Magnesium-iron self-heating powder capable of efficiently self-heating food and preparation process of magnesium-iron self-heating powder

A preparation process and self-heating technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of magnesium powder residue, bonding, slow start-up speed, etc., to improve bonding strength, significant working environment, and avoid residual problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

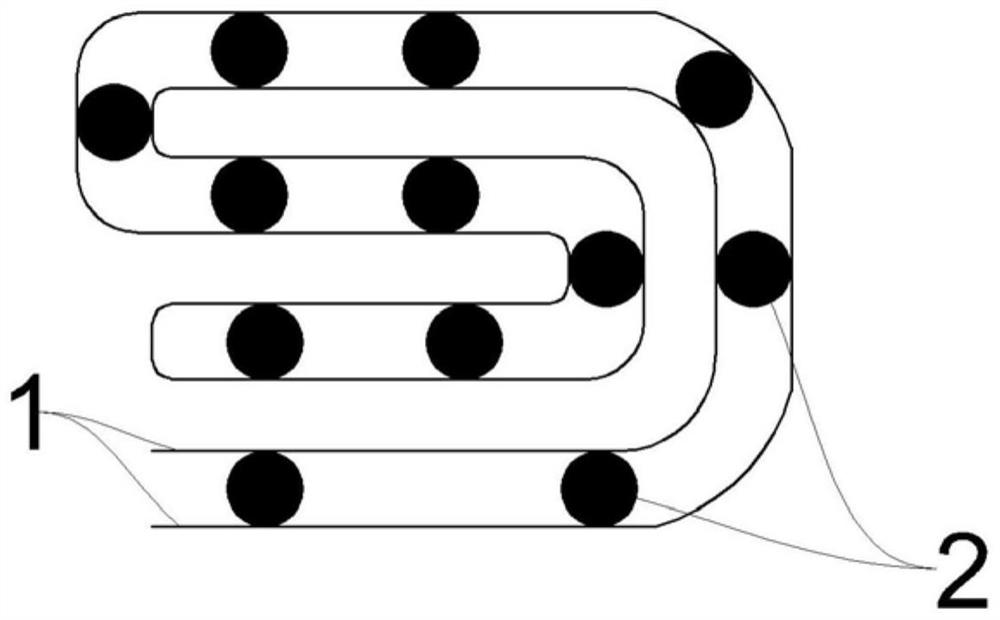

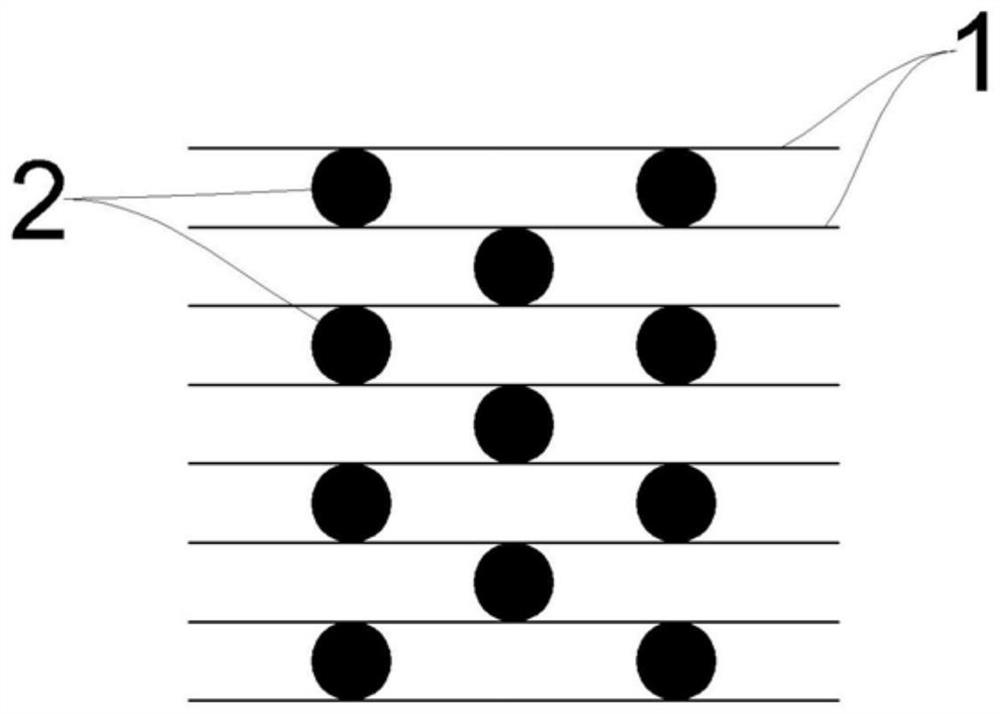

[0031] see figure 1 and figure 2 , a magnesium-iron self-heating powder capable of efficiently self-heating food according to the present invention, the powder is a core structure, and two adjacent layers of magnesium flakes 1 are evenly wrapped with continuous iron wires 2 . In the core structure, the continuous iron wire is wrapped in the magnesium sheet to ensure a good combination between the two, forming an effective micro-battery in water or salt solution, quickly starting the self-corrosion reaction, and releasing heat; by adjusting the number of iron wires And position, can effectively control the ratio of magnesium and iron in the self-heating powder of magnesium iron, and then control the corrosion reaction efficiency of the self-heating powder. In particular, the use of continuous iron wire instead of common dispersed iron powder can further ensure rapid and continuous heating of the magnesium-iron self-heating powder in the corrosion reaction.

[0032] The thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com