Pyrolyzation and desorption device for sludge

A sludge and hot gas technology, applied in pyrolysis sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problems of expensive treatment chemicals, human health hazards, ecological environment damage, etc. , to achieve the effect of realizing resource utilization, improving heating effect and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

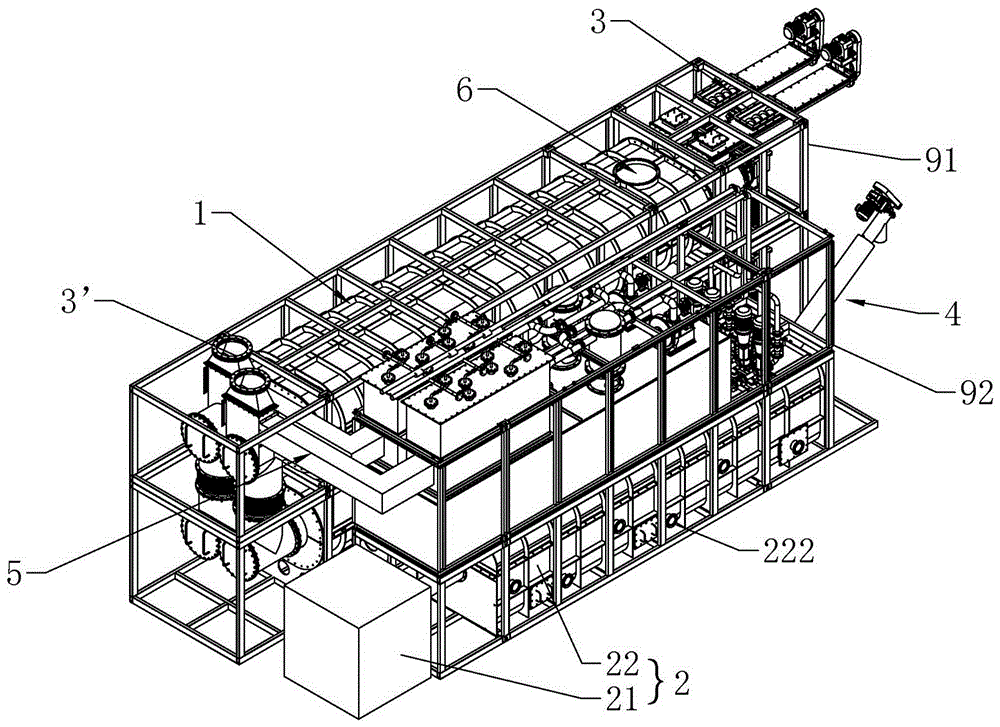

[0043] according to Figure 1 ~ Figure 3 Shown, a kind of sludge thermal desorption device, comprising:

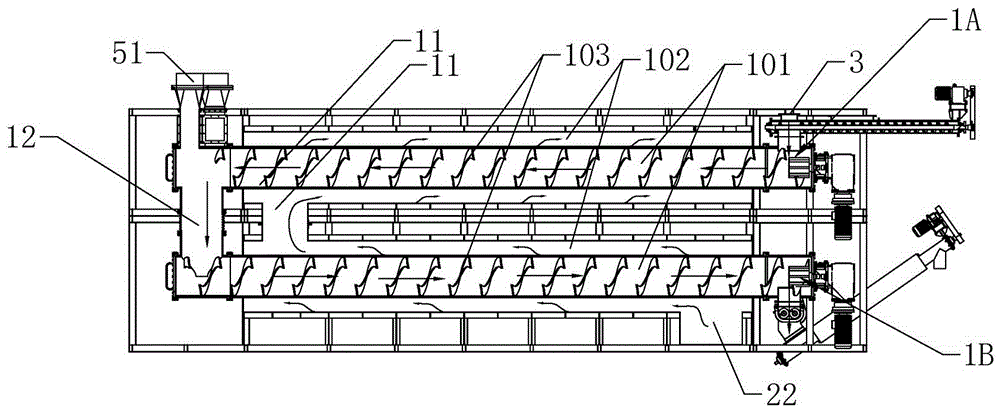

[0044]The pyrolysis and desorption furnace body 1 is used for the pyrolysis and desorption of sludge and the transmission of sludge. The pyrolysis and desorption furnace body 1 is a nested structure of inner and outer chambers, including a pyrolysis and desorption chamber 101 for holding sludge and a coating In the heating chamber 102 outside the thermal desorption chamber 101, the thermal desorption chamber 101 is provided with a conveying mechanism 103, and the conveying mechanism 103 is a shaftless screw auger; the thermal desorption furnace body is divided into 1, and the upper furnace body 1A is arranged up and down. and the lower furnace body 1B, a hot gas ascending channel 11 is set between the upper furnace body 1A and the lower furnace body 1B to communicate with the heating chamber 102 of the two, and a material falling channel 12 is set between the upper furnace...

Embodiment 2

[0052] according to figure 1 As shown, the pyrolysis and desorption furnace body 1, the material inlet 3 and the material outlet 4 are arranged in the first skid 91, the hot gas generating device 2 and the tail gas processor 8 are arranged in the second skid 92, and the first skid 91 and The detachable connection between the second skids 92 .

Embodiment 3

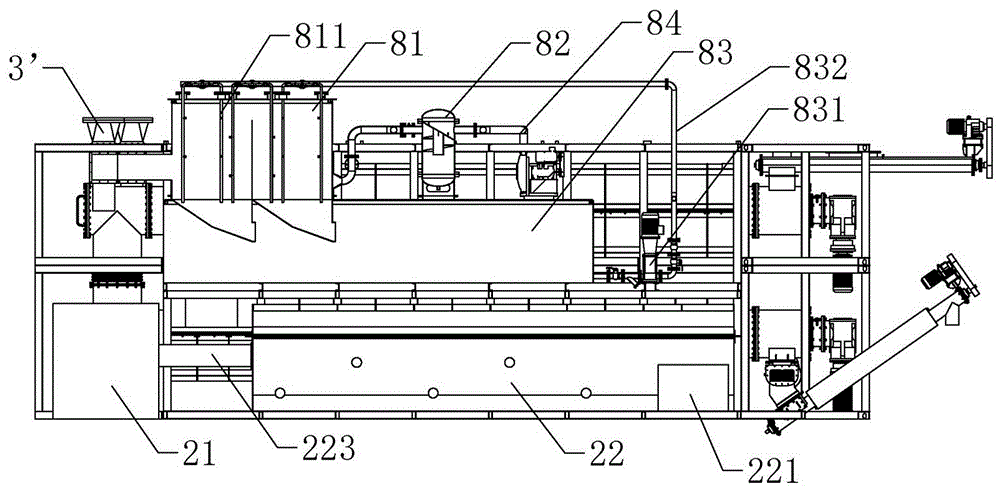

[0054] The thermal desorption and desorption device also includes a gas generator as shown in the figure, the gas generator is a nitrogen generator or a superheated steam generator, and the gas outlet of the gas generator is directly connected with the thermal desorption chamber 101, and nitrogen or superheated steam is used as The protective gas directly heats the oily sludge in an oxygen-free or oxygen-deficient protective atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com