Patents

Literature

172results about How to "Control reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temporary plugging agent for horizontal well staged fracturing of controllable rubber breaking and preparation method thereof

ActiveCN102344788AGel break time controllableComplete gel breakbackDrilling compositionSodium bicarbonateMagnesium

The invention relates to a temporary plugging agent for the horizontal well staged fracturing of controllable rubber breaking and a preparation method thereof. The temporary plugging agent consists of diol, an inorganic oxidation strengthening agent, borate, sodium bicarbonate, a controlled-release microcapsule rubber-breaking agent and water, wherein the weight ratio of the components is (10-14): (5-8): (1-1.5): 3: (2-3): 100; the diol is white powder or particles, the molecular weight is 70-100 thousands; the inorganic oxidation strengthening agent is magnesium oxide or aluminum oxide; and the controlled-release microcapsule rubber-breaking agent is covered citric acid or solid nitric acid which is obtained by the boiling granulating technology. The temporary plugging agent performs a crosslinking reaction under 70-90 DEG C of well temperature to form a rubber plug which can bear more than 30MPa of differential pressure, thus the fracturing construction can be performed smoothly; and after fracturing, the capsule dressings of the controlled-release microcapsule rubber-breaking agent are damaged and the viscosity of the rubber-breaking solution is less than 10mPa.s, thus the temporary plugging agent is hydrated and degraded and then is discharged out of the ground through flowback and the harm to the formation is lower.

Owner:PETROCHINA CO LTD

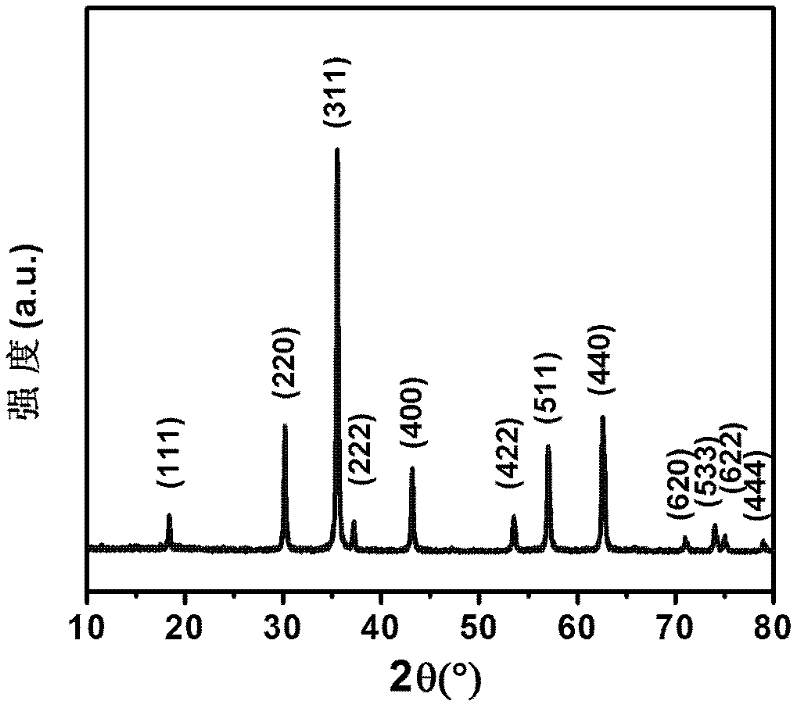

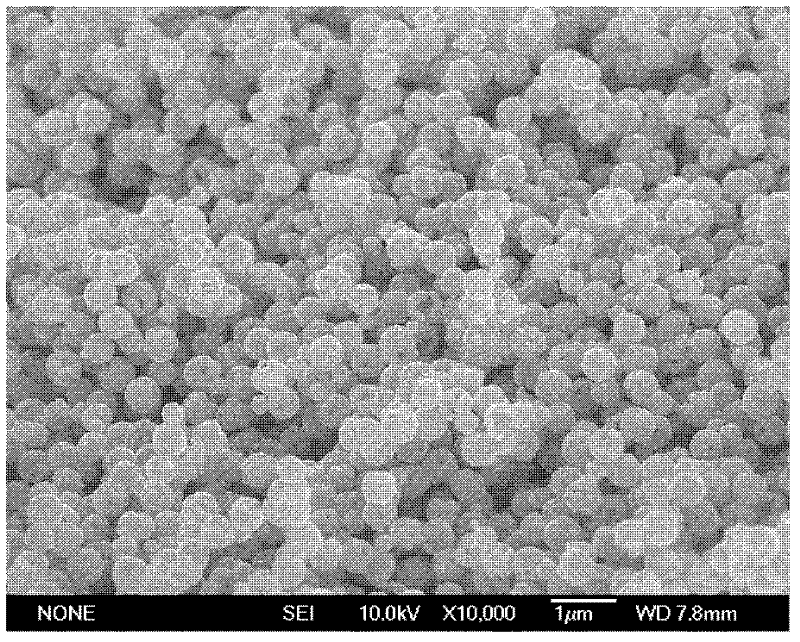

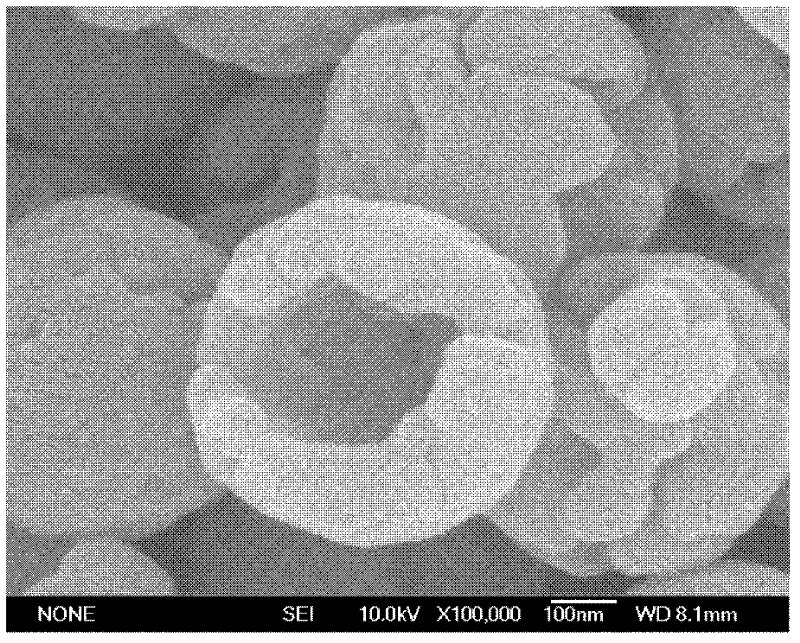

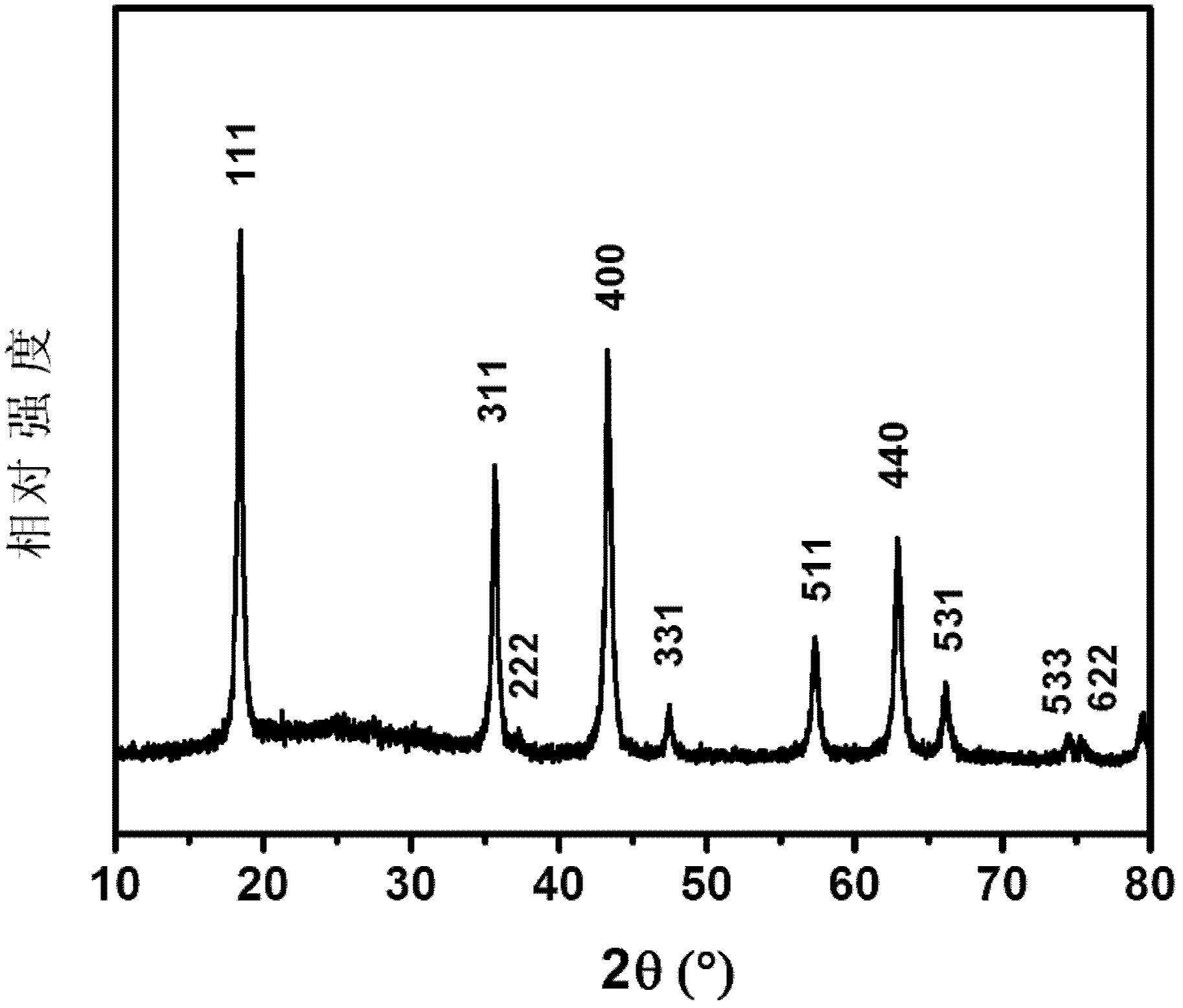

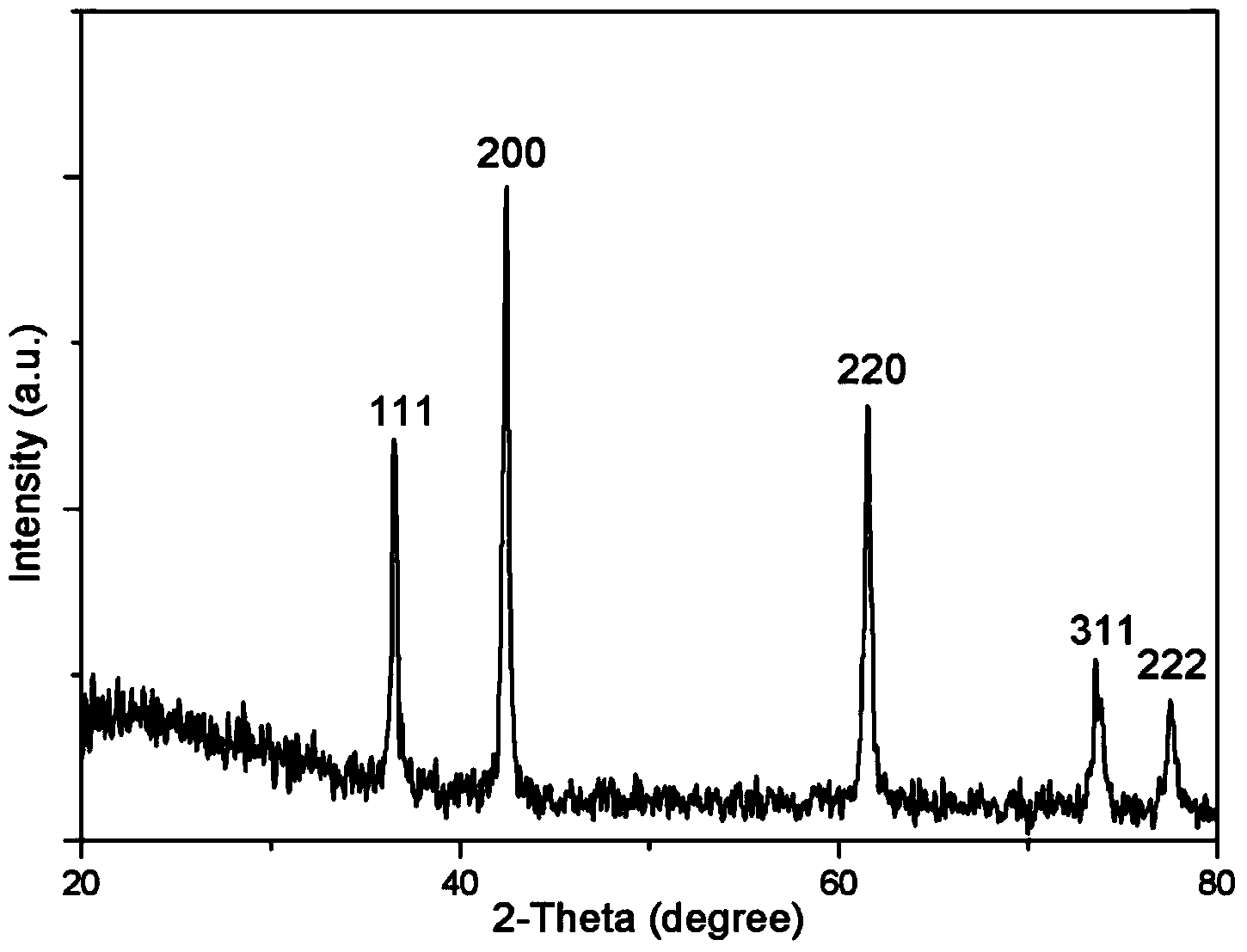

Spherical ferrate having hollow structure and preparation method thereof

InactiveCN102531066APromote formationHigh viscosityNanotechnologyIron compoundsPhysical chemistryNanocrystal

The invention discloses spherical ferrate having a hollow structure and a preparation method thereof. The ferrate MFe2O4 is of a hollow-structured spherical particle formed by self-assembling of nanocrystals having a particle size of 10-50nm, wherein M is Co, Ni or Zn, the diameter of the particle is 0.1-1mu m, and the thickness of a shell layer is 30-200nm. The spherical ferrate can be used as a negative electrode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

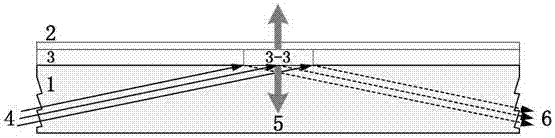

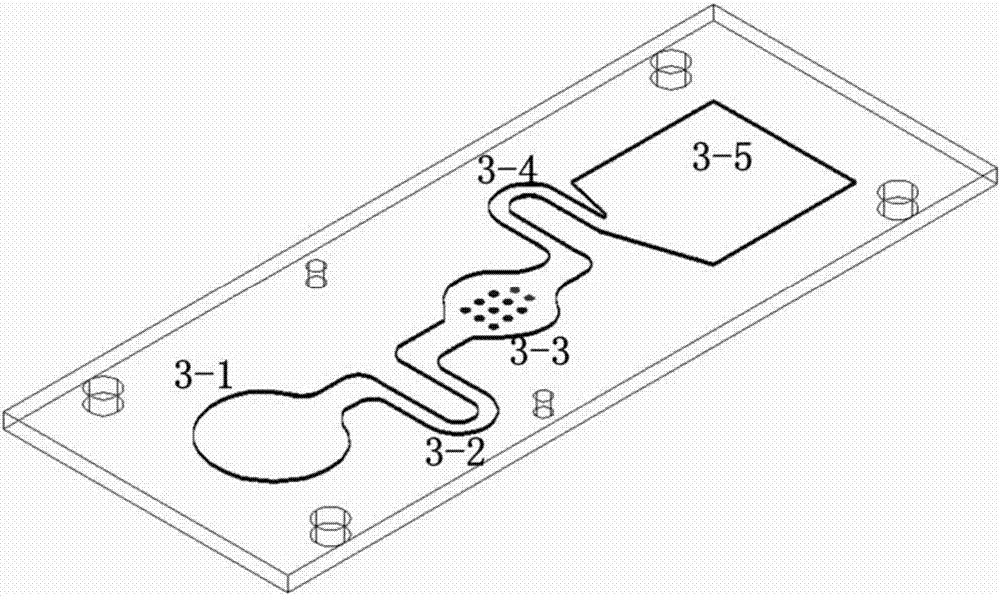

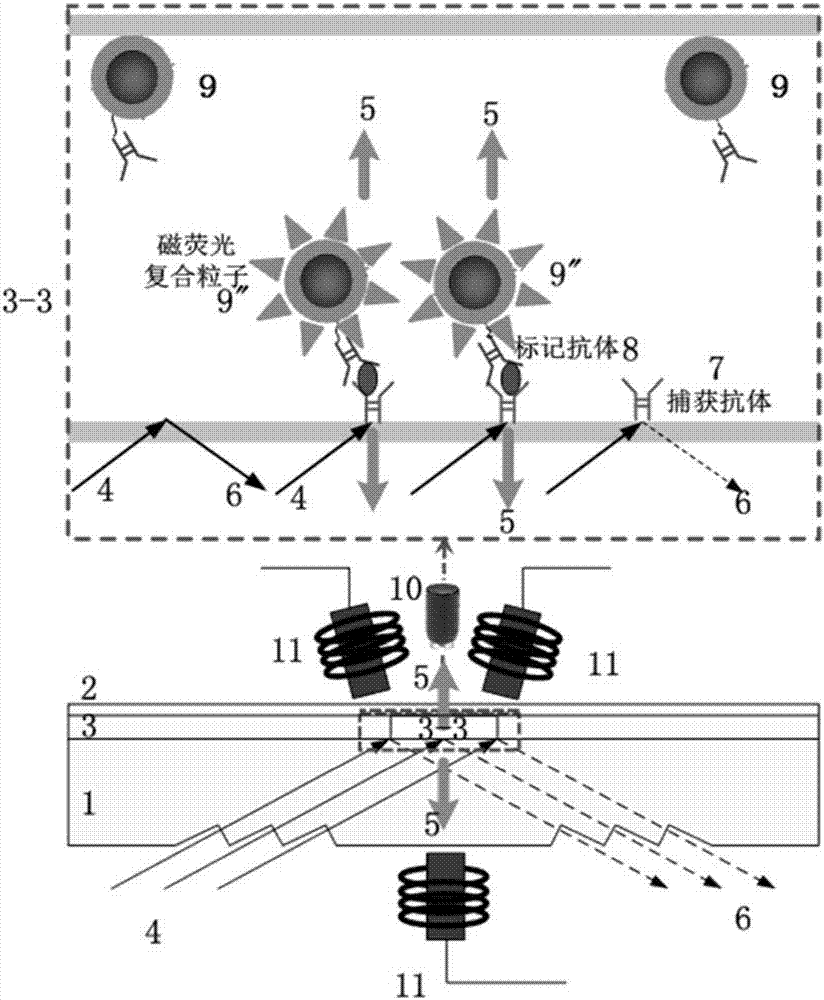

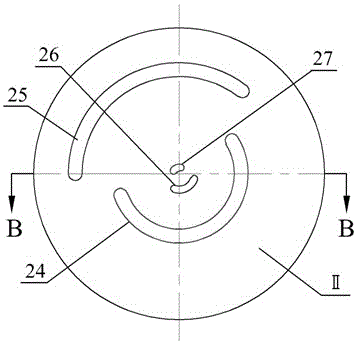

Micro-fluidic chip based on magnetic fluorescence composite particle

ActiveCN106994370ARealize one-step detectionImprove reaction speedLaboratory glasswaresFluorescence/phosphorescenceFluorescencePoint-of-care testing

