Patents

Literature

36results about How to "Reduce ozone usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated flue gas treatment device and method

ActiveCN104857835ARealize resource utilizationReduce wateringCombination devicesMagnesium nitratesLiquid wasteReaction layer

The invention discloses an integrated flue gas treatment device and method. The device comprises flue gas treatment equipment, ozone supply equipment, hydrogen peroxide supply equipment, evaporation and concentration equipment, cyclic sedimentation equipment and the like, wherein the flue gas treatment equipment comprises an ozone spray oxidation reaction layer, a hydrogen peroxide spray oxidation reaction layer, an absorber spray area, a slurry circulation area and a dust and mist removal area; both the ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are arranged in the absorber spray area; the dust and mist removal area is positioned above the absorber spray area; both the evaporation and concentration equipment and the cyclic sedimentation equipment are arranged in the flue gas treatment equipment. The device and the method disclosed by the invention are suitable for comprehensive treatment of flue gas containing SO2, NOX, Hg and dust and resource utilization of liquid waste in coal fired boilers, iron and steel sintering machines, pellets, industry kiln stoves and the like.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

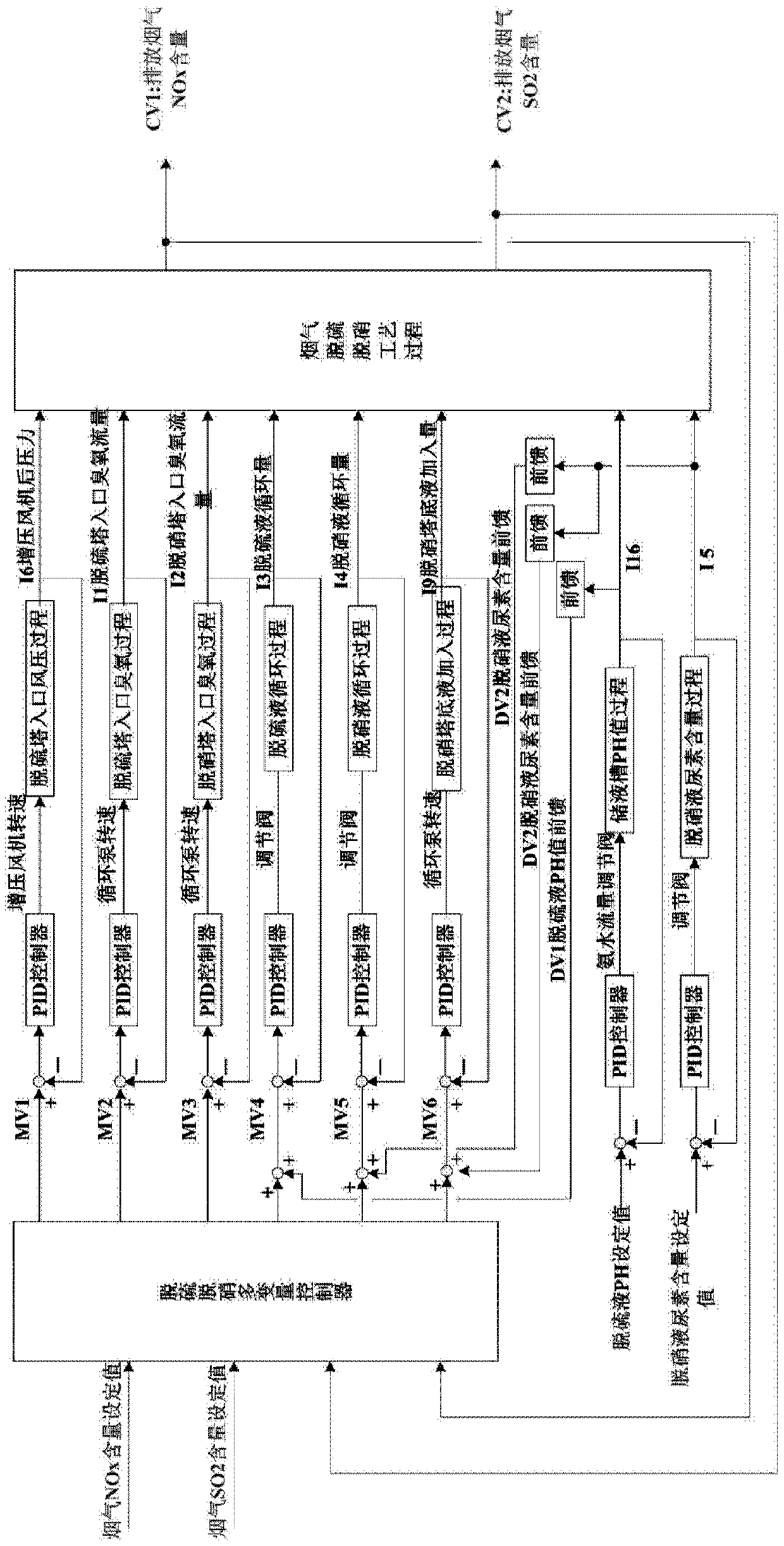

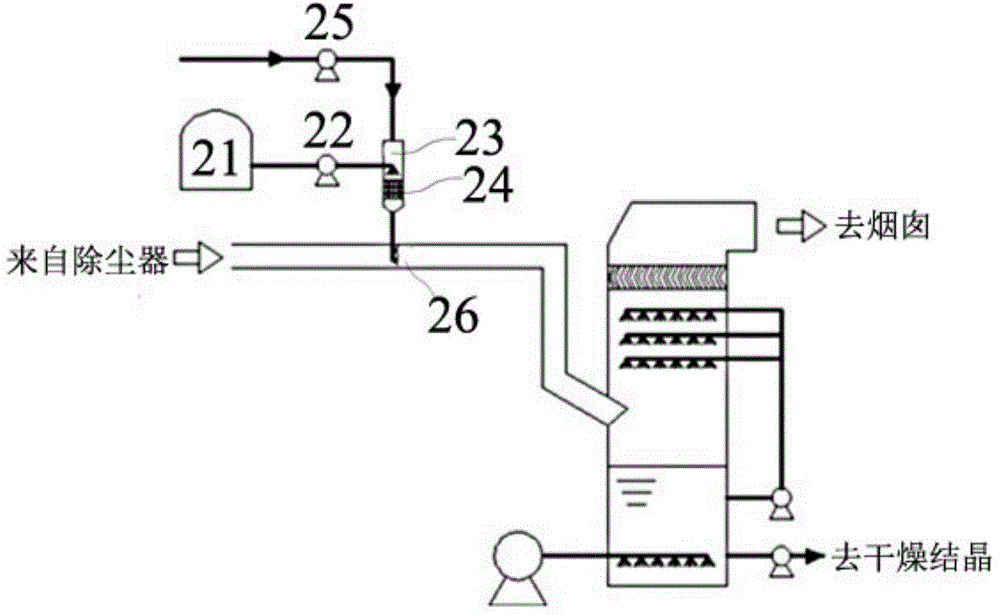

Flue gas desulfurization and denitration integrated equipment controlled through multiple variables and control method thereof

InactiveCN105498497ARealize automatic controlOvercoming compositional fluctuationsNitrous oxide captureGas treatmentComputer control systemControl signal

Provided is flue gas desulfurization and denitration integrated equipment controlled through multiple variables. The equipment comprises process parameter detection devices, process parameter adjustment devices and a computer control system, the computer control system is connected with all the parameter detection devices and parameter adjustment devices, process parameter signals of all the detection devices are received, a desulfurization and denitration process multivariable control algorithm is run, and a control signal is output to all the adjustment devices. The invention provides a control method of the equipment. According to the control method, the desulfurization and denitration control precision can be improved, the running cost is reduced, the defects that in the desulfurization and denitration process, large time delay, great inertia and desulfurization and denitration index fluctuation, caused by various internal disturbance, of discharged flue gas are overcome, and environmental protection index bounder control is achieved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

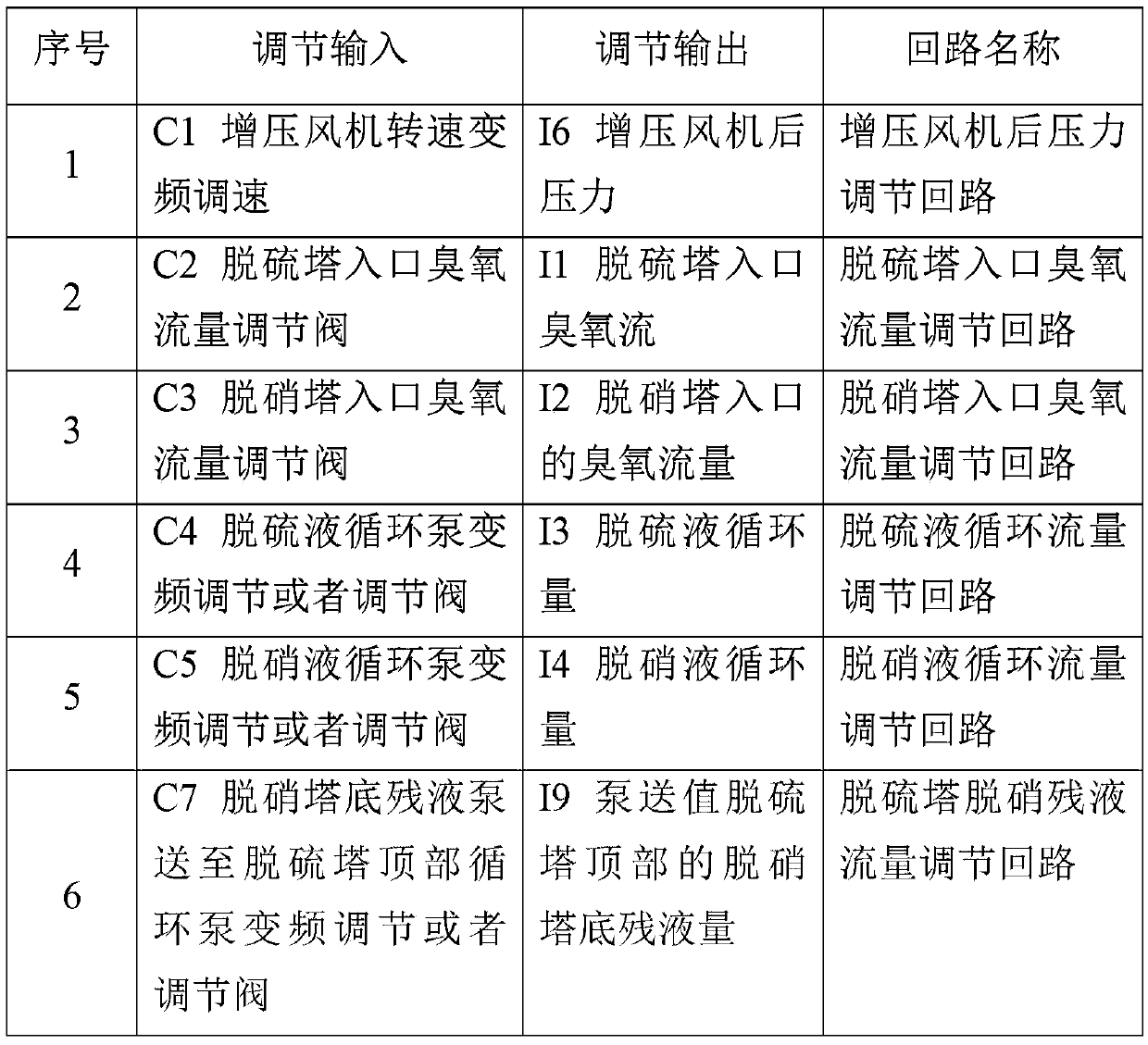

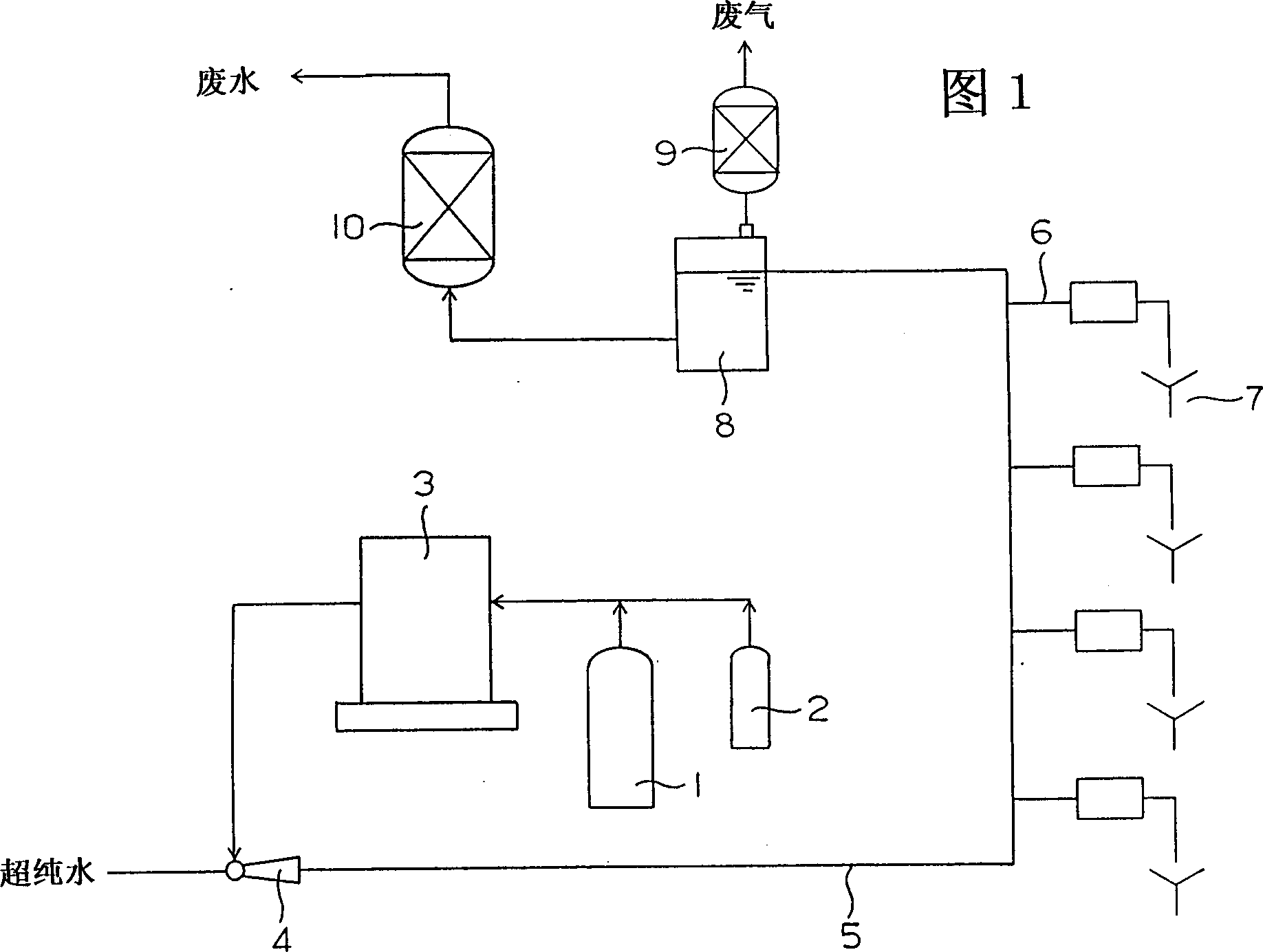

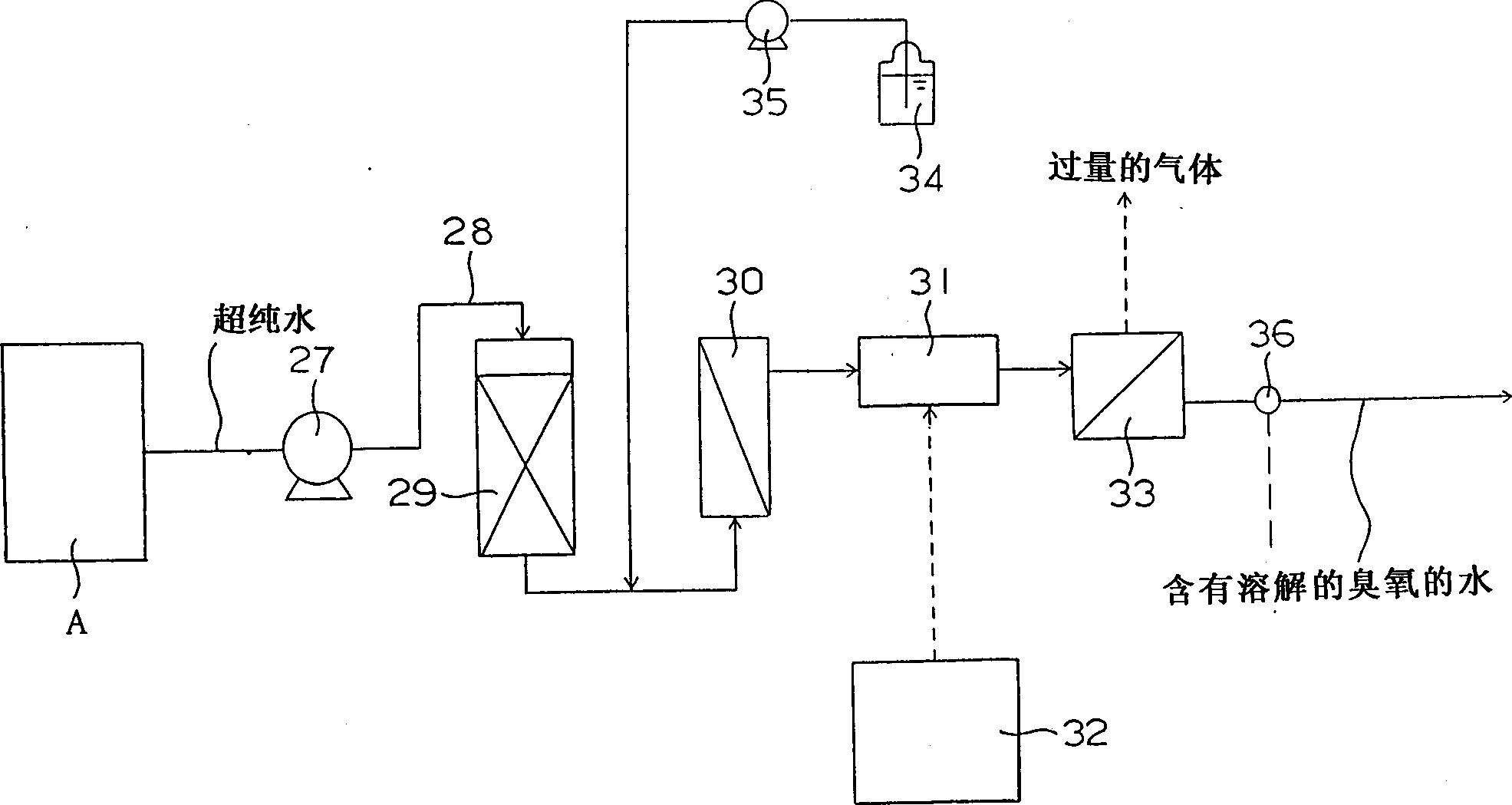

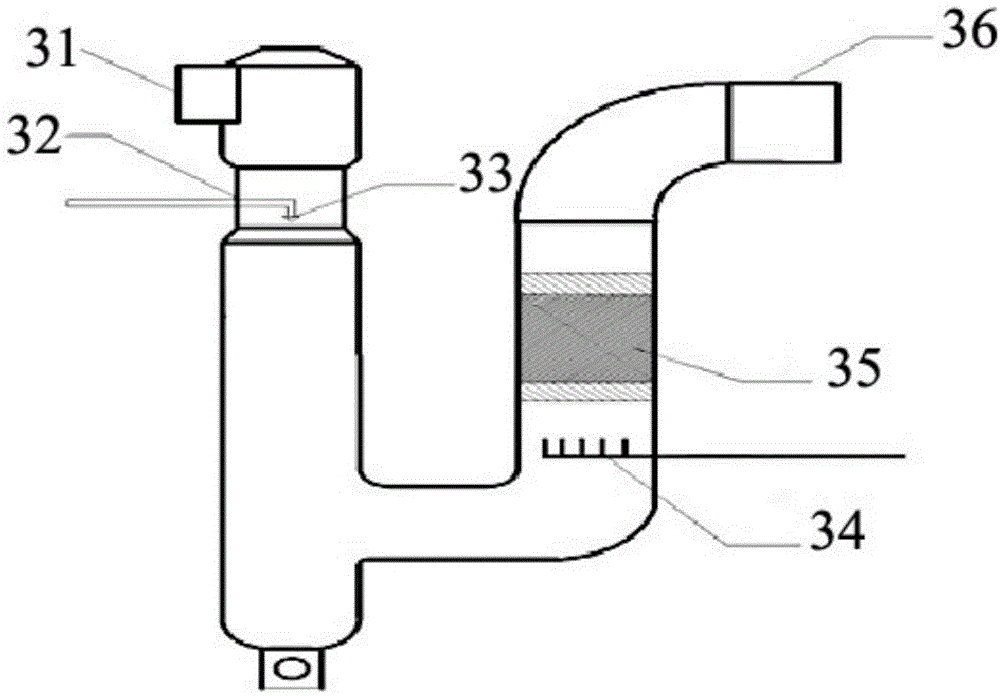

Apparatus for producing water containing dissolved ozone

InactiveCN1351514ARaise the ratioImprove qualityWaste water treatment from ceramic industriesTransportation and packagingFiltrationDecomposition

An apparatus for producing water containing dissolved ozone which comprises (A) a piping for supplying ultrapure water through which ultrapure water is supplied, (B) a catalytic reaction portion which is connected with the piping for supplying ultrapure water and in which the ultrapure water is brought into contact with an oxidation-reduction catalyst, (C) a filtration apparatus by which the ultrapure water treated in the catalytic reaction portion is filtered and (D) an apparatus for dissolving ozone in which ozone is dissolved into the ultrapure water discharged from the filtration apparatus; and an apparatus for producing water containing dissolved ozone which comprises an apparatus for producing ultrapure water which is equipped with an apparatus for irradiating with ultraviolet light, an apparatus for dissolving ozone in which ozone is dissolved into the ultrapure water produced in the apparatus for producing ultrapure water and a catalytic reaction portion which is packed with an oxidation-reduction catalyst and disposed between the apparatus for irradiating with ultraviolet light and the apparatus for dissolving ozone. Substances promoting decomposition of ozone which are contained in ultrapure water in very small amounts are removed and water containing dissolved ozone which shows little decrease in the concentration of ozone and has a great residual fraction of ozone dissolved in water after transportation for a long distance can be obtained.

