustable in speed, and realizes heat recovery and low energy consumption.

Owner:广州凯燃环保工程技术有限公司

Novel metal manufacturing equipment for electronic parts and components

The invention discloses novel metal manufacturing equipment for electronic parts and components. The novel metal manufacturing equipment for the electronic parts and components comprises a machine body A; supporting legs are fixed to the periphery of the bottom face of the machine body A and provided with traveling idler wheels; a generating cavity is formed in the machine body A; a through pipe Acommunicates with the left end wall of the generating cavity and extends out of the generating cavity; a valve part A communicates with the upper end face of the through pipe A; a through pipe B communicates with the upper end face of the valve part A; a heating pipe is fixedly arranged in the left end wall of the generating cavity; a screen is fixedly arranged between the left end wall and the right end wall of the generating cavity; and a diffusion tank is fixedly arranged in the screen and fixed to the lower end wall of the generating cavity. The novel metal manufacturing equipment is simple in structure and convenient to use, the manufacturing cost of metal parts for the electronic parts and components is effectively reduced, the hydrogen preparation efficiency is high, the speed is adjustable, heat recovery is achieved, energy consumption is low, operation is simple, and time and labor are saved.

Owner:佛山常百乐机械设计有限公司

Colorized heat-insulating waterproof coating

InactiveCN106497418AGood extensibilityImprove flex resistanceFireproof paintsAntifouling/underwater paintsAcetic acidEthyl ester

Colorized heat-insulating waterproof coating is disclosed. The coating is prepared by adding a film forming agent, a solvent, an auxiliary agent, an ultraviolet ray absorbing agent and pigment and a filler in order into a plastic tank, stirring the materials for 8-10 min until the materials are fully mixed, stirring the mixture at a speed of 1500 r / min for 25-28 min to fully disperse the mixture, adding a coalescing agent, performing high-speed dispersion for 3-5 min to obtain a dispersion system, adding a mixed solvent including acetone and ethyl acetate in a mass ratio of 1:1 to adjust viscosity, adding a sodium hydroxide solution to adjust the pH value to be 8-9, and fully mixing the mixture to obtain the waterproof coating. The film forming agent is adopted as an important raw material of the coating after the film forming agent is modified, and tensile strength and hardness of film of the film forming agent are significantly improved, and therefore the prepared coating has good weatherability and waterproofness under outdoor conditions and has reflective insulation and decoration functions. A preparing process of the coating is simple.

Owner:南宁马瑞娜装饰工程有限公司

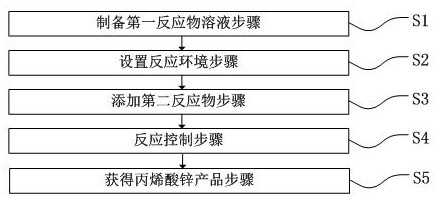

Method for producing zinc acrylate at low temperature

PendingCN113979857AGood dispersionImprove liquidityOrganic compound preparationCarboxylic acid salt preparationZinc compoundsDouble bond

The invention discloses a method for producing zinc acrylate at low temperature. The method for producing zinc acrylate at low temperature comprises the following steps: preparing a first reactant solution, setting a reaction environment, adding a second reactant, controlling reaction and obtaining a zinc acrylate product. Through verification of a series of synthesis experiment researches and a large number of product application experiments, a more reasonable process and proper raw materials are optimized and screened out. A cheap and effective reaction raw material concentration adjusting medium is selected, the reaction speed is adjusted, the double-bond self-polymerization degree is controlled within the range of not influencing the use performance of the product, and the process performance requirements of good dispersion and fluidity of the materials in the reaction process are guaranteed. A condensation reflux reaction with a zinc compound is conducted at the low temperature, such that the application effectiveness of the zinc acrylate molecular structure is effectively protected, and the process requirements of low energy consumption and low emission can be met; and after the reaction is finished, drying and crushing to prepare a zinc acrylate product meeting performance requirements.

