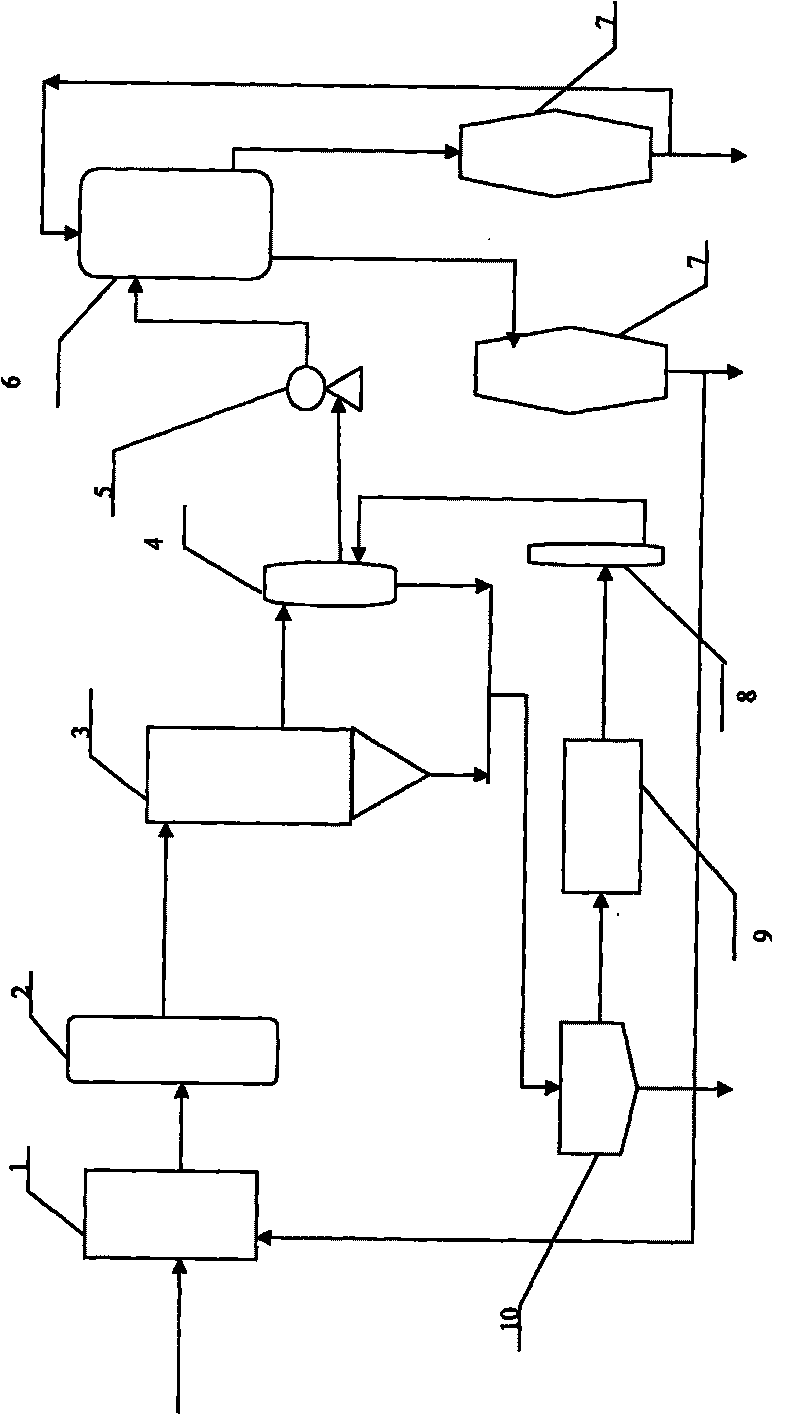

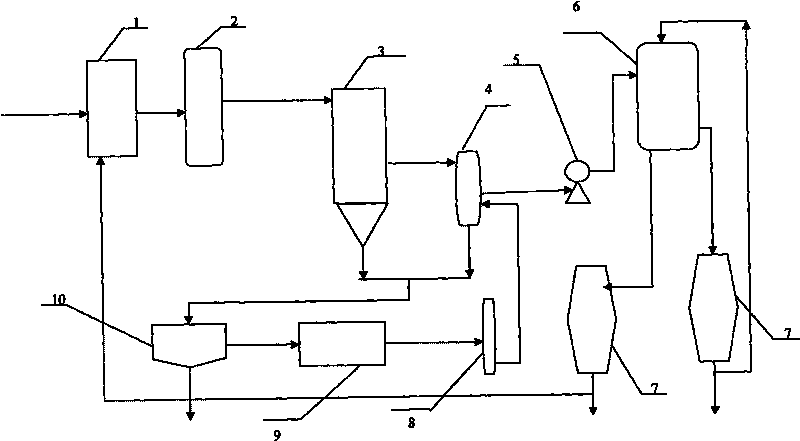

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

A plasma and DC arc technology, applied in the field of coal cracking process, can solve the problems of unstable operation, low safety factor and short working time of plasma coal-to-acetylene technology, so as to improve the long production process, prolong the operating life, improve the The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0024] The difference between embodiment 2 and embodiment 1 is that the generator is a gas film reactor, which can protect the inner wall of the reactor from coking with energy efficiency, and ensure the long-term and stable operation of the reactor.

Embodiment 3

[0025] The difference between embodiment 3 and embodiment 1 is that the generator is a water film reactor, which can effectively prevent the coking of the reactor and make the reactor run smoothly for a long period of time.

Embodiment 4

[0026] The difference between embodiment 4 and embodiment 1 or 2 is that: the pulverized coal powder feeding section adopts circumferential rotation feeding, which can increase the contact time between pulverized coal and hydrogen plasma, increase the utilization efficiency of pulverized coal, and produce The yield of organic components such as acetylene and ethylene is higher by 0.2%--2.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com