Owner:KURITA WATER INDUSTRIES LTD

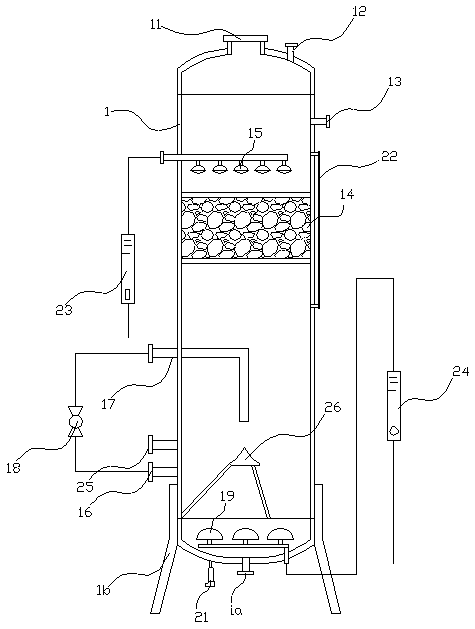

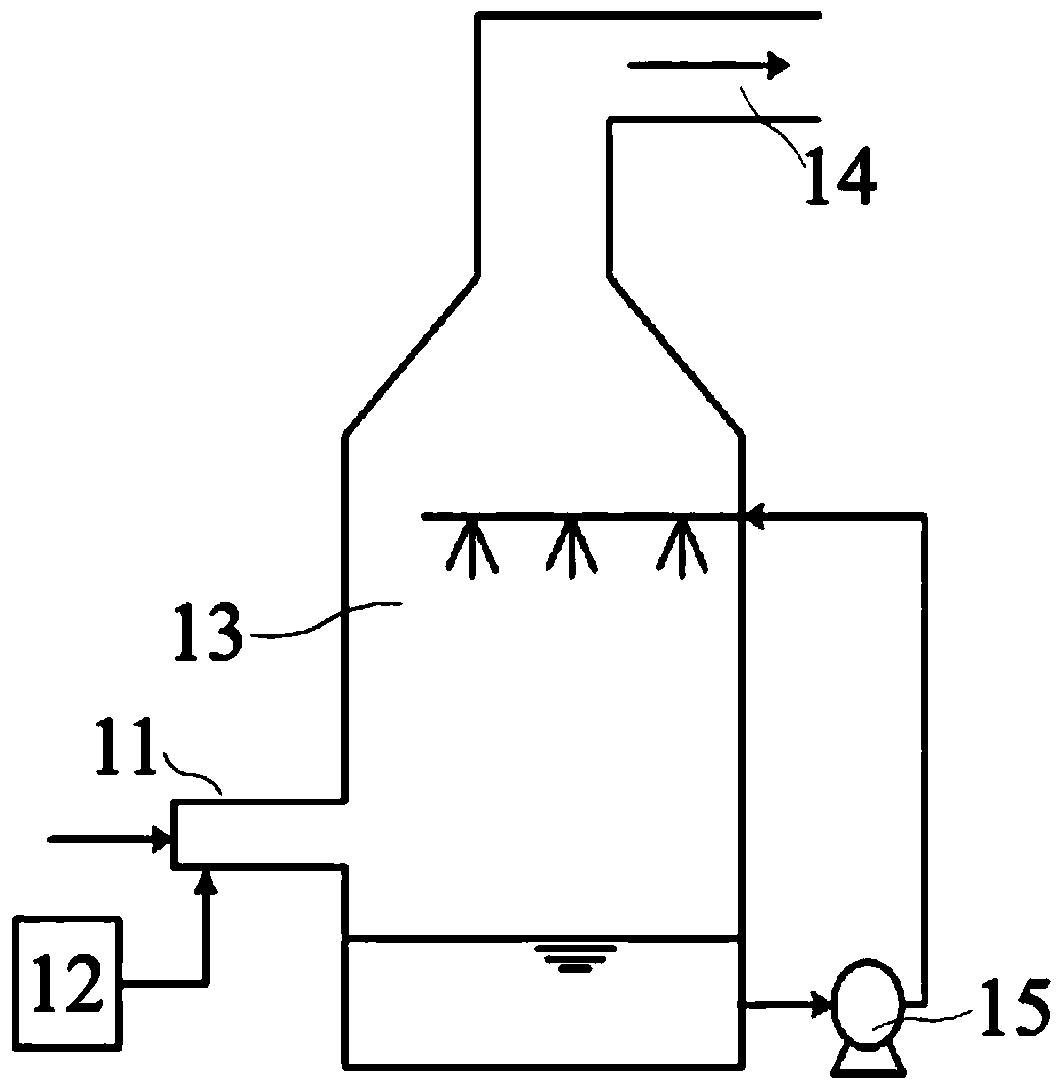

Comprehensive utilization device for desulfurization and denitrification

ActiveCN105169905AIncrease concentrationImprove desulfurization efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationEngineering

The invention provides a comprehensive utilization device for desulfurization and denitrification. The device comprises an evaporator, a desulfurization and denitrification tower, an ammonia water tank, a concentration and separation tower, wherein a desulfurization chamber and a denitration chamber are arranged inside the desulfurization and denitration tower; the denitrification chamber is arranged above the desulfurization chamber; an ammonia-water atomization spray nozzle is arranged inside the desulfurization chamber; a flue gas inlet of the desulfurization and denitration tower is arranged below the ammonia-water atomization spray nozzle; an ozone and flue gas mixer is arranged inside the denitration chamber and communicates with an ozone source arranged outside of the desulfurization and denitration tower; the ozone and flue gas mixer is composed of a horizontal coil pipe and a vertical straight pipe; the horizontal coil pipe is arranged outside of the vertical straight pipe; the lower side of the horizontal coil pipe is provided with a plurality of first gas jet outlets; the inner side of the horizontal coil pipe is provided with a plurality of first cylindrical pins; the vertical straight pipe is provided with a plurality of second gas jet outlets; the outer side wall of the vertical straight pipe is provided with a plurality of second cylindrical pins; and the first gas jet outlets and the second jet outlets form a downward inclined angle a. The comprehensive utilization device provided by the invention has good desulfurization and denitrification rates, can obtain an ammonium sulfate solution with higher concentration at the same time, facilitates to production of a high-grade ammonia fertilizer, and achieves comprehensive utilization of desulfurization and denitrification of the flue gas.

Owner:SHANDONG HUANNENG DESIGN INST

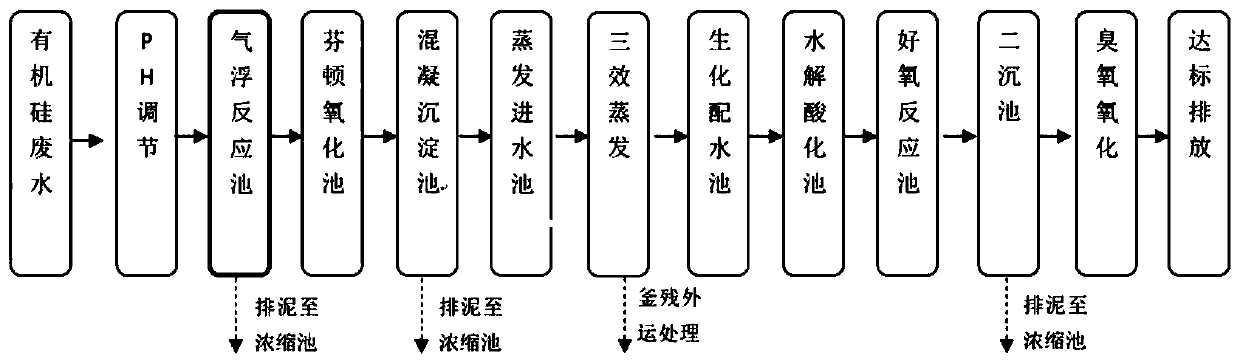

Treatment method of organic silicon production wastewater

InactiveCN110981074AIncrease stickinessReduce foamingFatty/oily/floating substances removal devicesWater treatment compoundsActivated sludgeHydrolysis

The invention discloses a treatment method of organic silicon production wastewater. The treatment method comprises the following steps: introducing organic silicon wastewater into an air floatation process, removing the floating oil in the wastewater, collecting the floating oil, returning to a production recovery process so as to be treated, introducing air floatation effluent into a pH regulating tank, regulating the pH value to 3-4, introducing into a Fenton oxidation tank, adding a ferrous sulfate solution and hydrogen peroxide, and carrying out a Fenton oxidation reaction; introducing the wastewater after Fenton oxidation into multi-effect evaporation, evaporating to remove the salt, pumping the evaporation condensate into a biochemical system, and carrying out biodegradation on theorganic matters in the wastewater by using an active sludge method and adopting facultative anaerobic hydrolysis and continuous aerobic treatment processes; and externally transporting the residual sludge, carrying out mud-water separation on biochemical aerobic effluent, carrying out hydrogen peroxide-ozone coupling oxidation on the supernatant to finally achieve the COD of smaller than or equalto 60 mg / L.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

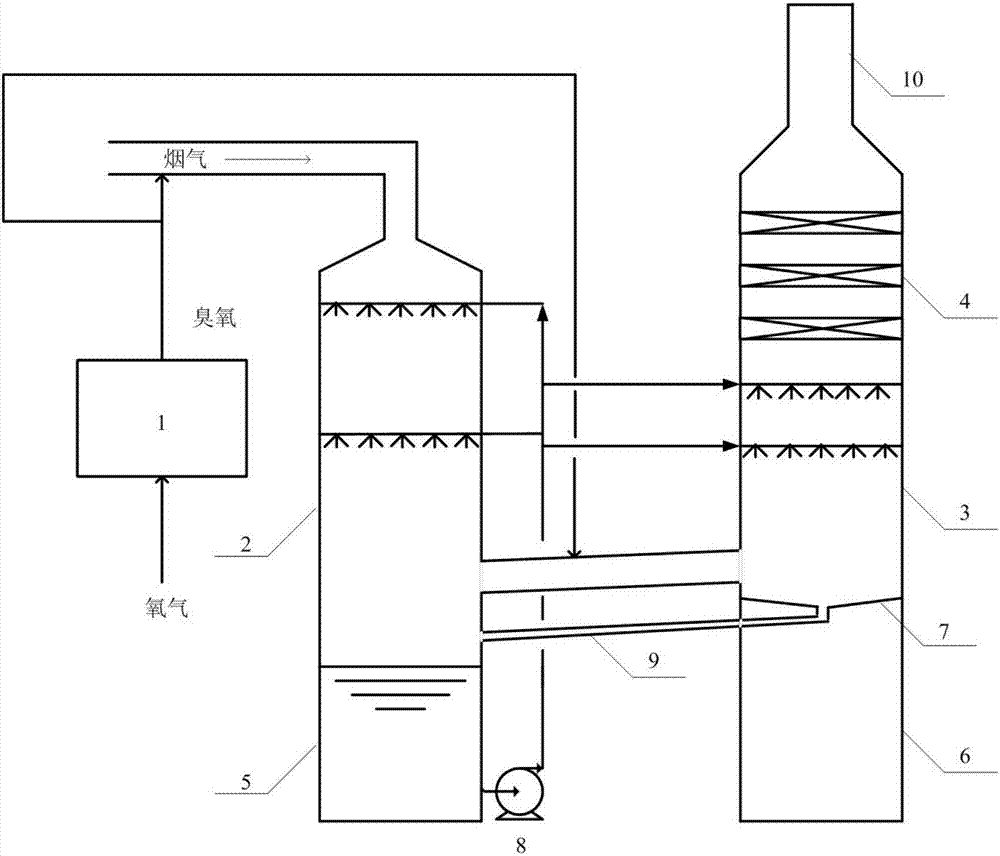

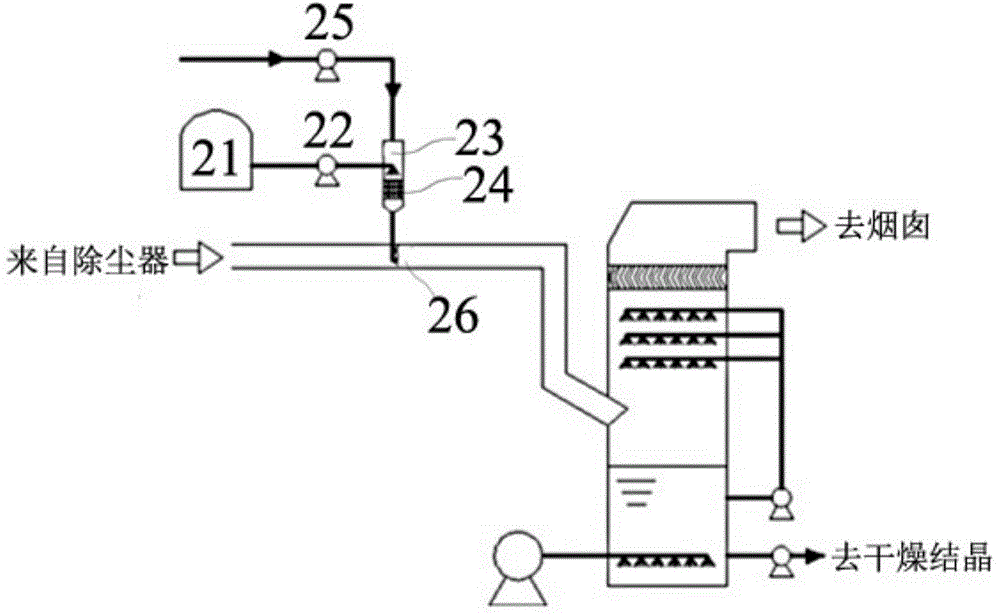

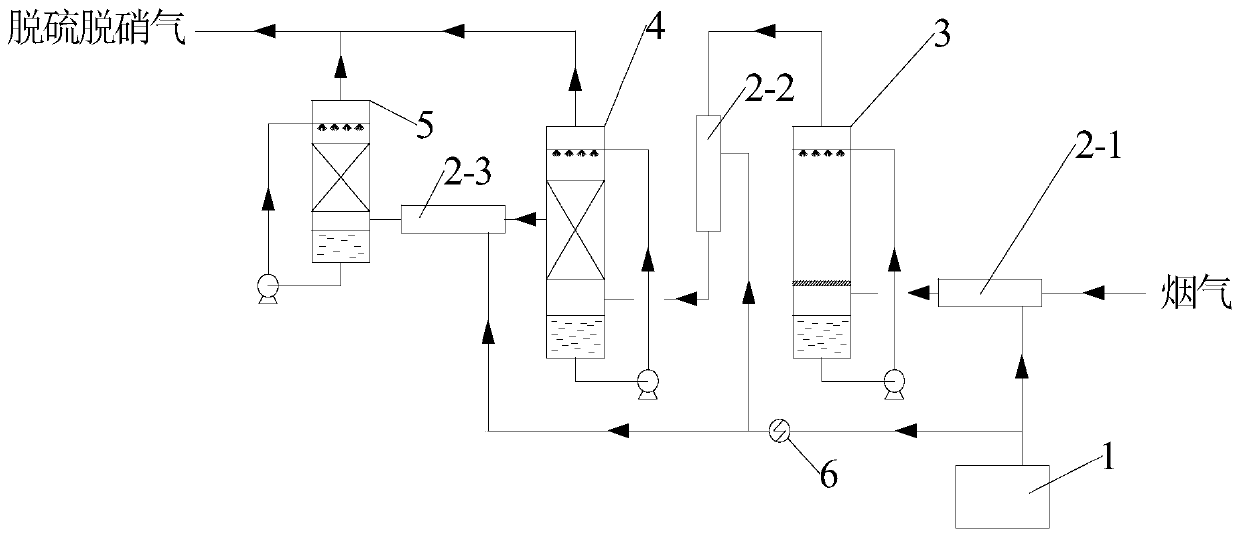

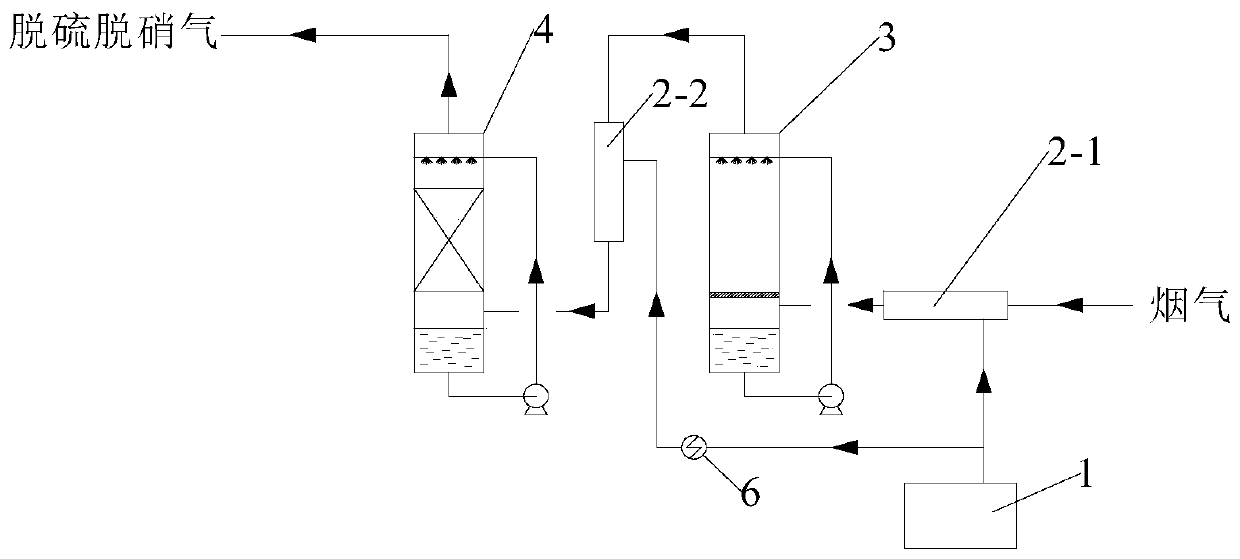

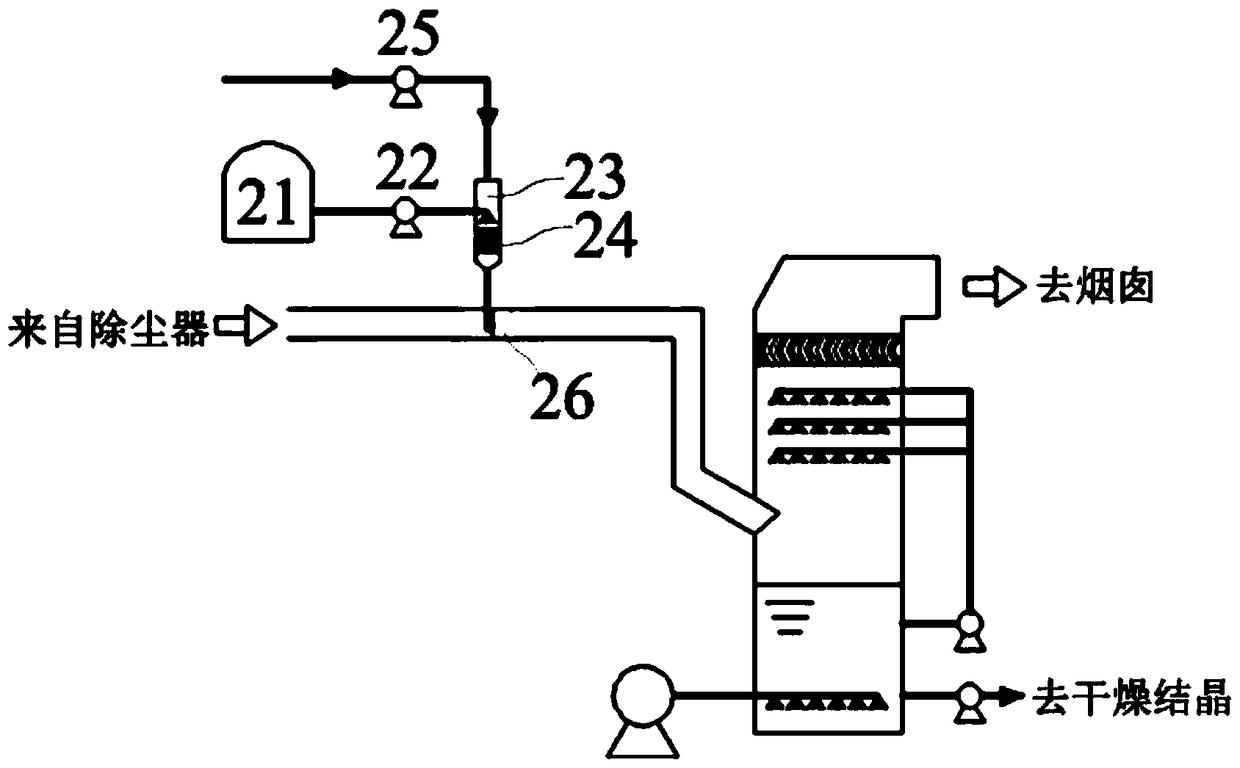

Device and method for performing ozone step-by-step oxidative absorption and desulfurization and denitration for industrial flue gas

