Patents

Literature

402 results about "Hydrogen compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrogen compressor is a device that increases the pressure of hydrogen by reducing its volume resulting in compressed hydrogen or liquid hydrogen.

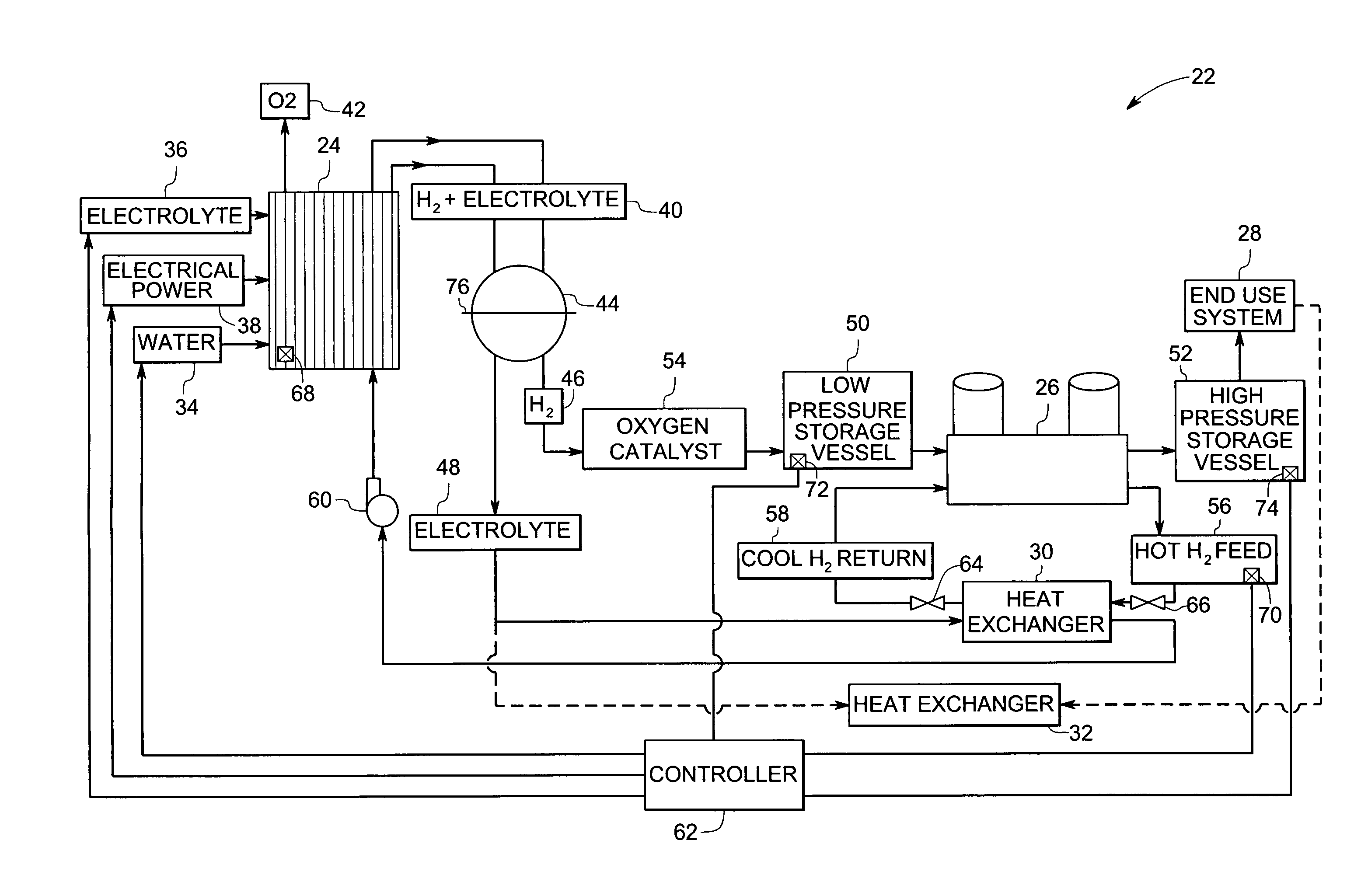

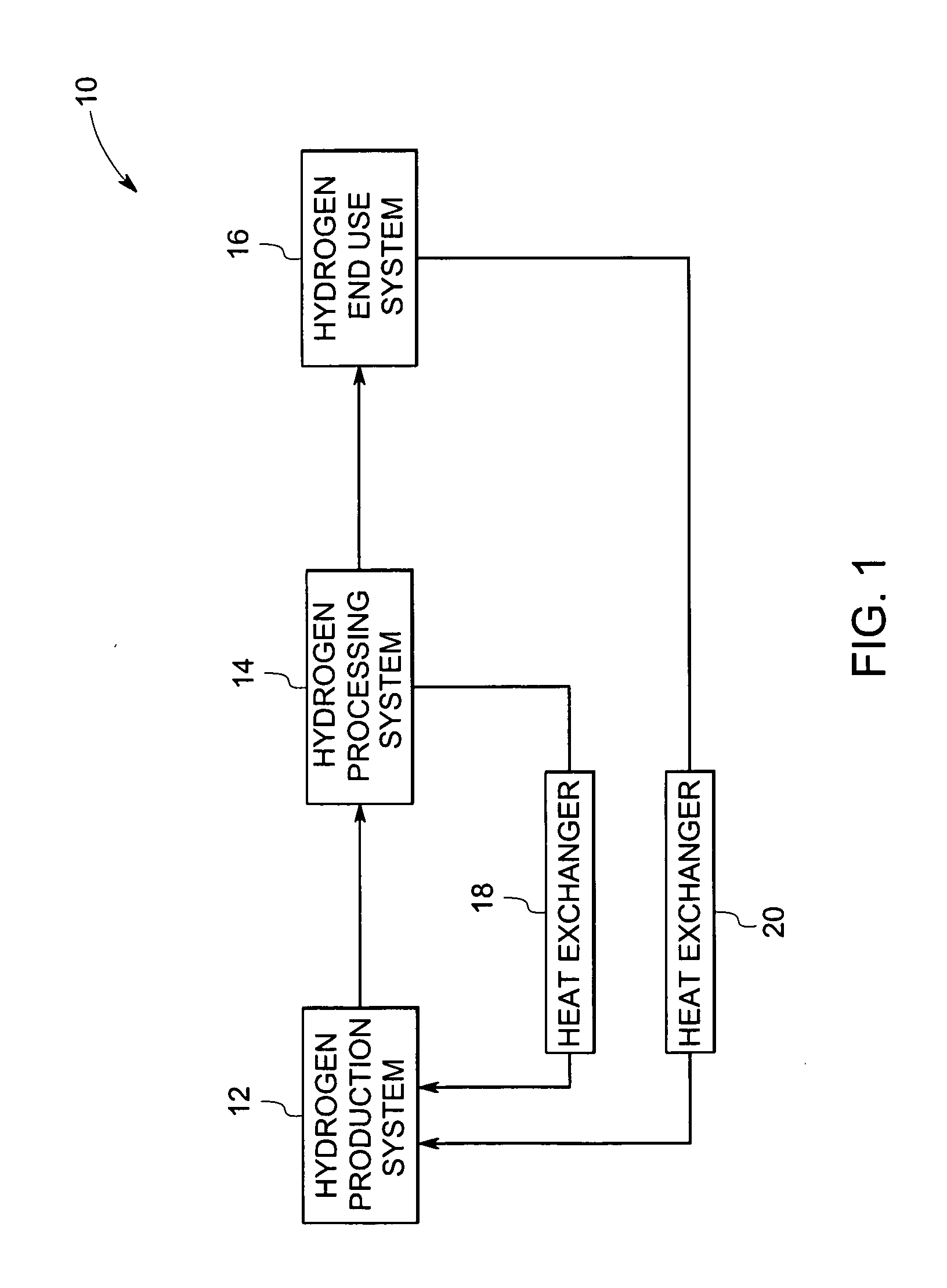

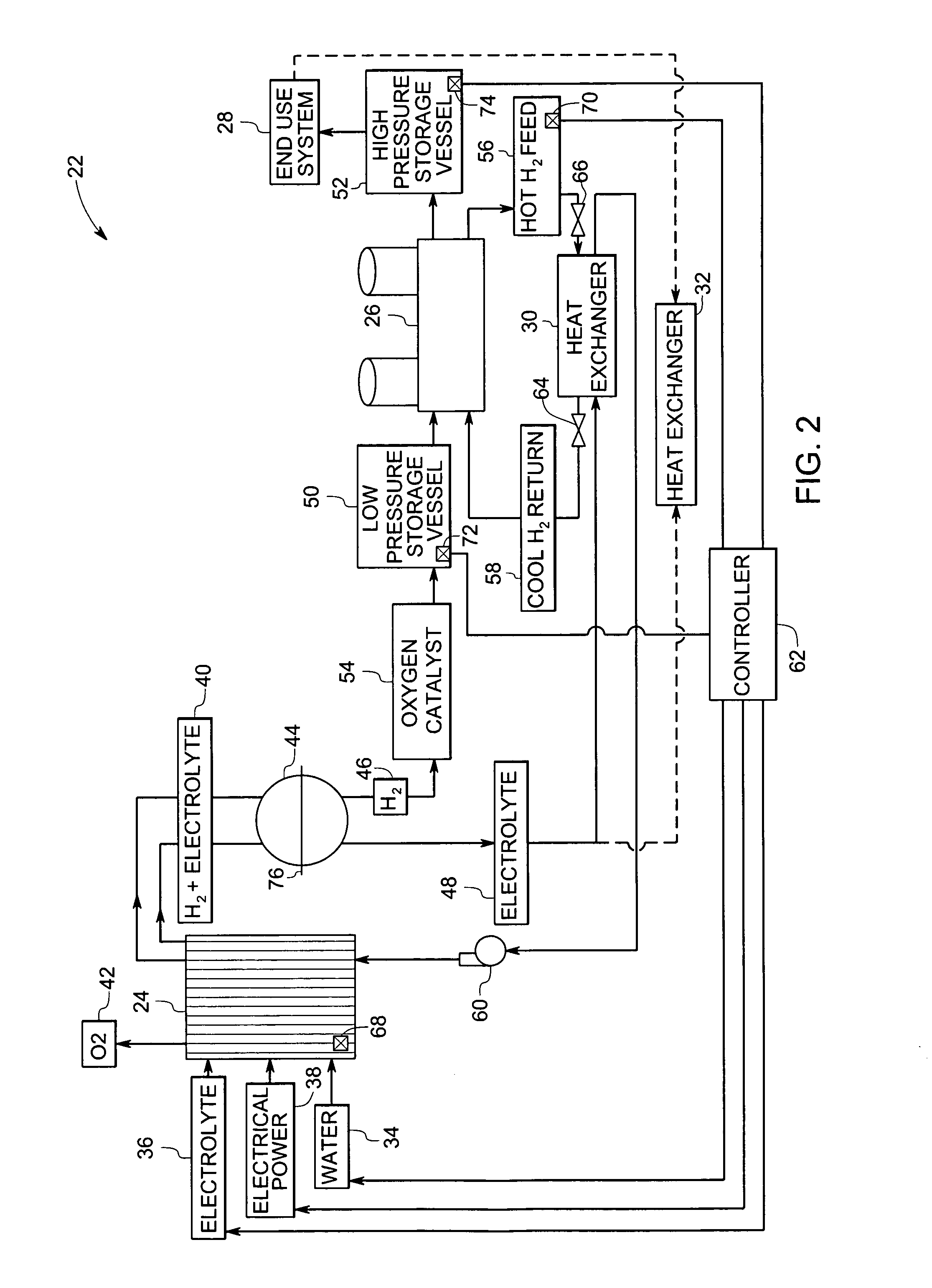

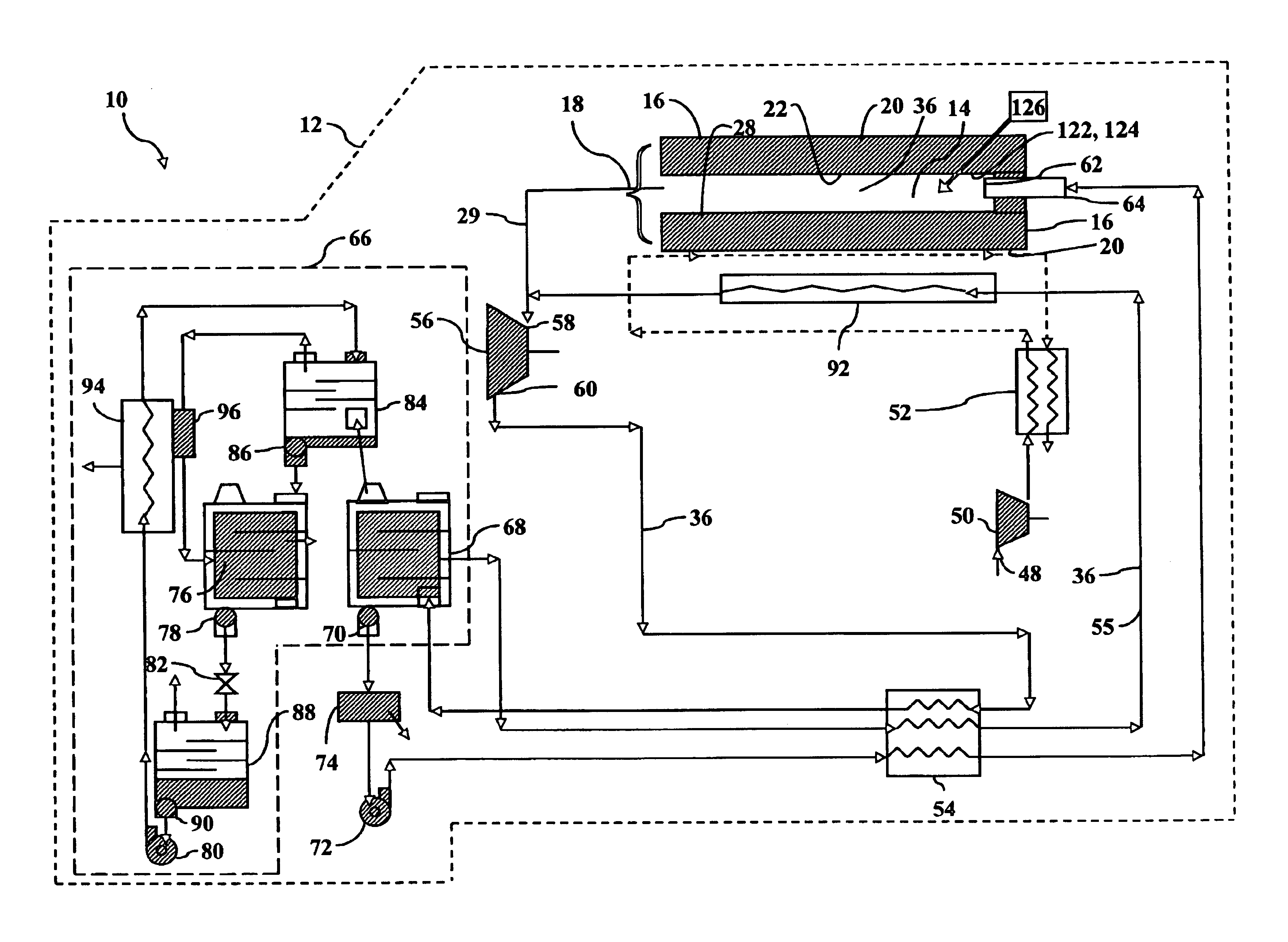

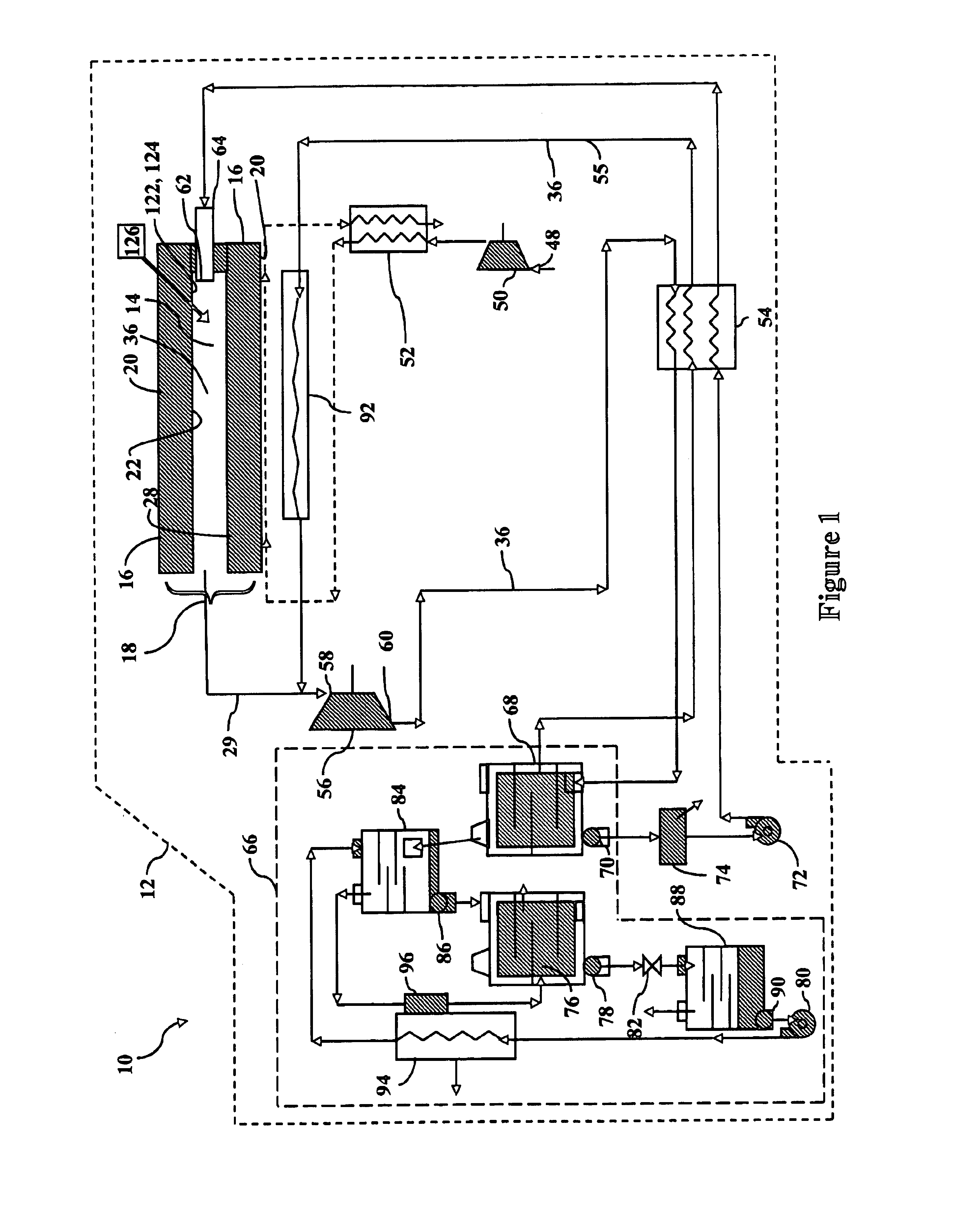

Integrated hydrogen production and processing system and method of operation

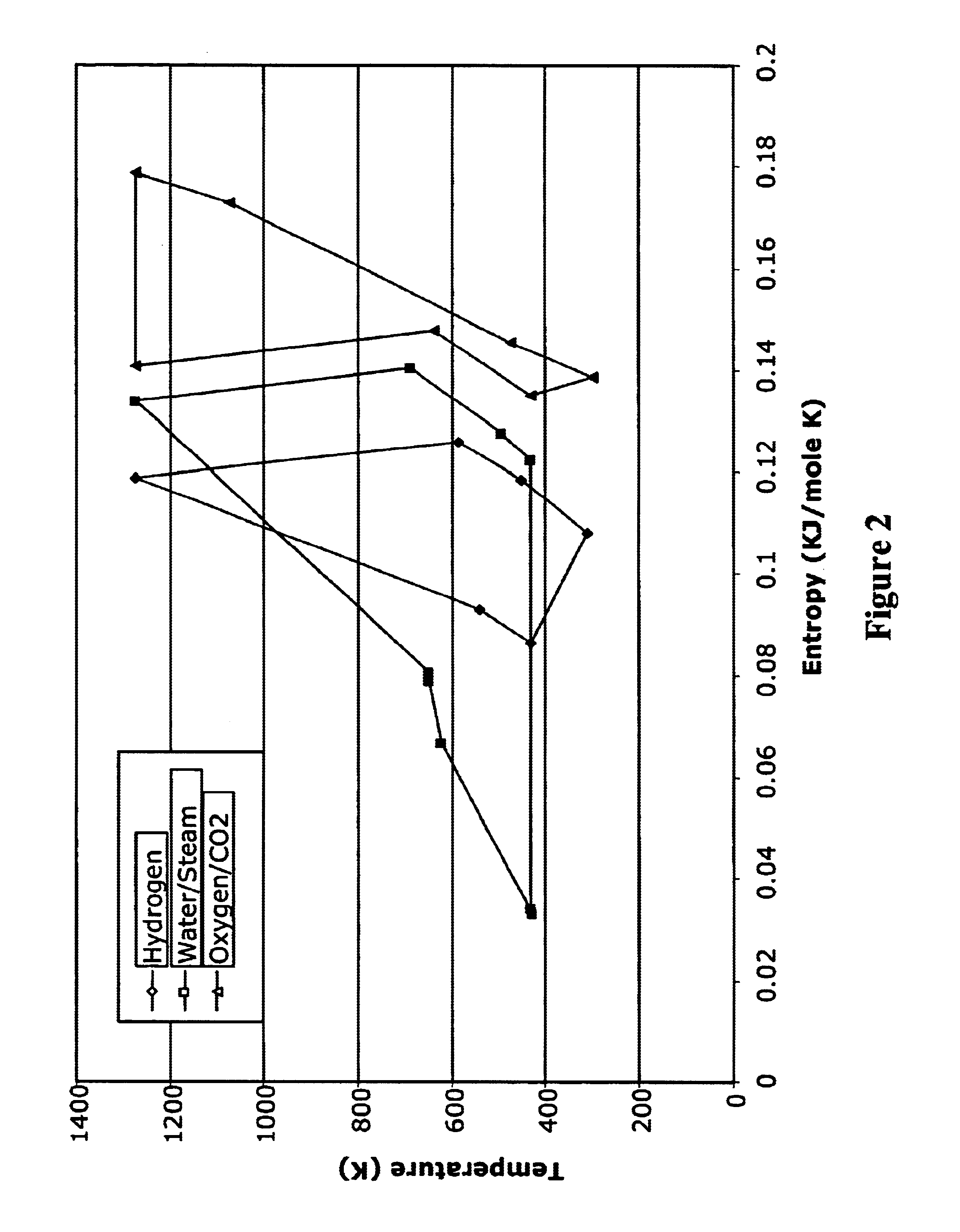

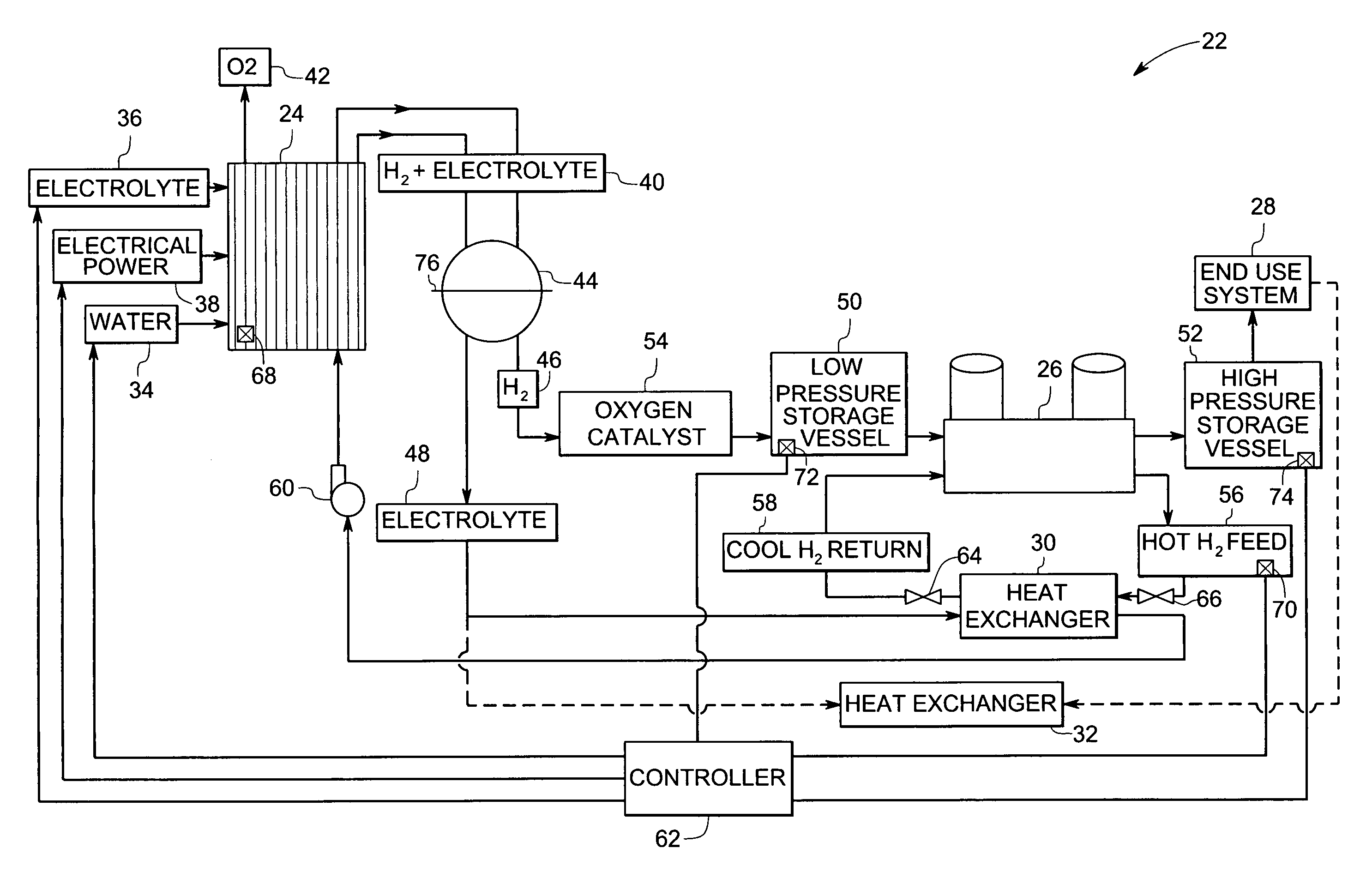

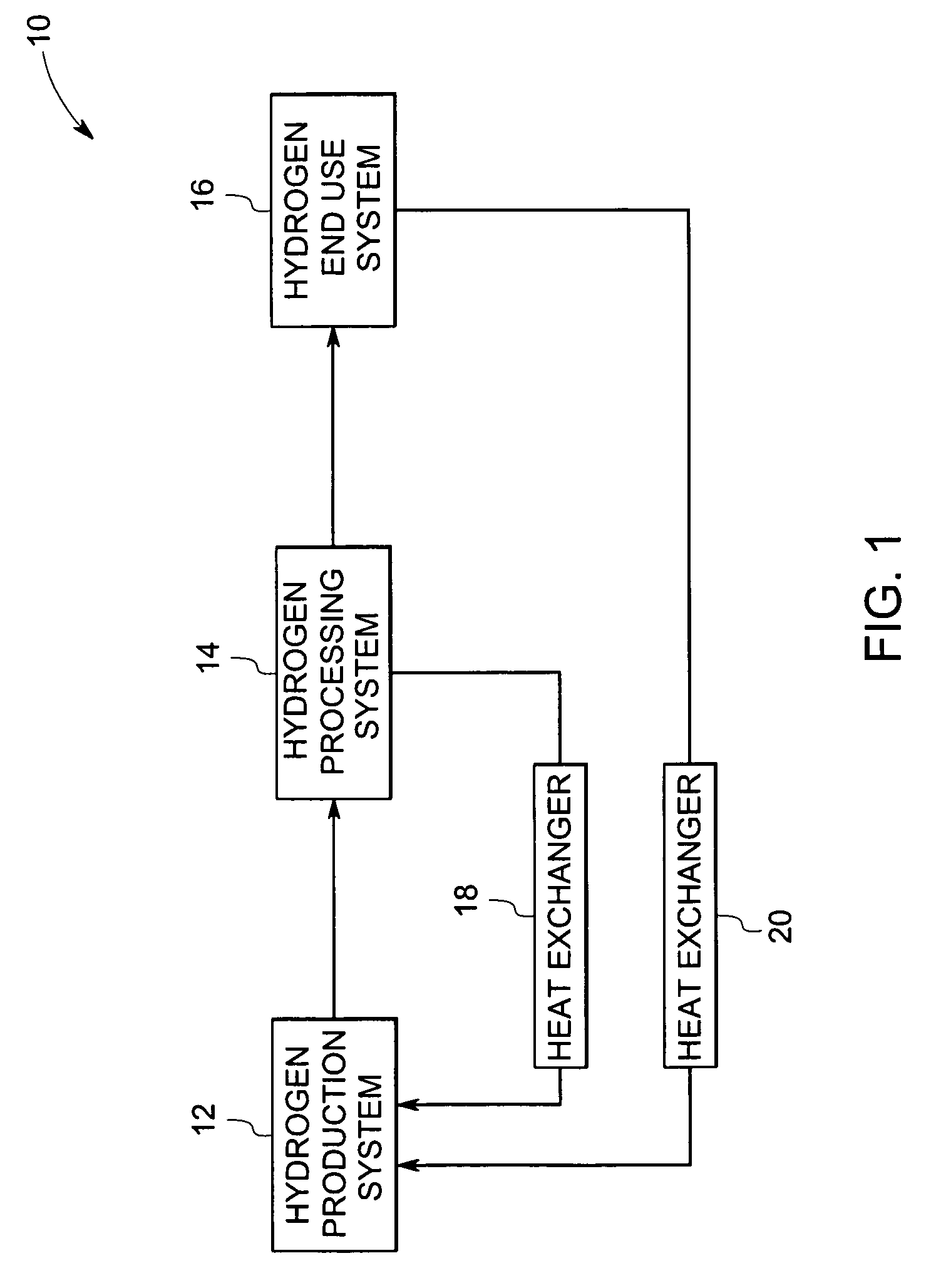

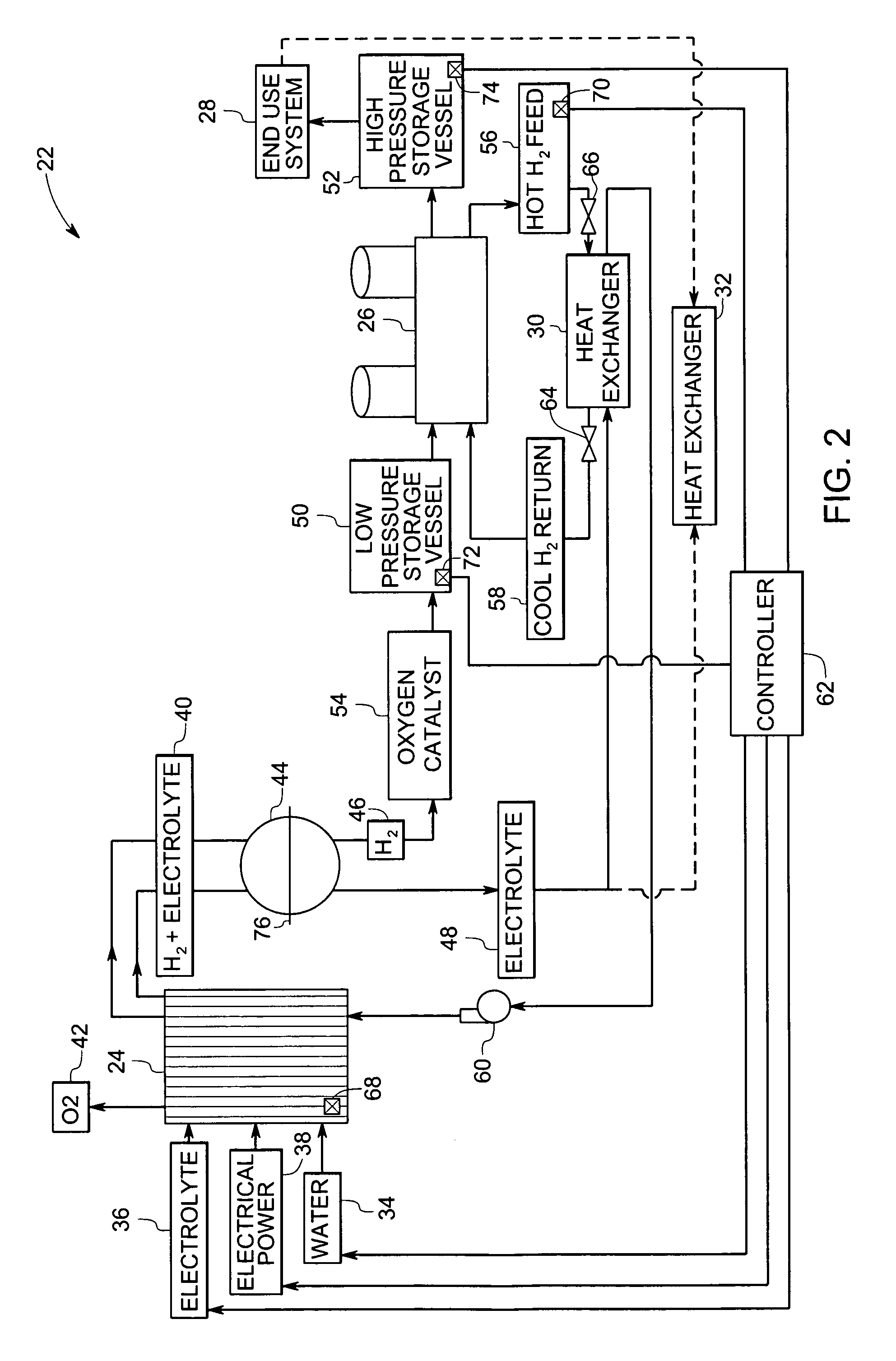

InactiveUS20070000789A1Increase temperatureCellsPhotography auxillary processesElectrolysisProcess engineering

A method of operating an integrated hydrogen production and processing system is provided. The method includes operating an electrolyzer to produce hydrogen from water and utilizing heat generated from the electrolyzer to increase a temperature of an electrolyte in a first mode of operation. The method also includes heating the electrolyte in a second mode of operation by extracting heat from a hydrogen compressor to increase or maintain the temperature of the electrolyte during periods when electrolysis is not performed in the electrolyzer or during startup of the electrolyzer.

Owner:GENERAL ELECTRIC CO

Start-up method for ex-situ prevulcanization secondary activity center hydrogenation catalyst

ActiveCN103773436AChange processLess investmentHydrotreatment operations starting-upHydrocarbon oil crackingNaphthaEngineering

The invention discloses a start-up method for an ex-situ prevulcanization secondary activity center hydrogenation catalyst. After resistance to air loss of a device is qualified, circulating hydrogen compressor working load is adjusted to 0-20% of a maximum load, the catalyst reacts at a low temperature to release heat; when the bed layer temperature rise to 60-150 DEG C, start-up activation oil is introduced, the circulating hydrogen compressor working load is adjusted to 60-100% of the maximum load for wetting of the catalyst; the start-up activation oil is cycled in a reaction system closed path, the catalyst bed temperature is risen to 180 to 230 DEG C by heat exchange; a proper amount of olefin-enriched naphtha is added into the start-up activation oil, the catalyst bed temperature is risen to 300-380 DEG C to complete start-up activation. The start-up method, in the premise of no influence on the use properties of the secondary activity center hydrogenation catalyst, can better use the catalyst characteristics, reduce the device energy consumption, and reduce the device investment cost, and the start-up process can be simplified.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid-solid two-phase hydrogenation method for hydrocarbon oil

The invention discloses a method of hydrocarbon oil liquid-solid two-phase hydrogenation; the method avoids the recycle hydrogen and the recycle hydrogen compressor; hydrogen is mixed with fresh raw oil and a part of recycle oil under the existence of solvent or diluent; after the gas is separated in the mixer, the mixture is fed into the reactor and is contacted with the catalyst for reaction after the gas is separated on top of the reactor; the other part of the recycle oil is mixed with hydrogen and solvent or diluent and the gas is separated; the mixture is all or partially fed into the bed of the catalyst; the effluent of the reaction is discharged from the bottom of the reactor for separation; the separated solvent or the diluent is used for recycle use; the liquid product is used as the product or the recycle oil; the solubility of hydrogen in solvent or diluent is more than the solubility of hydrogen in the mixture of fresh raw oil and solvent or diluent.

Owner:CHINA PETROCHEMICAL CORP +1

Combusting hydrocarbons excluding nitrogen using mixed conductor and metal hydride compressor

InactiveUS6951111B2Control rateIncrease vapor pressureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberHydride compressor

