Patents

Literature

302results about How to "Reduce post-processing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

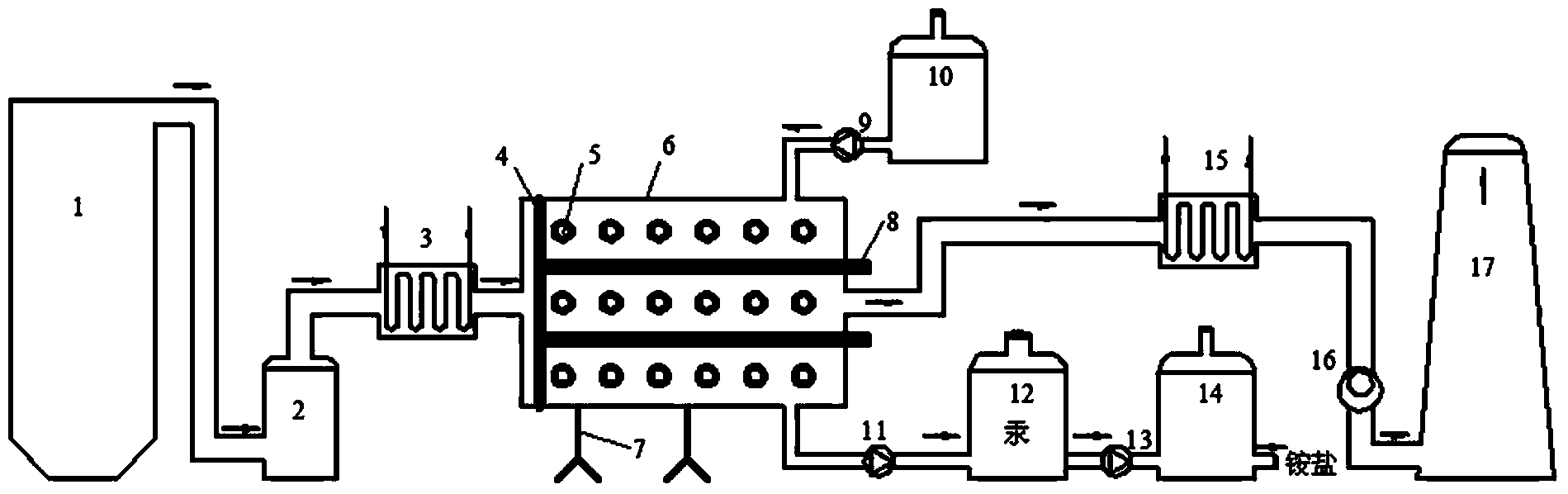

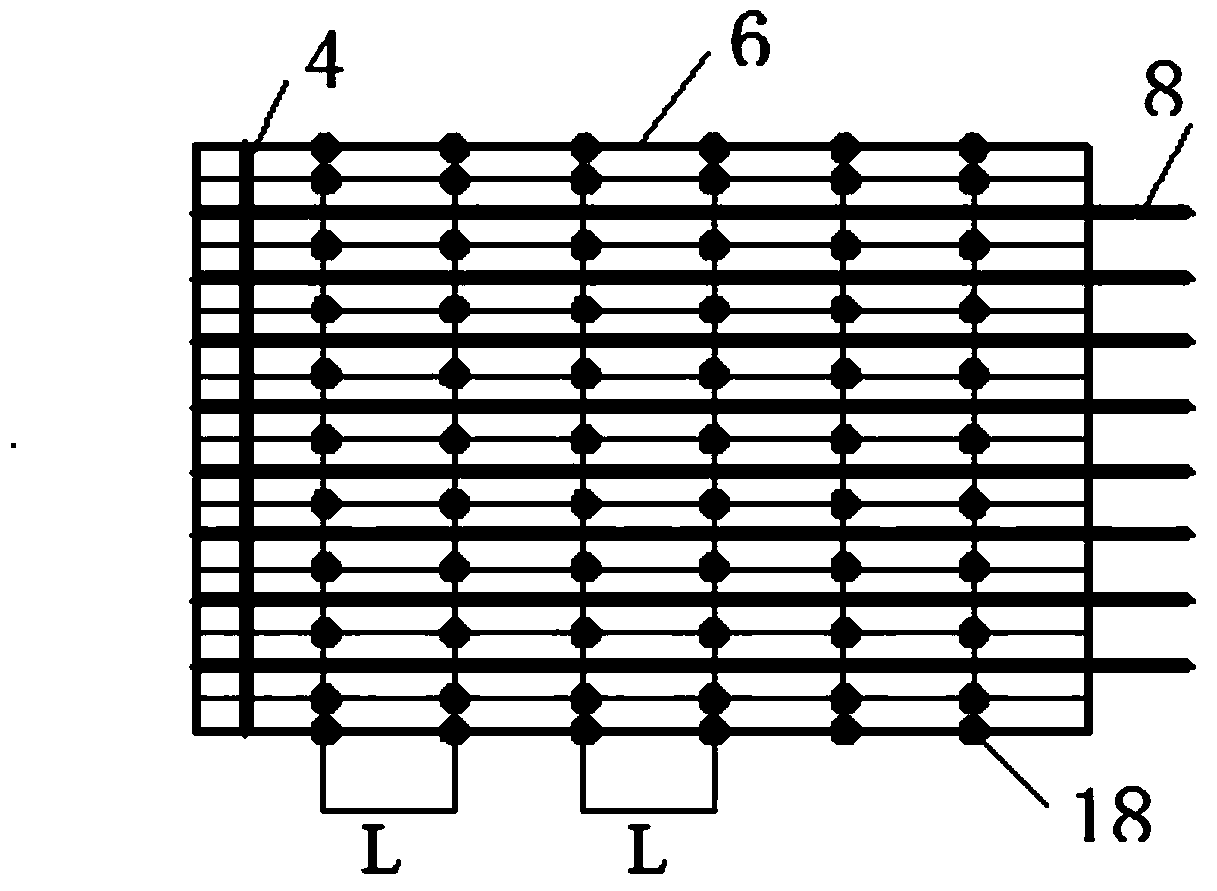

System and method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate

ActiveCN103638796ALow investment costLow running costDispersed particle separationAir quality improvementSulfate radicalsResource utilization

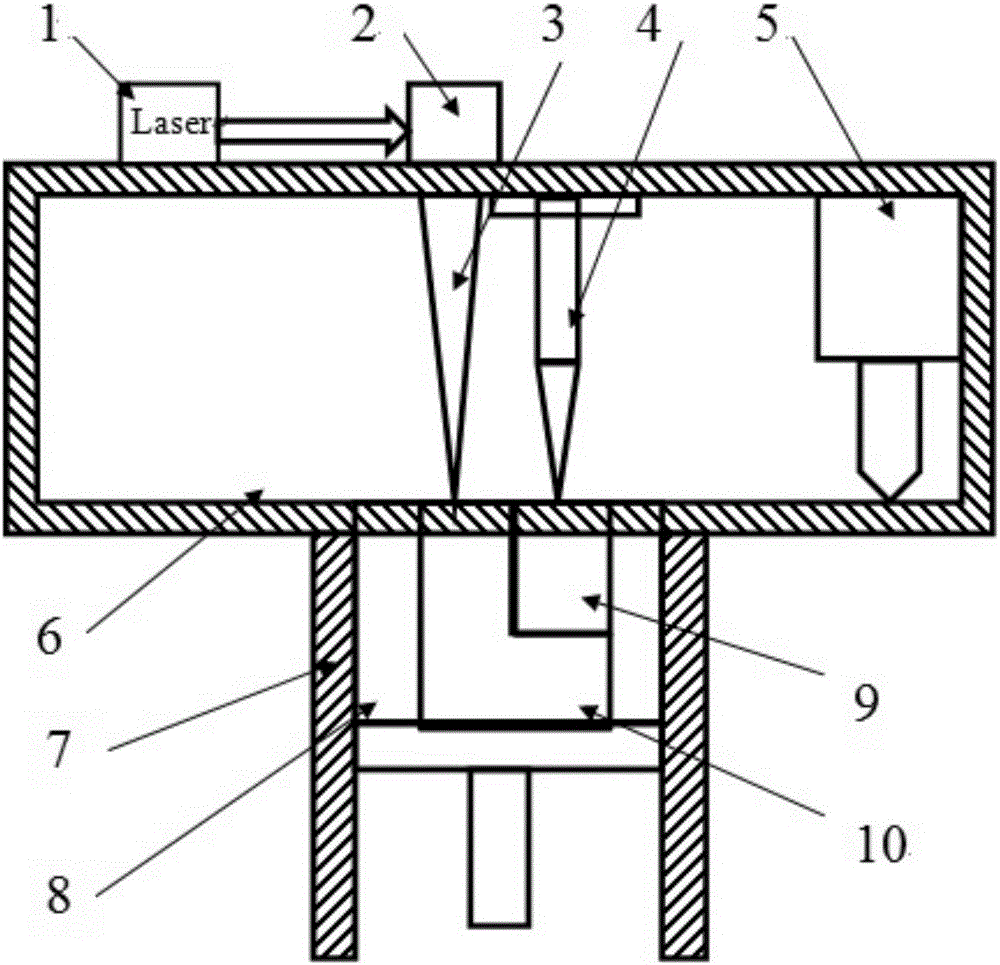

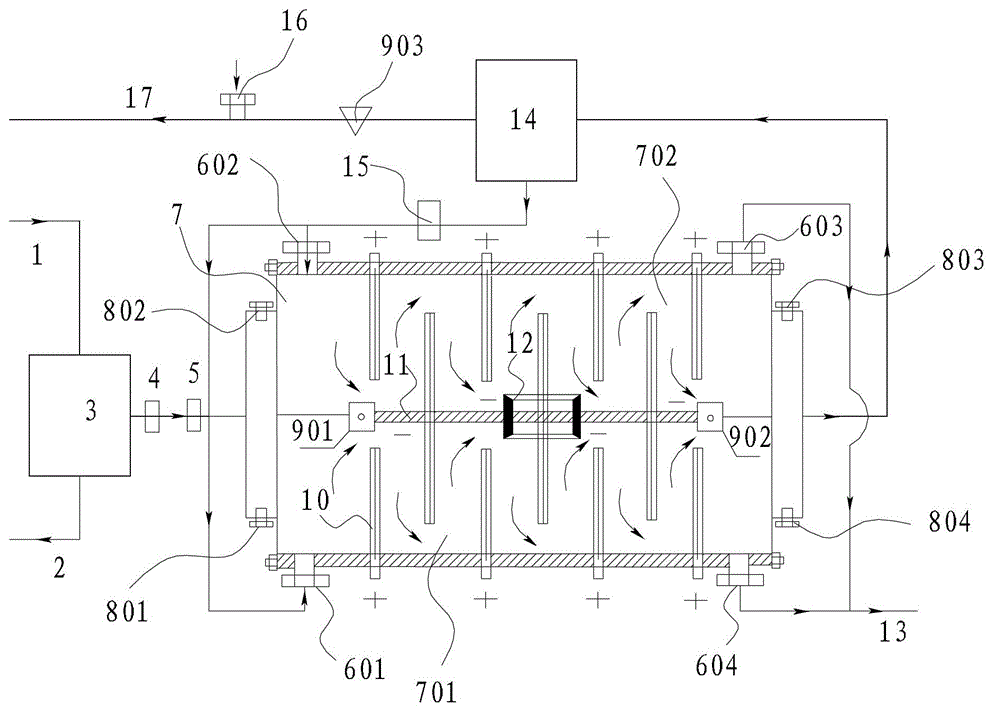

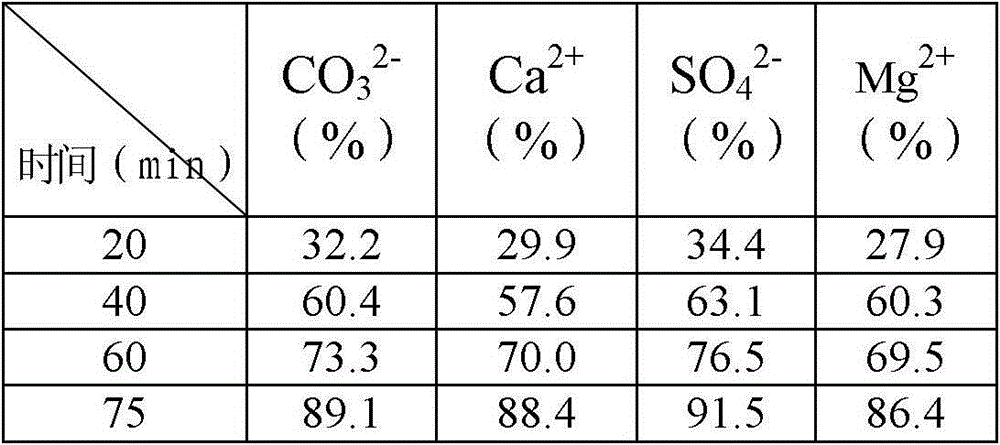

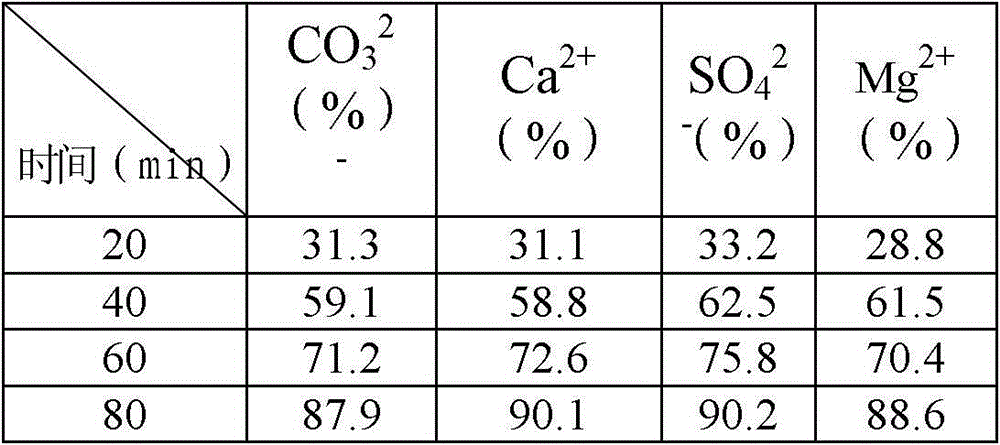

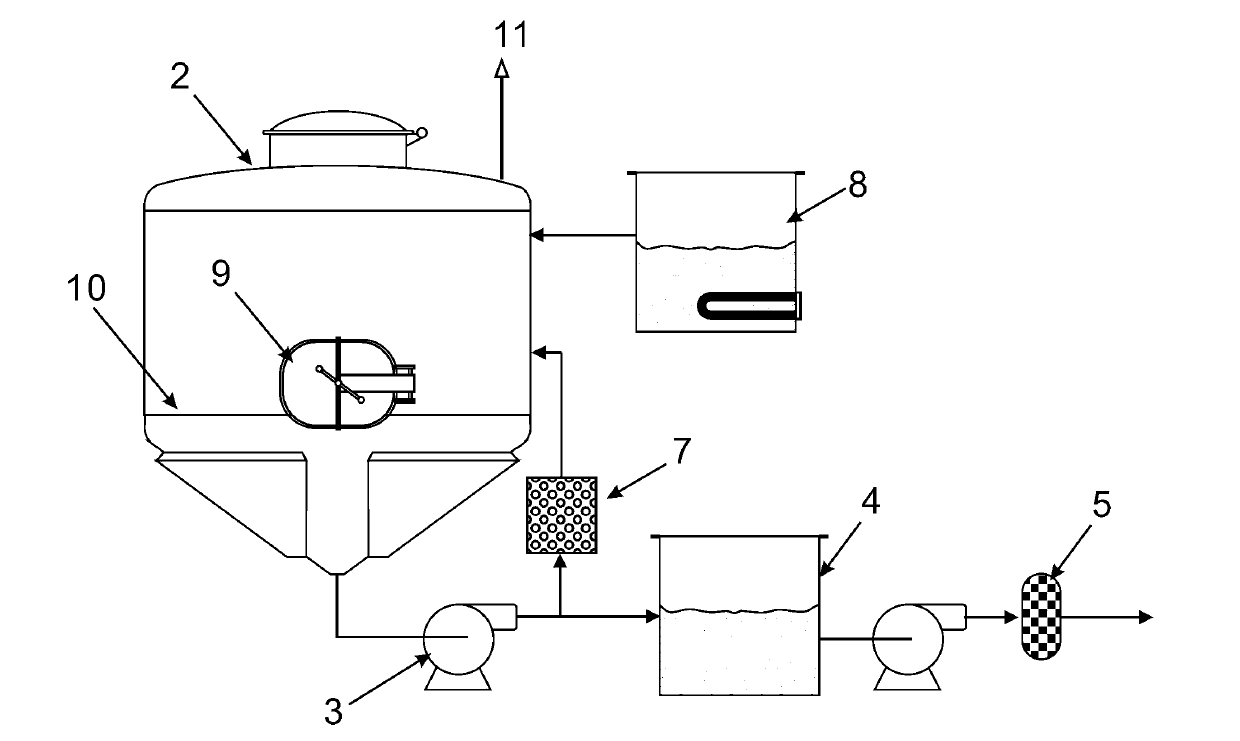

The invention discloses a system and a method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate. The system is mainly provided with a boiler or kiln, a deduster, a flue gas temperature regulator, a photochemistry reactor, a liquid spraying system as well as a byproduct post-processing system. Flue gas discharged from the boiler or kiln enters the photochemistry reactor arranged on a flue channel after being subjected to dedusting and temperature regulation, and an ammonium persulfate solution from the liquid spraying system is sprayed into the photochemistry reactor in a mist form; an UV (ultraviolet) lamp in the photochemistry reactor emits UV light to perform catalytic decomposition on ammonium persulfate, releases sulfate radical free radicals with high oxidizing property (SO4-.), and meanwhile oxidizes and removes SO2, NOx and mercury in the flue gas. Oxidized products are subjected to resource utilization after being processed by the byproduct post-processing system. The method has the prominent advantages that the method can be used for removing multiple pollutants in coal burned flue gas synchronously, has no secondary pollution during removing, and can be used for transforming aging units and the like, and the system is a novel flue gas purifying system with a wide application prospect.

