Patents

Literature

158 results about "Foam separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foam separation is a chemical process which falls into a category of separation techniques called "Adsorptive bubble separation methods". It is further divided into froth flotation and foam fractionation.

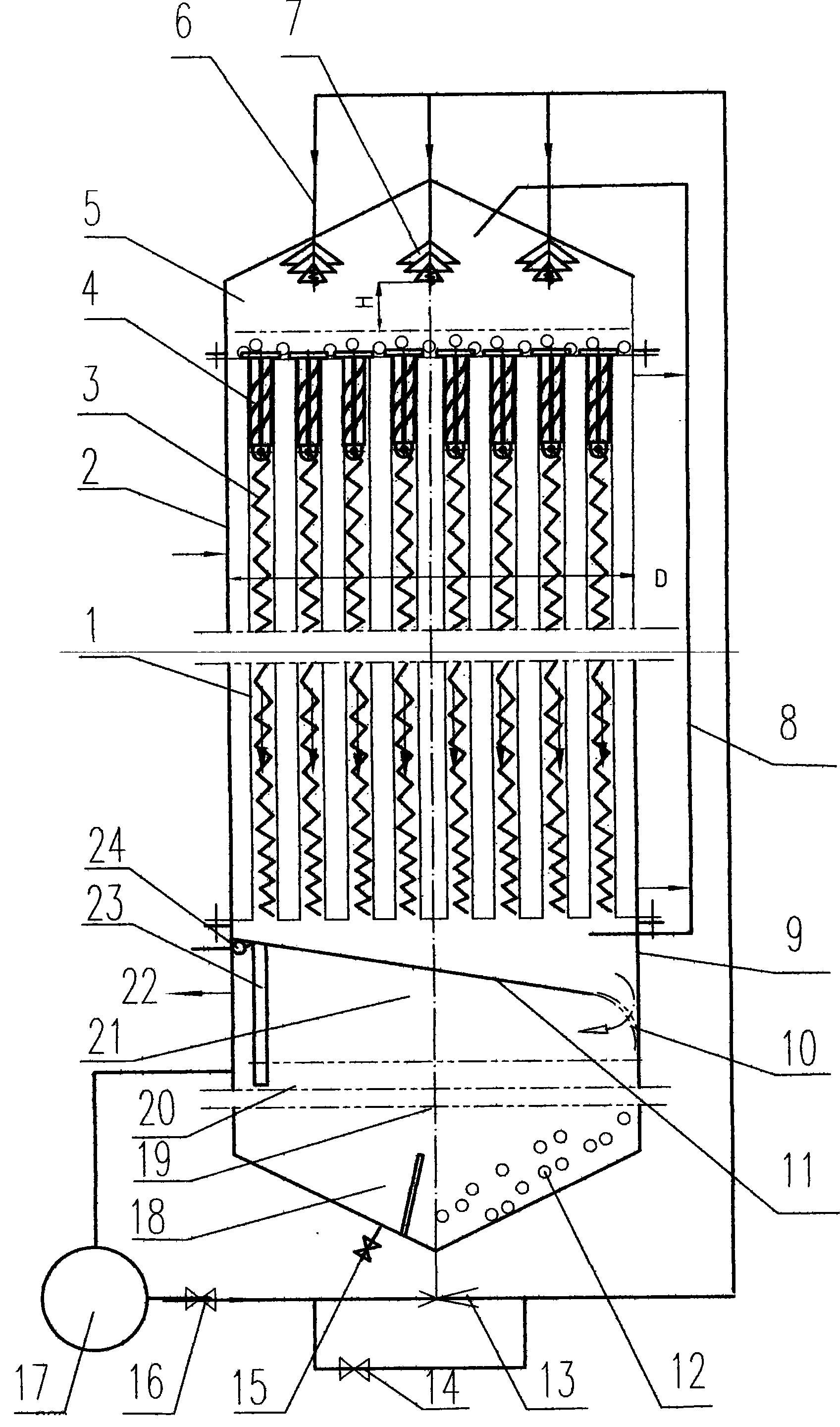

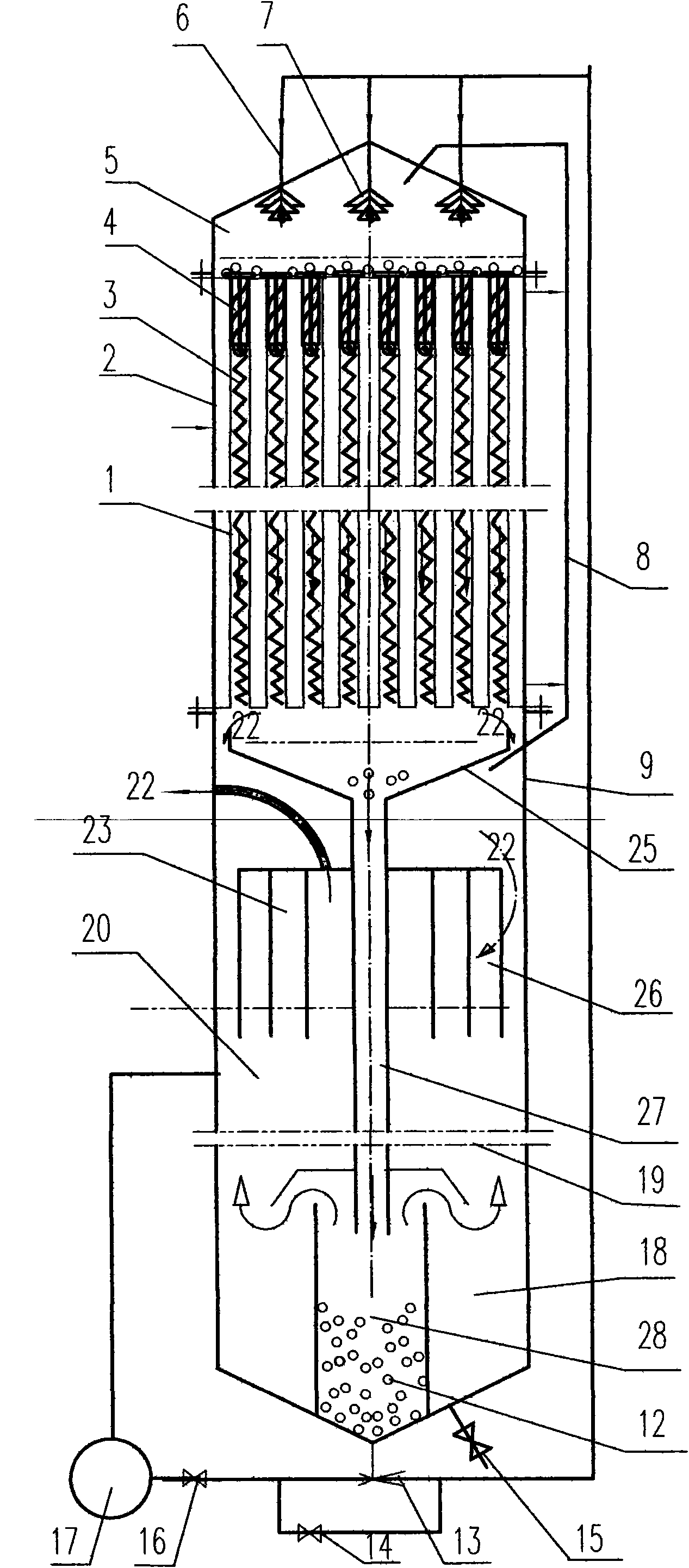

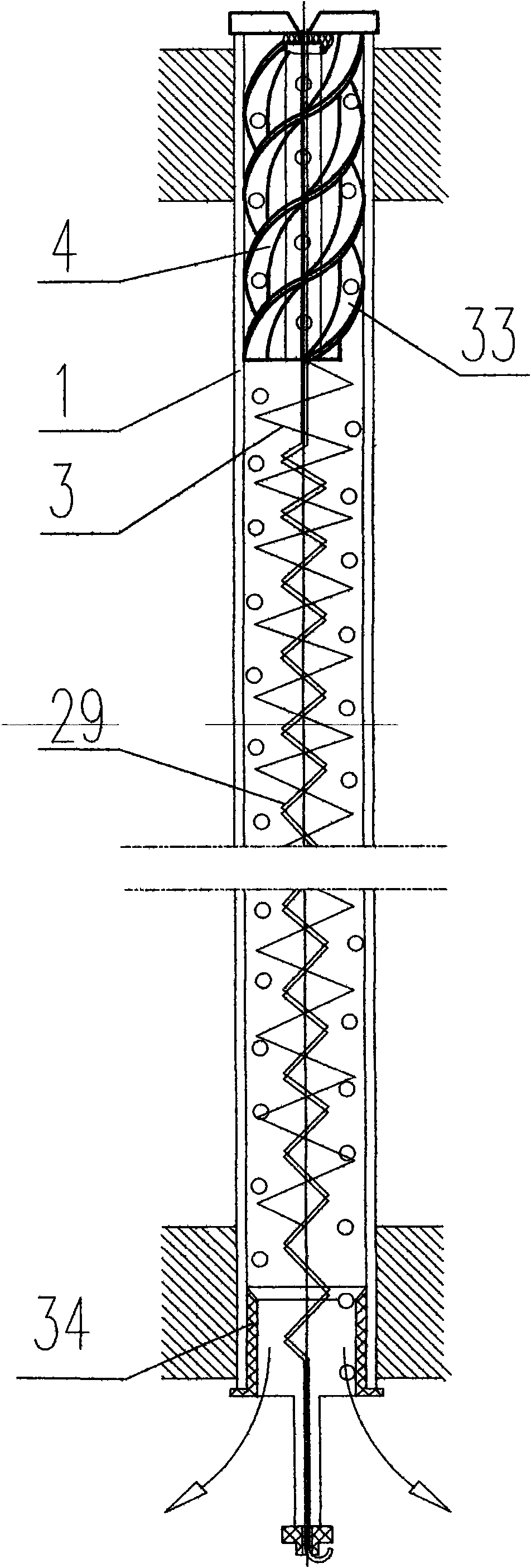

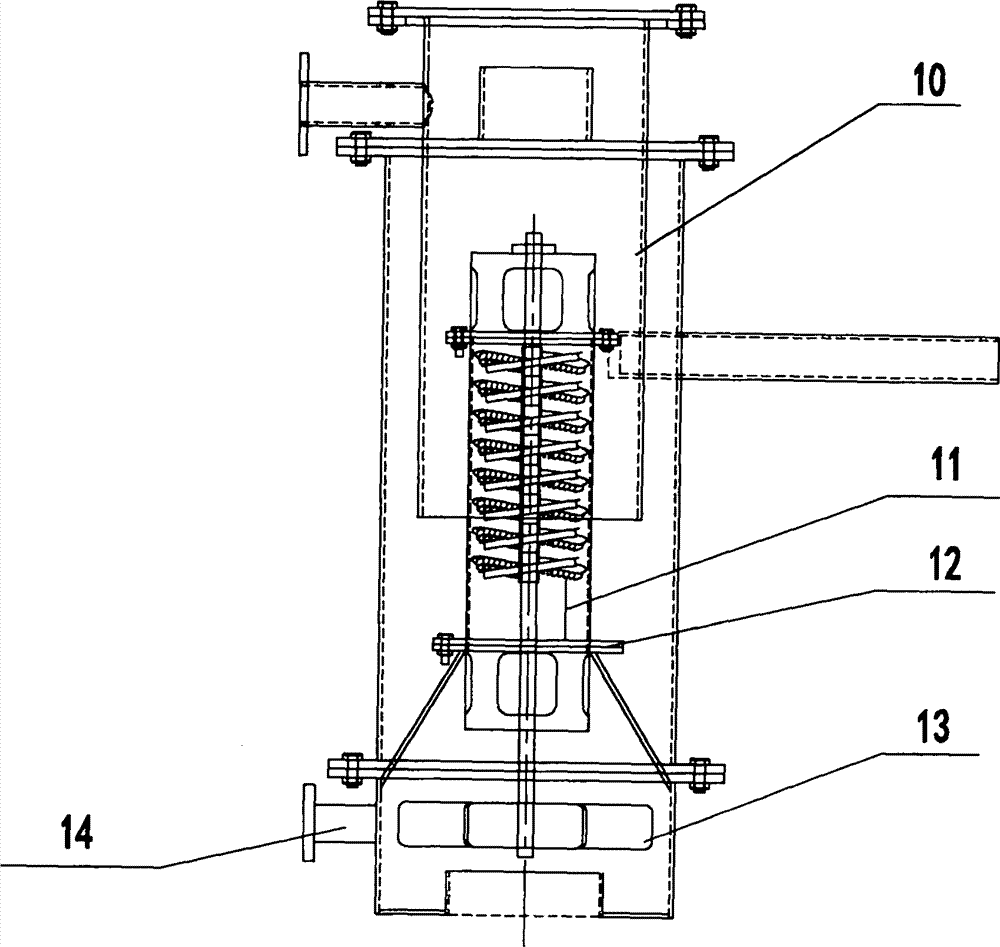

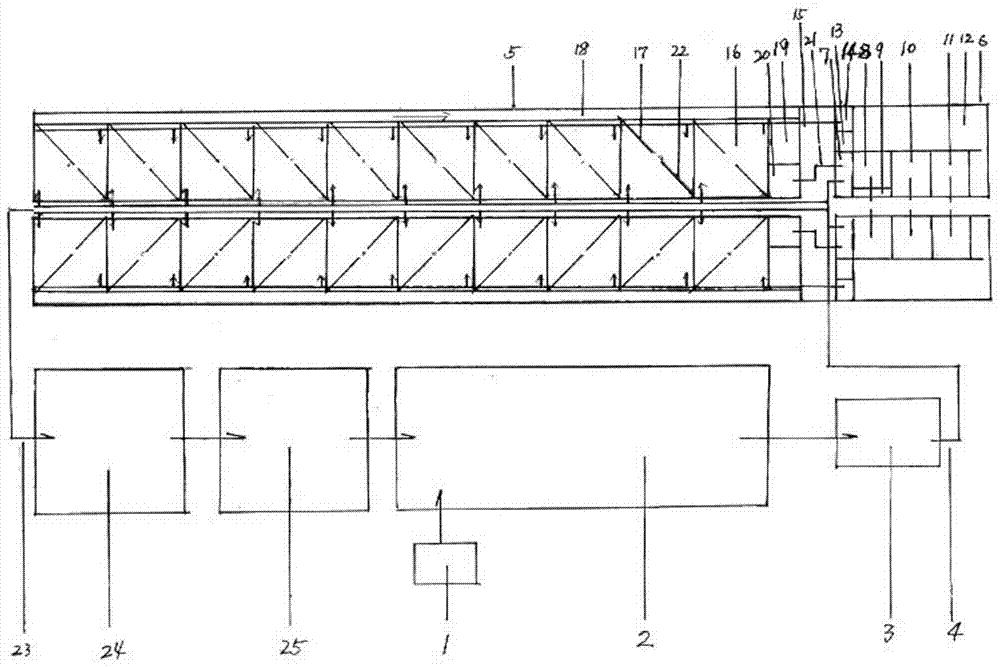

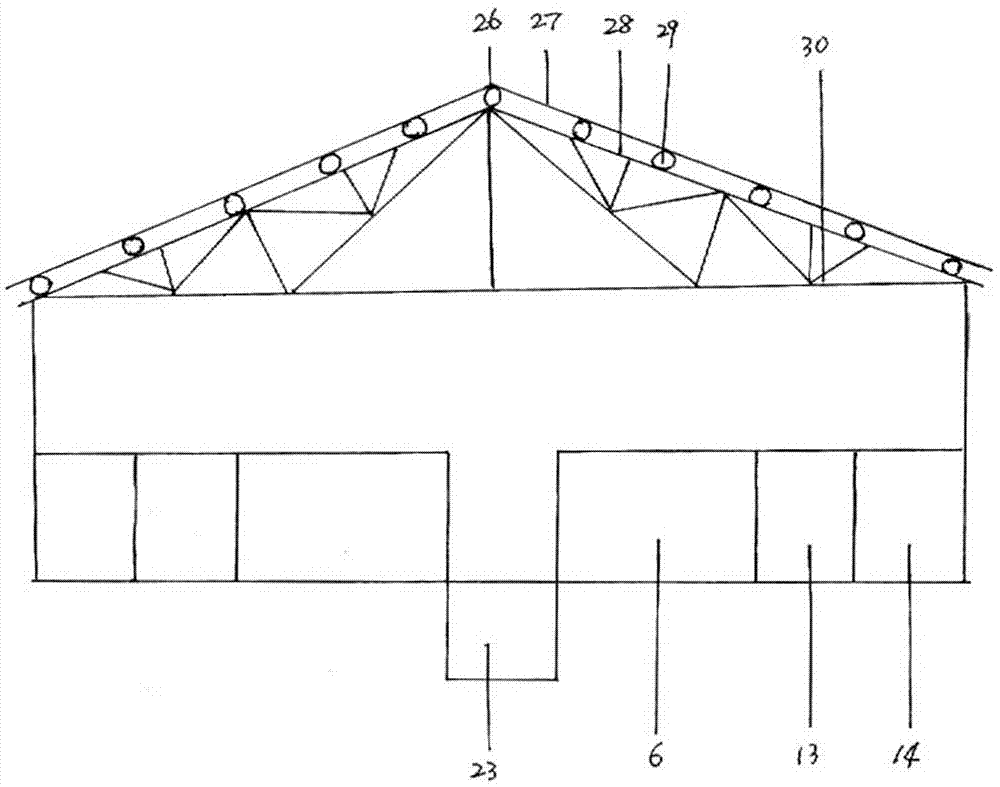

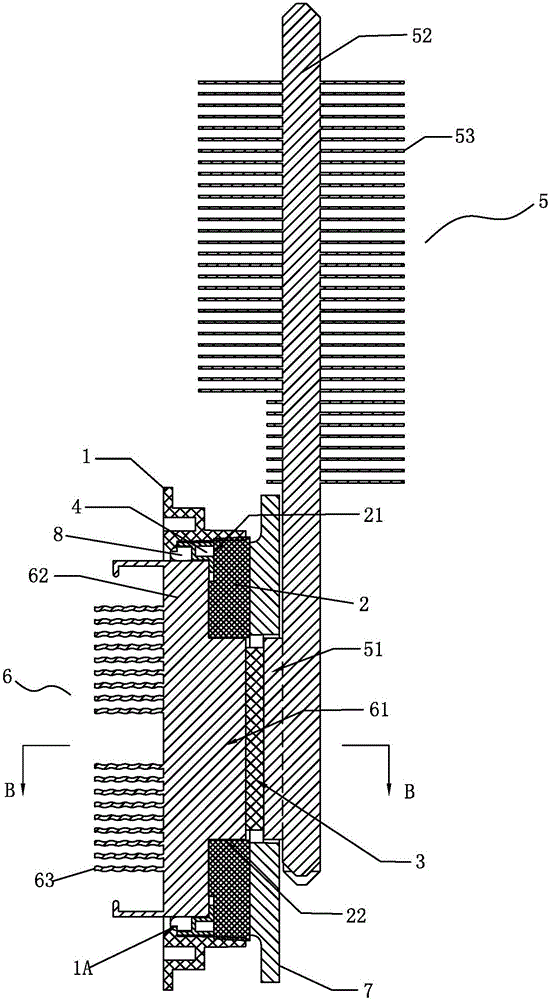

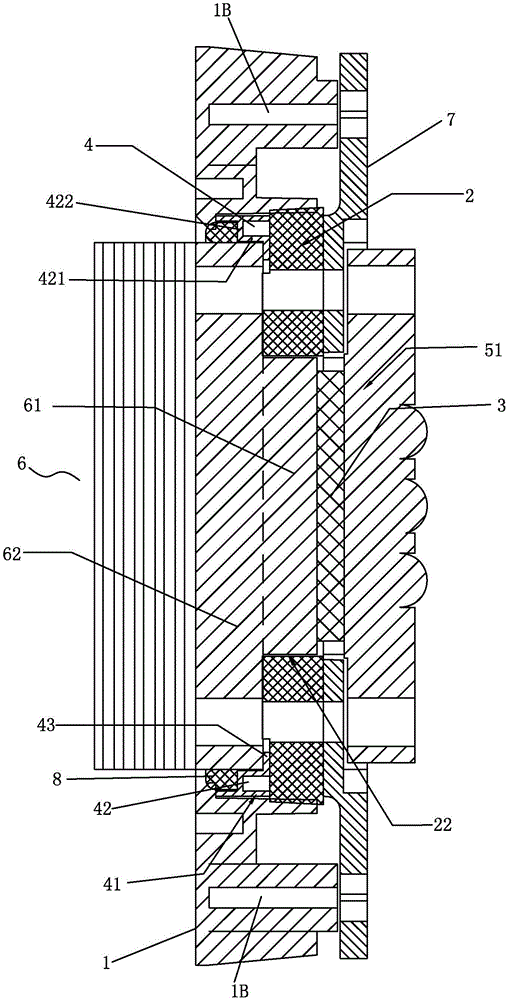

In-tube auto-cleaning antiscale falling-film evaporation device

ActiveCN102641601ASolve the problem of fouling cleaning that is not suitable for falling film flow evaporators in tubesSimple structureEvaporator accessoriesEvaporationEngineering

