System and method for treating industrial circulating cooling water

A circulating cooling water and treatment system technology, applied in the field of environmental technology and water treatment, can solve the problems of high energy consumption of the device, low elution efficiency, complicated electrode regeneration process, etc., to improve the concentration ratio, improve the economic benefits of the enterprise, reduce The effect of drug dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

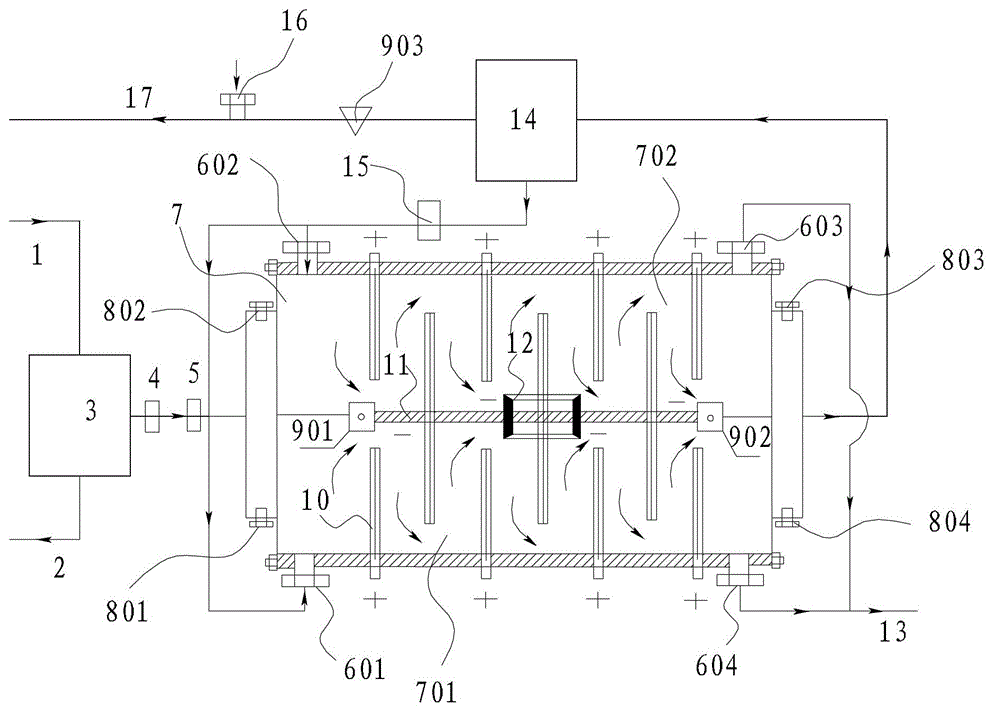

Method used

Image

Examples

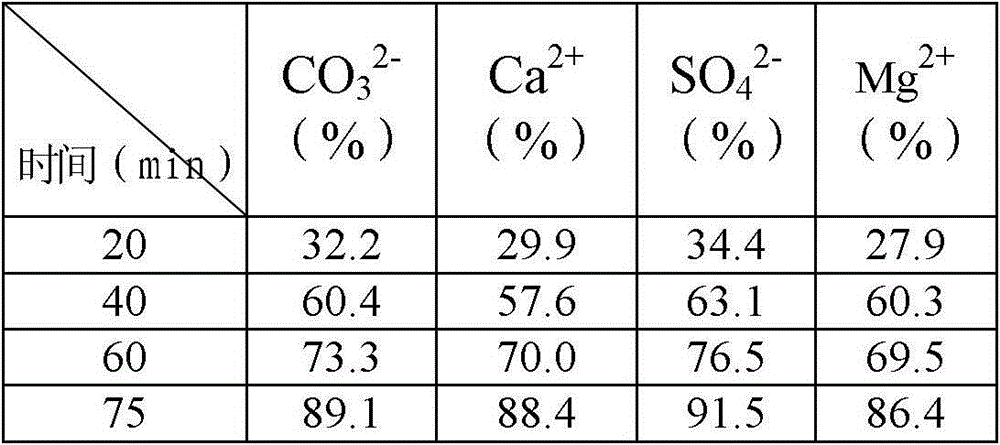

Embodiment 1

[0061] The number of electrode sheets is 100 pairs, the electrode sheet spacing is 1mm, the electrode sheets are stable, the cooling water flow rate in the reaction tank is 0.6m / min, the voltage is controlled at 2V, and the current density is 0.1A / m 2 , first use a reaction chamber to determine the adsorption and desorption reaction time through the readings of the first conductivity meter and the second conductivity meter. The reaction chamber first performs adsorption, and when the difference between the readings of the second conductivity meter and the readings of the first conductivity meter is less than 40% of the reading of the first conductivity meter, desorption is carried out. The adsorption time and desorption time are close to 3:1, It is about 75min and 25min respectively. According to the ratio of adsorption and desorption time, this reaction tank needs to set up four reaction chambers. After the first reaction chamber starts to work for 25 minutes, open the second ...

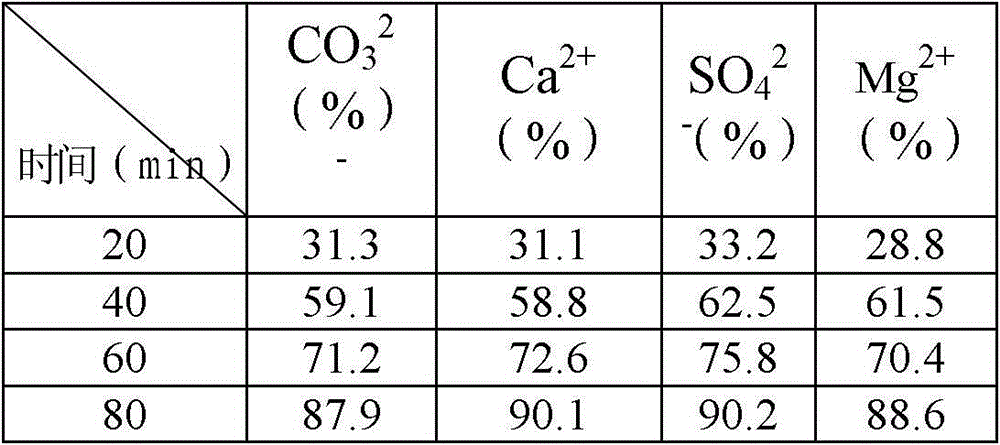

Embodiment 2

[0067] The number of electrode sheets is 100 pairs, the distance between the electrode sheets is 1.5mm, the properties of the electrode sheets are stable, the cooling water flow rate in the reaction tank is 0.5m / min, the voltage is controlled at 2V, and the current density is 0.1A / m 2 , first use a reaction chamber to determine the adsorption and desorption reaction time through the readings of the conductivity meter. The reaction chamber first performs adsorption, and when the difference between the readings of the second conductivity meter and the reading of the first conductivity meter is less than 50%, desorption is carried out. The adsorption time and desorption time are close to 4:1, which are about 80 minutes and 20 minutes respectively. According to the ratio of adsorption and desorption time, the reaction tank needs to be equipped with five reaction chambers. When the first reaction chamber starts to work for 20 minutes, the second reaction chamber is opened for adsorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com