The invention provides a micro-fluidic chip based on a magnetic fluorescence composite particle. The micro-fluidic chip comprises a chip bottom-layer plate, a chip channel layer and a chip upper-layer cover plate which are sequentially arranged from bottom to top, wherein the chip channel layer comprises a sample introduction area, a sample introduction channel, an optical detection area, a waste liquid channel and a waste liquid storage area which are sequentially connected; a capture recognition reagent is fixed to the lower side of the optical detection area; mark recognition reagent-magnetic fluorescence composite particles are pre-fixed on the inner upper sides of the sample introduction area, the sample introduction channel or the optical detection area. The invention also provides an optical detection device. The micro-fluidic chip provided by the invention can be used for sample trace substance analysis through magnetism enrichment and separation reaction and a fluorescence optical detection technology, meets the requirements on quick, sensitive and convenient detection of low-concentration substances in a micro-sample, solves the problems of complicated and expensive instrument equipment, inconvenience, slow detection speed and the like of an existing method, and has a favorable application value in the POCT (Point-of-Care Testing) detection field.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

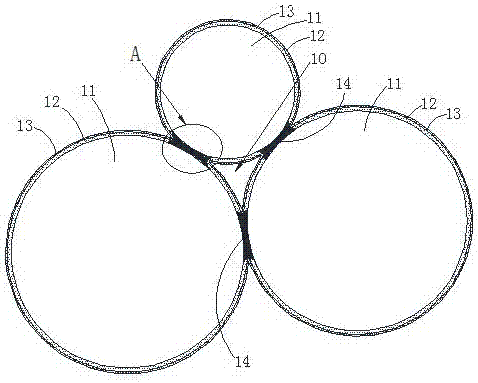

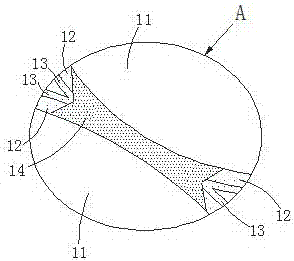

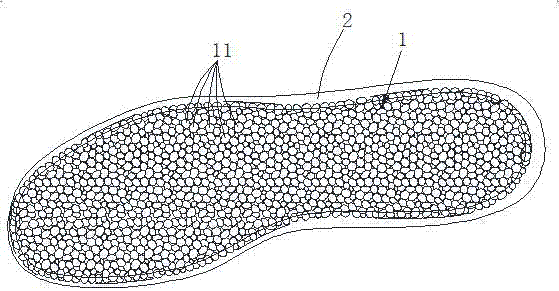

Production process of E-TPU (expanded thermoplastic polyurethane) shoe material

InactiveCN107353428APromote environmental protectionReduce usage requirementsSolesDevices for pressing relfex pointsMaterials preparationThermoplastic polyurethane

The invention relates to a production process of an E-TPU (expanded thermoplastic polyurethane) shoe material. The production process of the E-TPU shoe material comprises the steps implemented in sequence as follows: a, material preparation: 75-92 parts of TPU foamed particles, 5.9-19 parts of glue A, 0.9-4.8 parts of glue B and 0.38-1.5 parts of an accelerator are prepared by weight; b, addition of the glue A: the TPU foamed particles and the glue A are stirred uniformly; c, addition of the glue B: the glue B is added after the materials in the step b are mixed uniformly, and the materials are stirred uniformly; d, addition of the accelerator: the accelerator is added after the materials in the step c are mixed uniformly, the materials are mixed uniformly, and the mixture is injected into a die cavity; e, foaming: the die cavity is moved into an oven, foaming molding is performed at 50-70 DEG C for 2-3 min, and the molded shoe material can be obtained. The TPU particles can account for 90%-92% by weight of the shoe material, the weight reduction limit of the current shoe material is reached, and the E-TPU shoe material has the characteristics of being ultralight, ultrahigh in elasticity, more environment-friendly, low in cost and capable of performing massaging.

Owner:陈茂双

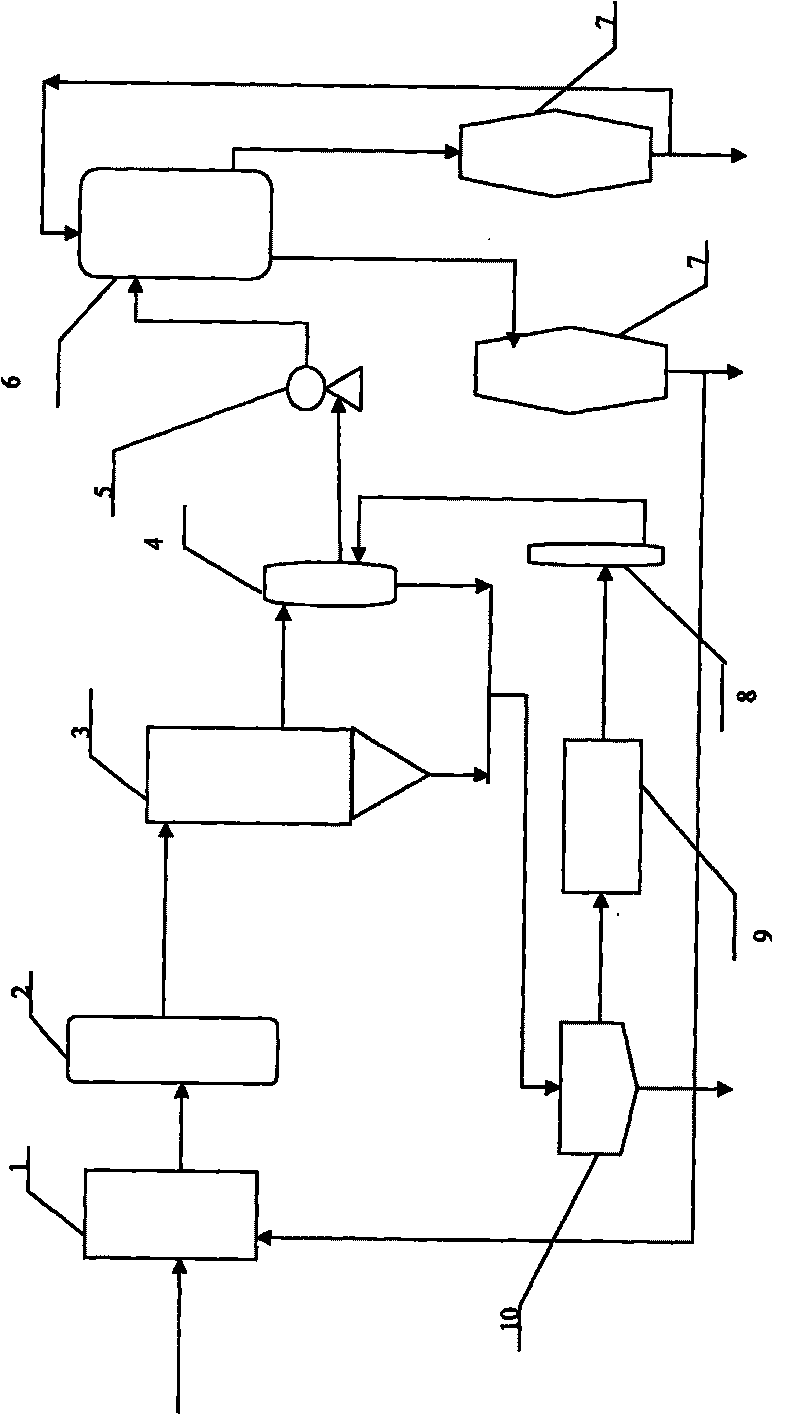

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

ActiveCN101734995AThorough treatmentNo pollution in the processHydrocarbonsHydrocarbon preparationCoal dustProcess design

The invention relates to a device and a method for producing acetylene by hydrogen direct current arc plasma cracking coal. The method comprises the following steps: the hydrogen coal dust is fed into a plasma reactor, enters a quenching machine for quenching after the reaction, then enters a cyclone separator for preseparation between gas and solid; the gas part enters a rinsing dust removing tower for dedusting, is sent to a compressor for compression by a booster fan, then enters a pressure swing adsorption tower for adsorption and concentration, and simultaneously, the gas out of the pressure swing adsorption tower enters the compressor again and is sent to an adsorption tower for extracting hydrogen; the solid dust separated by the cyclone separator and the rinsing dust removing tower forms solution with water; a ceramic membrane device is utilized to carry out liquid and solid separation; the solid dust is sent to a power plant to be served as raw materials; and water enters therinsing tower for recycling. The invention has reasonable process design and high economic efficiency, can be used in combination or separately, and can be directly used in the processes for producing hydrogen chloride, acetylene ethane derivative, methanol and the derivatives and the like.

Owner:XINJIANG TIANYE GRP

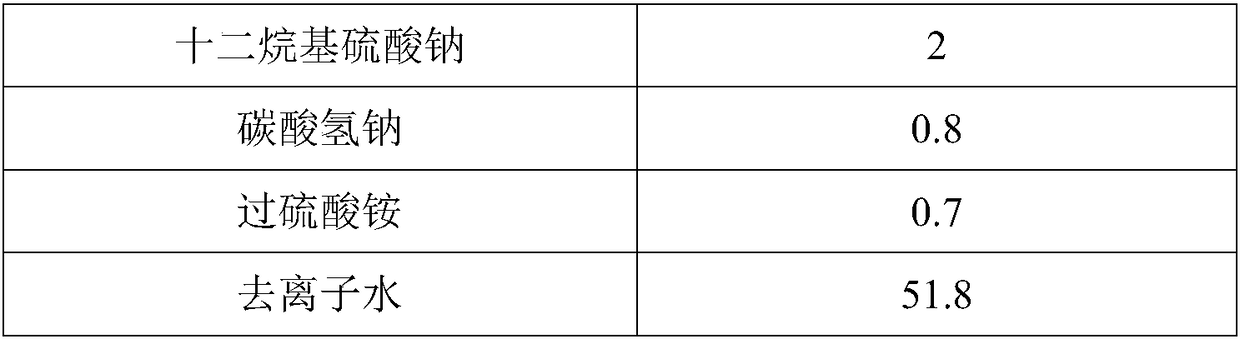

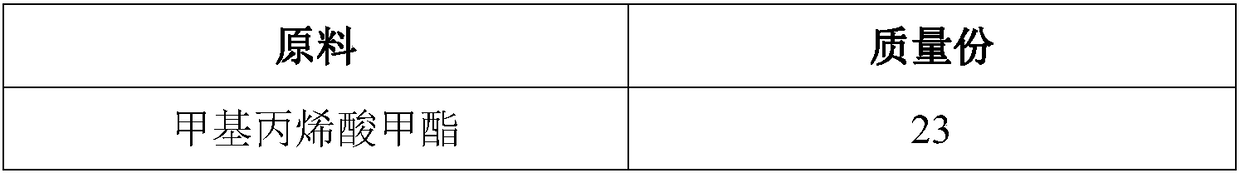

Emulsion with core-shell structure and environment-friendly interior wall coating containing emulsion

InactiveCN108484834AGood low temperature film formingImprove stain resistanceAntifouling/underwater paintsPaints with biocidesLatex particleDefoaming Agents

The invention discloses an emulsion with a core-shell structure and an environment-friendly interior wall coating containing the emulsion. The emulsion with the core-shell structure is obtained by semi-continuous polymerization of methyl methacrylate, styrene, butyl acrylate and methacrylic acid, wherein the environment-friendly interior wall coating consists of the emulsion with the core-shell structure, titanium white powder, a filler, a dispersing agent, a wetting agent, a defoaming agent, a thickening agent, a bactericide, a mildew inhibitor, a pH regulator and water. The latex particles in the emulsion with the core-shell structure provided by the invention have a soft-shell hard-core structure, wherein soft shells can ensure that the prepared coating product also has excellent low-temperature film forming property without the addition of a film-forming auxiliary agent, and hard cores can ensure that the prepared coating product has high hardness after film formation of the coating product, does not turn soft or sticky at a high temperature, and still has the basic properties of excellent stain resistance, washing resistance and the like. The environment-friendly interior wallcoating provided by the invention does not contain volatile organic compounds (VOC), is safe and environmentally friendly, and has high hardness and excellent stain resistance and washing resistanceafter the film formation.

Owner:NIPPON PAINT GUANGZHOU

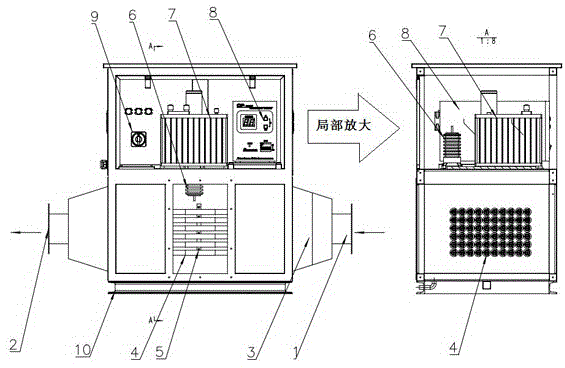

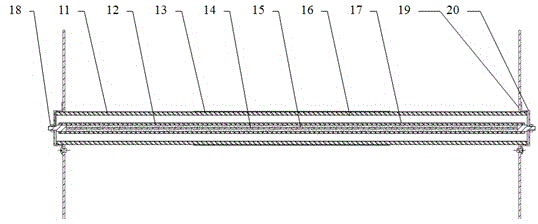

High-flow low-temperature plasma industrial waste gas treatment device

ActiveCN104437019ASimple designReduce equipment costsDispersed particle separationIndustrial wasteInductor

The invention discloses a high-flow low-temperature plasma industrial waste gas treatment device. The device comprises a treatment device tank body arranged on a base and a gas inlet and a gas outlet which are formed on two sides of the treatment device tank body, the treatment device tank body comprises a treatment device circuit control part and a treatment device gas treatment part, wherein the treatment device circuit control part comprises a high voltage through-wall wiring china bottle, a high voltage pulse power supply, a boosting transformer and a matching inductor which are mutually connected with each other, a modulating pulse power supply and a power supply switch control panel; to-be-treated industrial waste gas enters from the gas inlet at the treatment device gas treatment part, and then is discharged from the gas outlet after orderly passing through a gas inlet flow-evening plate and a DBD electrode group. Multi-group co-axial type DBD electrodes can be driven through a single power supply, the driving number can be dozens to hundreds groups of co-axial DBD electrodes, and each electrode can produce uniform discharging, and can produce uniform discharging under small driving power.