Provided is a combustion engine having a combustion chamber. The combustion engine comprises an engine housing having an air intake port, a mixed conductor, a water intake port, an exhaust turbine and a hydrogen compressor assembly. The air intake port provides air to the mixed conductor which provides an oxygen-pure fraction of air to the combustion chamber by conducting oxygen ions in the air from a retentate side to a permeate side when the oxygen partial pressure on the permeate side is less than that on the retentate side. The water intake port provides water to the combustion chamber for combustion with hydrocarbon fuel and the oxygen-pure fraction of the air to produce exhaust fluid. The exhaust fluid expands in the exhaust turbine causing the turbine rotor to rotate producing mechanical energy. The hydrogen compressor assembly extracts hydrogen from the exhaust fluid and provides hydrogen to the exhaust turbine.

Owner:CHENTEK

Integrated hydrogen production and processing system and method of operation

Owner:GENERAL ELECTRIC CO

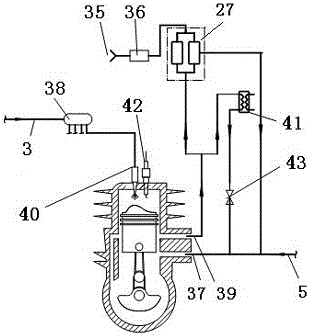

Hydrogen fuel car

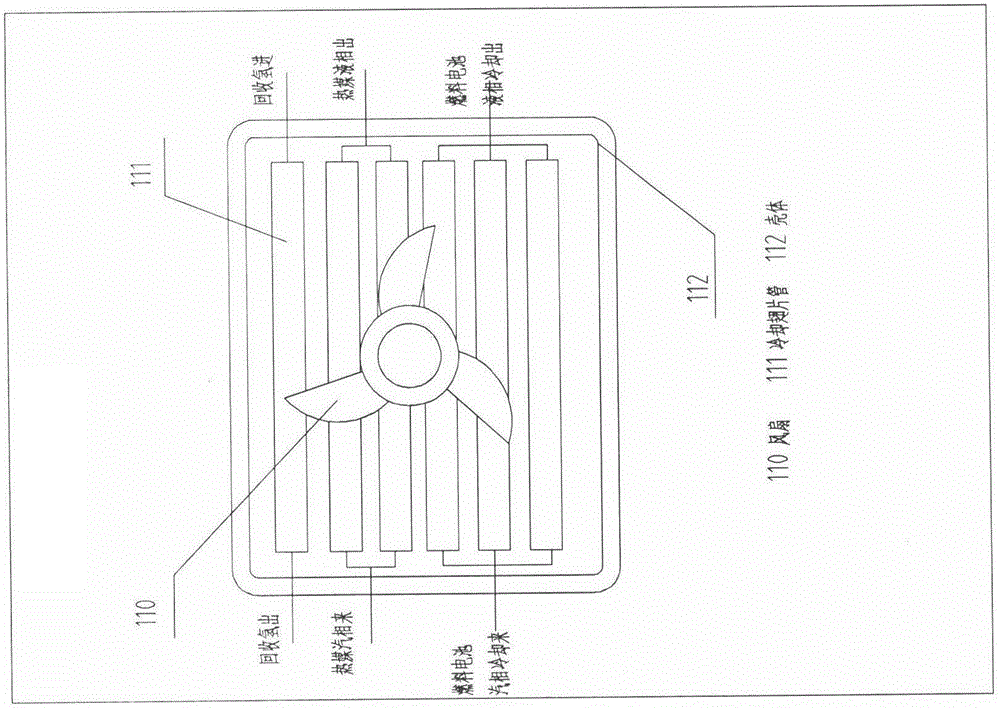

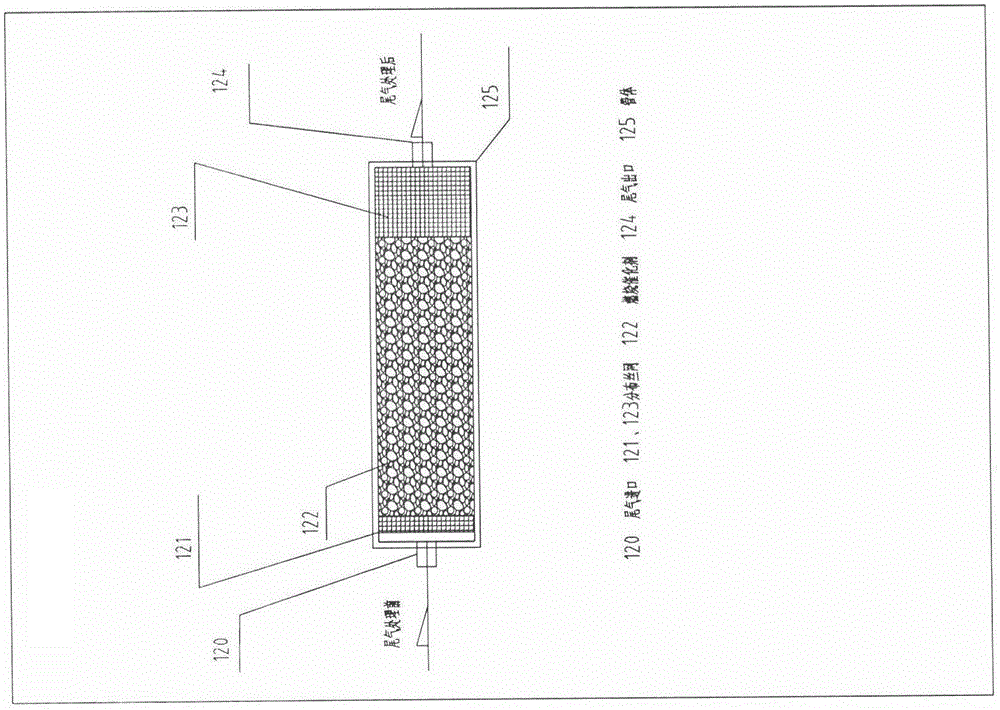

ActiveCN106541816AEasy to useHigh thermal efficiencyHybrid vehiclesInternal combustion piston enginesAir filterHydrogen fuel cell

The invention relates to a hydrogen fuel car. The hydrogen fuel car comprises a car body, wheels, a power generator, a battery group, a hub motor, a hydrogen storing unit, a hydrogen internal combustion engine, a hydrogen fuel battery and an exhaust gas concentrated heat exchange unit, wherein the hydrogen storing unit is provided with two hydrogen outlets, one hydrogen outlet is connected to the hydrogen internal combustion engine through the exhaust gas concentrated heat exchange unit, a hydrogen compressor and a hydrogen buffering tank, and the other hydrogen outlet is connected to the hydrogen fuel battery. An air inlet is connected to the hydrogen internal combustion engine and the hydrogen fuel battery through an air filter and the exhaust gas concentrated heat exchange unit, and an exhaust opening of the hydrogen internal combustion engine is connected to an exhaust gas emission opening through the exhaust gas concentrated heat exchange unit. The hydrogen internal combustion engine is connected with a shaft of the power generator, both the power generator and the hydrogen fuel battery are connected with a battery group circuit, and the battery group is connected with the hub motor. By utilizing the hydrogen internal combustion engine to drive the power generator to generate power and utilizing the hydrogen fuel battery to generate power and drive the car to run, no greenhouse gas is emitted in the whole process, the pollution of emitted gas to air is reduced, and the use performance and safety of the hydrogen fuel car are obviously improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

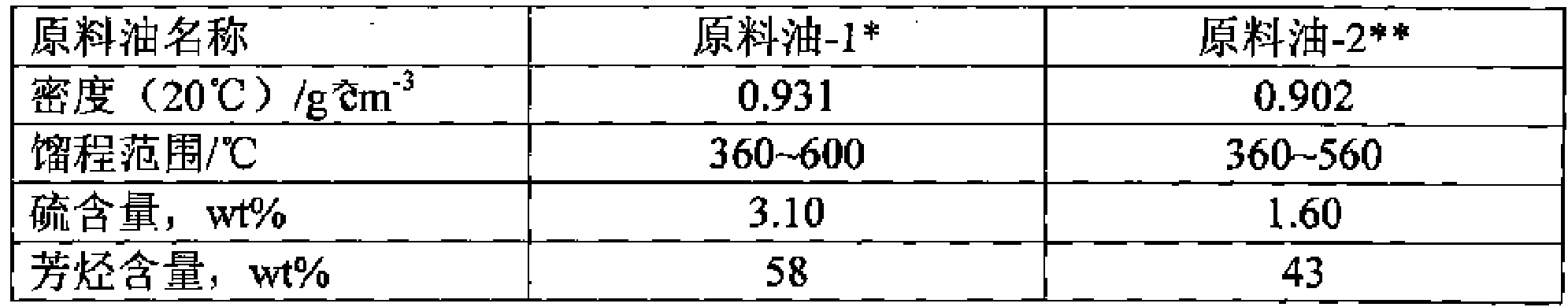

Heavy fraction oil hydrotreating method

ActiveCN101376841ATo achieve the effect of deep desulfurizationIncrease throughputTreatment with hydrotreatment processesHydrogenSulfur

The invention relates to a hydrotreatment method. Heavy diesel fractions are used as material oil; under the hydrotreatment conditions, the material oil and hydrogen are mixed and pass through a first hydrotreatment reaction area; the oil generated by the hydrotreatment is separated in a high pressure separator; the gas obtained through separation is desulfurized; the liquid obtained through separation is mixed with the hydrogen after being desulfurized and pressurized by a circulated hydrogen compressor and then pass through a second hydrotreatment reaction area; the oil generated by the hydrotreatment is separated in the high pressure separator; the gas obtained through separation directly enters the first hydrotreatment reaction area; the liquid obtained through separation obtains a low-sulfur light oil product and a heavy oil product in a fractionating tower. Compared with the prior art, the method can effectively improve the hydrotreatment depth of the material oil; besides, the two hydrotreatment reaction areas only need one set of hydrogen circulating system; the device investment and the operation cost are low.