Owner:JIANGSU UNIV

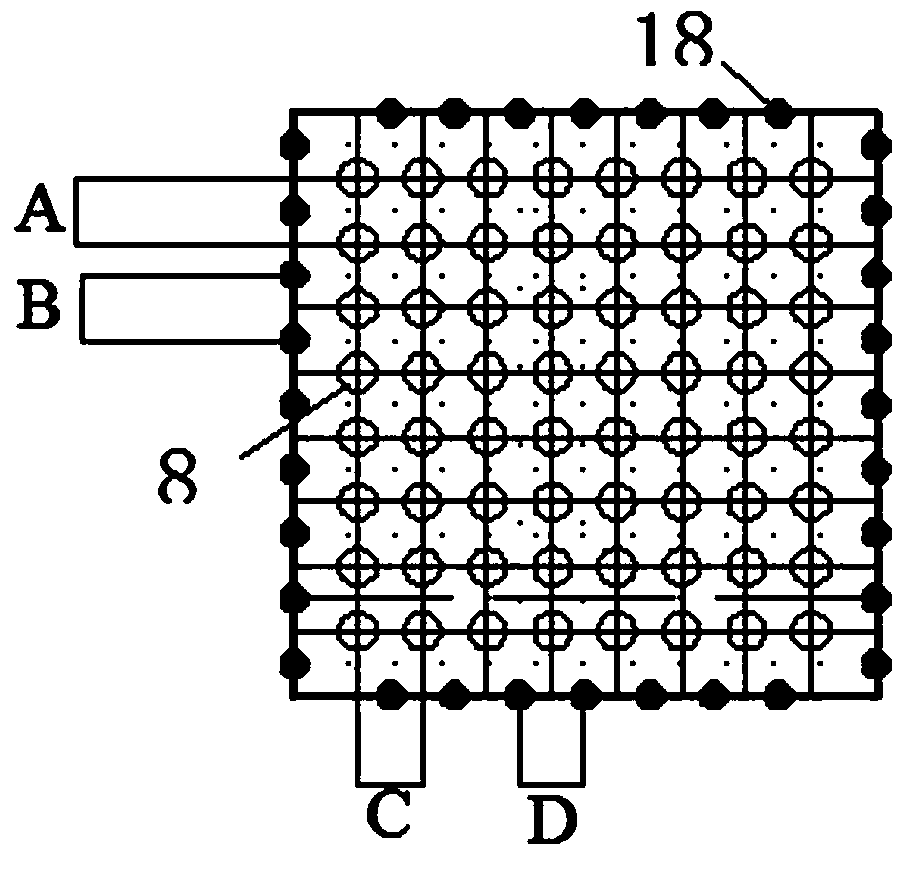

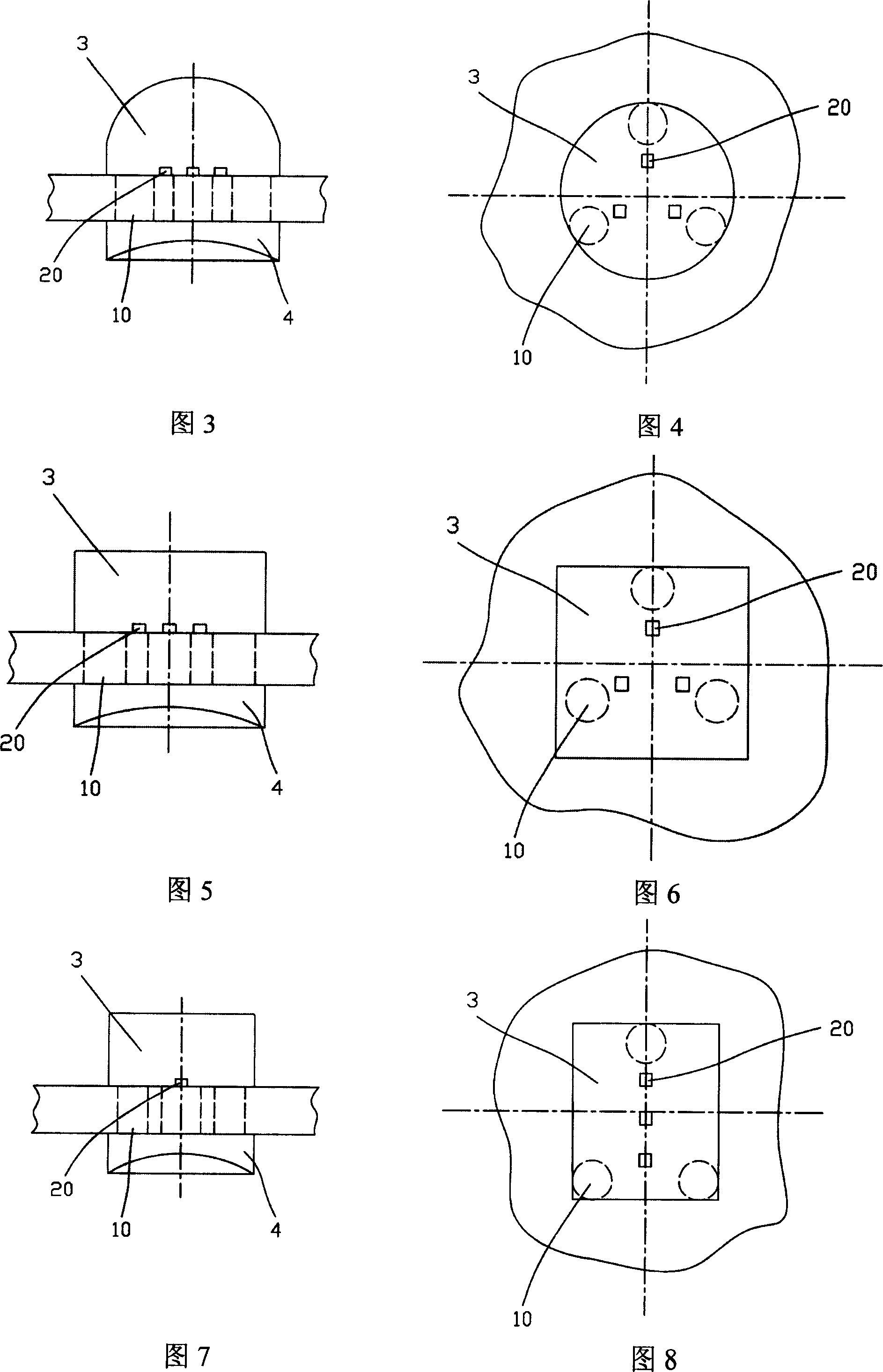

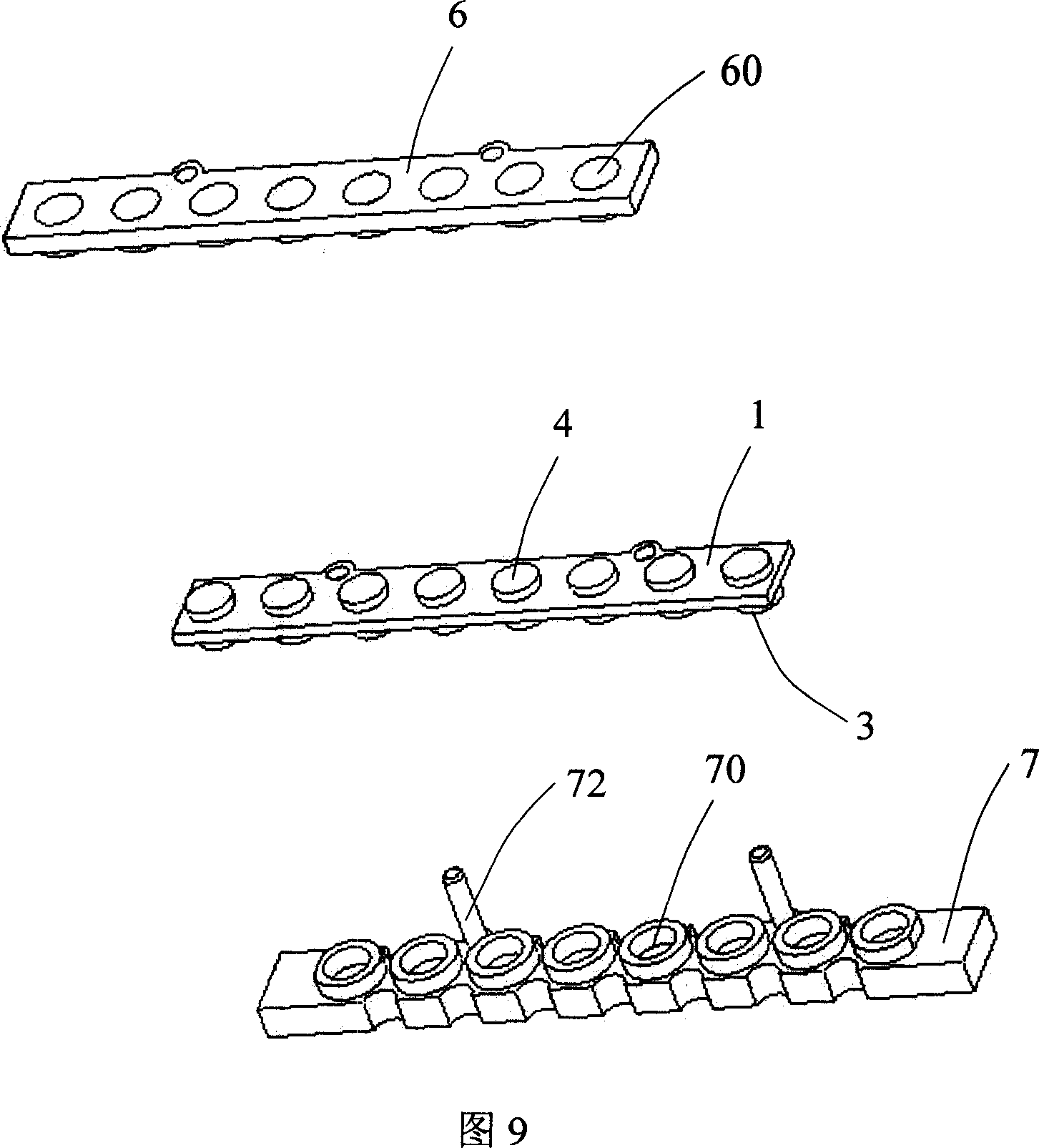

LED packaging structure and packaging method

InactiveCN101013689AObvious differenceSignificant originalitySemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention relates to one LED sealing structure, which comprises circuit board, several LED light units on circuit front, wherein, the circuit board back is set with terminal to outer circuit. The invention also provides one LED sealing method, which comprises the following steps: processing special mode board; binding LED light chip; mode loading with down mode board facing down with each LED light unit contained into each module particle; glue injecting and fixing step.