InactiveCN106955571AHigh removal rateReduce ozone usageGas treatmentDispersed particle separationOzone generatorFlue gas

The invention provides a device and a method for performing ozone step-by-step oxidative absorption and desulfurization and denitration for industrial flue gas. The device comprises a flue gas absorption system and an ozone generator, wherein the flue gas absorption system comprises two stages of absorption towers which are in series connected front and rear; a flue gas inlet of the absorption tower at the first stage is connected with a flue gas pipeline, and a flue gas outlet of the absorption tower at the first stage is connected with a flue gas inlet of the absorption tower at the second stage through a flue gas pipeline; and an outlet of the ozone generator is connected with flues arranged on the front end of the two stages of the absorption towers. According to the method provided by the invention, ozone is separately sprayed into the flues at the front ends of the two stages of the absorption towers in certain proportion, flue gas is subjected to first-stage flue gas absorption after being oxidized by first-stage ozone, so that most of SO2 and NOX are removed; second-stage flue gas absorption is performed after second-stage ozone oxidization is performed, so that the rest of SO2 and NOX is removed. The device has the advantages of small ozone dose, compact equipment, low investment and operation cost, and the like, and is suitable for deep desulfurization and denitration treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

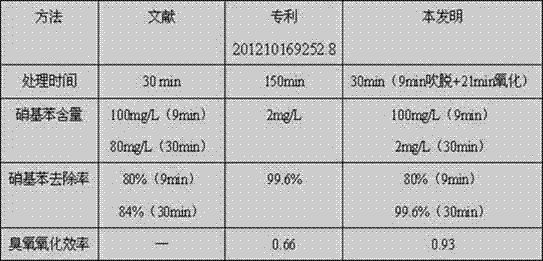

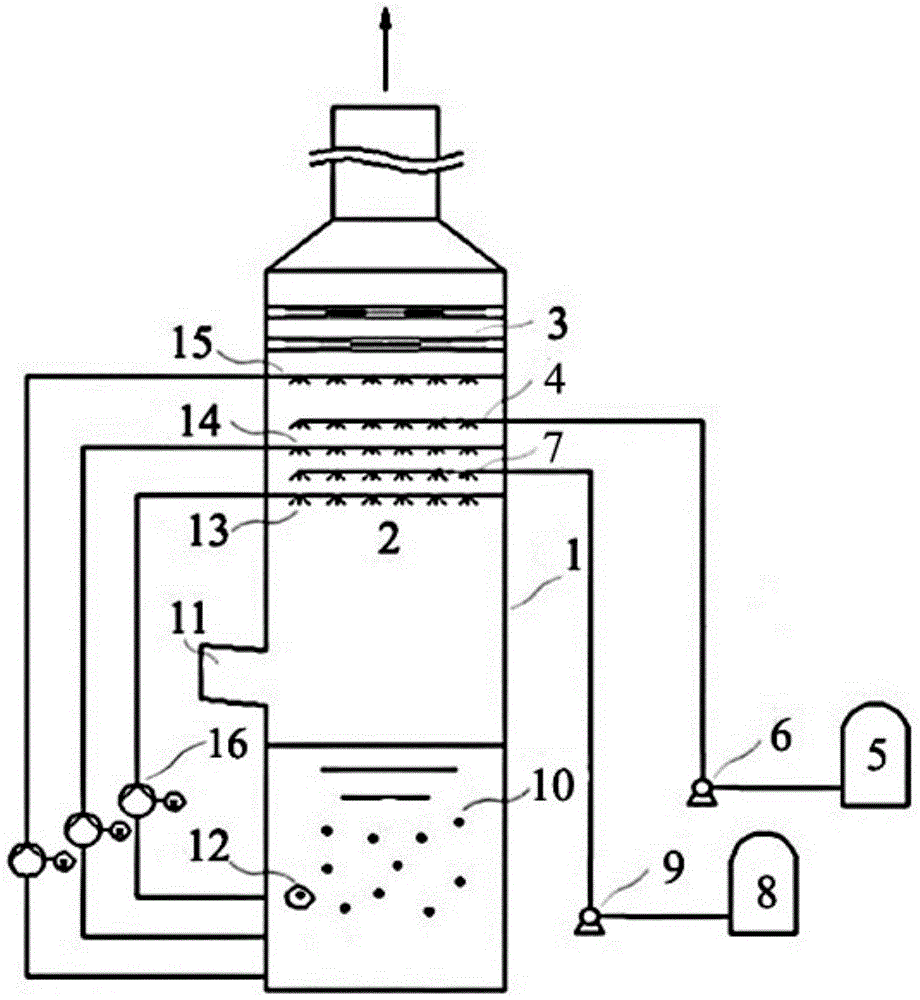

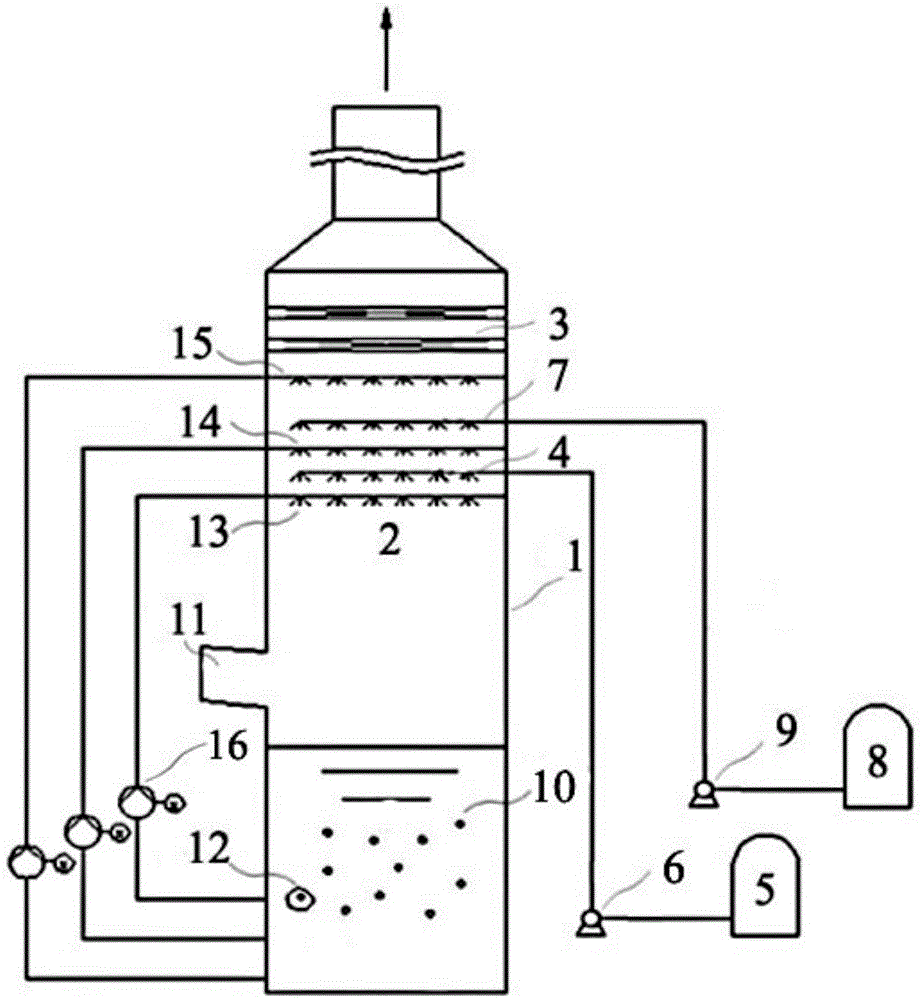

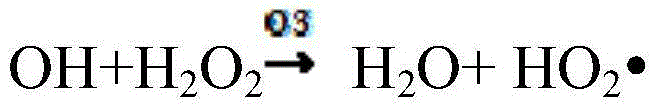

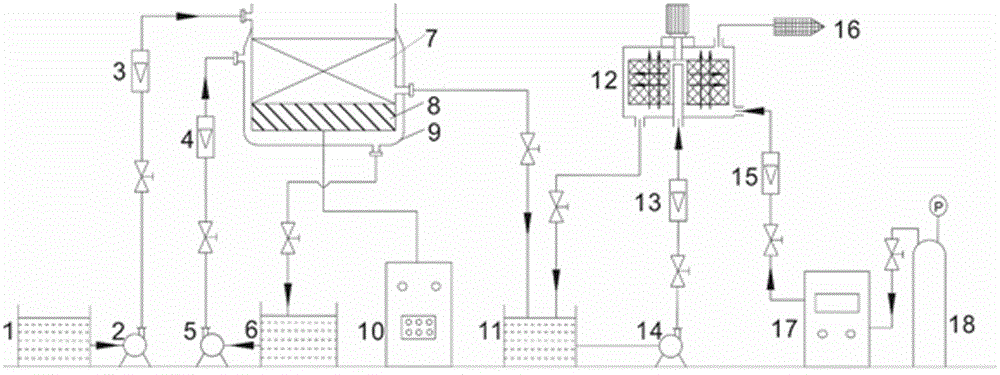

Device for degrading waste water containing high-concentration nitrobenzene through air stripping-ozone/ultrasound oxidation and treatment method of device

InactiveCN104710062AReduce processing timeImprove oxidation efficiencyMultistage water/sewage treatmentNature of treatment waterHigh concentrationAdvanced oxidation process

The invention provides a device for degrading waste water containing high-concentration nitrobenzene through air stripping-ozone / ultrasound oxidation and treatment method of the device, belongs to the technical field of high-concentration nitrobenzene-containing waste water treatment, and aims to solve the problem of high cost of ozone-based advanced oxidation process for treating high-concentration nitrobenzene-containing waste water. The method comprises the following steps: firstly, high-concentration nitrobenzene-containing waste water is in contact with air in a hypergravity device to complete air stripping mass transfer process; after the air stripping mass transfer process is completed, the waste water is subjected to ultrasonic wave degradation, the degraded waste water is fed into the hypergravity device to react with ozone gas, the waste water containing ozone returns to an ultrasound liquid storage pot, and then nitrobenzene is degraded under an ultrasonic wave synergistic effect. The air-stripping method is used to enable target pollutant content in the waste water to be reduced to carry out oxidation reaction, so that waste water quality change is reduced to the largest extent, and the intermediate product production amount is further reduced, the ozone and hydroxyl free radical consumption substance production amount can be reduced, the oxidation efficiency is improved, the ozonation efficiency is improved by 40%-50%, the treatment time is shortened by 80%, the usage amount of ozone is reduced by 70%, and the treatment cost is reduced by 50%.

Owner:ZHONGBEI UNIV

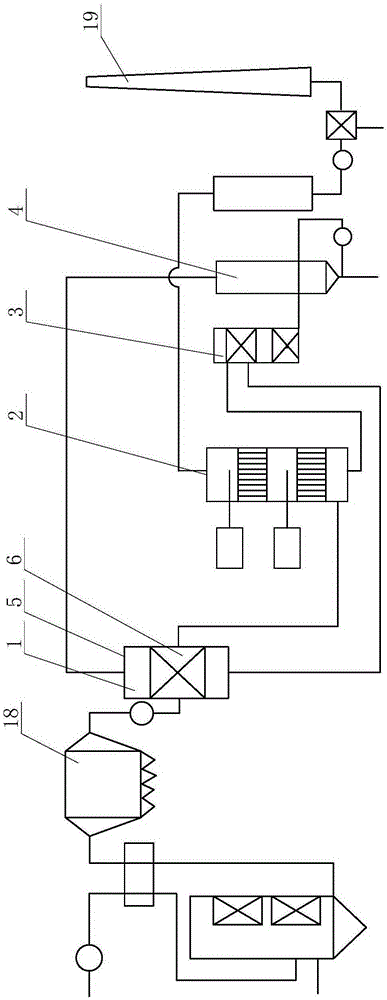

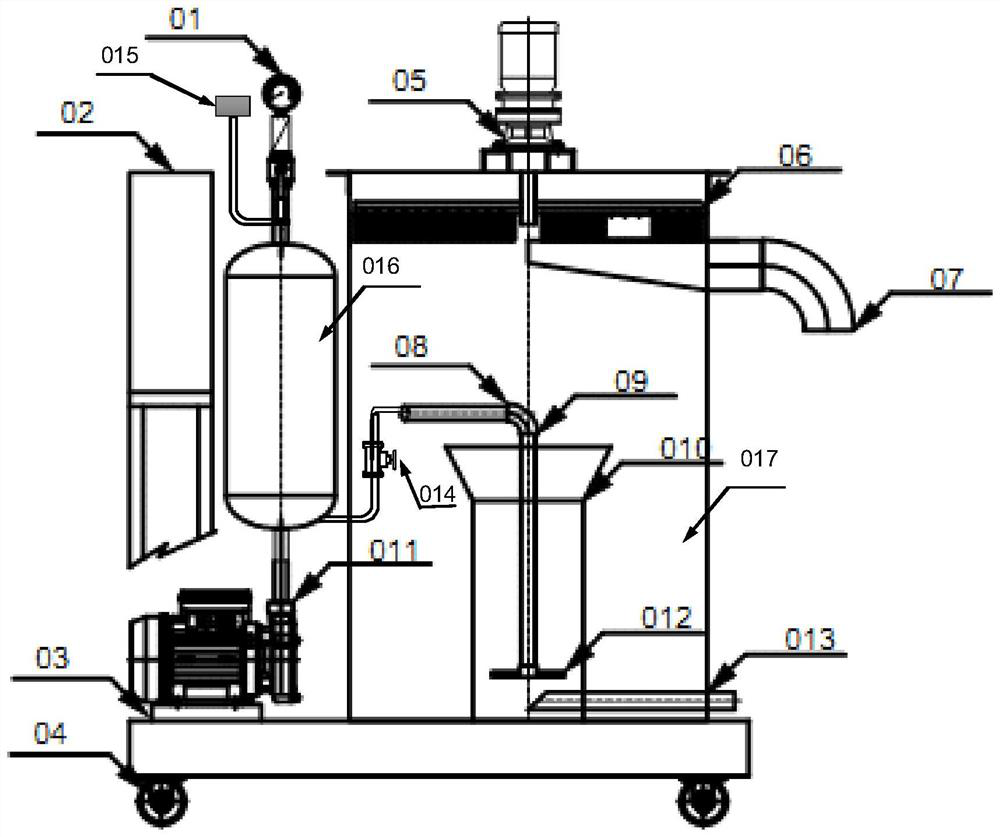

Flue gas treatment device and method

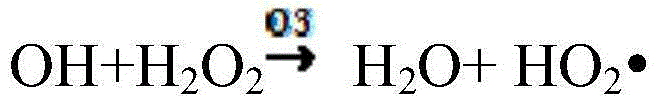

InactiveCN104941417AReduce ozone usageLow running costCombination devicesAir quality improvementChemistryFlue gas

The invention discloses a flue gas treatment device and method, namely an integrated flue gas desulfurization, denitrification, demercuration, dedusting and defogging device and method. The device comprises flue gas treatment equipment, ozone supply equipment, hydrogen peroxide supply equipment and the like, wherein the flue gas treatment equipment comprises an ozone spray oxidation reaction layer, a hydrogen peroxide spray oxidation reaction layer, an absorbing sprinkling area, a slurry storage area and a dedusting and defogging area; both the ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are arranged in the absorbing sprinkling area; the dedusting and defogging area is positioned above the absorbing sprinkling area. The device and the method provided by the invention are suitable for integrated desulfurization, denitrification, demercuration, dedusting and defogging treatment of flue gas which contains SO2, NOX, Hg<0> and dust, and is produced by coal burning boilers, steel sintering machines, pellets, industrial furnaces and the like, and can solve the problem that a conventional process is complex in equipment, high in running cost and energy consumption, and low in demercuration and denitration efficiencies.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