Owner:CHINA PETROLEUM & CHEM CORP +1

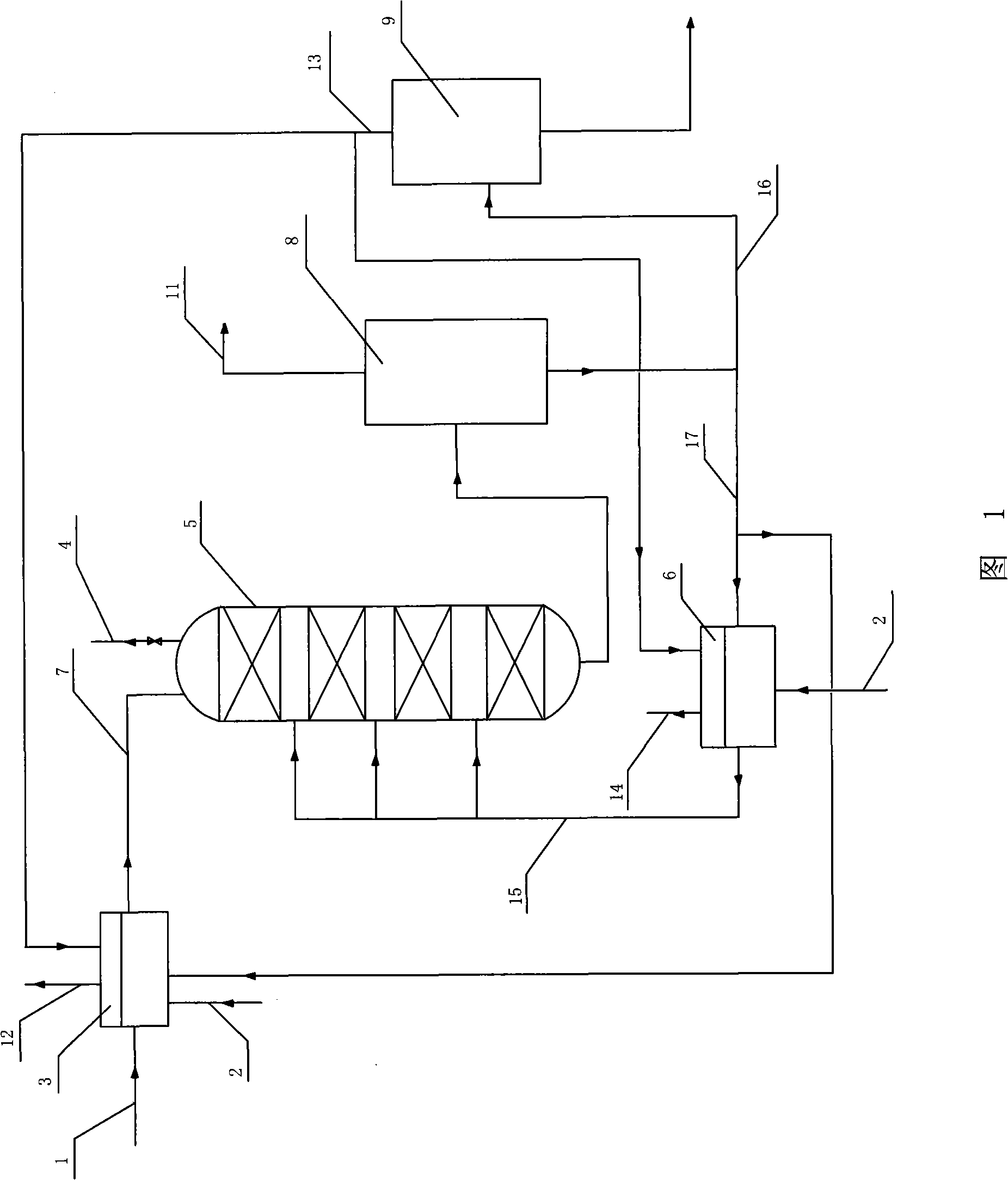

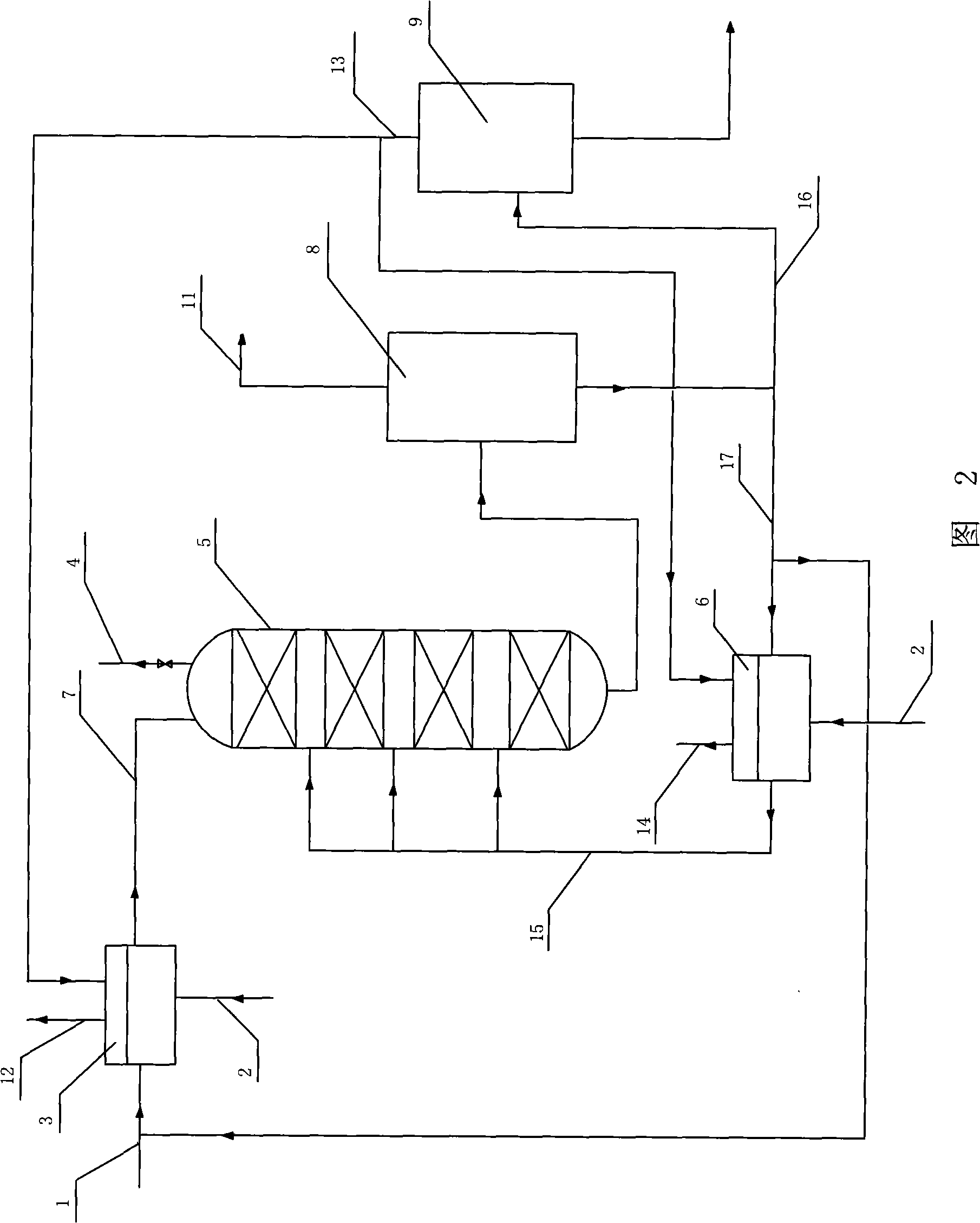

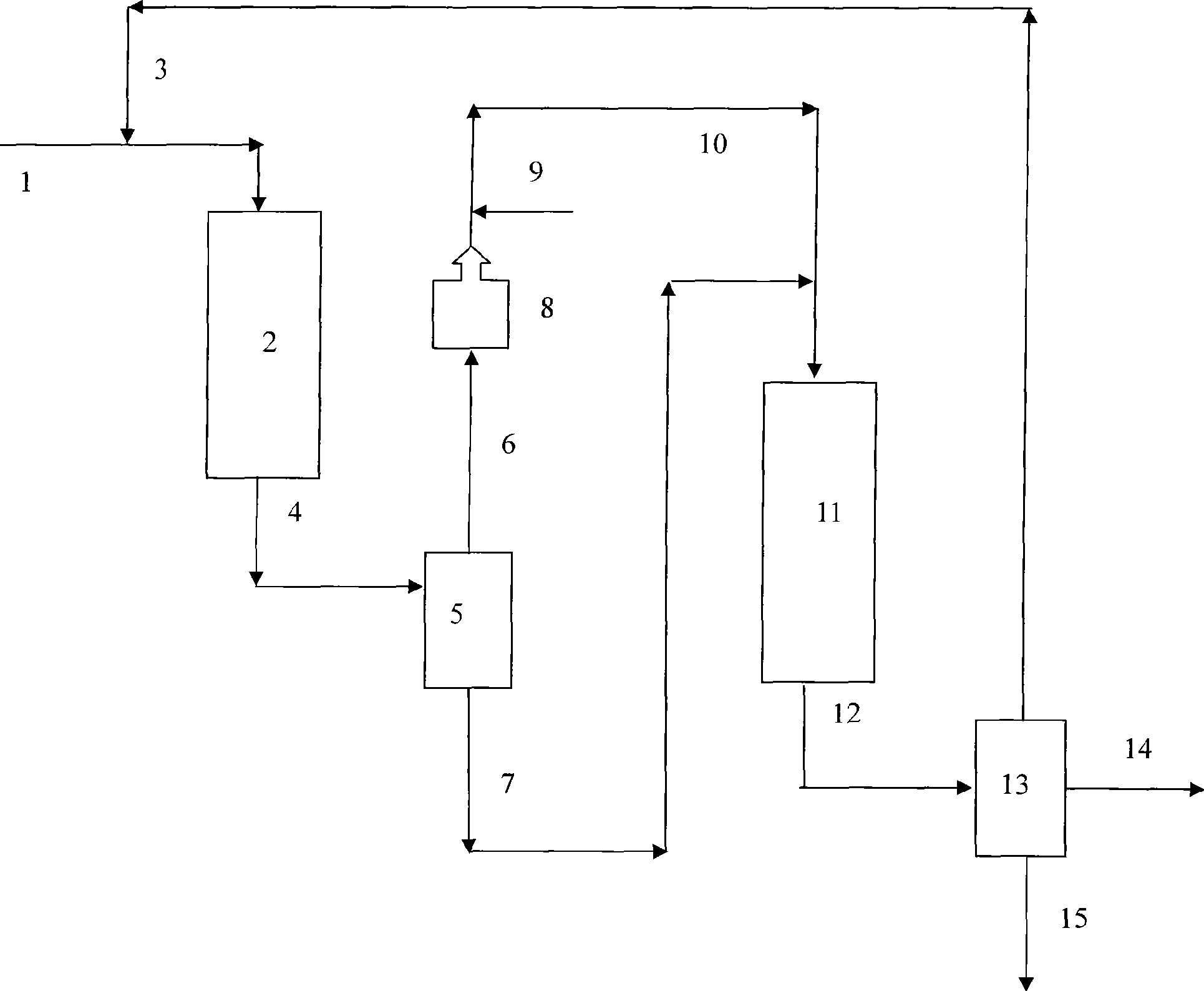

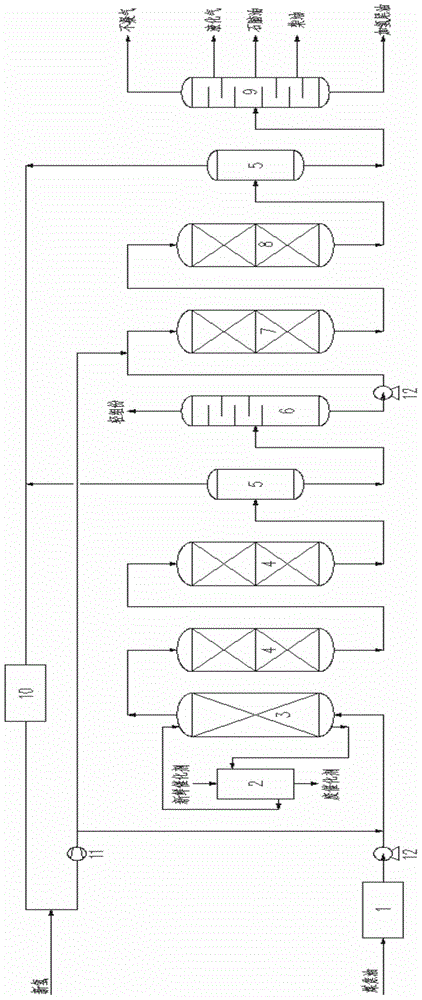

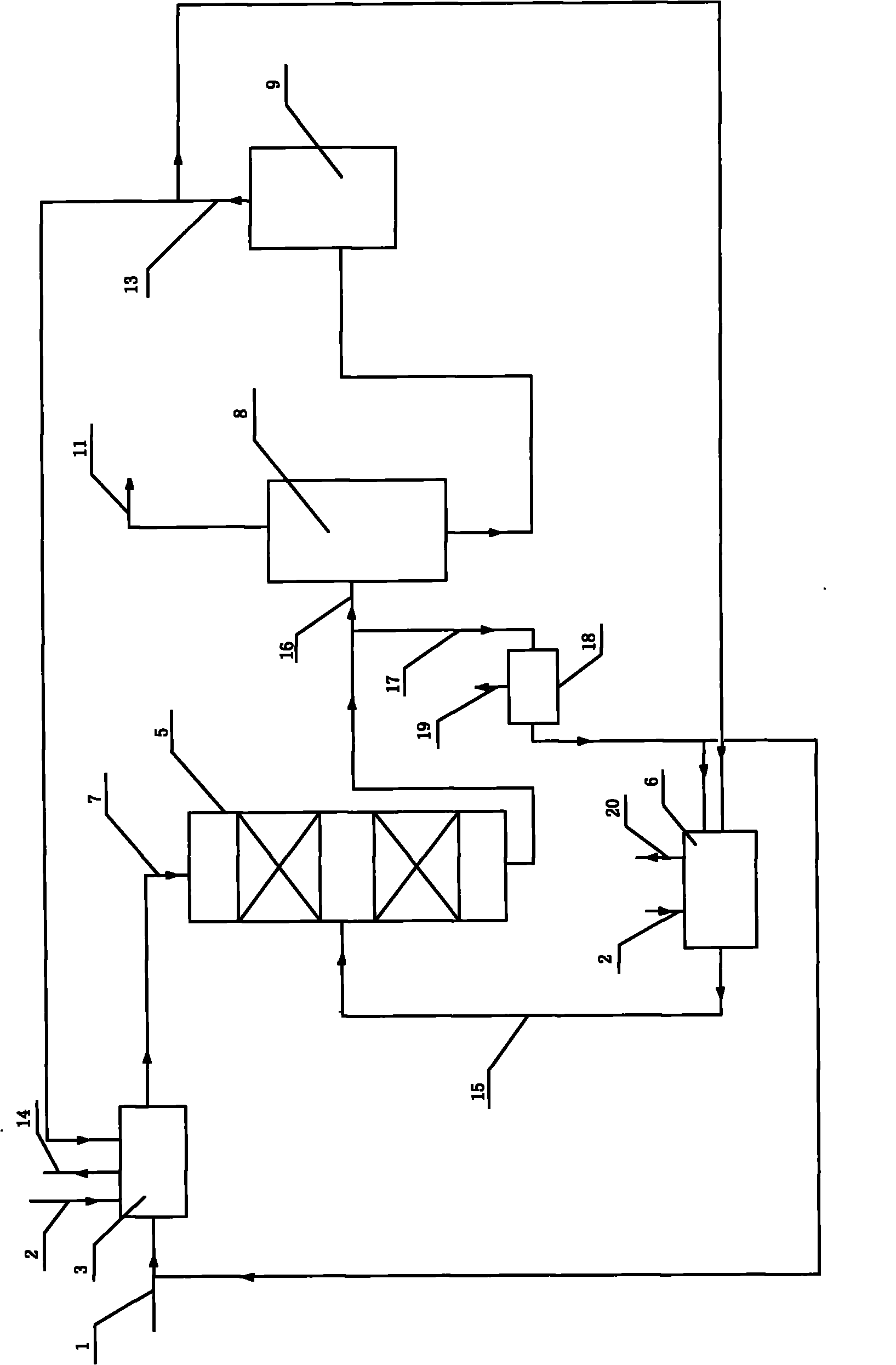

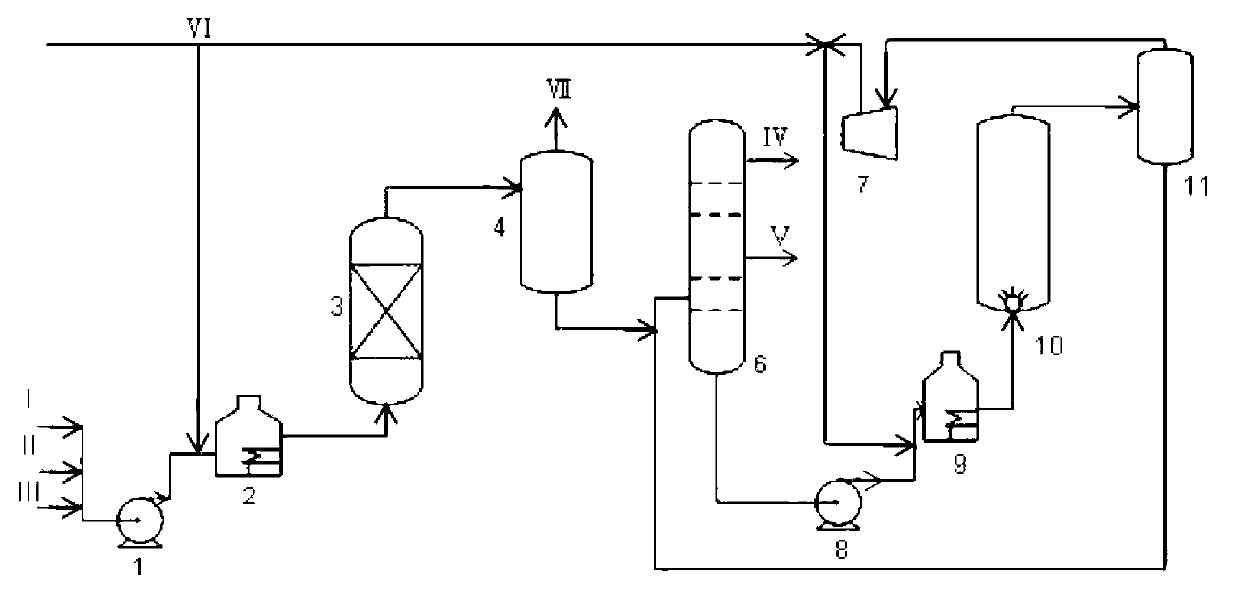

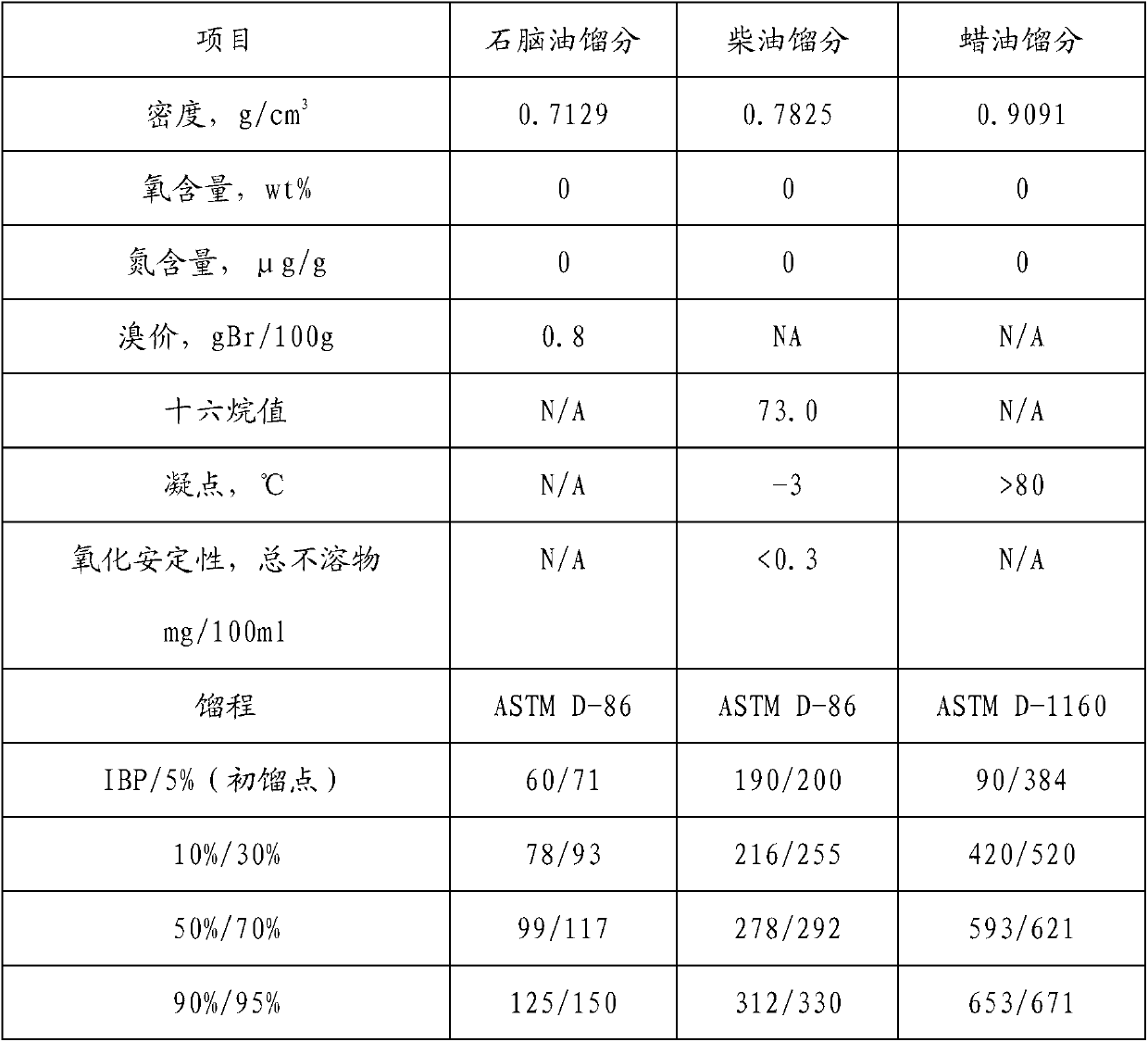

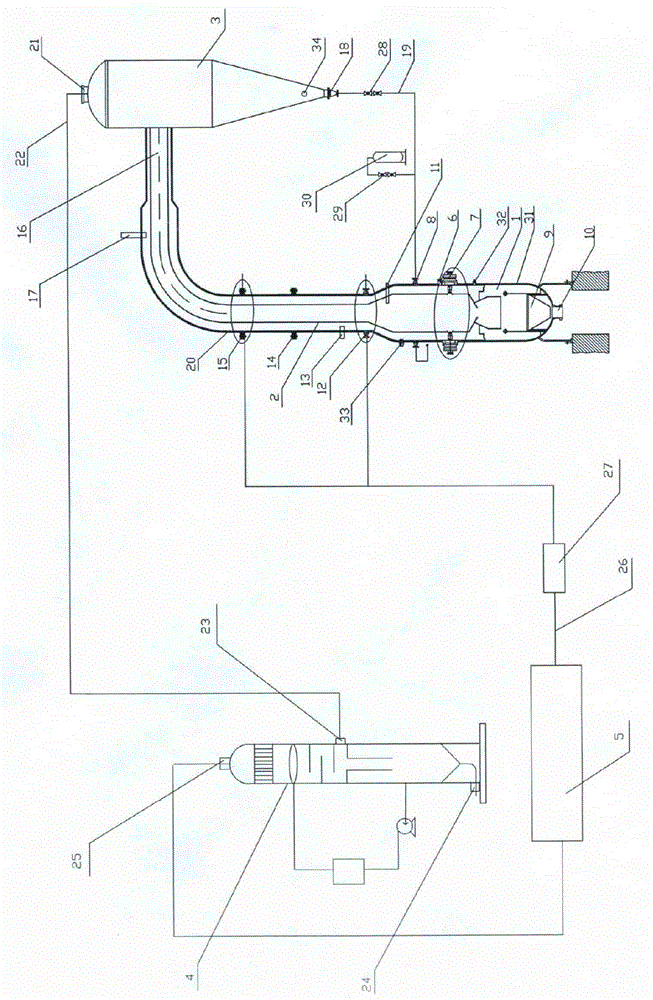

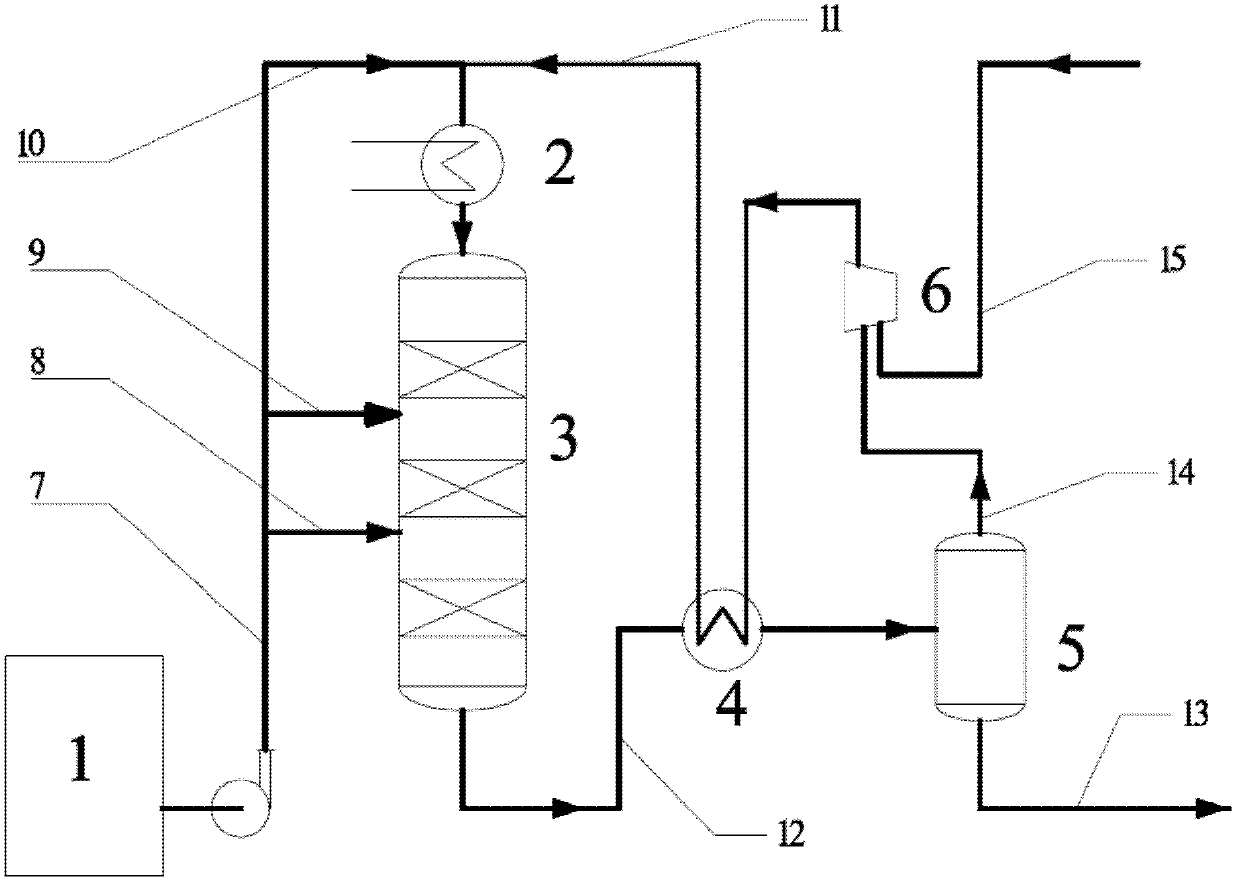

Combined coal tar whole fraction hydroprocessing system and application thereof

InactiveCN104862004AReduce the difficulty of separationTreatment with hydrotreatment processesFixed bedEngineering

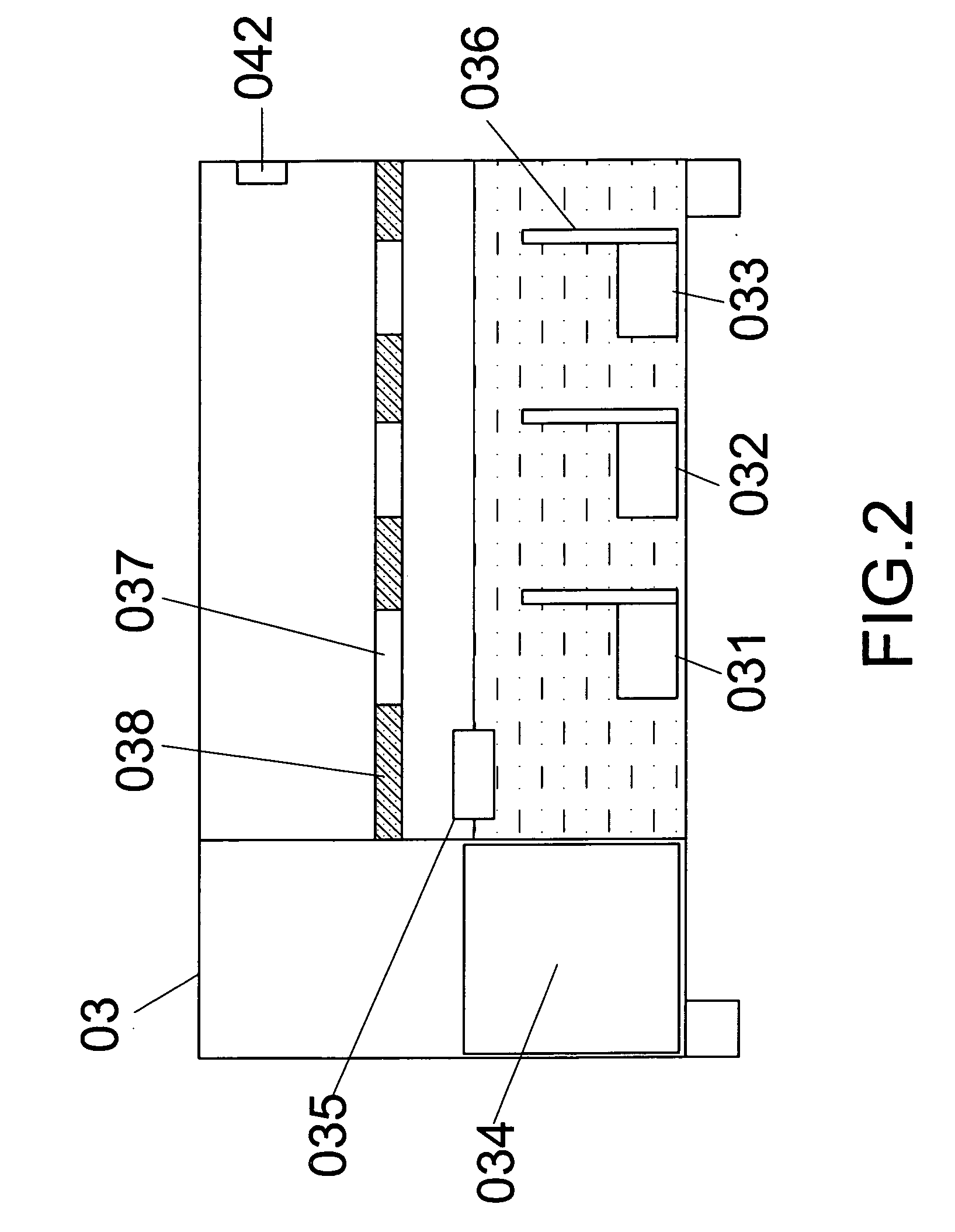

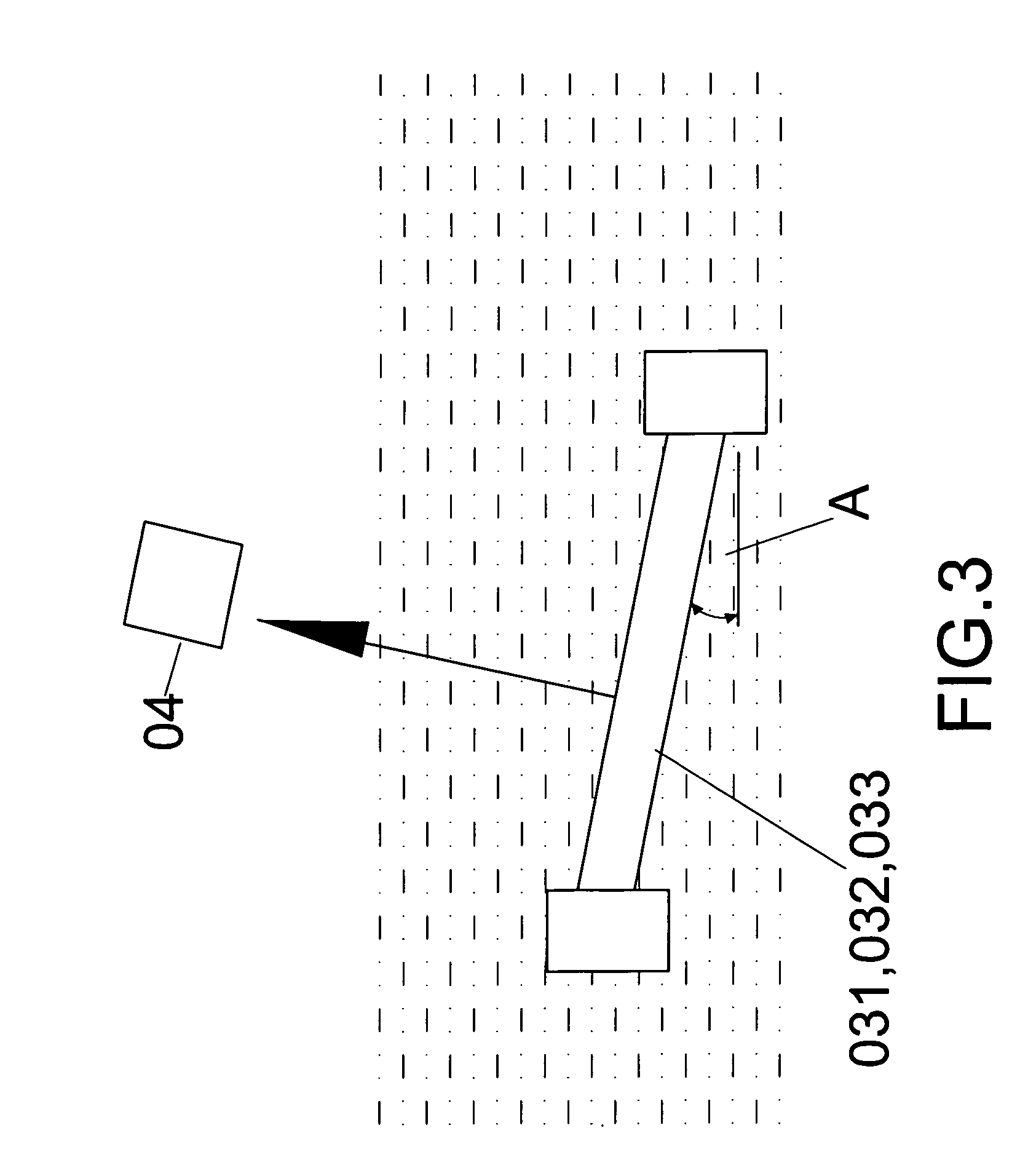

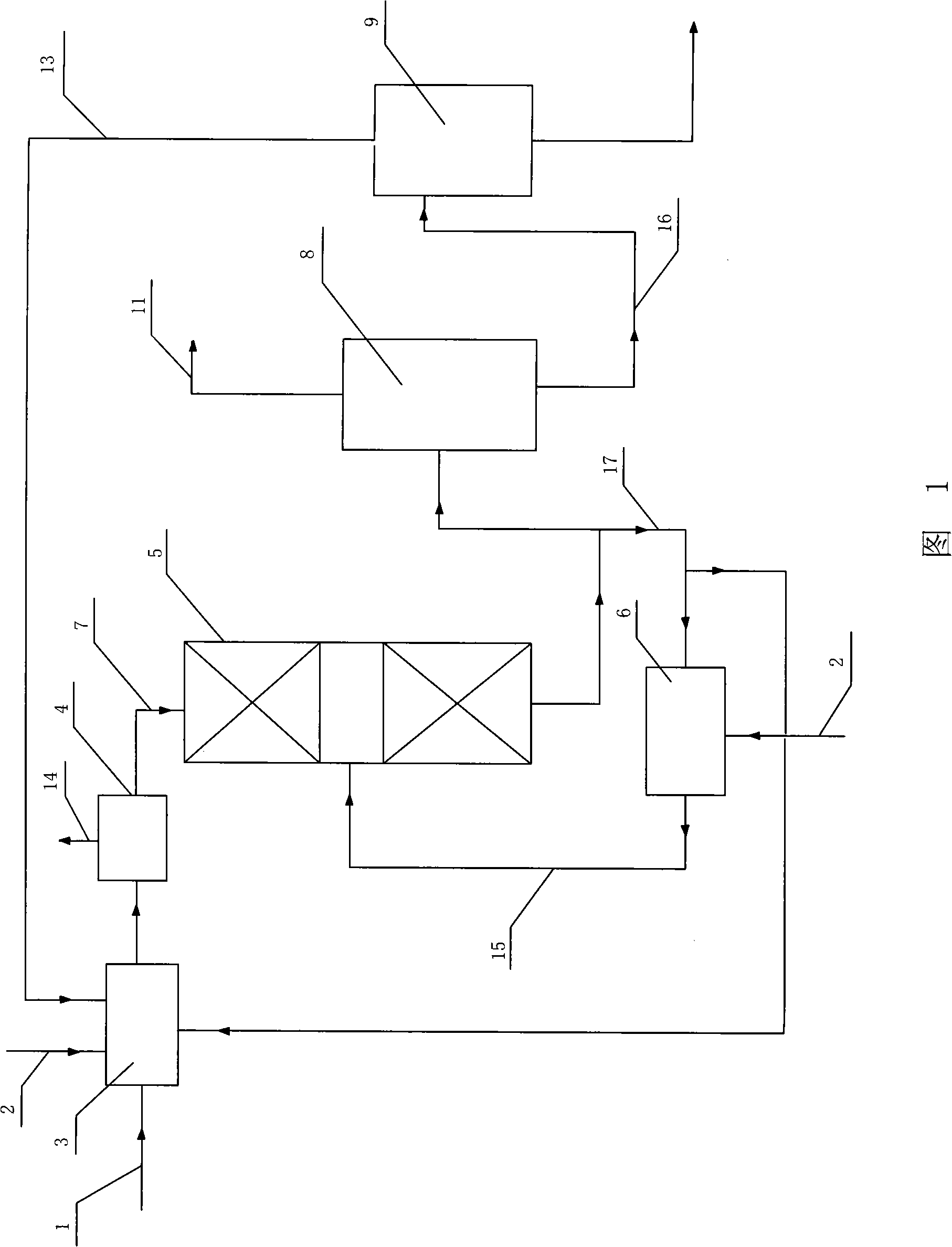

The invention relates to a combined coal tar whole fraction hydroprocessing system and an application thereof. The system comprises a desalination dehydration impurity-removing refining system 1 which is connected with a hydrogen compressor 11 and an up-flow moving bed hydrofining reactor 3 respectively through one hydrogenation feeding pump 12, the up-flow moving bed hydrofining reactor 3 is respectively connected with a catalyzer on-line feeding system 2 and two series connection fixed bed hydrofining reactors 4, the fixed bed hydrofining reactors 4 are connected with separators 5, the separators 5 are respectively connected with a hydrogen refining system 10 and a flash tower 6, the flash tower 6 is connected with a fixed bed hydrocracking reactor 7 through the other hydrogenation feeding pump 12 and then sequentially connected with a fixed bed hydrofining reactor 8, the separators 5 and a fractionating tower 9. Compared with combined coal tar whole fraction hydroprocessing systems in the prior art, the combined coal tar whole fraction hydroprocessing system has the advantages that the process is simpler, the conversion rate is higher, operation is stable, product properties are good, and the system can be used for production processes of excellent light fuels by poor raw materials such as various coal tar, shale oil and residual oil.

