Technology for foam separation of different surfactants

A surfactant and foam separation technology, applied in the direction of foam dispersion/prevention, can solve problems such as difficult drainage and large flow resistance, and achieve the effects of no pollution in operation, increased concentration ratio, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The first step is to design and manufacture a new type of foam separation tower with spiral components

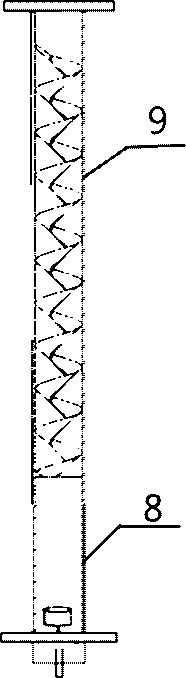

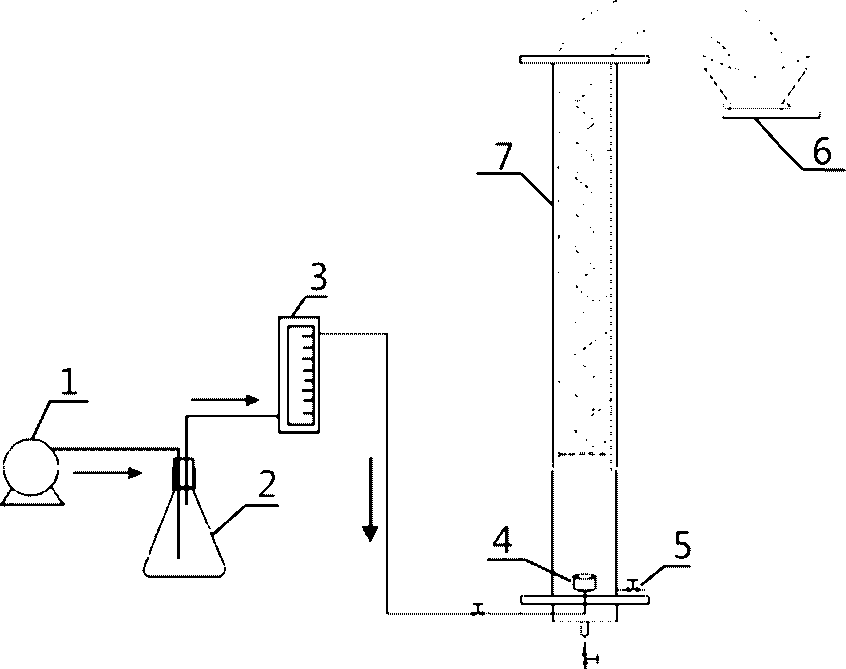

[0027] Manufacture of a new type of foam separation tower with helical components as attached figure 1 As shown, the tower is composed of an air compressor 1, a buffer bottle 2, a gas flow meter 3, a gas distributor 4, a spiral foam separation tower 7, and a foam collection device 6. The air compressor 1 sends the compressed air to the buffer bottle 2 through the rubber hose, and the air from the buffer bottle 2 enters the gas flow meter 3, and the gas flow meter 3 is used to adjust the gas velocity entering the foam separation tower. The air from the gas flow meter 3 enters the air distributor 4 at the bottom of the spiral foam separation tower 7 through the rubber hose, and the air enters the spiral foam separation tower 7 through the air distributor 4, and the bottom valve 5 is used to adjust the solution to be separated in the foam separation tower 7 liquid lev...

Embodiment 3

[0065] The first step is to design and manufacture a new type of foam separation tower with spiral components

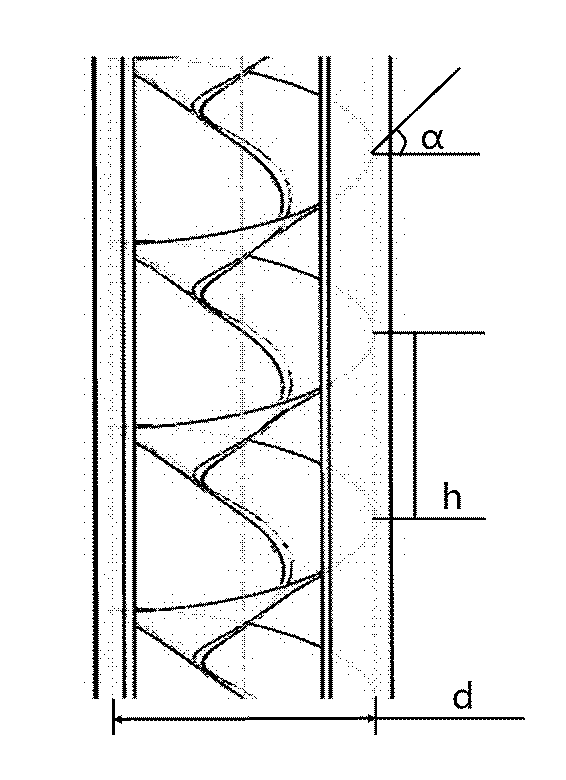

[0066] It is pointed out that the inner diameter of the spiral foam separation tower 7 is 50 mm, the height is 1200 mm, the ratio of the pitch h of its components to the diameter d of the components is 1.4, the pitch is 70 mm, and the angle of inclination is 45 °. Others are the same as those in Example 1. first step;

[0067] The second step, the foam separation system

[0068] Choose bio-surfactant soy protein;

[0069] The third step, foam separation surfactant soybean protein process

[0070] 1. Prepare surfactant soybean protein solution

[0071] Prepare a solution of surfactant soybean protein, the concentration of which is 0.3-0.5g / L;

[0072] 2. Adjust the pH value of the prepared surfactant soybean protein solution

[0073] Regulate the pH of the prepared surfactant SDS solution with a concentration of 1mol / L hydrochloric acid or 1mol / L sodium hydroxide...

Embodiment 4

[0084] The first step is to design and manufacture a new type of foam separation tower with spiral components

[0085] It is pointed out that the inner diameter of the spiral foam separation tower 7 is 50 mm, the height is 1200 mm, the ratio of the pitch h of its components to the diameter d of the components is 1.6, the pitch is 80 mm, and the inclination angle is 50 °, and others are the same as those in Example 1. first step;

[0086] The second step, the foam separation system

[0087] Choose biological and non-biological mixed surfactants soy protein and SDS;

[0088] The third step, foam separation surfactant soybean protein and SDS process

[0089] 1. Prepare surfactant soybean protein and SDS solution

[0090] A surfactant solution containing soybean protein and SDS is selected, wherein the concentration of soybean protein is 0.20-0.30 g / L; the concentration of SDS is 0.050-0.10 g / L.

[0091] 2. Adjust the pH value of the prepared surfactant soybean protein and SDS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com