Owner:青岛益林原科贸有限公司

A kind of method for preparing iron-nickel-phosphorus electroless coating

InactiveCN101906624BHigh in ironAdjust reaction speedLiquid/solution decomposition chemical coatingMetal impuritiesSurface level

The invention belongs to the technical field of chemical deposition, and specifically relates to a new method for preparing an iron-nickel-phosphorus chemical coating, which can be widely used in (micro)electronic industry, aerospace and general engineering. The method controls the concentration of free Fe2+ ions and Ni2+ ions in the solution through a complex complex system composed of potassium sodium tartrate, trisodium citrate, two organic mixed additives with -N(CH2COOH)2 groups, and ammonia water, and inhibits nickel The reduction speed and at the same time increase the iron reduction speed, thereby increasing the iron content in the coating. The complex complex system can complex with impurity ions and increase the concentration of metal impurity ions that the solution can accommodate. It is especially suitable for preparing high iron on silicon chips and copper surfaces. content of iron-nickel-phosphorus electroless plating. The composition of the coating obtained on the surface of the silicon wafer is: the atomic percentage of iron is 0-50% controllable, the percentage of phosphorus atomic is 2-18%, and the balance is nickel; the atomic percentage of iron obtained on the surface of the copper sheet It is controllable from 0-90%, the atomic percentage of phosphorus is 2-16%, and the balance is nickel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