Owner:NANJING SUMAN PLASMA TECH CO LTD

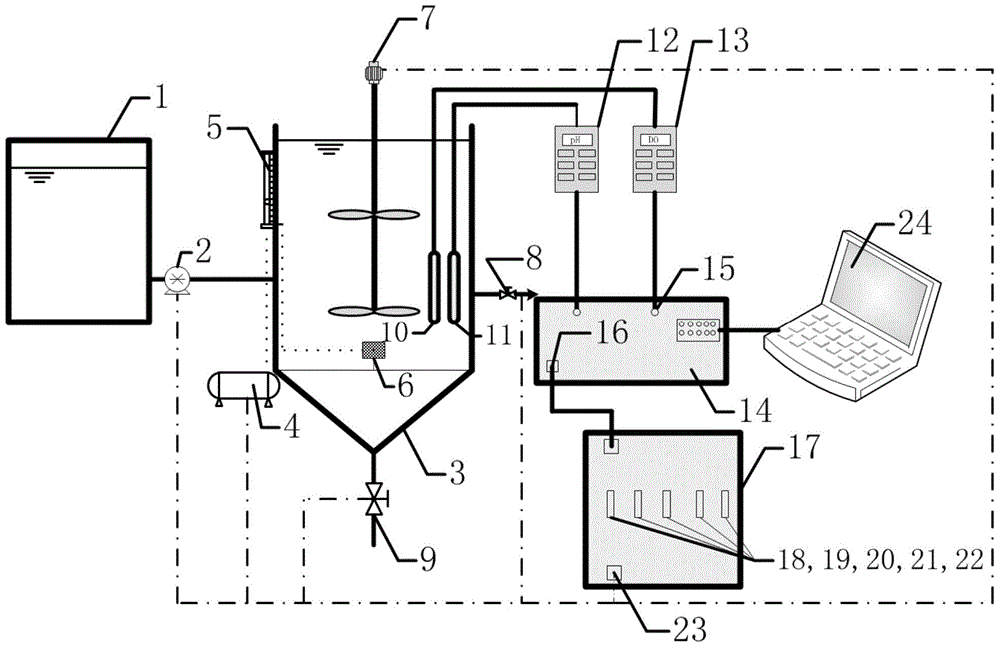

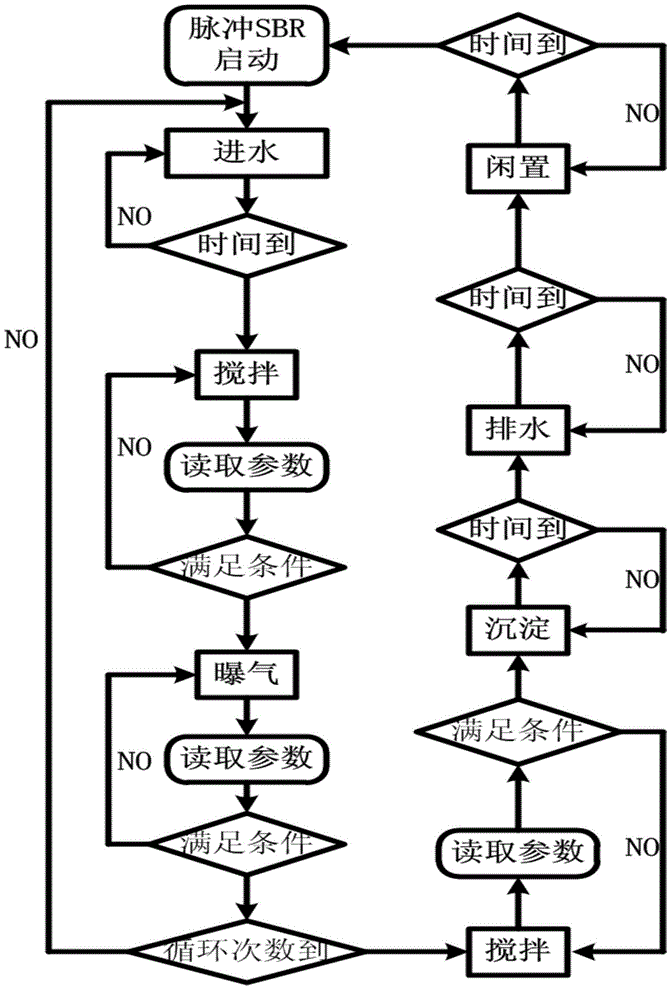

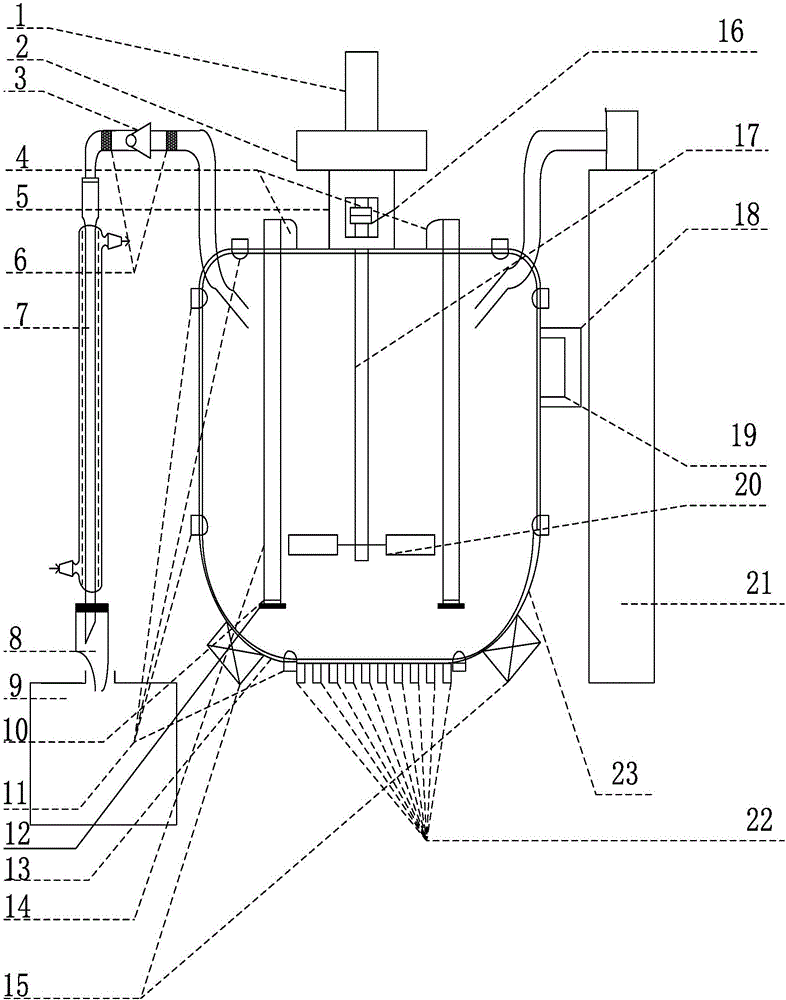

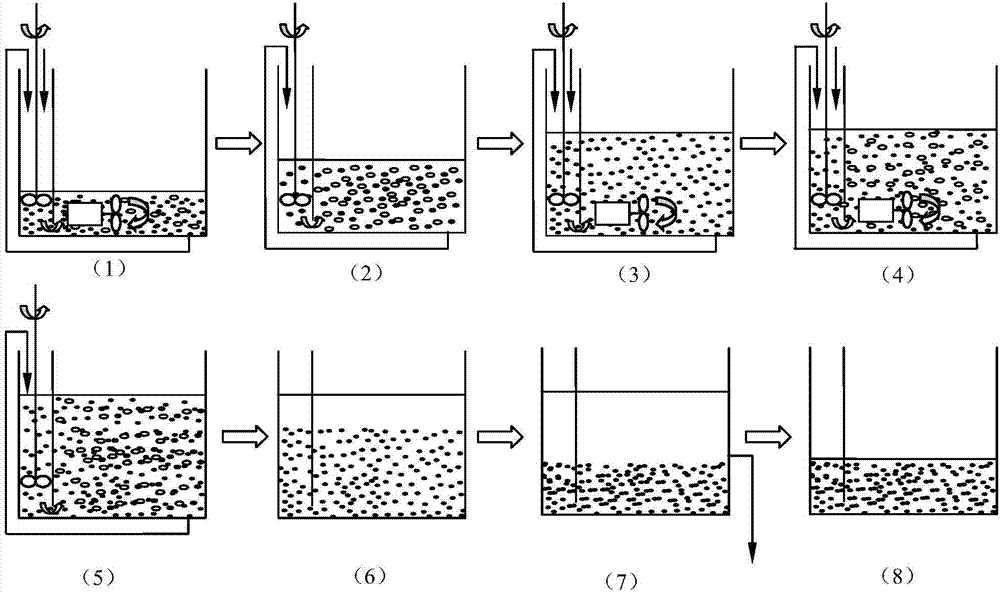

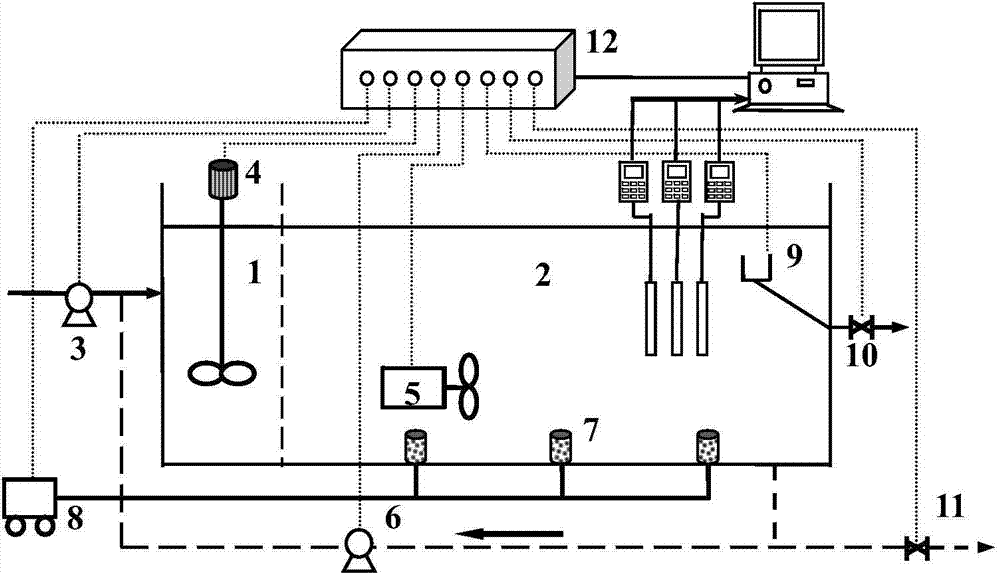

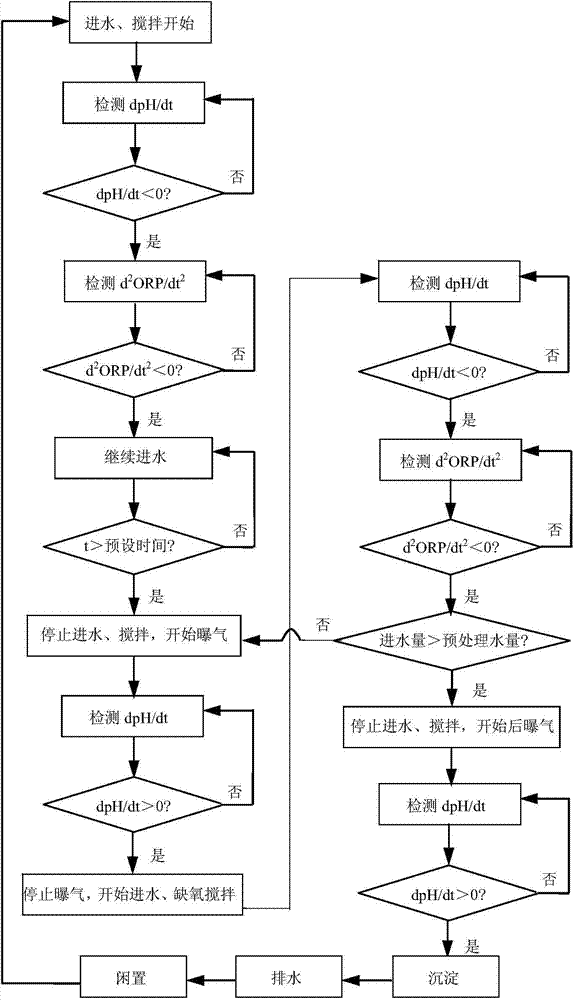

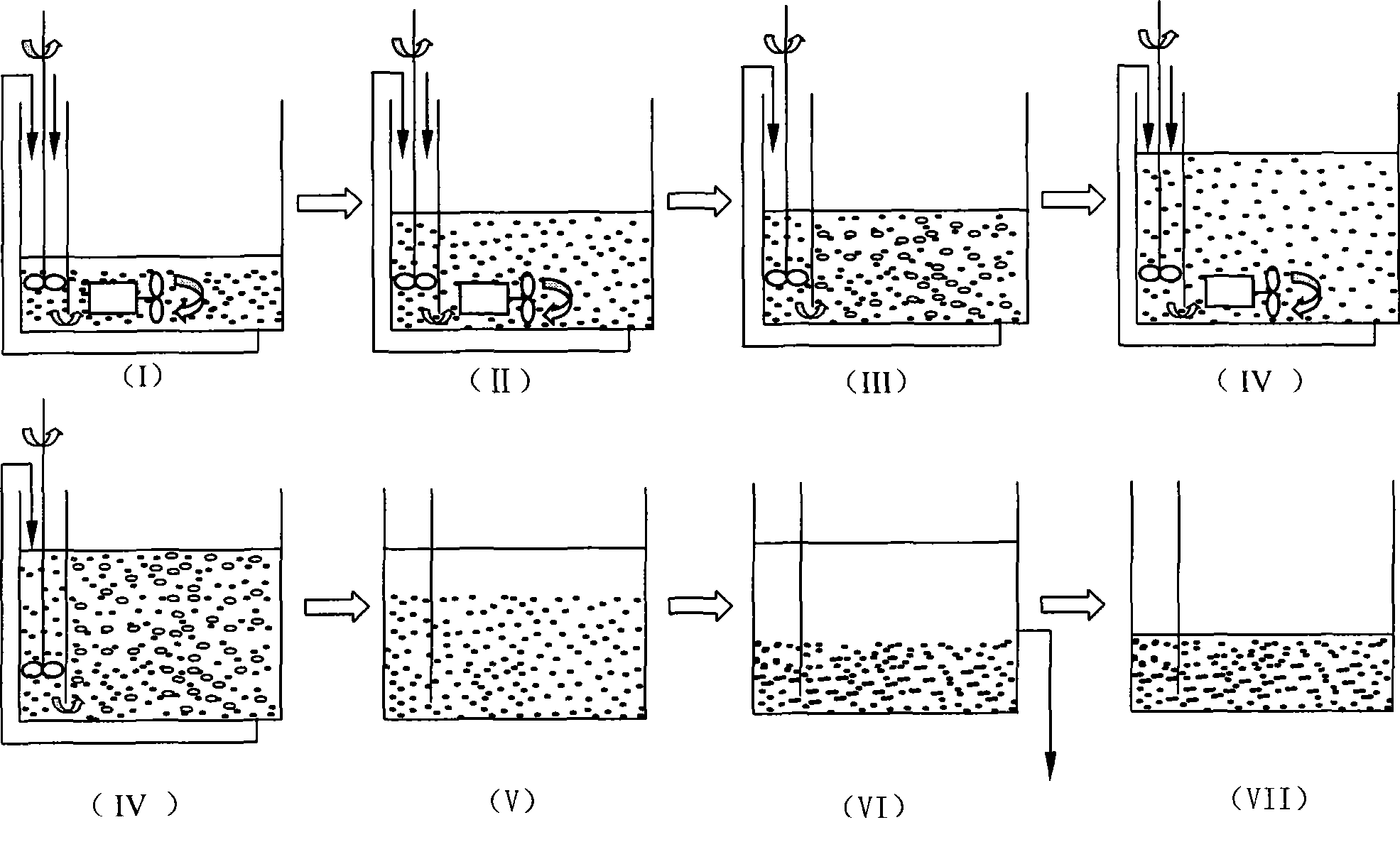

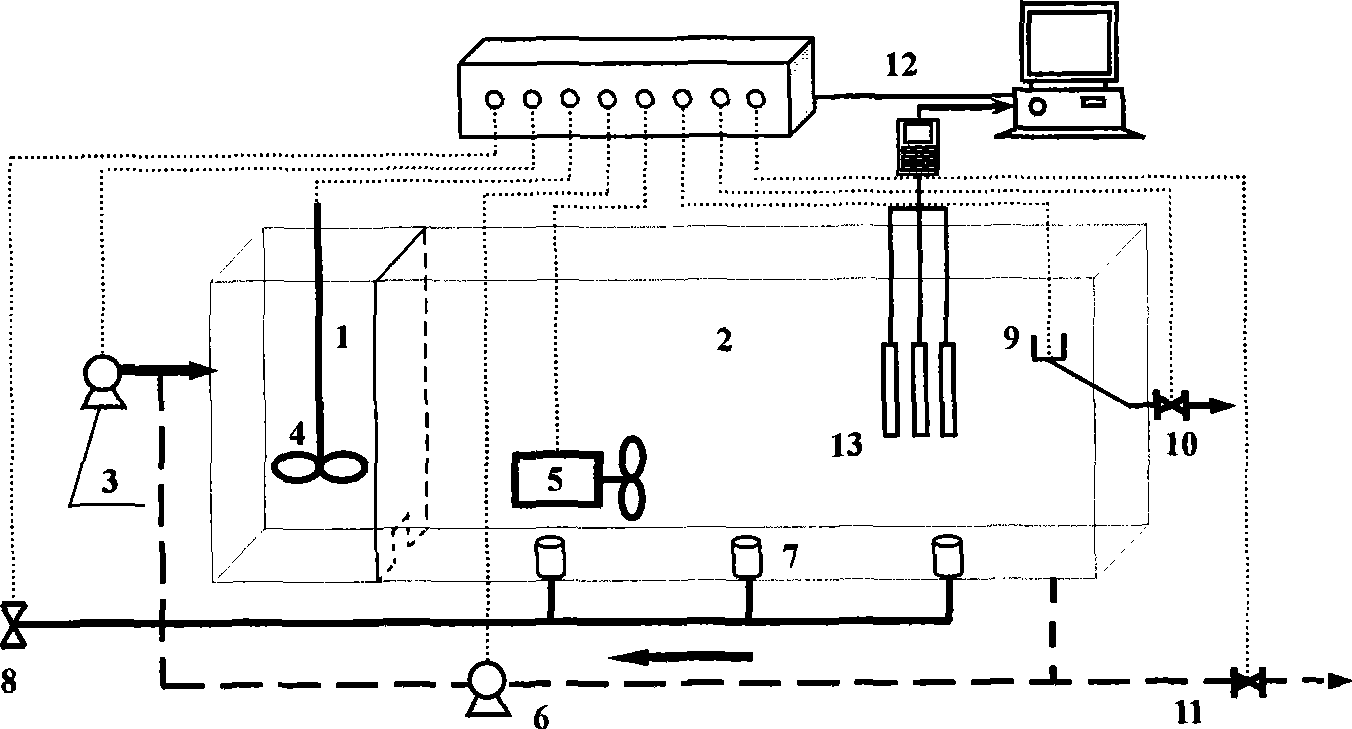

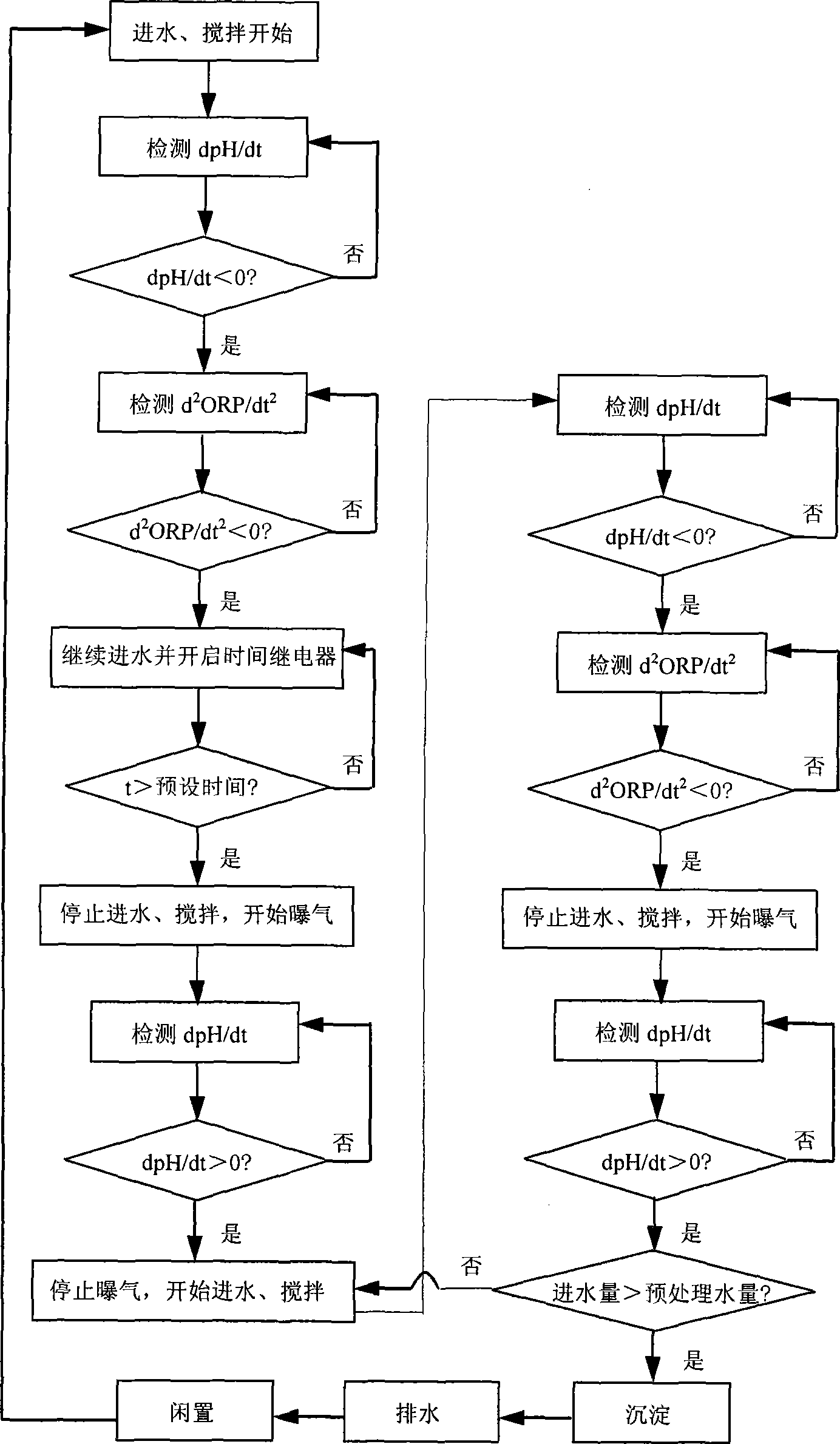

Device and method for treating urban sewage through repeated-water-inlet SBR by fully utilizing carbon source in raw water

ActiveCN105036334AImprove denitrification effectLow costTreatment with aerobic and anaerobic processesSequencing batch reactorTotal nitrogen

The invention discloses a device and a method for treating urban sewage through a repeated-water-inlet SBR by fully utilizing a carbon source in raw water, and belongs to the field of biological sewage treatment through a biochemical method. The device comprises a raw water box, a sequencing batch reactor (SBR) and a computer. The method comprises the following steps: feeding urban sewage into the SBR, and then performing stirring and aeration; repeating the stirring and aeration for 2-3 times; after the final aeration is finished, continuously performing stirring, precipitating and water discharging. In the stirring processes, the pH values of denitrification ending points are monitored in a real-time time, and in the aeration processes, the DO and pH values of shortcut nitrification ending points are monitored in a real-time manner. The carbon source in the raw water is fully utilized for denitrification, one part of organic matters in the raw water is directly utilized, and the other part of organic matters is stored into sludge to be used as an internal carbon source to be utilized by the denitrification reaction in the final stirring process. The anoxic denitrification time and the aerobiotic aeration time can be accurately controlled, the utilization rate of the carbon source in the raw water and the total nitrogen removal rate are improved, and the energy consumption is reduced.

Owner:BEIJING UNIV OF TECH

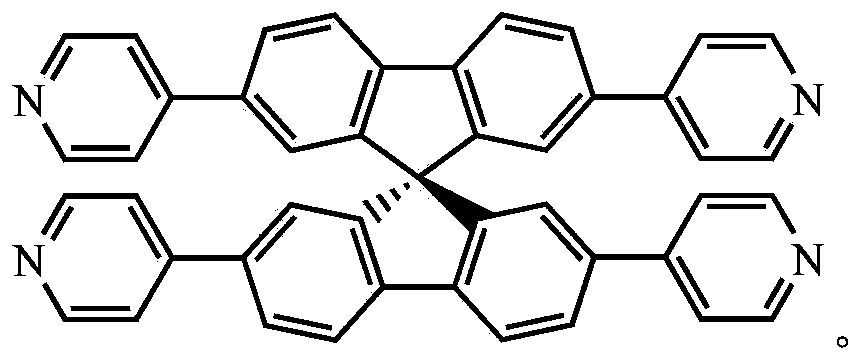

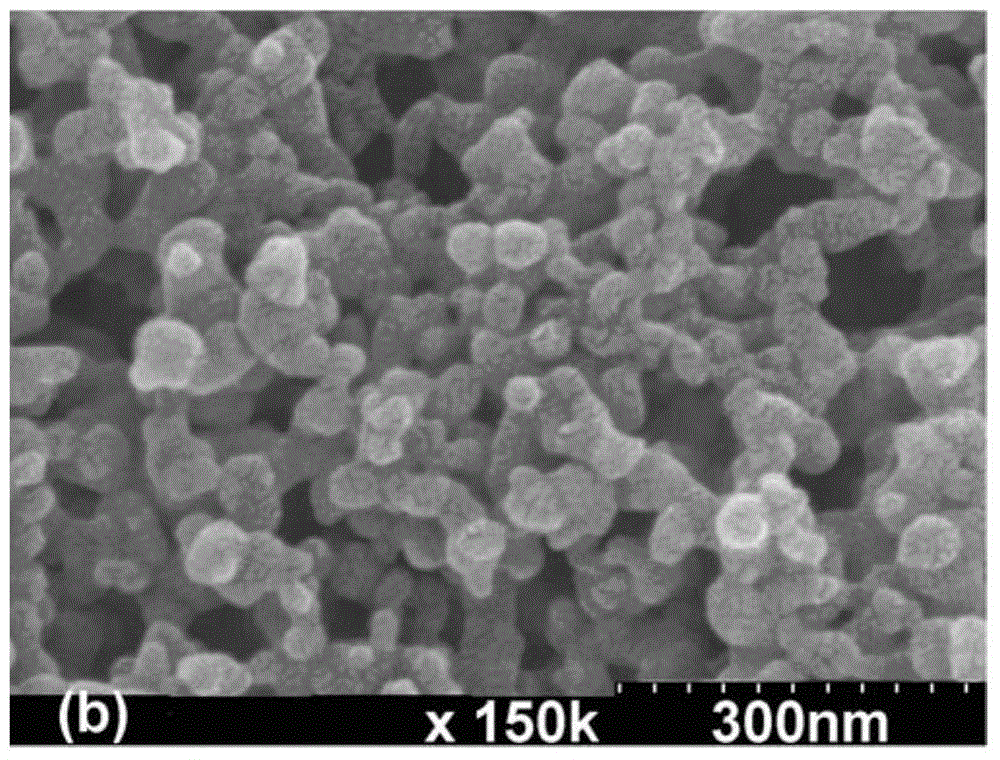

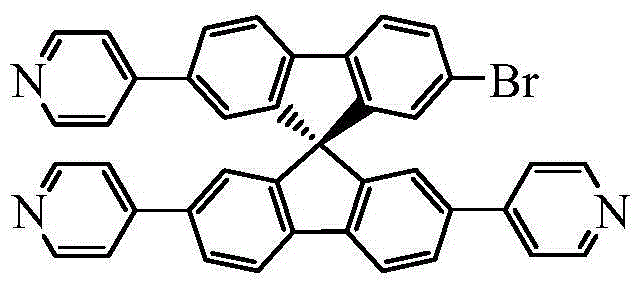

Spirofluorene copper pyridine micro-nano particle and preparation method thereof

InactiveCN103396356ALow priceStrong delocalizationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMicro nanoNitrogen