Owner:袁继海 +2

Hydrogen fuel supply system

Owner:WANG HSU YANG

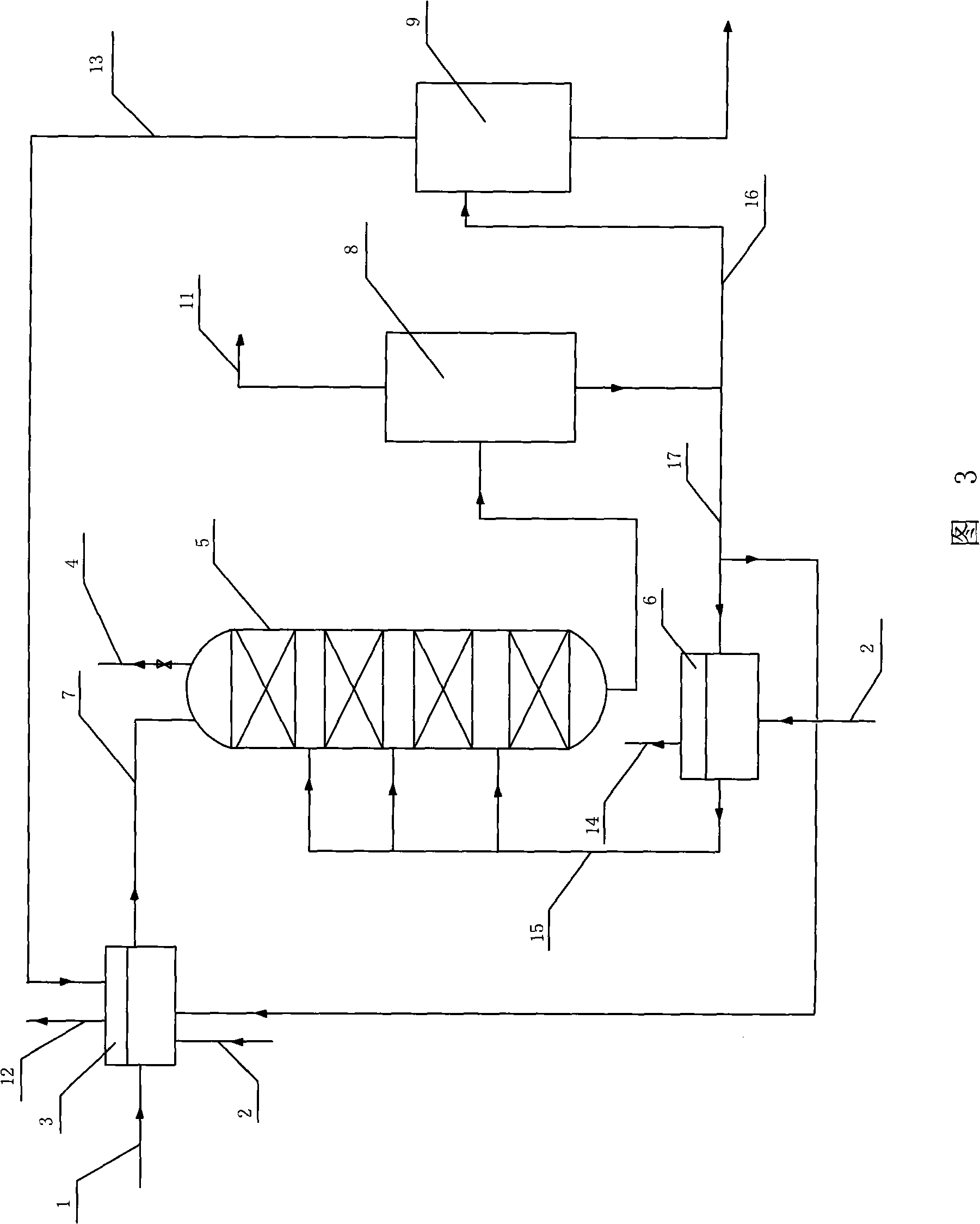

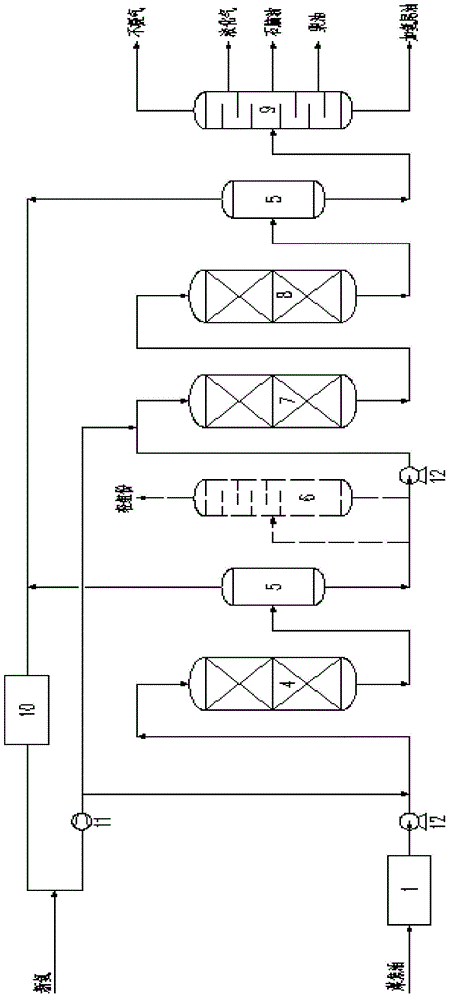

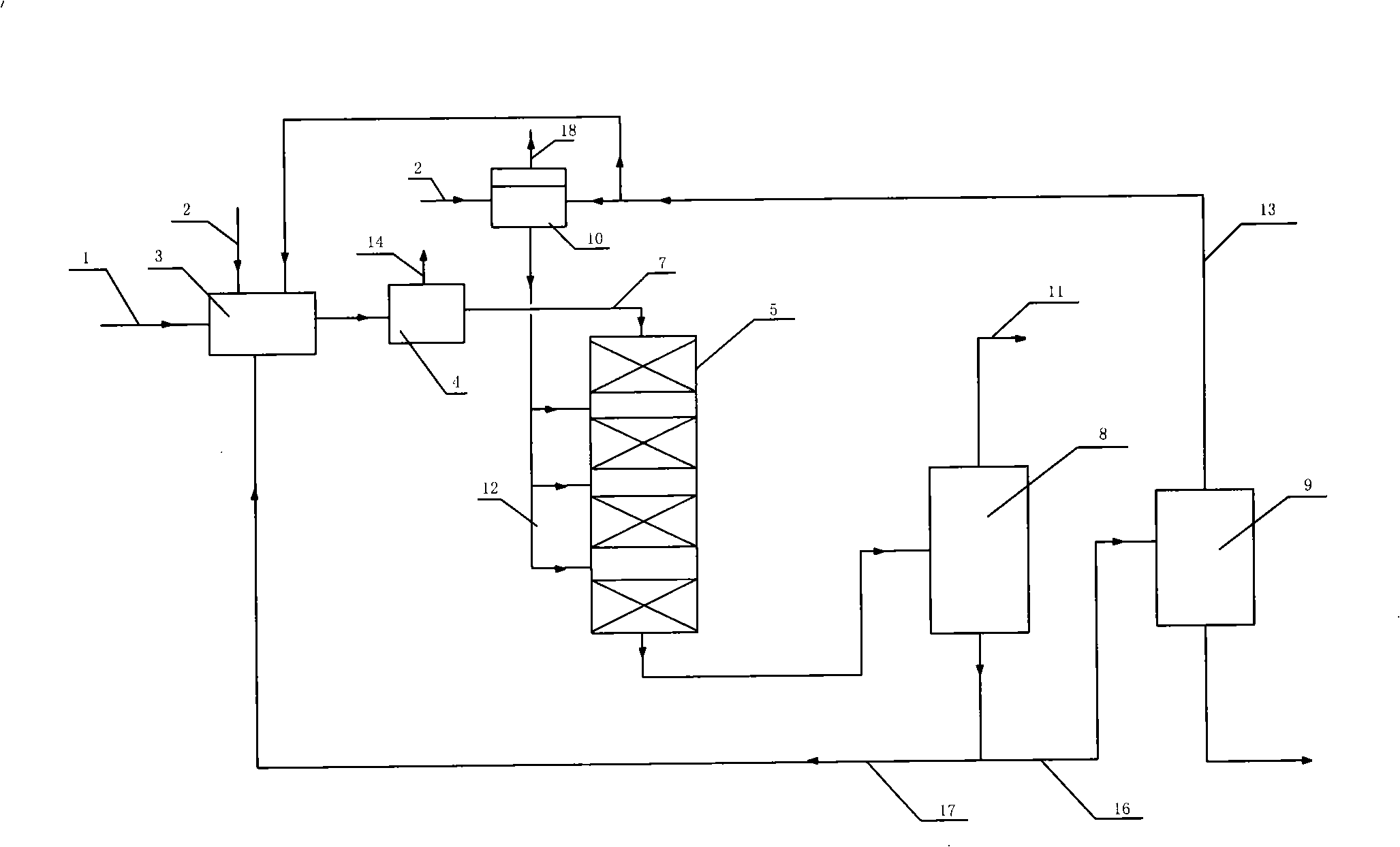

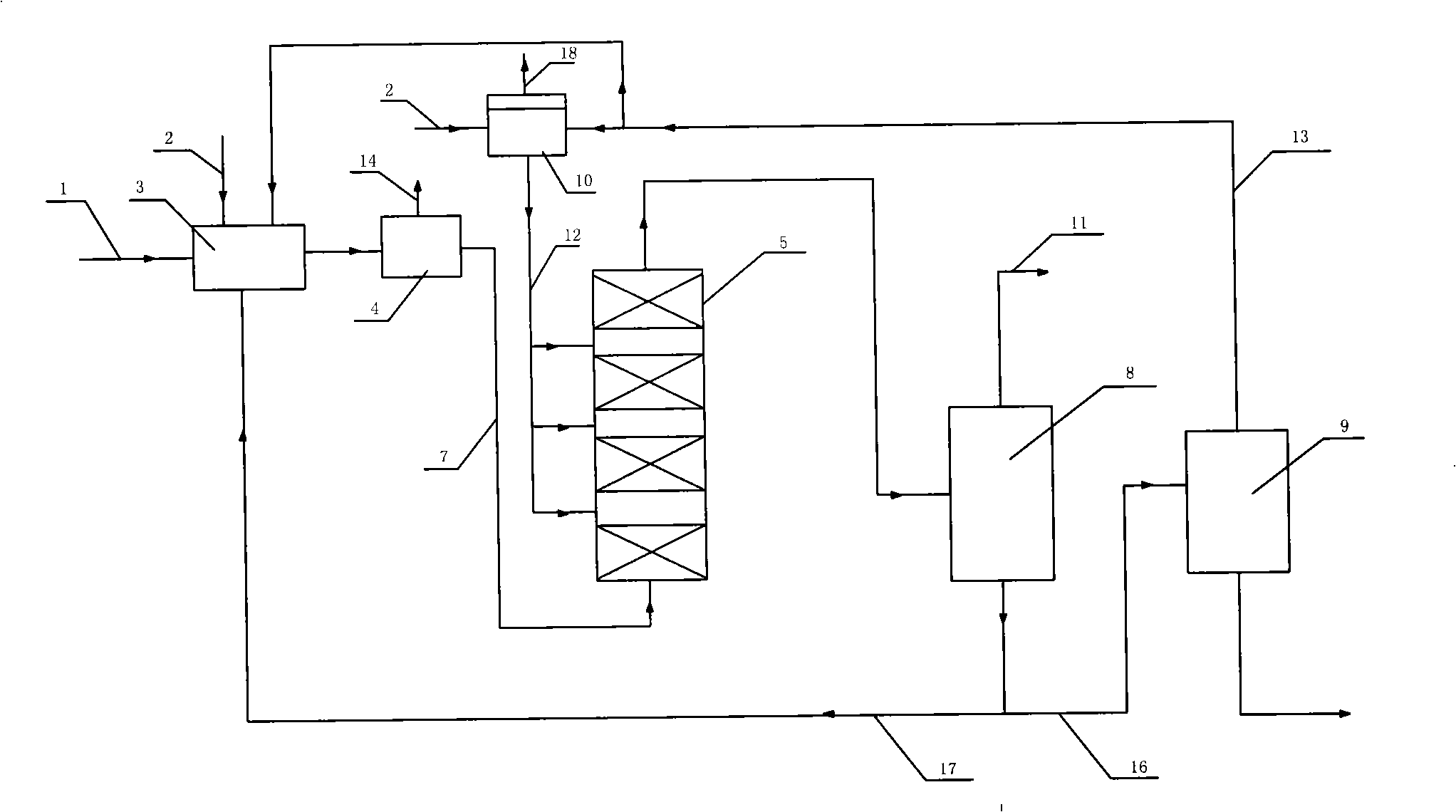

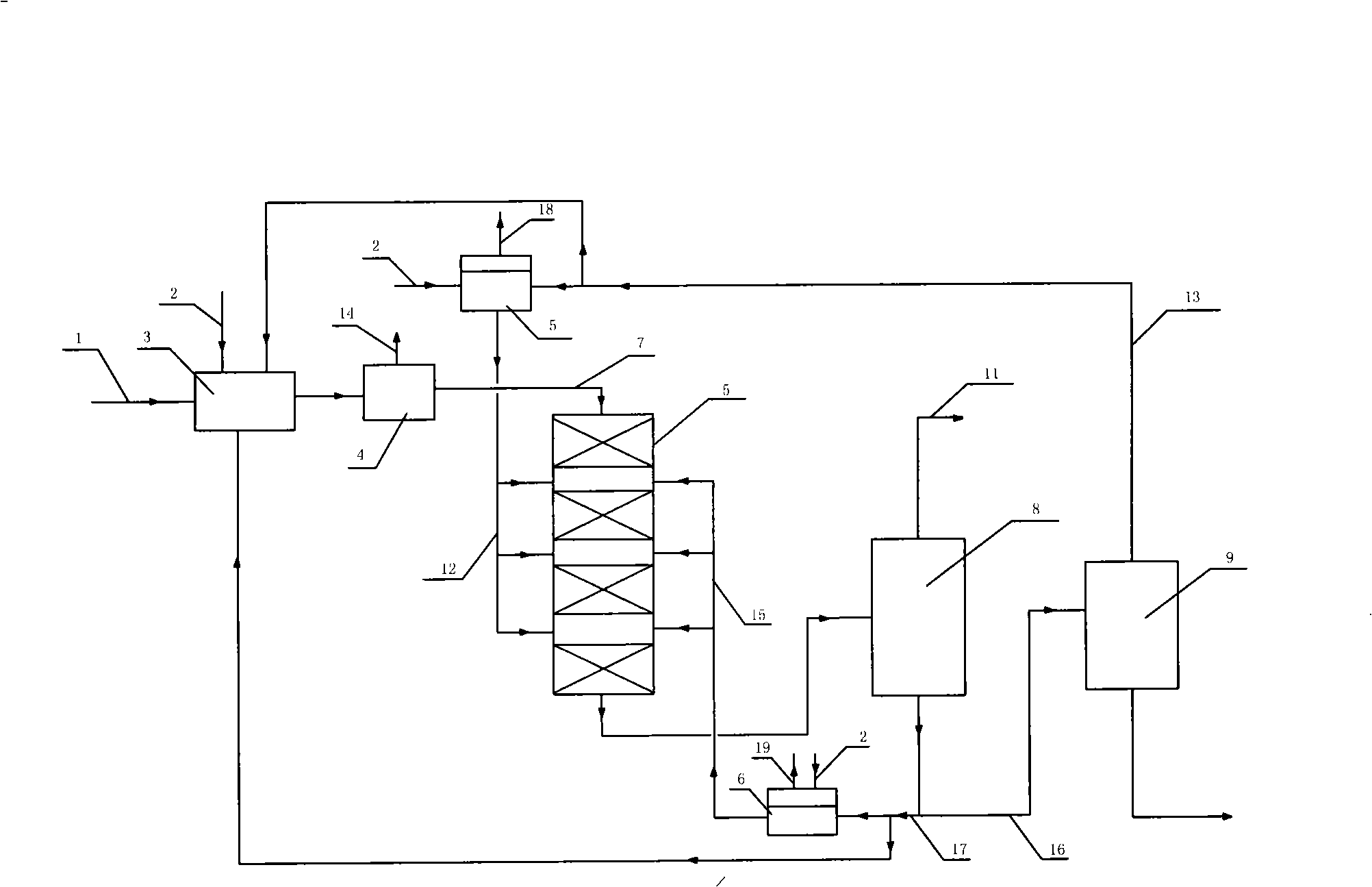

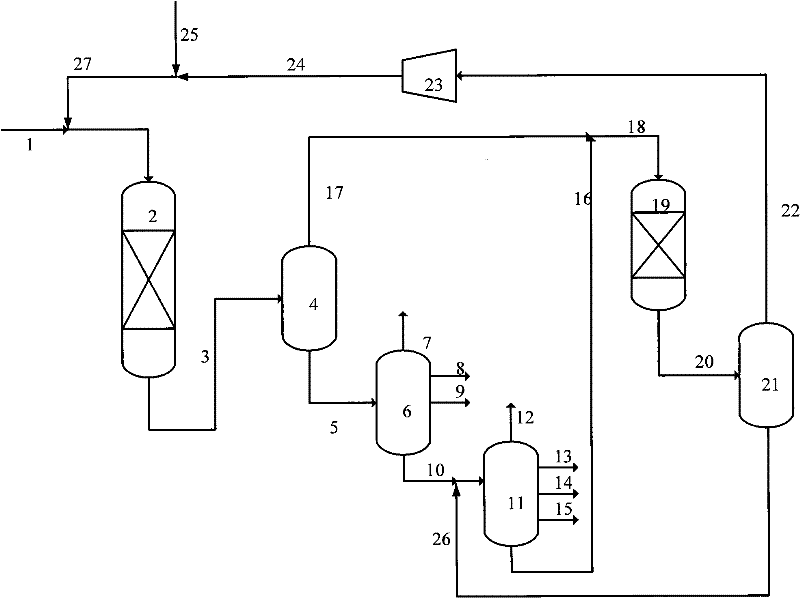

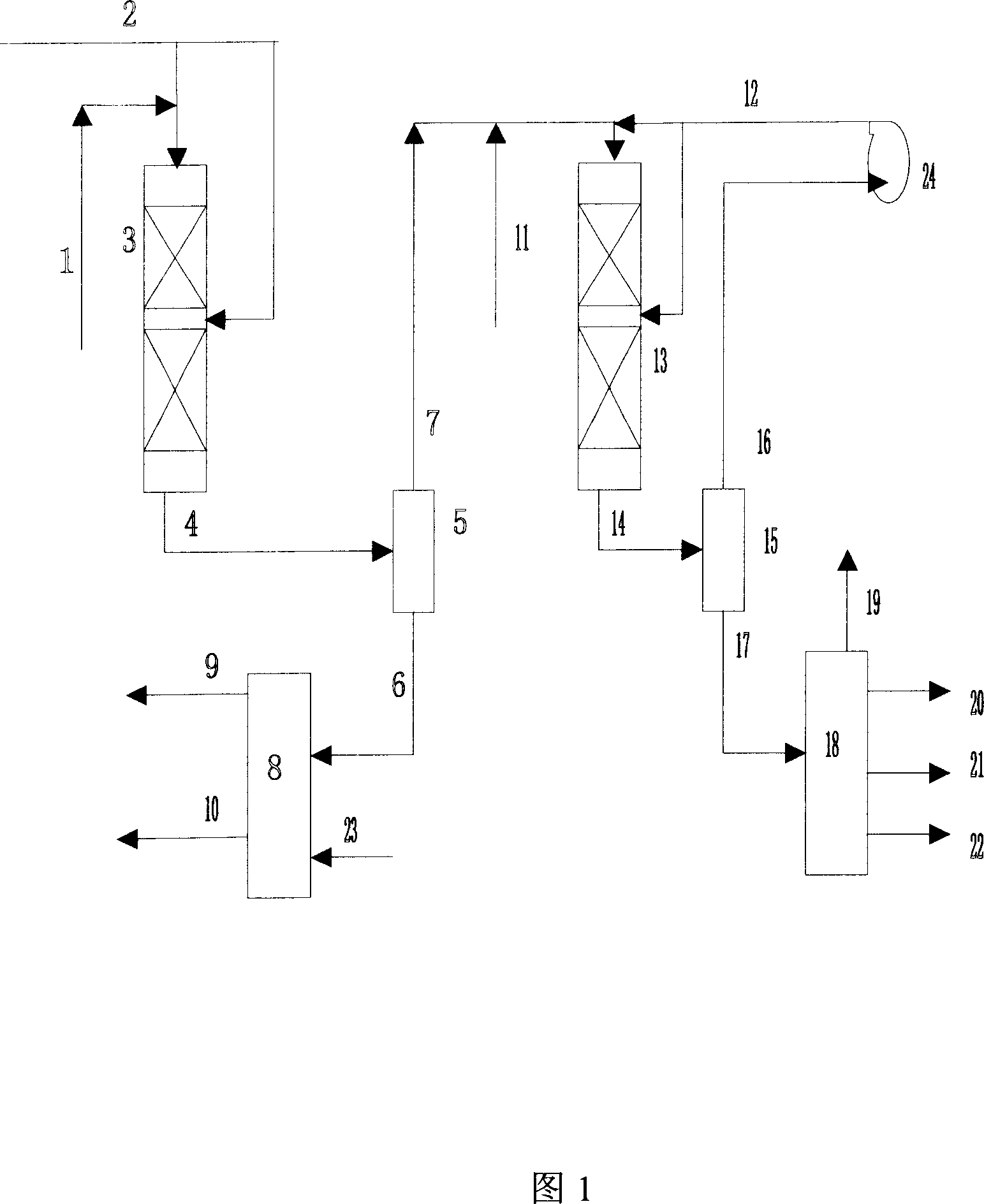

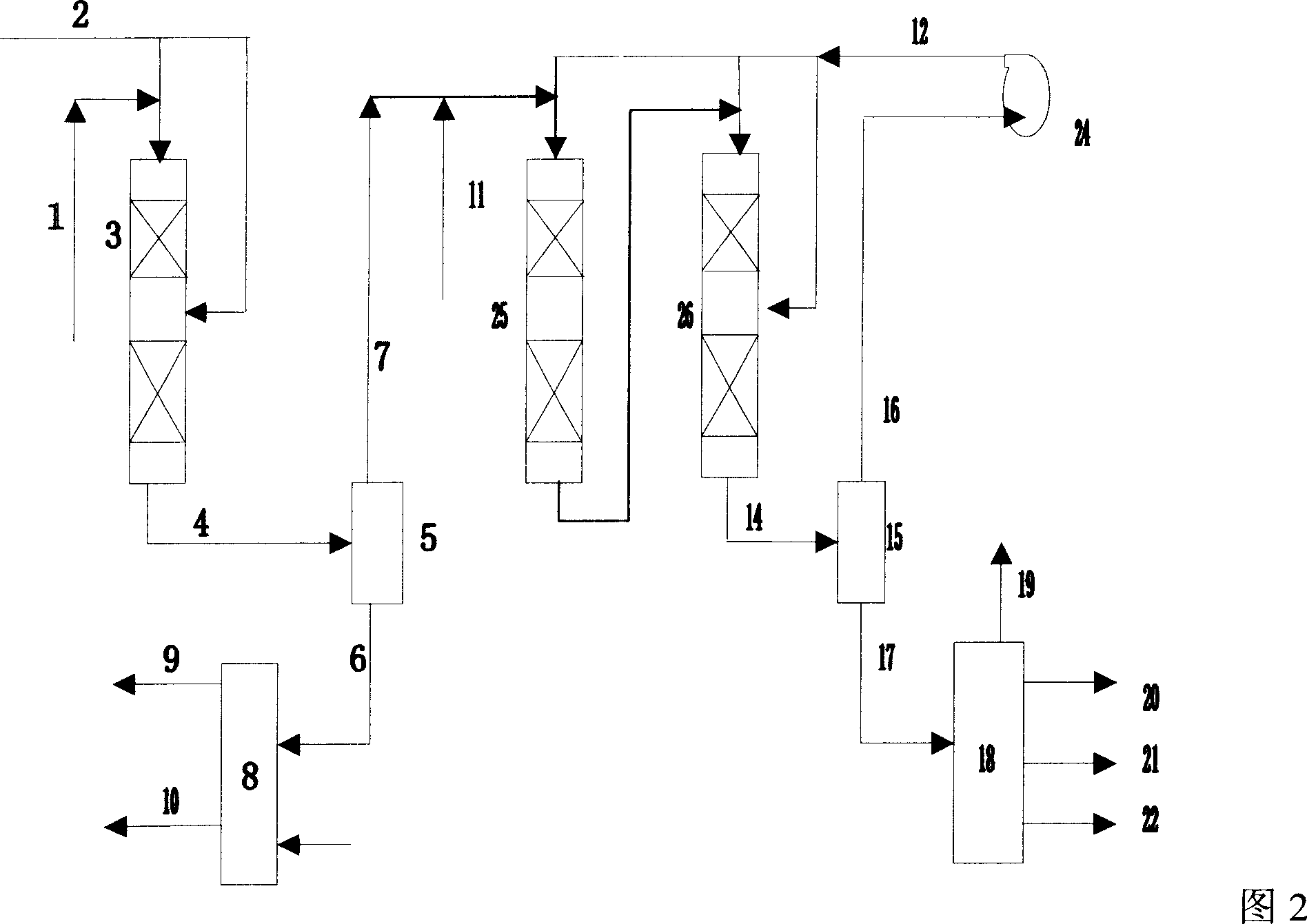

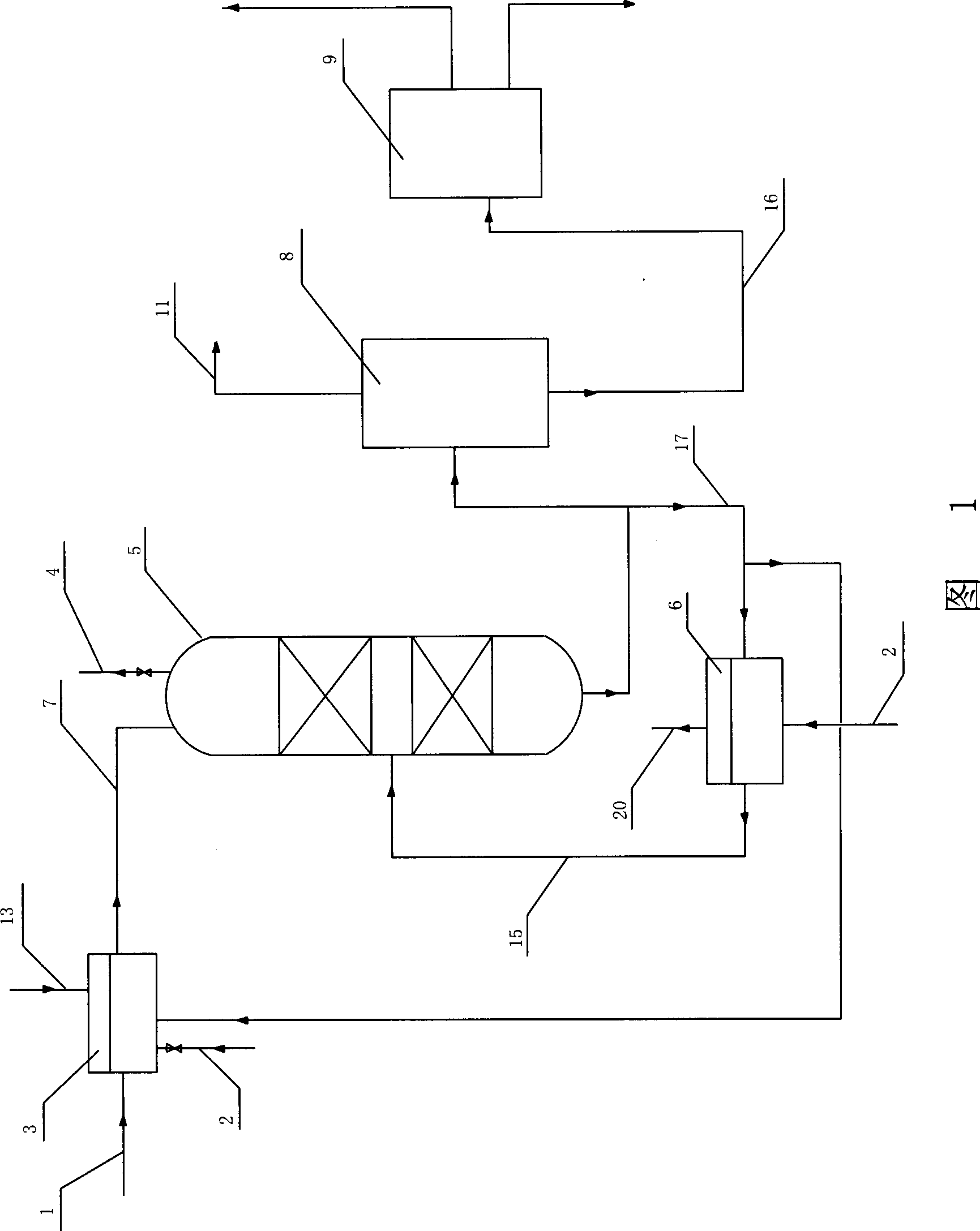

Hydro-conversion combination method for coal tar fraction with different boiling ranges

ActiveCN101629103AHigh yieldReduce dosageTreatment with hydrotreatment processesHydrogenHydrogen compressor

The invention relates to a hydro-conversion combination method for a coal tar fraction with different boiling ranges, which comprises the following steps that: a first hydrogen fraction mainly comprising a coal tar light fraction is converted and separated at a first hydrogen device; a second hydrogen fraction mainly comprising a coal tar heavy fraction is converted and separated at a second hydrogen device; and two sets of the hydrogen devices share a circular hydrogen compressor; and the hydrogen light fraction obtained by the second hydrogen device enters a reaction part or a high fractionoil separating part of the first hydrogen device. The method can select respective proper hydrogen refining reaction conditions for the coal tar fraction with different boiling ranges, has the advantages of improving the quality of products, stabilizing the operation, reducing the energy consumption and catalyst consumption, prolong the operation cycle, simplifying the flow and the like, and is particularly suitable for large-scale classified combined hydro-conversion of medium-high temperature coal tar wide fractions.