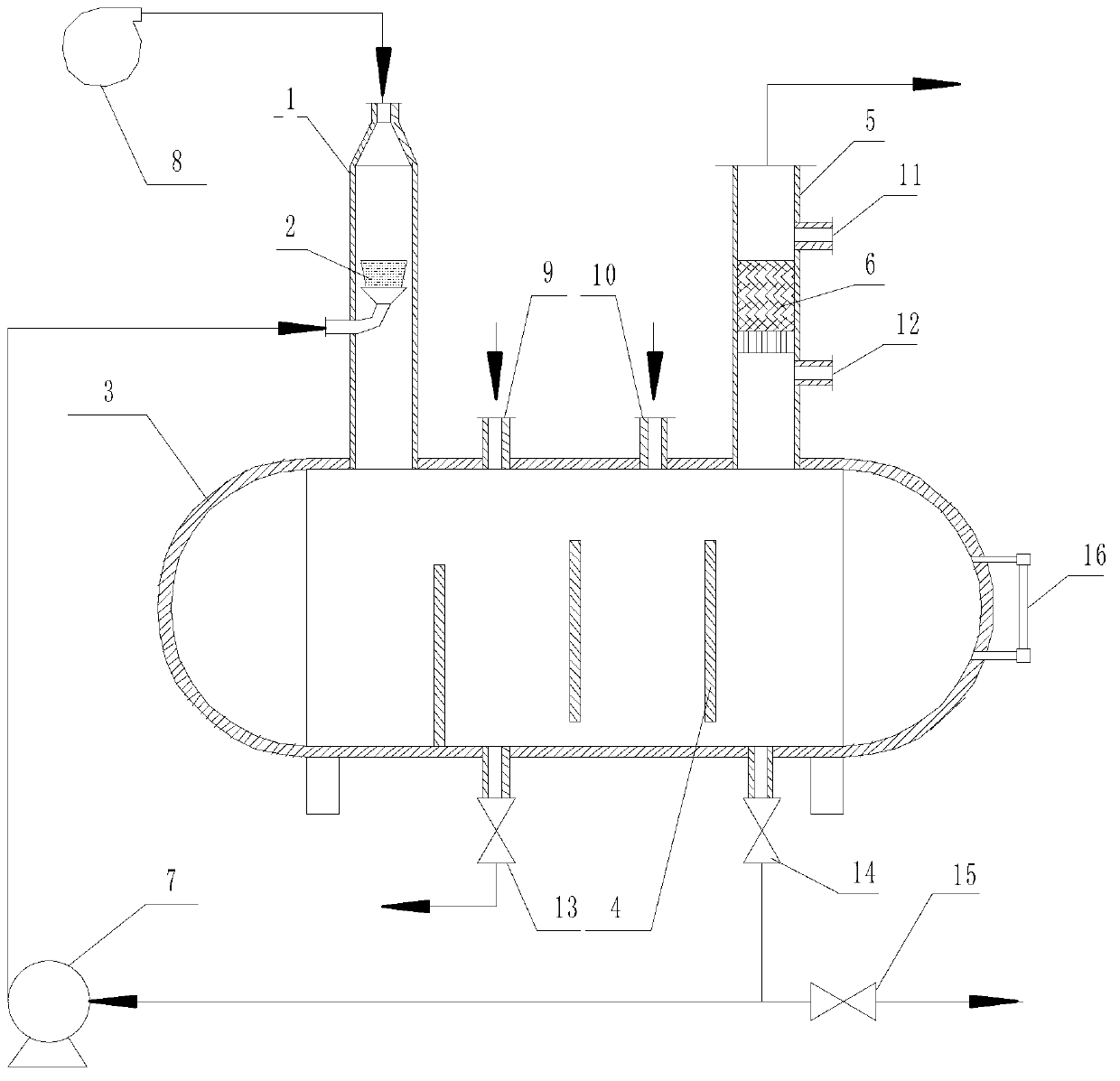

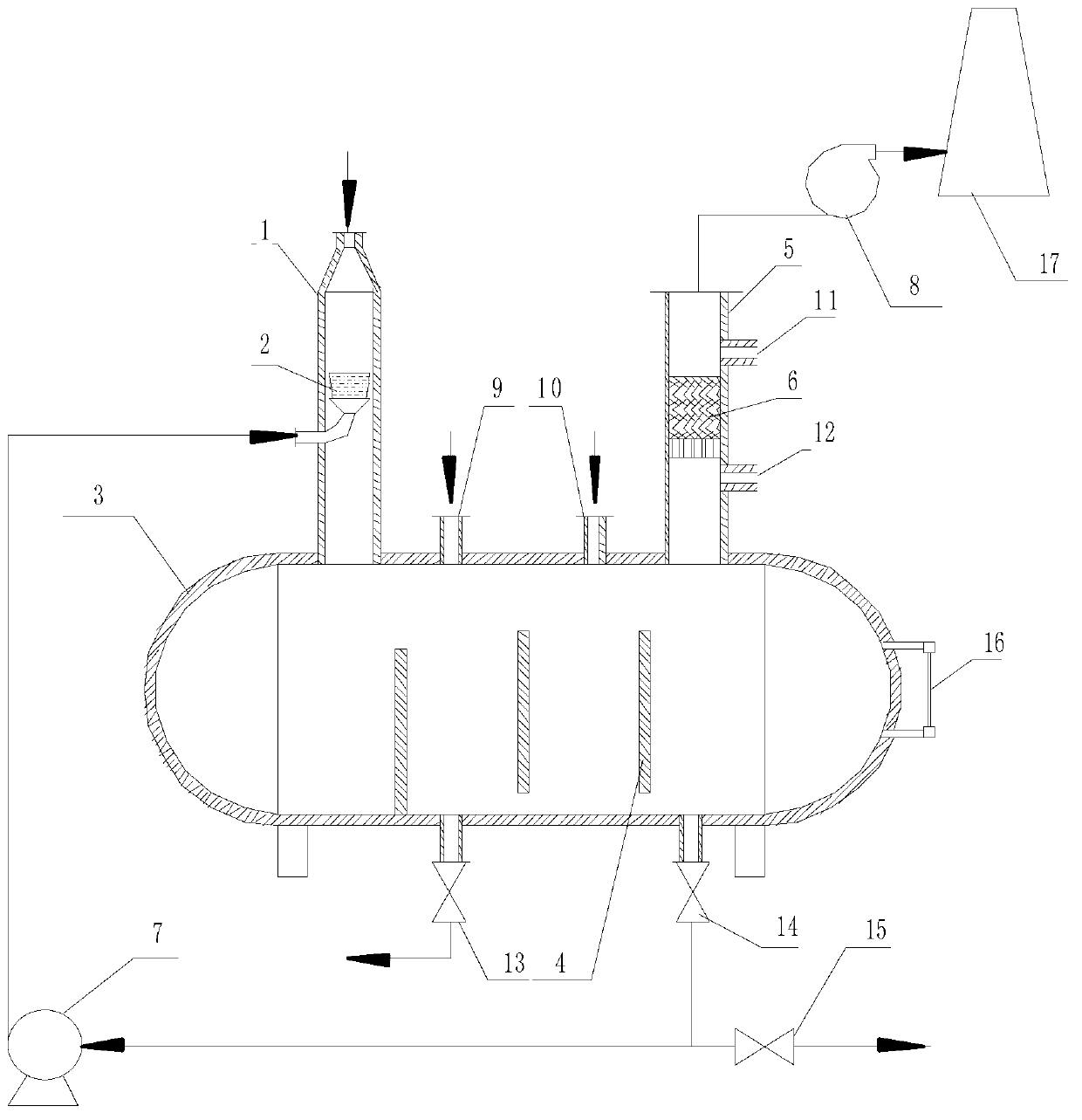

An in-tube auto-cleaning antiscale falling-film evaporation device. A few fluidized cleaning ceramic balls are added into mother liquor. Uniformly-distributed film-forming screws not only realizes automatic uniform distribution of liquid in each heating tube, but also promotes uniform film formation on tube inner walls. Liquid film screws and steam screws mounted in the heating tubes can significantly increase circumferential component velocities of falling-film liquid flow and secondary steam flow, enhance convection heat transfer of the liquid film, reduce the amount of splashing liquid foams falling directly, enable the fluidized ceramic balls to generate centrifugal force so as to tightly adhere to the tube inner walls for effective cleaning and scale prevention. A lower tube case is provided with a secondary steam liquid foam separation structure, and a circulating tank meeting crystallization requirements, and the structure is compact. The fluidized ceramic balls realize circulating cleaning through venturis, and the concentration of the fluidized balls is adjusted through a by-pass valve. Therefore, the evaporation device which can prevent scale formation in heat tube inner walls can realize auto-cleaning high yield and energy saving, meet requirements for long-term continuous production, and is especially suitable for heat pump evaporation.

Owner:浙江建装工程技术研究有限公司

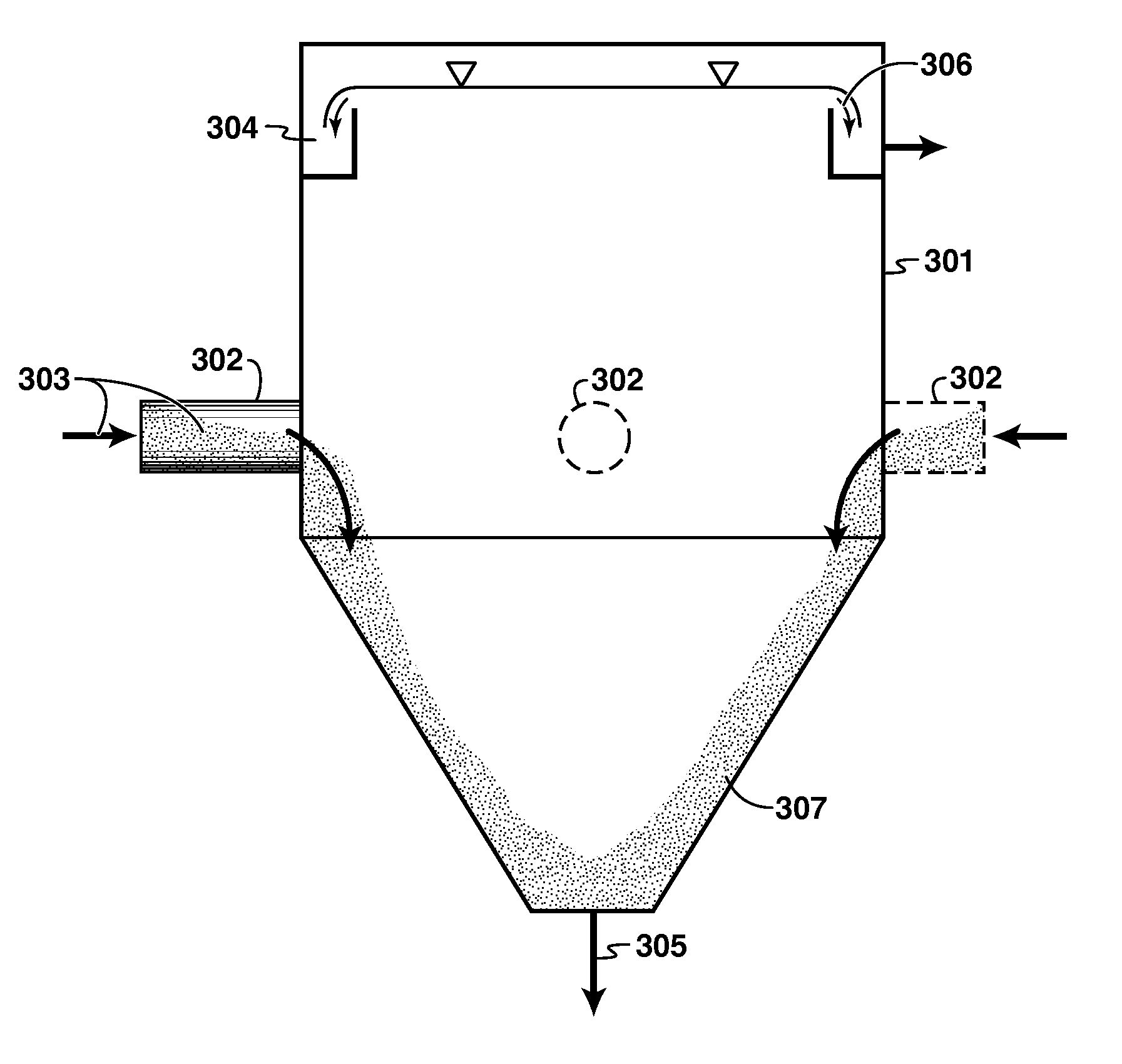

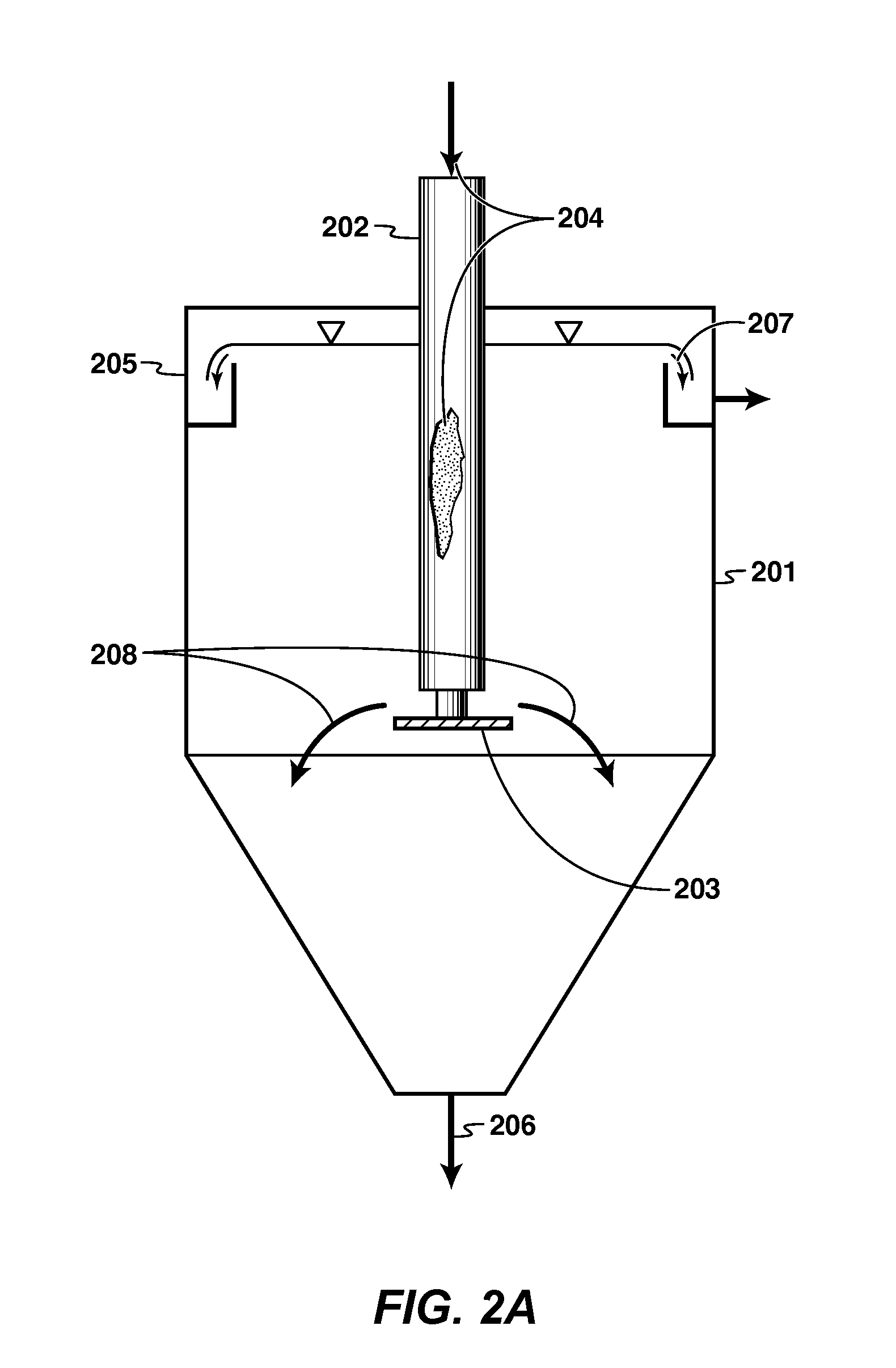

Feed Delivery System For A Solid-Liquid Separation Vessel

InactiveUS20110011769A1Easy to separateMinimize dispersionDewatering/demulsification with mechanical meansLiquid displacementBi modalEngineering

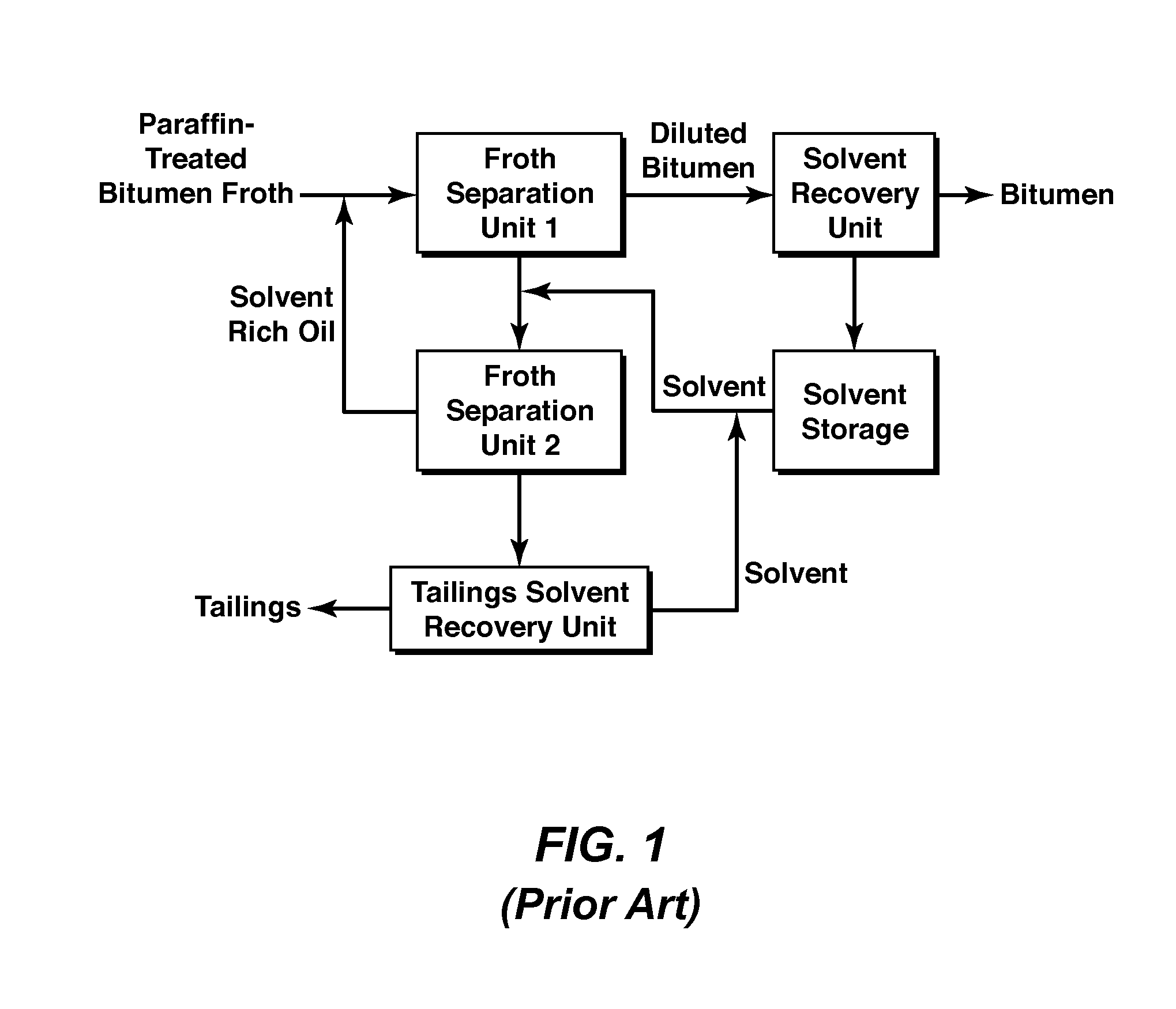

A method of delivering feed, for example a paraffinic solvent treated bitumen froth, to a separation vessel, for example a froth separation unit (FSU). The feed is delivered from one or more side inlets that may be substantially normal to, and flush with, the wall of the vessel. In contrast to certain conventional feed systems used in gravity separators which use a distributor plate to widely distribute the feed with a vessel, the feed is delivered such that it flows down the inside wall of the vessel. This feed delivery is characterized by a Richardson number of greater than 1.0. Such feed delivery is particularly useful where the feed has particles with a bi-modal size distribution to be separated from an overflow stream. The gentle flow serves to mitigate the upward flux of the smaller particles, for example mineral solids, by being trapped below the larger particles, for example precipitated asphaltene aggregates.