Owner:深圳市联众达光电有限公司

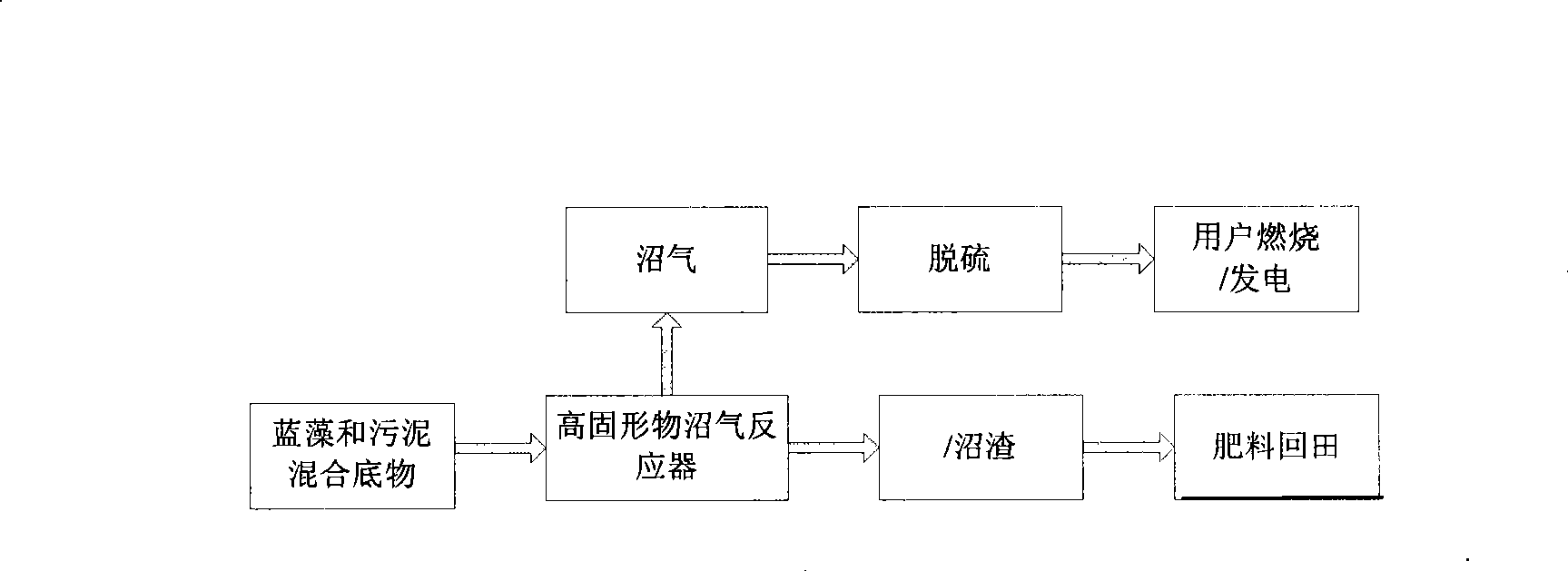

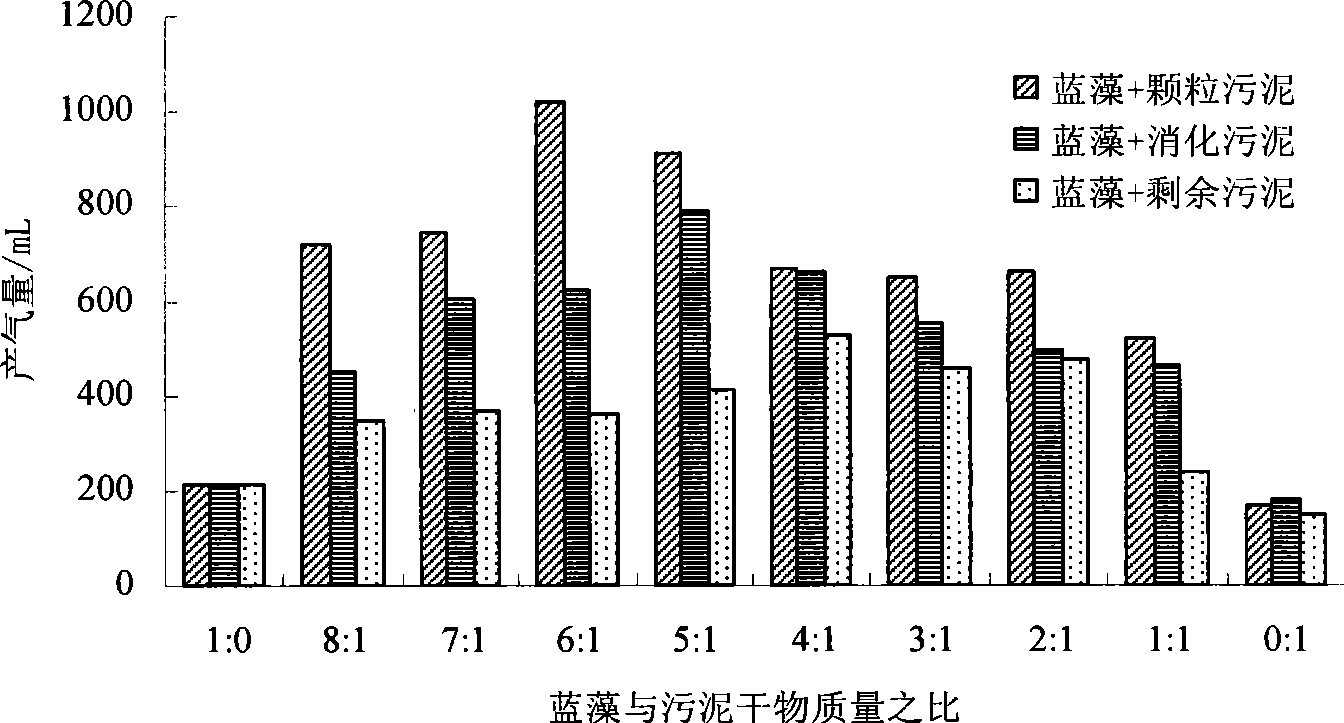

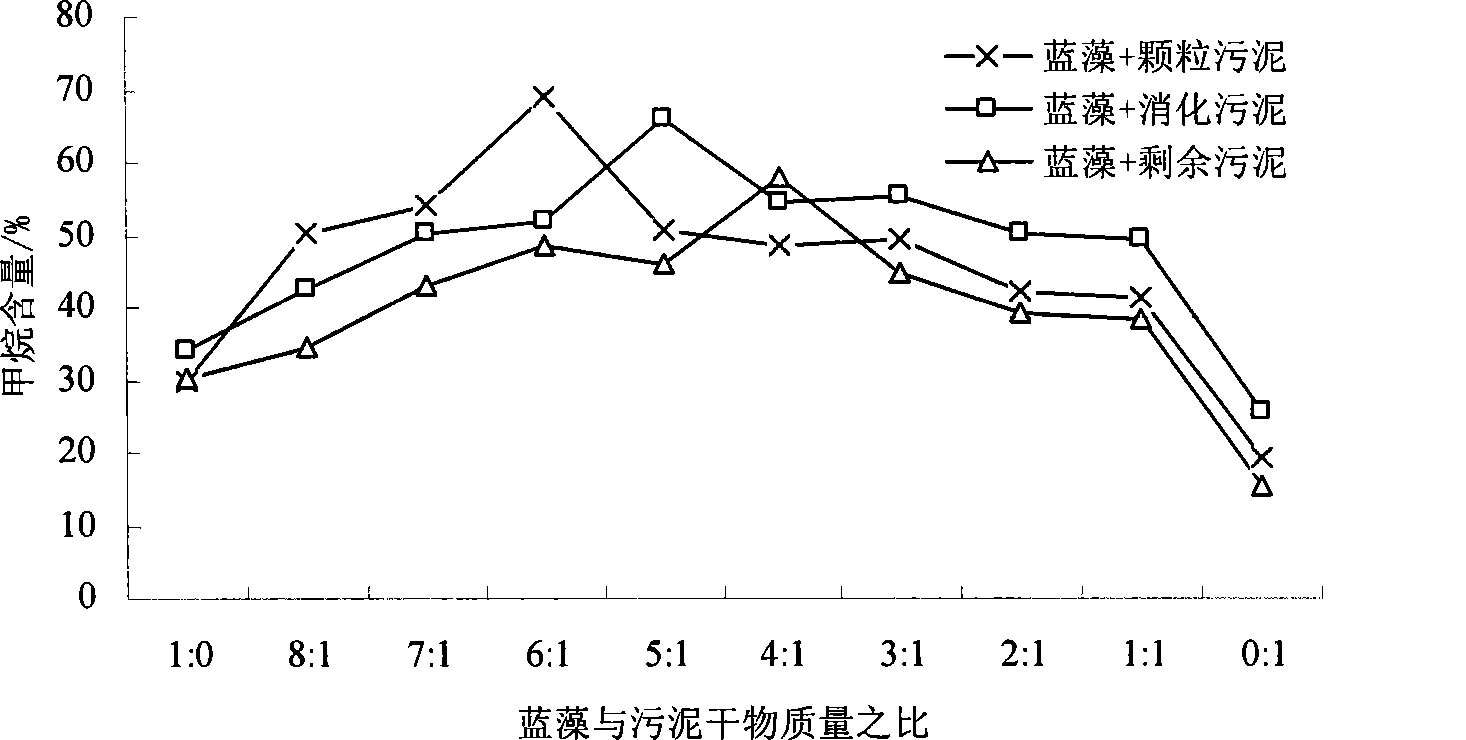

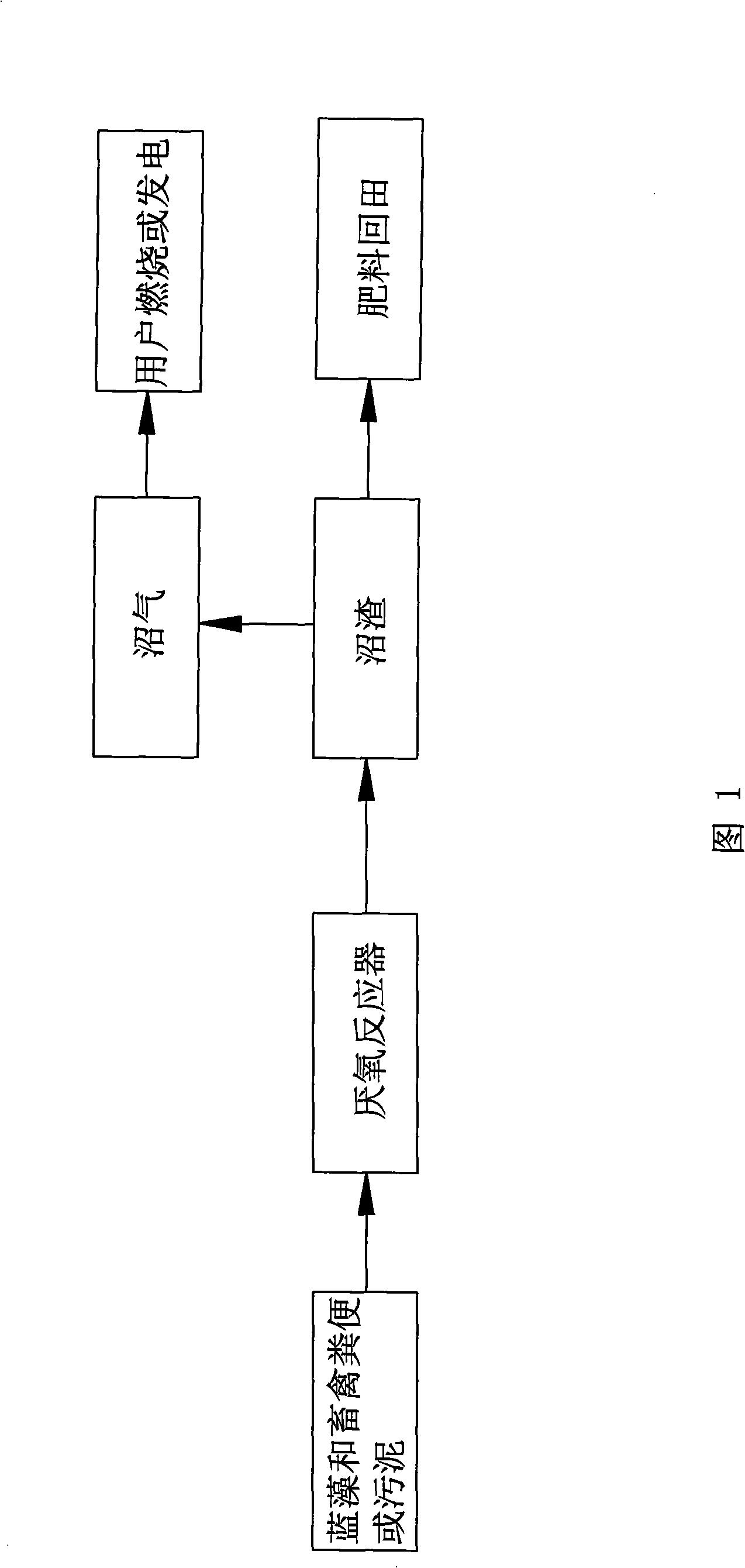

Method for producing marsh gas through mixed anaerobic fermentation of blue algae and sludge

InactiveCN101418316AReduce energy consumptionReduce pretreatment costsBio-organic fraction processingClimate change adaptationCombustionMunicipal sewage

The invention provides a method for producing biogas by the anaerobic fermentation of mixed blue algae and sludge, which belongs to the technical field of environmental protection purification and waste resource treatment. In the method, the blue algae and the sludge are mixed for the anaerobic fermentation to produce the biogas, and the whole process is completed in an anaerobic reactor; the blue algae and the sludge are mixed in the rector, N2 is introduced to form the anaerobic state, and the blue algae and the sludge are fermented at a temperature of between 35 and 37 DEG C; and in the rector, the blue algae is discontinuously and periodically added, the degradation condition of the material is observed, at the same time, the organic matter concentration of the discharged material and the concentrations of CH4 and CO2 in gas generated from fermentation are measured until the reactor is stably operated. The biogas generated is subjected to desulphurization treatment and supplied to users for combustion or collected for power generation; and the dregs generated are used as a fertilizer for farmlands. The method for producing the biogas by the anaerobic fermentation of the mixed blue algae and the municipal sludge has the advantages of having the effect of answering multiple purposes, thoroughly eliminating algae toxins, combining the blue algae utilization and the treatment of the sludge from a municipal sewage plant, and solving organic pollution problems in both the rural and urban areas.

Owner:JIANGNAN UNIV

Production of feed additive

InactiveCN101028035AReduce manufacturing costLow investment costFood processingAnimal feeding stuffFood additiveAnimal science

An additive of forage for increasing the content of peptide, the utilization rate of protein and the growth speed of animals is prepared from one or more kinds of feed protein through solid fermenting by bacillus and / or bacterium lactis and / or yeast.

Owner:刘唤明

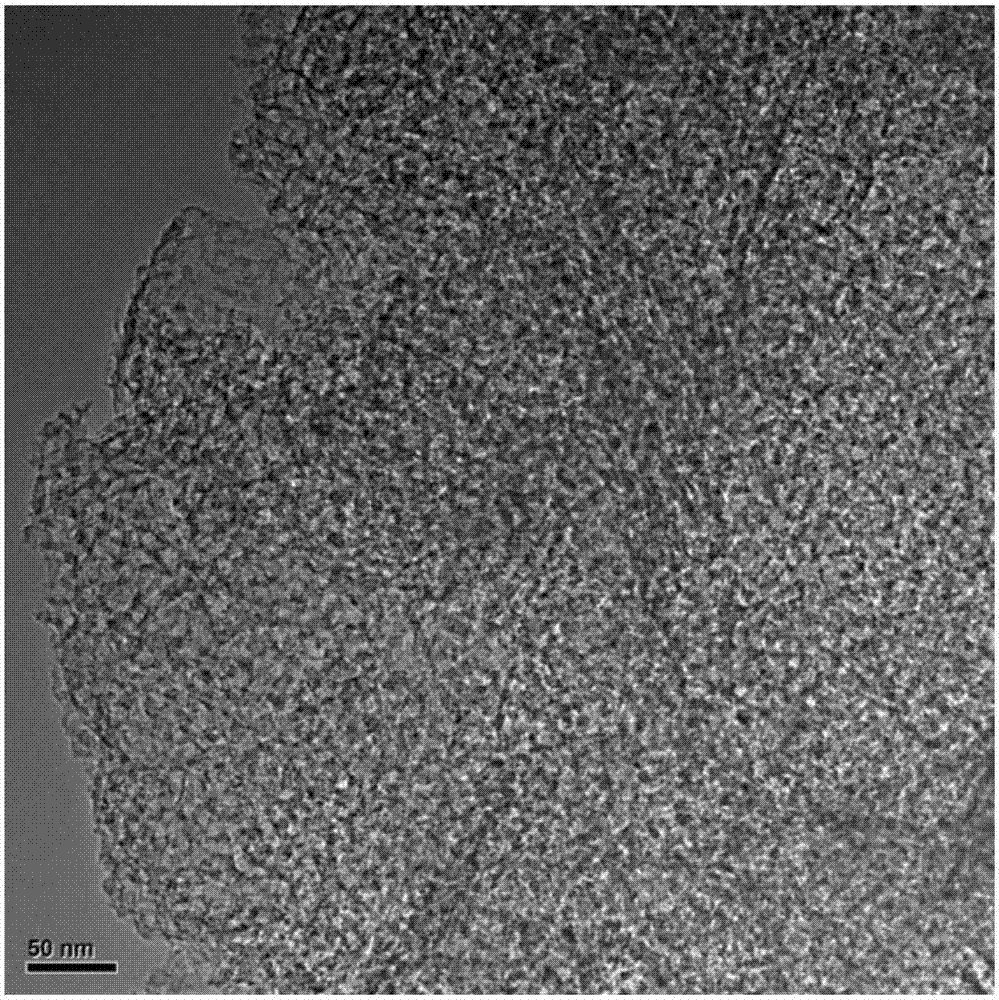

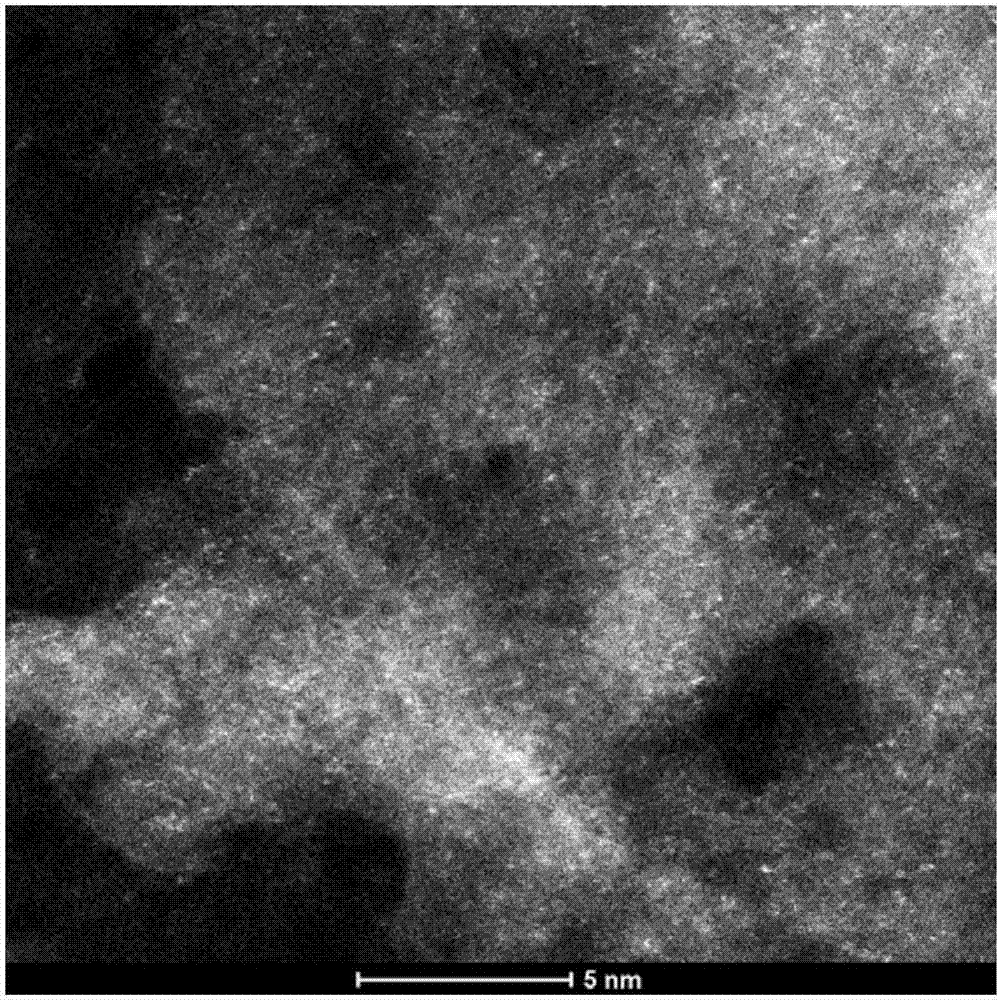

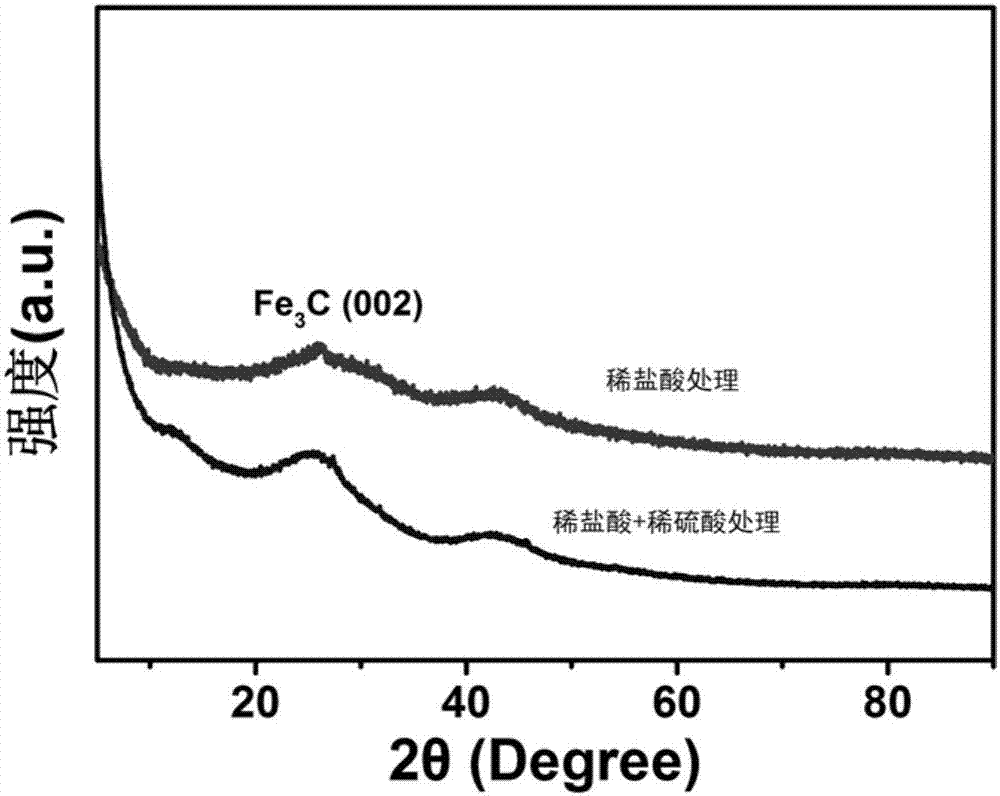

Monatomic iron nitrogen-doped porous carbon catalyst as well as preparation method and application thereof

ActiveCN107376970AReduce post-processing costsThe production process is economical and environmentally friendlyPhysical/chemical process catalystsOrganic chemistryHydrogen oxidation reactionBy-product

The invention provides a monatomic iron nitrogen-doped porous carbon catalyst as well as a preparation method and application thereof. In the catalyst, monatomic iron is taken as an active component, a nitrogen-doped porous carbon material is taken as a carrier, and iron is dispersed on the surface and the interior of the nitrogen-doped porous carbon material in a monatomic form, wherein every 100 wt% of the monatomic iron nitrogen-doped porous carbon catalyst contains 1.0-3.0 wt% of iron and 4.0-9.0 wt% of nitrogen. The invention also provides a method for catalyzing a nitrogen heterocyclic compound with the monatomic iron nitrogen-doped porous carbon catalyst for a dehydrogenation oxidation reaction and application of the monatomic iron nitrogen-doped porous carbon catalyst for catalyzing the nitrogen heterocyclic compound for the dehydrogenation oxidation reaction. The catalyst has an excellent catalytic effect; a product is analyzed by GC-MS (gas chromatography-mass spectrometer) after a catalytic reaction is ended; and an analysis result indicates that no by-product is produced, and the activity of the catalyst is not obviously reduced after the catalyst is used for 5 times.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method and device for manufacturing metal additive materials

ActiveCN105834422AGuaranteed forming qualitySimple structureAdditive manufacturing apparatusIncreasing energy efficiencyOrganic solventMetal powder

The invention discloses a method for manufacturing metal additive materials. The method includes the steps that a part structure and a supporting structure are built layer by layer, wherein the supporting structure is built by using an adhesive agent for bonding metal powder materials; and after part formation is completed, the adhesive agent is melted by high-temperature heating or dissolved by an organic solvent, and the supporting structure is removed. The invention further discloses a device for manufacturing the metal additive materials, and the device is included in the method. The device comprises a high-energy beam source, an optical unit, a forming chamber, a forming cylinder and a powder laying device, wherein the forming cylinder and the powder laying device are located in the forming chamber; the forming chamber is further provided with an adhesive spraying device which is used for providing the adhesive agent needed for building the supporting structure included in the method. The supporting structure built by the adoption of the method and device can be removed only by making the adhesive agent melted with high-temperature heating or dissolved with the organic solvent after part formation is completed, and no subsequent machining treatment is needed, so that cost for the subsequent treatment is reduced, and the forming efficiency is improved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