The invention discloses a spirofluorene copper pyridine micro-nano particle and a preparation method thereof. The preparation method of the spirofluorene copper pyridine micro-nano particle comprises the following steps of: adding a certain amount of metal salt solution into organic ligand containing end-ground nitrogen atoms; stirring for 0.5-10 hours at a certain temperature; ageing for 1-10 hours, centrifugally separating, washing and drying to obtain the corresponding metal-ligand micro-nano particle. Moreover, the application of the micro-nano particle in C-C (Carbon-Carbon) coupling reaction is successfully researched. The preparation method disclosed by the invention can be used for preparing different metal-ligand micro-nano particles, and can be used for effectively adjusting the size of the particle diameter and the surface smoothness to obtain sheet metal-ligand micro-nano particles which are uniform in particle diameter, different in surface smoothness and excellent in physical and chemical performances. According to the catalysis experiment, the metal-ligand micro-nano particle which is prepared by the method disclosed by the invention has good catalytic activity when being used as a catalyst, and has a wide application prospect in the catalytic field. In the whole preparation process, the operation is simple, the material cost is low and the device investment is less, therefore, the spirofluorene copper pyridine micro-nano particle is suitable for large-scale production.

Owner:NINGBO UNIV

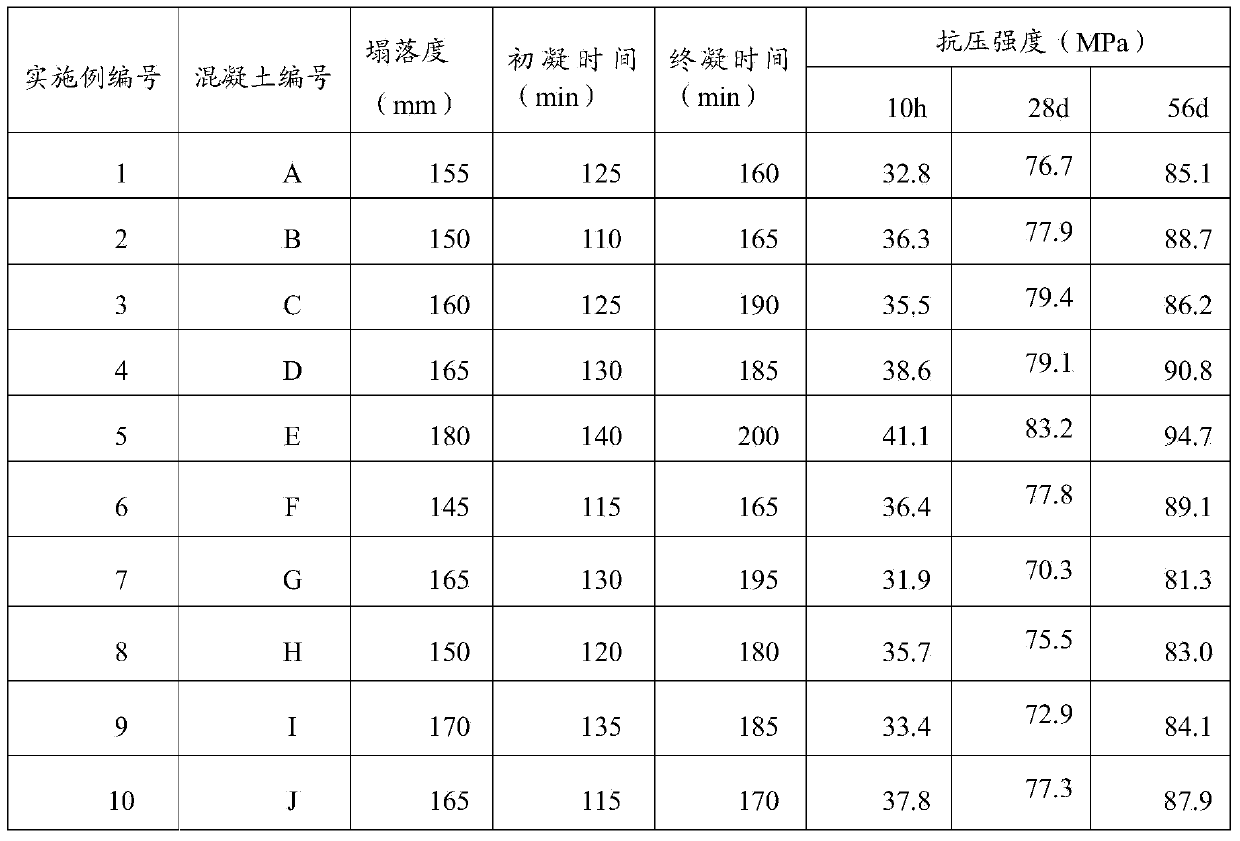

Early strength concrete and preparation method thereof

The invention provides early strength concrete and a preparation method thereof and belongs to the technical field of concrete engineering. The early strength concrete is prepared from the following raw materials: a gelling material, aggregate, a compound additive and water, wherein the gelling material comprises ordinary portland cement, glass powder and silica fume; the aggregate comprises stones and sand; the compound additive comprises triethanolamine, sodium hydroxide and a polycarboxylate superplasticizer. The preparation method of the early strength concrete comprises the following steps: uniformly stirring a gelling material with sodium hydroxide to obtain a mixture, wherein the gelling material comprises cement, glass powder and silica fume; adding the stones and the sand into the mixture, and uniformly stirring; sequentially adding triethanolamine, a superplasticizer and water into the uniformly stirred material, and uniformly stirring, thereby preparing the early strength concrete. The early strength concrete prepared by adopting the preparation method has the advantages of short curing time and high early strength.

Owner:北京中联新航建材有限公司

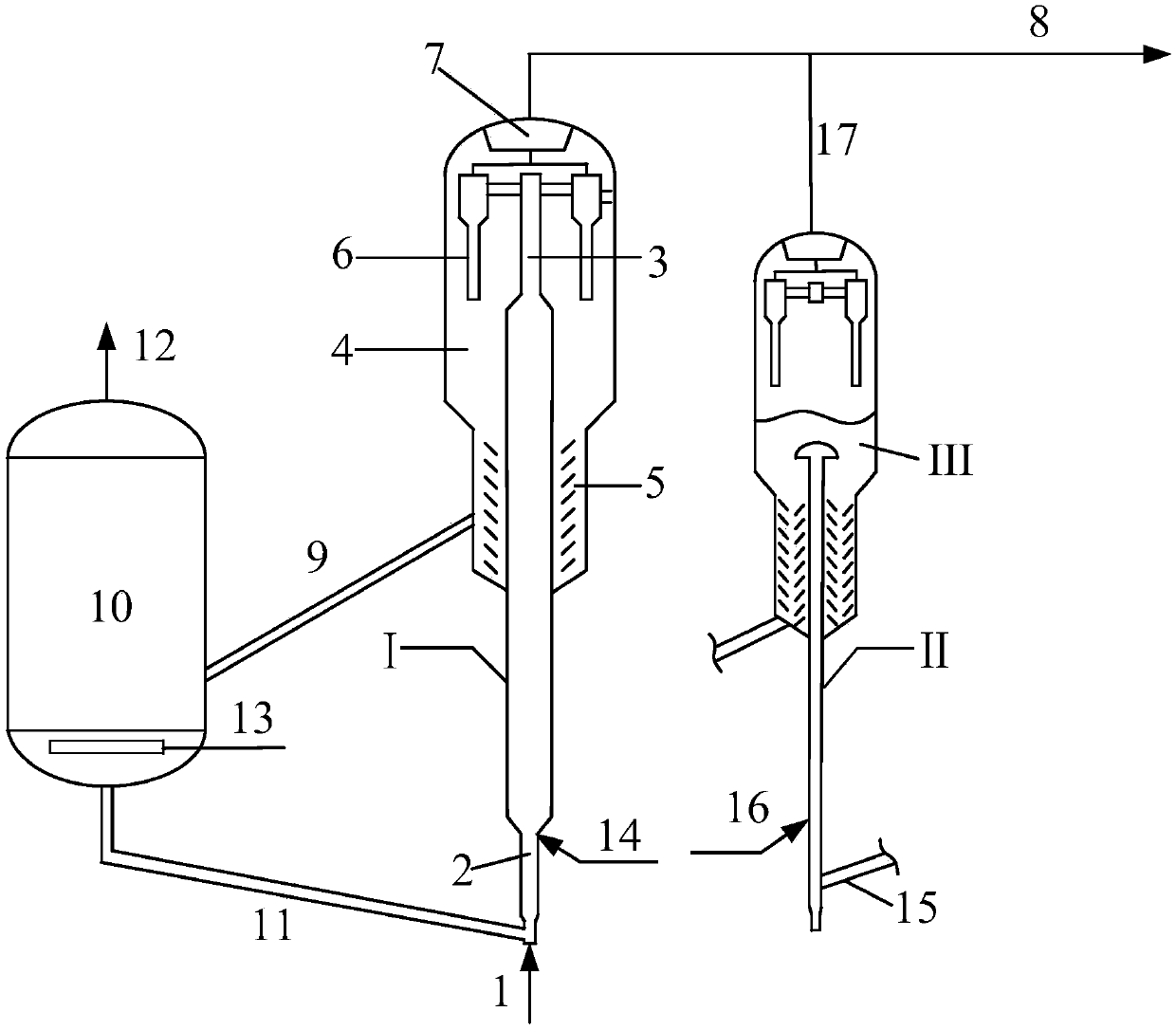

Catalytic cracking method and system for producing propylene and light aromatic hydrocarbons

ActiveCN110724561AHigh densityHigh yieldTreatment with plural serial cracking stages onlyCatalytic crackingPtru catalystFluidized bed