Owner:EXXONMOBIL UPSTREAM RES CO

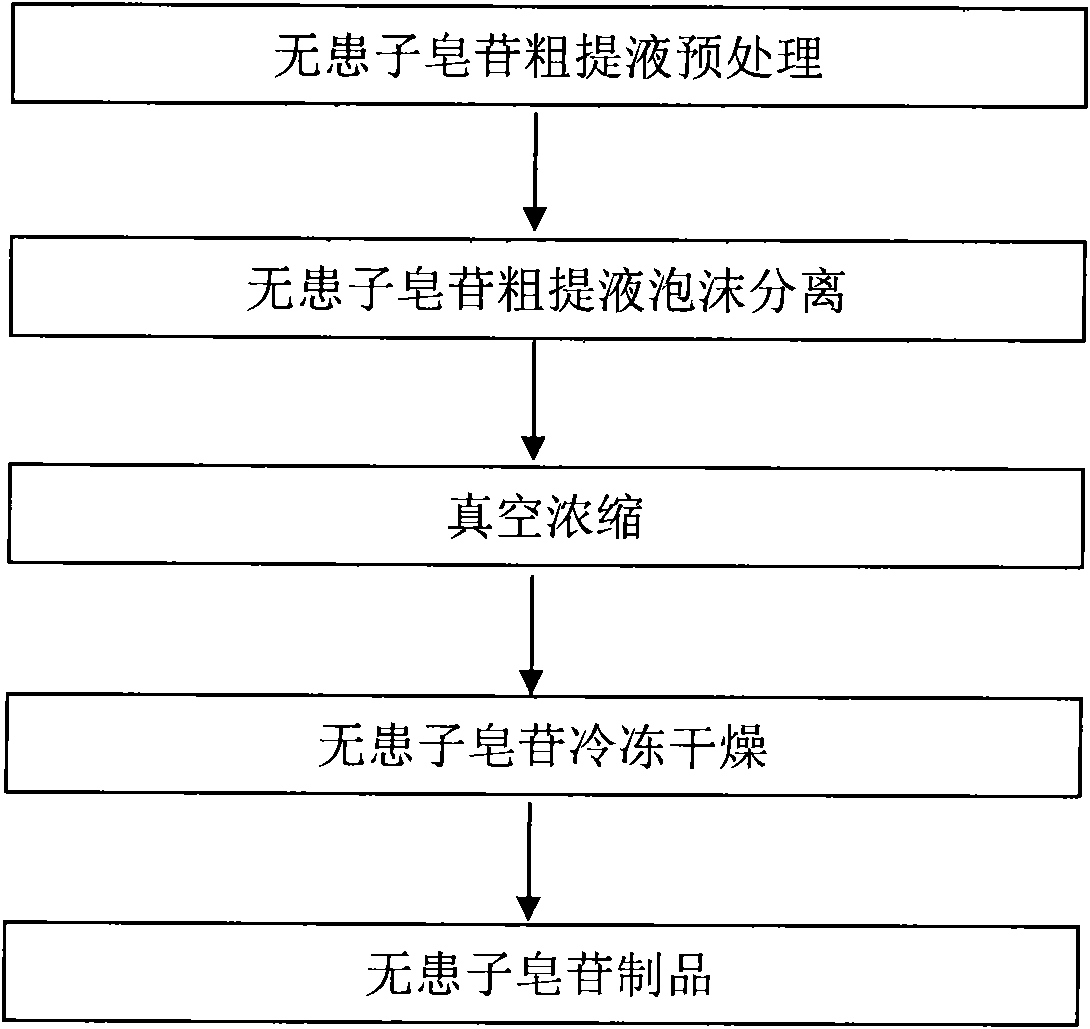

Method of separating soapnut saponin with foam separation method

InactiveCN101624416AHigh yieldSimple extraction processSteroids preparationFreeze-dryingFoam separation

The invention provides a method of separating soapnut saponin with the foam separation method, in particular a novel method of separating soapnut saponin from crude soapnut saponin extract with the foam separation method. The soapnut saponin with the high purity of 89-94 percent is obtained by the pretreatment, the foam separation, the vacuum concentration and the freeze drying of the crude soapnut saponin extract. Compared with the method of separating the soapnut saponin with resin, the invention simplifies the extracting process, lowers the power consumption, reduces the pollution and has wide application prospect.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

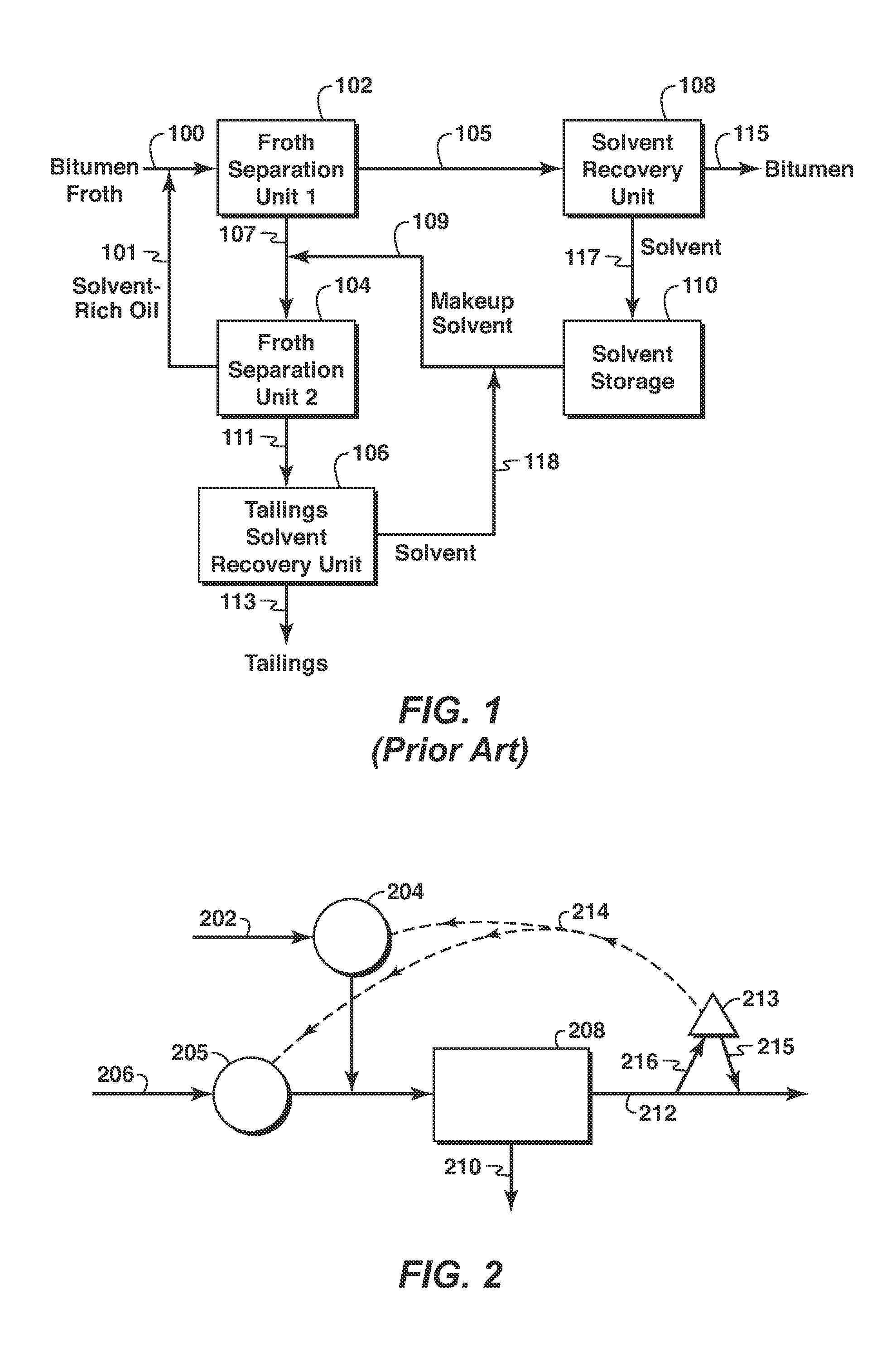

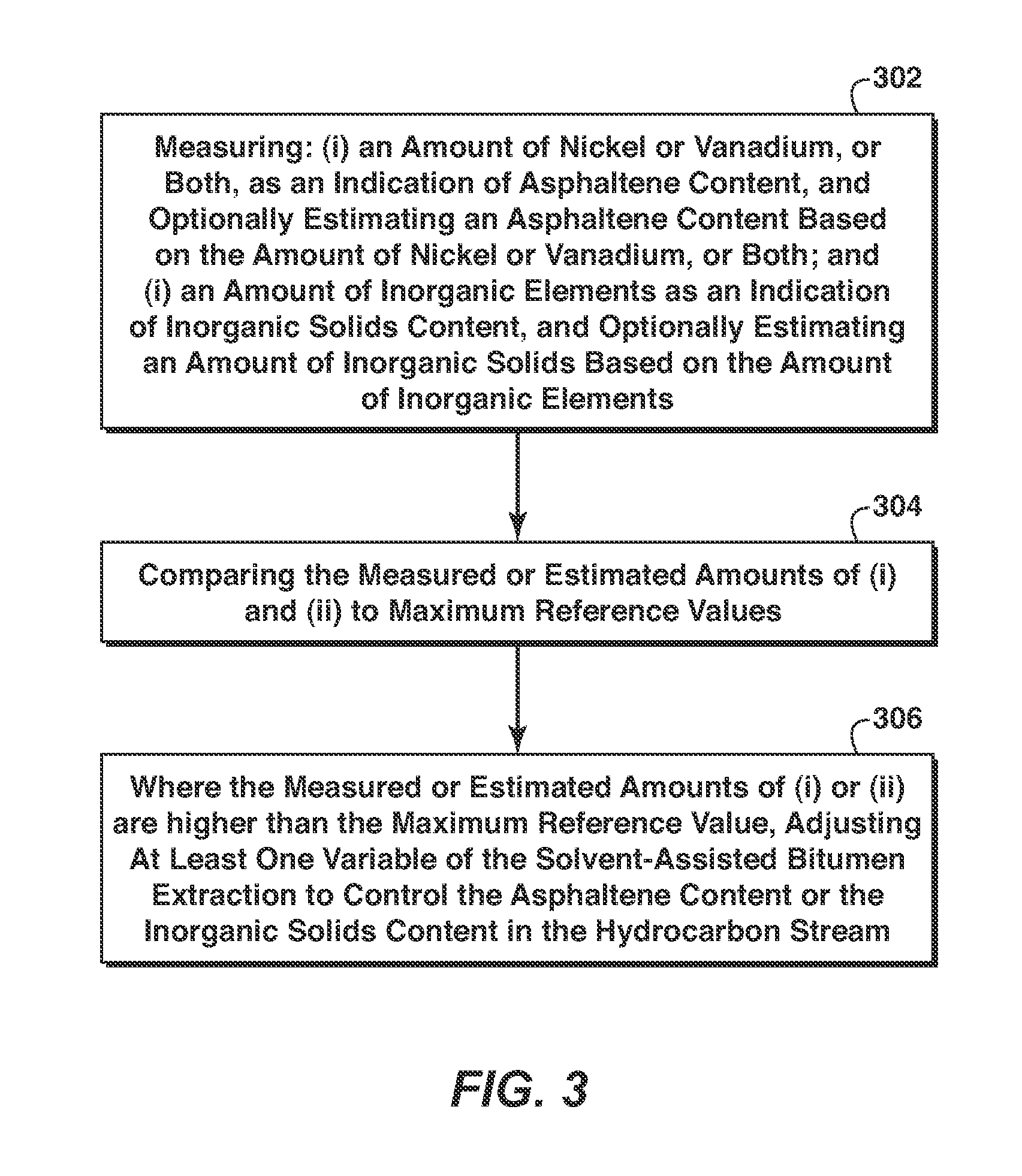

Controlling bitumen quality in solvent-assisted bitumen extraction

InactiveUS20130168294A1Improve bitumen qualityQuality improvementMaterial analysis using wave/particle radiationMaterial analysis by optical meansSulfurPorphyrin

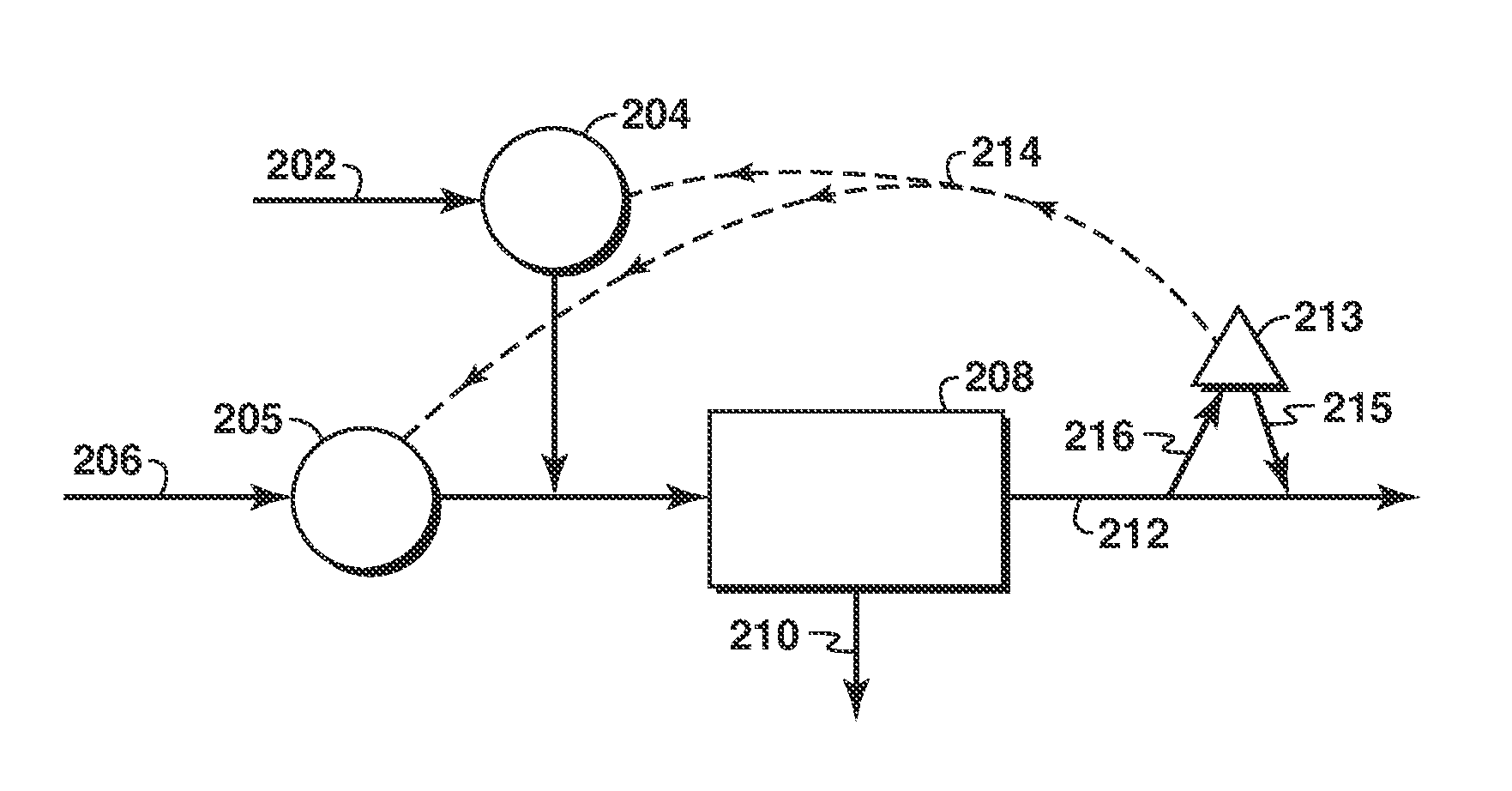

Described herein is a method of controlling bitumen quality in a process stream within a solvent-assisted bitumen extraction operation, for instance a hydrocarbon stream from a froth separation unit (FSU). Bitumen quality is a measure of the amount of selected contaminants in the process stream. Contaminants may include asphaltenes (comprising metal porphyrins), sulfur, and inorganic solids (comprising inorganic elements, e.g. Si, Al, Ti, Fe, Na, K, Mg, and Ca). First, the amounts of selected contaminants are measured. Next, these measured values are compared to maximum reference values. If one or more of these contaminants is higher than the maximum reference value, at least one variable of the solvent-assisted bitumen extraction is adjusted to improve bitumen quality.

Owner:EXXONMOBIL UPSTREAM RES CO

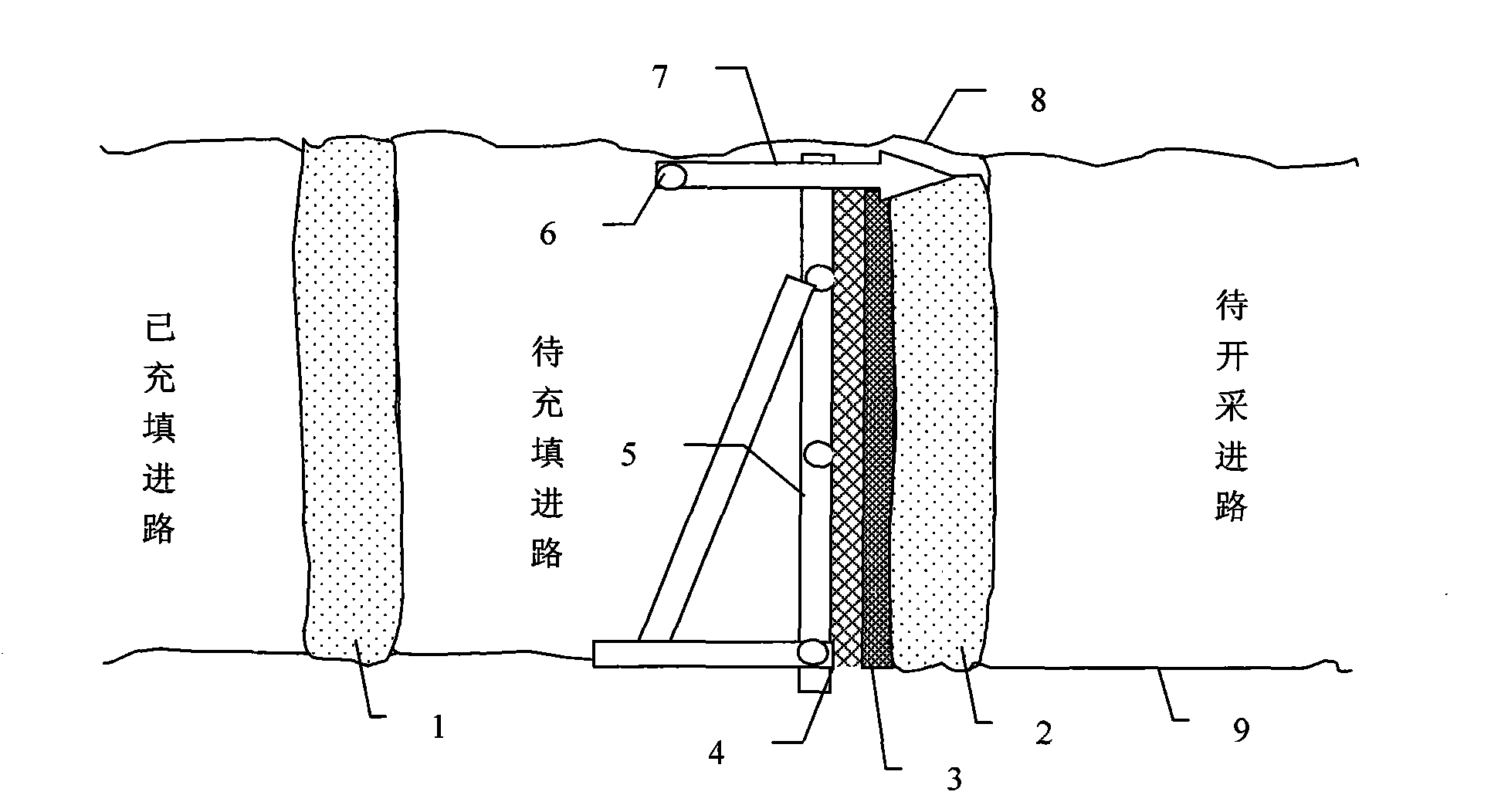

Construction method for cast-in-situ foam separation wall for tailing filling mining

InactiveCN104005786AFast constructionGuaranteed to stand on its own feetMaterial fill-upFalseworkInlet channel

The invention provides a construction method for a cast-in-situ foam separation wall for tailing filling mining. The construction method comprises the following steps of: step 1, clearing a bottom plate and setting up a scaffold at the solid side of a mined-out inlet channel close to an inlet channel to be mined; step 2, fixing a force-bearing grating on the scaffold, and then hanging and bonding a separation cloth on the force-bearing grating; step 3, fixing the scaffold coated with the force-bearing grating and the separation cloth by a diagonal bracing, and surrounding a cavity with an open upper portion among the solid side, the bottom plate and the scaffold; step 4, injecting foam slurry in the cavity, and after the foam slurry is solidified to achieve a certain strength, detaching the scaffold, removing the force-bearing grating, and then obtaining the cast-in-situ foam separation wall. The construction method is rapid in construction, convenient to pour, and good in application performance.