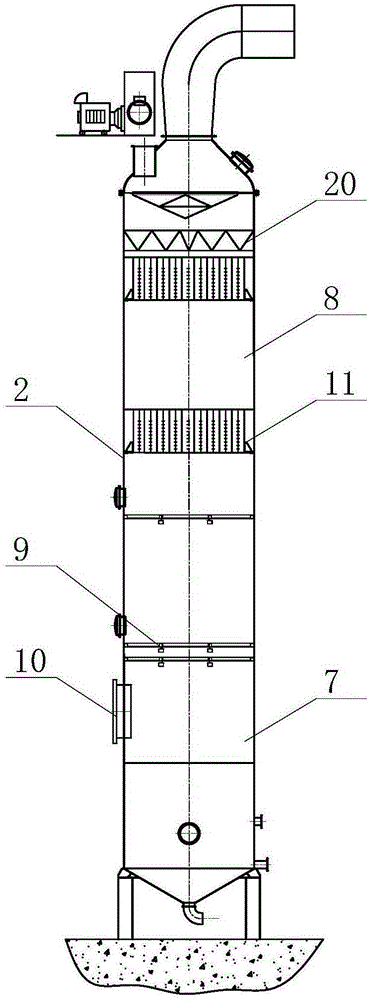

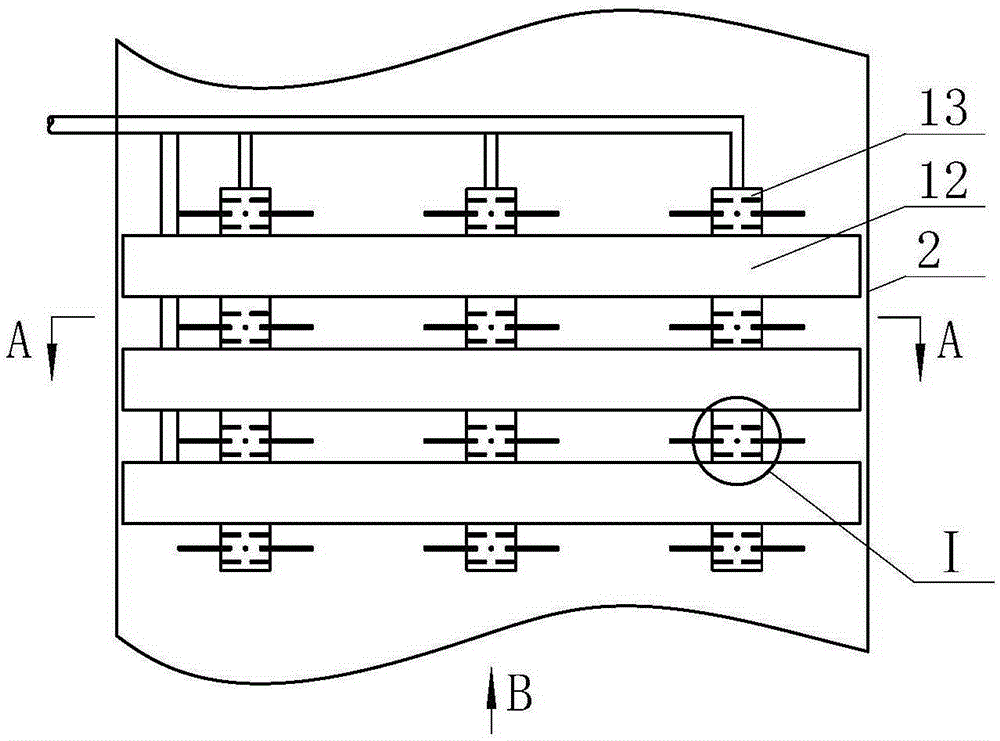

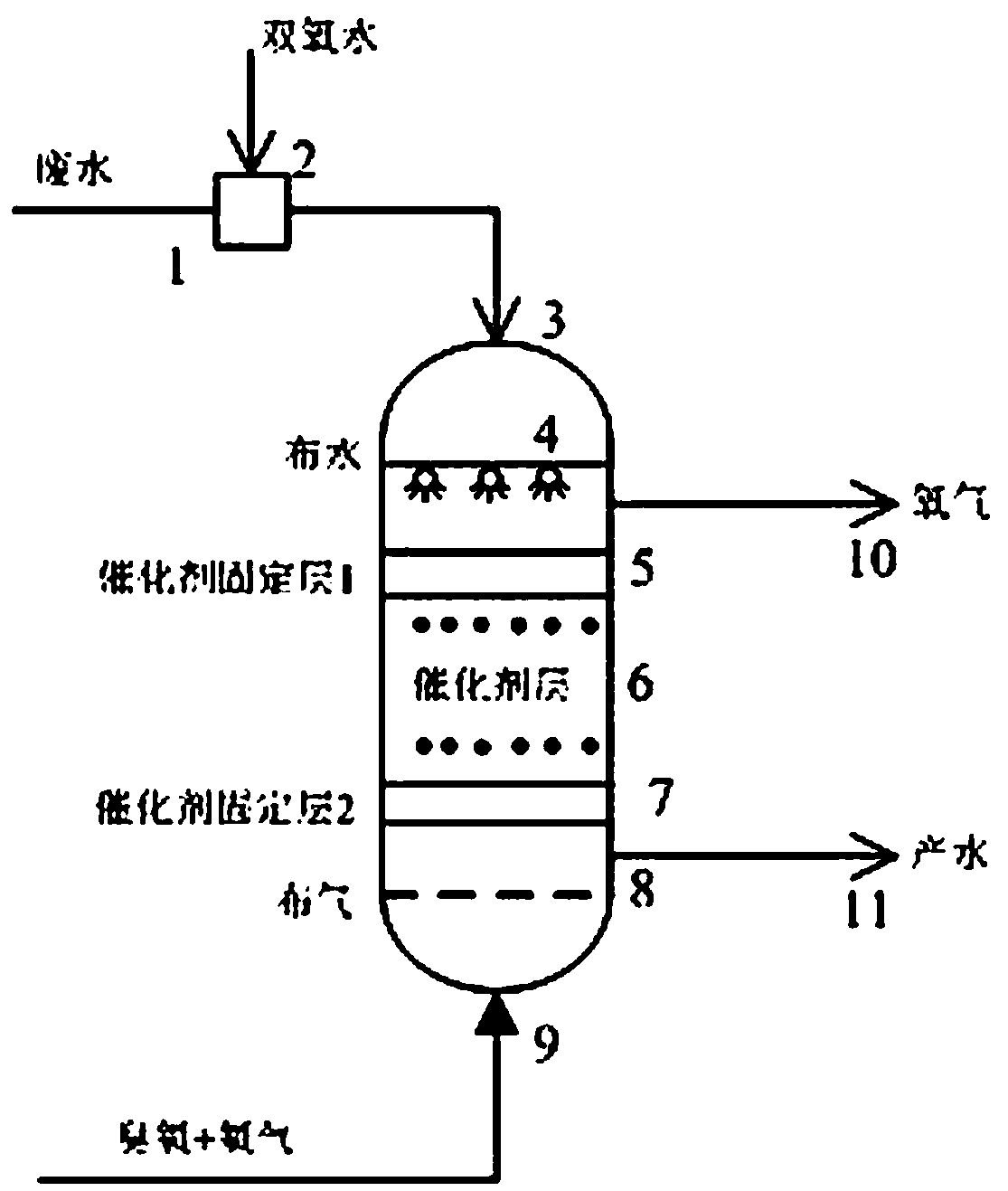

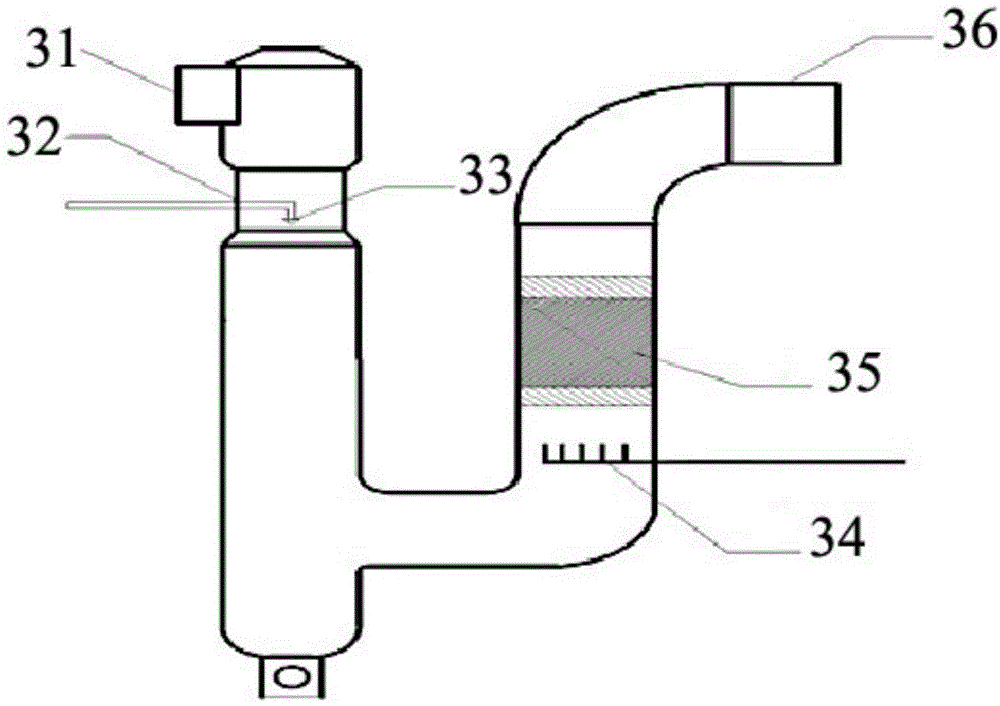

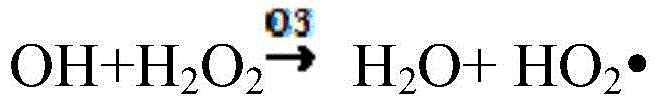

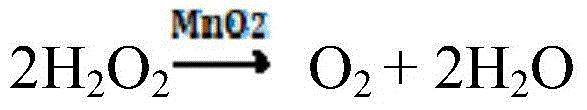

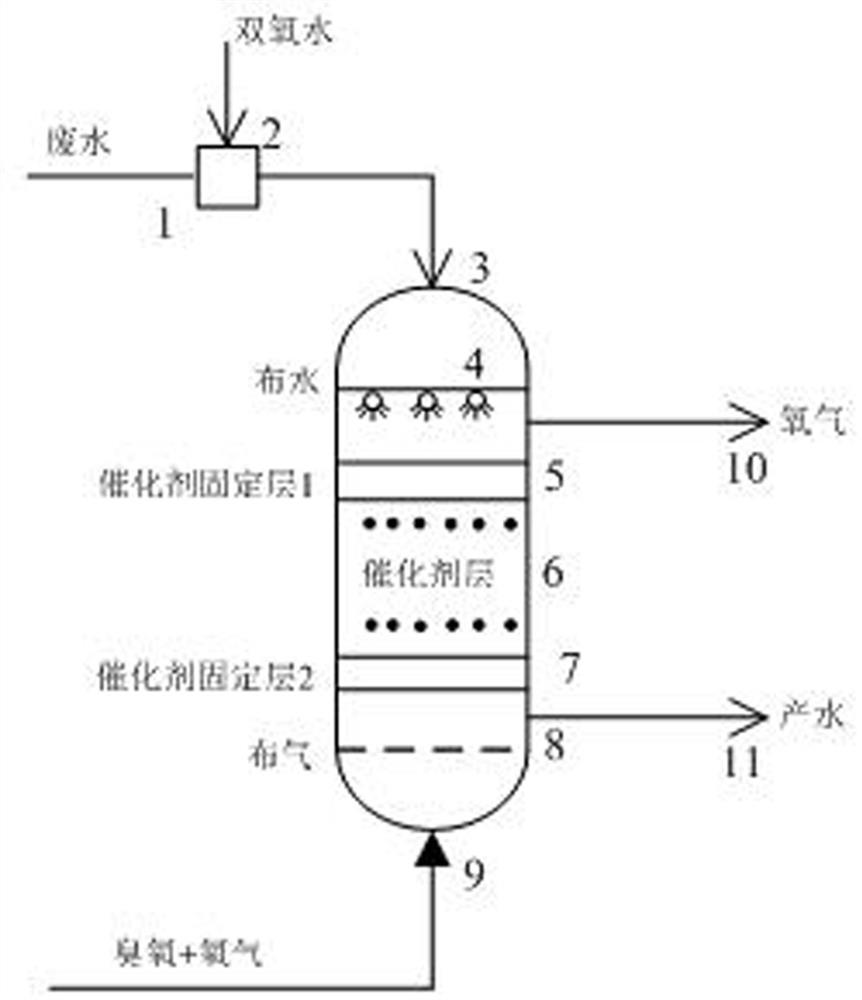

Method and device for ozone heterogeneous catalytic oxidation of COD in wastewater

ActiveCN107585852AImprove utilization efficiencyReduce ozone usageMolecular sieve catalystsWater/sewage treatment by oxidationCatalytic oxidationOxygen

The invention relates to a method and device for ozone heterogeneous catalytic oxidation of COD in wastewater. According to the method, a solid catalyst is used for decomposing ozone into hydroxyl free radicals with stronger oxidability; then an oxidation reaction occurs between the hydroxyl free radicals and organic matters in the wastewater; and the organic matters are converted into carbon dioxide and water, so that the purpose of reducing the COD in the wastewater is achieved. In the method, the mass ratio of the ozone to the COD in the wastewater is (0.5-1):1, the usage amount of the solid catalyst is 0.2-2g / L, and the residence time is 0.1-2 hours. A catalytic oxidation tower for realizing the method is designed, the upper part of the tower is a mixed liquid distribution area of wastewater and hydrogen peroxide; the middle part is a catalyst area; and the lower part is a mixed gas distribution area of oxygen and ozone. The method and device provided by the invention have the advantage of solving the problems that the utilization rate of ozone in ozone catalytic oxidation is low, and the oxidation rate is low.

Owner:UNIV OF JINAN

Method and device for degrading nitrobenzene waste water through reinforced iron-carbon micro-electrolysis-ozonation method

PendingCN105884092AIncrease reaction rateReduce ozone usageWater/sewage treatment with mechanical oscillationsWater contaminantsElectrolysisReaction rate

The invention belongs to the technical field of ozonation waste water treatment, and particularly relates to a method and device for degrading nitrobenzene waste water through a reinforced iron-carbon micro-electrolysis-ozonation method. The problems that in the prior art, after an iron-carbon micro-electrolysis bed operates for a long time, filler is passivated and inactivated, an electrolytic reaction is blocked, and the efficiency improving range of a catalyst to ozonation degradation of the waste water is limited are solved. Firstly, the nitrobenzene waste water is placed in an iron-carbon micro-electrolysis bath, ultrasonic waves are used for assisting, nitrobenzene hard to degrade is fast reduced into aniline easy to degrade under the common action of ultrasound / iron-carbon micro-electrolysis, and meanwhile Fe2+ is released into the waste water after the electrolytic reaction; then the waste water is fed into supergravity equipment to fully react with ozone, and residual organic pollutants in the waste water are deeply oxydatively degraded. The reaction rate of iron-carbon micro-electrolysis is overall increased by 6-10 times, meanwhile, the concentration of free Fe2+ in the waste water is increased by 5-8 times, and the use amount of the ozone in the subsequent supergravity-ozonation method is greatly reduced.

Owner:ZHONGBEI UNIV

Flue gas desulphurization-denitration integrated device and method

InactiveCN104941412AIncrease productionImprove removal efficiencyDispersed particle separationAir quality improvementReaction layerFlue gas

The invention discloses a flue gas desulphurization-denitration integrated device and method. The flue gas desulphurization-denitration integrated device comprises a flue gas desulphurization-denitration device, an ozone supplement device and a hydrogen peroxide supplement device. The flue gas desulphurization-denitration device comprises an ozone spray oxidation reaction layer, a hydrogen peroxide spray oxidation reaction layer, an absorption spray zone and a slurry storage zone. The ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are arranged in the absorption spray zone. The flue gas desulphurization-denitration integrated device and method are suitable for desulphurization-denitration integrated treatment on SO2- and NOX-containing flue gas produced by a coal-fired boiler, a steel sintering machine, pelletizing and an industrial kiln, and solve the problem that the existing flue gas desulphurization-denitration integrated method has a high operation cost, utilizes complex equipment and has low denitration efficiency.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

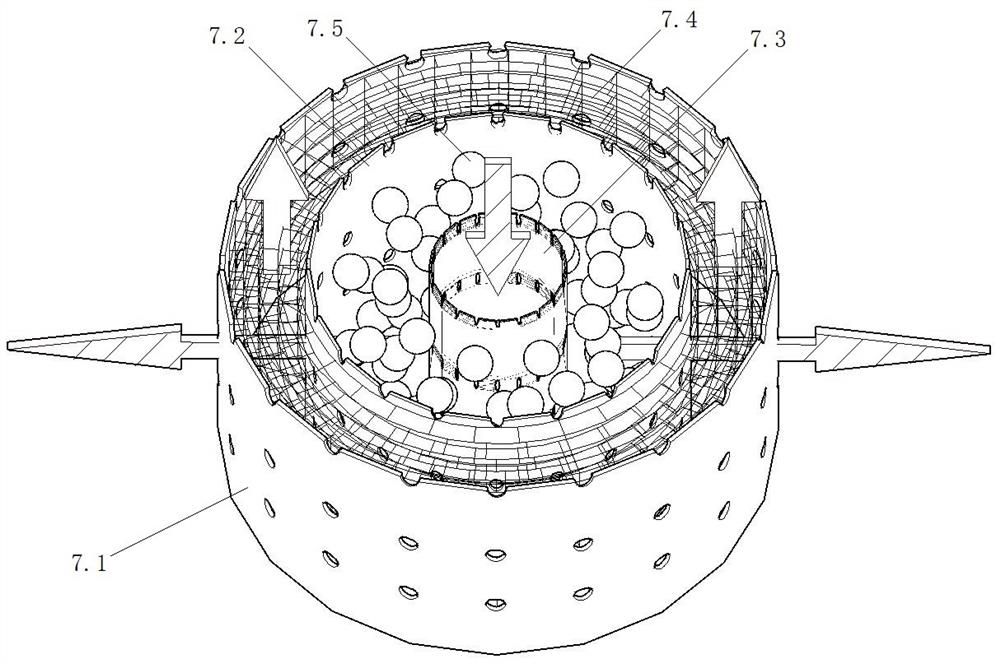

Catalytic ozonation reactor for sewage treatment

PendingCN113526649AThoroughly oxidizedReduce churnWater treatment compoundsSpecific water treatment objectivesPtru catalystCatalytic oxidation

The invention relates to a catalytic ozonation reactor for sewage treatment, and aims to solve the technical problem that an existing catalytic ozonation reactor is unreasonable in structural design, large in catalyst filling amount, complex in aeration and backwashing system, low in reaction depth, high in concentration of gas-phase residual ozone after reaction and the like. A catalyst supporting grid is designed to divide a reactor into a lower ozone direct oxidation zone and an upper ozone catalytic oxidation zone, and the catalytic oxidation zone is filled with a catalyst A and a catalyst B in sequence. The reactor not only utilizes ozone direct oxidation and free radical indirect oxidation processes, but also utilizes the characteristics of different catalysts to carry out ordered matching, so that the ozone utilization efficiency is improved, the heavy metal content in effluent is reduced, and meanwhile, ozone and sewage are fully mixed by using a gas-liquid mixing pump. According to the scheme, the efficiency problem of an existing ozone reactor is well solved, and the reactor is particularly suitable for advanced treatment of sewage.

Owner:大连一名环保科技有限公司

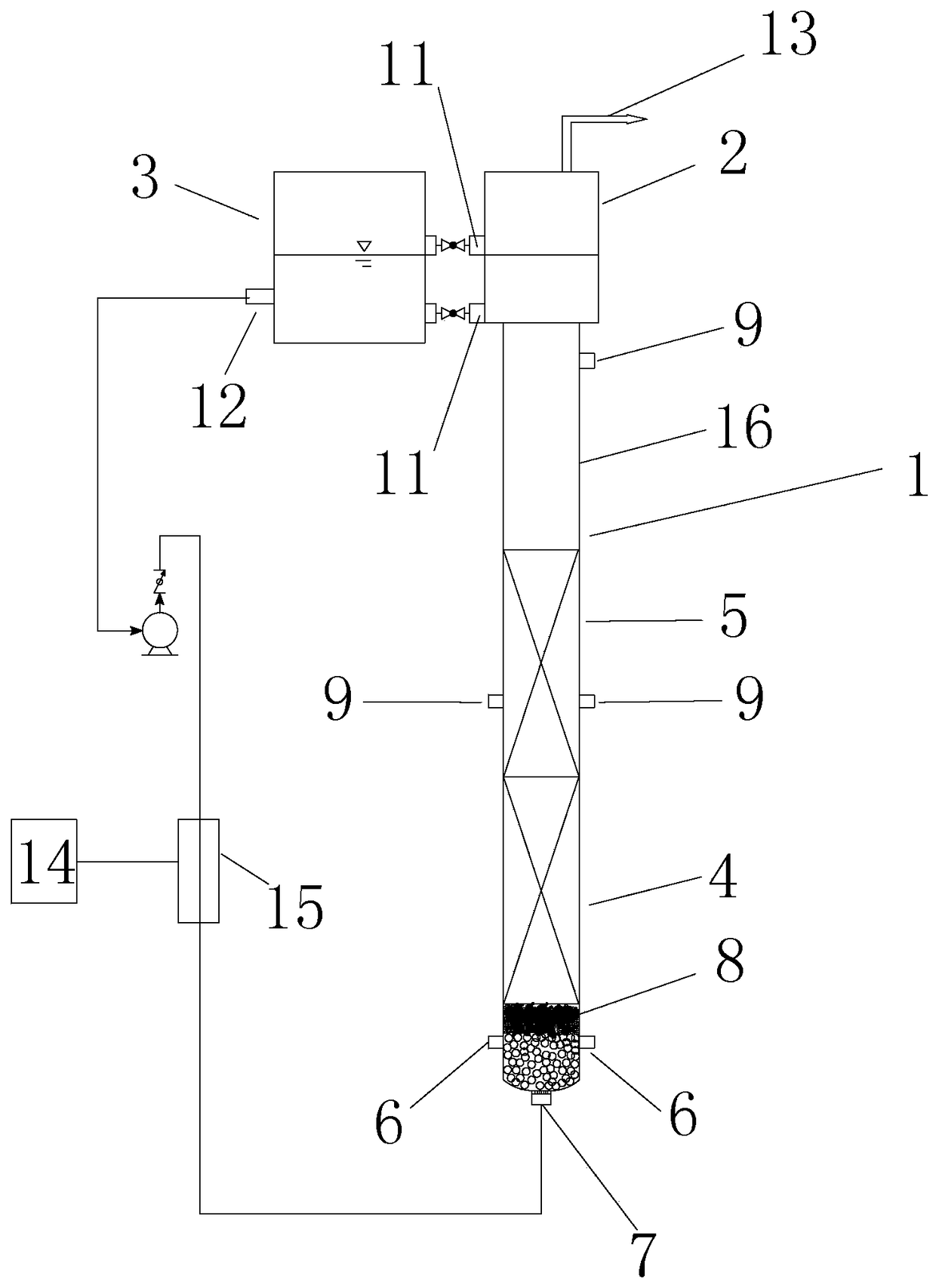

A fluidized bed ozone oxidation tower

ActiveCN105347462BImprove reaction efficiencyReduce processing costsTreatment involving filtrationChemical/physical/physico-chemical processesRefluxFluidized bed

The invention discloses a fluidized bed type ozone oxidation tower which comprises a tower body, a water outlet tank arranged at the top of the tower body, a reflux tank communicated with the water outlet tank and an ozone device. The bottom of the tower body is provided with sewage inlets; the interior of the tower body is divided into a water flow adjusting area, a fluidized bed filling area, a fluidized bed reaction expansion area and a reaction buffer water outlet area from bottom to top; a water flow adjusting device is arranged in the water flow adjusting area, and the fluidized bed filling area is filled with an ozone catalyst; a reflux water inlet is formed in the water flow adjusting area of the tower body; the water outlet tank is provided with a water draining port, the reflux tank is provided with a reflux water outlet, and the height of the water draining port is larger than that of the reflux water outlet; the water outlet tank is communicated with the reflux tank through two communicating pipes, the height of one communicating pipe is not larger than that of the reflux water outlet, and the height of the other communicating pipe is not smaller than that of the water draining port; the reflux water outlet is communicated with the reflux water inlet through a pipeline provided with a gas-liquid mixing device; the ozone device is connected with the gas-liquid mixing device; the top of the water outlet tank and the top of the reflux tank are sealed, and the top of the water outlet tank is provided with an exhaust pipe.

