Coal tar heavy fraction fluidized-bed hydrocracking method and system thereof

A hydrocracking and heavy fraction technology, applied in the field of coal chemical industry, can solve the problems of catalyst activity greatly affected, catalyst activity reduction, catalyst bed clogging, etc., achieve high catalyst utilization rate, high conversion rate, and solve bed clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

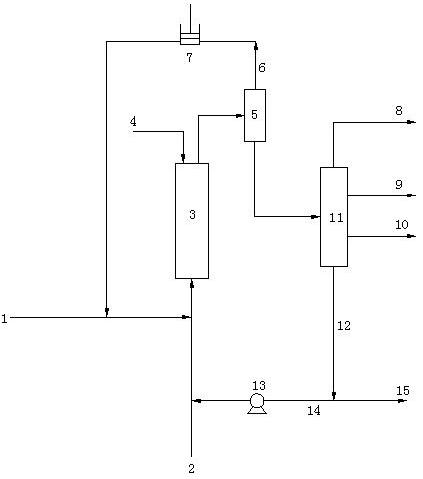

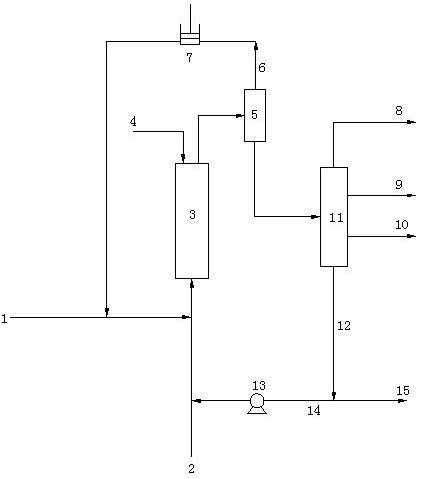

[0023] The above coal tar heavy fraction ebullating bed hydrocracking system is used to mix high-pressure hydrogen 1 and circulating hydrogen 6, coal tar heavy fraction 2 and circulating tail oil 14, and the mixed hydrogen and mixed oil are produced by ebullating bed reactor 3 The bottom enters, the catalyst 4 enters from the top of the ebullated bed reactor 3, and the reaction product output from the top of the ebullated bed reactor 3 enters the high-pressure separator 5, and the circulating hydrogen 6 separated by the high-pressure separator 5 returns through the circulating hydrogen compressor 7 The ebullated bed reactor 3 is recycled. The separated liquid phase product oil is sent to fractionation tower 11 for separation, and its product is gaseous hydrocarbon 8 (C 1 ~C 4 ), gasoline fraction 9 (C 5 ~170°C fraction), 10 diesel fractions (170~350°C fraction), 12 tail oils (greater than 350°C). A part of the tail oil is returned to the ebullated bed reactor 3 for recyclin...

Embodiment 5~8

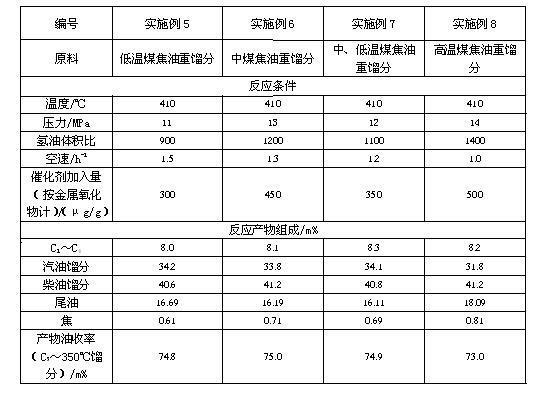

[0028] The method and system for ebullating bed hydrocracking of the heavy fraction of coal tar mentioned above are adopted, and the test method and process are the same as those of the above-mentioned Examples 1-4.

[0029] In the test, the addition amount of 4 kinds of heavy fractions of coal tar is 15kg / h, and the supported catalyst used is a strip-shaped molybdenum-nickel catalyst with silicon oxide as the carrier, and the molybdenum content in the catalyst is 10% (according to MoO 3 Calculation), the nickel content is 6% (calculated as NiO), and the bulk density of the catalyst is 0.7g / cm 3 , the specific surface area is 200m 2 / g, the pore volume is 0.50mL / g, and the catalyst particle diameter is 0.20mm. The reaction conditions and results of the ebullating bed hydrocracking test are shown in Table 3.

[0030] Table 3 Reaction conditions and results of fluidized bed hydrocracking test

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com