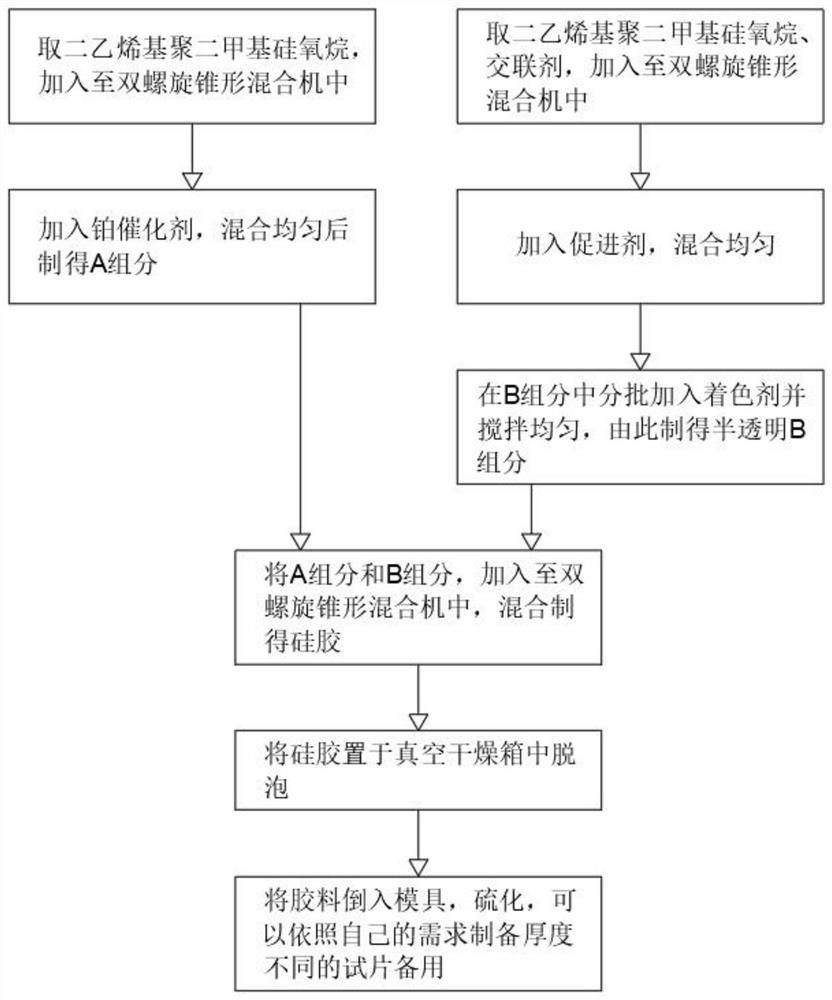

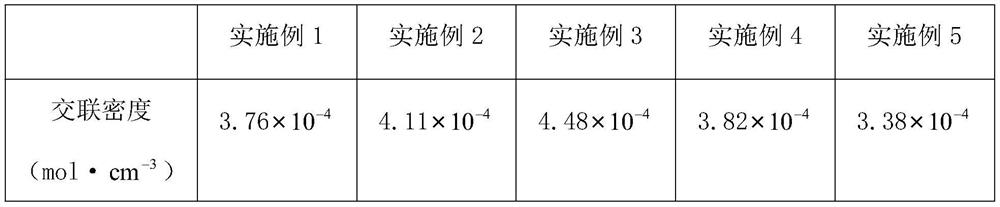

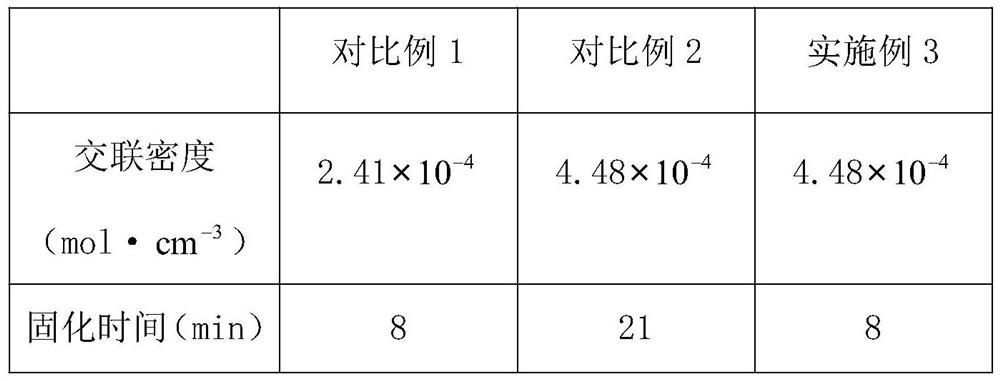

Integrated black silica gel OCR for improving performance based on crosslinking density and preparation method ofintegrated black silica gel OCR

The invention relates to the technical field of polymer nano organic silicon materials, in particular to an integrated black silica gel OCR with performance improved based on crosslinking density and a preparation method of the integrated black silica gel OCR. The integrated black silica gel OCR is prepared by mixing a component A and a component B in proportion, wherein the component A is prepared from the following raw materials of divinyl polydimethylsiloxane and a platinum catalyst, and the component B is prepared from the following raw materials of divinyl polydimethylsiloxane, a cross-linking agent, an accelerant and a coloring agent. According to thepreparation method of the integrated black silica gel OCR, a cross-linking agent is added into an OCR liquid silica gel bonded by traditional glue, the cross-linking agent is hydrogen-containing silicone oil, is reactive silicone oil containing SiH bonds, can play a role in adjusting the understanding cross-linking density, increases the cross-linking density of silica gel, and enables the mechanical strength of the silica gel to be better; and through cooperation of acetenyl cyclohexanol and a platinum catalyst, a curing reaction can be prompted, and the curing reaction speed is adjusted.

Owner:睿合科技有限公司

Anticorrosion prestressed bars and its manufacture method

InactiveCN1247814CComposition is stableImprove adhesionCeramic shaping apparatusMetallic material coating processesCooking & bakingPre stress

An anticorrosion prestressed steel bar is prepared from the ordinary steel bar through pretreating, washing, sensitizing, washing, blackening, washing, posttreating and baking. Its advantages are high anticorrosion performance, low cost, high adhesion of film layer, and no poison, odour and irritative smell of its discharged substance.

Owner:LIUZHOU OVM MASCH CO LTD

Magnesium-iron self-heating powder capable of efficiently self-heating food and preparation process of magnesium-iron self-heating powder

PendingCN113881407AQuick start of self-corrosion reactionContact continuous and effectiveHeat-exchange elementsCorrosion reactionAluminium powder

The invention relates to magnesium-iron self-heating powder capable of efficiently self-heating food and a preparation process of the magnesium-iron self-heating powder. According to the magnesium-iron self-heating powder capable of efficiently self-heating food, the powder is of a roll core structure, and continuous iron wires are evenly wrapped in every two adjacent layers of magnesium sheets; the thickness of a single-layer magnesium sheet in the powder is not more than 1mm; the diameter of the iron wire in the powder does not exceed 0.5 mm; the powder also comprises sodium chloride or potassium chloride; and the powder further comprises aluminum powder and / or quick lime. According to the preparation process of the magnesium-iron self-heating powder, magnesium and iron are effectively fixed together by adopting a multiple folding and rolling method, utilizing an extrusion plastic deformation effect and combining a roll core structure so as to form the high-activity magnesium-iron self-heating powder, so that the starting and reaction speed of a self-corrosion reaction are adjusted, efficient heating of self-heating food is realized, and the self-heating powder is suitable for large-scale rapid popularization.

Owner:CMCI BEIJING TECH DEV CO LTD

Efficient low-consumption material catalyzing and combusting device

InactiveCN108613157AEasy maintenanceEasy to installHydrogenRecuperative heat exchangersHydrogenPipe fitting

The invention discloses an efficient low-consumption material catalyzing and combusting device. The efficient low-consumption material catalyzing and combusting device comprises a shell A, four supporting feet with the same size are arranged on four corners of the bottom face of the shell A, the bottom faces of the supporting feet are fixedly provided with suction cups used for being absorbed on the ground, a hollow cavity is formed in the shell A, a pipe fitting A extending out of the shell A is connected with the left end wall of the hollow cavity, a valve body A is connected with the upperend face of the pipe fitting A, the upper end face of the valve body A is connected with a pipe fitting B, a resistance wire is fixedly arranged in the left end wall of the hollow cavity, a filter device is fixedly arranged between the left end wall and the right end wall of the hollow cavity, and an emission box is fixedly arranged in the filter, and the emission box is fixed to the lower end wall of the hollow cavity. The efficient low-consumption material catalyzing and combusting device is simple in structure, convenient to use, high in hydrogen preparing efficiency, adjustable in speed, and capable of achieving heat recycling and low energy consumption.