Owner:何巨堂

Liquid phase hydrogenating method of hydrocarbon oil

InactiveCN101993720AReduce dosageReduce lossesHydrocarbon oils refiningHydrocarbon oils treatmentSolubilityHydrogen

The invention discloses a liquid phase hydrogenating method of hydrocarbon oil. In the method, recycle hydrogen and a recycle hydrogen compressor are cancelled; hydrogen reacts with fresh raw oil and partial recycle oil in the presence of a solvent or a diluent to form a mixture flow, and the mixture flow enters a reactor to contact with a catalyst; the other part of or all recycle oil is mixed with hydrogen, and an obtained mixture enters the reactor by a path or branches from spaces between catalyst bed layers of the reactor; partial reaction effluent is subjected to hydrogen sulfide removal and then used as recycle oil, and the other part enters a separator; and the solubility of the hydrogen in the solvent or the diluent is larger than that in the mixture of the fresh raw oil and the solvent or the diluent.

Owner:CHINA PETROCHEMICAL CORP +1

Two-phase hydrogenation process

InactiveCN101338219AReduce dosageReduce lossesHydrocarbon oils refiningLiquid productHydrogenation process

The present invention discloses a biphase hydrogenation method, which cancels circulating hydrogen and a circulating hydrogen compressor. Hydrogen is mixed with fresh crude oil and circulating oil under the existence of a solvent or a diluting agent so as to form a mixture flow; the mixture flows into a reactor to contact a catalyst; after the other part of the circulating oil is mixed with hydrogen for gas discharging, a circuit or a shunt circuit enters the reactor between reactor catalyst bed layers; after the solvent or the diluting agent is mixed with hydrogen for gas discharging, a circuit or a shunt circuit enters the reactor between reactor catalyst bed layers; the reacted effluent is used for gas-liquid separation and the liquid phase further separates the solvent or the diluting solvent for recycling use; a part of the separated liquid product is used as the product and the other part is used as the circulating oil.

Owner:CHINA PETROCHEMICAL CORP +1

Hydrocarbon oil hydrogenation technique

The present invention discloses a hydrocarbon oil-hydrogenating technique. The technique is free from circulating hydrogen and a circulating hydrogen compressor; with solvent or diluting agent, hydrogen is mixed with fresh raw oil and part of circulating oil to form mixed material flow, which enters into a reactor to be contacted with catalyst; another part or all of circulating oil is mixed with hydrogen; one route or branch passes between the catalyst beds of the reactor to enter into the reactor; one part of reaction outflow is used as circulating oil, and the other part is used as the product after the gas and the solvent or the diluting agent are separated out; and the dissolubility of hydrogen in the solvent or the diluting agent is larger than the dissolubility of hydrogen in the mixture of the fresh raw oil and the solvent or the diluting agent.

Owner:CHINA PETROCHEMICAL CORP +1

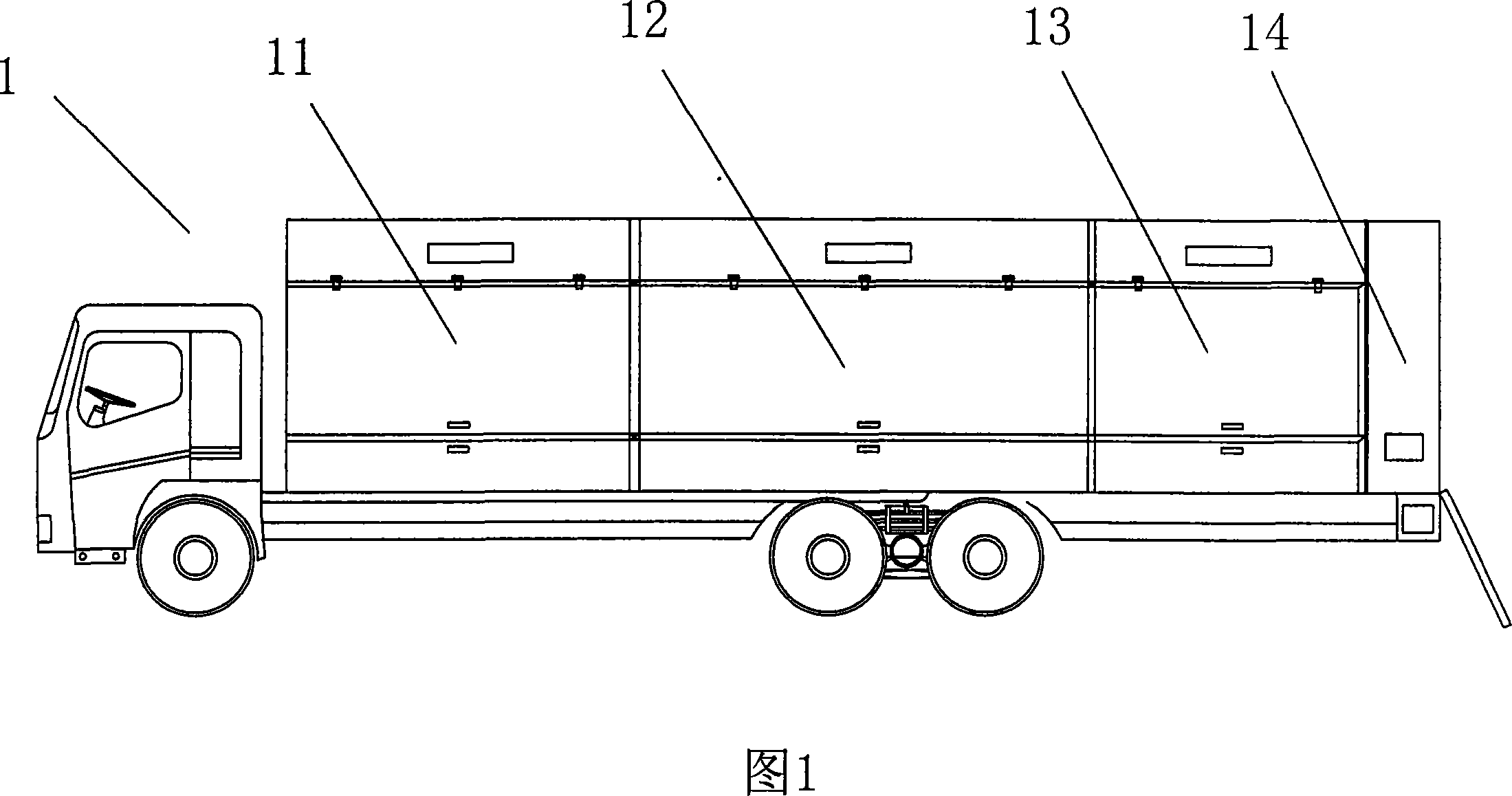

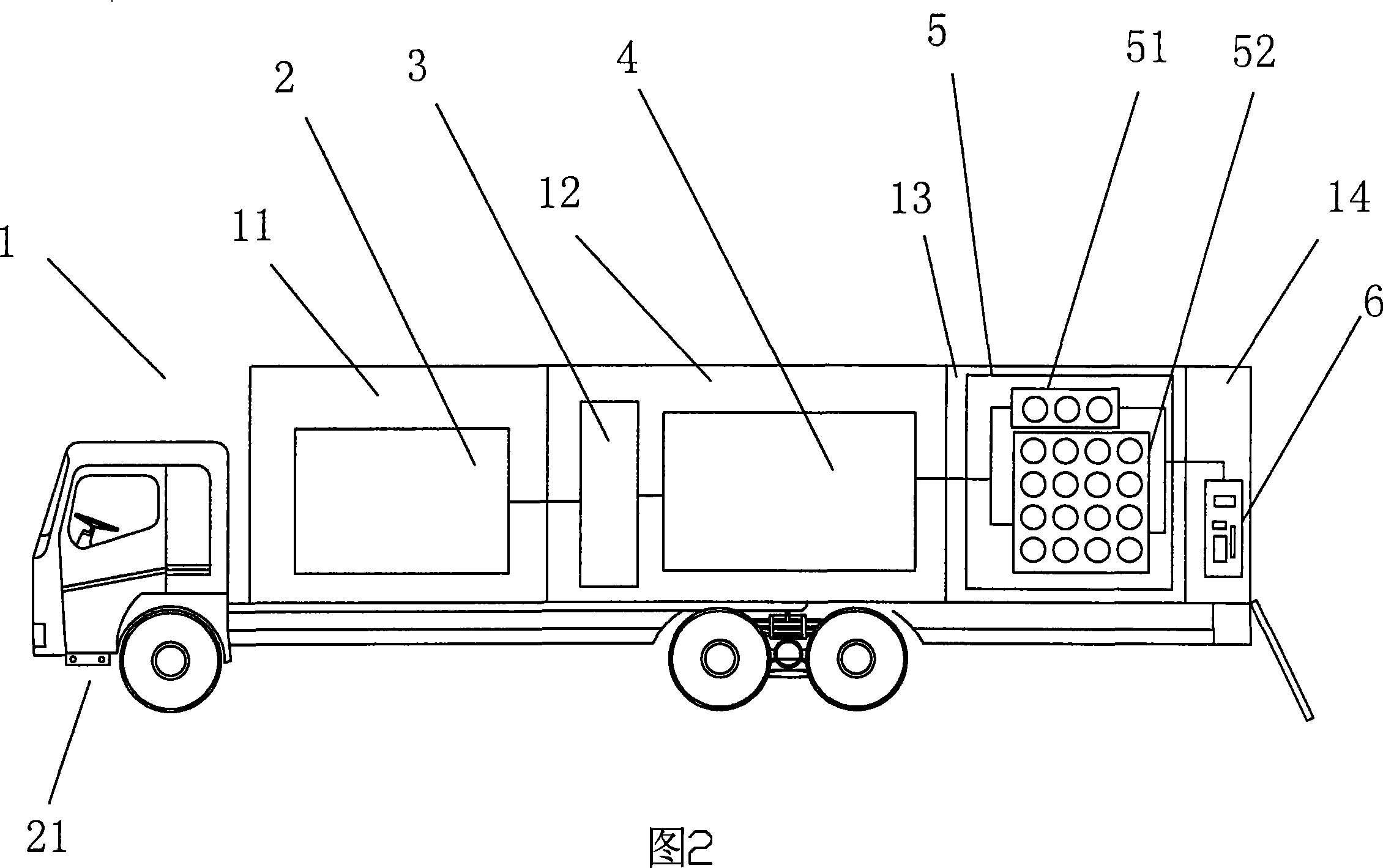

Vehicle mounted hydrogen producing hydrogenation station

The invention relates to an on-board hydrogen producing and adding station, characterized in that it comprises special transport vehicle; in the carriage of special transport vehicle, deflation water electrolysis equipment, low-pressure hydrogen storing group, special hydrogen compressor, high-pressure hydrogen storing group and hydrogen selling machine, which are connected in series, are set; said deflation water electrolysis equipment, low-pressure hydrogen group, special hydrogen compressor, high-pressure hydrogen storing group and hydrogen selling machine are all connected with a control system in electricity; transformer are set in said special transport vehicle to introduce outer power supply and allocate it to said deflation water electrolysis equipment, low-pressure hydrogen storing group, special hydrogen compressor, hydrogen selling machine and the control system. In the invention the whole hydrogen producing and selling equipment is loaded in the carriage of a truck, the agility of hydrogen producing and selling is improved greatly.

Owner:袁家桢

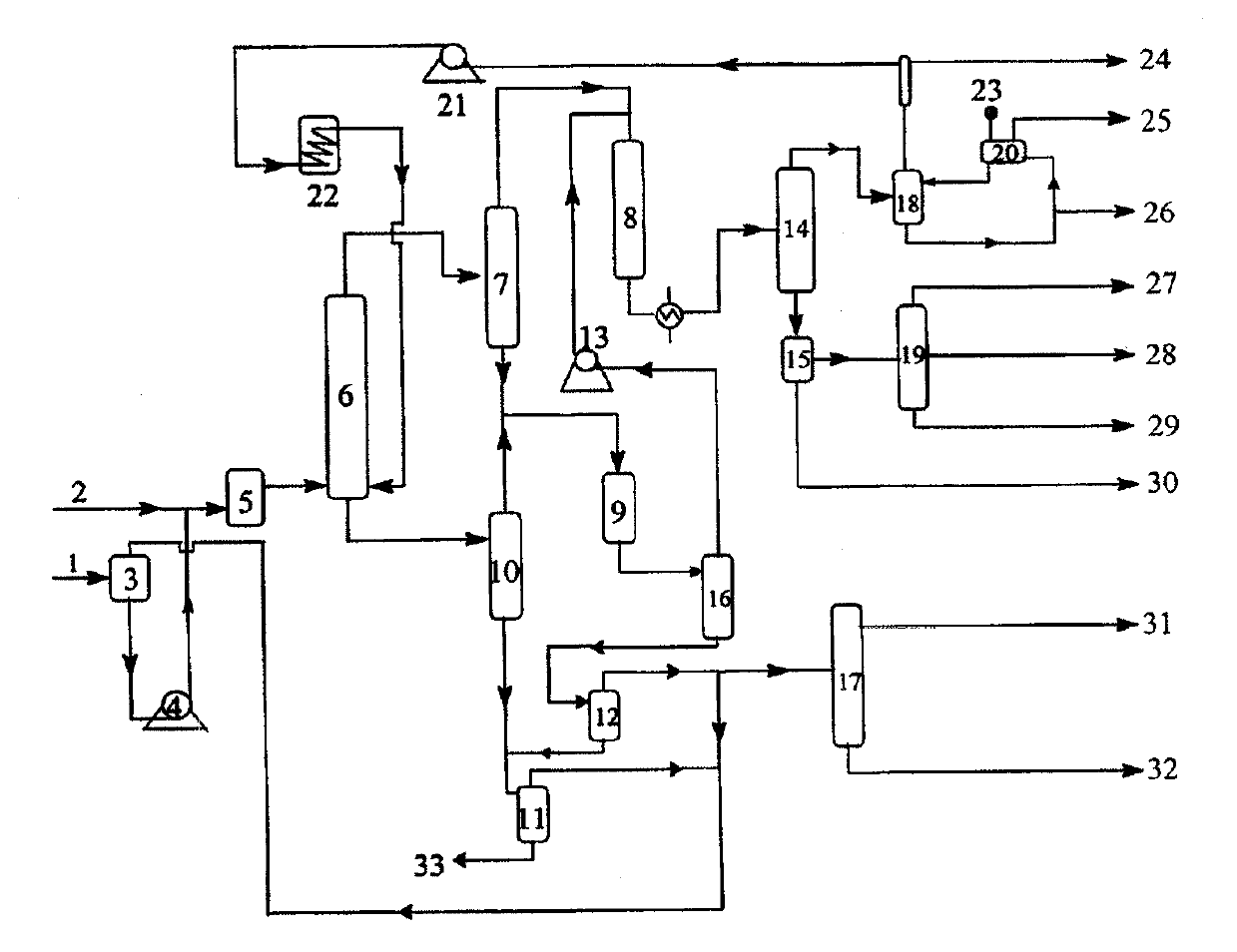

Hydrogen liquefaction equipment provided with three turbo expander units connected in series

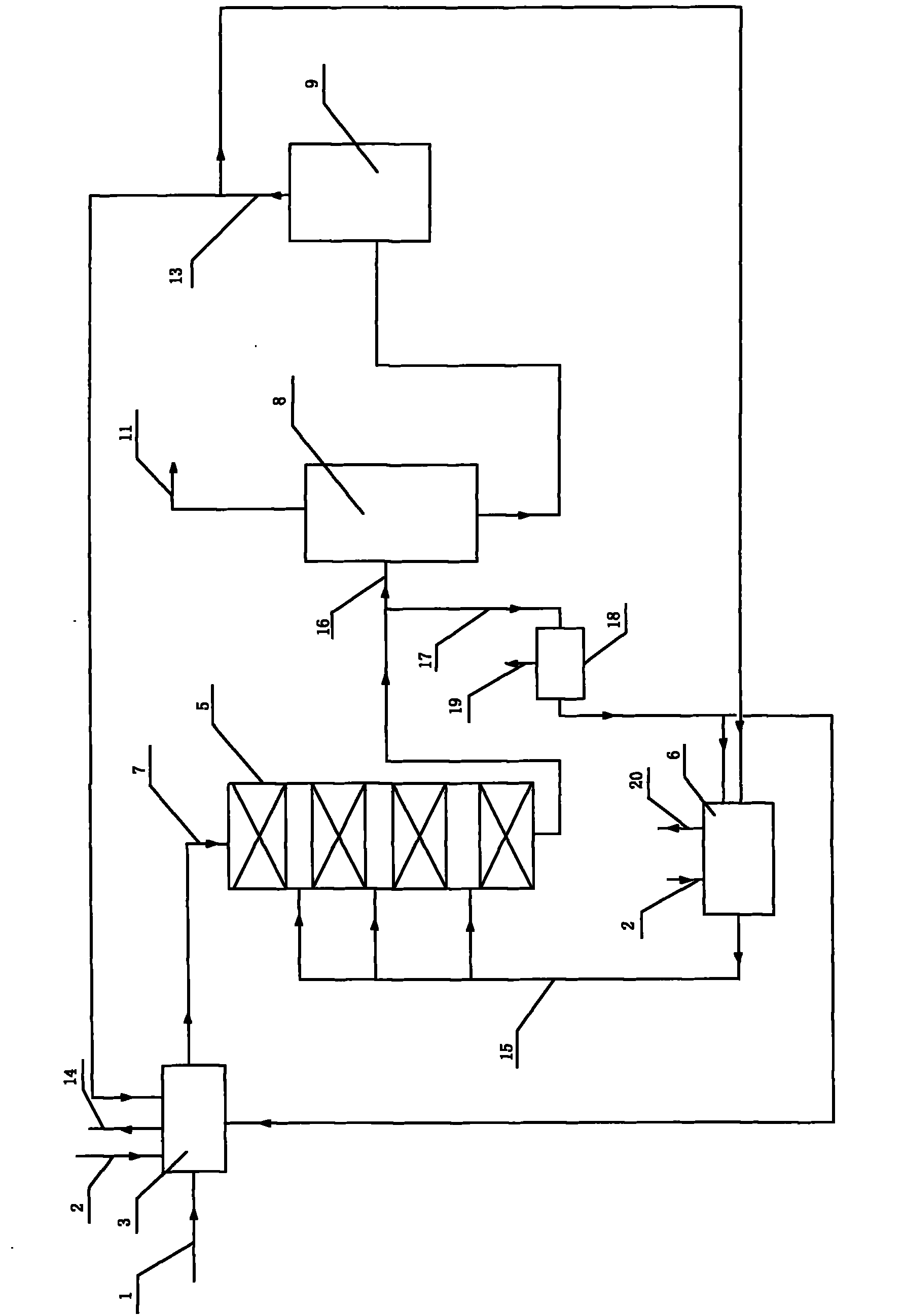

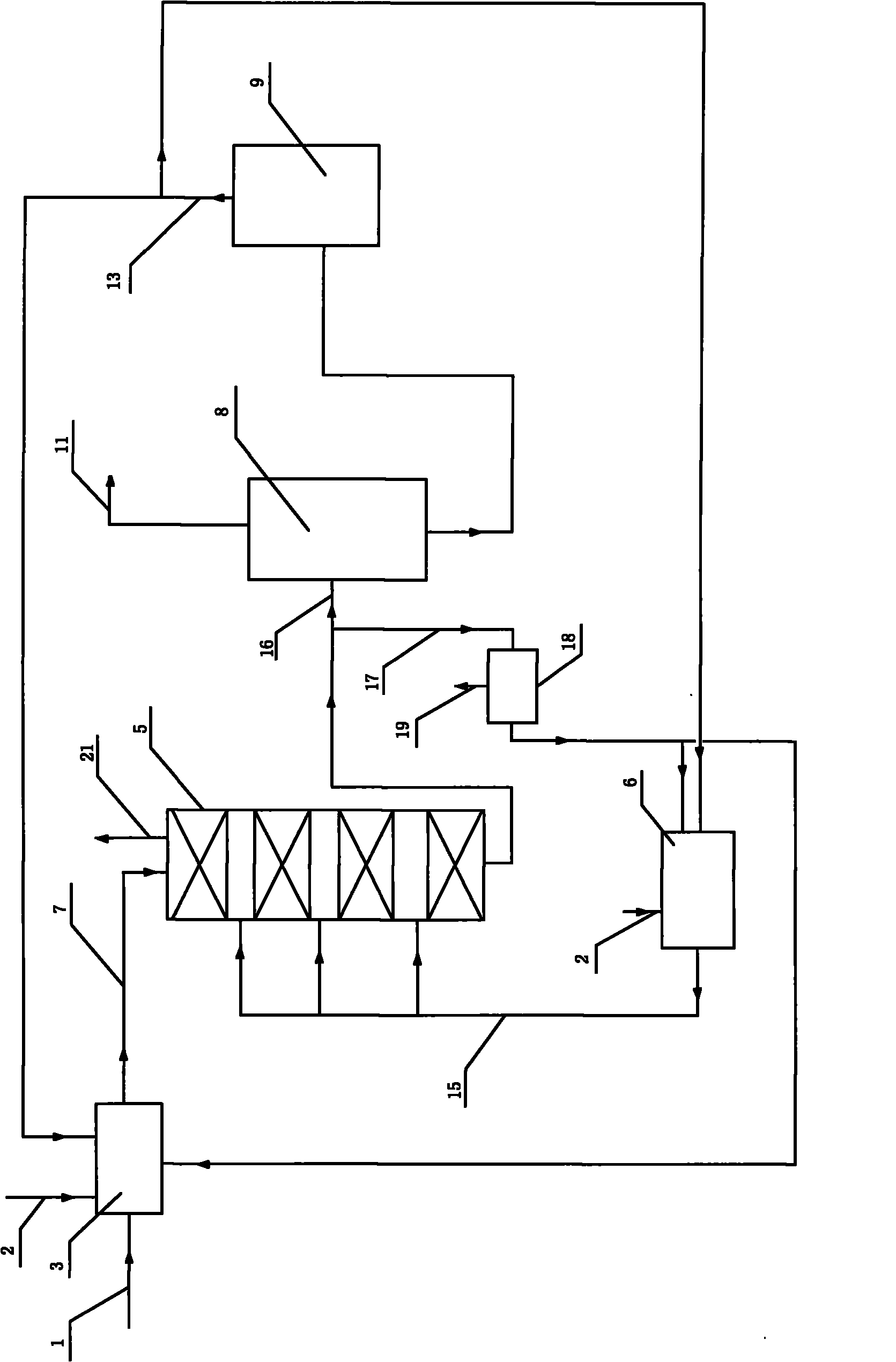

PendingCN112361711AHigh hydrogen liquefaction efficiencyReduce energy consumptionSolidificationLiquefactionConvertersHydrogen compression