The invention relates to a catalytic cracking method and system for producing propylene and light aromatic hydrocarbons. The method comprises the following steps that light raw material oil is introduced into adilute phase conveying bed from the lower part of the dilute phase conveying bed to be contacted with a first catalytic cracking catalyst and to be subjected to first catalytic cracking reaction from bottom to top to obtain a first reaction product and a semi-spent catalyst; the obtained first reaction product and the semi-spent catalyst are fed into a dense-phase fluidized bed to continue to be subjected to a second catalytic cracking reaction to obtain a second reaction product and a first spent catalyst; and preheated inferior heavy oil is introduced into a fast fluidized bed fromthe lower part of the fast fluidized bed to be contacted with a second catalytic cracking catalyst and to be subjected to a third catalytic cracking reaction from bottom to top to obtain a third reaction product and a second spent catalyst. By virtue of the catalytic crackingmethod and system, the yield of propylene and light aromatic hydrocarbons is high, and the yield of coke and dry gas is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

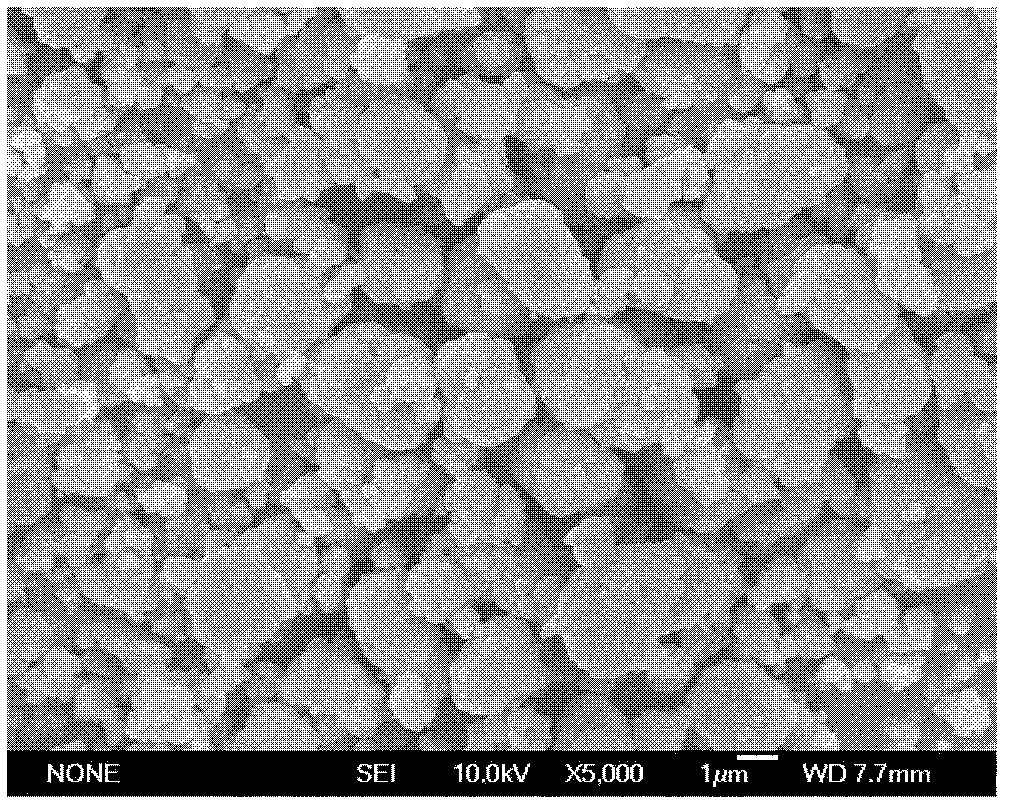

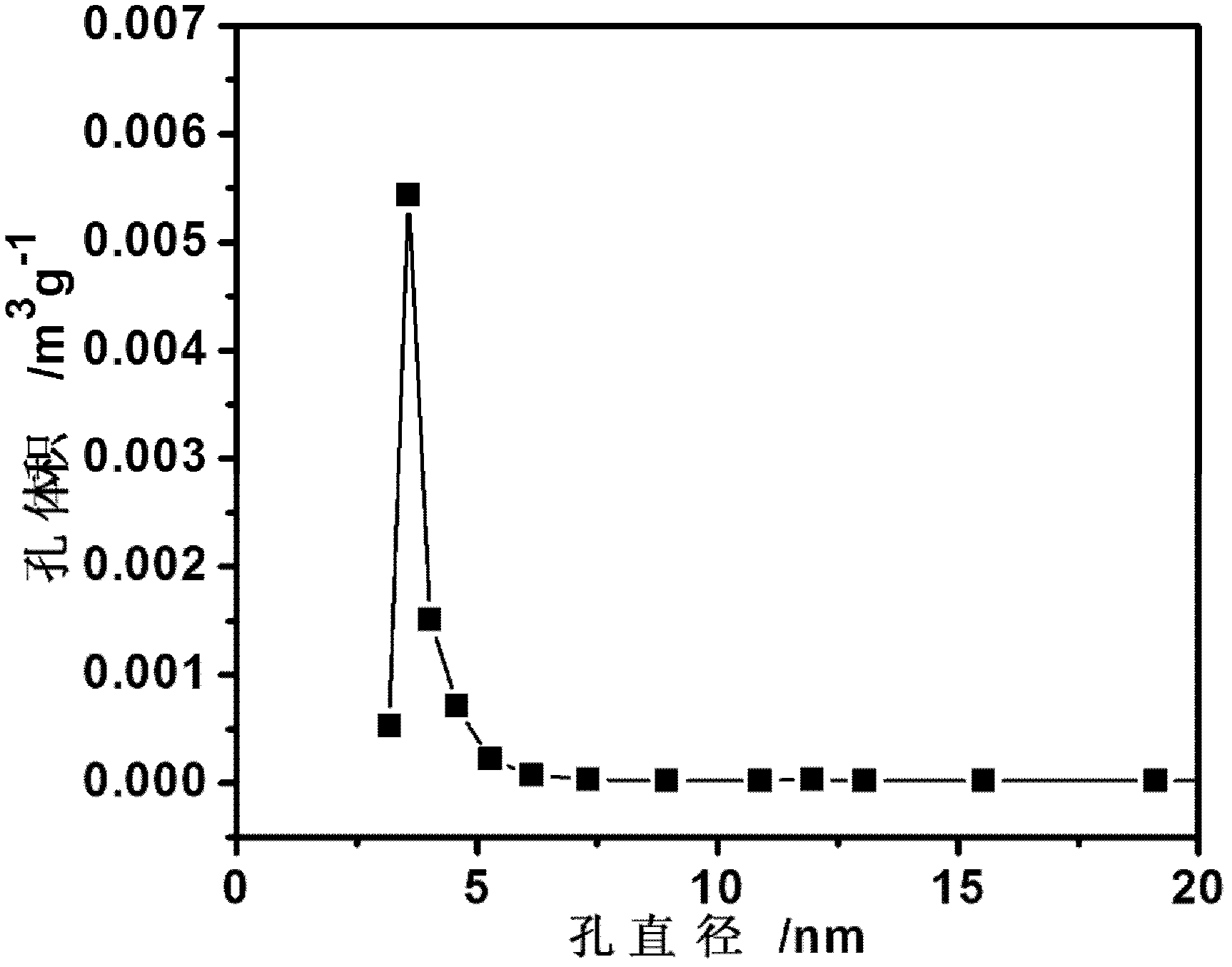

Carbon-coated mesoporous lithium titanate anode material of lithium ion battery and method for preparing carbon-coated mesoporous lithium titanate anode material

ActiveCN102544468APromote hydrolysisPromote migrationCell electrodesTitanium compoundsElectrical batteryPhysical chemistry

The invention discloses a carbon-coated mesoporous lithium titanate anode material of a lithium ion battery and a method for preparing the carbon-coated mesoporous lithium titanate anode material. A particle aggregate with the diameter of 0.1 to 10 mu m is formed by self-assembling nano-crystals with the diameter of 5 to 150 nm. The material has a mesoporous structure, the average pore diameter of the material is 2 to 6 nm, and the carbon content of the material is 0.5 to 5 percent. A lithium titanate sample can serve as an anode material of the lithium ion battery.

Owner:重庆中纳科技有限公司

Cell viability detection kit and preparation method and application thereof

InactiveCN101551382AExtended storage timeControl reaction timeColor/spectral properties measurementsBiological testingDiluentViable Cell Count

The invention relates to a cell viability detection kit and a preparation method and an application thereof. The invention is applicable to live cell counting, and is a determining method for directly detecting the cell proliferation, and is also a detection method for estimating the cell totoxicity of the drugs, peptide growth factors and other substances, and is applicable to detect the suspended cell and the anchorage-dependent cell cultured in the cell culture plates. The invention consists of a WST-8 mixed solution storage solution, a reaction stop solution and a buffer diluent solution, wherein the WST-8 mixed solution storage solution contains 50mmol / L WST-8 solution, 2mmol / L PMS and 1mmol / L PIPES buffer solution; the reaction stop solution is 10%(W / V) sodium dodecyl sulfate; and the buffer diluent solution is 1mmol / L PIPES solution.

Owner:ZHENJIANG XUANGUANG BIOCHEM

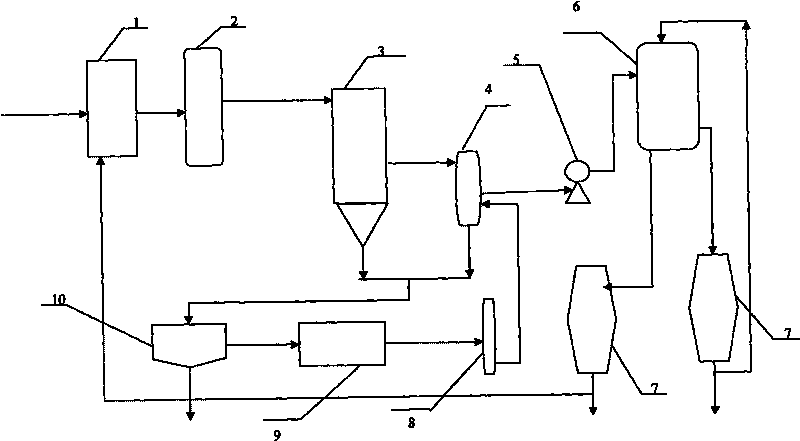

Production process of melamine-formaldehyde resin foam sponge

The invention discloses a production process of melamine-formaldehyde resin foam sponge. The production process comprises the following steps: melamine and paraformaldehyde are taken and mixed evenly; the mixed material is conveyed into a first screw machine by a material pump, and lye is added at a feed inlet of the first screw machine; an auxiliary material solution is added to the feed end, the middle position or the tail end of the first screw machine; transparent resin extruded from an outlet of the first screw machine enters a second screw machine to be subjected to a polymerization reaction continuously in the second screw machine; the transparent resin discharged out of the tail of the second screw machine enters a third screw machine after passing through a cooling device; a foaming agent, an emulsifier, a stabilizer and a curing agent are fed from the middle of the third screw machine and mixed with the resin uniformly; the resin mixed uniformly is introduced into a microwave foaming furnace for foaming, and the melamine-formaldehyde resin foam sponge with high aperture ratio is formed. The production process of the melamine-formaldehyde resin foam sponge has high utilization rate and high yield, the melamine-formaldehyde resin foam sponge with stable production quality can be produced continuously, and the aperture ratio is high.

Owner:郑州峰泰纳米材料有限公司

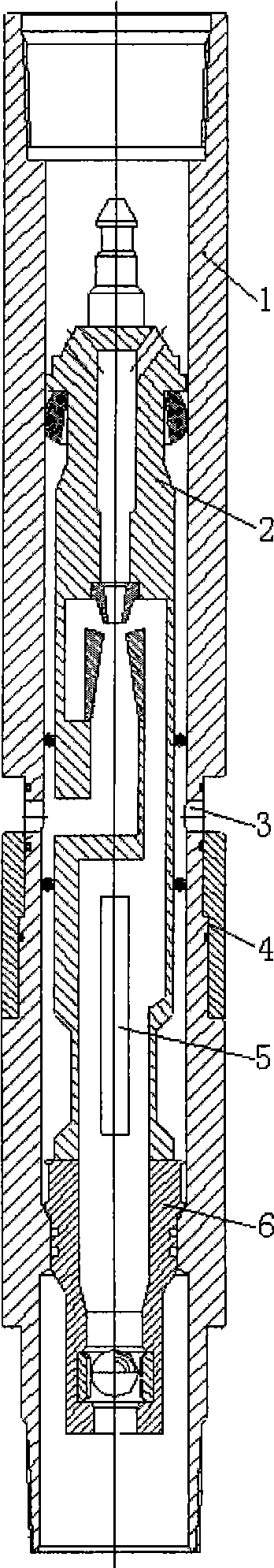

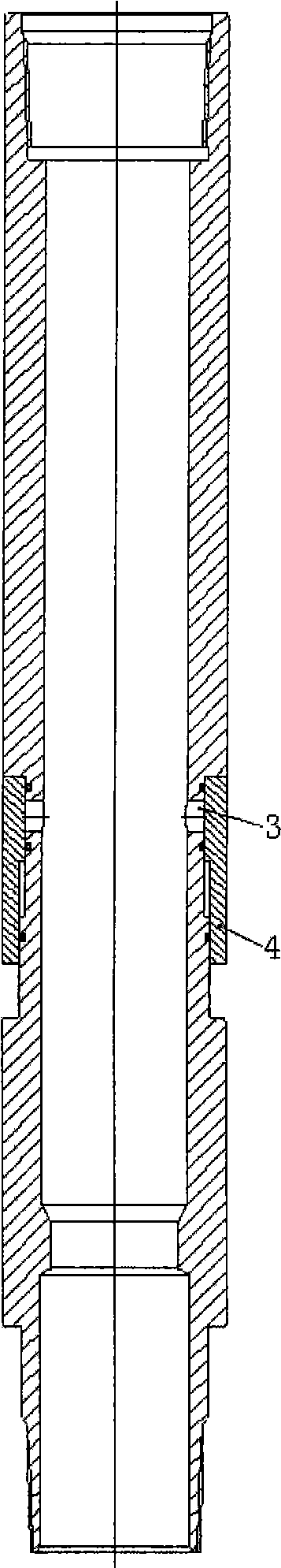

Multifunctional combination operation process and device for injection pump unit

ActiveCN101519954AReduce labor intensityShorten construction timeSurveyFlexible member pumpsSleeve valveFracturing fluid

The invention relates to a multifunctional combination operation process and a device for an injection pump unit. The process comprises the following steps: A, driving a pipe column into a well; B, acidifying, fracturing, testing discharged fluid and cleaning a pipe; and C, carrying out oil extraction or water injection production. The step B comprises the following processes: driving a pipe cleaning column into the well, cleaning the pipe at a seat seal position of a packer, and pulling out the pipe cleaning column; driving a multifunctional combination operation process device for the injection pump unit into the well; feeding prepad fluid or fracturing fluid into the well by an oil pipe, and closing a sleeve valve so that the fluid enters a target layer through a flow passage when the pressure of the oil pipe is more than the pressure of the sleeve; closing the well to react; opening the well, and emptying the discharged fluid from the oil pipe until the pressure at a wellhead is zero and no overflow is generated; pressing by reverse circulation so that the pressure of the sleeve is 15MPa higher than oil pressure, and communicating the empty flow passage of an oil lantern ring; cleaning the well in a reverse circulation mode by clear water; testing the discharged fluid, namely, feeding a fixed valve and a sinking pump into a working cylinder from the wellhead, solving the yield of the discharged fluid and testing the pressure of strata; and stopping pump drainage after the fluid is drained for 30 minutes. The device comprises the working cylinder outside which a sliding sleeve is arranged and inside which the sinking pump and the fixed valve are arranged, and a pressure gauge is arranged in the sinking pump.

Owner:胜利油田胜利泵业有限责任公司

Method for performing aldol condensation reaction in micro-channel reactor

InactiveCN108191592AAvoid contactToxicOrganic compound preparationOrganic chemistry methodsEquivalence ratioKetone

The invention relates to a method for performing an aldol condensation reaction in a micro-channel reactor. The aldol condensation reaction is performed in the micro-channel reactor under the action of a catalyst at 60 to 170 DEG C and 0 to 5 MPa in the situation that alpha-H aldehyde ketone and other aldoketones in molecules are in the molar ratio of 0.8-1.2:1. According to the aldol condensationreaction involved in a process provided by the invention, the reaction time is shortened by thousands of times; the raw material conversion rate and the product selectivity are improved by 15 percentat least. The process provided by the invention can realize instantaneous uniform mixing; the equivalence ratio of materials in a reaction process is reduced; the using amount of a catalyst in a reaction process is reduced; Cannizzaro side reactions and polymerization reactions are reduced. The process provided by the invention also reduces the use of some additional solvents so as to reduce theproduction cost; the process provided by the invention also improves the safety of a reaction process, so that the types of reactions are safer and more environment-friendly; meanwhile, the micro-channel reactor used by the process provided by the invention is small in occupied area and high in capacity, so that the production efficiency and the production capacity are greatly improved.

