Method for preparing double-shell CoO/Co3O4 hollow nanoparticles

A technology of hollow nanoparticles and particles, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex methods and few researches and preparations of hollow cobalt oxide nanomaterials in the shell, etc. Achieve the effects of simple process, high product quality and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

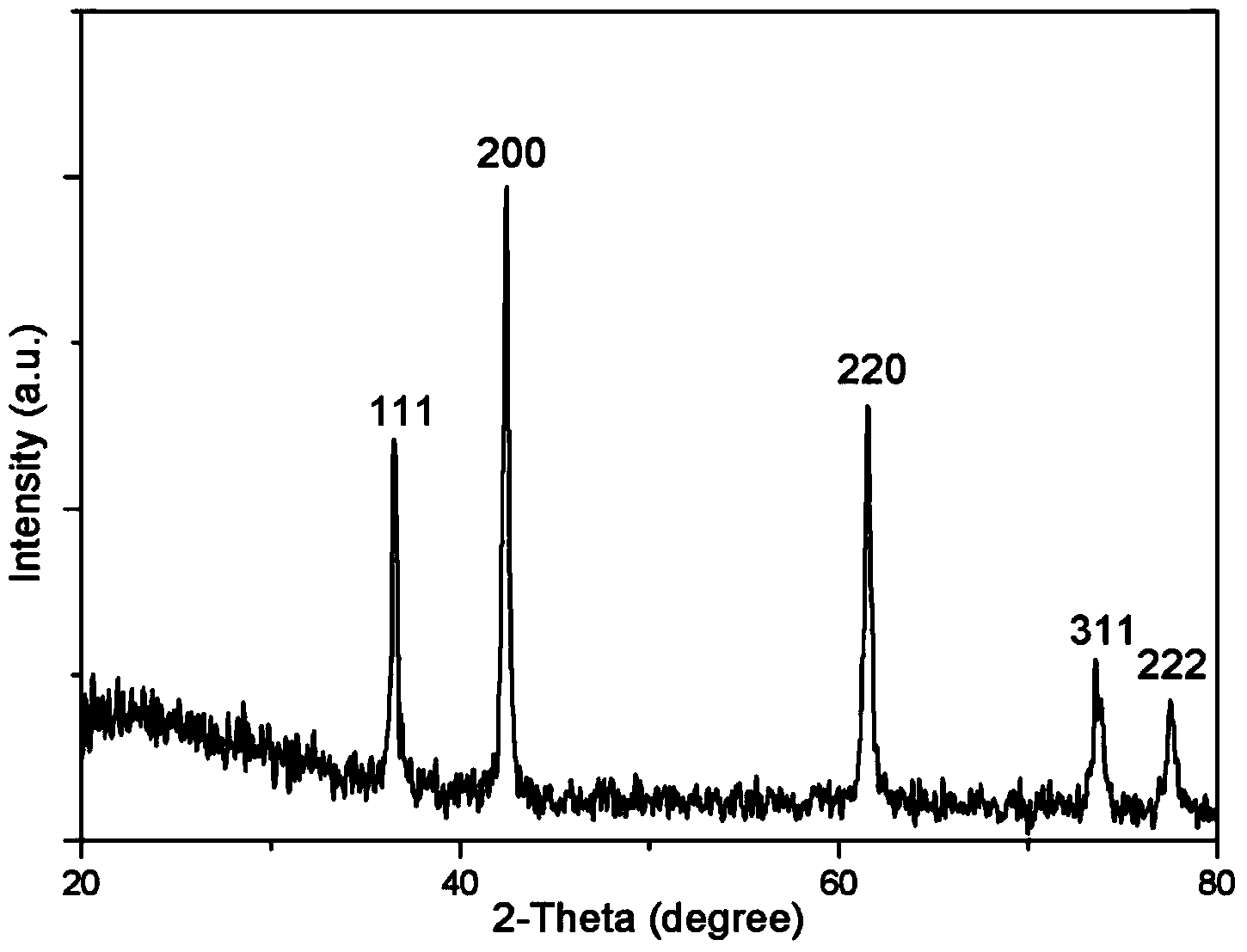

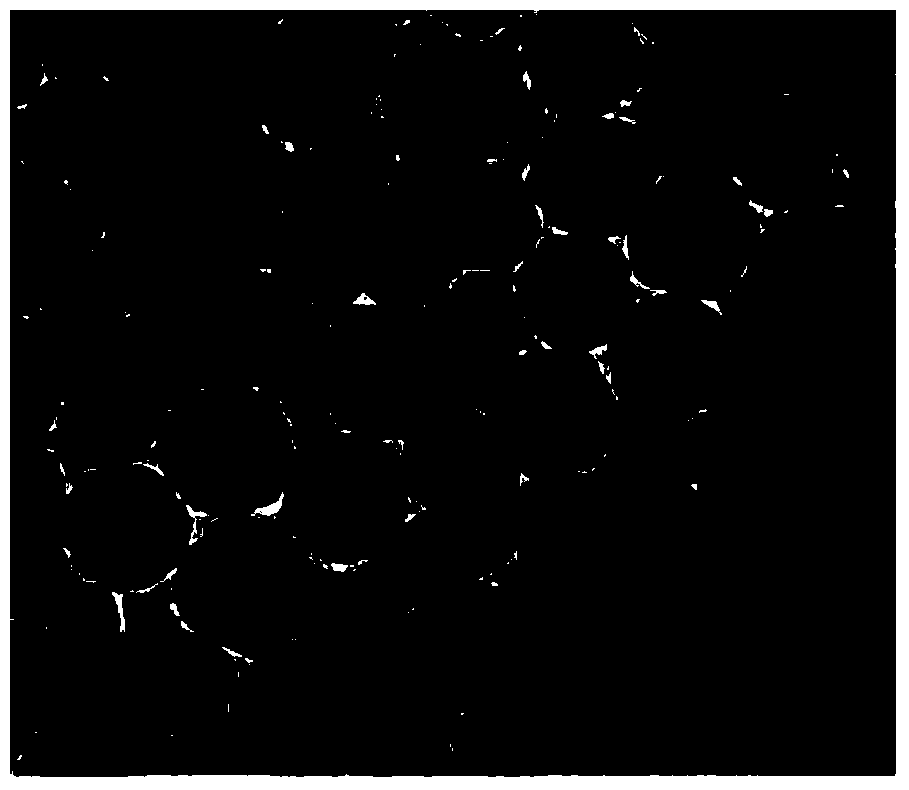

[0033] Weigh 1mmol of cobaltous acetylacetonate (0.2571g) and dissolve it in 20ml of octadecene, measure oleic acid and oleylamine (accounting for 20% of the entire reaction system), add it to the above solution at a molar ratio of 4:10, and transfer to In a 40ml reaction kettle, stir evenly for 10 minutes, seal the reaction kettle, raise the temperature to 260°C, and keep it warm for 8 hours. The product obtained by the reaction was centrifuged, washed and dried to obtain a tan powder. like figure 1 Shown product is identified as cobaltous oxide through X-ray powder diffraction; Carry out morphology analysis to cobaltous oxide with transmission electron microscope (TEM), from figure 2 It can be seen that its morphology is double-layer hollow nanoparticles; the morphology of cobaltous oxide is analyzed by scanning electron microscope (SEM), and the image 3 It can be seen that the morphology is hollow nanoparticles.

Embodiment 2