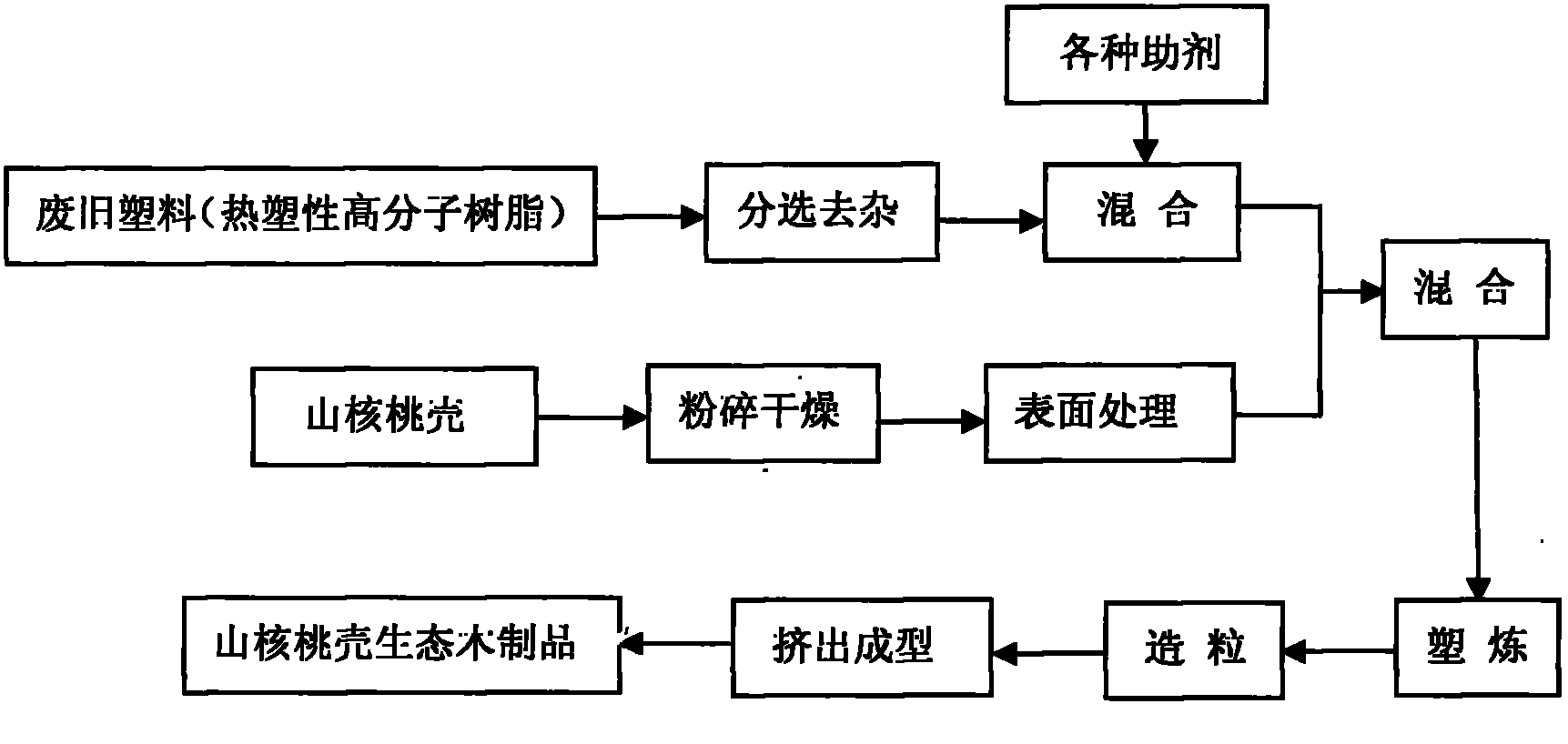

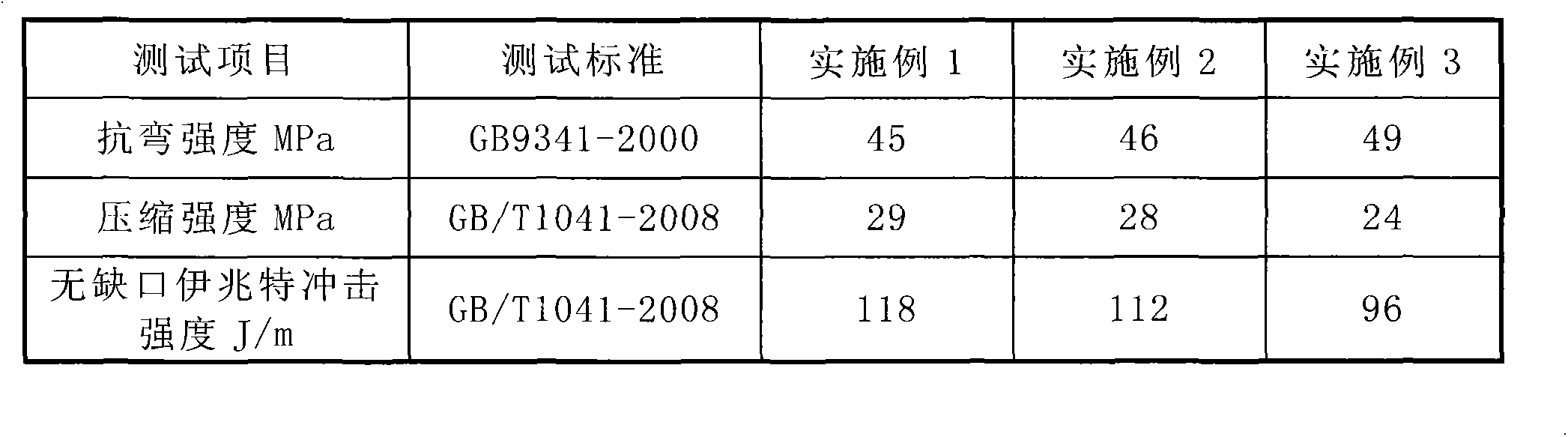

Hickory nut shell ecologic wood composite material and preparation method thereof

The invention relates to a plastic-wood composite material and provides a hickory nut shell ecologic wood composite material and a preparation method thereof. The hickory nut shell ecologic wood composite material is prepared from following components including, by weight, 50-60 parts of a thermoplastic high-molecular resin, 40-50 parts, or 30-40 parts, of hickory nut shell powder, 10-20 parts of wood powder, 8-10 parts of light calcium carbonate, 10-14 parts of a compatilizer, 2-4 parts of a thermal stabilizer, 2-4 parts of a lubricant, 2-3 parts of a plasticizer, and 1-3 parts of an antioxidant and an ultraviolet stabilizer. A comprehensive technology comprising deep process of raw materials and extrusion moulding and the like is employed. Deep process waste of wild hickories and waste plastic resources are employed. The composite material in the invention has dual-characteristics, which exist in common plastic-wood, of wood and plastic, is better in mechanical performances and is more rigid, durable, wear-resistant and weather-resistant. The method is simple and convenient, is low in manufacturing cost, can be recovered and recycled, can save energy resources and can protects environment.

Owner:LIAONING CHANGBAIXIANZI BIOTECH

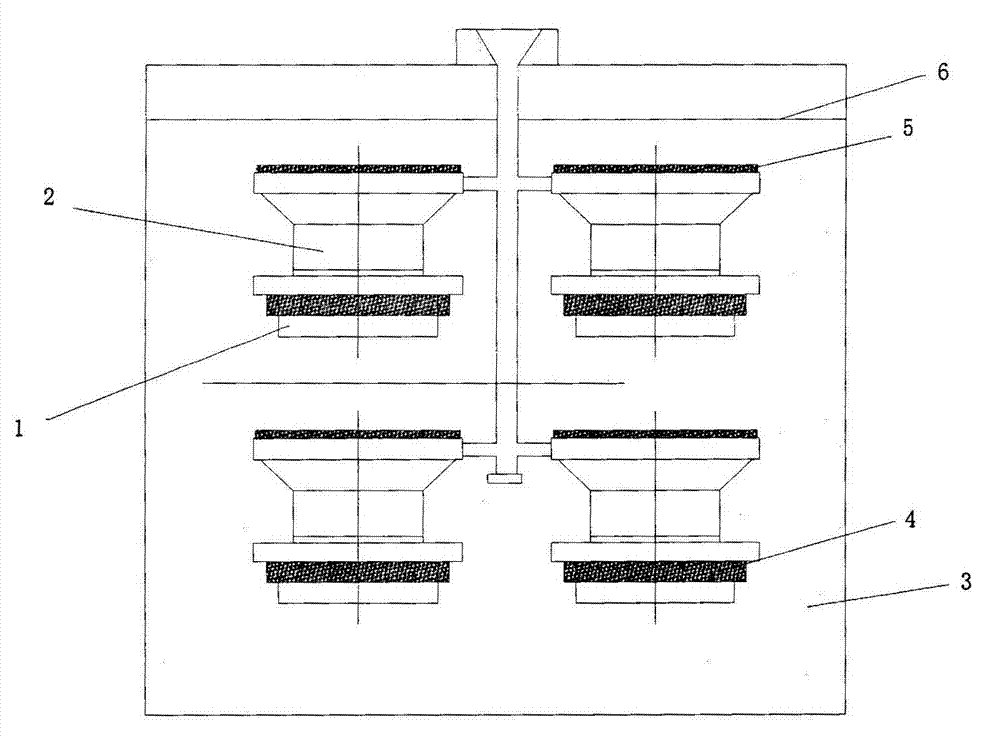

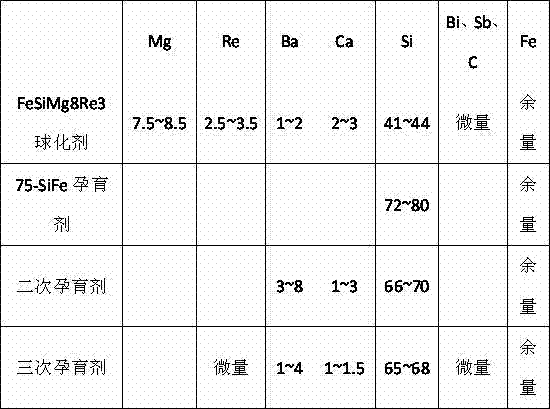

Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

The invention discloses a manufacturing process of a spheroidal graphite cast iron casting of a wind power yaw variable-pitch device. The process comprises the following processes of mould making, foaming and moulding, paint brushing, boxing and shaping, electric furnace smelting, tundish-covering nodulizing treatment, vacuum-assist pouring and three-time inoculation treatment, wherein the boxing and shaping process is a layered assembling process, so that the production efficiency can be improved and the process yield can be increased; cold iron is vibrated and reasonably arranged, so that the compactness of tissues in the casting can be improved and the defect of shrinkage porosity can be avoided; by virtue of the processes of electric furnace smelting and tundish-covering nodulizing treatment, the nodulizing rate of the casting can be stabilized and increased and the mechanical properties of the casting can meet the technical quality requirements of wind power castings; the spheroidal graphite cast iron casting manufactured by the process is compact and uniform in tissue, hardly has defects, has good surface quality and high size precision; the casting forming of multiple layers of castings can be realized; and the production efficiency and the process product yield are improved.

Owner:CHTC HEAVY IND

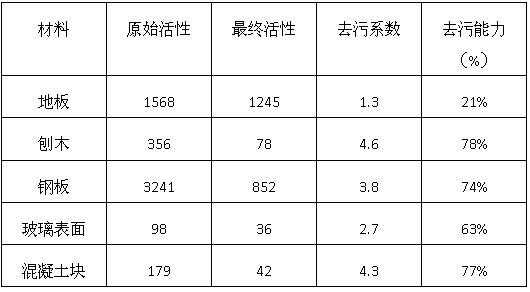

Peelable nano-grade decontamination coating

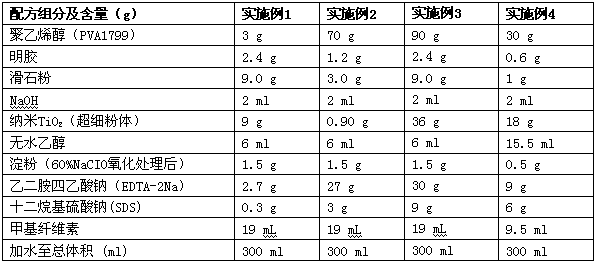

InactiveCN103214903AEasy to peelHigh tensile strengthLiquid surface applicatorsAntifouling/underwater paintsPolyvinyl alcoholUltimate tensile strength

The invention discloses a peelable nano-grade decontamination coating. According to mass volume percentages, the coating comprises but not limited to 1-30% of polyvinyl alcohol, 0.3-12% of nano-TiO2, 0.7-13% of a detergent, and at least one auxiliary agent with which polyvinyl alcohol can be dehydrated and a peelable polymer film can be formed. According to the peelable nano-grade decontamination coating provided by the invention, with the added TiO2, and with the effective combination of the auxiliary agents, the formed polymer film has the advantages of easy peeling, large tensile strength, and breakage preventing. A decontamination effect is substantial. In prior art, nuclear-contaminated solid surface and solid surfaces contaminated by some other substances cannot be washed by using large amount of water, and a decontamination amount is low. With the coating, the defects are solved. When the product is used in decontamination, a post-treatment garbage amount is low, and post-treatment cost is low. The characteristics are outstanding compared to those of prior art.

Owner:周国庆

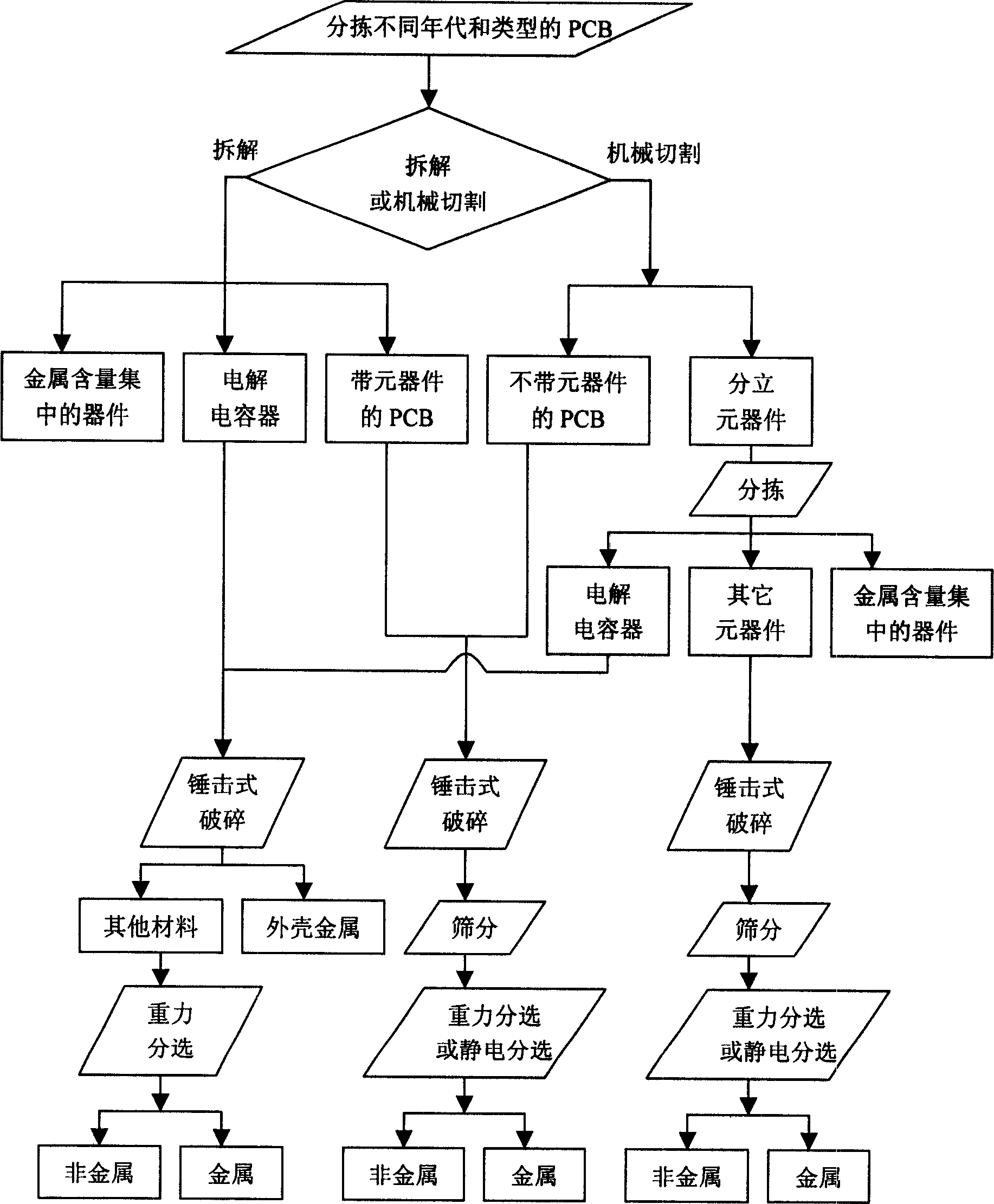

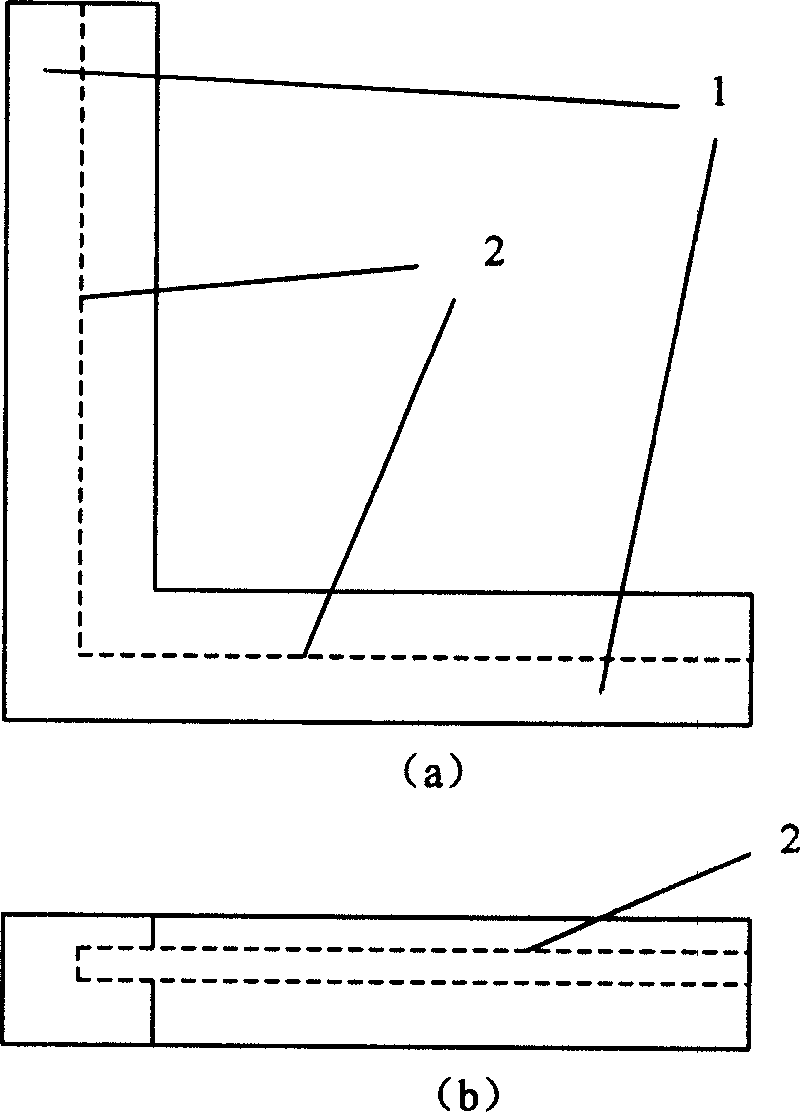

Recovering and treating process for waste printed circuit board and special clamp

InactiveCN1586746AConducive to secondary development and utilizationEasy to purifySolid waste disposalPositioning apparatusElectrolysisResource recovery

The present invention belongs to the field of electric appliance resource recovering and reusing technology. The technological process of recovering and treating waste printed circuit board includes the following steps: sorting printed circuit boards; separating electrolytic capacitor and other elements and devices mechanically from the printed circuit board; crushing printed circuit board, sieving and separating metal and non-metal gravitationally or electrostatically; crushing electrolytic capacitor, separating the shell metal, separating metal and non-metal of electrolytic capacitor gravitationally, crushing other elements and devices, separating metal and non-metal of other elements and devices gravitationally. The special clamp for separating electrolytic capacitor and other elements and devices mechanically from the printed circuit board is an L-shaped one with continuous single-end notches in two arms.