Owner:YANTAI UNIV

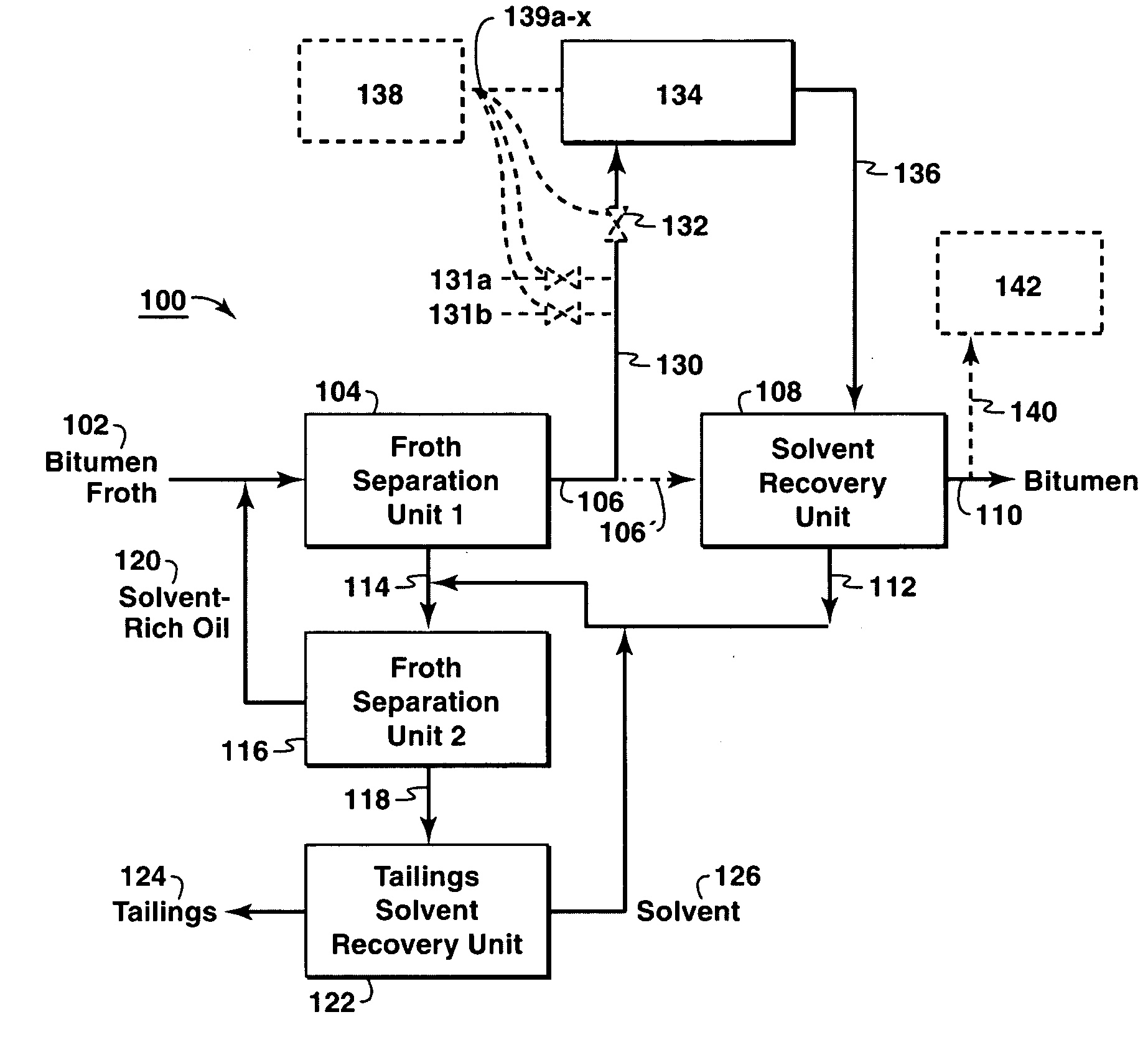

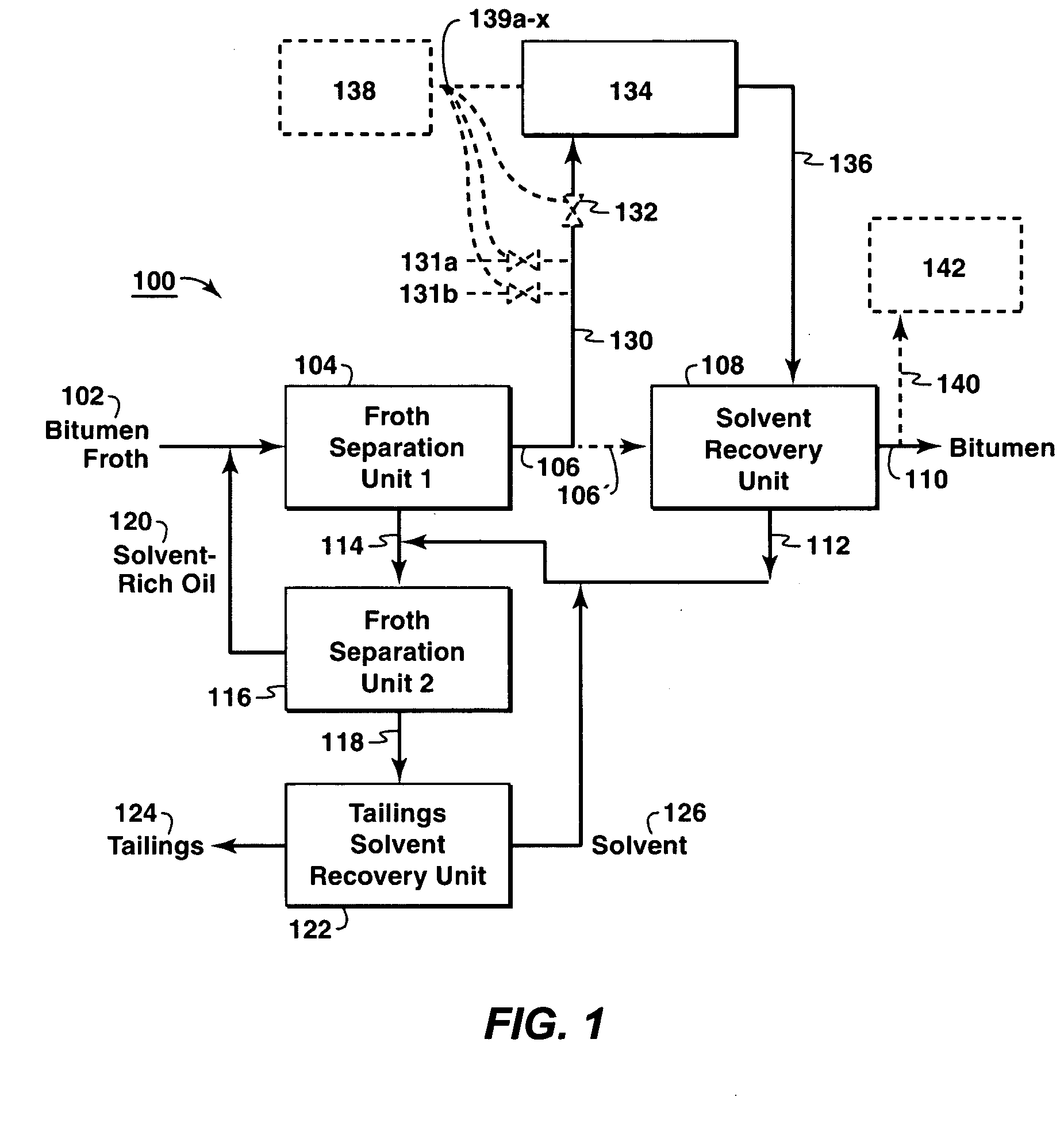

Optimizing Heavy Oil Recovery Processes Using Electrostatic Desalters

ActiveUS20090321323A1Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionFoam separationDesalter

The invention relates to improved bitumen recovery processes and systems. The process may include providing a bitumen froth feed stream, separating the stream in a froth separation unit to produce a diluted bitumen stream, treating the diluted bitumen stream in an electrostatic desalter to produce a treated bitumen stream, and separating the treated bitumen stream into a solvent recycle stream and a bitumen product stream. The system may include a combined AC / DC desalter with a control unit for optimizing the treatment process to produce a product bitumen stream using less solvent and smaller separators than conventional bitumen froth treatment plants and processes.

Owner:EXXONMOBIL UPSTREAM RES CO

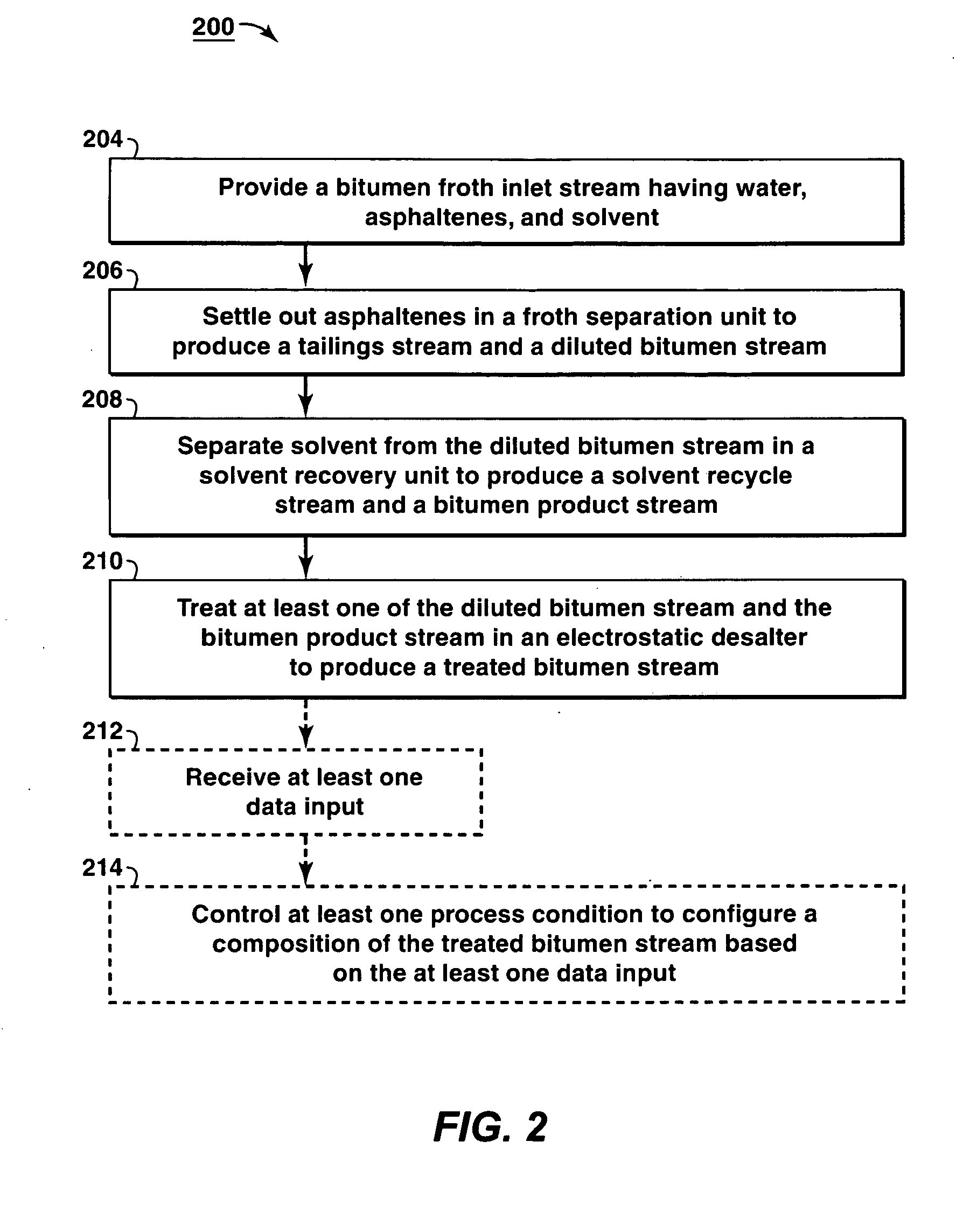

Polymyxin E separation preparation method

InactiveCN1800201AHigh yieldSimple extraction processPeptide preparation methodsBacteria peptidesPolymixin EFoam separation

The invention provides a method for separately preparing for polymyxin E, which uses foam separation method to extract and separate the polymyxin E from fermentation liquor. The fermentation liquor obtains polymyxin E raw medicine by first treatment, form separating, vacuum evaporation and spray drying.

Owner:HEBEI UNIV OF TECH

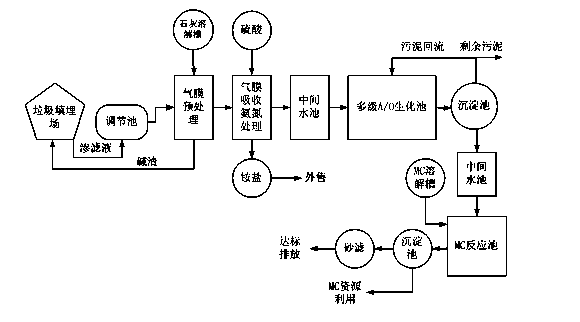

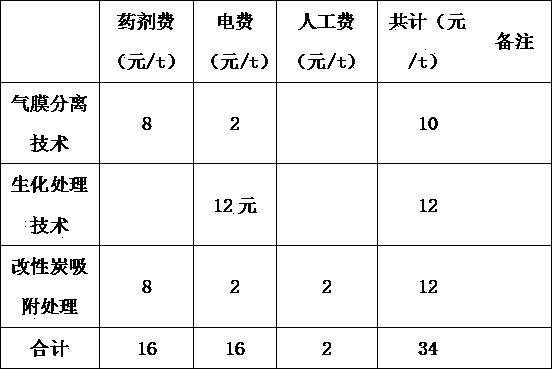

Method for processing city household garbage leachate

InactiveCN103626353AImprove economyStable emissionsMultistage water/sewage treatmentHigh concentrationSolubility

The invention discloses a method for processing city household garbage leachate. Aiming at the garbage leachate's characteristics of high ammonia nitrogen content and difficult biodegradation, people develop the processing method by combining and optimizing the following technologies: lime pretreatment, gas-film acid absorption, high efficient multi-grade AO biochemical treatment, and modified carbon absorption. The processing method comprises the following steps: subjecting the garbage leachate to a foam separation process so as to reduce the grease and surfactant content in the garbage leachate; adding lime into the garbage leachate so as to adjust the pH value of the garbage leachate and convert the ammonia nitrogen into a free state; subjecting the garbage leachate to processes of micro-filtration and ultrafiltration so as to eliminate macromolecular organic substances, then subjecting the garbage leachate to a gas-film acid absorption treatment so as to effectively eliminate the nitrogen ammonia with a high concentration in the garbage leachate to meet the requirements of biochemical treatment, subjecting the garbage leachate to go through an AO biochemical treatment system so as to further eliminate the pollutants such as total nitrogen, ammonia nitrogen, COD, BOD, and the like in the garbage leachate, so that after the processes mentioned above, only organic matters that are difficult to degrade and soluble are left in the garbage leachate, adopting modified carbon as an absorbent and a counter-current multi-grade absorption technology to effectively eliminate the organic matters difficult to degrade in the garbage leachate to make the garbage leachate meet the national discharging standard, and finally discharging the qualified garbage leachate.

Owner:宋乾武 +1

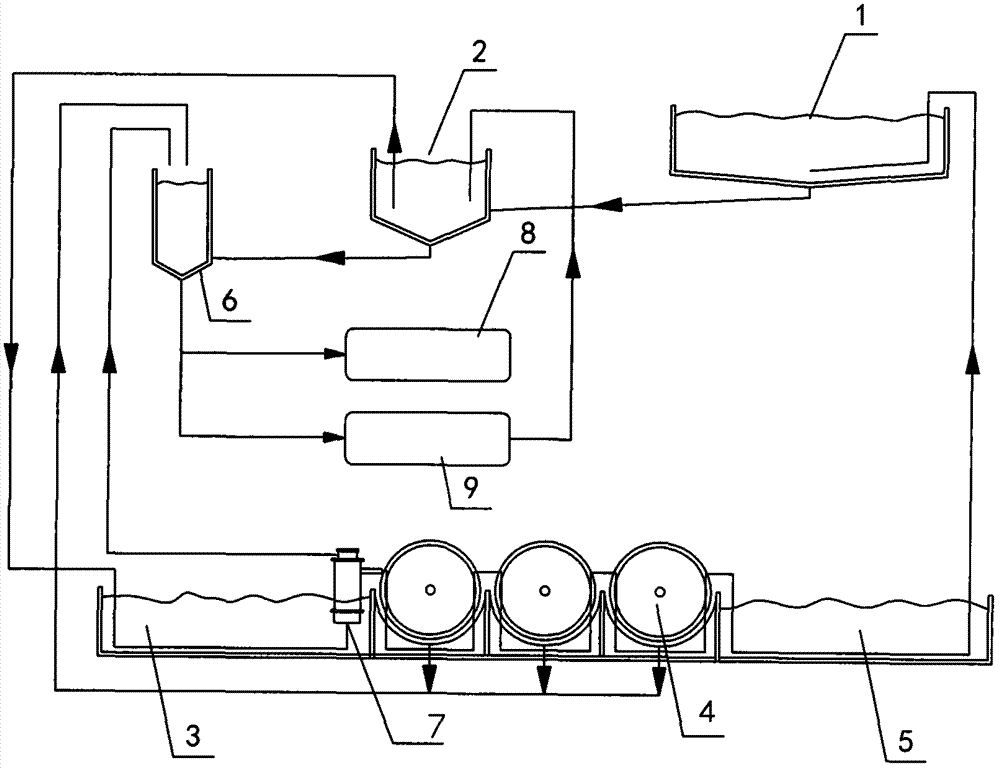

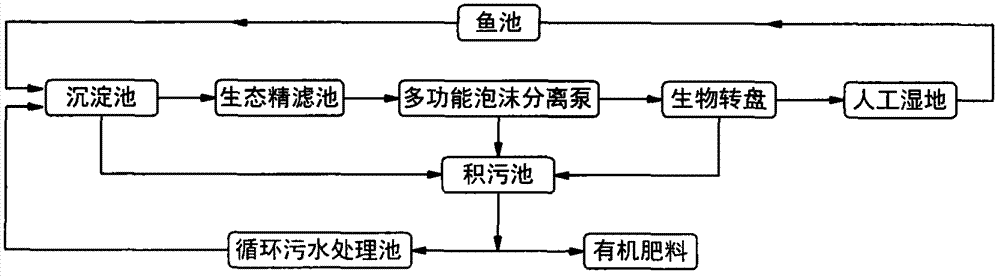

Culture system and culture method for culturing aquatic product by using circulating water

InactiveCN104326630AGuaranteed living environmentImprove filtering effectClimate change adaptationPisciculture and aquariaConstructed wetlandWater treatment system

The invention relates to a culture system and a culture method for culturing an aquatic product by using circulating water. The culture system for culturing the aquatic product by using the circulating water comprises a breeding tank and a circulating water treatment system communicated with the breeding tank, wherein the circulating water treatment system comprises a sedimentation tank communicated with the breeding tank, a dirt accumulation tank communicated with the sedimentation tank, an ecological refined filtration tank communicated with the sedimentation tank, a multi-functional foam separation pump communicated with the ecological refined filtration tank, a biological turn plate communicated with the multi-functional foam separation pump, and an artificial wetland pool of which one end is communicated with the biological turn plate and the other end is communicated with the breeding tank. The culture method for culturing the aquatic product by using the circulating water comprises a step of breeding the aquatic product in the breeding tank and a step of treating the circulating water. The culture system and the culture method for culturing the aquatic product by using the circulating water have the advantages that the culture system is simple in structure, and the culture system and the culture method are low in cost, applicable to miniaturization and capable of removing harmful organics and balancing the pH value.