The invention discloses hydrogen liquefaction equipment provided with three turbo expander units connected in series. The hydrogen liquefaction equipment comprises a vacuum box, a hydrogen purification device, a pre-cooling device, a first hydrogen compressor unit, a second hydrogen compressor unit, a first turbo expander unit, a second turbo expander unit, a third turbo expander unit, a first low-temperature adsorber, a second low-temperature adsorber, heat exchangers, ortho-parahydrogen converters, regulating valves, throttle valves and a liquid hydrogen storage tank. According to the hydrogen liquefaction equipment, 5-10 tons of liquefied hydrogen can be produced every day, three turbo expander units are connected in series for refrigeration, a hydrogen refrigeration circulating systemconnected to high-pressure throttling refrigeration in parallel is adopted, raw material hydrogen is converted, cooled and liquefied through the multiple stages of ortho-parahydrogen converters, and the hydrogen liquefaction equipment has the advantages of being high in hydrogen liquefaction efficiency and low in energy consumption.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

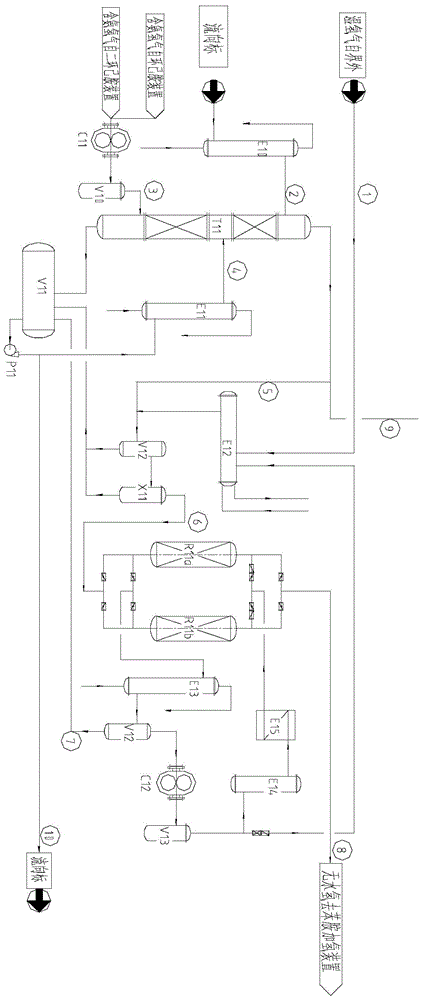

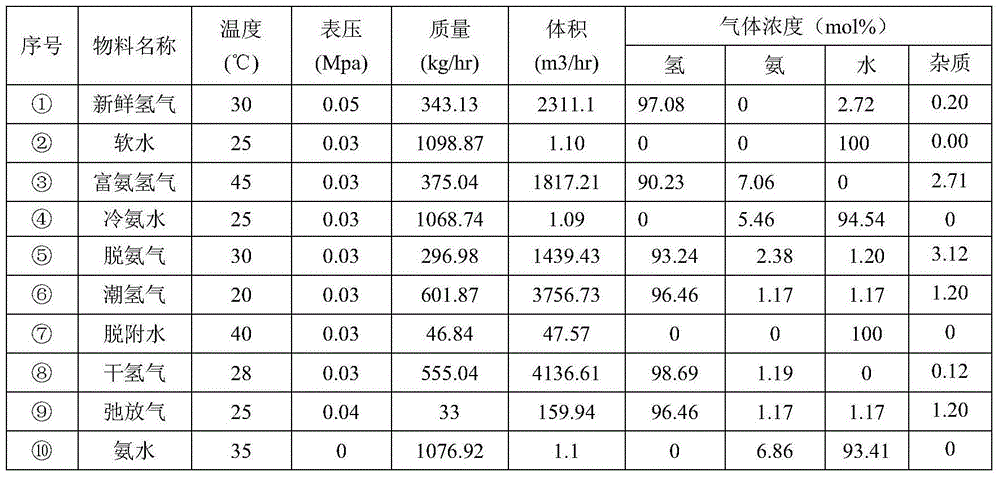

Method for preparing refined hydrogen through deamination in tail gas generated by preparation of cyclohexylamine and dicyclohexylamine through aniline hydrogenation

InactiveCN104445067AHigh purityAchieving zero emissionsHydrogen separationAmmonia preparation/separationWater vaporGas phase

The invention relates to a tail gas refining method, and in particular relates to a method for preparing refined hydrogen through deamination in tail gas generated by preparation of cyclohexylamine and dicyclohexylamine through aniline hydrogenation, belonging to the technical field of chemical engineering. The method comprises the following steps: allowing tail gas discharged by a cyclohexylamine device and a dicyclohexylamine device to enter an ammonia absorption tower by virtue of a Roche hydrogen compressor and a degreaser, wherein most of ammonia is absorbed by water to be converted into ammonia water to be output from the tower bottom in the tower, and the gas output from the tower top is water-containing hydrogen; allowing the water-containing hydrogen to pass through a water segregator, a fiber filter and a water adsorption tower so as to further remove water vapor, thereby obtaining the refined hydrogen. The concentration of the refined hydrogen can be 98.0-99.8 percent, the material and energy consumption is reduced, and the aims of energy conservation and emission reduction are achieved. The refined hydrogen can serve as recycling gas to be used for an aniline hydrogenation reaction, and gas phase zero emission is realized.

Owner:NANJING UNIV OF TECH

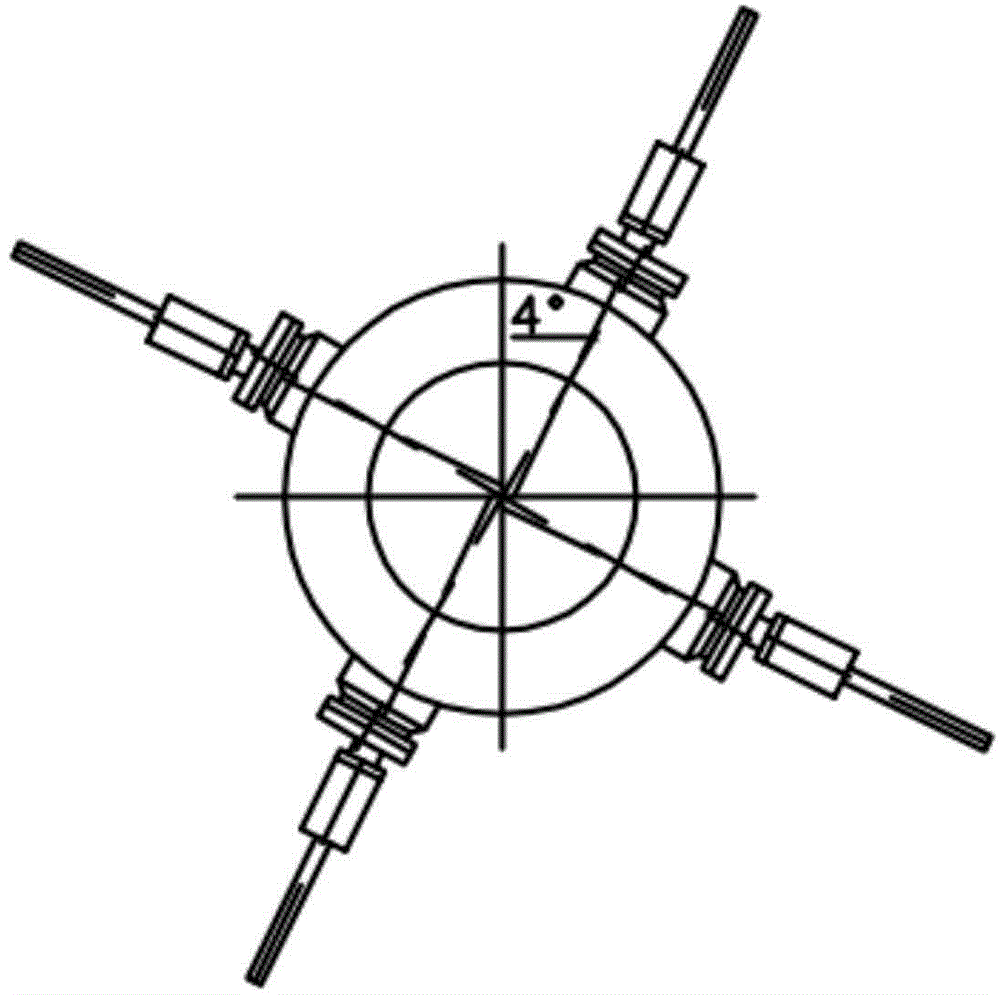

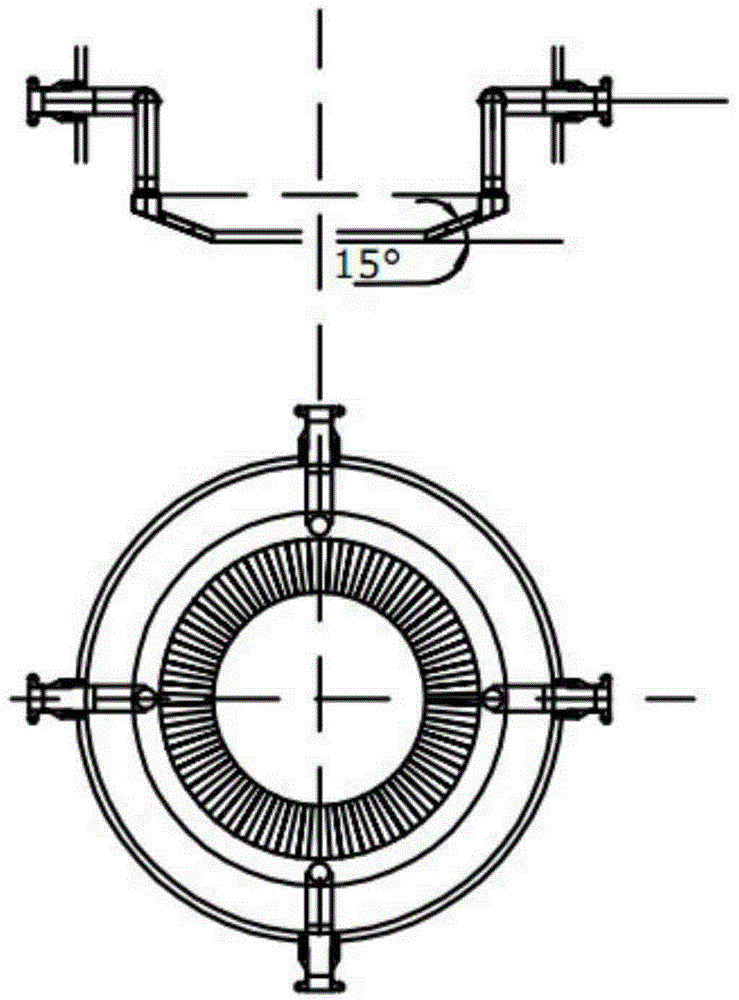

Low temperature Fischer-tropsch synthetic oil hydrofining and / or hydrogenation heterogeneous cracking system and technology

ActiveCN103131468AReduce temperature gradientAxial distribution is reasonableTreatment with hydrotreatment processesHydrogen concentrationHydrogen compressor

The invention relates to a low temperature Fischer-tropsch synthetic oil hydrofining and / or hydrogenation heterogeneous cracking system and a technology thereof. A hydrofining unit uses a liquid phase hydrogenation mode and a downward feeding mode, and thus the distribution of hydrogen concentration along the axial direction of a reactor is more reasonable. Besides, due to the fact that hydrogen consumed in a liquid phase hydrofining reaction process is from liquid phase saturated dissolved hydrogen, a circulating hydrogen compressor can be eliminated when the hydrofining unit is operated separately, and thus device investment and operating cost are reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

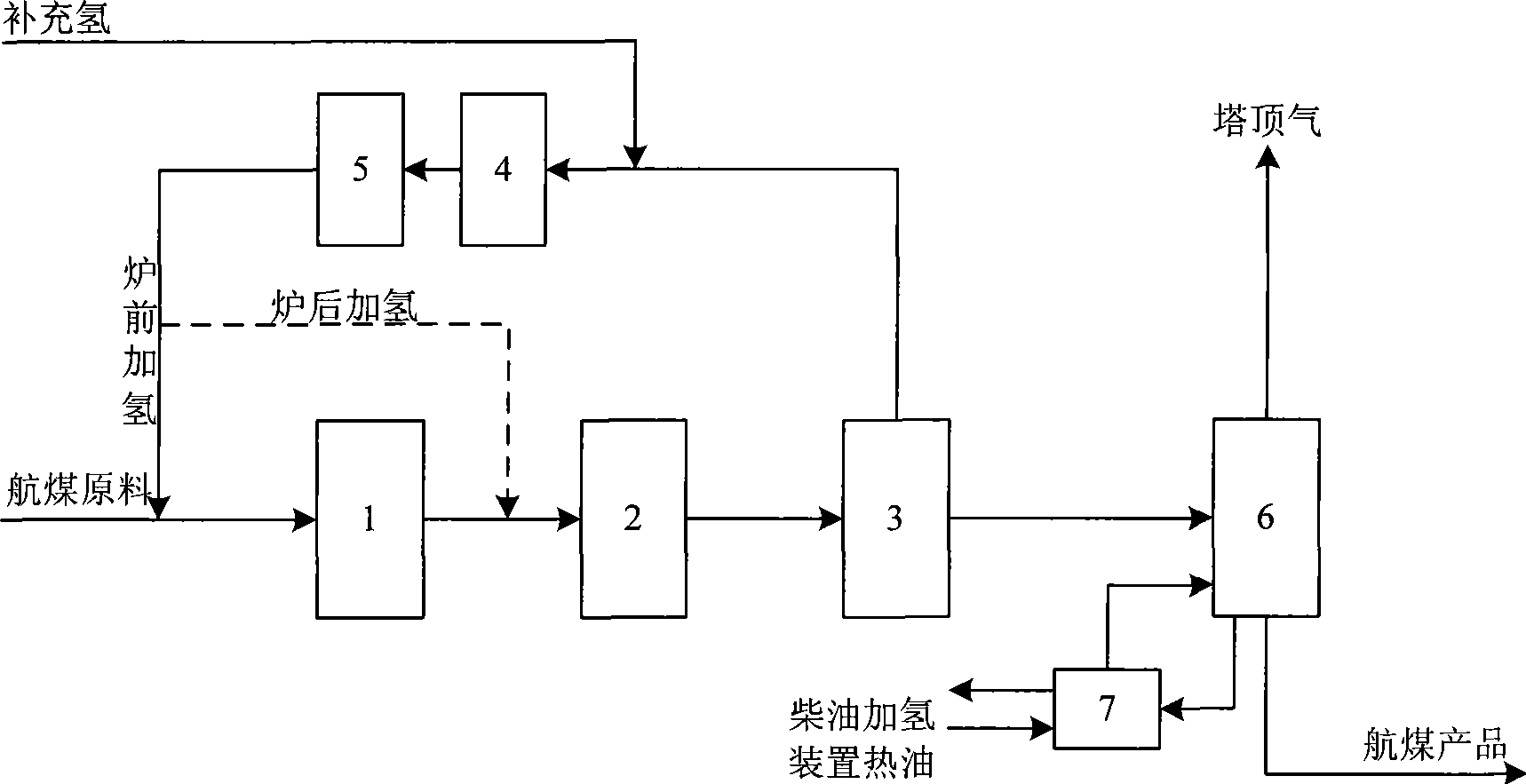

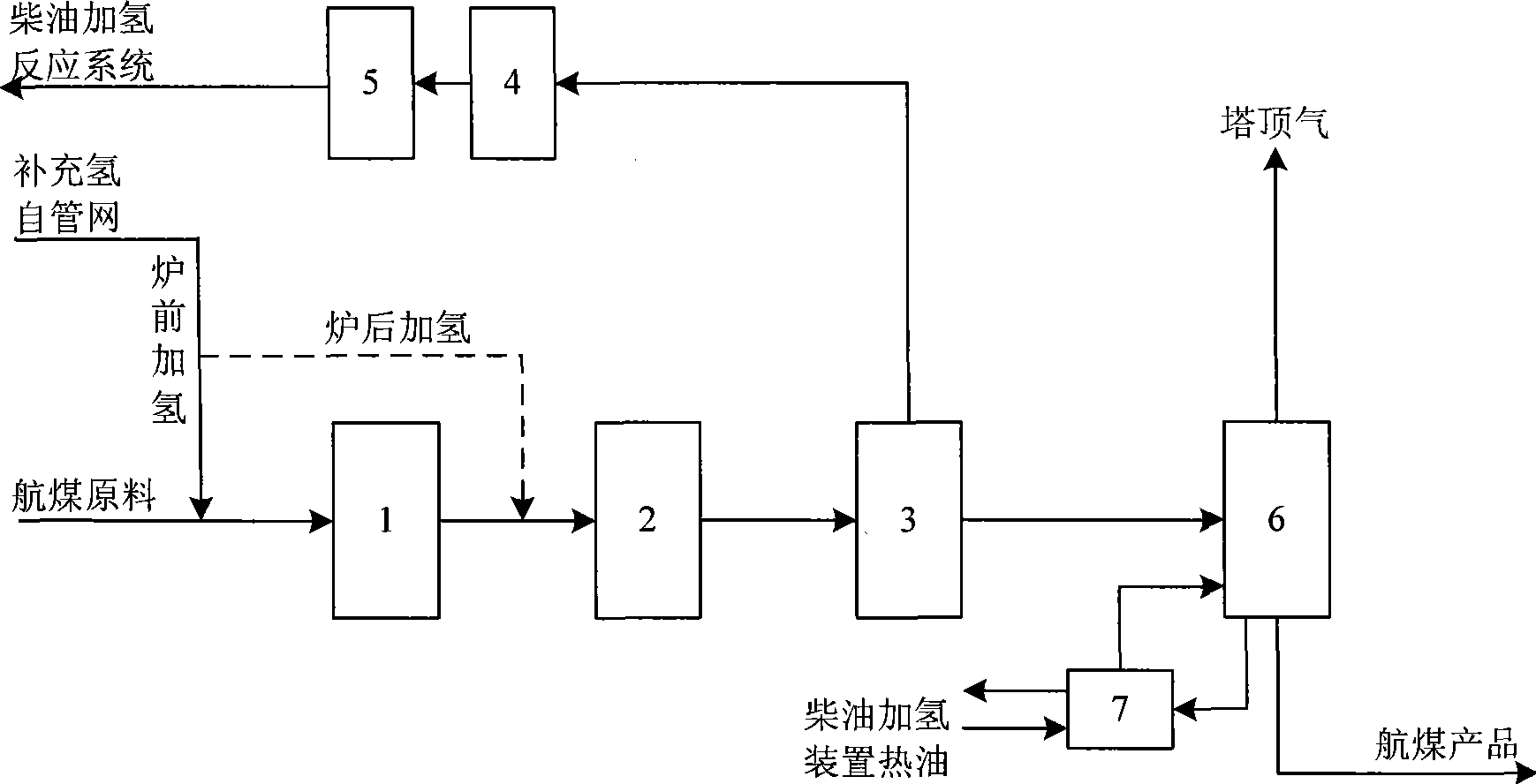

Hydrofining process integration method

ActiveCN101445747ASave one-time investment equipmentSave equipment footprintHydrocarbon oils refiningThermal energyProcess integration

The invention provides a hydrofining process integration method, which comprises: (1) a jet fuel hydrofining device is not provided with a hydrogen gas compressor and uses hydrogen from other hydrofining device which is arranged by a hydrogen pipe network or combination; hydrogeneous gas obtained by hydrogenation reaction enters into the other hydrofining device; (2) the product of the jet fuel hydrofining device - stripping tower uses hot oil of the other hydrofining device as heat source to strip air. Aiming at the characteristic that the jet fuel hydrofining device often makes up a combination unit with the other hydrofining device, the jet fuel hydrofining device has small relative handing capacity and low hydrogen consumption, the method rationally uses devices and heat energy resources of the combination unit, optimizes flow proposal of the jet fuel hydrofining device, and has the advantages of conserving energy, lowering consumption, reducing investment outlay, etc.