Owner:BEIJING GEOENVIRON ENG & TECH

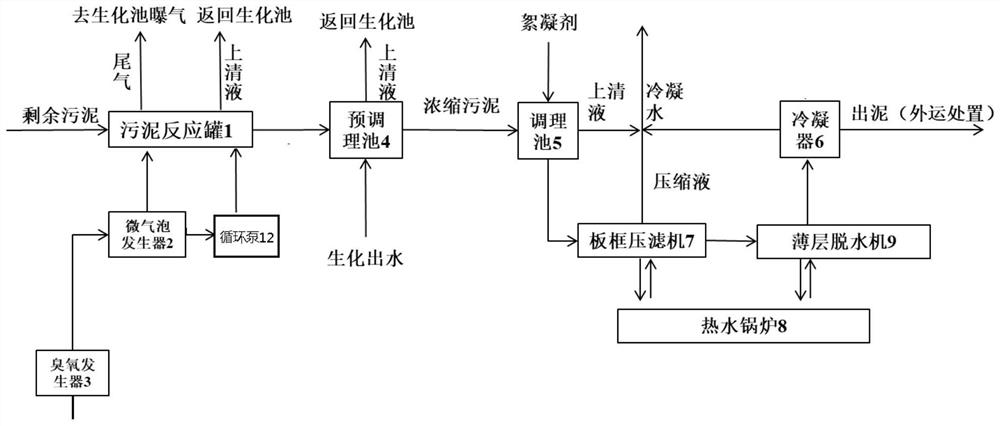

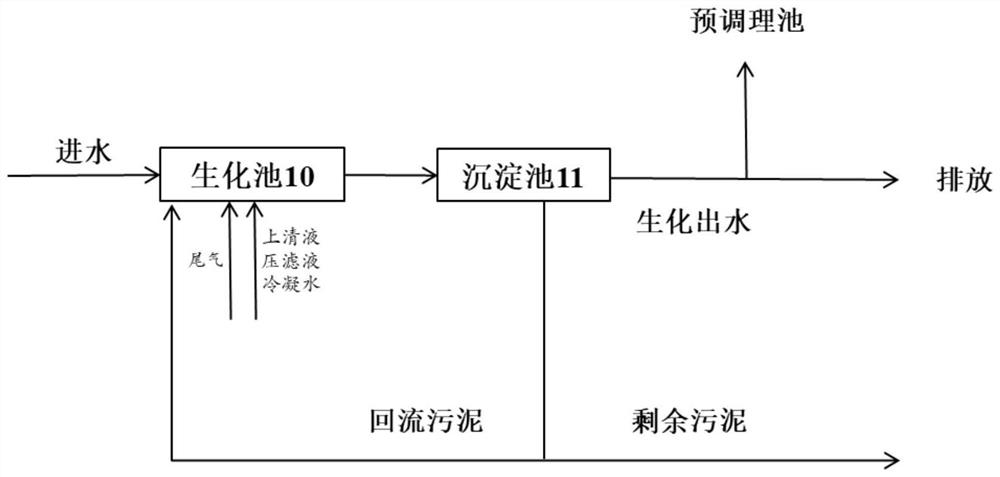

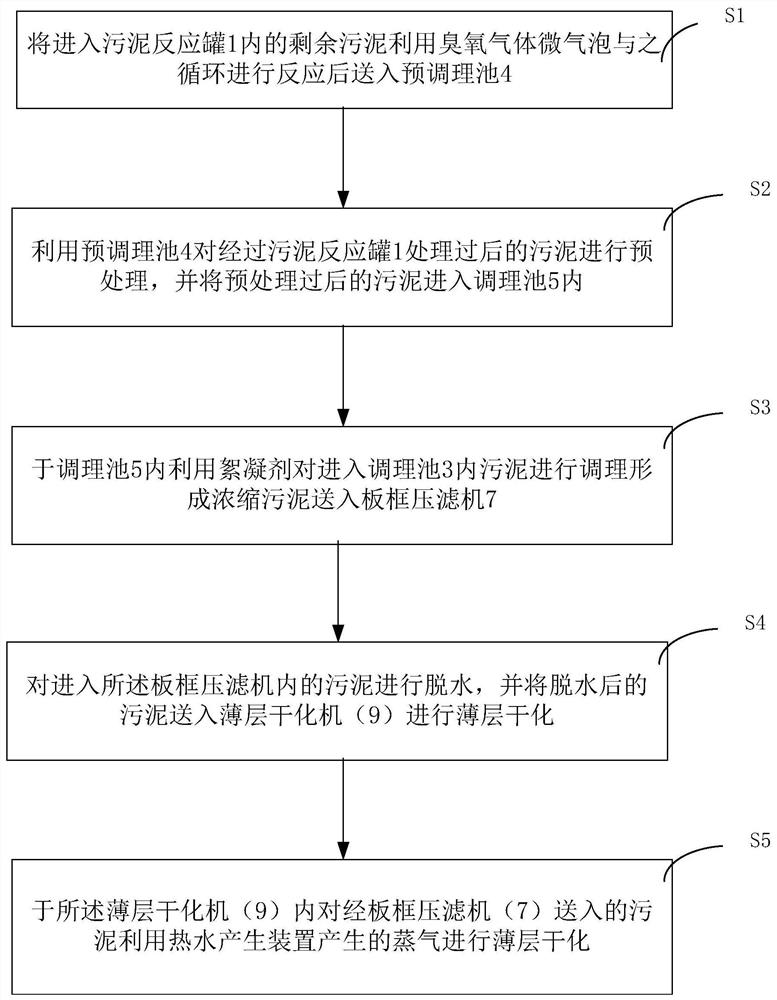

Microbubble ozonation-thin layer drying combined treatment device and method for excess sludge

InactiveCN113292215AImprove resource utilizationImprove drying effectSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationWater vaporProcess engineering

The invention discloses a microbubble ozonation-thin layer drying combined treatment device and method for excess sludge. The device comprises: a sludge reaction tank (1), which is used for enabling the excess sludge entering the sludge reaction tank (1) to cyclically react with ozone gas microbubbles and then to be fed into a pre-conditioning pool (4); the pre-conditioning tank (4), which is used for pre-treating the sludge treated by the sludge reaction tank (1) and feeding the pre-treated sludge into a conditioning tank (5); the conditioning tank (5), which is used for conditioning the sludge entering the conditioning tank (5) by using a flocculating agent to form concentrated sludge; a plate-and-frame filter press (7), which is used for dewatering the sludge entering the plate-and-frame filter press (7) and feeding the dewatered sludge into a thin-layer drying machine (9) for thin-layer drying; and the thin-layer drying machine (9), which is used for carrying out thin-layer drying on the sludge fed by the plate-and-frame filter press (7) by utilizing hot water vapor.

Owner:SHANGHAI MUNICIPAL WATER RESOURCES DEV & UTILIZATION NAT ENG CENT

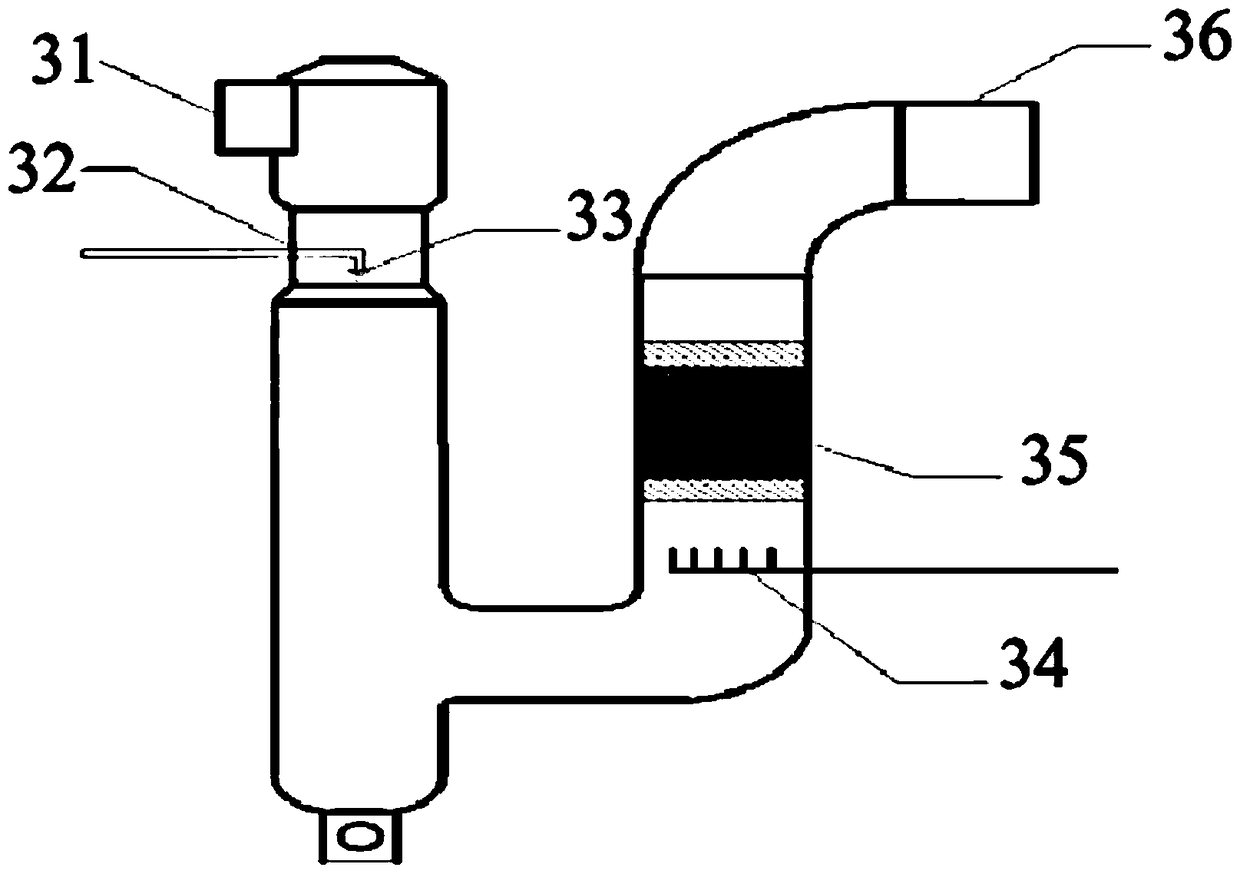

Flue gas denitration device and method

ActiveCN104941430AIncrease productionImprove removal efficiencyDispersed particle separationReaction layerFlue gas

The invention discloses a flue gas denitration device and method. The flue gas denitration device comprises a flue gas denitration device, an ozone supplement device and a hydrogen peroxide supplement device. The flue gas denitration device comprises an ozone spray oxidation reaction layer, a hydrogen peroxide spray oxidation reaction layer, an absorption spray zone and a slurry storage zone. The ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are arranged in the absorption spray zone. The flue gas denitration device and method are suitable for denitration integrated treatment on NOX-containing flue gas produced by a coal-fired boiler, a steel sintering machine, pelletizing and an industrial kiln, and solve the problem that the existing flue gas denitration method has a high operation cost, utilizes complex equipment and has low denitration efficiency.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

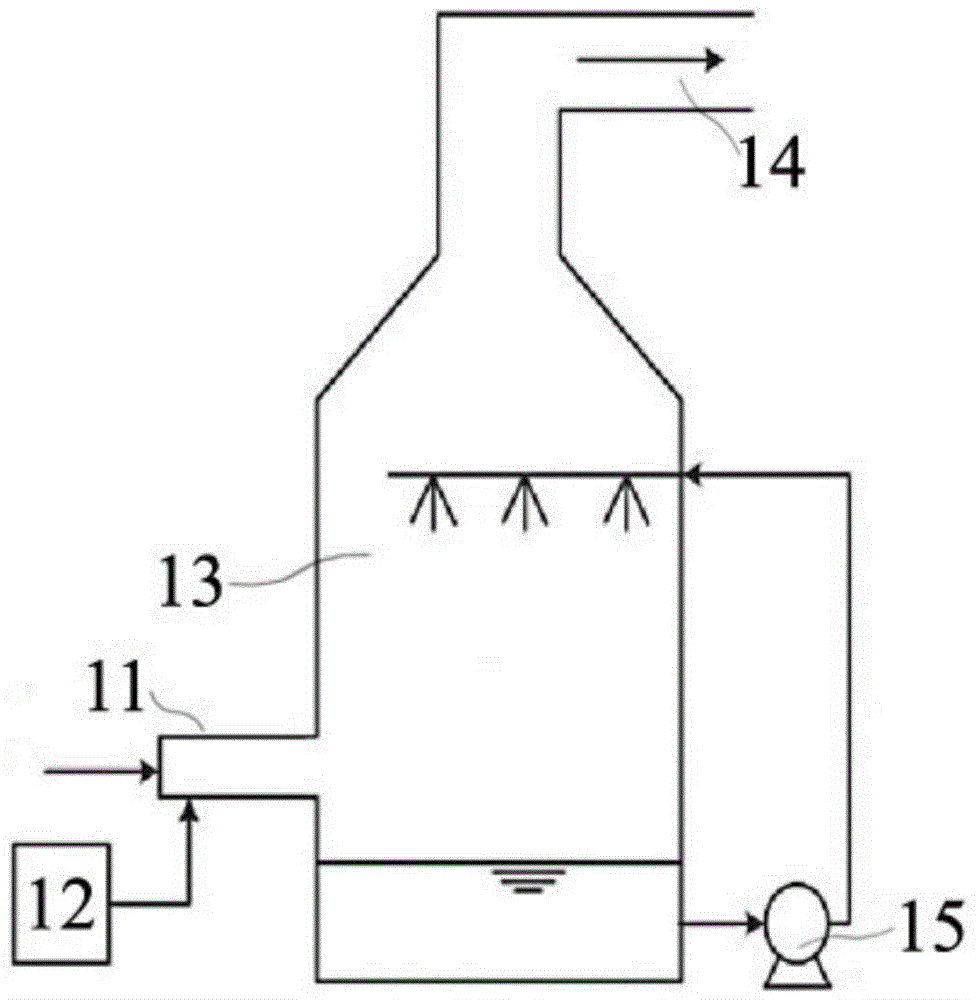

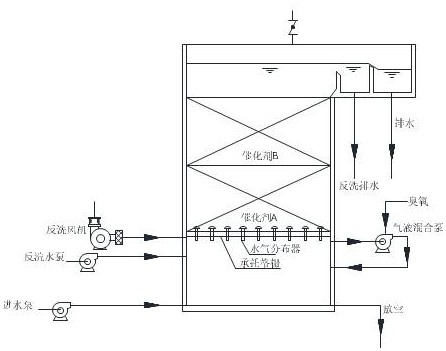

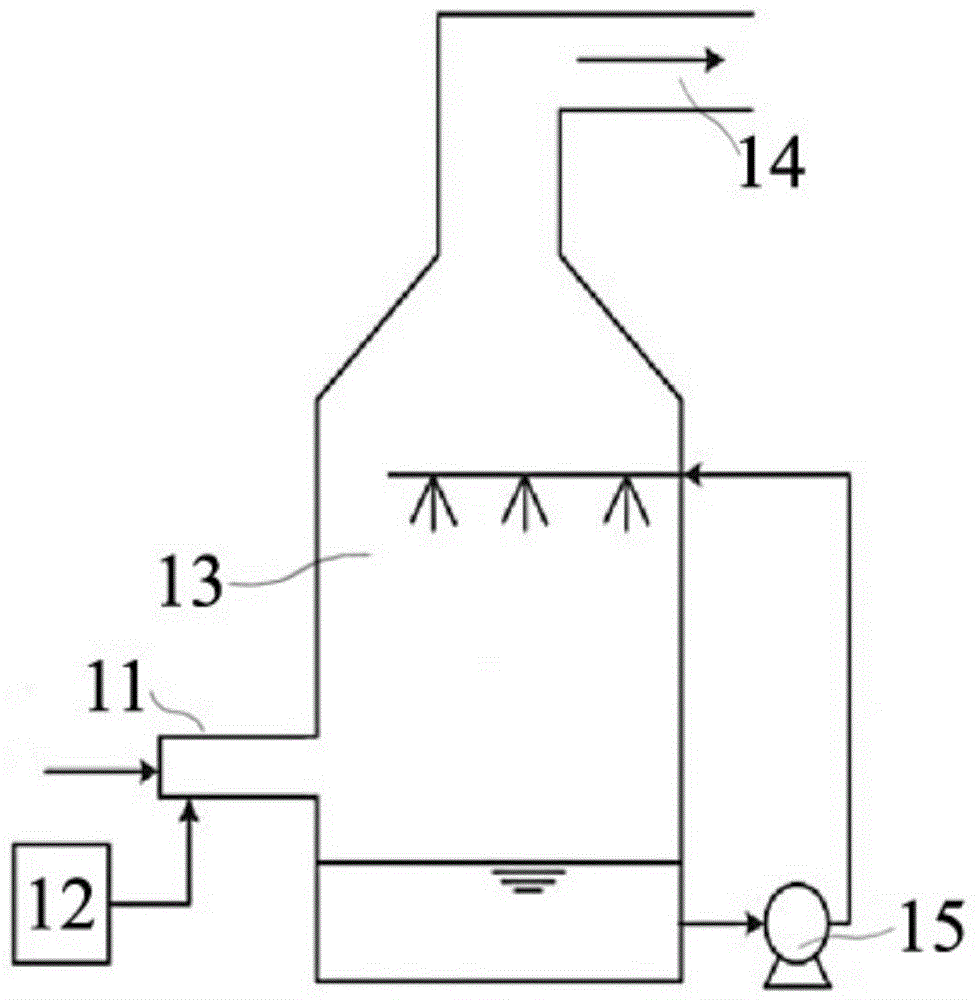

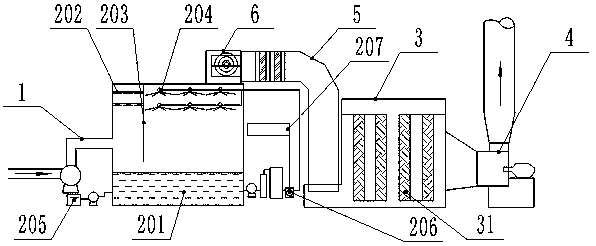

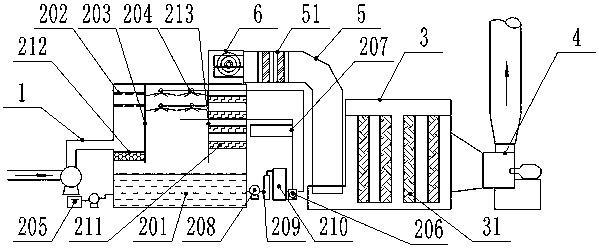

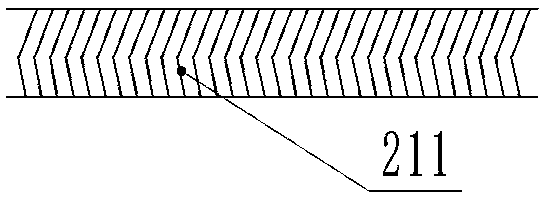

Biological pollution control method for industrial aquaculture wastewater

InactiveCN103253830AProtect environmentReduce ozone usageMultistage water/sewage treatmentBiochemical engineeringWater quality

The invention discloses a biological pollution control method for industrial aquaculture wastewater, which comprises a tank body, wherein a microporous gas distribution disc is arranged at the bottom of an inner cavity of the tank body; a dispersion cone is arranged above the microporous gas distribution disc; a spray head is arranged near the top of the inner cavity of the tank body; a circulating pipe penetrates near the bottom of the tank body; the circulating pipe passes through a water pump and is then connected with a backflow pipe near the middle part of the tank body through a pipeline; the backflow pipe extends into the tank body and is open downward above the dispersion cone; a sensor module capable of detecting the water quality also penetrates in the tank body; a tail gas discharge port is also formed in the top of the tank body; and a water outlet pipe is arranged on the side surface of the tank body. The method disclosed by the invention has the advantages of novel structure, thorough elimination of biological pollution, high treatment speed, low using cost, good safety, low environmental stress, low ozone dosage and small residual amount of ozone.