Owner:叶剑

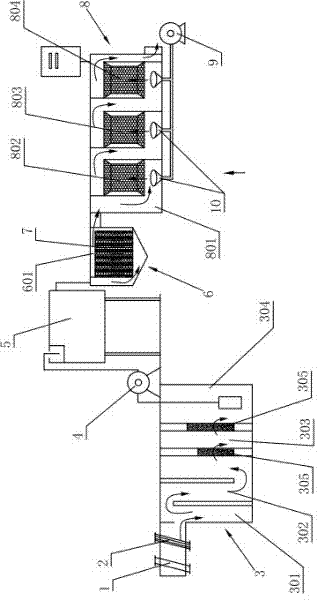

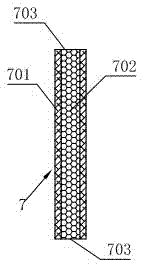

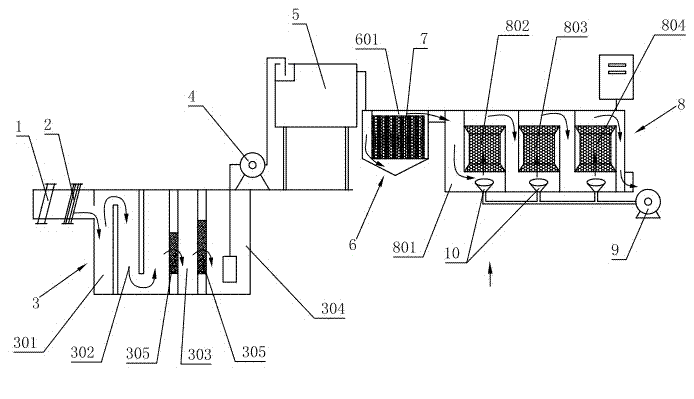

Domestic waste water biochemical treatment device

InactiveCN102260026ACompact structureReduce manufacturing costEnergy based wastewater treatmentMultistage water/sewage treatmentEcological environmentStraight tube

The invention relates to a life miscellaneous wastewater biochemical treatment device and is characterized in that the life miscellaneous wastewater biochemical treatment device comprises a septic tank, a high water tank, a straight-tube sedimentation chamber and a micro-aeration biological filter tank which are connected in sequence; the septic tank and the high water tank are connected by a water pump; the high water tank is disposed higher than the septic tank, the straight-tube sedimentation chamber and the micro-aeration biological filter tank; a thick grid and a fine grid are disposed inside an input pipe of the septic tank, which is equipped with a sedimentation chamber, an oil and foam separation tank and two filter tanks; the straight-tube sedimentation chamber comprises a sedimentation chamber housing and a straight-tube filter core; the micro-aeration biological filter tank comprises a biological filter tank housing, at least two biomass tanks are equipped inside the biological filter tank housing, and a micro-aeration head is arranged on the lower portion of each biomass tank. The invention has a simple and compact structure and requires low manufacturing cost. According to the invention, biomass balls are used as the carriers of biological bacteria and the biochemical treatment method is adopted to process organic wastewater, thus reducing the processing cost, raising the processing effect and minimizing the pollution of the life miscellaneous wastewater to the environment as well as the destruction of the life miscellaneous wastewater to the ecological environment.

Owner:无锡强工机械工业有限公司

Light-transmitting biological purifying recirculating water fish culture system

InactiveCN106857363APromote growthStabilize ecological balanceClimate change adaptationPisciculture and aquariaFilter feederEcological environment

The invention discloses a light-transmitting biological purifying recirculating water fish culture system, including a water source, a water distribution workshop, a sun bio filter, a water division pool, a foam separation pool, a foam separation tank, a sewage discharge pool, a biological packing pool, an ultraviolet disinfection pool, an oxygenation water supply pipeline, a fish culture workshop, and a secondary wetland sewage treatment system. Therefore, through a creative biological purifying method, industrialized recirculating water fish culture is satisfied, and a bio filter with suitable illumination condition is built. Thus, various alga which is beneficial for purifying water quality, and rooted filter feeders and active microbial films can be cultivated in the bio filter, so water environment, cultured fishes, and microbe content and other factors form stable ecological balance, just like marine ecological environment. Thus, a marine fishery pollution-free healthful aquaculture base is established.

Owner:QINHUANGDAO LIANGFENG MARINE ECOLOGY SCI & TECH DEV CO LTD

Method for extracting and separating panax japonicus saponin and polysaccharide

InactiveCN101838338ADoes not damage the structureImprove separation efficiencySugar derivativesSteroidsOrganic solventFoam separation

The invention relates to a method for extracting and separating panax japonicus saponin and polysaccharide from the panax japonicus, which comprises the following steps of: extracting the panax japonicus; adjusting a pH value; performing foam separation; and purifying panax japonicus polysaccharide. The method has the advantages of high separating efficiency, high purity, large extraction volume, low energy consumption, simple device, low cost, no introduction of an organic solvent pollutant, no damage to the structure of the panax japonicus saponin and the like. A surfactant is not necessary to add in the foam extraction process, so the problems of recovery of the surfactant and the pollution caused by the recovery are solved.

Owner:CHINA THREE GORGES UNIV

Printing and dyeing wastewater processing technique

InactiveCN101381178AReduce chromaReduce CODMultistage water/sewage treatmentWater/sewage treatment by oxidationEmission standardTherapeutic effect

The invention provides a printing-dyeing wastewater treatment process, which belongs to the technical field of wastewater treatment. The treatment process uses a foam separation technique together with Fenton oxidation to treat printing-dyeing wastewater containing more than two dyes, and concretely comprises the following: a step of collecting and filtering the printing-dyeing wastewater containing more than two dyes; a step of detecting and pretreating, which is to detect the pigment composition, chemical oxygen consumption, color, pH value and suspended solid content of the dyes contained in the printing-dyeing wastewater and to regulate the pH value of the wastewater to between 6.0 and 8.0 by use of hydrochloric acid or sodium hydroxide; a step of separating foam and decolorizing, which is to add Dodecyl trimethyl ammonium bromide as surfactant to the wastewater treated through the previous step and then to decolorize by use of a bubbling tower; and a step of carrying out Fenton oxidation to the wastewater obtained in the previous step. The COD of the treated wastewater meets the national emission standard. The process overcomes the disadvantage that the prior printing-dyeing wastewater treatment process is large in occupied area, causes secondary pollution, is low in color removal rate, great in treatment effect fluctuation, complex in process and high in cost, or can not achieve ideal effects.

Owner:天津市瑞德赛恩新材料开发有限公司

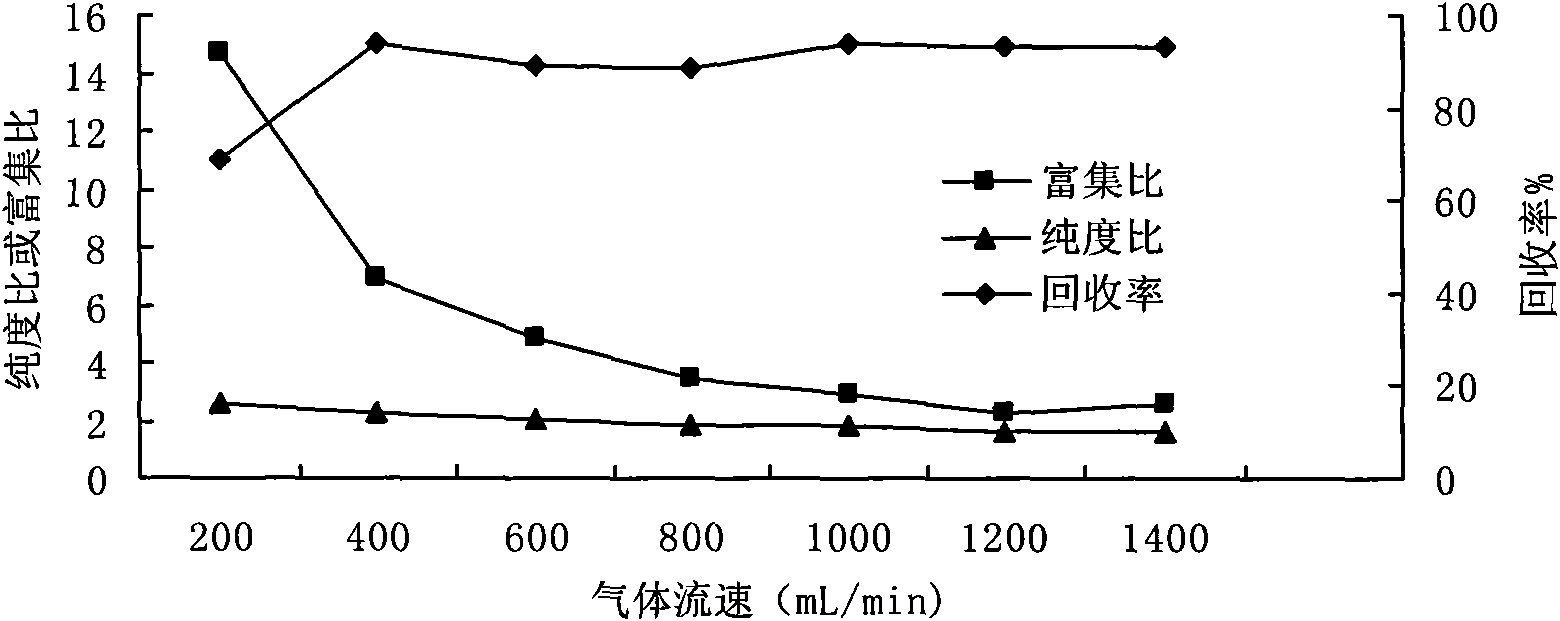

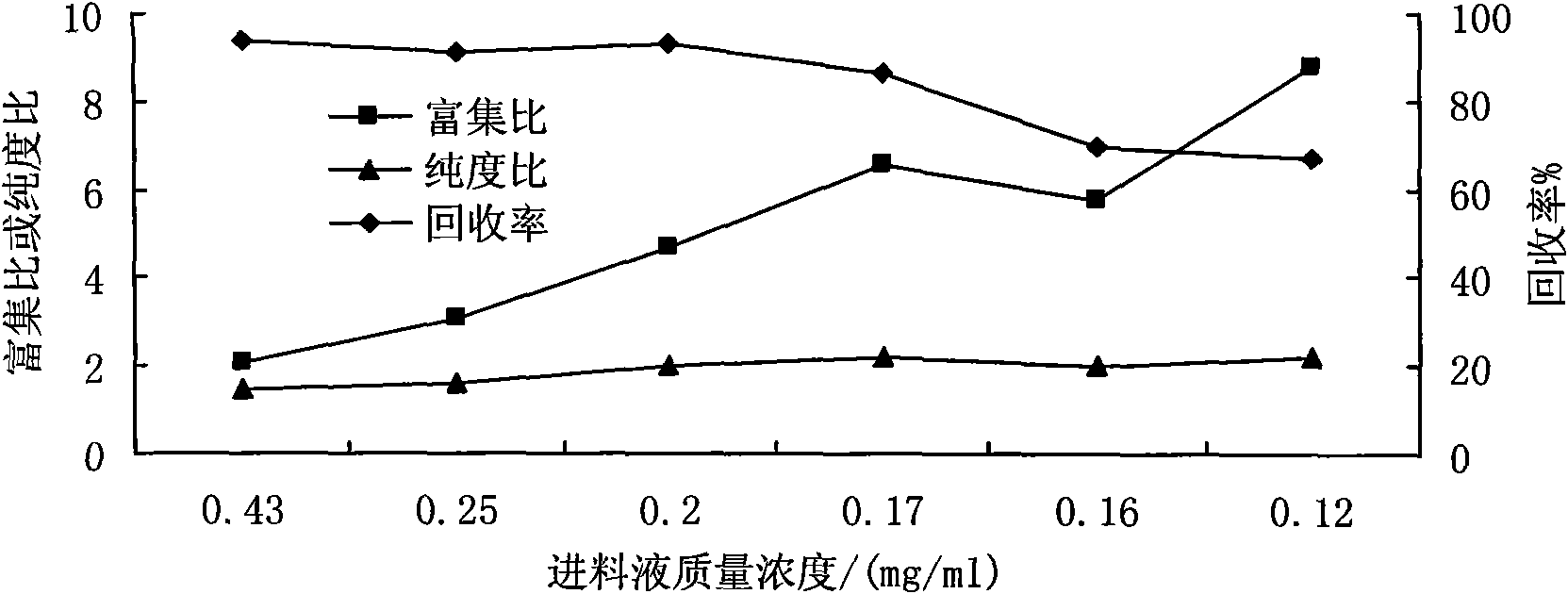

Process for concentrating soy isoflavone in soy protein waste water by foam separation method

ActiveCN102838576ALess investmentReduce energy consumptionOrganic chemistryMultistage water/sewage treatmentSOY ISOFLAVONESThree stage

The invention relates to a process for concentrating soy isoflavone in soy protein waste water by a foam separation method. The process comprises the following steps of: (1) collecting and detecting waste water generated by producing soy protein; (2) regulating the pH of the waste water generated by producing the soy protein; and (3) carrying out three-stage foam separation. According to the process, the concentration ratio (the concentration ratio of the soy isoflavone is 5.8-11.0) of the soy isoflavone not only can be greatly improved, but also the recovery rate (the recovery rate of the soy isoflavone is 80-90 percent) can be increased.

Owner:HEBEI UNIV OF TECH

Technique for processing anionic dye printing and dyeing wastewater

InactiveCN101172673ALess investmentReduce energy consumptionNature of treatment waterWater/sewage treatment by flotationDyeing wastewaterChrominance

The invention provides a treatment process of anionic dye dyeing waste water, which belongs to the field of waste water treatment, and disposes the anionic dye dyeing waste water by use of the foam separation technology. The invention has the exact steps as follows: 1. the anionic dye dyeing waste water is collected and detected; 2. the anionic dye dyeing waste water is pretreated; 3. the process of foam separation circular decoloring means adding cationic surfactant hexadecyl trimethyl ammonium bromide into the anionic dye dyeing waste water and decoloring for four times in a bubble column; and 4. vaporizing and crystallizing. The invention has advantages of simple device, small investment, few energy consumption and convenient operation, not only has high chrominance removal rate and small treating effect fluctuation, but also obtains the dye coarse product used for the dyeing process again.

Owner:HEBEI UNIV OF TECH

Method for preparing lucid ganoderma polysaccharides

The invention discloses a method for preparing lucid ganoderma polysaccharides. The method comprises the following steps: using lucid ganoderma as a raw material; after overflow circulation ultrasonic shattering and extracting, separating a supernatant through high-speed centrifuging, removing proteins from the supernatant through circular current foam separation, and carrying out microwave vacuum drying to obtain lucid ganoderma polysaccharide powder. Due to the adoption of overflow circulation ultrasonic shattering and extracting, the shattering efficiency of the lucid ganoderma can be increased, the extracting rate of the lucid ganoderma active polysaccharides is increased, and automation operation can be conveniently carried out. The preparing method has the advantages of simplicity, low energy consumption, short time and capability of well preserving the natural activity of the lucid ganoderma polysaccharides and is suitable for industrial production. The obtained lucid ganoderma polysaccharides can be used for preparing different types of food, health food or drugs.

