Method for preparing rubber by using oil shale semi-coke-based mineral/biochar material as reinforcing aid

A technology of oil shale semi-coke and reinforcing additives, which is applied in the fields of solid waste resource utilization and rubber deep processing. High-value utilization and other issues to achieve high elongation at break, excellent mechanical properties, and stable supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Acid etching of oil shale semi-coke: Weigh 500g of oil shale semi-coke powder (broken, <200 mesh), disperse into 2.5L, 2M hydrochloric acid solution, stir and react at 90°C for 6h, centrifuge 1. Washing with deionized water for 3 times, press filtering and drying to obtain acid-etched oil shale semi-coke;

[0032] (2) Preparation of rubber products: Add 100 parts of styrene-butadiene rubber raw rubber (parts by mass, the same below) into the mixer and plasticize for 10 minutes, then add 4 parts of zinc oxide, 2 parts of stearic acid, accelerator ( ZDMC) 3 parts, silane coupling agent Si-69 3.5 parts, acid-etched oil shale semi-coke 10 parts, white carbon black 40 parts and sulfur 3 parts, mixed at 60°C for 0.5h, and adjusted the roller during the mixing process Cut the knife several times to get the rubber compound; then put the rubber compound into the flat vulcanizing machine after 12 hours, and vulcanize it at 17Mpa and 160°C for 0.5 hour to get the rubber produc...

Embodiment 2

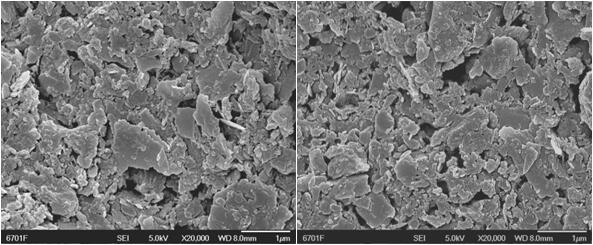

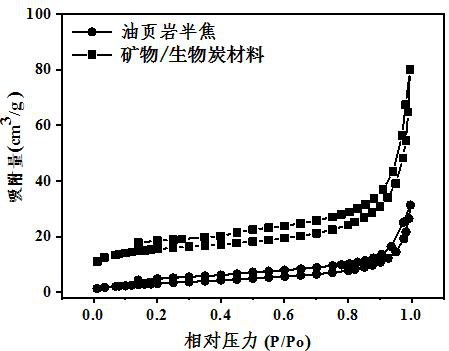

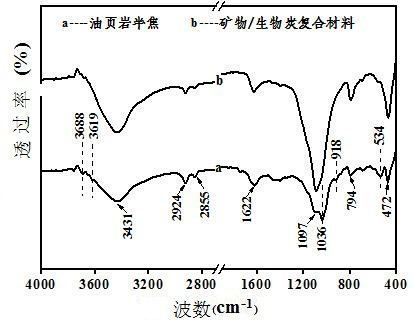

[0034] (1) Preparation of oil shale semi-coke-based mineral / biochar materials: Weigh 500g of oil shale semi-coke powder, disperse into 5L, 0.5M hydrochloric acid solution, stir and react at 90°C for 6h, centrifuge, remove Wash 3 times with ion water and press filter to obtain acid-etched oil shale semi-coke; then add acid-etched oil shale semi-coke into the rotary kiln, and calcine for 2 hours at 700°C under the protection of argon atmosphere to obtain oil shale semi-coke-based minerals / biochar material;

[0035] (2) Preparation of rubber products: Add 100 parts of styrene-butadiene rubber raw rubber into the mixer and plasticize for 10 minutes, then add 3 parts of zinc oxide, 2 parts of stearic acid, 3 parts of accelerator (TBBS), silane coupling 2 parts of Si-69 agent, 5 parts of oil shale semi-coke-based mineral / biochar material, 45 parts of white carbon black and 2 parts of sulfur were mixed at 55°C for 0.5h, and the roller distance was adjusted several times during the ...

Embodiment 3

[0037] (1) Preparation of oil shale semi-coke-based mineral / biochar materials: Weigh 500g oil shale semi-coke powder, disperse into 5L, 1M sulfuric acid solution, stir and react at 90°C for 4h, centrifuge, deionize Washing with water for 3 times and press-filtering to obtain acid-etched oil shale semi-coke; then adding acid-etched oil shale semi-coke into the cracking furnace, and calcining at 800°C for 2 hours under the protection of helium atmosphere to obtain oil shale semi-coke-based minerals / biochar material;

[0038] (2) Preparation of rubber products: Add 100 parts of styrene-butadiene rubber raw rubber into the mixer and plasticize for 10 minutes, then add 3.5 parts of zinc oxide, 2 parts of stearic acid, 3 parts of accelerator (TMTD), silane coupling 3 parts of agent Si-69, 5 parts of oil shale semi-coke-based mineral / biochar material, 45 parts of white carbon black and 2 parts of sulfur were mixed at 60°C for 0.5h, and the roller distance was adjusted several times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com