Owner:BEIJING UNIV OF TECH

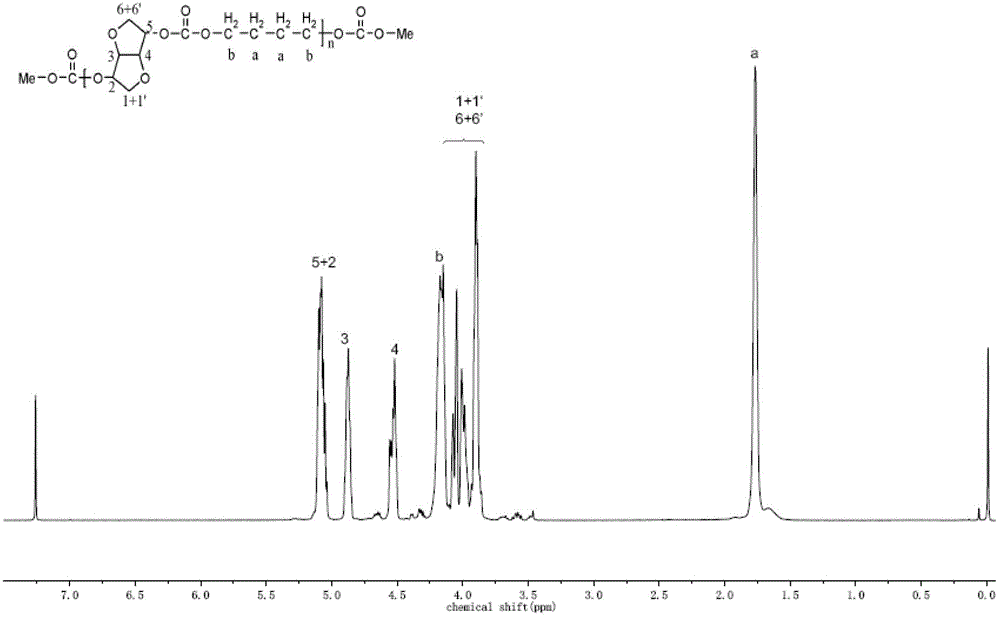

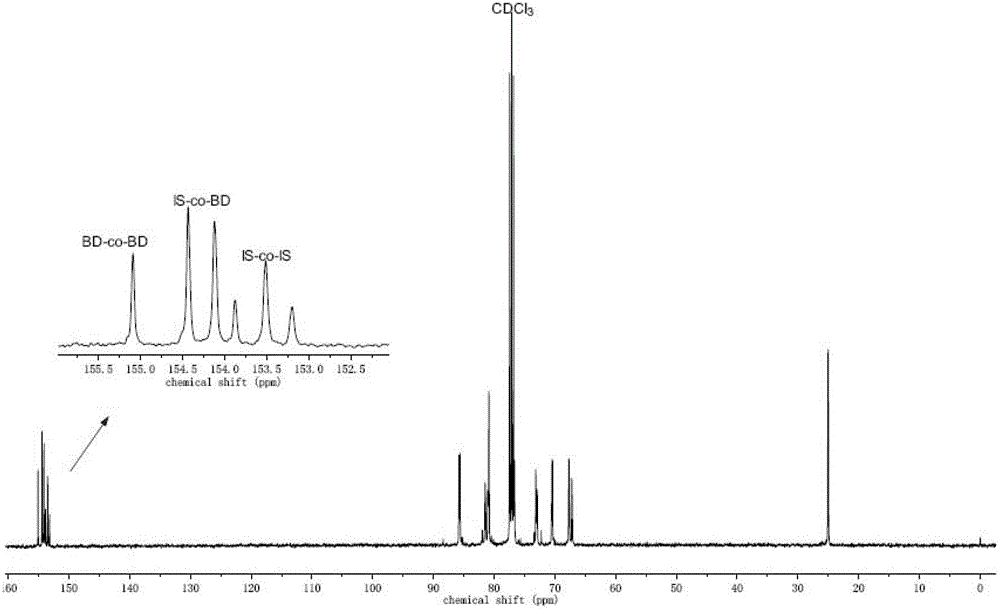

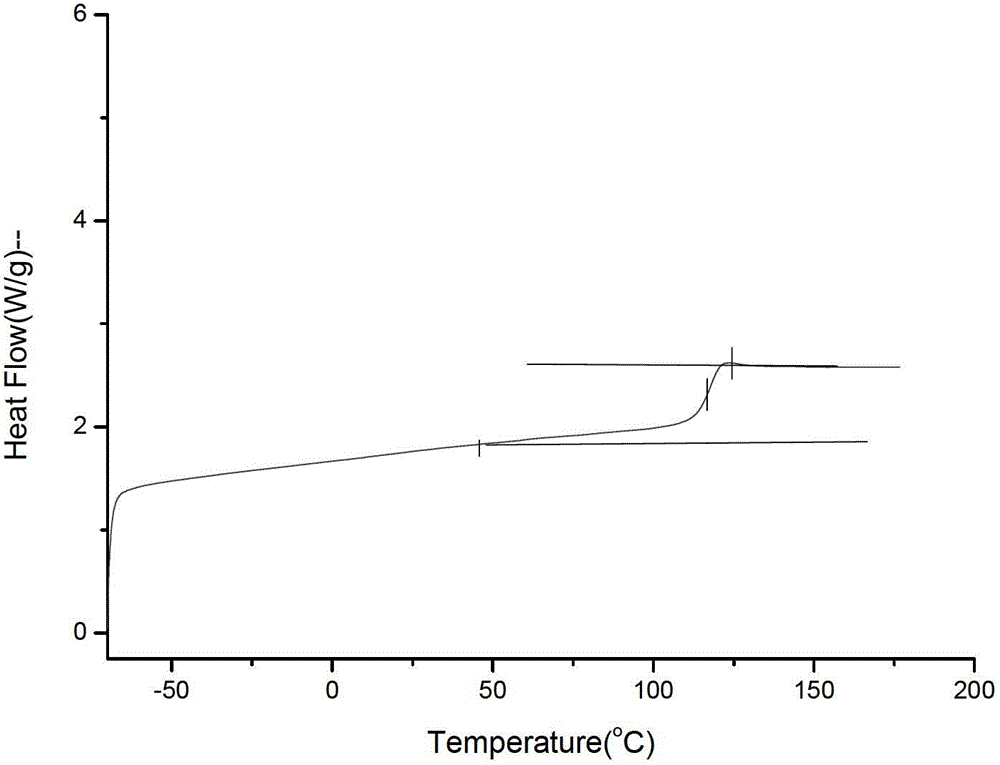

High-heat resistant aliphatic polycarbonate based on 1,4:3,6-dianhydro-hexanehexol, and preparation method and application thereof

The invention discloses high-heat resistant aliphatic polycarbonate based on 1,4:3,6-dianhydro-hexanehexol, and a preparation method and application thereof. According to the method, 1,4:3,6-dianhydro-hexanehexol and aliphatic diol respectively react with, or are mixed and then react with carbonic ester under the action of a catalyst in an inert gas atmosphere to realize ester interchange, and a resultant prepolymer undergoes polycondensation under the action of a polycondensation catalyst so as to obtain a product. The method costs little, can effectively improve transparency and the color of 1,4:3,6-dianhydro-hexanehexol type polycarbonate, uses a small amount of catalysts during reaction process and avoids complex separating process for the catalysts. The obtained product is a colorless or faint yellow transparent solid and has a number-average molecular weight of 1.5*10<4> to 2.0*10<5> and a glass-transition temperature of 100 to 175 DEG C. Prepared from biological raw materials and aliphatic diol, the product does not contain any residual phenyl ring and has no toxicity, usable as a food package material like a water cup and a water bottle or as a medical material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for producing soft twist yarn towels

InactiveCN101705568ARelieve pressureStanding fluffyBiochemical fibre treatmentDry-cleaning apparatus for textilesYarnPulp and paper industry

The invention discloses a method for producing soft twist yarn towels. In the method, 100-percent cotton yarns spun with long stapled cotton are used as blank warps and subjected to warping, weaving and grey cloth post-processing to produce the soft twist yarn towels, wherein the coefficient of twist of the blank warps is 240 to 270. The method has the advantages that: a step of removing water soluble yarns is saved in the post-processing, so the post-processing cost is reduced, the pressure for waste water treatment is relieved and a green and environmental-protection effect is achieved; and the produced products have pile loops, are loose and offer a soft hand feel.

Owner:SUNVIM GROUP

Improved blue algae treatment utilization method

InactiveCN101255075ABe harmlessDo resourcesBio-organic fraction processingWaste based fuelPhylum CyanobacteriaAutomatic control

This invention is an improved method for dealing with cyanobacteria, which can realize a harmless and resourceful treatment of cyanobacteria with automatic control, low operation cost, no secondary pollution and easy management. The method is characterized in that cyanobacteria and animal manure or sludge and other biomass can be used together as the fermentation material to obtain biogas through anaerobic digestion and the biogas is used to generate power or is burned for a direct use, and the biogas residue and biogas slurry are recovered to field or the biogas residue can be developed into feeds or organic fertilizers.

Owner:WUXI MASHENG ENVIRONMENT ENERGY TECH CO LTD

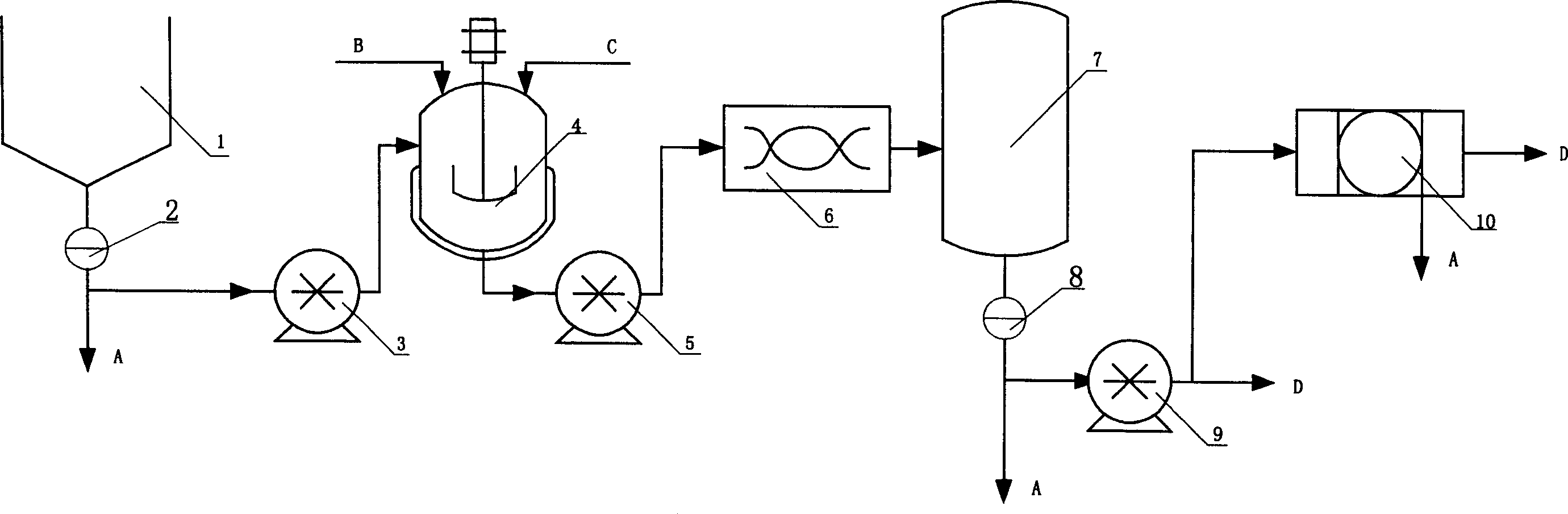

Method for catalyzing phosphotungstic acid ionic liquid to prepare biodiesel

ActiveCN104194948AHigh activityReduce dosageFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystReaction temperature

The invention belongs to the technical filed of ionic liquid catalysis preparation of biodiesel and particularly relates to a method for catalyzing phosphotungstic acid ionic liquid to prepare biodiesel. The method comprises the following steps: by taking biolipid and methanol as raw materials, taking a phosphotungstic acid ionic fluid as a catalyst to prepare the biodiesel by virtue of ether exchange reaction, wherein a molar ratio of the biolipid to the methanol is (1:20) to (1:50), the ionic liquid accounts for 1-10% of the mass of the biolipid, the reaction temperature is 45-64 DEG C and the reaction time is 3-11 hours. The method has the following advantages that firstly, the ionic liquid is simple in preparation process and relatively low in cost; secondly, the catalyst is high in activity, less in dosage, gentle in reaction condition and short in reaction time; and thirdly, the ionic liquid is stable in performance, capable of being repeatedly used, simple in separating process, low in after-treatment cost, free of pollution, free of corrosion on equipment, environmentally friendly, and capable of being expected to become a clean process route with competitive force.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

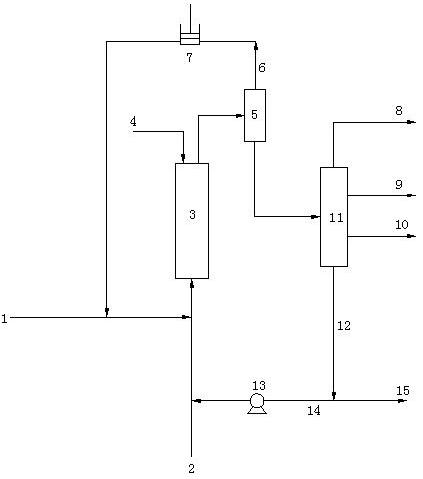

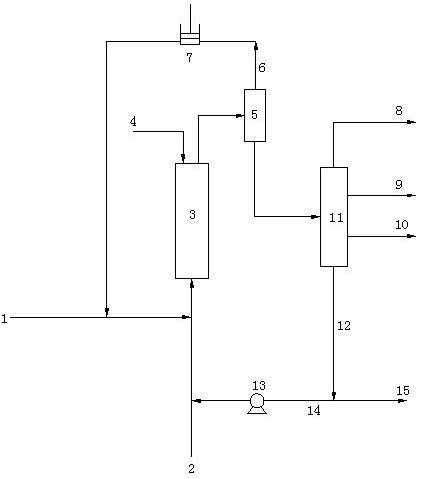

Coal tar heavy fraction fluidized-bed hydrocracking method and system thereof

InactiveCN101962572AIncrease profitSimple processTreatment with hydrotreatment processesLiquid productHydrogen

The invention relates to the field of coal chemical industry, in particular to a coal tar heavy fraction fluidized-bed hydrocracking method. The method comprises the following steps: the raw materials of coal tar heavy fractions are mixed with hydrogen and then enter a fluidized-bed reactor from the bottom thereof, and a supported catalyst enters the fluidized-bed reactor from the top thereof; under the action of the supported catalyst, the coal tar heavy fractions and the hydrogen carry out hydrocracking reaction in the fluidized-bed reactor; and the obtained reaction product is delivered from the top of the fluidized-bed reactor and then subject to gas-liquid separation, the separated hydrogen returns to the fluidized-bed reactor to be recycled, and the separated liquid product is subject to distillation separation to obtain gaseous hydrocarbon, gasoline fractions, diesel fractions and tail oil. In the invention, by directly adopting the fluidized-bed hydrocracking method, the coal tar heavy fractions can keep light weight, the yield of the fuel oil product hydrogenated by coal tar can be effectively increased, and blockage phenomenon of a catalyst bed layer can be effectively eliminated; and the method of the invention has the characteristics of simple and reasonable process, long-term operation, a small amount of the catalyst adopted, low cost, high yield of the oil generated by the product and good quality.

Owner:DALIAN UNIV OF TECH

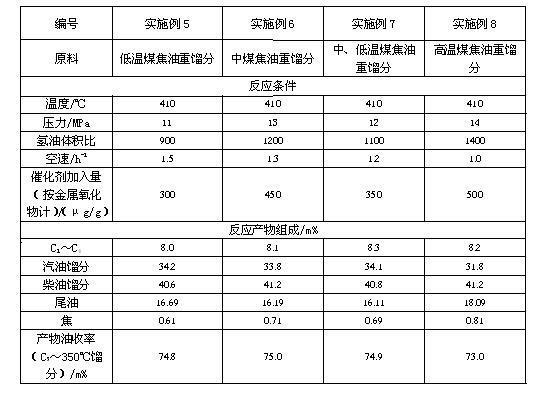

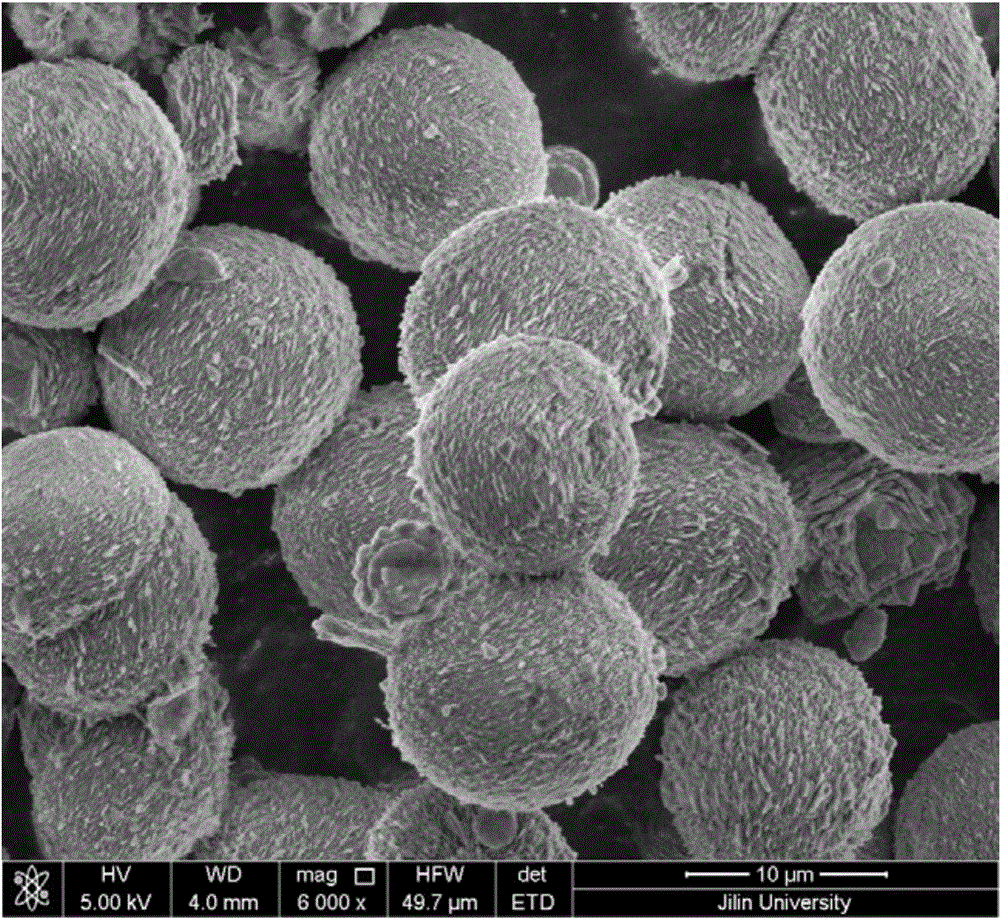

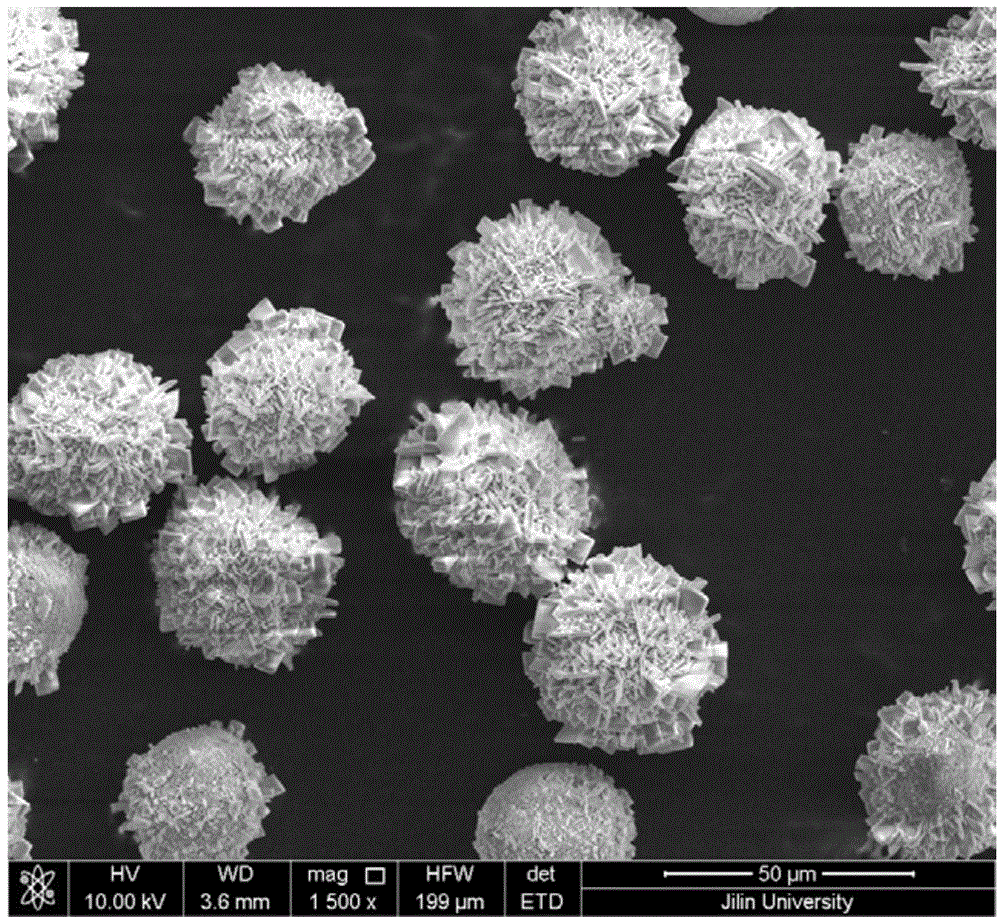

Method for preparing SrCuSi4O10 and BaCuSi4O10 blue pigments through hydrothermal technique