Owner:福建省神六保健食品有限公司

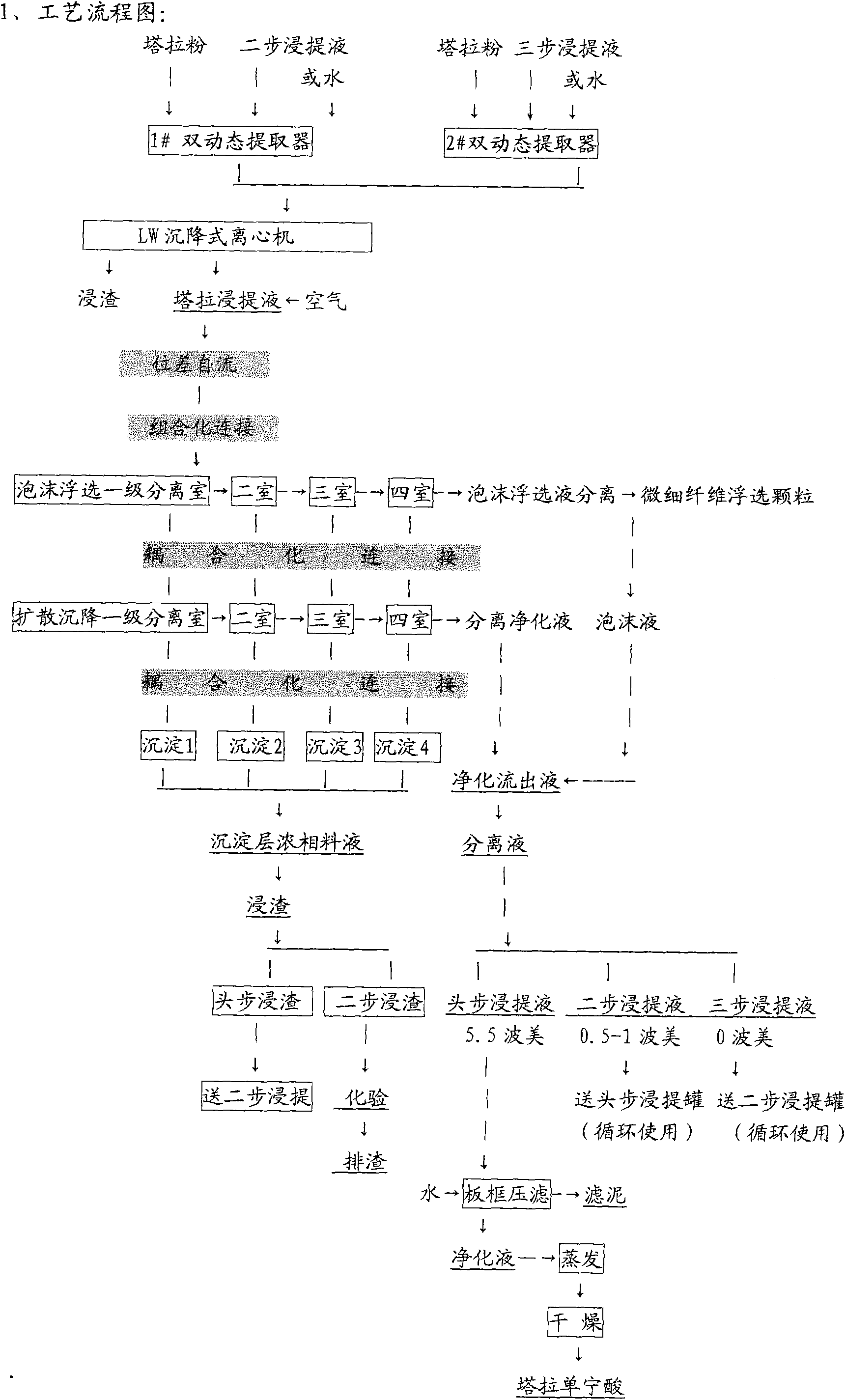

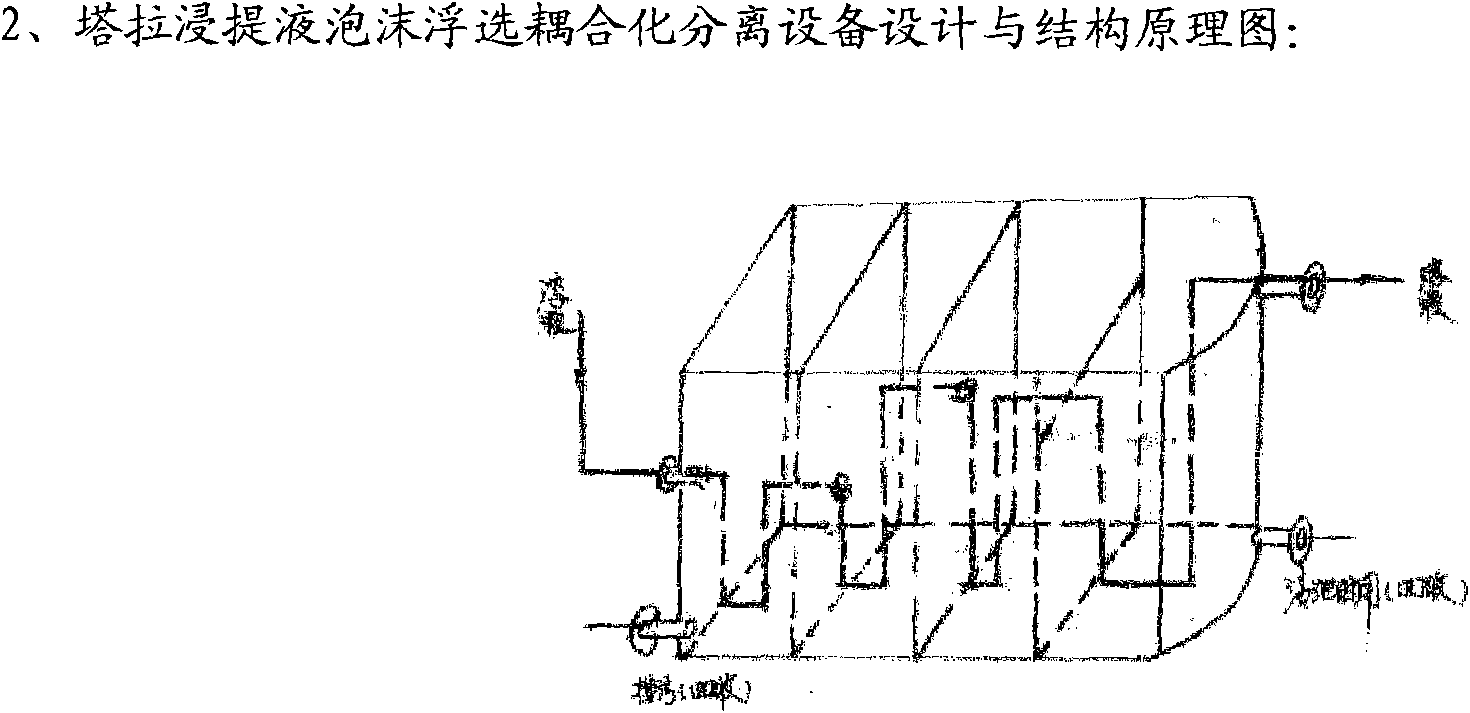

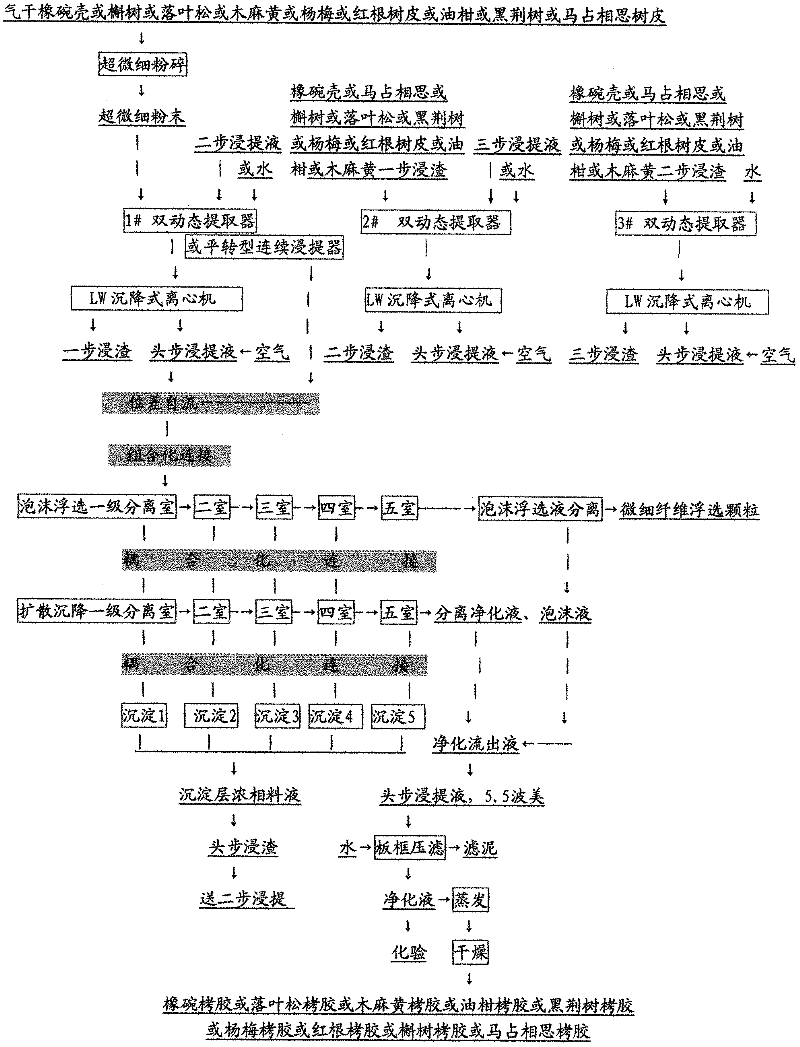

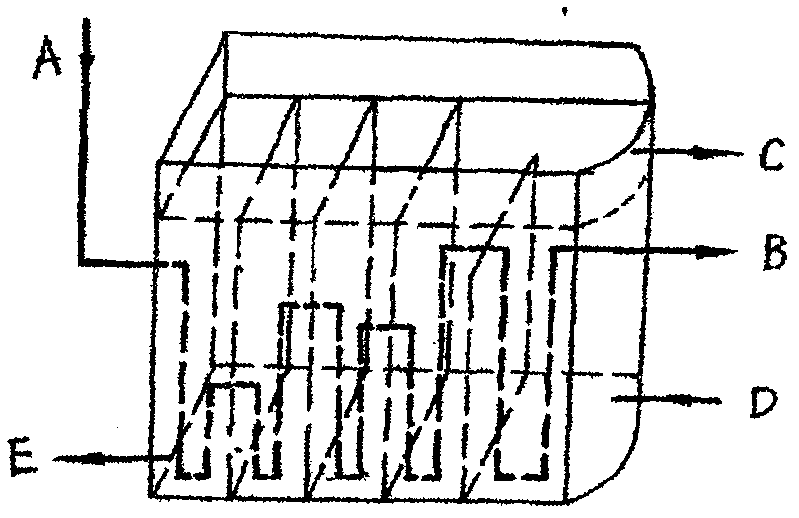

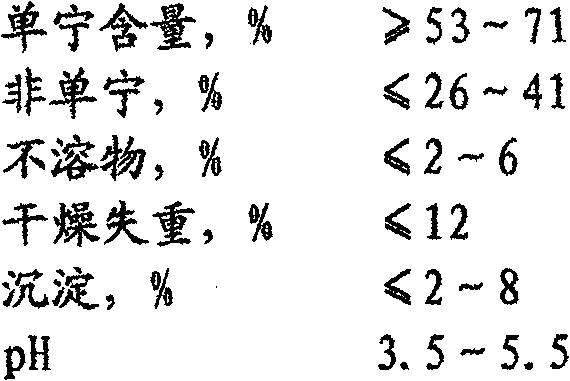

Preparation method of tara industrial tannic acid

The invention relates to a preparation method of tara industrial tannic acid. In the preparation method, tara powder is taken as a raw material, the problems of filtration, sol, superfine fiber particles, undissolved substances, high non tannis and the like in the producing and processing technology of tara tannis are successfully solved through combination and coupling technologies such as double dynamic lixiviation, spiral sedimentation centrifugal separation (horizontal type spiral unloading centrifugal separation), foam separation, sedimentation separation, plate-frame pressure filtration and the like and equipment processing, so as to obtain the qualified tara industrial tannic acid. The preparation method has the advantage of advanced technology; and by using the preparation method, low-temperature, efficient and industrialized production, combination and coupling extraction and a novel solid-liquid separation technique of the tara powder are achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

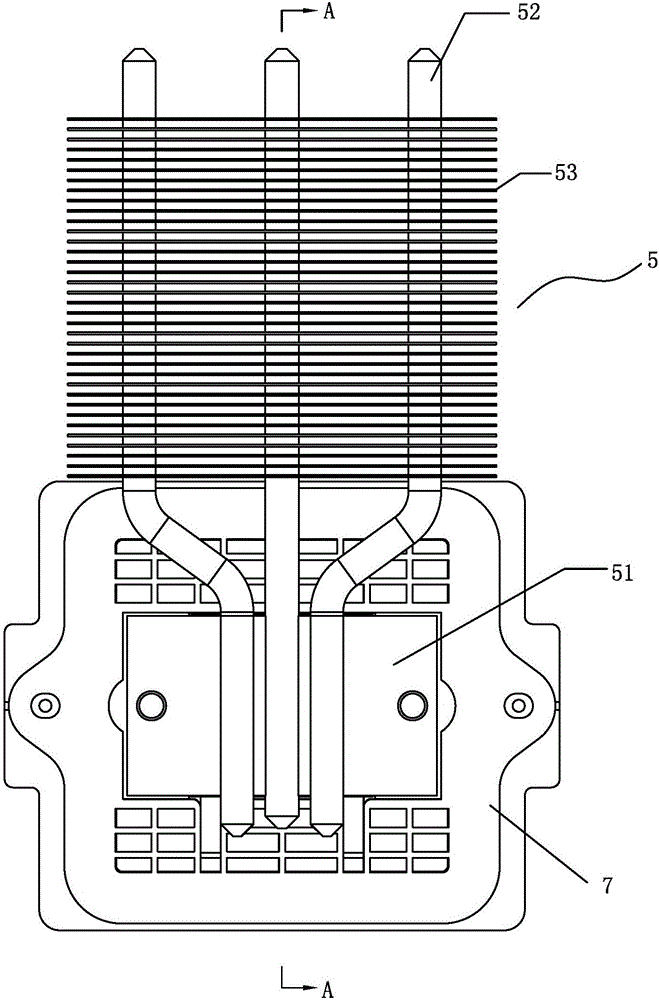

Heat pipe for electronic wine cabinet and cold and heat generation device

ActiveCN106123659ANo corrosionExtended service lifeIndirect heat exchangersMachines using electric/magnetic effectsDistilled waterEngineering

The invention discloses a heat pipe for an electronic wine cabinet. The heat pipe comprises a heat conduction block, a heat conduction pipe and a heat dissipation plate. A refrigerant is arranged in the heat conduction pipe. A cold and heat generation device comprises a shell with a front opening and a rear opening, and a foam separation medium is distilled water or purified water. The cold and heat generation device comprises the shell with the front opening and the rear opening, a foam partition plate, a semiconductor chilling plate, a heat insulation frame, the heat pipe, heat dissipation aluminum and a cover plate with a center hole. The heat dissipation aluminum comprises a cold conduction block, a base body and multiple cooling fins arranged on the base body. The heat pipe comprises the heat conduction block, the heat conduction pipe and the heat dissipation plate and further comprises the cover plate. The cover plate is buckled with the rear opening of the shell and presses the foam partition plate. The cover plate is fixedly connected with the shell through a screw. The heat conduction block is attached to the cover plate. The head portion of the heat conduction block penetrates the center hole of the cover plate to be attached to the semiconductor chilling plate. Due to the fact that the structure is adopted and the distilled water serves as the refrigerant in the heat conduction pipe, the characteristics that the distilled water has few impurities, no waste gas is discharged in the assembling process, and the heat conduction pipe is not corroded are given into full play, and the service life of the heat conduction pipe is prolonged.

Owner:ZHONGSHAN CANDOR ELECTRIC APPLIANCES CO LTD

Series tannin extract raw material ultra-fine crushing preparation as well as combined and coupled preparation process and method for series tannin extract products

The invention relates to a series tannin extract raw material ultra-fine crushing preparation as well as a combined and coupled preparation process and method for series tannin extract products. Prepared ultra-fine powder materials of valonia tannin extracts, larches, coast oaks, emblic leaf flowers, black wattles, myrica esculenta, red roots, live oaks and acacia mangium barks are respectively carried out by combined and coupled process and equipment processing of double-dynamic digestion or transition type continuous digestion, spiral sedimentation centrifuging separation (horizontal spiral unloading centrifuging separation), foam separation, sedimentation separation, plate frame filter pressing and the like, so as to correspondingly solve the problem that filtration, sol, micro-fine fiber grains, insoluble substances, non-tannin and the like in a producing and processing process of tannin extract raw materials are high. Therefore, the tannin extract products of industrial-grade valonia tannin extracts, larch tannin extracts, coast oak tannin extracts, emblic leaf flower tannin extracts, black wattle tannin extracts, myrica esculenta tannin extracts, red root tannin extracts, live oak tannin extracts and acacia mangium tannin extracts, which meet the industrial standard, are prepared.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

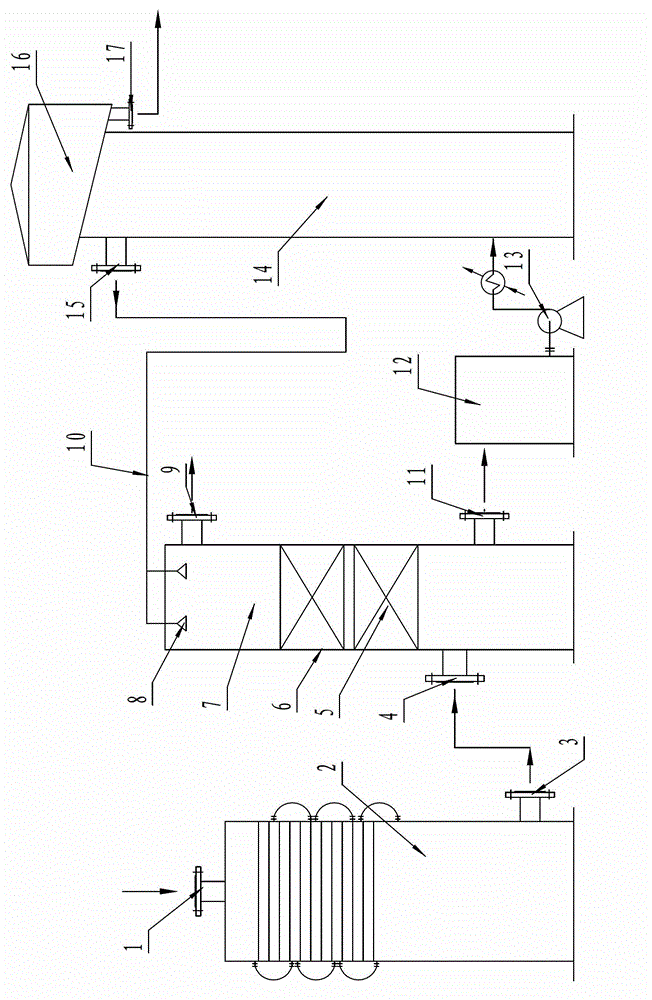

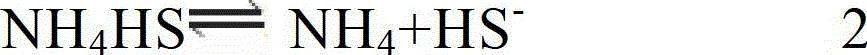

Coke oven gas desulfurization equipment

InactiveCN102977932AReduce concentrationIssues such as corrosionCombustible gas purificationHydrogenCoke oven

The invention discloses coke oven gas desulfurization equipment which belongs to equipment for removing sulfuretted hydrogen from ammonia and sulfuretted hydrogen-containing gases, and in particular relates to equipment for removing the sulfuretted hydrogen from coke oven gases. The coke oven gas desulfurization equipment has a structure that the coke oven gas desulfurization equipment mainly comprises a coal gas indirect cooler, a desulfurizing tower and a regenerating tower which are connected together through pipelines, the connection relationship of the devices is that a coal gas outlet of the coal gas indirect cooler is connected with a coal gas inlet on the bottom of the desulfurizing tower, a desulfurizing liquid nozzle is arranged on the top of the desulfurizing tower, a purified coal gas outlet is formed on the upper part of the desulfurizing tower, a desulfurizing liquid outlet on the bottom of the desulfurizing tower is connected with the regenerating tower through a solution circulating tank and a pump, a regeneration desulfurizing liquid outlet is formed on the upper part of the regenerating tower and is connected with the desulfurizing tower through a desulfurizing liquid circulating pipeline, a tower cover which contains a sulfur and foam separation device is arranged on the top of the regenerating tower, and a sulfur foam outlet is formed on the bottom of the tower cover. The coal gas indirect cooler is adopted to cool coal gas to 20-22 DEG C before desulfurization, the structure of the desulfurizing tower is improved, and the desulfurizing efficiency is increased.

Owner:济南冶金化工设备有限公司

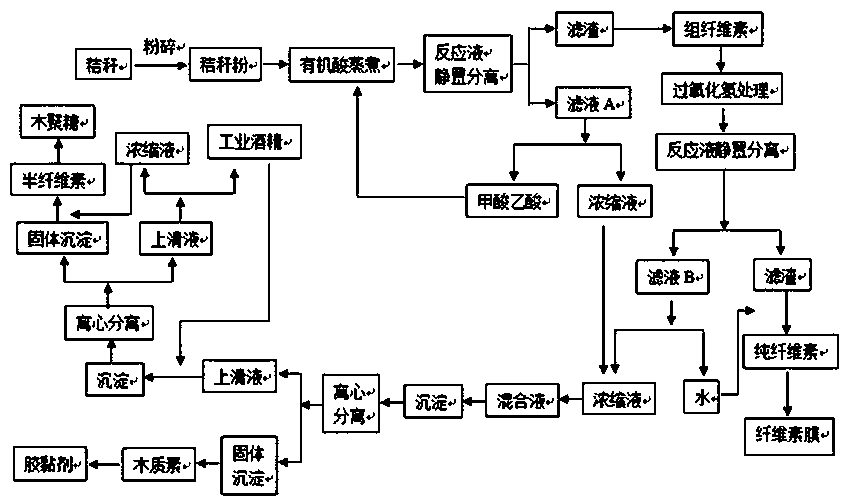

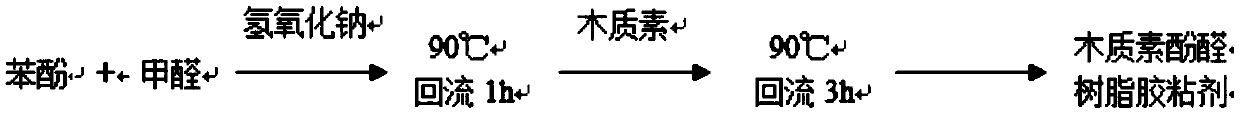

Separation and comprehensive utilization method of all components of crop straw

ActiveCN110241644AAffect the extraction ratePrevents hydrolytic breakagePulping with organic compoundsPulping with acid salts/anhydridesOrganic acidDistillation

The invention provides a separation and comprehensive utilization method of all components of crop straw. The separation and comprehensive utilization method of all the components of the crop straw comprises the steps of cooking crushed crop straw under the catalytic action of diluted hydrochloric acid by means of organic acid liquid, then conducting solid-liquid separation to obtain filter liquor, namely A liquid, washing filter residues with water until the filter residues are neutral, and then conducting drying to obtain crude cellulose; after the crude cellulose is treated by hydrogen peroxide, conducting solid-liquid separation to obtain filter liquor, namely B liquid, washing filter residues with water until the filter residues are neutral, and then conducting drying to obtain cellulose; conducting reduced pressure distillation on the A liquid and the B liquid separately, mixing obtained distilled products, after a pH is adjusted, conducting solid-liquid separation to obtain filter liquor, namely C liquid, washing sediment with water until the sediment is neutral, and then conducting drying to obtain lignin; adjusting a pH of the C liquid, then adding industrial alcohol, and then conducting solid-liquid separation; and washing sediment with water until the sediment is neutral, and then conducting drying to obtain hemicellulose. By means of the separation and comprehensive utilization method of all the components of the crop straw, the three components of the cellulose, the hemicellulose and the lignin in the straw can be successfully separated, and the recovery rates of the three components are high, so that comprehensive utilization of the straw is truly achieved.

Owner:河南省高新技术实业有限公司

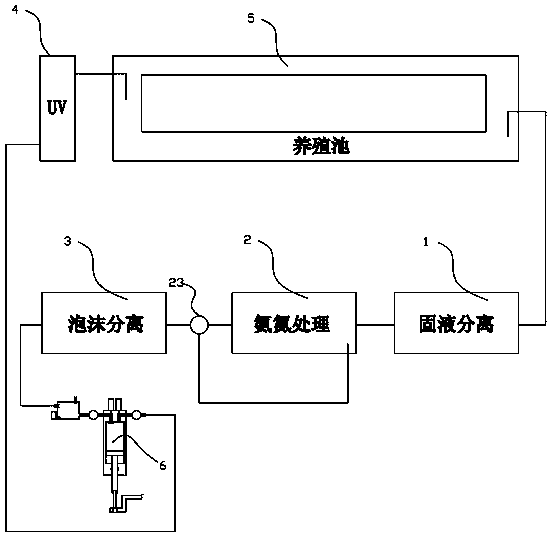

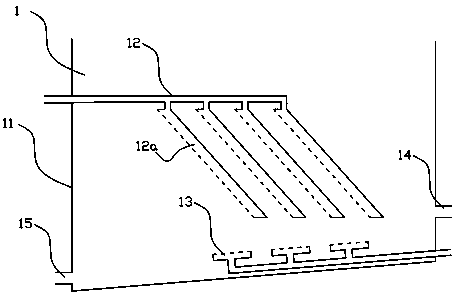

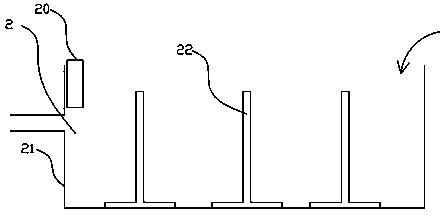

Sepia-lycidas flow-type artificial fry breeding device

InactiveCN103583434AReduce water changesEasy to handleClimate change adaptationPisciculture and aquariaInlet valveEngineering

The invention discloses a sepia-lycidas flow-type artificial fry breeding device. The sepia-lycidas flow-type artificial fry breeding device comprises a solid-liquid separation pond, an ammonia-nitrogen processing pond, a foam separation pond, a mechanical degerming device, an ultraviolet lamp and a culture pond which are sequentially connected to form a loop. The mechanical degerming device comprises a cylinder provided with an inner cavity; a piston capable of being driven by external force to slide in a reciprocating mode is arranged in the inner cavity of the cylinder; the cylinder is further provided with a liquid inlet channel and a liquid discharging channel, a liquid inlet valve rod is arranged in the liquid inlet channel, and a liquid discharging valve rod is arranged in the liquid discharging channel; the liquid inlet valve rod and the liquid discharging valve rod can be driven by the external force to control the inner cavity of the cylinder to be communicated with or insulated from the outside in a time-segmented mode; the liquid inlet channel is connected with a homogenate tank which can provide homogenate fluid; an air groove is formed in the inner wall of the cylinder; the distance between the two end portions of the air groove is greater than the thickness of the piston. The sepia-lycidas flow-type artificial fry breeding device has the advantages of being small in water change quantity, good in water processing effect, low in operating cost and manufacturing cost, good in stability, capable of producing a great number of fries and controlling the ammonia-nitrogen processing scale according to requirements, good in disease control effect and environmentally friendly.