Owner:ZHEJIANG OCEAN UNIV

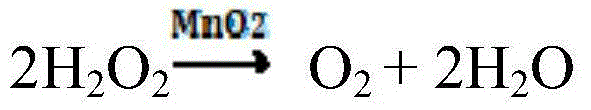

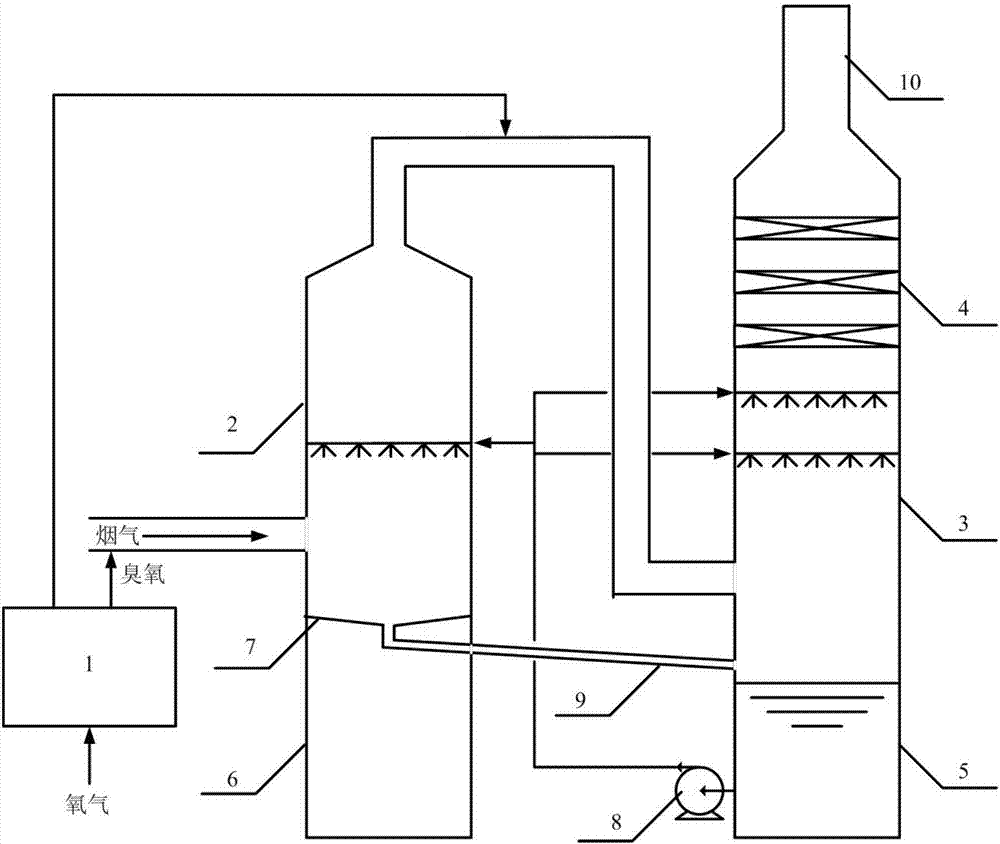

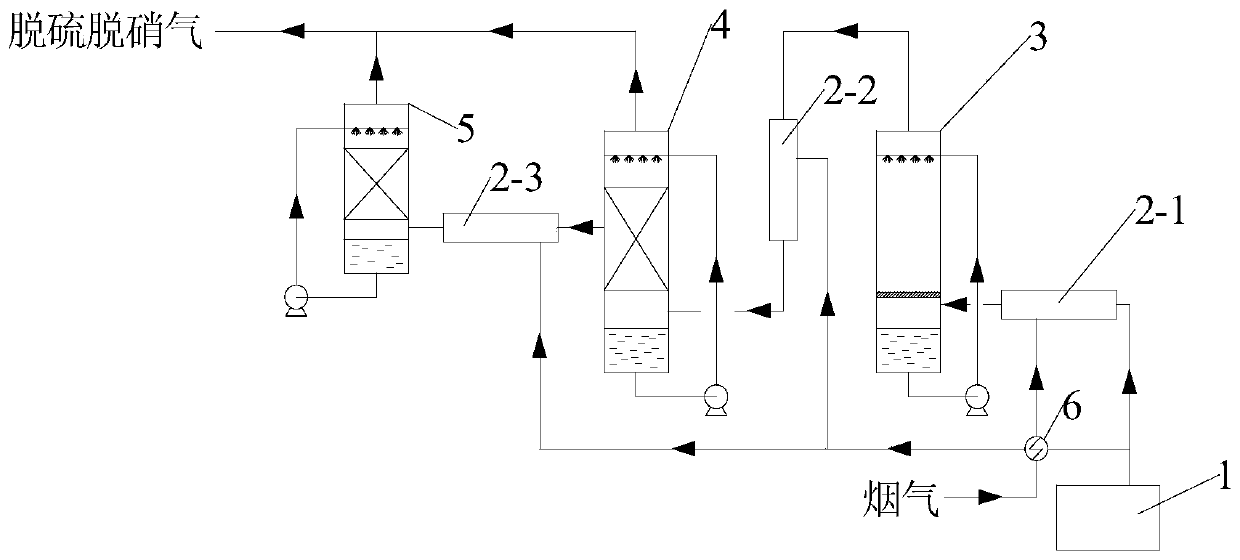

Flue gas desulfurization and denitration system and method

PendingCN110743340AHigh removal rateReduce ozone usageGas treatmentDispersed particle separationNitrogen oxidesEmission standard

The invention provides a flue gas desulfurization and denitration system and method. The flue gas desulfurization and denitration system comprises a desulfurization unit, a denitration unit and an ozone generation unit; the denitration unit is divided into two denitration towers, and a material enters the second denitration tower after being discharged from the side line of the first denitration tower, so that the effects of reducing the ozone consumption and improving the denitration temperature and the denitration efficiency are achieved. The flue gas desulfurization and denitration method is simple to operate, the desulfurization and denitration effects are improved under simple operation conditions by reasonably distributing the ratio of ozone to nitric oxide and the liquid-gas ratio and selecting a proper spraying liquid, and the desulfurized and denitrated gas can reach the emission standard after being subjected to aftertreatment.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