InactiveCN103601202AHigh purityMorphological rulesAlkaline-earth metal silicatesLuminescent compositionsDispersityLevel structure

The invention provides a method for preparing SrCuSi4O10 and BaCuSi4O10 blue pigments through a hydrothermal technique, and belongs to the technical field of hydrothermal chemistry. The method uses copper oxide powder or copper salt, barium salt or strontium salt, and silicate as raw materials, and NH4OH as a mineralizing agent and comprises the following hydrothermal reaction processes: mixing a reactant with distilled water according to a stoichiometric ratio of an objective product, adjusting the pH value of a solution to be greater than 10 and less than 14, putting in a high-pressure reactor so as to enable the filling degree to reach 40%-90%, sealing and reacting for 5-72 hours at the temperature of 230-300 DEG C; and cooling and filtering so as to obtain products. The invention provides a new reaction route and a green preparation method for SrCuSi4O10 and BaCuSi4O10 difficult to prepare. The products are multi-level structure microparticles, have high purity, regular morphology and good dispersity and are uniform in particle size. The preparation method is simple, efficient and high in yield; waste liquid generated in a hydrothermal reaction process can be recycled.

Owner:JILIN UNIV

Method for extracting microalgal oil

InactiveCN107129860ANothing producedGeneration and solutionLiquid carbonaceous fuelsFatty-oils/fats productionOil and greaseRotary evaporator

The invention relates to a method for extracting microalgal oil. The extraction method comprises the following steps: (1) performing pretreatment, namely uniformly mixing a eutectic solvent with microalgae powder, stirring the mixed solution at a room temperature, performing centrifugal separation on the mixed solution, and performing freeze drying on the obtained solid phase so as to obtain pretreated microalgae powder; (2) performing oil extraction, namely adding the pretreated microalgae powder and an organic solvent into an extracting tank, and heating for extracting; and (3) performing post-treatment, namely cooling the obtained extracting solution to the room temperature after oil extraction, adding deionized water, stirring and standing, finally putting the upper organic phase into a rotary evaporator so as to evaporate the organic solvent, thereby obtaining the microalgal oil. The method for extracting microalgal oil, disclosed by the invention, has the advantages of low cost, high extraction rate, and green environment friendliness.

Owner:SHAOGUAN COLLEGE

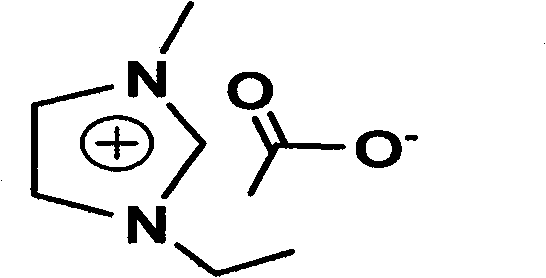

Application of ionic liquid to preparation of reducing sugar by cellulose hydrolysis

InactiveCN102071266ALow viscosityEasy to operateFructose productionGlucose productionCelluloseIon exchange

The invention relates to dissolution of straws and hydrolysis of celluloses, in particular to a method for preparing reducing sugar by dissolving the straws and hydrolyzing the celluloses in ionic liquid. The method comprises the following steps of: adding 1-ethyl-3-methylimidazole acetate serving as a straw solvent into Fe3+-containing aqueous solution and reacting in the presence of acidic ionic liquid serving as a catalyst under normal pressure at the temperature of between 110 and 140 DEG C for 0.5 to 5 hours; quenching with cold water; neutralizing with alkali liquor to prepare cellulose hydrolyzate; and measuring reducing sugar content by a 3,5-dinitrosalicylic acid method, wherein the reducing sugar in the hydrolyzate and the ionic liquid can be separated by an ion exchange method and the ionic liquid can be repeatedly used. Experiment results show that the reducing sugar yield is up to 93 percent to the maximum extent. Compared with the conventional straw cellulose hydrolysis method, the method has the advantages of solving the problems of complicated pretreatment, low hydrolysis activity, high corrosion to equipment, high cellulose solvent viscosity, inconvenience of operation and the like and providing a new approach for full utilization of the straws.

Owner:JIANGNAN UNIV

Method for producing polymerized iron chloride by utilizing acid-washing waste liquid of steel

InactiveCN102603015AReduce post-processing costsTake advantage ofIron halidesAfter treatmentSodium chlorate

The invention discloses a method for producing polymerized iron chloride by utilizing the acid-washing waste liquid of steel. The method for producing the polymerized iron chloride by utilizing the acid-washing waste liquid of the steel comprises the following steps of: (1) adding the acid-washing waste liquid of steel and a stabilizing agent into a reaction tank and fully stirring evenly so as to obtain a liquid material 1; (2) adding a sodium chlorate solution into the liquid material 1 continuously for reacting until the content of ferrous chloride in the mixture is lower than 0.5 percent so as to obtain a liquid material 2; and (3) adding a polymerization initiator into the liquid material 2 for carrying out a polymerizing reaction so as to obtain a polymerized iron chloride product after finishing the reaction. According to the method for producing the polymerized iron chloride by utilizing the acid-washing waste liquid of the steel, the polymerized iron chloride is prepared by utilizing the acid-washing waste liquid of the steel, the after-treatment cost of the acid-washing waste liquid of the steel industry is lowered, and resources are fully utilized; sodium chlorate is adopted as an oxidizing agent, the use of chlorine gas is avoided, a favorable production environment is formed, and the potential safety hazard is eliminated; and the method disclosed by the invention has simple technological process and low equipment investment and is suitable for industrialized production.

Owner:蓝保(厦门)水处理科技有限公司

Oil-containing dross dehydration process

InactiveCN1803654AReduce dosageReduce operating costsWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateResource recovery

The invention relates to a dewatering technique with chemical regulation and supersonic wave for oil-contained scum. Wherein, after the initial deposition to remove some water, using NaOH or Na2CO3 to regulate the pH value of scum to weak base state; adding flocculant (polyferroaluminium chloride or polyacrylamide) to stir evenly and send to supersonic treatment part for some minutes; then leading into deposition tank or pond to separate scum and water. The treated product can be recovered or send into incinerator for final treatment.

Owner:NANJING UNIV OF TECH

Process for catalytic synthesis of phthalide from phthalic anhydride

InactiveCN1884272AHigh activityImprove stabilityCatalyst carriersOrganic chemistryNickel catalystBenzoic anhydride

The invention relates to a method for synthesizing phthalide catalyzed by benzoic anhydride in liquid phase, especially relates to method with loading nickel catalyst. Said method employs phthalide as reacting solvent, prepares phthalide through selective hydrogenation with benzoic anhydride under catalysis of loading nickel catalyst; the ratio by weight between said benzoic anhydride and phthalide is 1: 0.1-10, the reacting temperature is 130-200 Deg. C, reacting pressure is 1.0-5.0 Mpa; said loading nickel catalyst is catalyst with nickel loaded on SiO2, diatom earth, activated char, TiO2, ZrO2, TiO2-SiO2, TiO2-Al2O3 or TiO2-ZrO2, and the loading amount of nickel is 5-50 wt.%. The invention is characterized by high activity and stability of used loading nickel catalyst, no pollution of process, direct usage of phthalide as solvent, low cost for post treatment, and simple process.

Owner:ZHEJIANG UNIV OF TECH

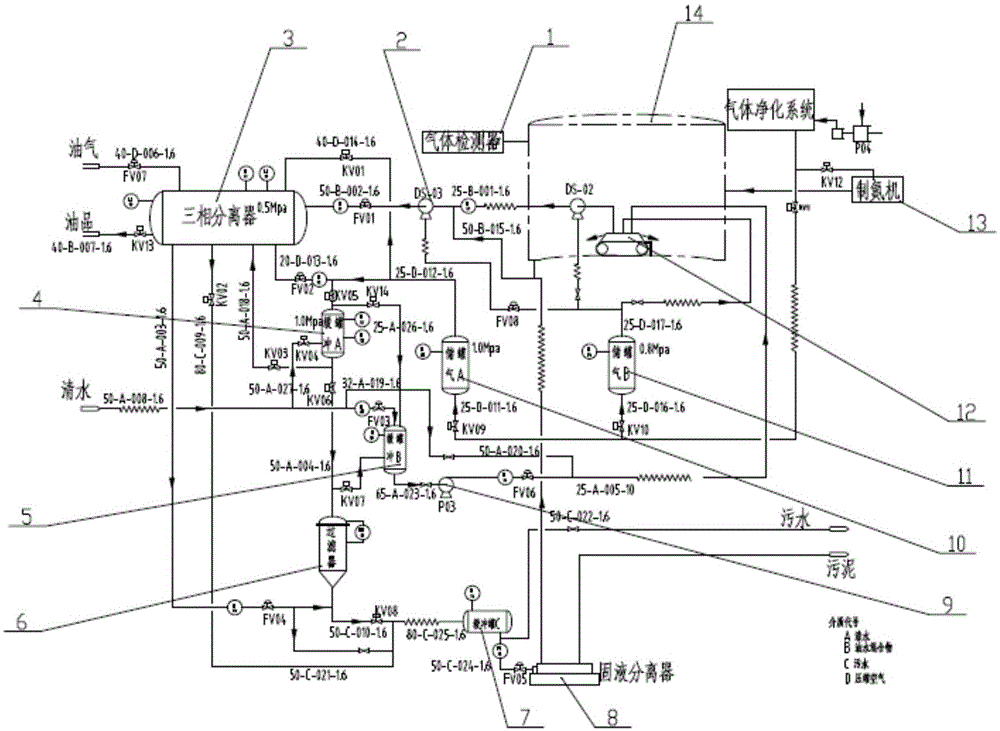

Cleaning device and method of finished oil tank

InactiveCN105032871AReduce post-processing costsReduce water consumptionFatty/oily/floating substances removal devicesWater contaminantsComing outSludge

The invention discloses a cleaning device and method of a finished oil tank. The cleaning method comprises the following steps: a centrifugal machine and a cleaning pump supply high-pressure water to a cleaning robot, and the cleaning robot moves in a tank and sprays the high-pressure water at the bottom of the tank and on the wall of the tank, so that the storage tank is cleaned; the sewage generated during cleaning is reclaimed through a sewage sucking pump; after the sewage is primarily separated and filtered through three-phase separation equipment, cleaning water enters filtering equipment to be processed by secondary filtering; the filtered water is supplied to the robot through the centrifugal machine and the cleaning pump so as to realize the circulation of a cleaning medium. According to the cleaning method disclosed by the invention, through the technology of secondary filtering and the technology of filter-residue separation, the oil tank can be washed clean without using a large amount of clean water, so that the energy-saving purpose and the environment-friendly purpose are realized. The cleaning device is provided with filter-residue separation equipment, the sludge and the suspended solids, coming out of the three-phase separation equipment and the filtering equipment, pass through the filter-residue separation equipment, so that the water medium enters cleaning circulation; therefore, the using amount of the clean water in circular cleaning is reduced, and the treatment expenses of sewage and sludge in a later period are lowered.