Owner:ZHEJIANG OCEAN UNIV

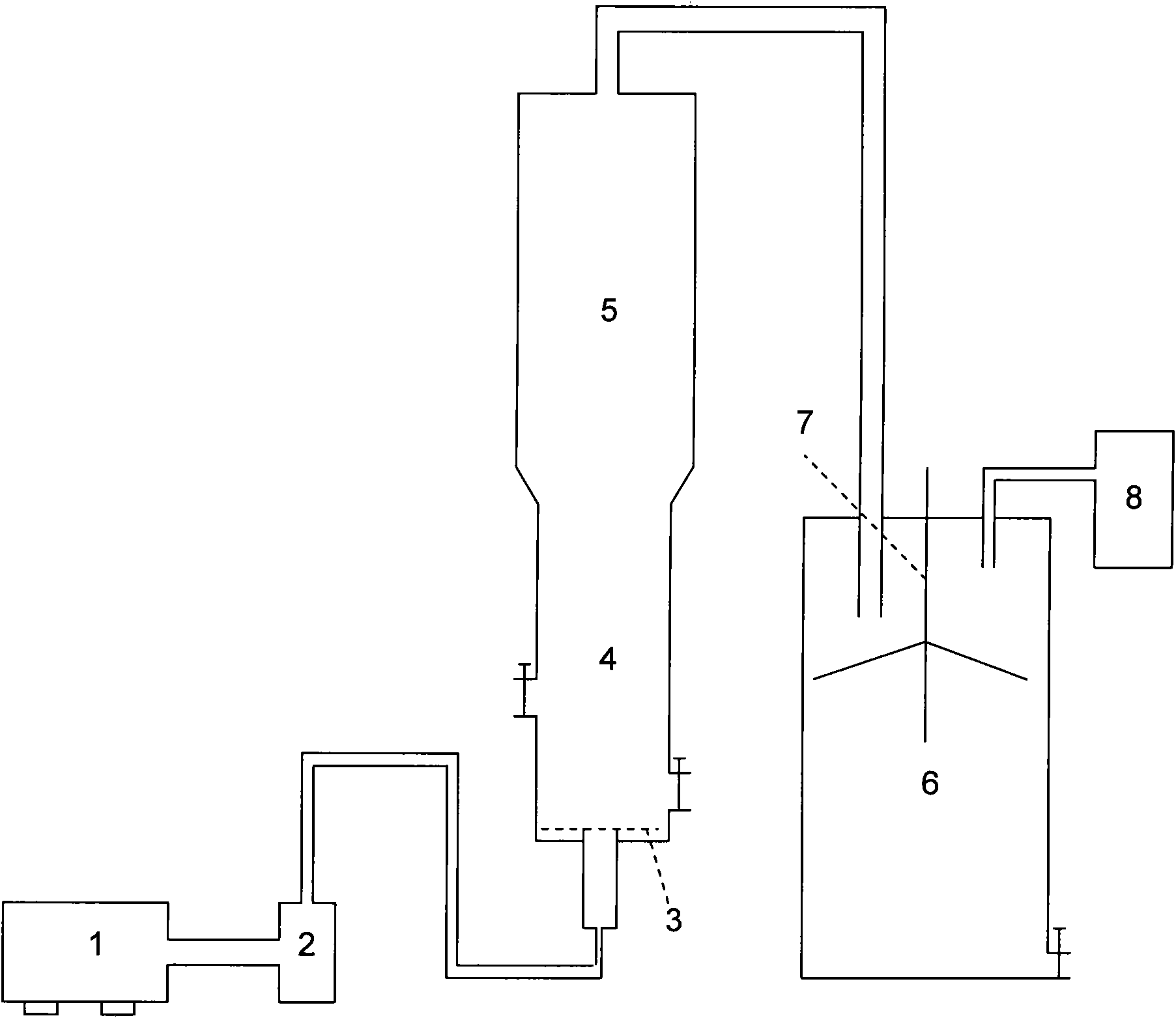

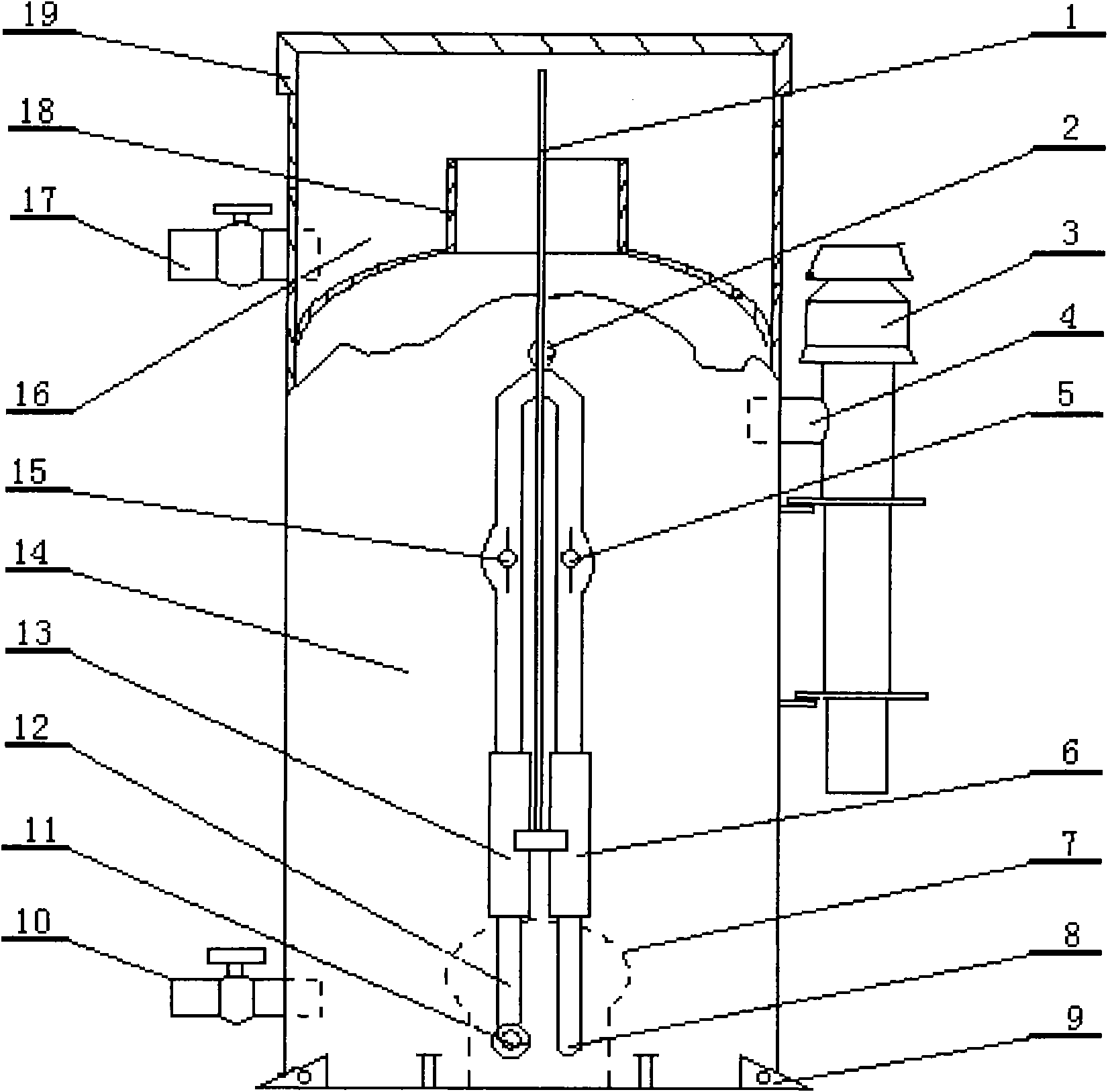

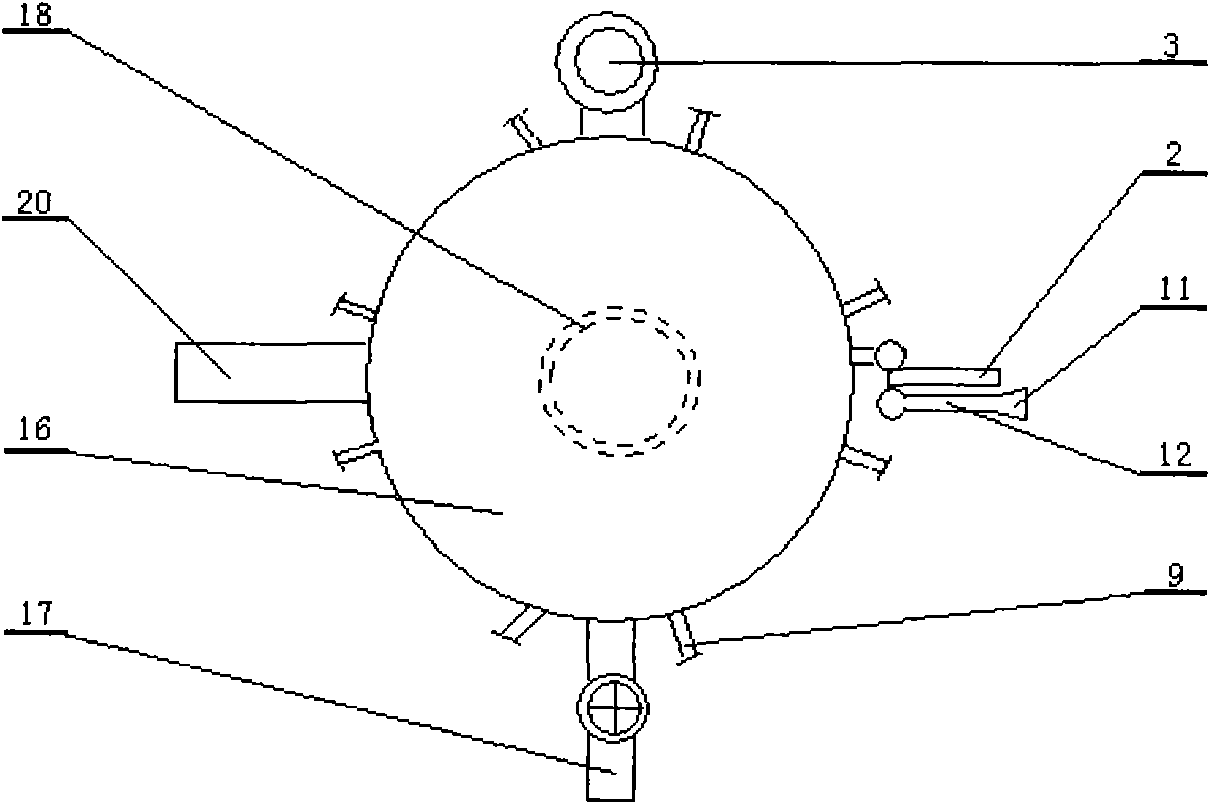

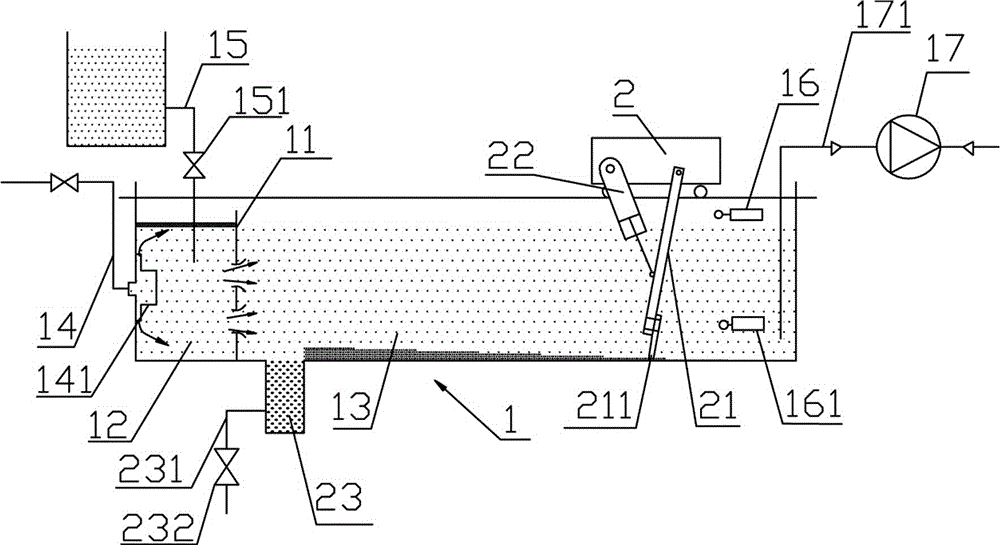

Multiphase flow rotation foam separation device and waste water/ gas treatment technology using same

InactiveCN102992418AReduce removal rateCause secondary pollutionCombination devicesWater/sewage treatmentLiquid wasteChemical oxygen demand

The invention discloses a multiphase flow rotation foam separation device and a waste water / gas treatment technology using the device. The technology and the device are used for high-ammonia nitrogen sewage treatment, can be used for replacing the conventional technologies such as aerobiotic aeration, steam stripping, air stripping and the like and have the advantages that the upper limit concentration is not limited, the ammonia nitrogen removal rate is more than 95%, and the chemical oxygen demand (COD) cr removal rate is more than 98%. The device has multiple functions such as ammonia nitrogen dissociation reaction, air stripping and ammonia recovery, thus being capable of easily completing high-ammonia nitrogen waste liquid full-loop operation in a matching way and realizing 'zero emission' in deed. The device can be used for treating various industrial flue gases with high temperature, high sulfur, high humidity and high dust content, integrates the functions of cooling, desulfurating and dust removing, and has the desulfurization rate being more than 90% and the dust removal rate being more than 99%; and after multiple stages of multiphase flow rotation foam separation devices are connected in series, the effect of electric precipitation can be achieved, but the project investment and energy consumption are far lower than those of electric precipitation.

Owner:HUNAN KEYING SPECIAL ENVIRONMENTAL PROTECTION EQUIP & TECH

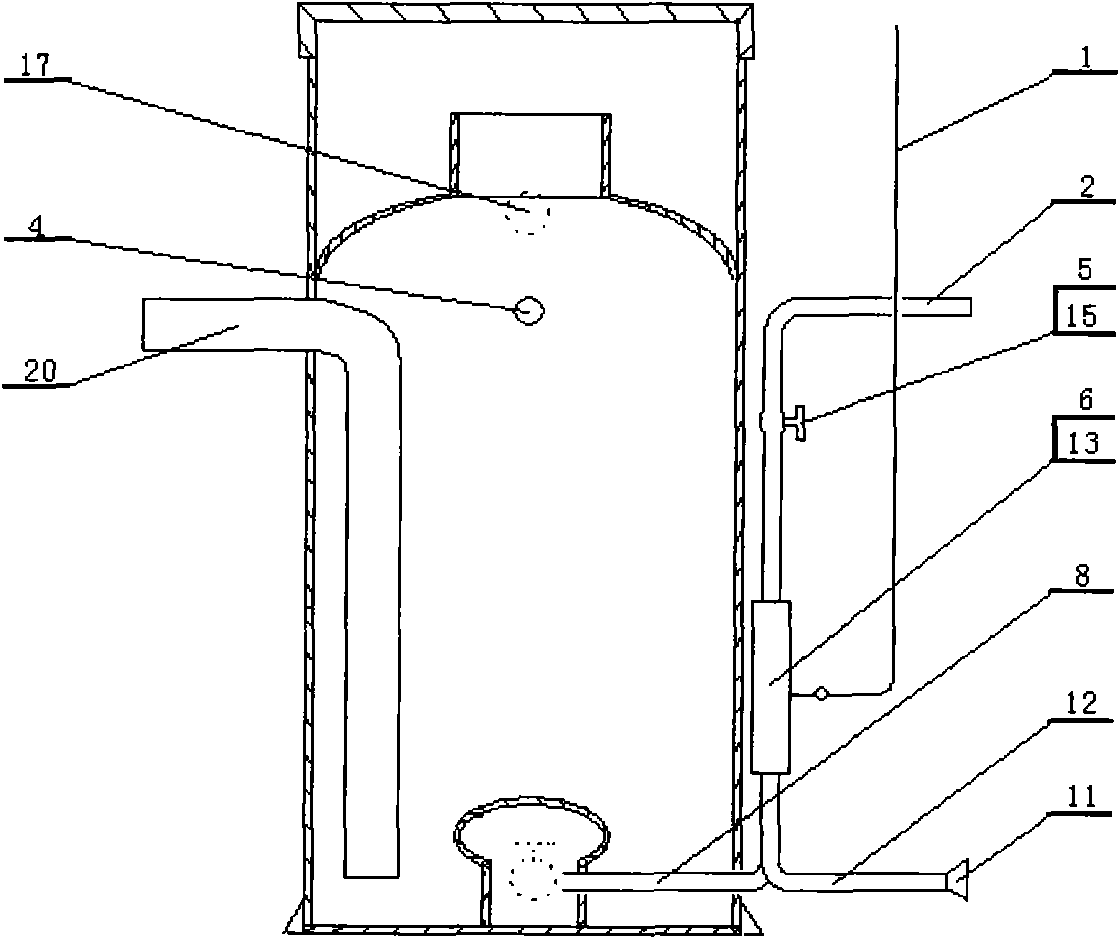

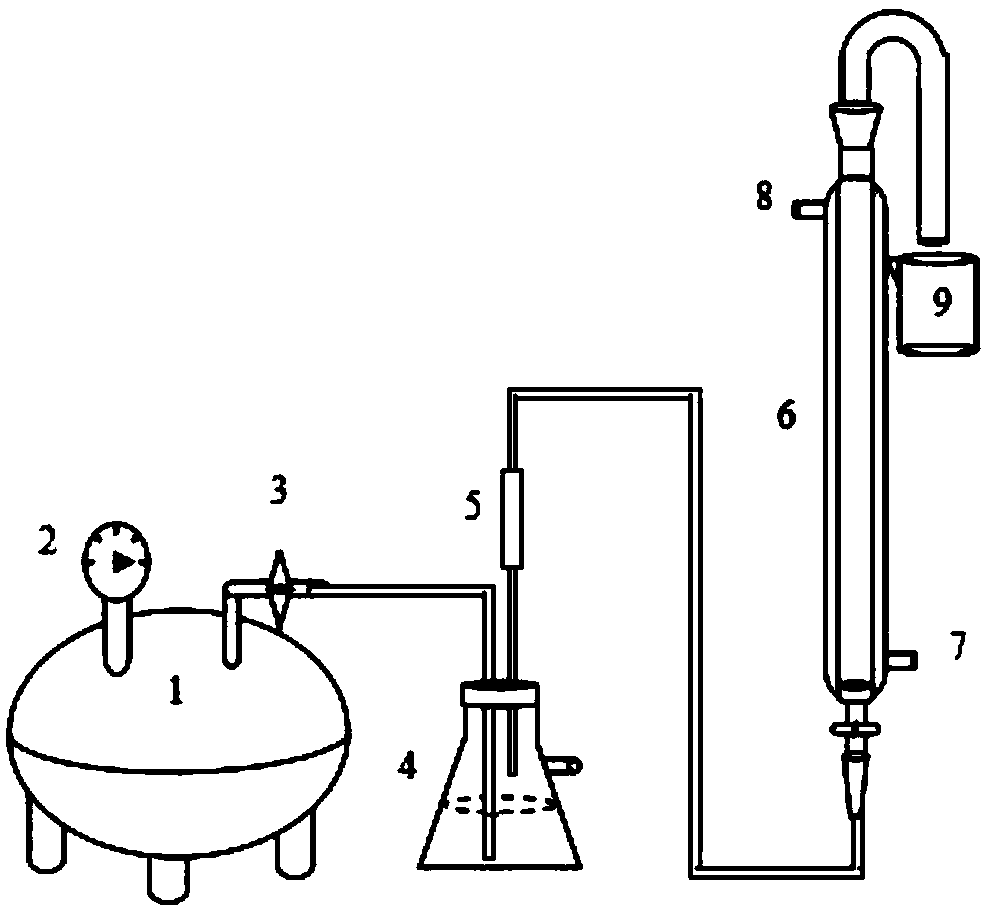

Foam separation-oxygenation integrated equipment

InactiveCN101935108AOvercome the many drawbacks of a single applicationSimple structureWater aerationSustainable biological treatmentDraining tubeConcentration ratio

The invention provides foam separation-oxygenation integrated equipment which is a cylindrical body. In the cylindrical body, the upper part thereof is provided with a sewage collecting chamber, the lower part thereof is provided with a foam generating chamber, and the bottom thereof is provided with a bubble disperser. A water pump is arranged at one side outside the cylindrical body and is connected in the foam generating chamber in the cylindrical body via an inlet pipe; a drain pipe and a discharge pipe are arranged outside of an opposite cylindrical body which has an included angle of 180 degrees with the water pump, the drain pipe is connected in the foam generating chamber in the cylindrical body, and the discharge pipe is connected in the sewage collecting chamber in the cylindrical body; and an air suction pipe and an ejector are arranged outside the cylindrical body which has an included angel of 90 degrees with the water pump, an outlet pipe is arranged in the opposite cylindrical body which has an included angle of 180 degrees with the air suction pipe and the ejector, and the outlet of the outlet pipe is arranged outside the upper part of the cylindrical body. The invention adopts a structural combination integrating foam separation with oxygenation, and can remove macromolecular organic pollutant in a dissolved form in the water body while oxygenating for the cultivation water body, the minimum removal concentration is 5mg / L in terms of COD, and the concentration ratio is 50 times; and in addition, the equipment has simple structure, energy conservation, environment protection and dual efficacies of foam separation and oxygenation of pond cultivation.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