Owner:DALIAN WONDERSUN BIOCHEM TECH

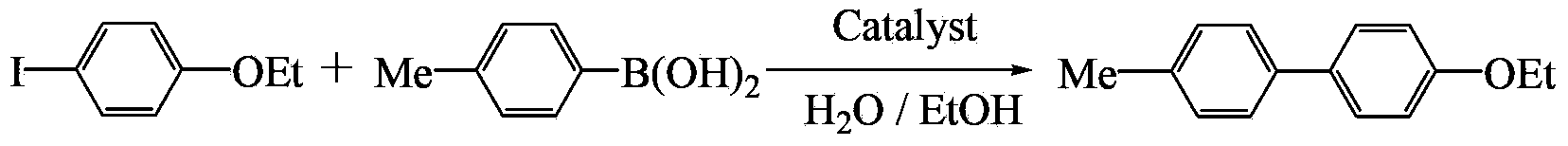

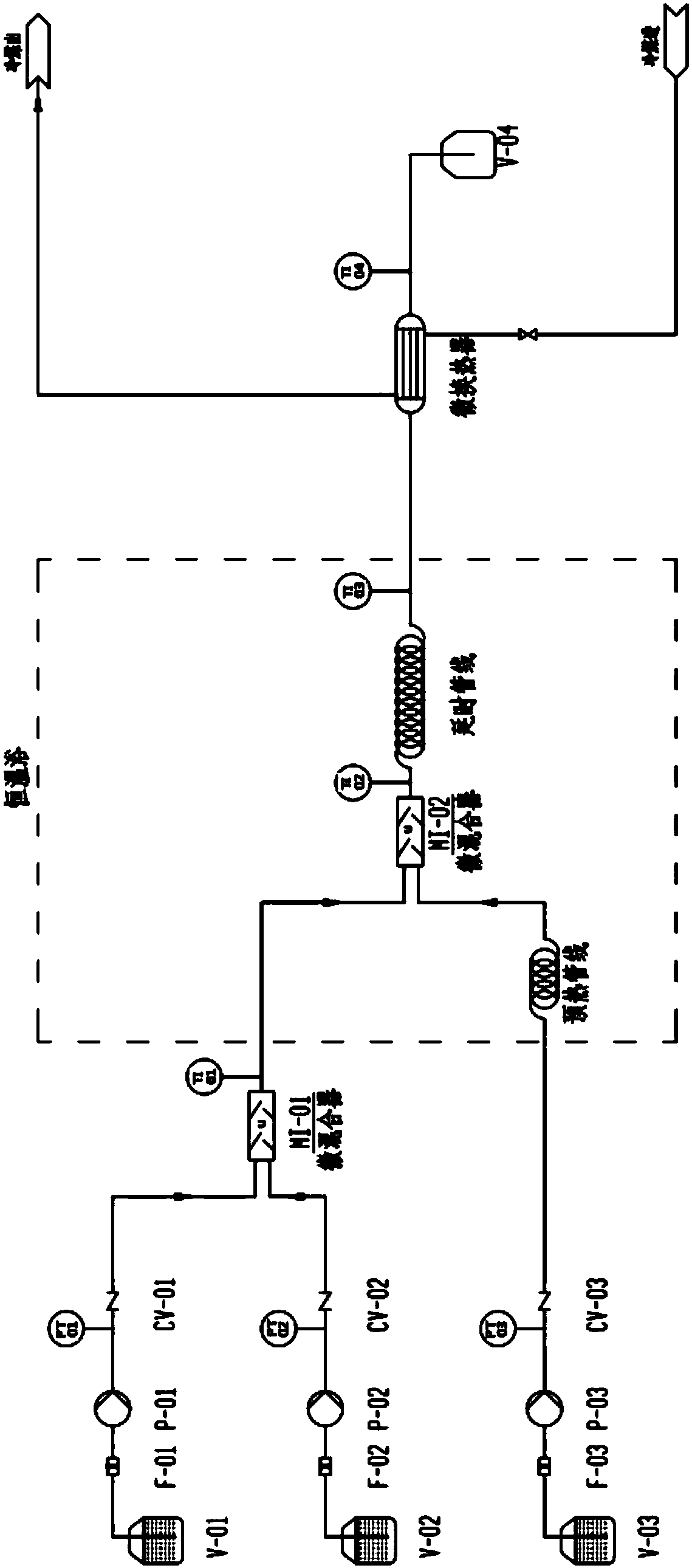

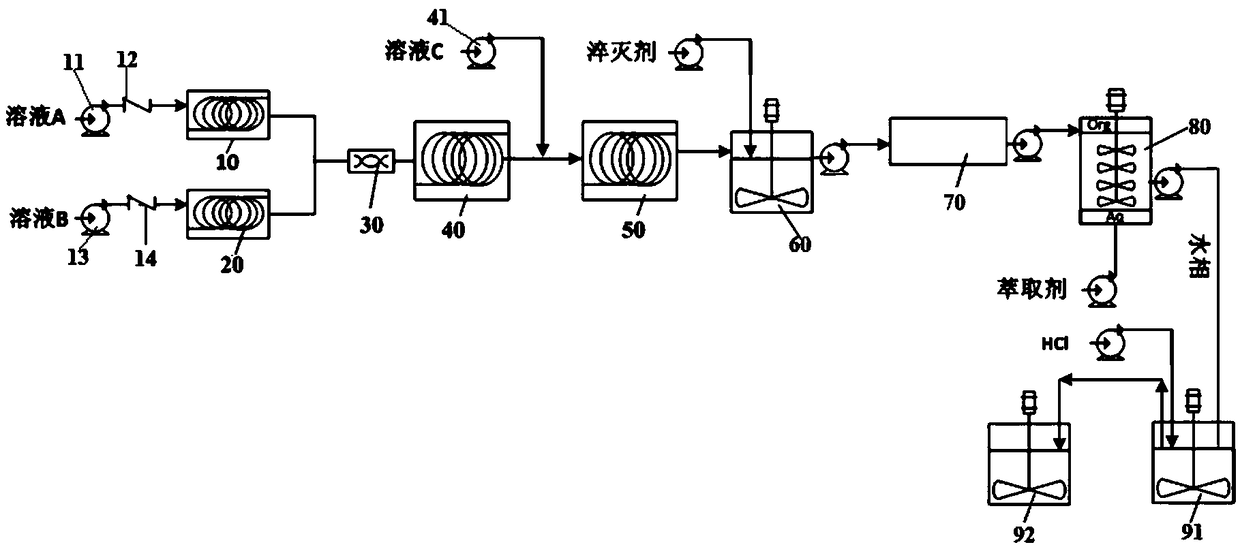

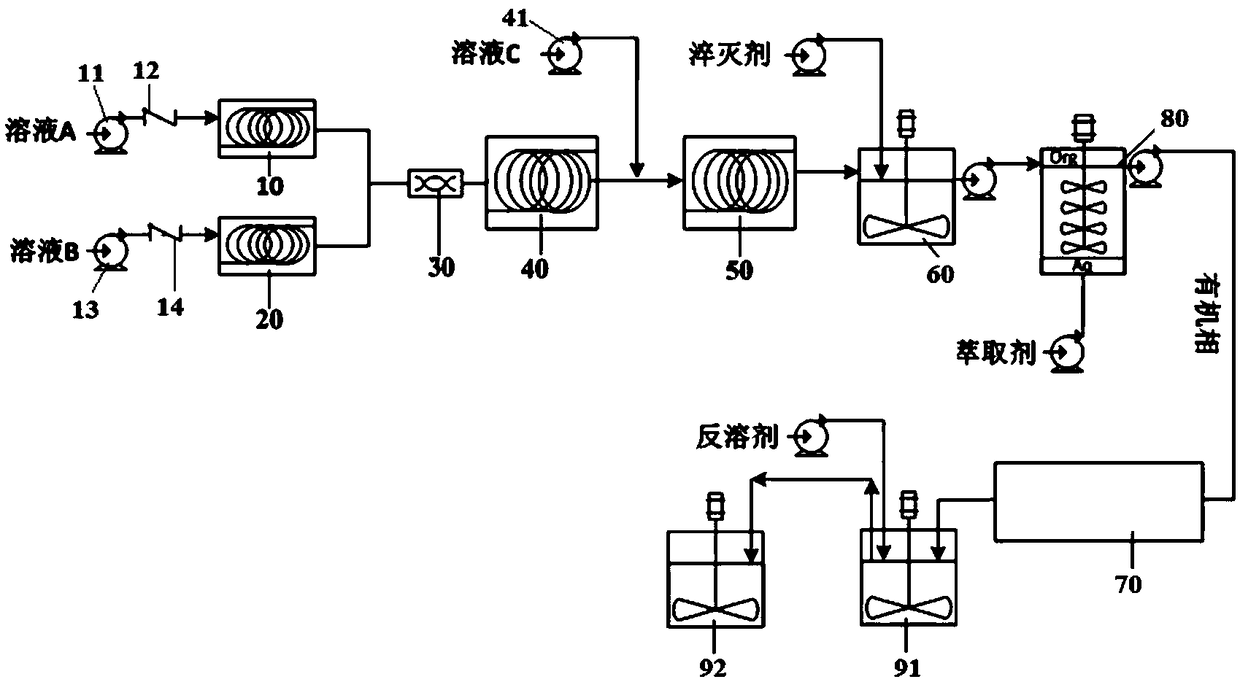

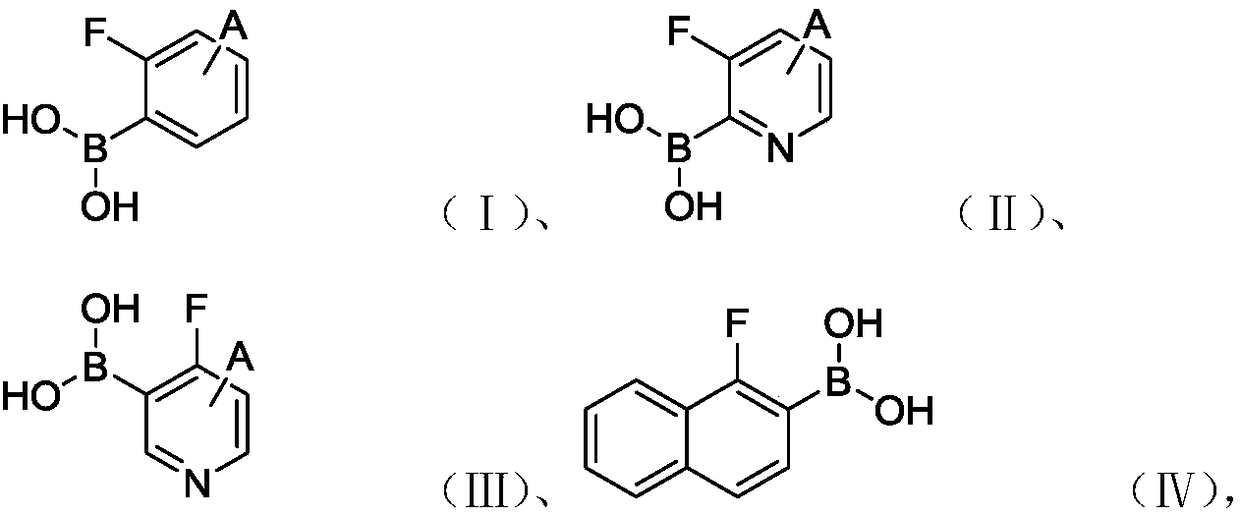

Continuous synthetic method for 2-fluorophenylboronic acid compound

ActiveCN109134521AReduce productionLow costGroup 3/13 element organic compoundsLithiumOrganic solvent

The invention provides a continuous synthetic method for a 2-fluorophenylboronic acid compound. The continuous synthetic method comprises the following steps: carrying out continuous lithiation reactions on a fluorobenzene compound, a first organic solvent and an alkyl lithium reagent in a first continuous reaction device to obtain a lithiated product; and carrying out boric acid reactions on thelithiated product and alkyl borate in a second continuous reaction device to obtain the 2-fluorophenylboronic acid compound. The fluorophenylboronic acid compound is prepared by taking fluorophenylboronic and derivatives thereof as raw materials which are easily available and quite cheap, so that the synthetic method is suitable for amplified production. In the whole synthetic process, a continuous synthetic process is adopted, and the reaction times in stages can be controlled precisely, so that the reaction time of the lithiation stage is controlled and the output of impurities is reduced favorably, and therefore, the purity and yield of the 2-fluorophenylboronic acid compound are improved. In a word, the continuous synthetic method for the 2-fluorophenylboronic acid compound provided bythe invention has the advantages of being low in cost, high in yield and the like.

Owner:天津凯诺医药科技发展有限公司

Method for preparing calcium carbonate in different grain sizes

InactiveCN103172100AIncrease profitIncrease valueCalcium/strontium/barium carbonatesRetention timeReaction temperature

The invention relates to a method for preparing calcium carbonate in different grain sizes by utilizing alkaline wastes. The method comprises the steps of mixing the alkaline wastes with a certain weight of water, then adding ammonium chloride solution to dissolve the product to prepare calcium chloride solution and introducing CO2 to generate calcium carbonate precipitates. According to the method, in a special tubular reactor, the reaction time for absorbing carbon dioxide by the alkaline wastes and the retention time of the products in the reactor is controlled by adjusting the fluid flow rate and the reaction temperature is also controlled, so as to prepare calcium carbonate in different grain sizes. The method has the beneficial effects that the process is simple; new byproducts are not generated; the ammonium chloride solution can be recycled; and the method is a new economical and environment-friendly process.

Owner:杨晓林

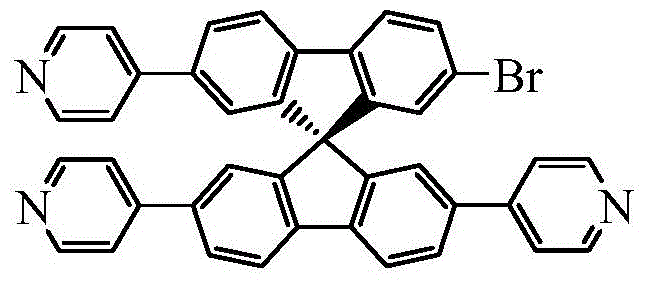

Spirofluorene pyridine palladium nanoparticles and preparation method thereof

ActiveCN103951611AStrong delocalizationAsymmetricalCarboxylic acid nitrile preparationOrganic compound preparationFunctionalized nanoparticlesReaction temperature

The invention discloses a spirofluorene pyridine palladium nanoparticles and a preparation method thereof. The method is as below: adding a certain amount of metal salt solution into the organic ligand containing pyridine units, stirring for 1-3 h at a certain temperature, aging for 3-5 h, conducting centrifugal separation, washing and drying to obtain corresponding metal-ligand nanoparticles. The preparation process is simple, low in cost and suitable for mass production; and by using different solvents, controlling the amount of reactants, reaction time and temperature, the method achieves effective regulation on particle size and dispersion of spirofluorene pyridine palladium nanoparticles. The prepared spirofluorene pyridine palladium nanoparticles are functionalized nanoparticles containing palladium, have stable performance, can be used for the catalysis of C-C bond coupling reaction, and have high catalytic efficiency and yield reaching 90-99%. Therefore, the spirofluorene pyridine palladium nanoparticles have broad application prospects in the field of catalysis.