Owner:AECC AVIATION POWER CO LTD

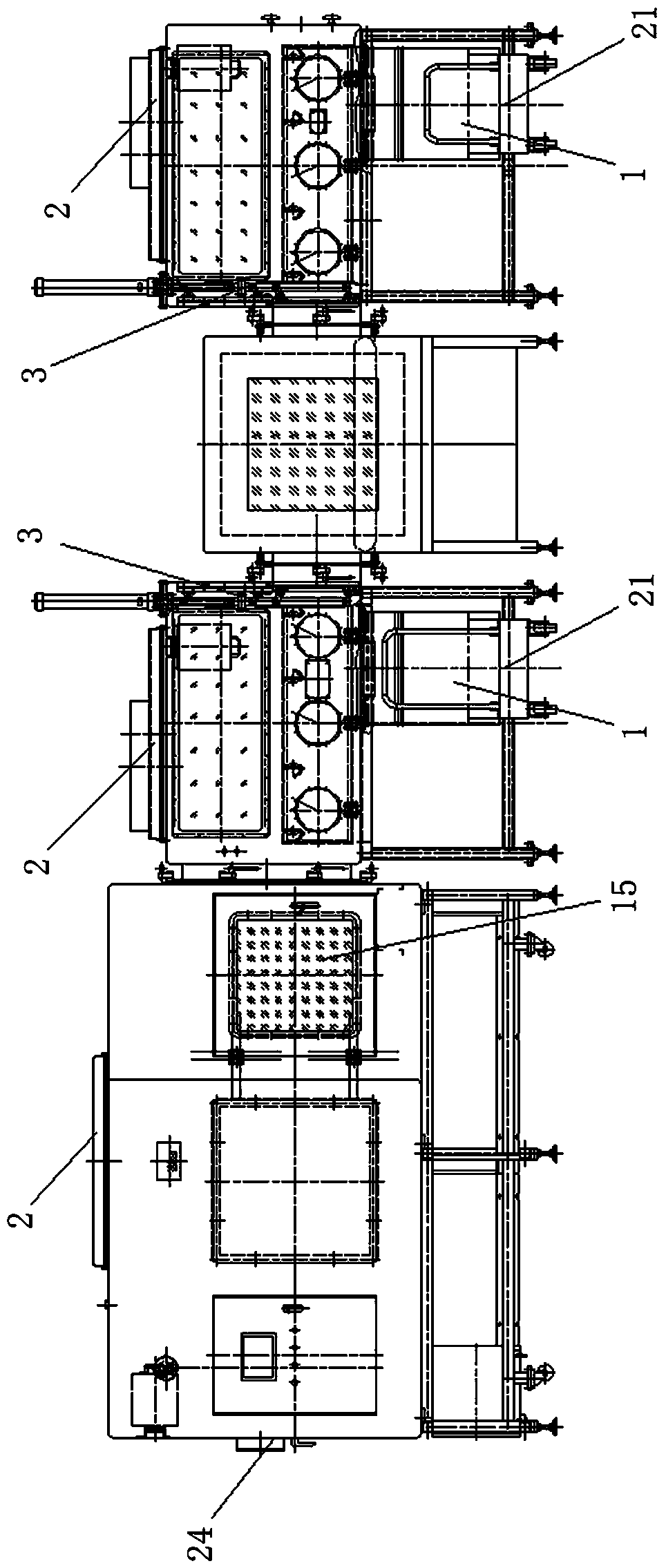

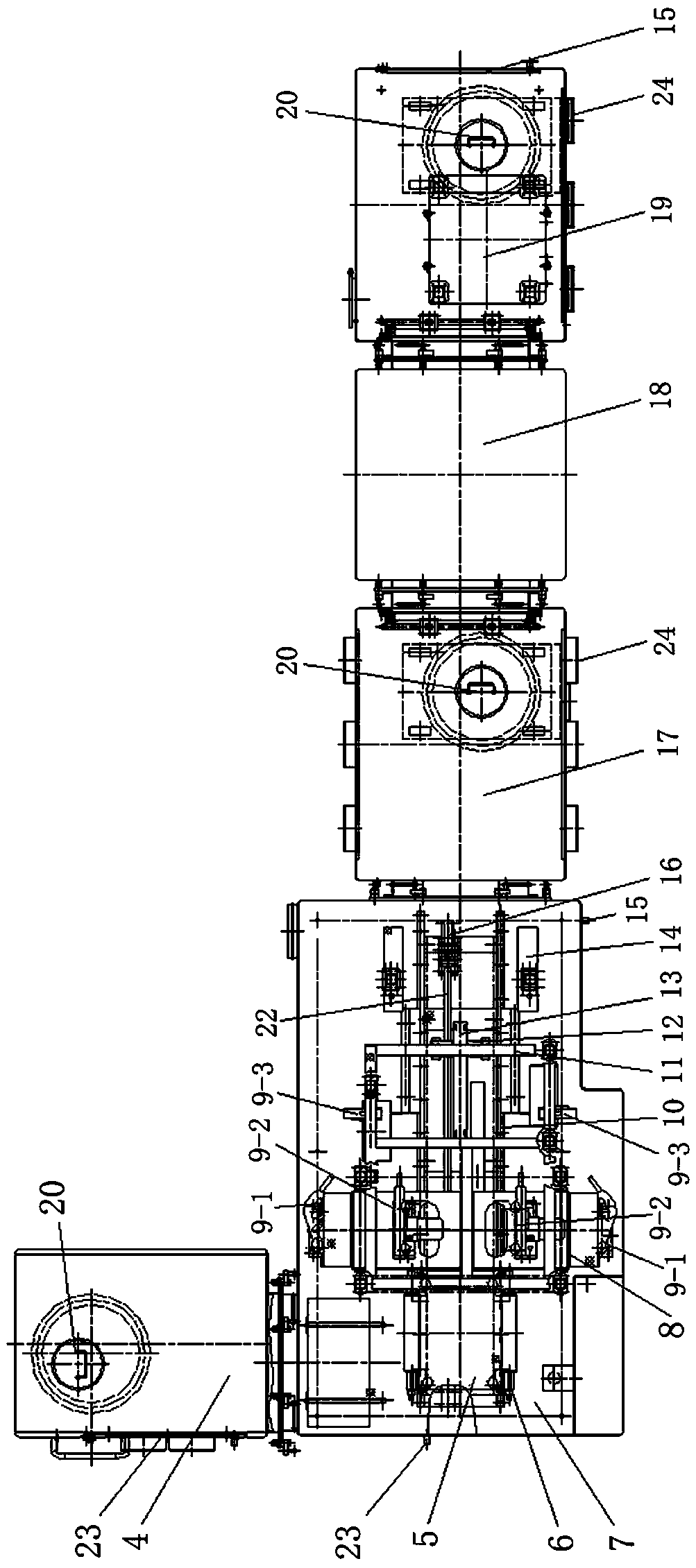

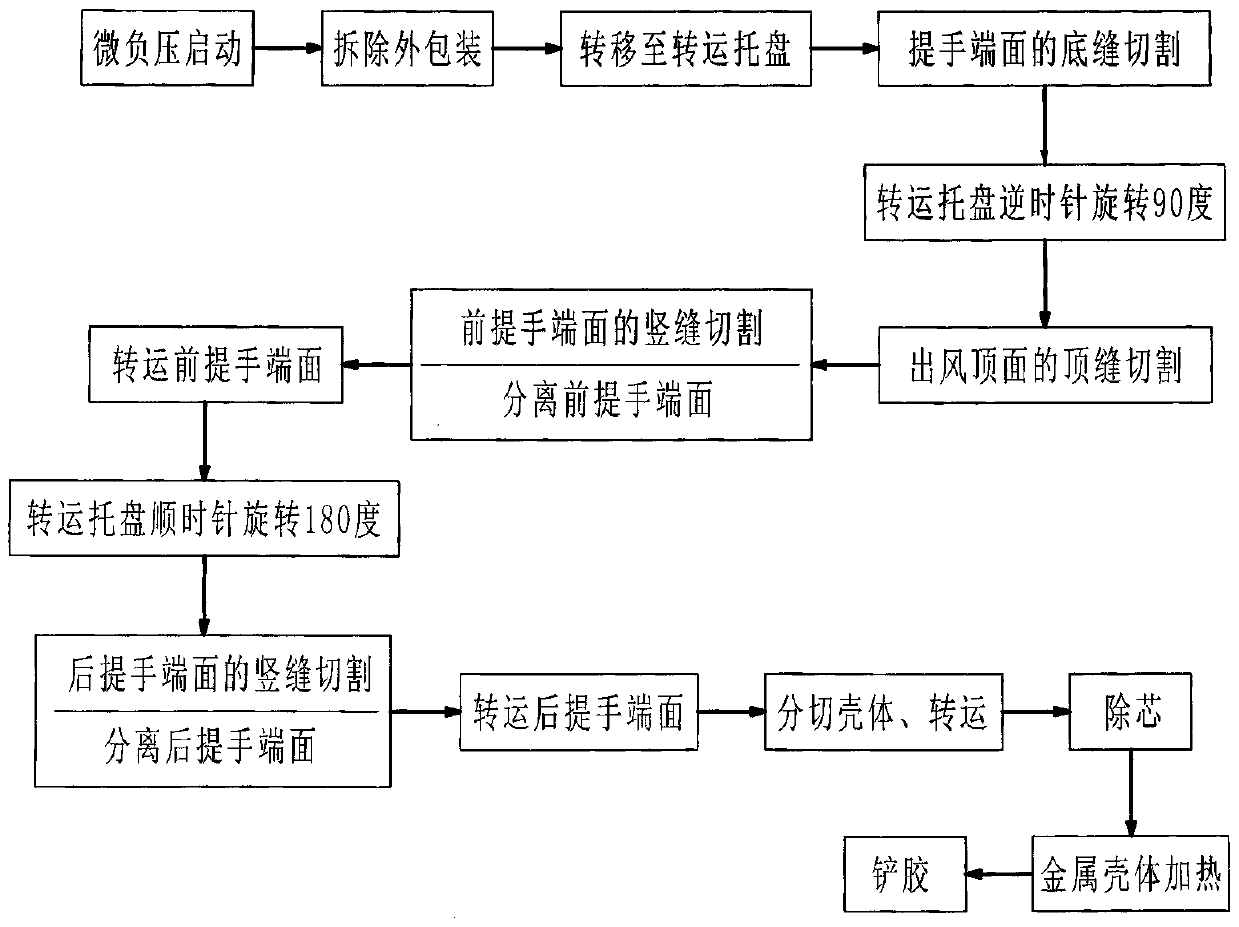

Device and method for disassembling low-radioactivity gather type waste filter

PendingCN107812781AGuaranteed safe collectionCause secondary pollutionSolid waste disposalPlastic recyclingAgricultural engineeringWaste treatment

The invention discloses a device and method for disassembling a low-radioactivity gather type waste filter. The low-radioactivity gather type waste filter to be disassembled is placed into a disassembling system, after an outer package is removed, a bottom seam cutting machine, a top seam cutting machine, a vertical seam cutting machine and a transfer tray are cooperated for carrying out bottom seam cutting on the front handle end face, top seam cutting on the air exhaust top face, vertical seam cutting on the front handle face and vertical seam cutting on the rear handle face of a metal shellof the low-radioactivity gather type waste filter, the front handle face and the rear handle face are separated in first batch, a core is recycled after cut, and the metal shell and glue attached tothe metal shell are heated in a tunnel type drying oven and subjected to glue shoveling treatment through a glue shoveling negative pressure ventilation cabinet to be classified and recycled. The gather type waste filter can be disassembled before waste treatment, meal materials and nonmetal materials are classified, and the device and method have the advantages of being high in automation degree,high in efficiency, safe and environmentally friendly, saving energy and the like.

Owner:HENAN HEJING CLEANING TECH

System and method for treating industrial circulating cooling water

ActiveCN102745843AImprove serious wasteHigh salinityMultistage water/sewage treatmentAutomatic controlLow voltage

The invention discloses a system and a method for treating industrial circulating cooling water. The system comprises two or more parallel reaction chambers, wherein electrode plates are respectively arranged in the parallel reaction chambers, and the plurality of reaction chambers are controlled by an automatic control system to carry out electric absorption and desorption regeneration. With thesystem, the serious waste phenomenon of the industrial circulating cooling water is successfully improved, on the basis of the original cooling circulating system, an electric desalination and absorption device is additionally arranged, so the salinity of the circulating cooling water is lowered, the utilization rate of the circulating water is increased, the concentration ratio of the circulating water is improved, and the cost is saved; the medicine dosage is reduced, so the costs for device operation and wastewater post-treatment are saved; and a device is operated under the condition of low voltage, so the electricity consumption can be saved, and the economic efficiency of an enterprise is improved. Consequently, the system has a very high practical application value.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Disposable protective garment for nuclear industry and processing method after disposable protective garment is used

InactiveCN103280250AReduce the amount of buriedReduce post-processing costsShieldingRadioactive decontaminationSingle usePollutant

The invention discloses a disposable protective garment for a nuclear industry and a processing method after the disposable protective garment is used. In the prior art, a traditional protective garment for the nuclear industry is large in waste processing amount, a large amount of money is wasted, and increasingly expansive long-term hidden danger to earthly environment is caused. The disposable protective garment is made of water solubility polyvinyl alcohol cloth or composite shell fabrics of the water solubility polyvinyl alcohol cloth and water solubility polyvinyl alcohol films. After the disposable protective garment is used at one time, the waste processing method comprises the following steps that the protective garment is dissolved in hot water, a minute quantity of radioactive ash stained on the protective garment is acquired through filtering collection, and eventually deeply-buried processing is conducted. Water solution filter liquor can be directly discharged to soil, microorganisms in the soil fully degrade the water solution filter liquor, and no pollutant residual is left. Compared with the traditional protective garment, processing cost of waste is greatly saved, and ecological environment is protected.

Owner:GRI MEDICAL & ELECTRONICS TECH CO LTD

Nano zero-valent iron loaded magnetic nano illite-montmorillonite clay and preparation method and application thereof

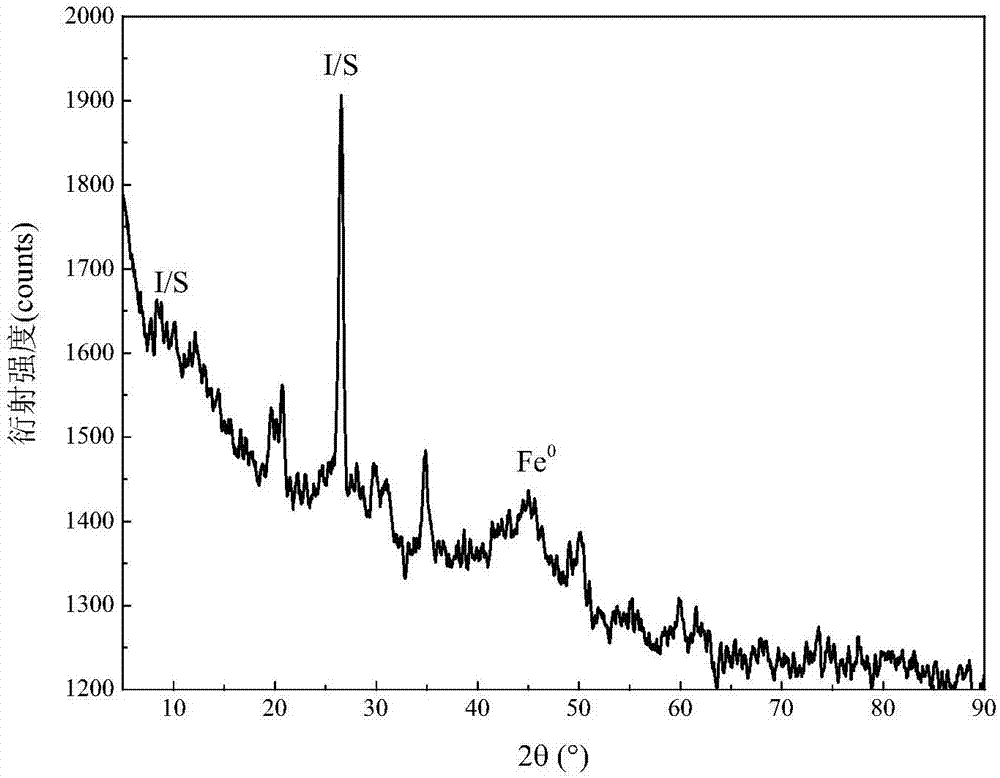

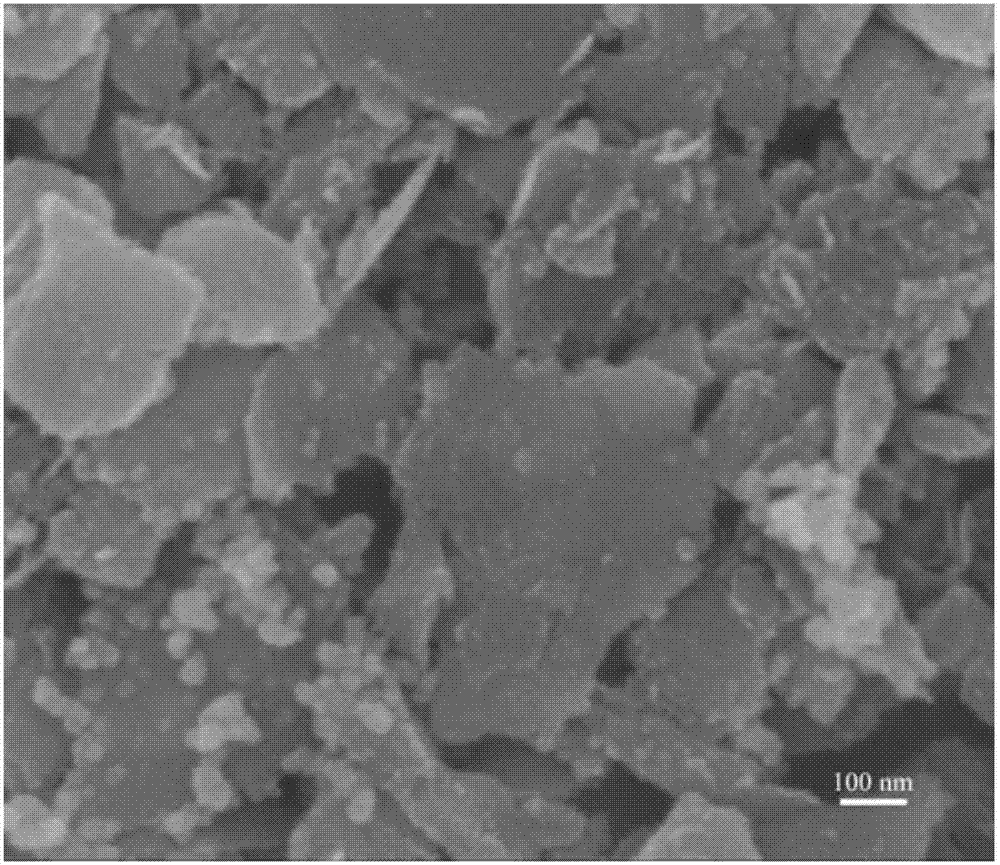

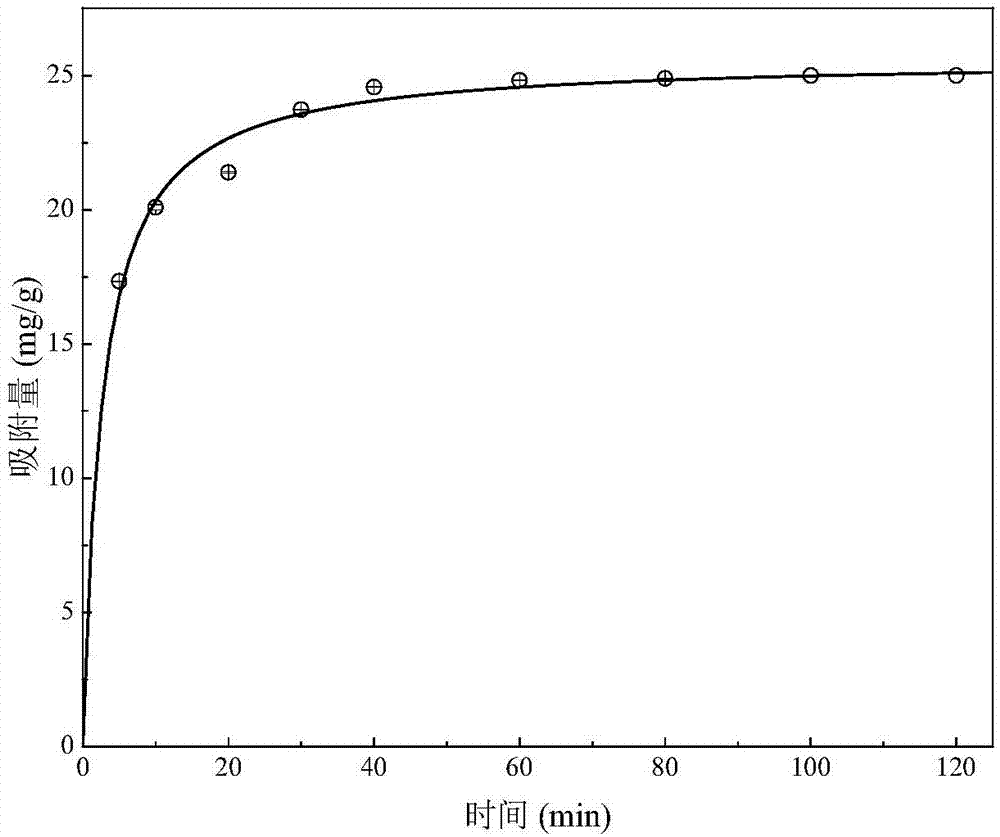

InactiveCN106964311AFine particleLamellar morphologyOther chemical processesWater contaminantsPotassium borohydridePotassium

The invention discloses a preparation method of nano zero-valent iron loaded magnetic nano illite-montmorillonite clay. The preparation method includes following steps: (1), adding deionized water into nano illite-montmorillonite clay to obtain a stable suspension; (2), adding ferric trichloride hexahydrate into the suspension, adding anhydrous alcohol, and ultrasonically stirring to obtain a precursor solution; (3), preparing sodium borohydrate or potassium borohydrate solution, and dropwise adding the solution into the precursor solution in a nitrogen atmosphere; (4), using a magnet for gathering to obtain a product, and washing; (5), performing vacuum drying and grinding on the product to obtain nano zero-valent iron loaded magnetic nano illite-montmorillonite clay powder. The invention further discloses the nano zero-valent iron loaded magnetic nano montmorillonite clay prepared by the method and application thereof. The nano zero-valent iron loaded magnetic nano illite-montmorillonite clay prepared by the method has high reaction activity and has remarkable treatment effect on wastewater containing hexavalent chromium, and an outer magnetic field can be utilized for separation after treatment is finished.