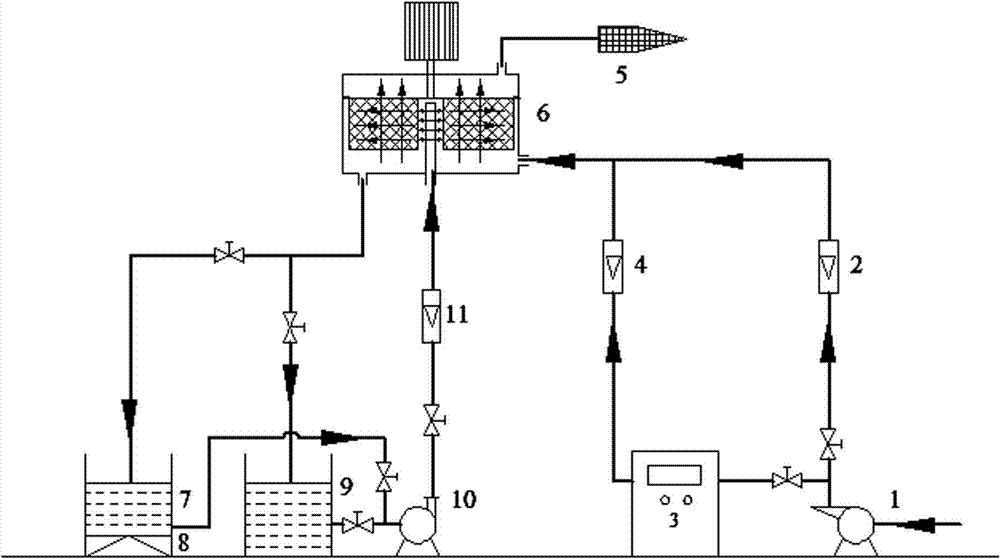

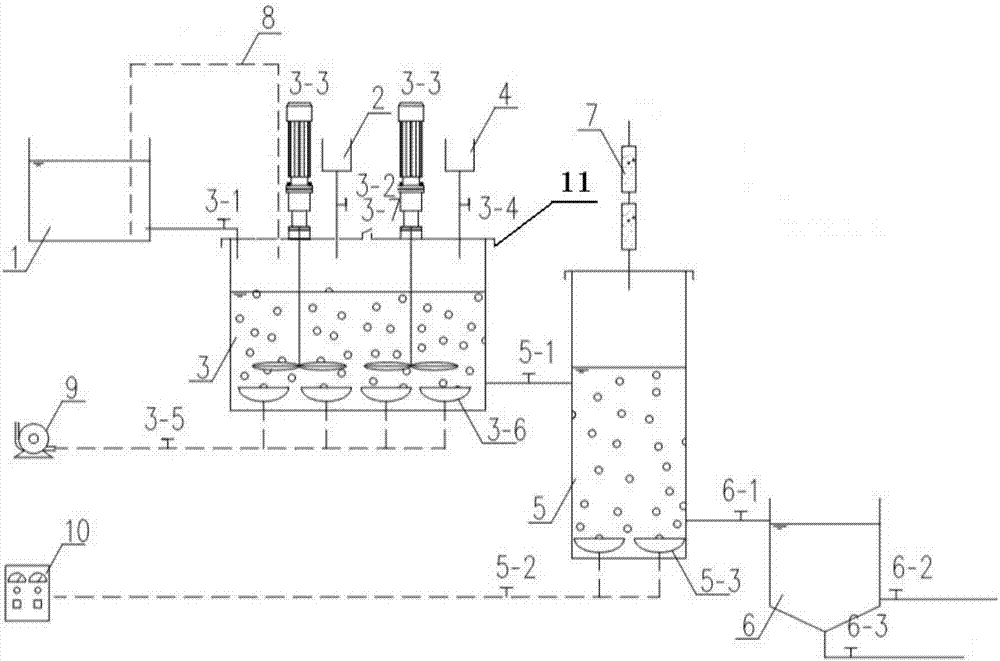

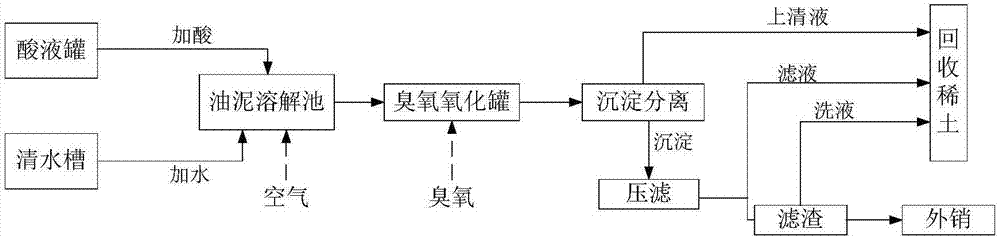

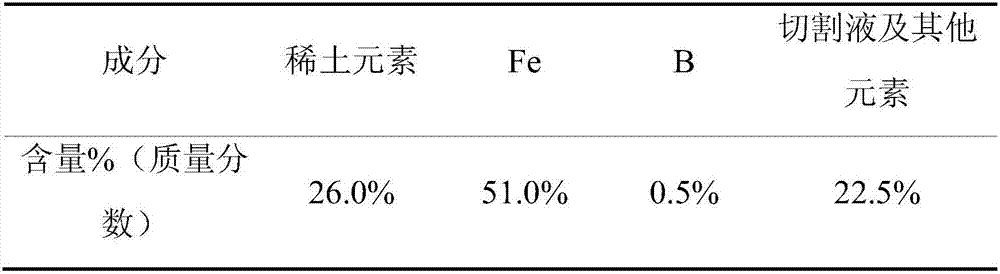

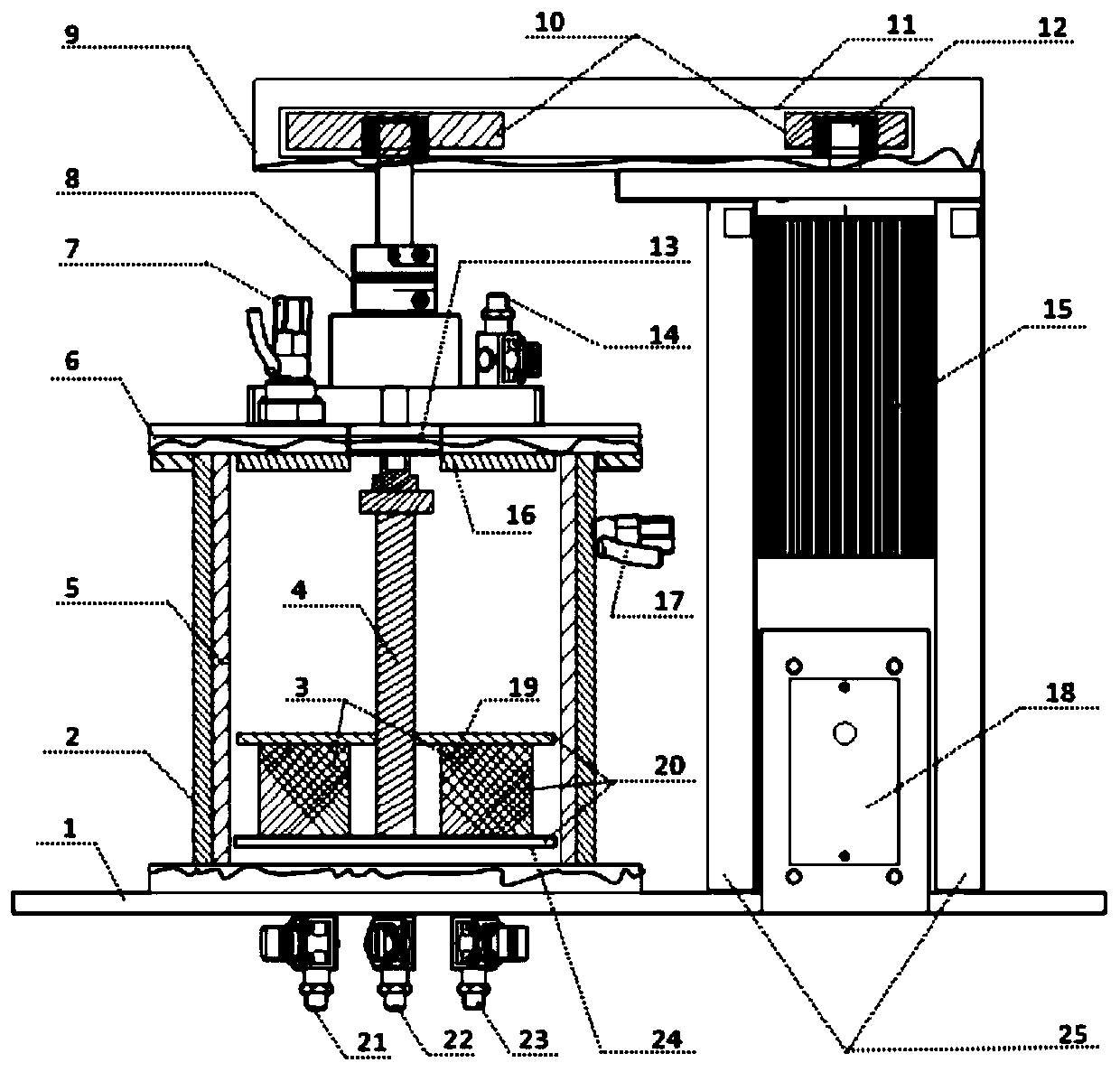

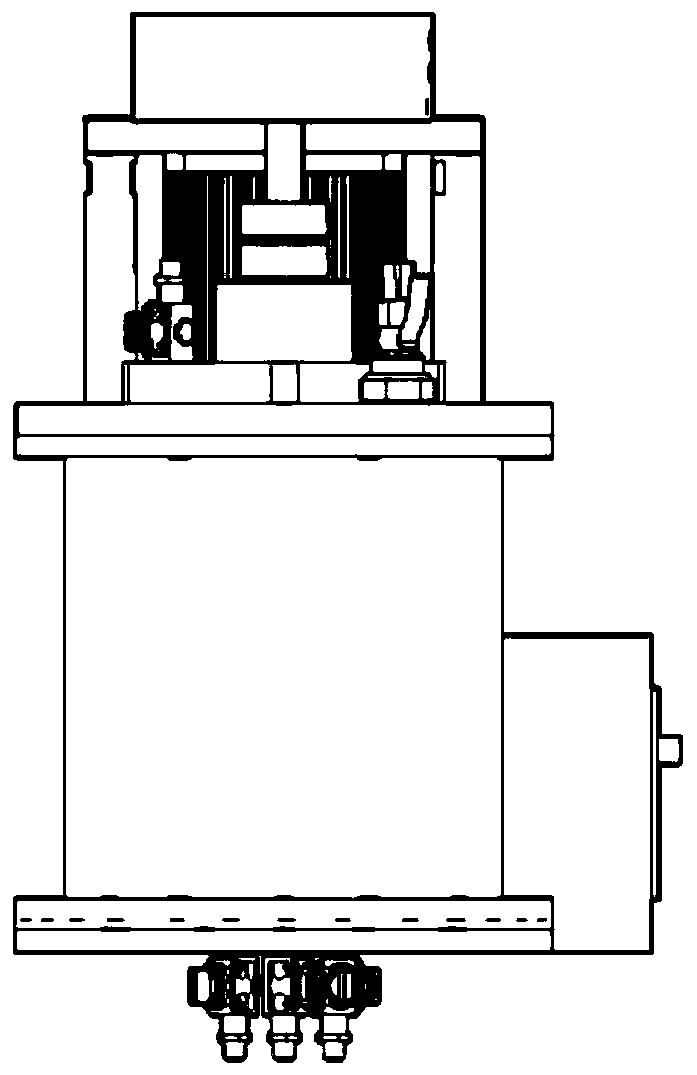

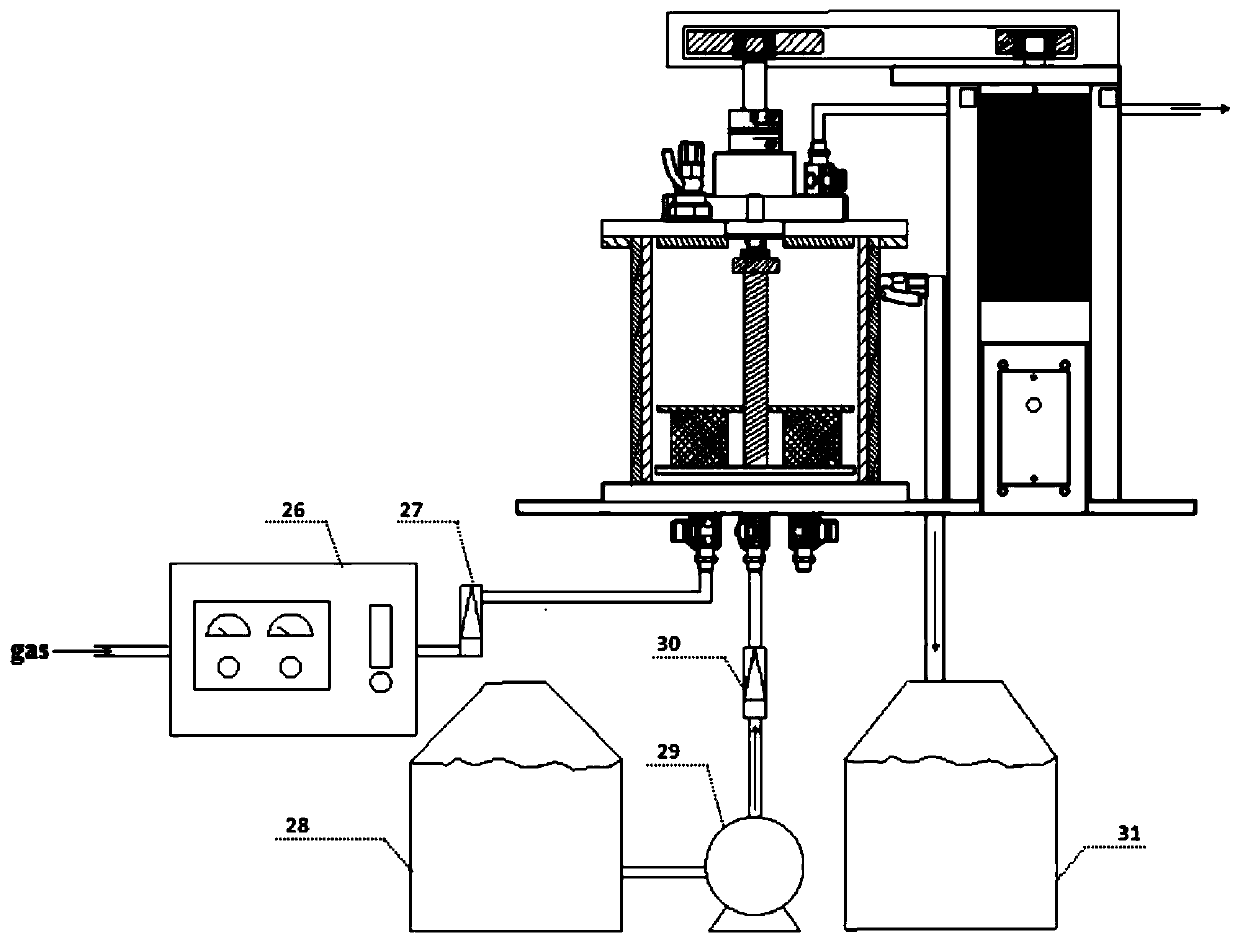

Equipment and method for removing iron and organic matters from neodymium-iron-boron oil sludge waste material through air and ozone two-stage oxidization by wet method at normal temperature

InactiveCN108004411AReduce the introductionHigh purityProcess efficiency improvementRare-earth elementOil sludge

The invention discloses equipment and a method for removing iron and organic matters from a neodymium-iron-boron oil sludge waste material through air and ozone two-stage oxidization by a wet method at normal temperature, and relates to a metal extracting method. The equipment mainly comprises a clean water sink (1), a dissolving pond (3), an ozone oxidation tank (5), a sedimentation pond (6), anair pump (9) and an ozone generating device (10); and the method for removing the iron and the organic matters comprises the following steps: performing acid dissolving, performing first-stage air oxidizing, performing second-stage ozone oxidizing, neutralizing to removing impurities, and separating a rare earth element-containing material liquid and filtered residue. The equipment and the methodare beneficial to improving the purity of the recycled rare earth element, reduces the emission of organic waste, and has high environmental benefit and low energy consumption.

Owner:CHANGCHUN INST OF TECH

Method and system for enhancing sludge air flotation concentration reduction and harmlessness by utilizing ozone

PendingCN114292005AAdd quality reductionAdd lessSludge treatment by oxidationSludgePathogenic bacteria

The invention relates to a method for enhancing sludge air flotation concentration decrement and harmlessness by using high-concentration ozone, which comprises the following steps: mixing sludge and an air flotation concentration medicament, feeding the mixture into a pressure container tank through a gas-liquid mixing pump, generating micro-nano bubbles by ozone through a micro-nano bubble generating unit, feeding the micro-nano bubbles into the pressure container tank through the gas-liquid mixing pump, and discharging the micro-nano bubbles. Uniformly mixing the sludge, the air flotation concentration medicament and the high-concentration ozone; pumping the mixed solution into an air floatation contact chamber, and after air floatation, opening a slag scraping plate to remove floating concentrated sludge; all the concentrated sludge floats upwards and is discharged through a sludge outlet after being removed by a slag scraping plate, and sludge supernate after air floatation is disinfected and then is discharged through a concentrated water outlet guide pipe as bottom effluent. On the premise of greatly reducing the consumption of ozone, the water content of the concentrated sludge is quickly increased to 90-92%, the air flotation concentration efficiency is greatly improved, most antibiotic pollutants and pathogenic bacteria in the supernate are removed, the chromaticity of the supernate is reduced, and sludge reduction and harmlessness are remarkably enhanced.

Owner:TONGJI UNIV +2

Flue gas denitrification device and method

ActiveCN104941430BIncrease productionImprove removal efficiencyDispersed particle separationReaction layerFlue gas

The invention discloses a flue gas denitrification device and method. The flue gas denitrification device of the present invention includes flue gas denitrification equipment, ozone supply equipment and hydrogen peroxide supply equipment, etc., wherein, the flue gas denitrification equipment includes ozone spray oxidation reaction layer and hydrogen peroxide spray oxidation reaction layer, absorption spray zone and slurry storage zone, the ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are all set in the absorption spray zone. The flue gas denitrification device and method of the present invention are suitable for the denitrification treatment of flue gas containing NOX such as coal-fired boilers, steel sintering machines, pellets, industrial kilns, etc., and can solve the problems of high operating cost, complicated equipment and low denitrification efficiency of the current flue gas denitrification process. Not a high question.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

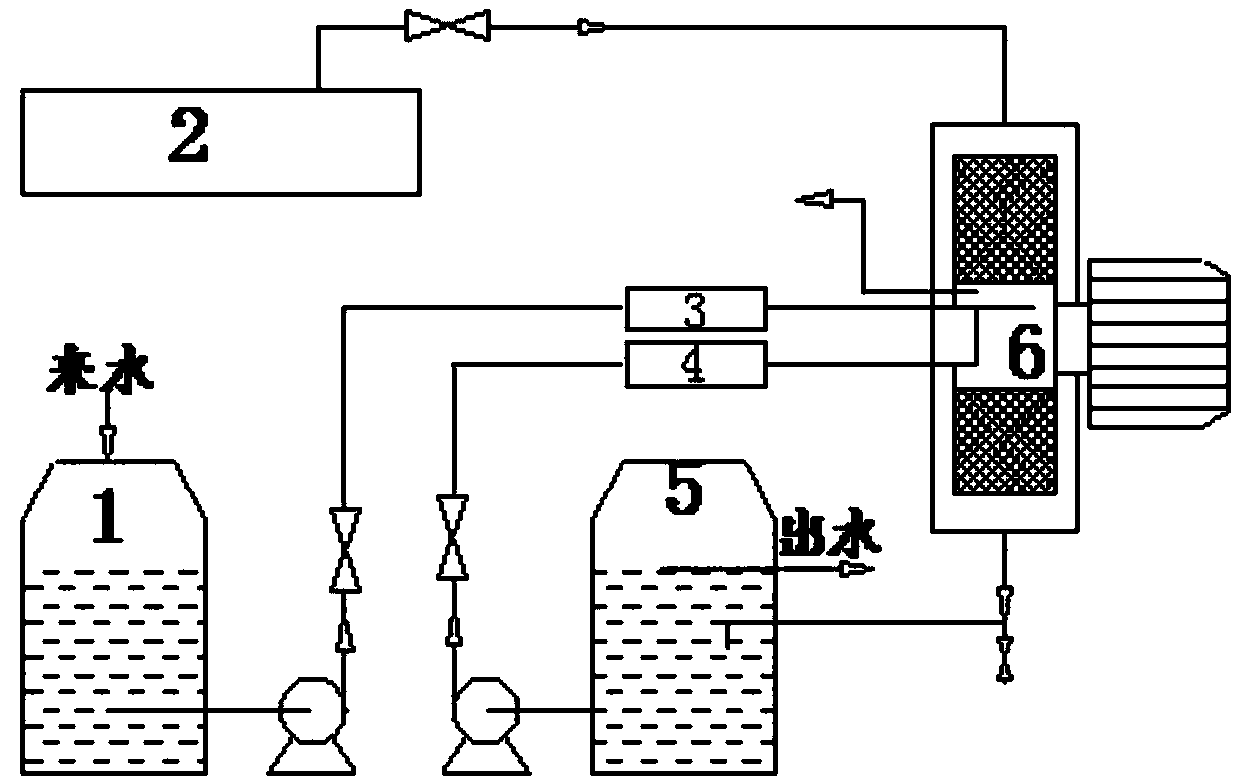

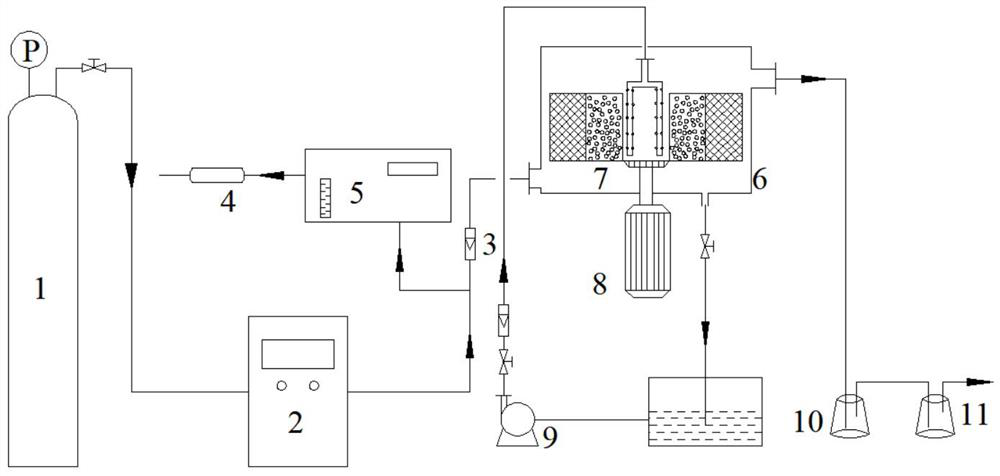

Water treatment device and method for reinforcing ozone mass transfer and oxidation process

ActiveCN110255698AIncrease contact areaHigh catalytic efficiencyWater treatment parameter controlWater/sewage treatment apparatusOzone generatorLiquid storage tank

The invention discloses a water treatment device and method for reinforcing an ozone mass transfer and oxidation process. The device comprises an ozone generator, a feed liquid storage tank, a reactor and a waste liquid storage tank. The device can be used for greatly reinforcing ozone gas-liquid mass transfer efficiency, and realizing efficient utilization of a solid catalyst in the oxidation process. So the device is capable of effectively reinforcing the ozone mass transfer and heterogeneous ozone oxidation process, and has extensive application prospect in multiple fields.

Owner:HUAQIAO UNIVERSITY

Circulating sewage treatment method and device

InactiveCN107867752AReduce contact timeSmall footprintWater/sewage treatment by oxidationWater flowSewage treatment

The embodiment of the invention provides a circulating sewage treatment method and device. The method comprises the steps that incoming water is conveyed to a high gravity reactor; gas containing ozone is conveyed to the high gravity reactor; a high gravity environment is formed in the high gravity reactor, and the high gravity level of the high gravity environment is G, so that the mass transferbetween the incoming water and the gas containing the ozone is carried out; water flowing out of the high gravity reactor is discharged out to a water outlet tank; and a part of the water in the wateroutlet tank is returned to the high gravity reactor for treating again. The method provided by the invention has a simple process and continuous operation; and the core device which is the high gravity reactor is small in size and small in occupied area.