Owner:广州凯燃环保工程技术有限公司

Novel equipment for producing hydrogen by using coal gas

InactiveCN108423636AIncrease flexibilityEasy maintenanceHydrogenSteam generation plantsHydrogenBiochemical engineering

Owner:佛山腾谱工业设计有限公司

ETFE film material processing equipment with negative pressure prevention function

PendingCN110586015ACircumstances to prevent negative impactEasy to adjustProcess control/regulationChemical/physical/physico-chemical stationary reactorsInternal pressureAgricultural engineering

The invention discloses ETFE film material processing equipment with negative pressure prevention function. The equipment comprises a shell mechanism, wherein the upper end of the shell mechanism is connected to a cover body mechanism, a heating mechanism is arranged in the shell mechanism, a stirring mechanism is arranged on the bottom portion of the shell mechanism, the lower portion of the shell mechanism is connected to a pressurizing mechanism, the shell mechanism comprises a main shell, a bottom shell, an inner shell, an upper filtering screen, a connecting pipe, a gas inlet pipe and a negative pressure preventing valve, the lower portion of the main shell is connected to the bottom shell, the main shell is welded to the upper side surface of the bottom shell in a sealed manner, andthe inner shell is welded in the main shell in a sealed manner. According to the present invention, the ETFE film material processing equipment has a novel structure, can automatically regulate internal pressure, can simultaneously avoid the high-pressure and negative-pressure environments, is the novel and practical ETFE film material processing equipment with the negative pressure prevention function.

Owner:无锡市惠鸿氟材料装备有限公司

Solenoid valve automatic adjustment circuit and its method

ActiveCN106594359BBurn out preventionAdjust reaction speedOperating means/releasing devices for valvesElectricityElectrical resistance and conductance

The invention relates to an automatic electromagnetic valve adjusting circuit and a method thereof. The automatic electromagnetic valve adjusting circuit comprises a coil K1 connected with a fuse FU1. The fuse FU1 is connected with a coil Y and a thyristor VS1. After a rectifier diode VD2 is connected with a resistor R1 and a resistor R2, the rectifier diode VD2 is connected with a resistor R3, a resistor R4 and a voltage stabilizing diode VD3. An audion VT1 is connected with the resistor R3 and connected with a capacitor C1 in parallel. A control loop of an electromagnetic valve is connected with a base electrode of the audion VT1 through a resistor R5 via a contact S1 and connected with a potentiometer R7. The potentiometer R7 is connected with the resistor R5, a resistor R6 and a capacitor C2 in series. One path of the audion VT1 is connected with the resistor R4, and the other path of the audion VT1 is connected with a trigger circuit of the thyristor VS1. A contact S2 is connected with 220VAC current and an electromagnetic valve Y. A coil K2 is connected with a controller B2 and a power source null line, and the coil K2 is connected with a +24V power source. The control loop of the circuit is completely separated from the power source and control of the electromagnetic valve, the situation that in the electromagnetic valve operation process, interference is caused to the controller due to overcurrent or reverse signals is avoided, and damage of the electromagnetic valve due to the sudden power getting or power losing is prevented.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Portable metal manufacturing device for electronic element

The invention discloses a portable metal manufacturing device for an electronic element. The device comprises a machine body A, wherein supporting foot columns which are provided with moving rollers are fixedly arranged around the bottom surface of the machine body A; a generation chamber is formed in the machine body A; a through pipe A which outwards extends out of the outer part is arranged inthe left end wall of the generation chamber in a communication manner; a valve A is arranged on the upper end surface of the through pipe A in a communication manner; a through pipe B is arranged on the upper end surface of the valve A in a communication manner; a heating pipe is fixedly arranged in the left end wall of the generation chamber; a sieve net is fixedly arranged between the left end wall and the right end wall of the generation chamber; a dispersing box is fixedly arranged in the sieve net and is fixed to the lower end wall of the generation chamber. The device is simple in structure, and convenient to use; the manufacturing cost of a metal part used in the electronic element can be effectively decreased; the hydrogen preparation efficiency is high; the speed can be adjusted;the heat can be recovered; the energy consumption is low; the operation is simple; and both time and force can be saved.

Owner:佛山常百乐机械设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com