Biological pollution control method for industrial aquaculture wastewater

A technology for aquaculture wastewater and biological pollution, applied in the field of purification of intensive aquaculture wastewater, can solve the problems of poor tolerance to extreme conditions, many limiting factors, unfavorable promotion, etc., and achieve low cost of use, good safety, and small residual ozone Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

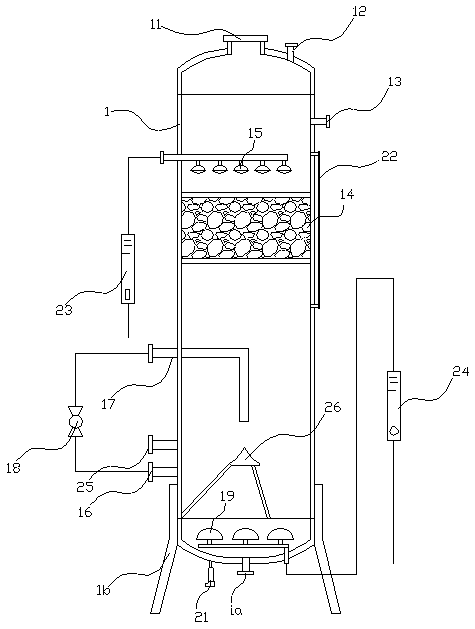

[0012] Example: refer to figure 1 A method for preventing and controlling biological pollution of industrialized farming wastewater, comprising the steps of:

[0013] A) Storm tank treatment;

[0014] B) wetland treatment;

[0015] The treatment of the storm tank is to pass the breeding waste water into the storm tank for treatment; the storm tank includes a tank body 1, and the bottom of the inner cavity of the tank body 1 is provided with a microporous gas distribution disc 19; above the microporous gas distribution disc 19, a dispersion cone is arranged 26; a spray head 15 is provided near the top of the inner cavity of the tank body 1; a circulation pipe 16 is installed near the bottom of the tank body 1; after the circulation pipe passes through the water pump 18, the pipeline is connected with a return pipe 17 located near the middle of the tank body 1; The pipe 17 extends into the tank body 1 and opens downward above the dispersing cone 26; the tank body 1 is also pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com