Owner:BEIJING WANBANGDA ENVIRONMENTAL PROTECTION TECH +1

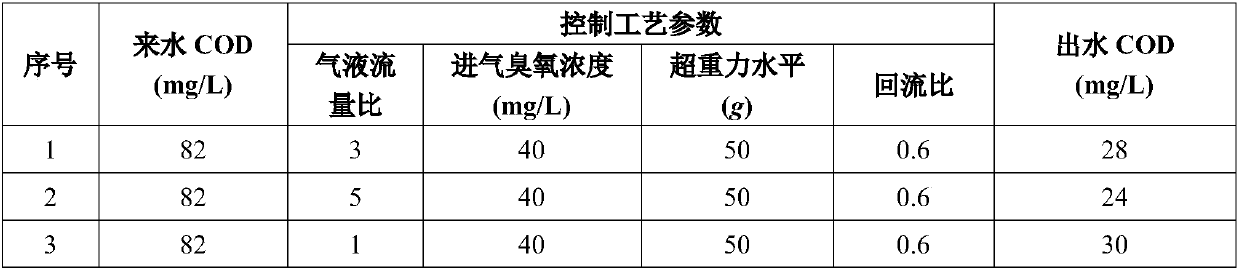

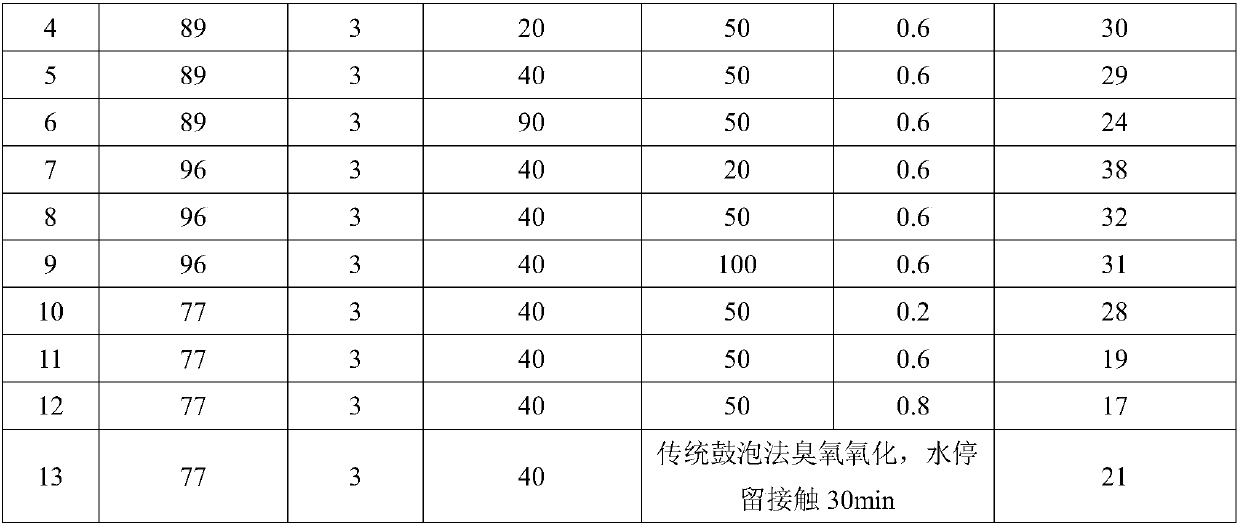

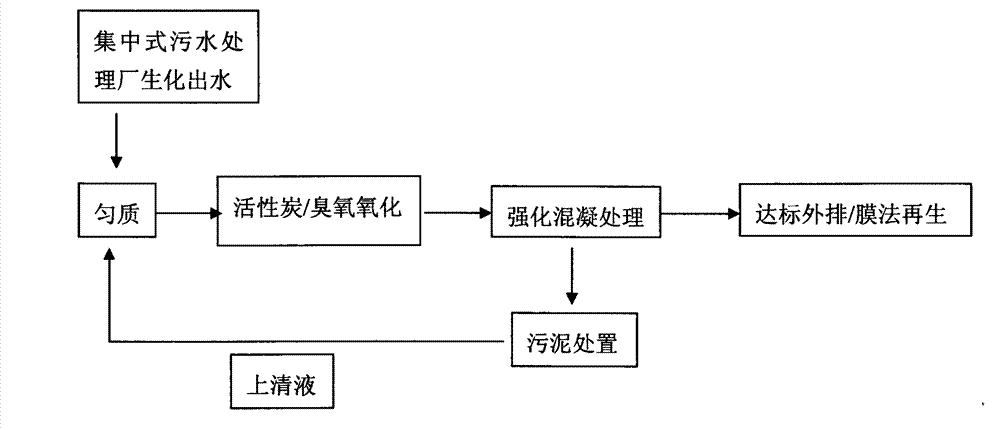

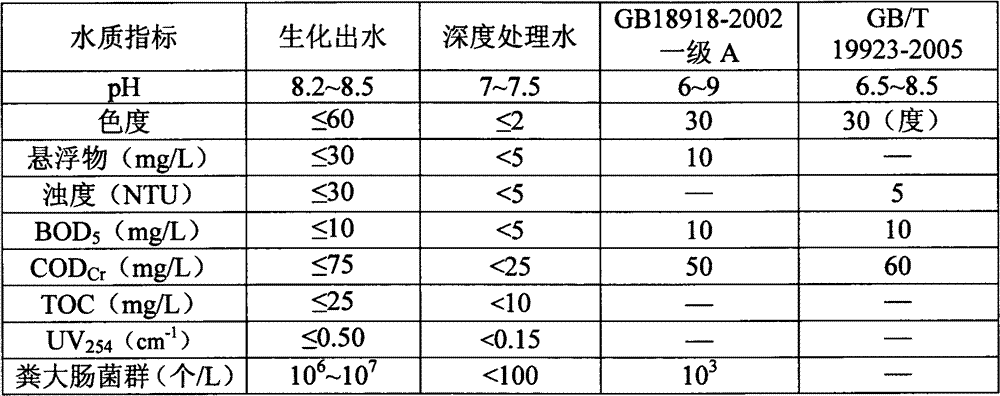

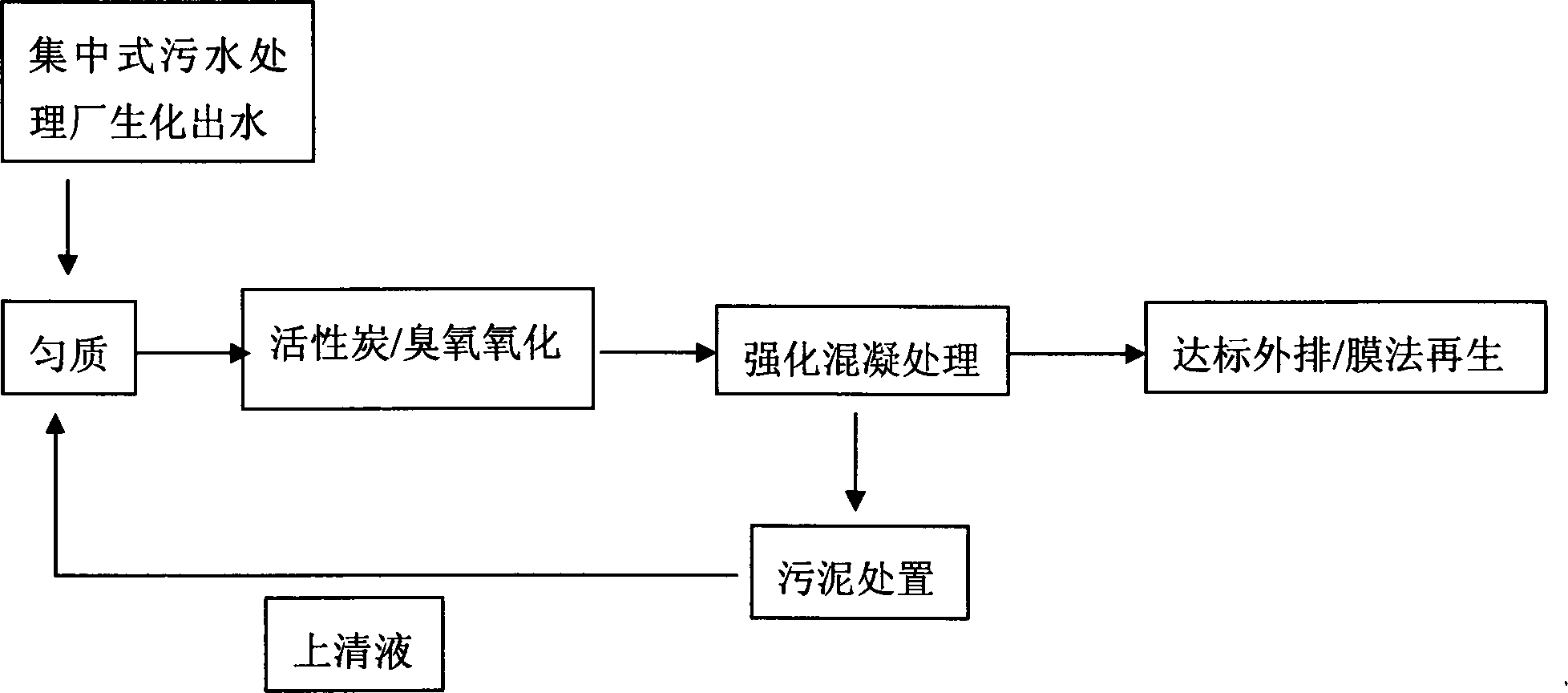

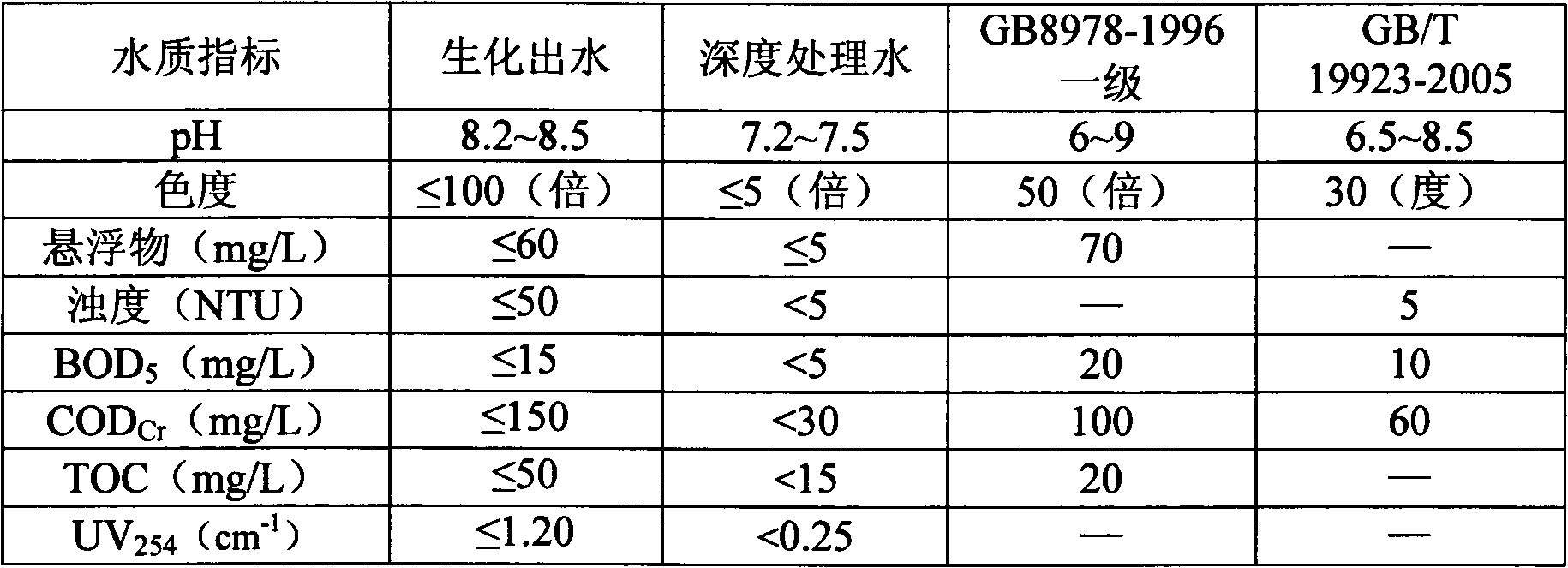

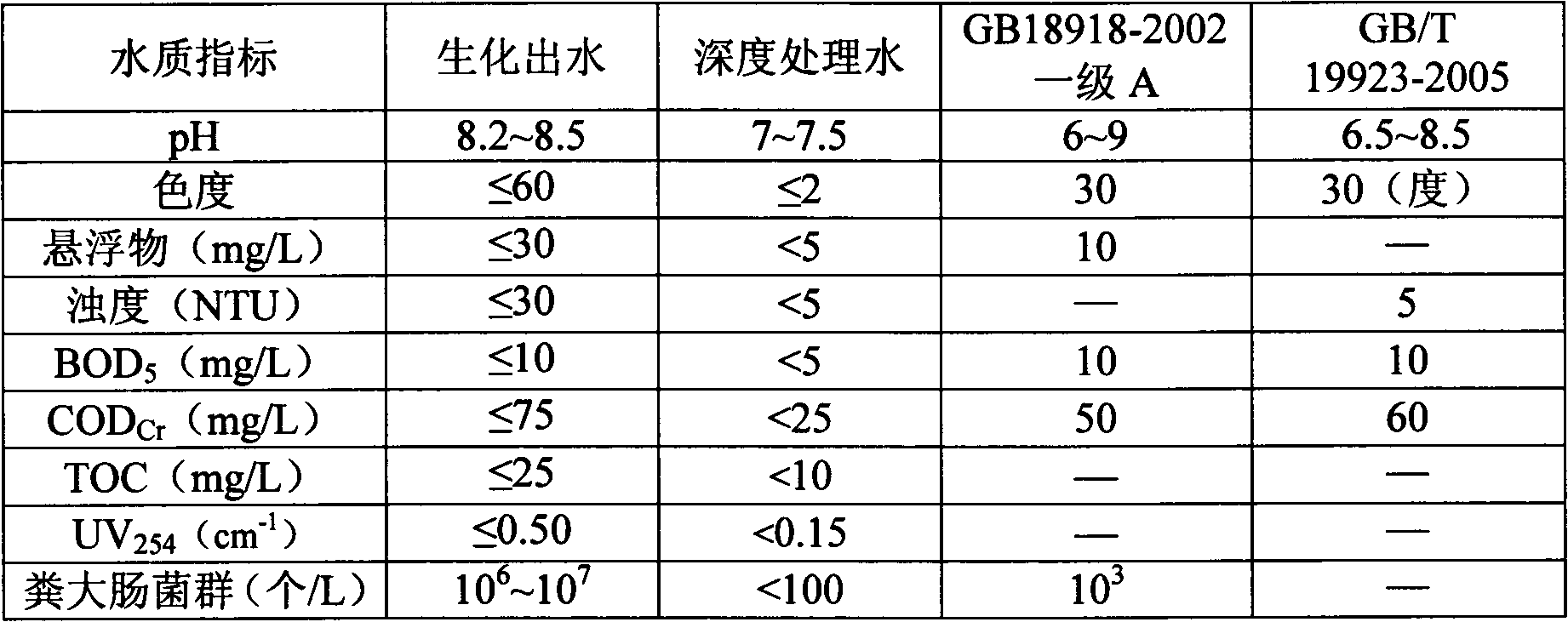

Advanced treatment process for biochemical effluent in centralized sewage treatment plant

InactiveCN102730881AEasy to operateSave activated carbonSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentActivated carbonWater quality

The invention discloses an advanced treatment process for biochemical effluent in a centralized sewage treatment plant. The treatment process comprises the following steps: subjecting the biochemical effluent to homogenzing, activated carbon / ozone oxidation treatment, and enhanced coagulation treatment in turn. The process provided by the invention is simple in operation, the quality of the treated effluent is better than emission standard, and conditions for realizing the recycling are created.

Owner:EAST CHINA UNIV OF SCI & TECH

System and process for treating organic waste gas with micro-nano oxygen bubbles and iron ions

ActiveCN110508113BEasy to operateReaction consumption is smallGas treatmentUsing liquid separation agentMicro nanoExhaust fumes

The invention relates to the technical field of organic waste gas treatment, in particular to a system and process for treating organic waste gases by micro-nano oxygen bubbles in cooperation with iron ions. The system comprises an air inlet device, a micro-nano oxygen bubble generation device, an adsorption purifier and an exhaust device, and the air inlet device, the micro-nano oxygen bubble generation device, the adsorption purifier and the exhaust device are connected in sequence; a water accumulating tank is arranged on the lower part of the micro-nano oxygen bubble generation device, a washing unit and a micro-nano oxygen bubble generation chamber are formed in the upper part of the micro-nano oxygen bubble generation device; an active carbon filter device is arranged in the adsorption purifier; and the exhaust device is provided with an exhaust fan device. The process includes the steps that organic waste gases to be treated is delivered to the micro-nano oxygen bubble generation device and enter the adsorption purifier through the spray and micro-nano bubble oxidation reaction, and clean gases enters the atmosphere after being discharged by the exhaust device. According tothe system and process, multi-level treatment of the organic waste gases can be realized, operation is convenient, more safety is achieved, and the treatment effect is good.

Owner:青岛润扬环境科技有限公司

Reaction device and method for integrated enhanced iron-carbon micro-electrolysis-ozone coupling treatment of nitrobenzene wastewater

InactiveCN114380430AFacilitate deep oxidative degradationAchieve zero additionWater contaminantsMultistage water/sewage treatmentElectrolysisOxygen tank

The invention provides an integrated reaction device and method for treating nitrobenzene wastewater through reinforced iron-carbon micro-electrolysis-ozone coupling, the device comprises an oxygen bottle, an ozone generator, a rotating packed bed, a pump and a nitrobenzene wastewater storage tank, and an annular rotor is rotationally arranged in the rotating packed bed; the rotor is sequentially provided with a rotor outer shell, an annular partition plate and a rotor inner shell from outside to inside, through holes are formed in the rotor outer shell, the annular partition plate and the rotor inner shell, the space between the rotor outer shell and the annular partition plate is filled with a metal wire mesh formed by winding metal wires, and iron carbon balls are stacked between the annular partition plate and the rotor inner shell. The rotating packed bed is provided with a gas inlet, a gas outlet, a liquid inlet and a liquid outlet; the nitrobenzene wastewater storage tank is connected with a pump; the pump is connected with a liquid inlet of the rotating packed bed; the oxygen bottle is connected with the ozone generator; the ozone generator is connected with a gas inlet of the rotating packed bed. According to the invention, the process procedure is simplified, the wastewater treatment cost is saved, and the waste of Fe < 2 + > can be effectively avoided.

Owner:ZHONGBEI UNIV

Method for treating organic matter in high-salinity industrial wastewater

ActiveCN108178364AReduce processing costsReduce ozone usageWater contaminantsTreatment involving filtrationWater qualityTreatment costs

The invention discloses a method for treating organic matter in high-salinity industrial wastewater. The method comprises the steps as follows: (1) the industrial wastewater has the chlorine ion concentration of 80-100 g / L, the pH value of 11-14 and the TOC content lower than 110 mg / L; (2) the pH value of the industrial wastewater is adjusted to 4-10 with hydrochloric acid; (3) part of organic matter in the industrial wastewater is adsorbed with activated carbon, and the industrial wastewater stays in an activated carbon device for 90-180 min; (4) the organic matter in the industrial wastewater is continuously treated with an ozonation technology, the industrial wastewater treated in the step (3) is guided to an ozone reaction device, and ozone is introduced into wastewater to react for atleast 20 min. The method has the active effects as follows: the organic matter in the high-salinity industrial wastewater is treated with an adsorption-oxidation combined technology, so that the consumption of ozone is greatly reduced, and the wastewater treatment cost can be effectively reduced. The method is convenient to operate and maintain. The effluent quality can meet the nation-specifiedemission standard.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

Advanced treatment process for biochemical effluent in centralized sewage treatment plant

InactiveCN102730881BEasy to operateSave activated carbonMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationActivated carbonWater quality

The invention discloses an advanced treatment process for biochemical effluent in a centralized sewage treatment plant. The treatment process comprises the following steps: subjecting the biochemical effluent to homogenzing, activated carbon / ozone oxidation treatment, and enhanced coagulation treatment in turn. The process provided by the invention is simple in operation, the quality of the treated effluent is better than emission standard, and conditions for realizing the recycling are created.

Owner:EAST CHINA UNIV OF SCI & TECH

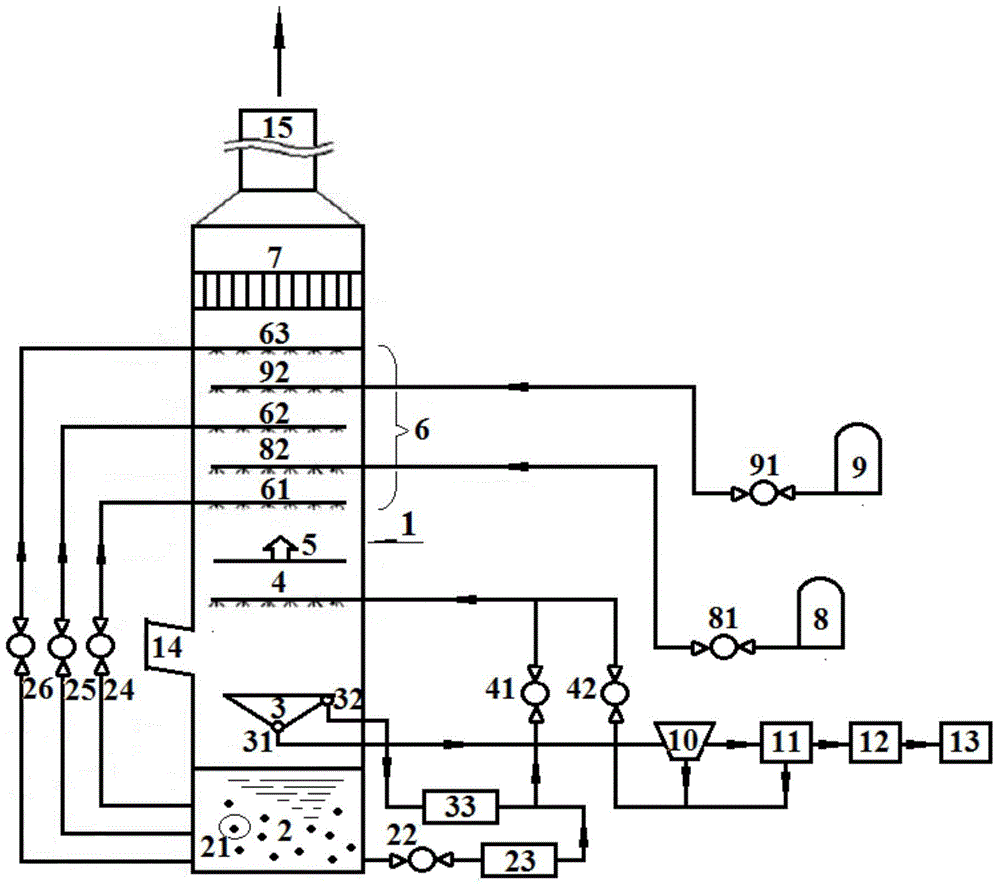

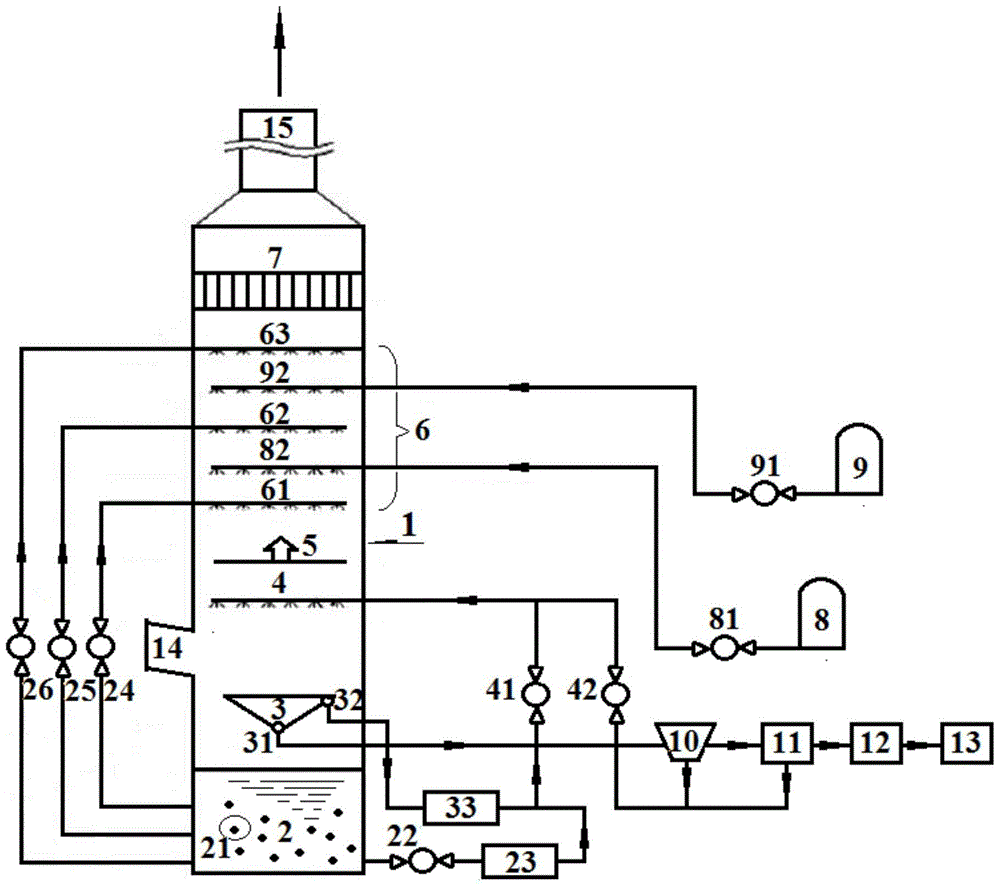

Flue gas integrated treatment device and method

ActiveCN104857835BRealize resource utilizationReduce wateringCombination devicesMagnesium nitratesLiquid wasteReaction layer

An integrated flue gas treatment device and method. The device comprises a flue gas treatment device, an ozone supply device, a hydrogen peroxide supply device, an evaporation and concentration device, a circulating sedimentation device, etc., wherein the flue gas treatment device comprises an ozone spray oxidation reaction layer (82), a hydrogen peroxide spray oxidation reaction layer (92), an absorption spraying area (6), a slurry circulation area and a dedusting and demisting area, both of the ozone spray oxidation reaction layer (82) and the hydrogen peroxide spray oxidation reaction layer (92) being arranged in the absorption spraying area (6); the dedusting and demisting area is located above the absorption spraying area (6); and both of the evaporation and concentration device and the circulating sedimentation device are arranged in the flue gas treatment device.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

A method and device for ozone heterogeneous catalytic oxidation of cod in wastewater

ActiveCN107585852BImprove utilization efficiencyReduce ozone usageMolecular sieve catalystsWater/sewage treatment by oxidationPtru catalystCatalytic oxidation

The invention relates to a method and device for ozone heterogeneous catalytic oxidation of COD in wastewater. According to the method, a solid catalyst is used for decomposing ozone into hydroxyl free radicals with stronger oxidability; then an oxidation reaction occurs between the hydroxyl free radicals and organic matters in the wastewater; and the organic matters are converted into carbon dioxide and water, so that the purpose of reducing the COD in the wastewater is achieved. In the method, the mass ratio of the ozone to the COD in the wastewater is (0.5-1):1, the usage amount of the solid catalyst is 0.2-2g / L, and the residence time is 0.1-2 hours. A catalytic oxidation tower for realizing the method is designed, the upper part of the tower is a mixed liquid distribution area of wastewater and hydrogen peroxide; the middle part is a catalyst area; and the lower part is a mixed gas distribution area of oxygen and ozone. The method and device provided by the invention have the advantage of solving the problems that the utilization rate of ozone in ozone catalytic oxidation is low, and the oxidation rate is low.

Owner:UNIV OF JINAN

Method for treating organic matter in high-salinity industrial wastewater

ActiveCN108178364BReduce processing costsReduce ozone usageWater contaminantsTreatment involving filtrationActivated carbonIndustrial waste water

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com