Harmless oil field mud and sand treating method and apparatus

A technology for harmless treatment of oily sludge and sand, applied in the direction of sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problems that cannot be directly applied to the treatment of oily sludge and sand in oil fields, and has not yet formed a mature treatment process. Stable effect, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

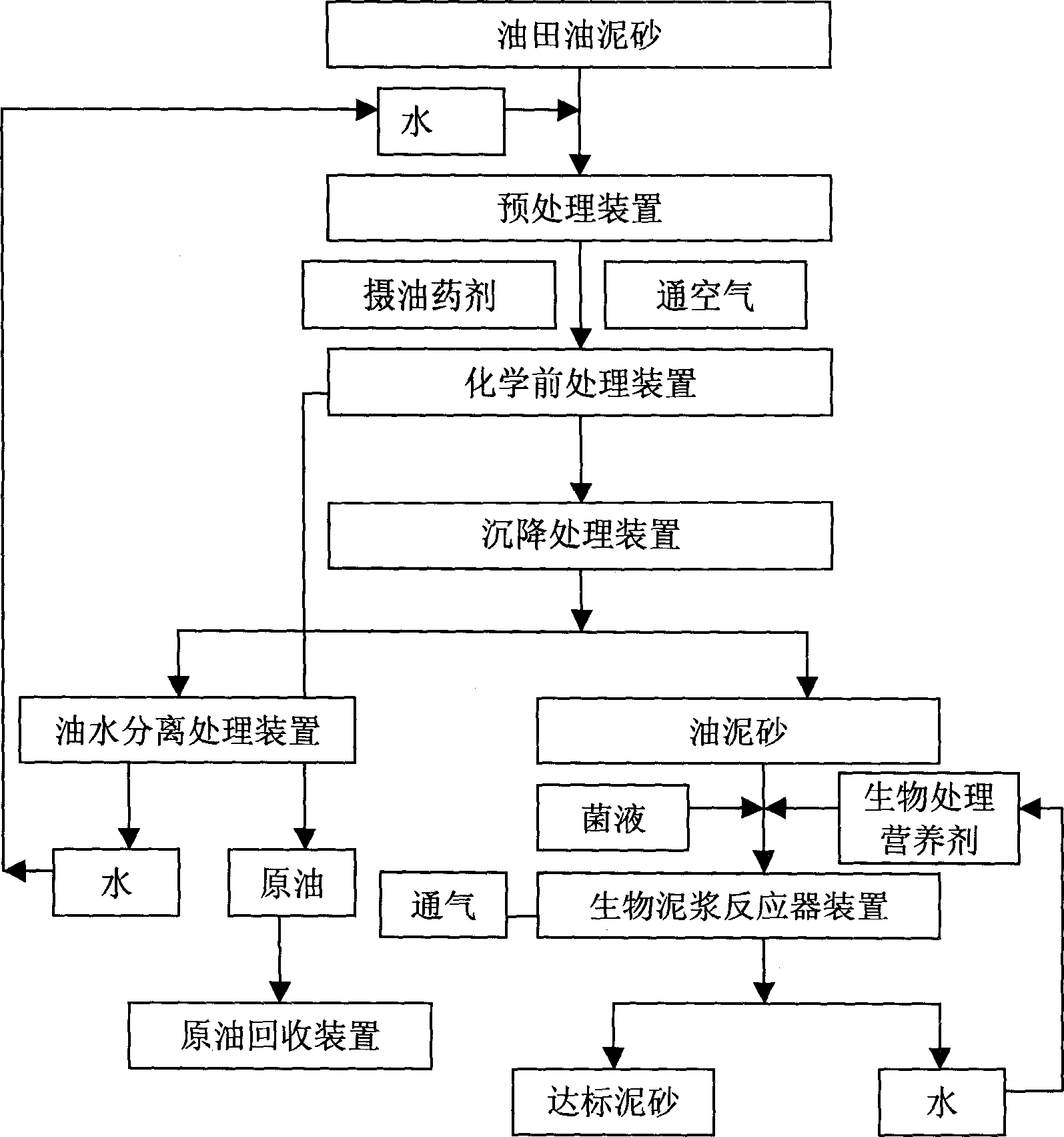

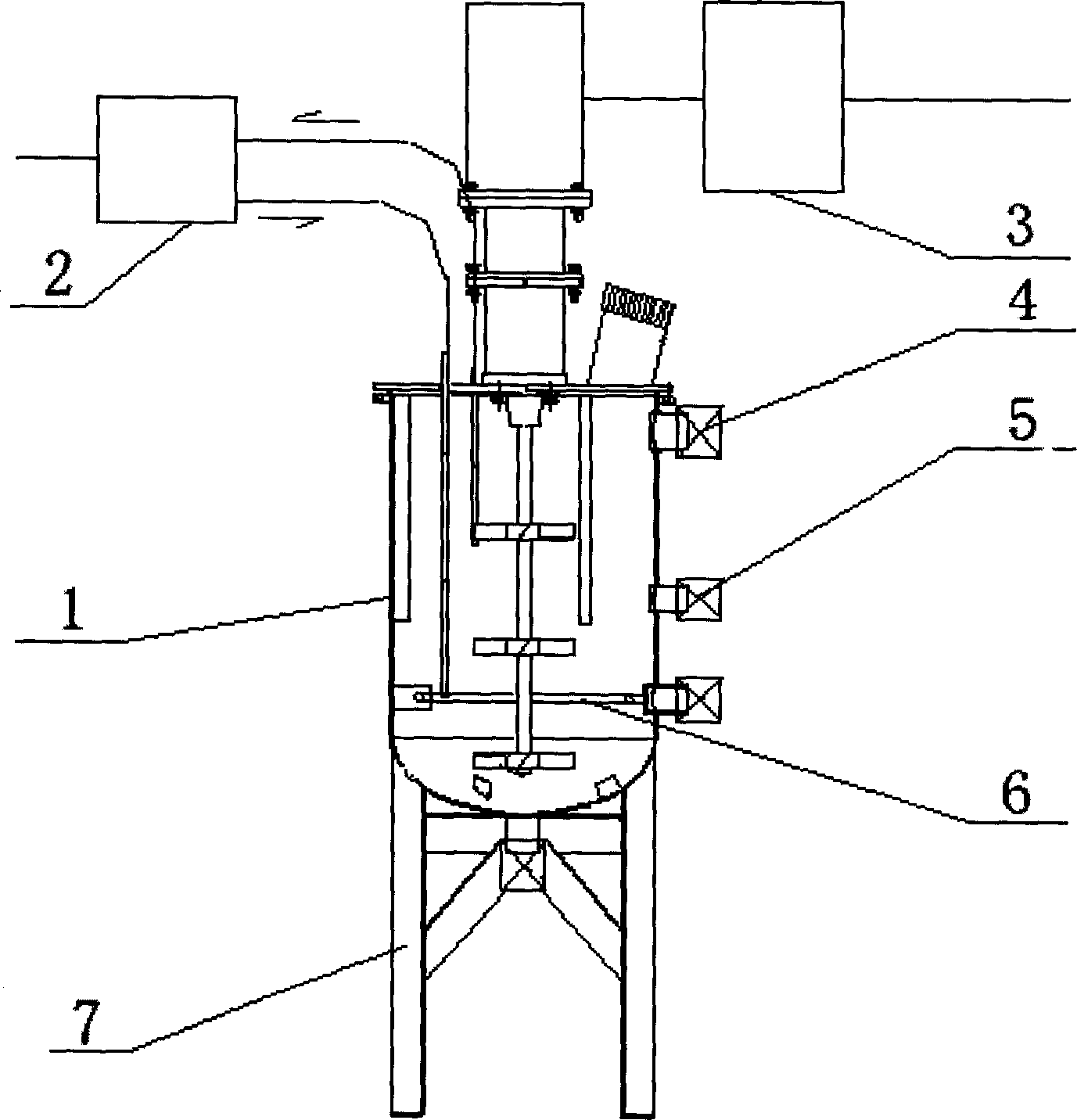

[0009] The present invention is described in further detail below in conjunction with embodiment: see appendix figure 1 and 2 , a method for harmless treatment of oilfield oil sludge sand, including oilfield oil sludge sand mud pretreatment, chemical pretreatment, sedimentation treatment and oil-water separation treatment, the oilfield oil sludge sand after the above treatment is subjected to biological treatment, and water and biological The treatment bacteria solution and biological treatment nutrients are added to the oil sludge sand, and the crude oil in the oil sludge sand is stripped and degraded through the reproduction and metabolism of bacteria. Considering economic and practical factors, the ratio of oil sludge sand to added water is preferably any one of 1:1-3, and of course the ratio of oil sludge sand to water can also be increased or reduced, such as 1:1-5. The water temperature is any one of 30°C to 40°C, and the added water can be clean water or oilfield sewag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com