Owner:铜陵市清华宝能源设备有限责任公司

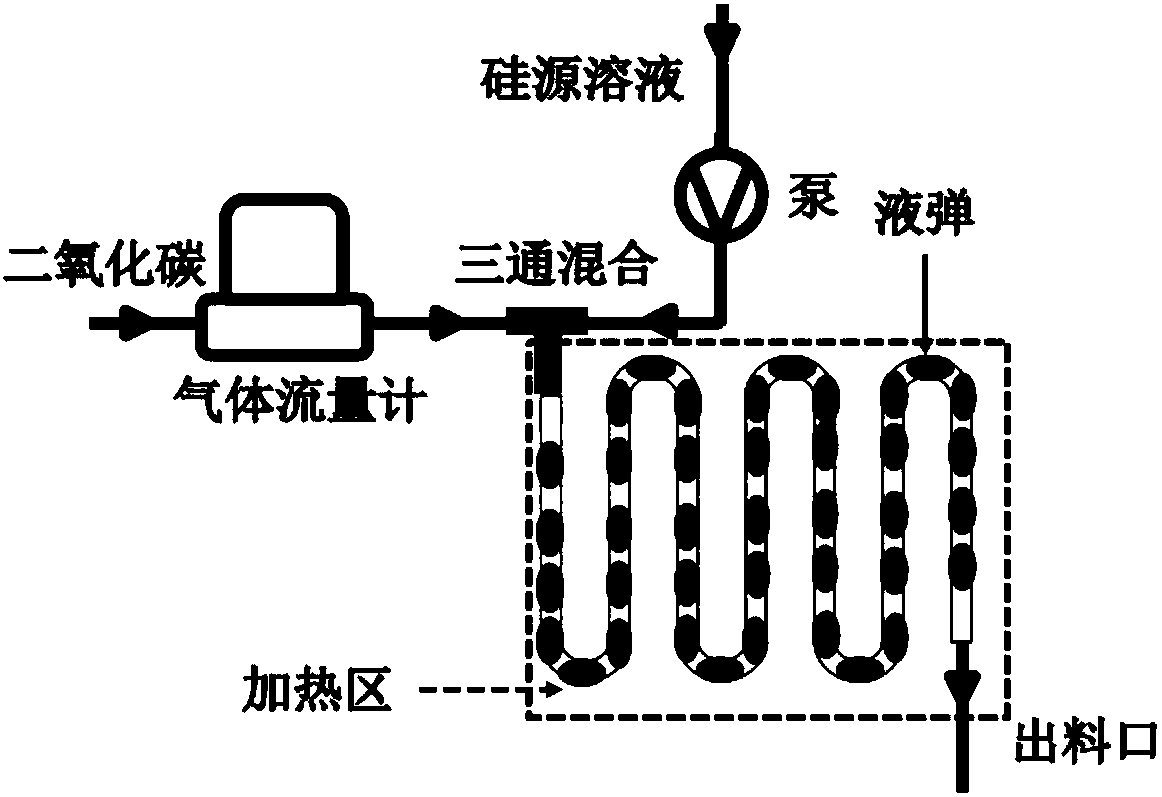

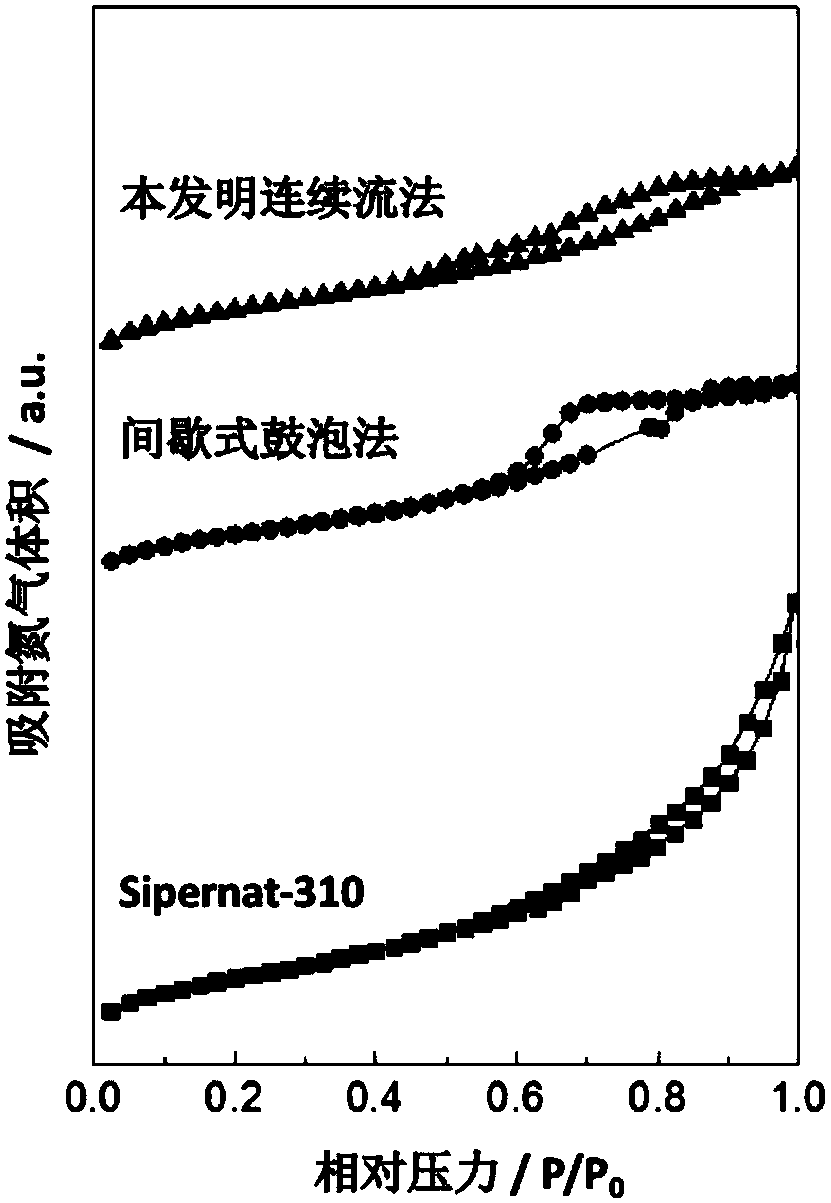

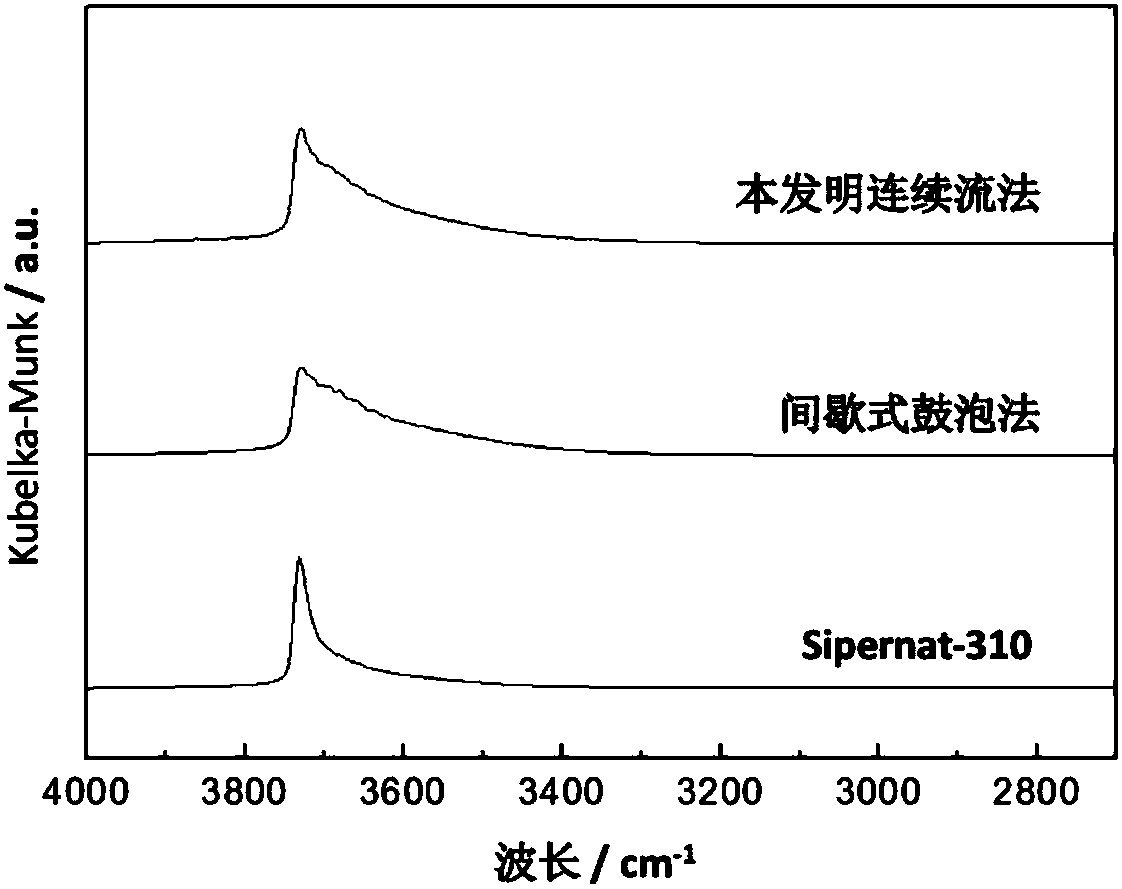

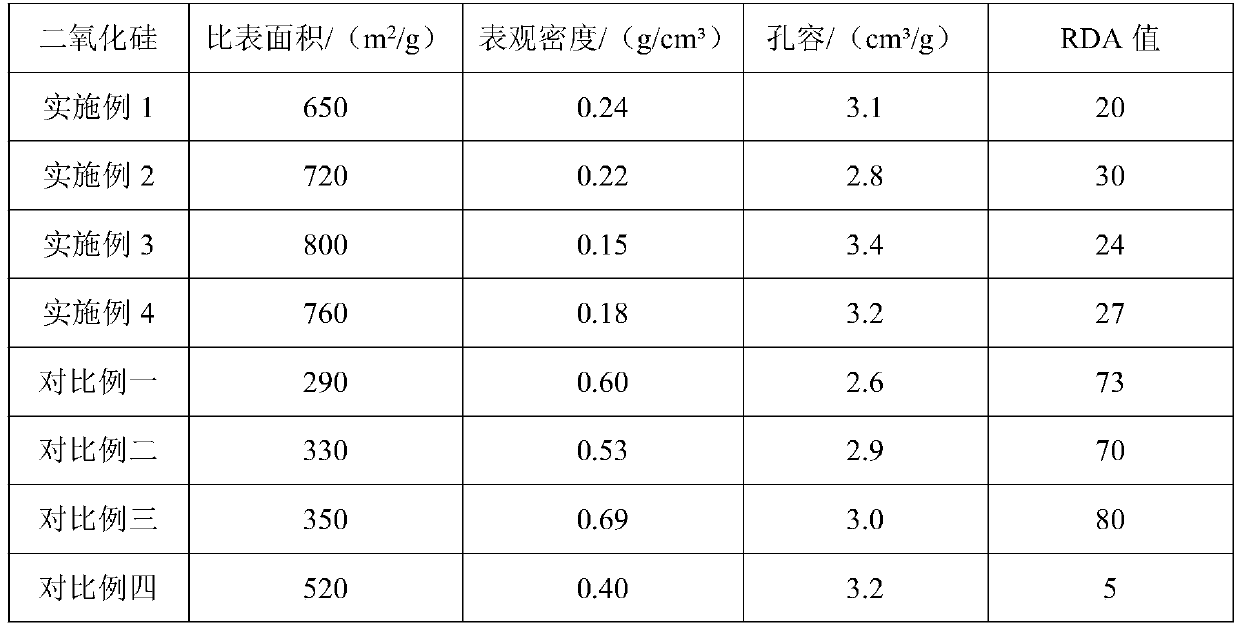

Method for preparing silicon dioxide with high specific surface area by using tubular continuous flow method

The invention discloses a method for preparing silicon dioxide with high specific surface area by using a tubular continuous flow method, and develops a novel precipitation method based on a small tube diameter tubular continuous flow method. The method is used for producing the silicon dioxide with high specific surface area, wherein a raw material for producing white carbon black is sodium silicate, silica sol or a mixed solution of sodium silicate and silica sol, and carbon dioxide gas serving as an acidifying agent goes through a gas-liquid alternating section flow formed by the tubular continuous flow method, so that the problem of mass and heat transfer on micro level is solved fundamentally. Therefore, according to the method disclosed by the invention, silicon dioxide with high specific surface area, small particles and stable product quality can be produced continuously.

Owner:合肥星巢环保科技有限公司

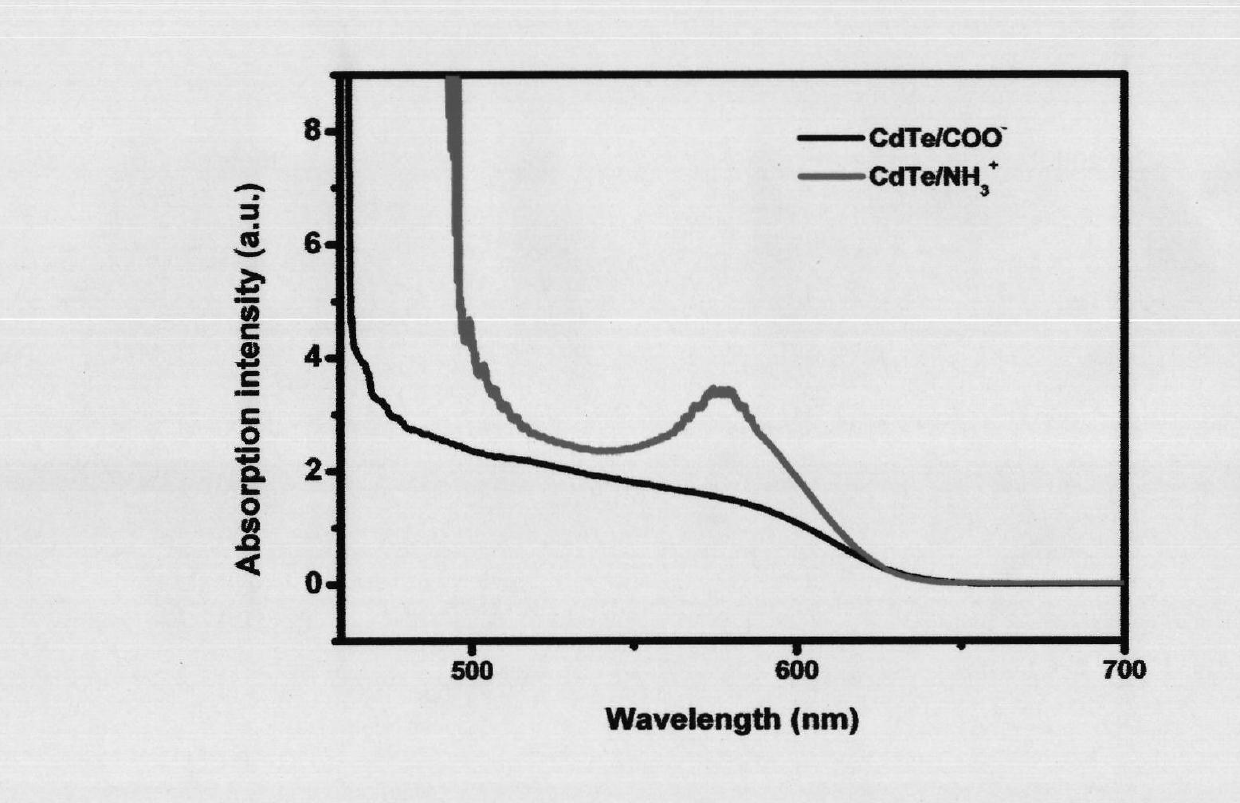

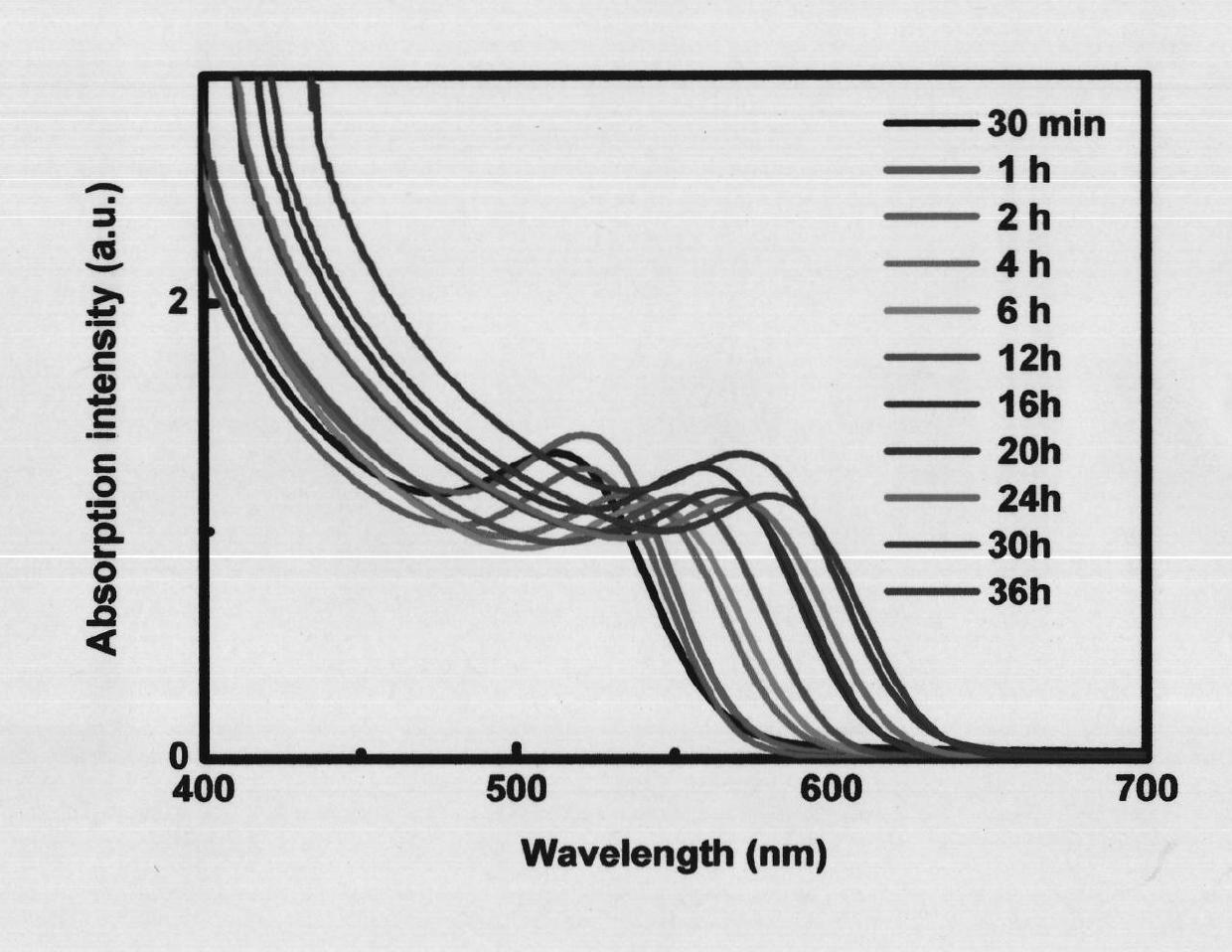

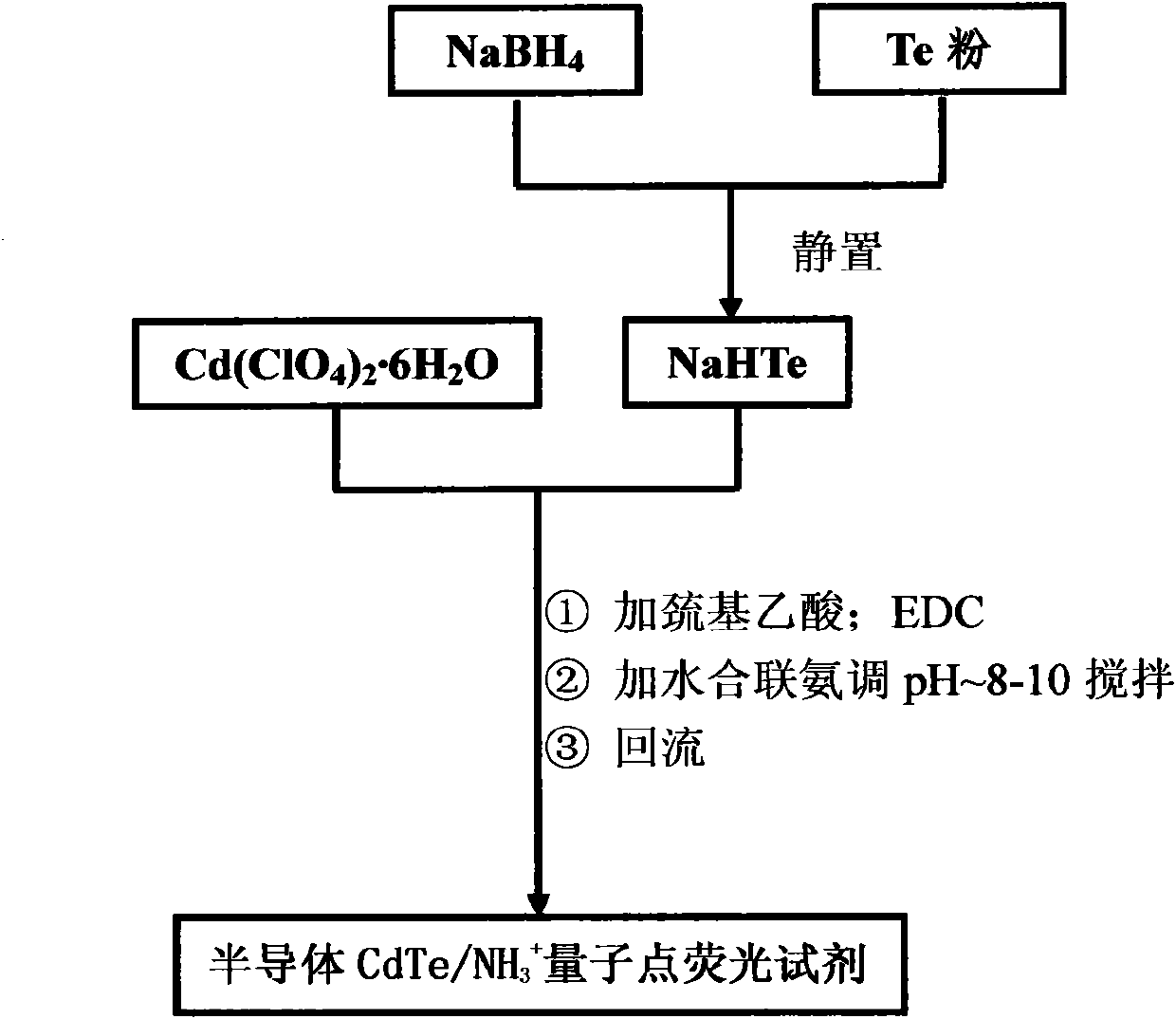

Method for preparing semiconductor quantum dot fluorescent reagent for imprint display and extraction

InactiveCN101906302AHigh fluorescence efficiencyEasy to makePerson identificationSensorsLow affinityHydrazine compound

The invention discloses a novel liquid semiconductor quantum dot fluorescent reagent, the surface of which has positive electricity property, for imprint display and extraction in the criminal investigation field. The liquid semiconductor CdTe / NH3+ quantum dot fluorescent reagent, the surface of which has positive electricity property, is prepared by surface modification of a traditional II-VI semiconductor CdTe quantum dot with a surface modified by mercaptoacetic acid through hydrazine hydrate. The fluorescent reagent solves the key technical problem of mutual repulsion and low affinity of the traditional mercaptoacetic acid modified semiconductor CdTe / COO- quantum dot fluorescent reagent under the alkali condition because the surface charge property is the same as the imprint residue charge property, so the fluorescent reagent has application advantages in the criminal science field. The liquid semiconductor quantum dot fluorescent reagent has the advantages of high fluorescence intensity, simple preparation process and good adhesion with fresh or old imprint, and is suitable for display and extraction of imprints on most impervious objects in criminal investigation.