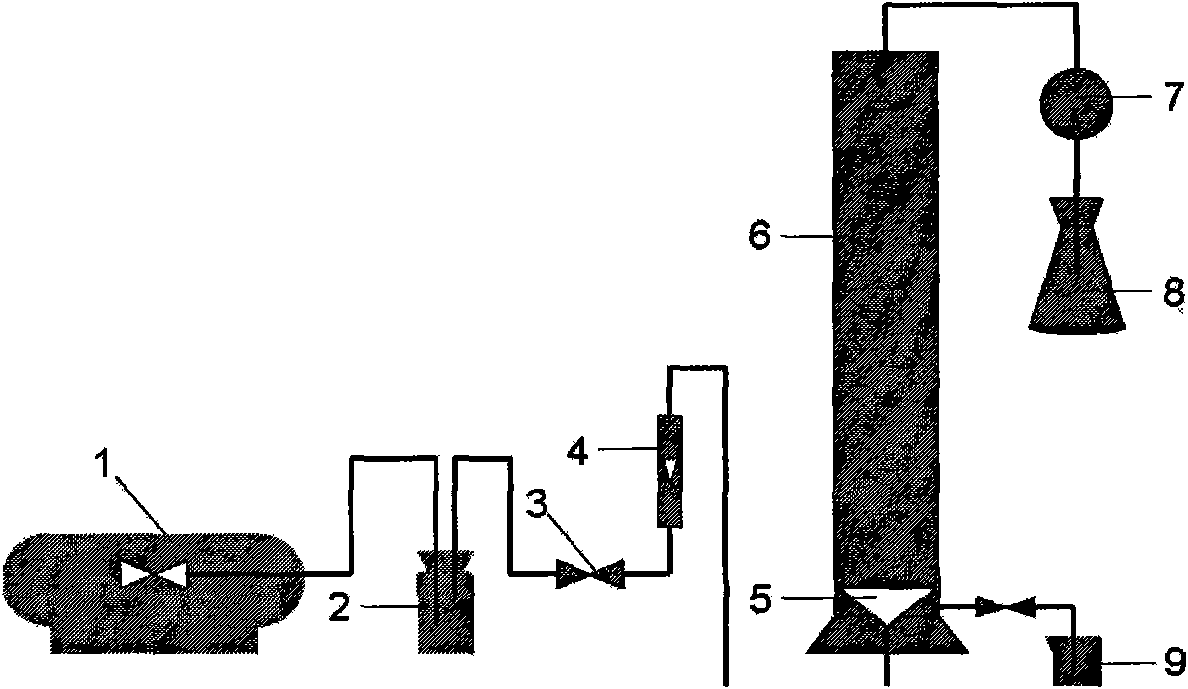

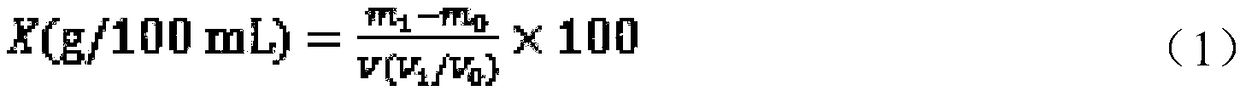

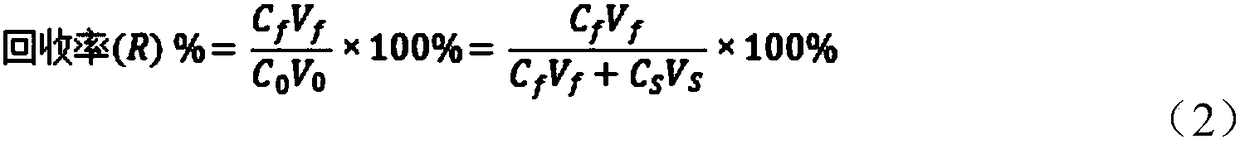

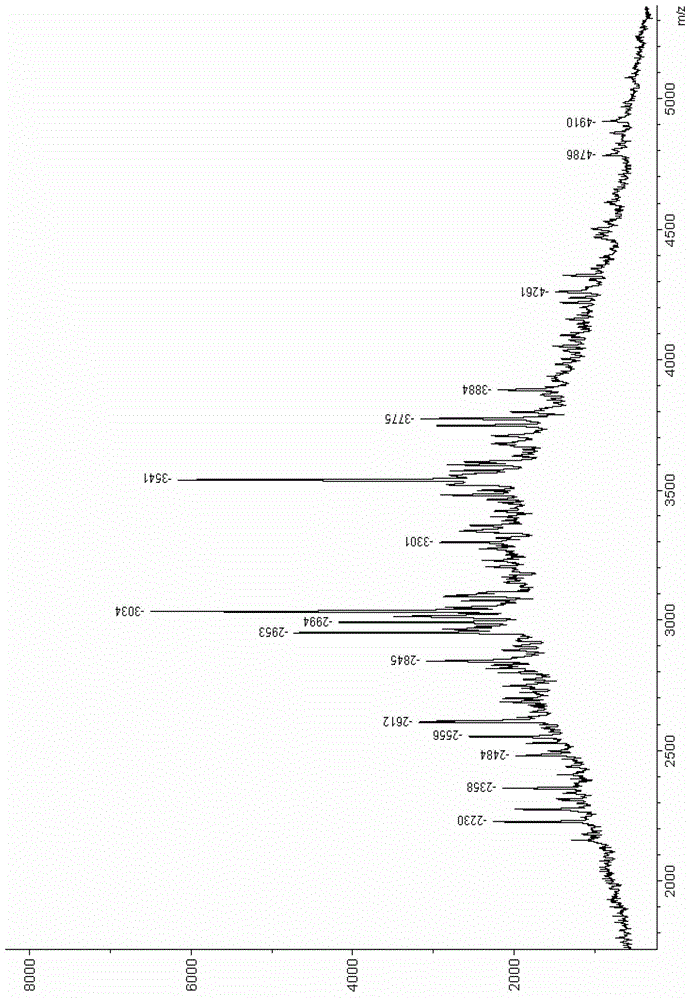

Method for separating whey protein from whey wastewater by foam separation method

ActiveCN108640342AEfficient recyclingHigh recovery rateWater/sewage treatment by centrifugal separationPeptide preparation methodsWhey proteinWastewater

The invention provides a method for separating whey protein from whey wastewater by a foam separation method. According to the method, by the study of multiple key factors, such as the whey protein concentration, gas velocity, temperature and pH, affecting the foam separation of yak whey protein, based on single-factor experiments, a process is optimized through a response surface method, and an optimal technological condition combination is obtained and comprises that the concentration of the whey protein is 100-160 [mu]g / mL, the gas velocity is 250-350 mL / min, the temperature is 40-50 DEG C,and the pH value is 3.5-4.5. Through verification tests, the recovery rate is 75-90% and the enrichment ratio is 8-10. The method is suitable for life characteristics of scattered nomads in Qinghai-Tibet Plateau, can effectively recover the whey protein from yak whey wastewater, also overcomes the difficulties that other technologies difficultly efficiently separate and enrich whey protein from low-concentration whey wastewater, and reduces the recovery cost of the whey protein.

Owner:QINGHAI NORMAL UNIV

Separation preparation method of protein in soybean protein wastewater

The invention discloses a separation preparation method of protein in soybean protein wastewater. The method comprises the following steps: (1) collecting and detecting soybean wastewater; (2) pretreating the soybean protein wastewater; (3) carrying out a two-stage foam separation technology; and (4) separating solid and liquid, and spray-drying. The method prevents protein decay during the separation process through adding antioxidants, and determines the numerical value ranges of two parameters of liquid filling height and operation time, thereby obtaining the powdery protein product. The separation preparation method provided by the invention effectively reduces the protein concentration in soybean protein wastewater, and obtained residual liquid can act as a raw material for extracting soybean oligosaccharides by a membrane separation method, so that the cost for processing soybean protein wastewater by a biochemical process and the production cost of soybean protein isolate are reduced; the separation preparation method of protein in soybean protein wastewater has favorable economical benefits and social benefits; the mass percentage of protein is 90% maximally, and the protein can act as a food-level protein product.

Owner:HEBEI UNIV OF TECH

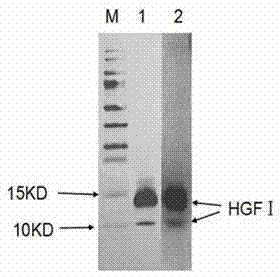

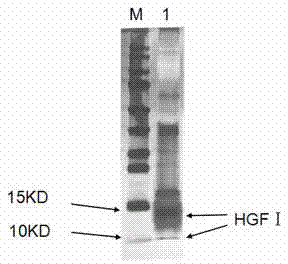

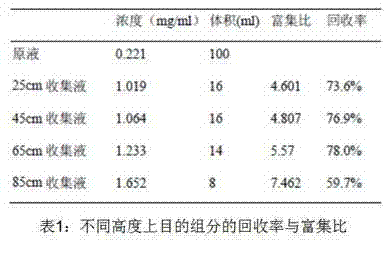

Foam distillation purification method

ActiveCN104117220ALow costReduce pollutionDistillation regulation/controlFractional distillationPurification methodsDistillation

A foam separation method for extraction and concentration of a surface active substance is different from traditional. The invention provides the foam rectification purification method which can extract, concentrate, rectify and purify the surface active substance. The method can be roughly divided into 7 steps: 1, estimating the contents of an objective component and an objective impurity in a material liquid; 2, determining the pH and the temperature T allowing the objective component to have highest surface activity in a tolerance range of the objective component; 3, determining the highest collect height beta and the corresponding apparent gas velocity Q; 4, determining the lowest collect height alpha; 5, determining the objective component enrichment ratio and recovery rate changed along with the height and between the height alpha and the height beta; 6, according to the data obtained in the steps 1-5 and according to purity requirements of a product, designing a purification strategy, trying to purify the material liquid, and carrying out fine adjustment on the purification strategy according to the detection result; and 7, producing according to all the production conditions determined in the steps 1-6. After purification by the method, a concentrated solution of the object component can be acquired, and the product with required purity is obtained.

Owner:NANKAI UNIV

Circulating lubricating system with automatic cleaning function

InactiveCN104607486AReduce generationImprove the lubrication effectSedimentation settling tanksSurface layerFoam separation

The invention discloses a circulating lubricating system with an automatic cleaning function. The circulating lubricating system comprises a settling pond, wherein a foam separation plate capable of blocking the foam on the surface layer of lubricating liquid is arranged in the settling pond, the settling pond is divided by the foam separation plate into a foam isolation area and an impurity settling area, a return liquid pipe is arranged in the foam isolation area, the lubricating liquid containing impurities enters the foam isolation area by virtue of the return liquid pipe and then enters the impurity settling pond so as to settle impurities, an impurity clearing device capable of clearing the impurities on the bottom of the impurity settling area is arranged in the impurity settling area, and a liquid pumping pipe capable of pumping the clean lubricating liquid is arranged on the rear end of the impurity settling pond. By adopting the circulating lubricating system with the automatic cleaning function, the foam can be reduced and isolated, and the impurities on the bottom of the settling pond can be online cleared.

Owner:苏闽(张家港)新型金属材料科技有限公司

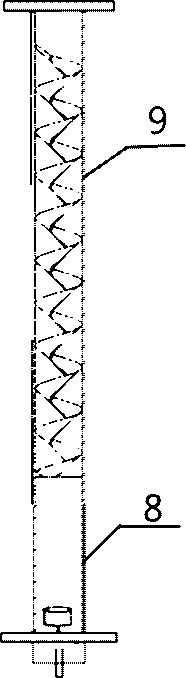

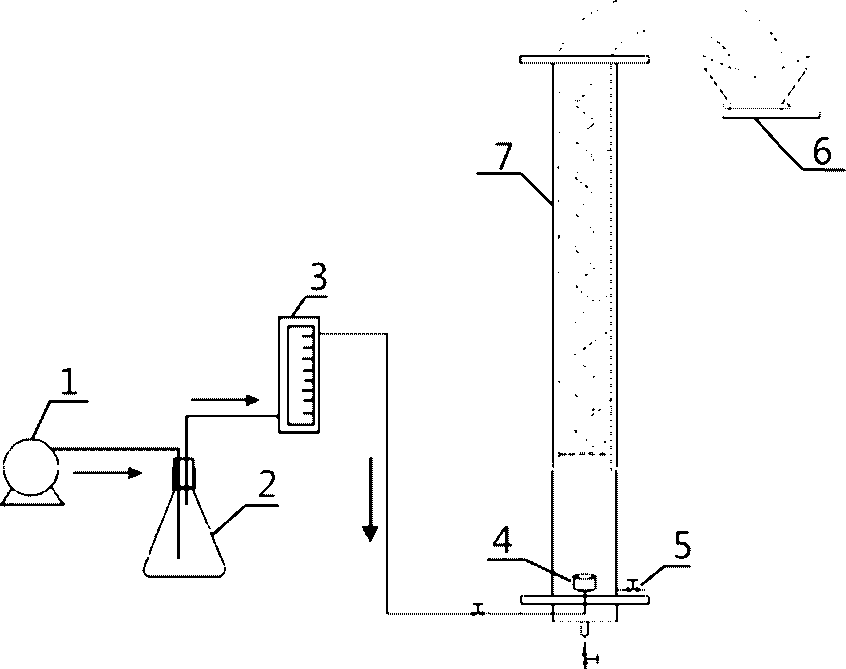

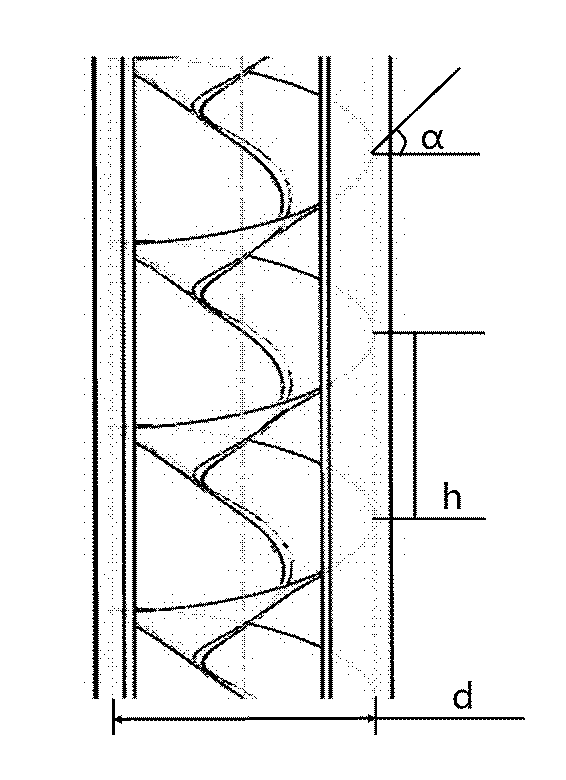

Technology for foam separation of different surfactants

InactiveCN102423552AIncrease the concentration ratioLess investmentFoam dispersion/preventionConcentration ratioFoam separation

The invention relates to a technology for foam separation of different surfactants. The technology comprises the steps of: 1) preparing a surfactant solution; 2) adjusting the pH value of the prepared surfactant solution to 6.0-6.5 with 1mol / L of hydrochloric acid or 1mol / L of sodium hydroxide; 3) adding the pH value adjusted surfactant solution obtained in step 2) into a foam separation column equipped with a helical component, with a loading amount about 15%-35% of the total volume of the foam separation column; 4) controlling the separation temperature at 20-30DEG C, adjusting a flowmeter to set the superficial gas velocity at 1.7-5.1mm / s, guiding foams out of the tower top and collecting them till no foaming. The centrifugal force generated by the centrifugal drainage structure of the invention depends on automatic flow of the foam phase in the helical component, and has no need for rotation of an additional machine, so that the concentration ratio of different surfactants from foam separation can be substantially enhanced.

Owner:HEBEI UNIV OF TECH

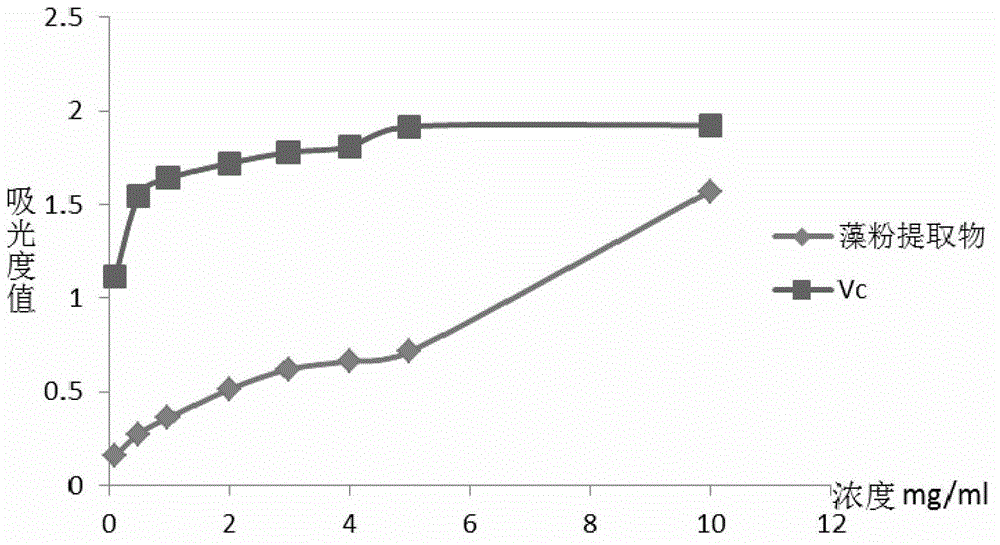

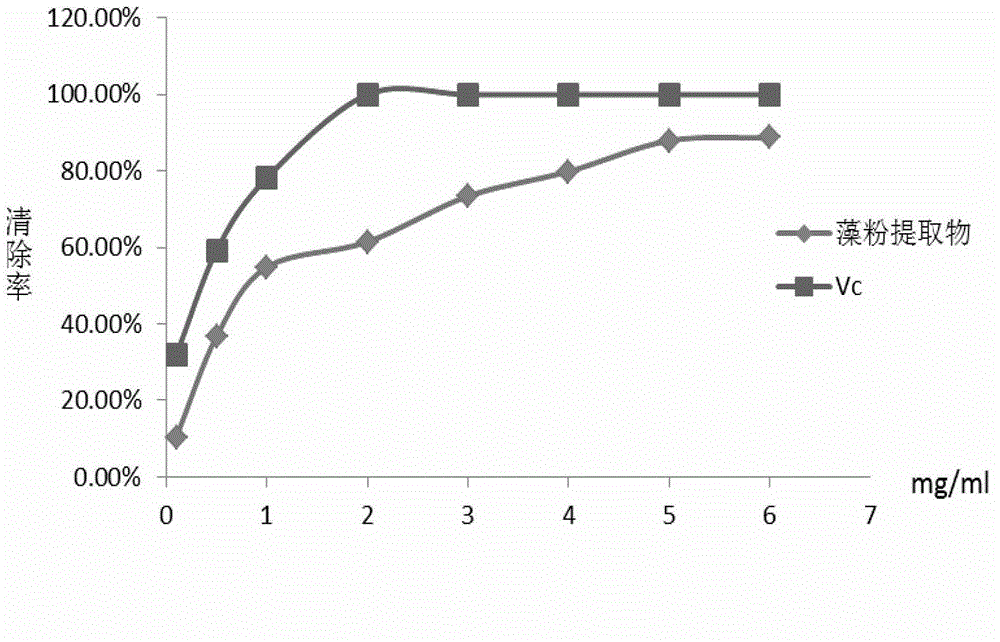

Method for extracting small-molecule peptides of spirulina

InactiveCN102875640AAntioxidantSimple processPeptide preparation methodsFood preparationHydrogenLiquid ratio

The invention provides a method for extracting small-molecule peptides of spirulina. The method includes: preprocessing the spirulina, adjusting the feed-liquid ratio to be 0.5-8g / L and the pH (potential of hydrogen) value to be 5-10, and performing foam separation of the spirulina after sufficient mixing so as to obtain foam extracting solution, namely small-molecule bioactive peptides with the molecular weight of 5000Da. The dissolution rate of spirulina protein obtained by the method can reach 12.6%, enrichment ratio can reach 4.4, and the highest recovery rate can reach 98%. Compared with a traditional method, the method for extracting the small-molecule active peptides is quite simple in process and does not need expensive equipment and apparatuses, extracting procedures are greatly simplified, extracting cost is greatly saved, and economic benefits are remarkable.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com