Owner:SOUTH CHINA UNIV OF TECH

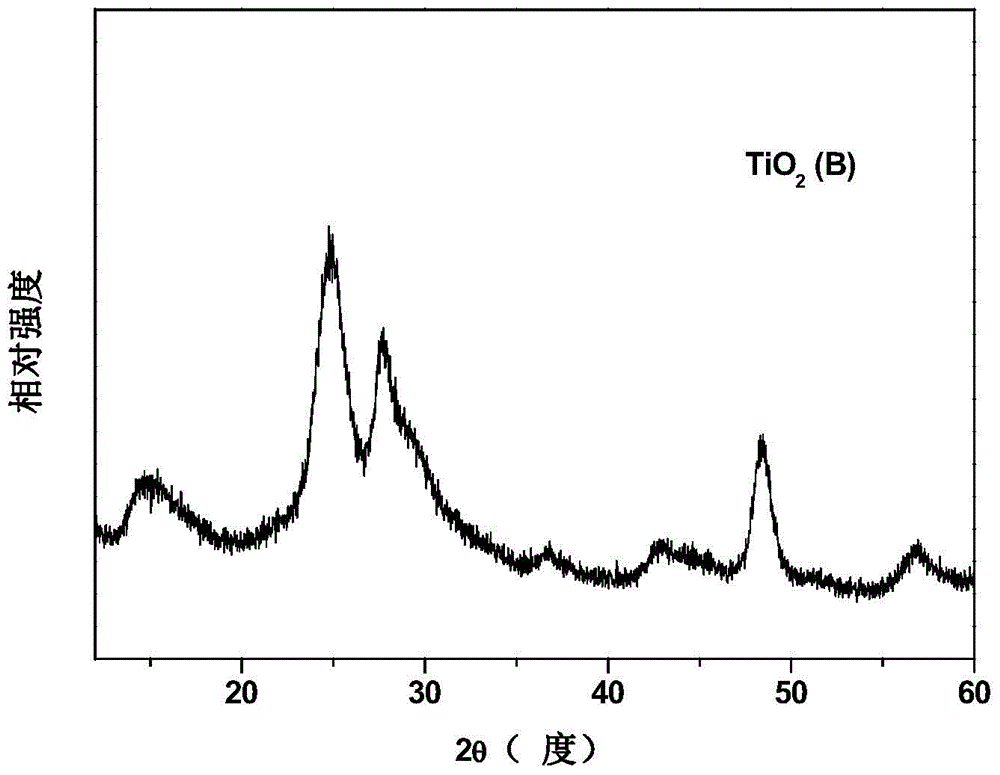

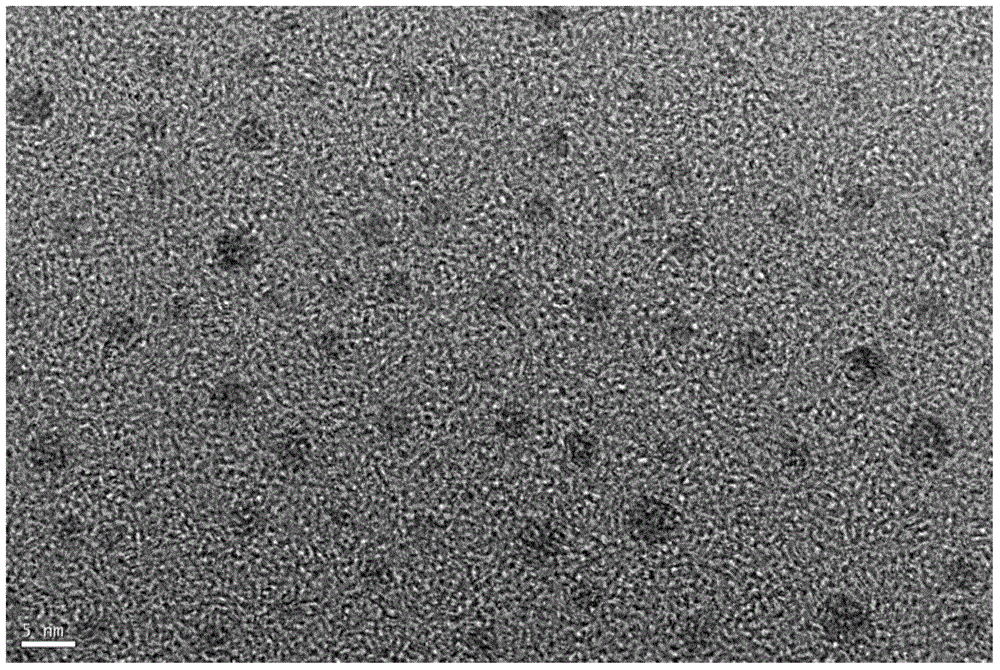

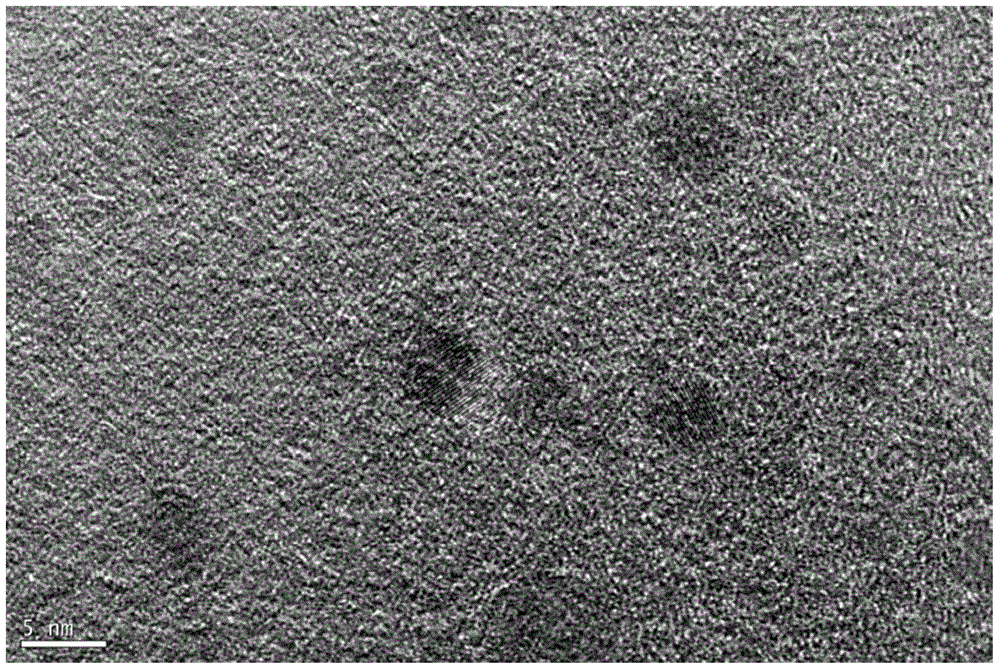

Method for preparing monodisperse titanium dioxide (B) nano particles

ActiveCN104310468AShort reaction timeLow reaction temperatureMaterial nanotechnologyTitanium dioxideNitrogen gasSolvent

The invention provides a method for preparing monodisperse titanium dioxide (B) nano particles, belonging to the technical field of preparation of inorganic materials. The method comprises the steps of by taking polyhydric alcohols as solvents, adding titanium tetrachloride under the protection of nitrogen, mixing uniformly through stirring, heating up to 160-200DEG C, then adding deionized water, reflux reacting for 2-7 minutes, cooling by a cold bath to stop the reaction, dripping acetone, stirring and precipitating, and washing, centrifuging and drying the obtained white precipitate. The method is simple to operate, saves complicated steps of traditional high temperature heating and burning, has short reaction time, and can prepare the target product without surfactants and guiding agents; and the prepared monodisperse TiO2-B nano particles have the grain size less than 5nm, and can be used in fields like lithium ion batteries, catalysis and so on.

Owner:吉林省润臻分离技术有限公司

Preparation method of calcium alginate microcapsule

ActiveCN101810595AOvercome the disadvantage of not being able to embed oil-soluble drugs in a homogeneous systemReduce usagePharmaceutical delivery mechanismPharmaceutical non-active ingredientsAromatic solventPolyethylene glycol

The invention discloses a preparation method of calcium alginate microcapsule, which comprises the following steps that: 1. sodium alga acid and polyethylene glycol with the average molecular weight of 200 to 1000 are dissolved into deionized water to prepare the sodium alga acid water solution which is used as a solution A, fatty acid calcium with the carbo-chain length of C5 to C11 is dissolved into alcohol solvent with the carbo-chain length of C2 to C11 or dissolved into aromatic solvent under the assistance of ethanol to prepare fatty acid calcium alcoholic solution or aromatic solution of fatty acid calcium which is used as a solution B. 2. The solution A is mixed with the solution B to prepare the calcium alginate microcapsule with the granularity being less than 50 micrometers. The raw materials are easy to obtain, the operation is simple, no particular equipment is required, and the calcium alginate microcapsule which can be used for embedding oil soluble medicine can be prepared without complicated processing procedures.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

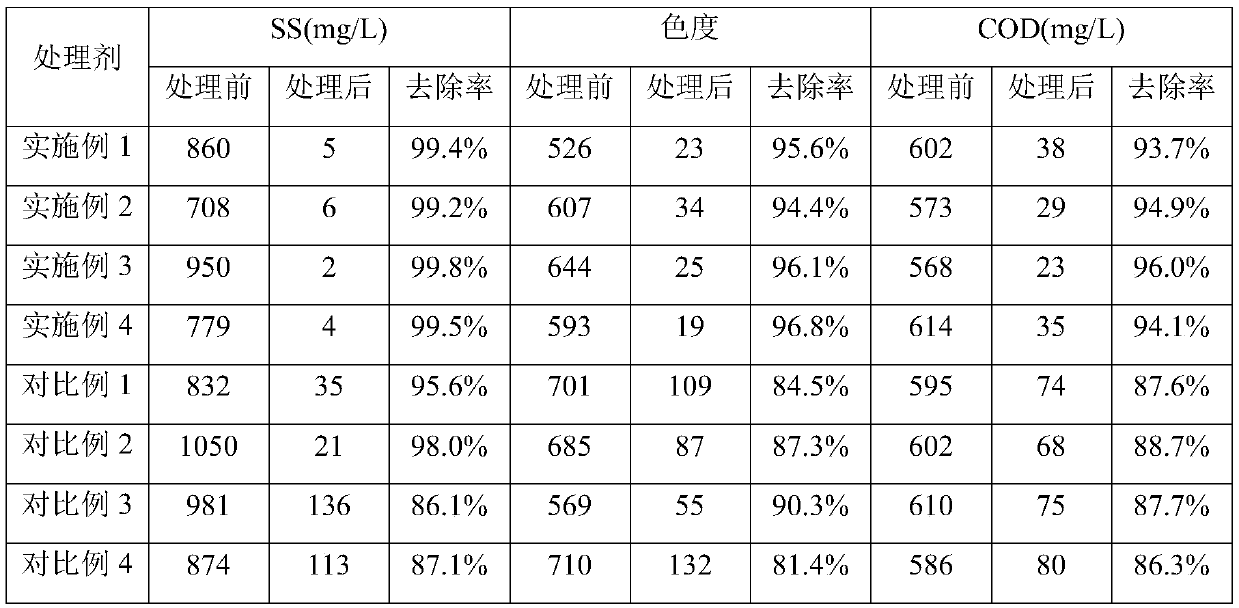

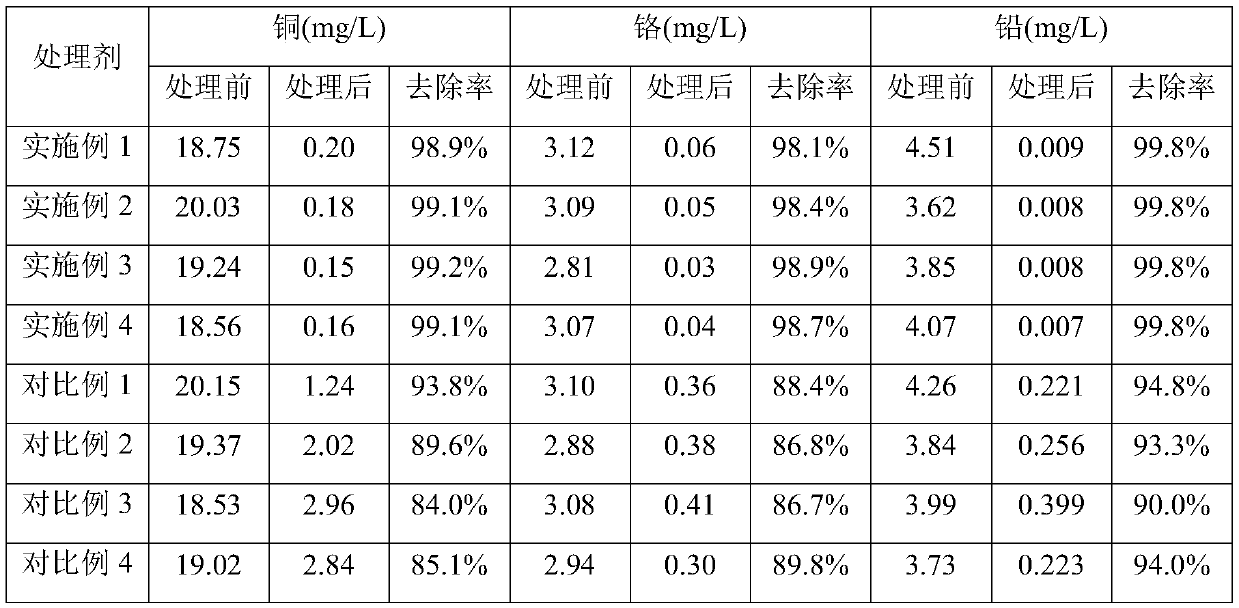

Composite flocculant for treating printing and dyeing wastewater

ActiveCN109734145AGood nucleation effectRealize separation and removalWater contaminantsWaste water treatment from textile industryFiberPolyvinyl alcohol

The invention discloses a composite flocculant for treating printing and dyeing wastewater. The composite flocculant for treating the printing and dyeing wastewater is prepared from the following rawmaterials in parts by weight: 15-25 parts of activated carbon fibers, 4-11 parts of acrylamide, 2-9 parts of sodium carboxymethyl cellulose, 5-17 parts of polyvinyl alcohol, 3-6 parts of a crosslinking agent, 0.003-0.006 part of an initiator, 3-5 parts of a polyethyleneimine-cellulose composite material, 10-15 parts of starch xanthate and 25-36 parts of modified bentonite. The composite flocculantprovided by the invention does not contain components which are complicated, have radiation and easily cause secondary pollution, all the used raw materials are natural, environment-friendly, low inprice and easy to obtain, the preparation method is simple, the feeding amount is small, the composite flocculant has multiple effects of flocculation sedimentation, adsorption decolorization, deodorization and the like, the sedimentation rate is high, the removal rates of organic matters, dye molecules and heavy metals are high, the structure and properties are stable, and the application range is wide.

Owner:XINXIANG UNIV

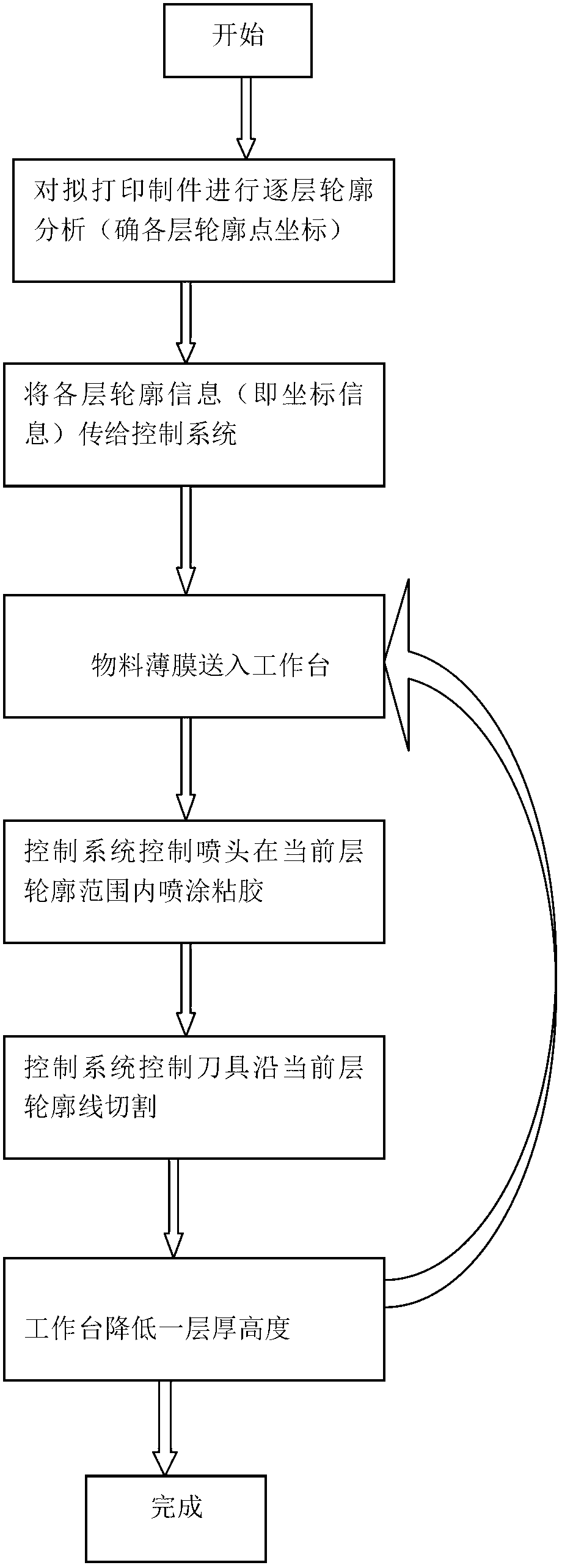

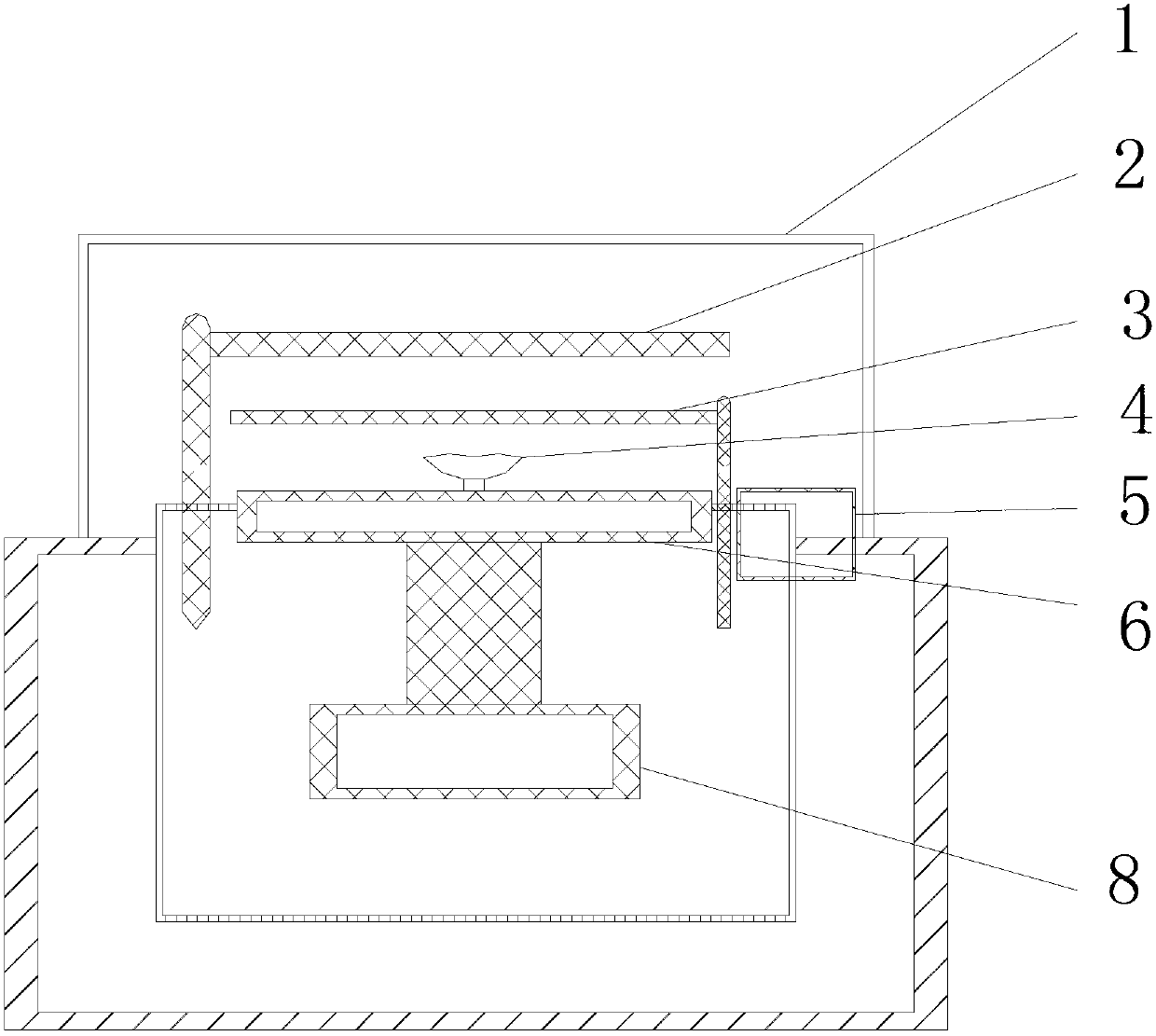

3D (Three-dimensional) desktop printing method and system

The invention relates to a 3D (Three-dimensional) desktop printing method and system. Compared with the traditional method, the difference is characterized in that an adhesive is only sprayed in the current layer of contour area in the printing process, and the cutting is carried out on a layer after the adhering is carried out on the layer. The method and the system provided by the invention have the beneficial effects of greatly saving processing auxiliary materials and reducing the manufacturing cost of processing equipment.

Owner:陈功举

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com