Owner:INNER MONGOLIA UNIVERSITY

Single chip microcomputer intelligent control microwave pyrolysis microalgae directional oil-making device

ActiveCN106000254AImprove conversion rateControl reaction temperatureProcess control/regulationEnergy based chemical/physical/physico-chemical processesMicrocontrollerThermal insulation

The invention discloses a single chip microcomputer intelligent control microwave pyrolysis microalgae directional oil-making device. The device comprises a motor, a speed reducer, an air pump, microwave sources, a bracket, filter screens, a condenser pipe, an ox horn pipe, a liquid collection bottle, a microwave burst, temperature inductors, a seal structure, a thermal insulation layer, waveguide pipes, residue outlets, a connecting sleeve, a stirring shaft, an electrical bin, a single chip microcomputer control system, stirring fins, an N2 bottle, and a pressure sensor array. The device also comprises a tank body. The single chip microcomputer intelligent control microwave pyrolysis microalgae directional oil-making device provided by the invention adopts a metal tank, has high strength, can bear a lot of reaction materials, the microwave sources irradiate microwave evenly into the metal tank through the four uniformly disposed waveguide pipes to heat the reaction materials. The single chip microcomputer controls the reaction through the temperature in the tank and the weight change of the reaction materials, can well improve the material conversion rate, and saves energy.

Owner:GUANGXI UNIV

Step-feed CAST nitrite denitrifying phosphorus removal method and process control device thereof

InactiveCN104743669ALow costReduce energy consumptionTreatment with aerobic and anaerobic processesCarbon sourceSewage

The invention discloses a step-feed CAST nitrite denitrifying phosphorus removal method and a process control device thereof and belongs to the technical field of SBR and modified process sewage biologic denitrification thereof. The device comprises a selector, a main reaction area, a water inlet pump, a stirrer, a submersible mixer, a return sludge pump, an aerator, an air compressor, a water decanter, a drain valve, a mud valve and a real-time control system. By adopting integration of a multiple-water inlet running mode and a real-time control system, an organic carbon source in the original sewage is furthest utilized and furthermore, the ammoxidation, denitrifying dephosphatation and phosphorus release time in each stage is scientifically and reasonably distributed. The anaerobic stirring time is increased and operation based on a variable-duration anoxic / aerobic mode is adopted, the anoxic phosphorus uptake effect of the selector in the aerobiotic time and the anoxic phosphorus uptake effect of the main reaction area in the anoxic time are reinforced, and the anaerobic stirring time and the aerobic aerating time are controlled by a real-time process control strategy.

Owner:LANZHOU JIAOTONG UNIV

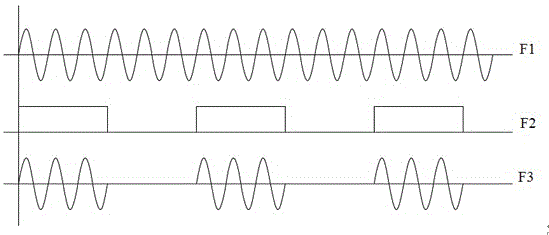

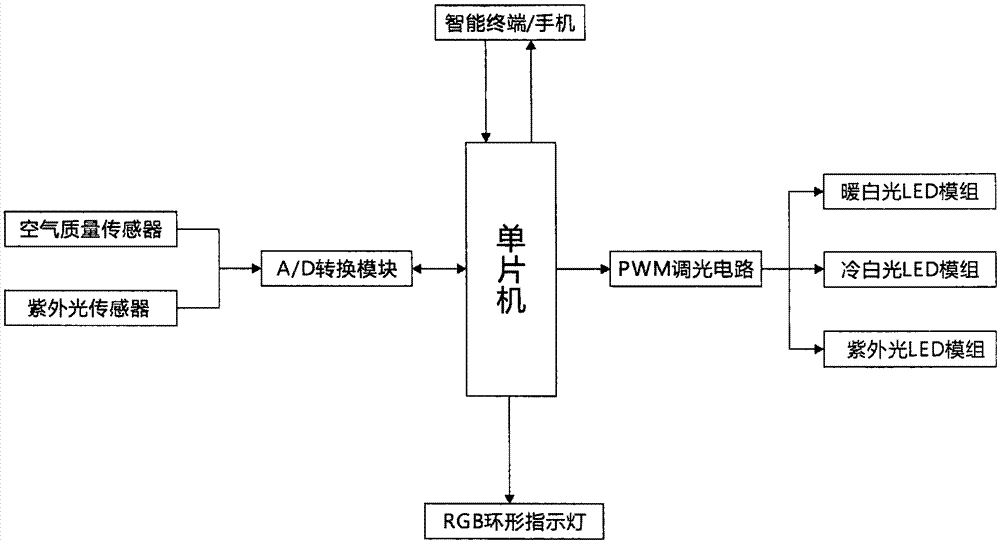

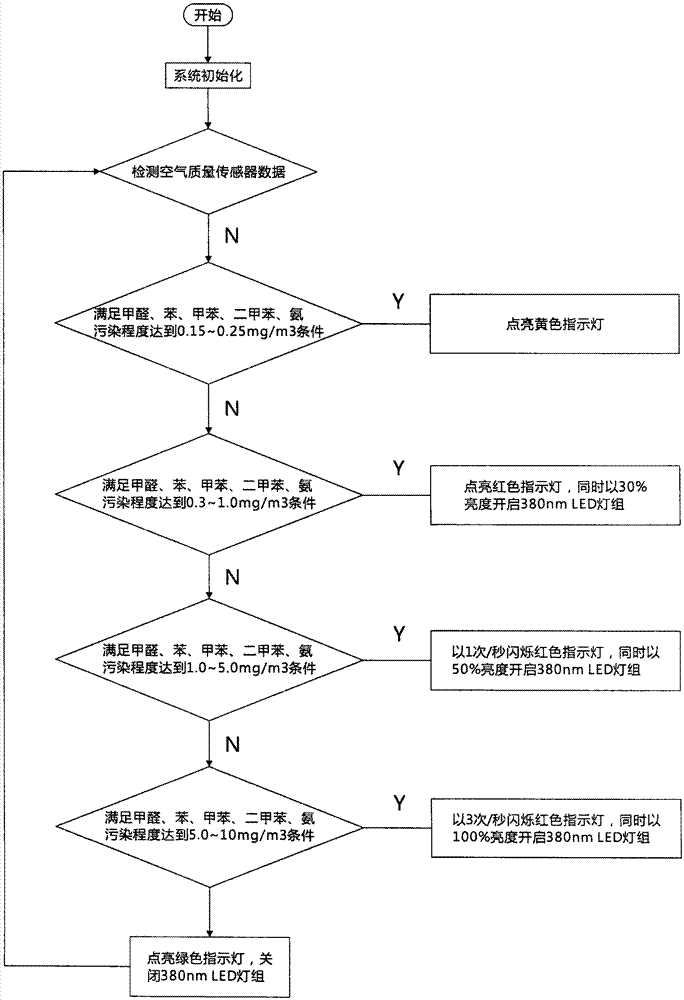

Intelligent air purifying LED advertising lamp box and control method thereof

InactiveCN106991933AStrong reductionStrong oxidation abilityMechanical apparatusGas treatmentMicrocontrollerLuminous intensity

The invention discloses an intelligent air purifying LED advertising lamp box. The intelligent air purifying LED advertising lamp box is characterized in that a photocatalyst nano-material is sprayed on the glass surface of the LED advertising lamp box. The photocatalyst nano-material absorbs luminous energy emitted by an LED light source having a wavelength of 380 nm, and the surface of the photocatalyst nano-material is excited to generate electrons (e-) and holes (h+). A tin oxide semiconductor gas sensor and a peripheral circuit thereof are employed to form a high-sensitivity air quality detector. A high-light-transmittance 380 nm filter, a light sensitive resistor and a peripheral circuit are employed to form an ultraviolet light leakage detector. On the intelligent control aspect, an embedded single-chip microcomputer, a wireless Bluetooth technology and a PWN dimming technology are mainly employed to connect various terminal devices. A working state indicating lamp can display the air quality degree visually and dynamically. When the ambient air pollution degree detected by an air quality sensor reaches preset upper and lower limiting values, the single-chip microcomputer emits a PWN signal, turns on and adjusts an ultraviolet light LED module, and adjusts the luminous intensity of the ultraviolet light LED module, and therefore the response time and intensity of the photocatalyst coating can be controlled, and air can be automatically purified.

Owner:IN THE LIGHT GAOKE BEIJING ENERGY SAVING INVESTMENT MANAGEMENT LIMITED BY SHARE

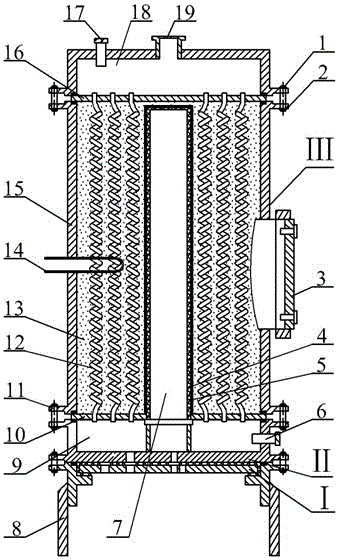

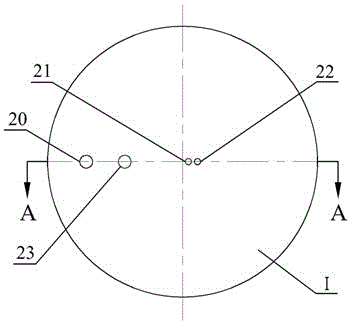

Gas-solid phase continuous reaction device with heat transfer enhancing function

ActiveCN106179167AControl reaction timeControl reaction processChemical/physical/physico-chemical stationary reactorsFeed devicesGas solidGas phase

The invention discloses a gas-solid phase continuous reaction device with a heat transfer enhancing function. The gas-solid phase continuous reaction device comprises a rotating disc (I), a fixed disc (II) and a reactor (III), wherein a gas phase inlet, a gas phase outlet, a cold fluid inlet and a hot fluid inlet are distributed in the rotating disc along the radial distribution; a gas phase inlet groove, a gas phase outlet groove, a cold fluid inlet groove and a hot fluid inlet groove are distributed in the fixed disc; distances between the grooves and the center of the rotating disc are equal to distances between corresponding holes of the rotating disc and the center of the rotating disc, the width of each groove is equal to the diameter of a corresponding hole, and a central angle of each groove (namely groove length) depends on reaction time period required to be controlled by a user. The gas-solid phase continuous reaction device has the characteristics of continuous operation, controllable reaction time, high equipment utilization rate, stable technological parameters, convenience in operation, guarantee of production safety, simple structure, low cost and the like.

Owner:NORTHWEST UNIV(CN)

Method for producing butanol by hydrolyzing and fermenting waste crops rich in hemicellulose

InactiveCN101696429AAvoid unfriendly disadvantagesAvoid the disadvantages of being unfriendly to the environmentMicroorganism based processesFermentationAcetic acidSalt content

The invention discloses a method for producing butanol by hydrolyzing and fermenting waste crops rich in hemicellulose, belongs to bio-energy production by biomass fermentation and provides a method for producing the butanol by hydrolyzing and fermenting through acetic acid pretreatment by using biomasses rich in the hemicellulose as raw materials. The method comprises the following steps: mixing and hydrolyzing the raw materials; adding acetic acid to a reaction mixed solution of crop wastes rich in the hemicellulose biomasses and water; and controlling the temperature and the time to hydrolyze and ferment. In the method, the acetic acid is applied to pretreat and hydrolyze the hemicellulose, and the acetic acid in hydrolysis liquid can be utilized by fermentation thalli, thereby overcoming the defects such as overhigh salt content of sulfuric acid hydrolysis and environmental pollution by post-treated wastes.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing double-shell CoO/Co3O4 hollow nanoparticles

ActiveCN103950994AEliminate interference from the external environmentThe method is simpleMaterial nanotechnologyCobalt oxides/hydroxidesCobalt oxideHigh pressure

The invention discloses a method for preparing double-shell CoO / Co3O4 hollow nanoparticles. The method for preparing double-shell CoO / Co3O4 hollow nanoparticles, provided by the invention, comprises the following step of mixing organometallic cobalt salt with an organic solvent, firstly preparing double-shell CoO hollow nanoparticles under high temperature and high pressure conditions, and then preparing double-shell Co3O4 hollow nanoparticles by a high temperature calcining process. The cobalt monoxide and cobalt oxide, prepared by the method disclosed by the invention, have the characteristics of high purity, uniform particle size, strong oxidation resistance, excellent magnetic performance and the like. The double-shell CoO / Co3O4 hollow nanoparticles have the advantages of good quality, simple technological process, wide range of application, and broad application prospects in preparation of lithium batteries, biomedical drug / gene transduction and energy storage.

Owner:CENT SOUTH UNIV

CAST sectional water inlet synchronous denitrification and dephosphorization strenghthening procedure control device and method

ActiveCN101434438ALow costReduce energy consumptionTreatment with aerobic and anaerobic processesReal-time Control SystemSludge

The invention relates to a control device and a method of a CAST segmental inflow and synchronous denitrification and dephosphorization reinforcement process, which belongs to the technical field of SBR and variant process spent water biological denitrification. The denitrification and dephosphorization effect of the currently used CAST technique is not desirable. The device comprises a selector, a main reaction zone, an inlet pump, a stirrer, a diving stirrer, a return sludge pump, an aerator, an air compressor, a decant machine, a drain valve, a mud valve, a real-time controlling system and a sensor. The real-time controlling system is used for controlling a time-delay device which is connected with the inlet pump, the stirrer, the diving stirrer, the return sludge pump, the air compressor, the decant machine, the drain valve and the mud valve, a computer, and a data collecting card connected on the computer. By the processes of inflow anoxia stirring, inflow anaerobism stirring, aeration, sedimentation, drainage and leaving unused, the synchronous denitrification and dephosphorization is realized. The device and the method have the advantages of good denitrification and dephosphorization effect, low operation cost, and being capable of realizing intelligent control, and the like.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

Process for producing melamine foam sponge

The invention discloses a process for producing melamine foam sponge, comprising the steps of mixing well melamine and paraformaldehyde; pumping the mixture to a first screw unit by a material pump, and adding alkali liquid to a feed port of the first screw unit; adding auxiliary solution to the feed end, middle or tail end of the first screw unit; feeding to a second screw unit, transparent resin extruded from an outlet of the first screw unit, and continuing polymerization in the second screw unit; allowing transparent resin from the tail of the second screw unit to pass through a cooling device and then enter a third screw unit; introducing a foaming agent, an emulsifying agent, a stabilizer and a curing agent from the middle of the third screw unit, and mixing well with the resin; introducing the mixed resin to a microwave foaming furnace for foaming to form high-porosity melamine foam sponge; the process of the invention makes high use of materials, has high yield, and can provide continuous production of melamine foam sponge with stable quality and high porosity.

Owner:郑州峰泰纳米材料有限公司

Low-density colored silica particle with porous structure and preparation method of low-density colored silica particle

The invention belongs to the technical field of precipitated silica and specifically relates to a low-density colored silica particle with a porous structure and a preparation method of the low-density colored silica particle. The preparation method comprises the steps: S1, dropwise adding a water glass solution into a sulfuric acid solution to prepare an acidic silica sol solution; S2, filling areaction tank with the sulfuric acid solution and hydroxyethyl cellulose, then, simultaneously and dropwise adding the acidic silica sol solution and the water glass solution, ending the operation ofdropwise adding the acidic silica sol solution, then, further and dropwise adding the water glass solution until the pH value reaches 3-4, adding a pigment, then, dropwise adding the water glass solution to reach an end-point pH value, and carrying out stirring until a gel is separated from a system; S3, adding ethanol and glycerol into the gel, and carrying out stirring; and S4, carrying out pressure filtering, drying, smashing, washing and drying on the gel to prepare the colored silica particle. The silica particle is good in suspension property, adsorption property and mild grinding property, suitable for application to household chemicals such as body wash, cleaning milk and toothpaste and good in application prospect.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com