[0035] Weigh 1mmol of cobaltous acetylacetonate (0.2571g) and dissolve it in 20ml of octadecene, measure oleic acid and oleylamine (accounting for 20% of the entire reaction system), add it to the above solution at a molar ratio of 4:10, and transfer to In a 40ml reaction kettle, stir evenly for 10 minutes, seal the reaction kettle, raise the temperature to 260°C, and keep it warm for 1 hour. The product obtained by the reaction was centrifuged, washed and dried to obtain a tan powder. The morphology of cobaltous oxide was analyzed by transmission electron microscopy (TEM). Figure 4 It can be seen that its morphology is cobaltous oxide solid nanoparticles.

Embodiment 3

[0037] Weigh 1mmol of cobaltous acetylacetonate (0.2571g) and dissolve it in 20ml of octadecene, measure oleic acid and oleylamine (accounting for 20% of the entire reaction system), add it to the above solution at a molar ratio of 4:10, and transfer to In a 40ml reaction kettle, stir evenly for 10 minutes, seal the reaction kettle, raise the temperature to 260°C, and keep it warm for 2 hours. The product obtained by the reaction was centrifuged, washed and dried to obtain a tan powder. The morphology of cobaltous oxide was analyzed by transmission electron microscopy (TEM). Figure 5 It can be seen that the products are cobaltous oxide solid nanoparticles and partial cobaltous oxide hollow nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com