Bioreactor and method for converting solid organic wastes by using bioreactor

A bioreactor and organic waste technology, applied in the treatment of bio-organic parts, the preparation and application of organic fertilizers, can solve the problems of difficult control of temperature and water content of materials, secondary pollution, etc., to eliminate air pollution, treat Thorough and convenient feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

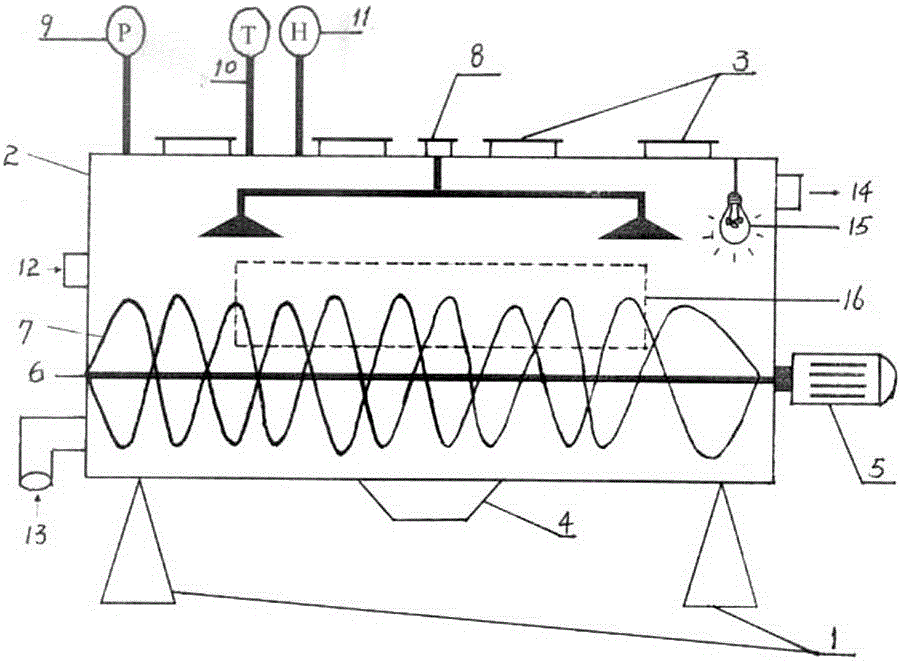

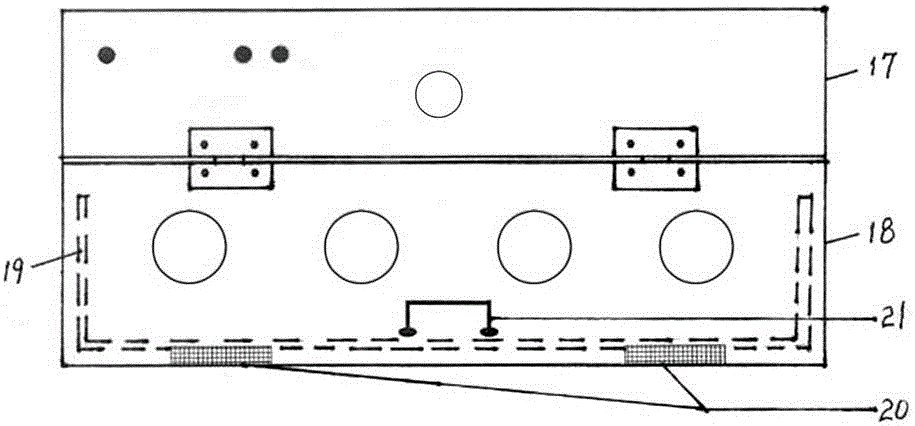

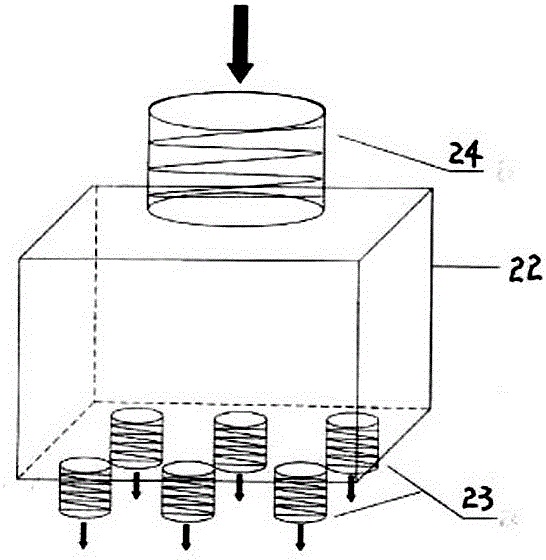

[0024] Such as figure 1 As shown, the bioreactor of the present invention includes a base 1, a closed reaction chamber 2 placed horizontally on the base 1, the top wall of the closed reaction chamber 2 is provided with a feed port 3, and the bottom wall is provided with a discharge port 4 , the bottom wall is in an arc-shaped structure, and the 4 discharge ports on the arc-shaped bottom wall are movable to be provided with sealing baffles; the lower part of the inner cavity of the closed reaction chamber 1 is horizontally provided with a stirring shaft 6 driven by a motor 5, and the stirring shaft 6 is provided with a stirring impeller 7, the stirring impeller 7 is a double helix structure, and its outer edge is covered with a flexible rubber film; a fermentation liquid inlet 8 is opened on the top wall, and the nozzle 9 placed above the closed reaction chamber cavity passes through The pipeline is connected with the fermentation liquid inlet 8; a pressure gauge 9, a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com