Owner:CHINA PETROCHEMICAL CORP +1

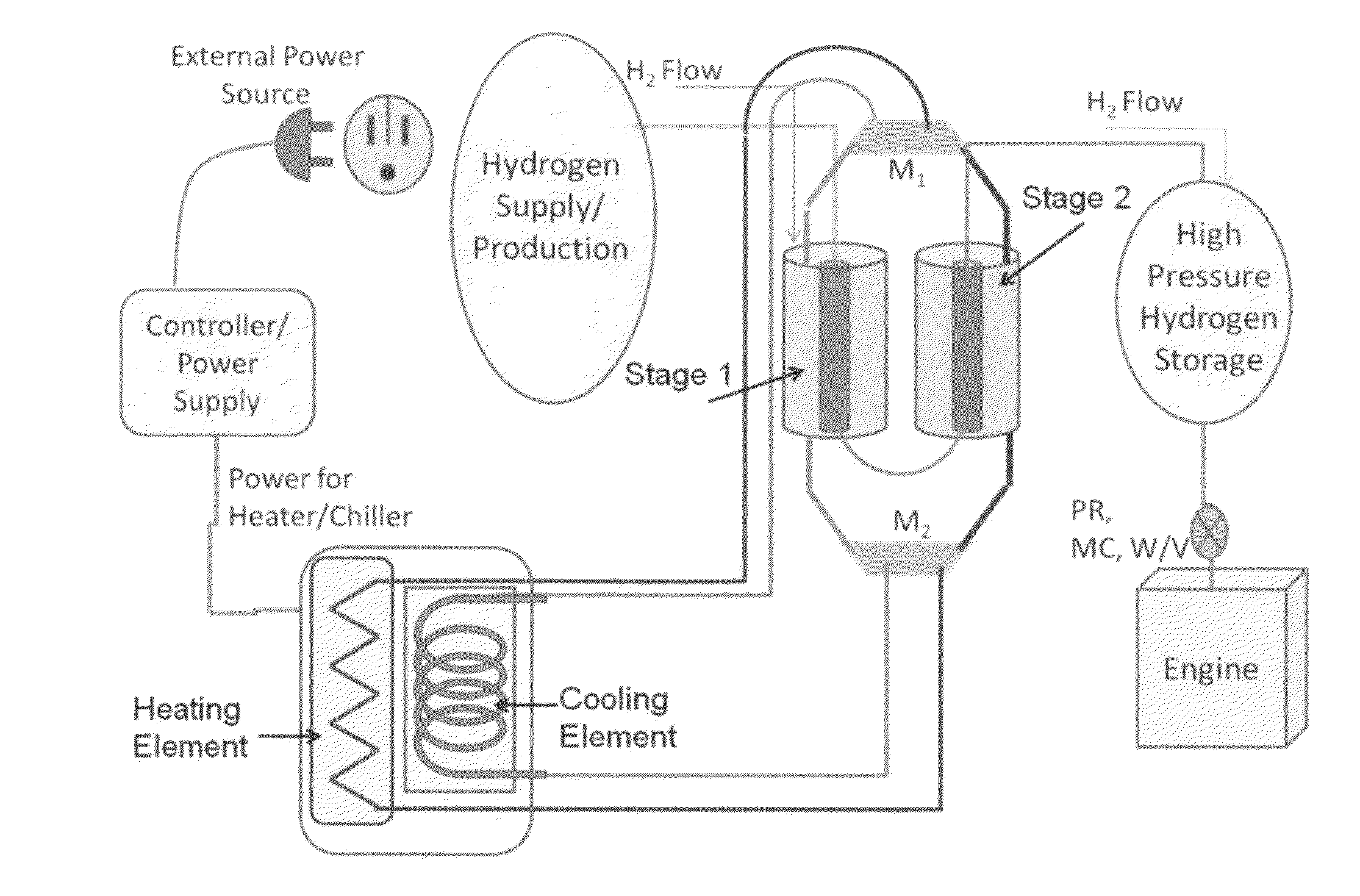

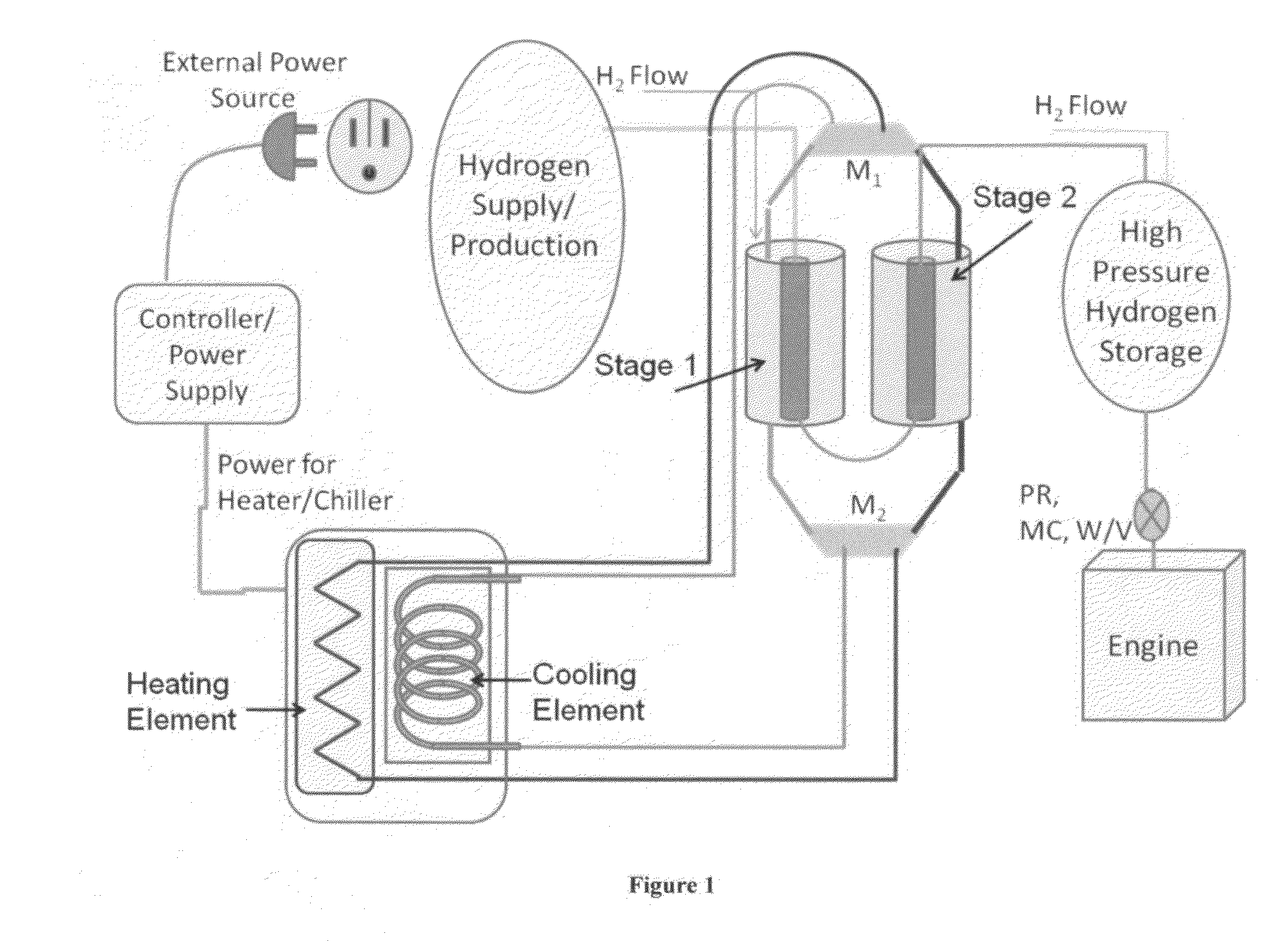

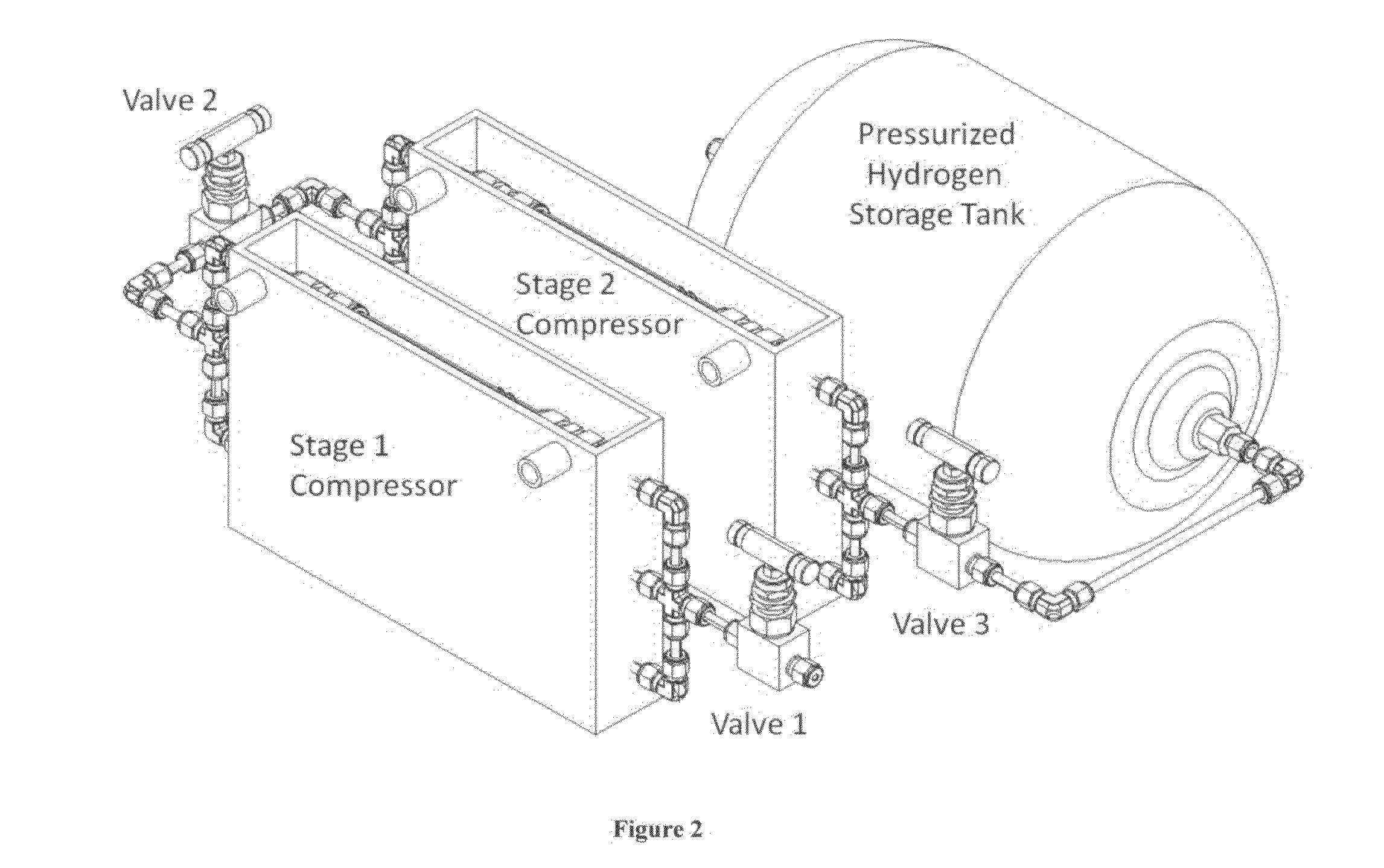

Multi Stage Hydrogen Compression & Delivery System for Internal Combustion Engines Utilizing Working Fluid

InactiveUS20110302932A1Reduce inconvenienceReduces safety issueFixed capacity gas holdersMulti-stage pumpsThermal energyWorking fluid

The multi stage hydrogen compression and delivery system for internal combustion engines utilizing a working fluid (HCDS-ICWF-Multi) consists of a thermally driven multi compression stage metal hydride hydrogen compressor in line with high pressure hydrogen storage tanks and a pressure regulating hydrogen delivery system that supplies a controlled release of hydrogen to the internal combustion engine. The working fluid carries the thermal energy needed to the metal hydride compression stages to drive the hydrogen compression. The compressor is intended to be inseparable from the storage tank to ensure safe operation.

Owner:HOPKINS RYAN REID

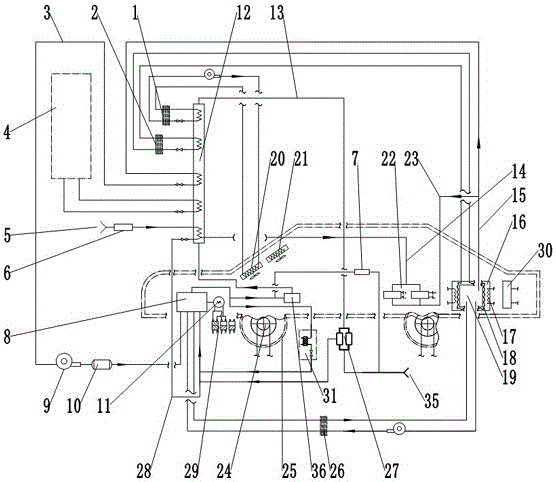

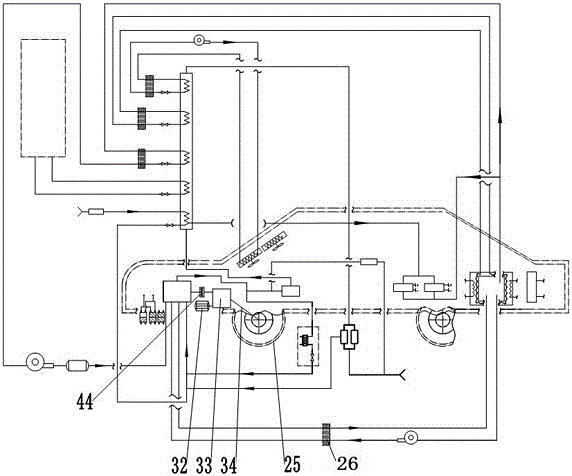

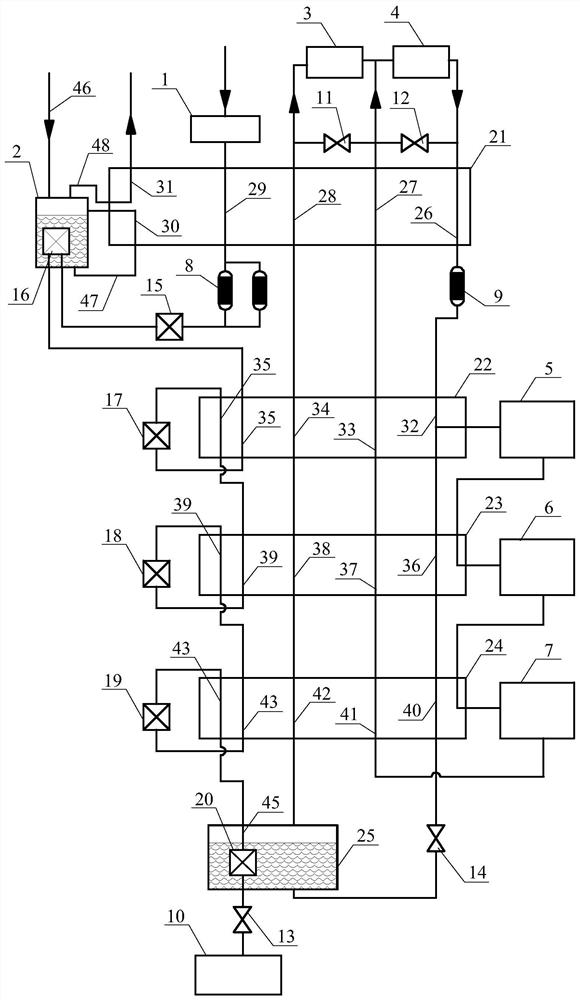

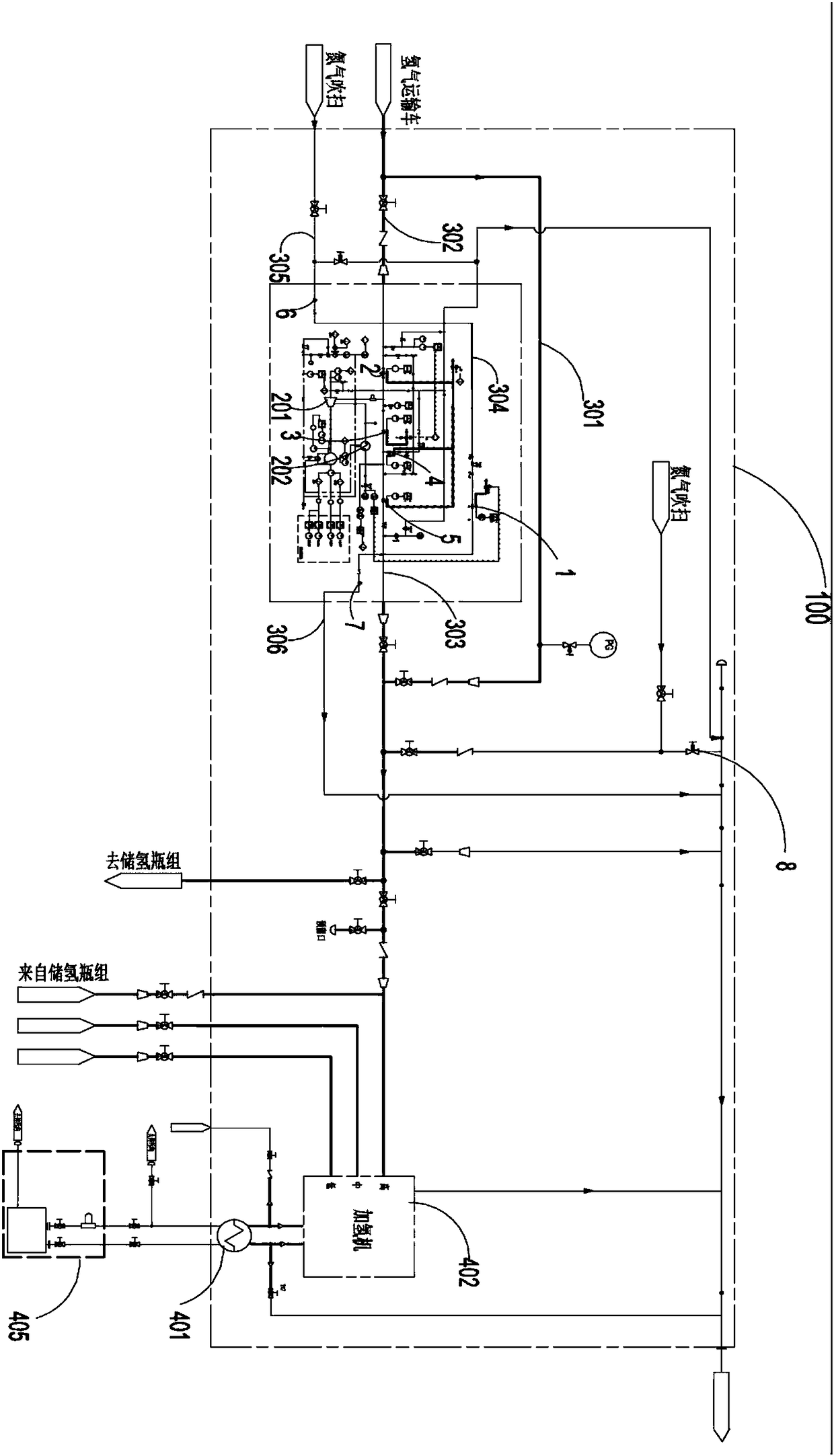

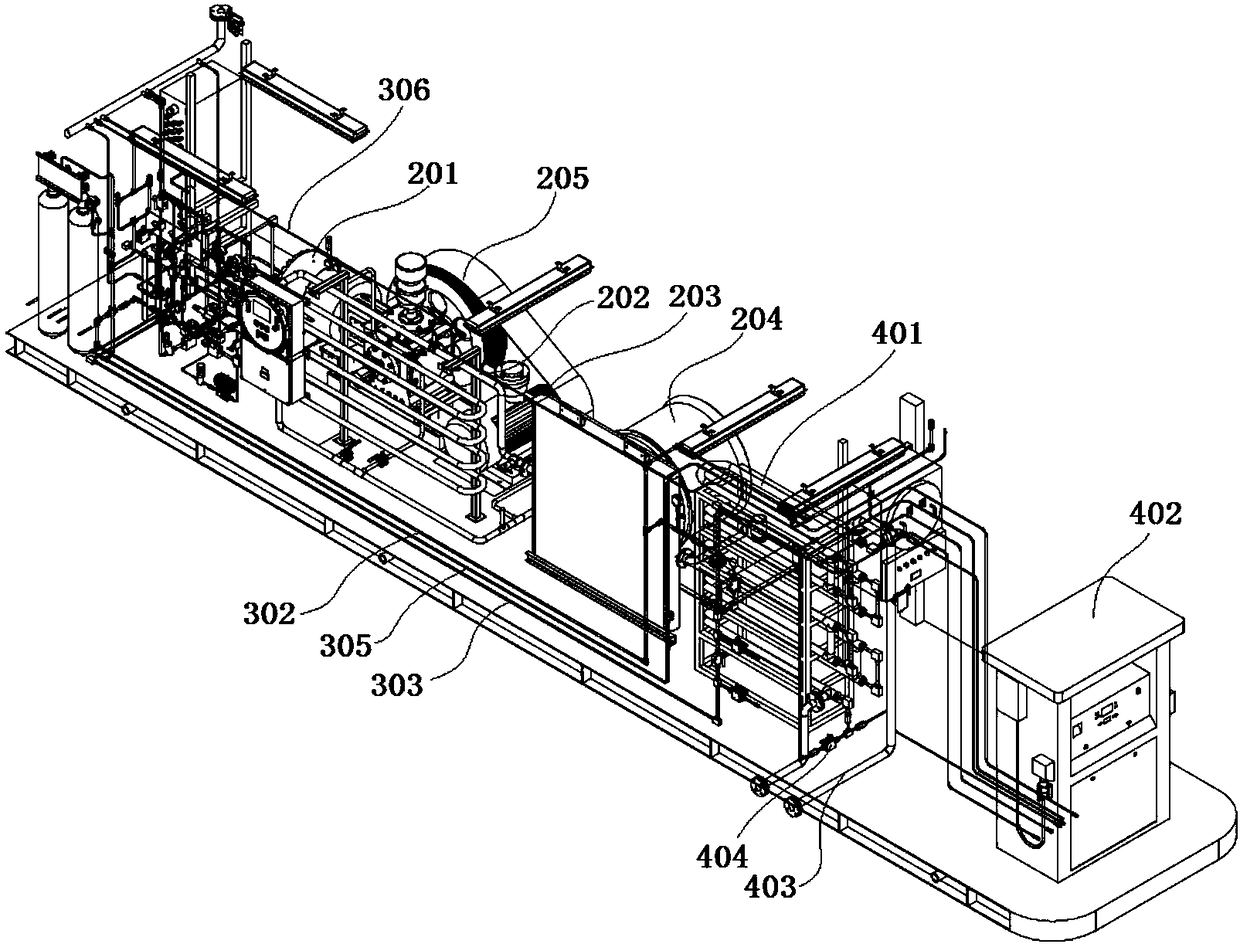

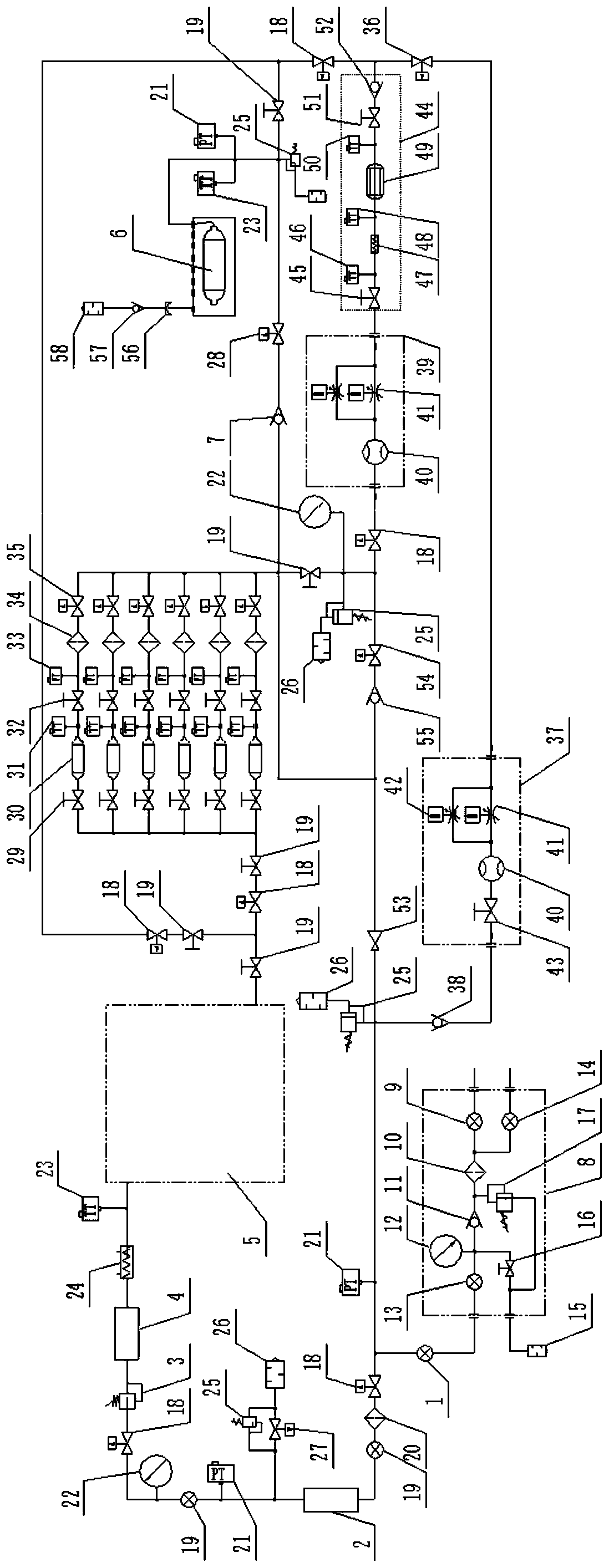

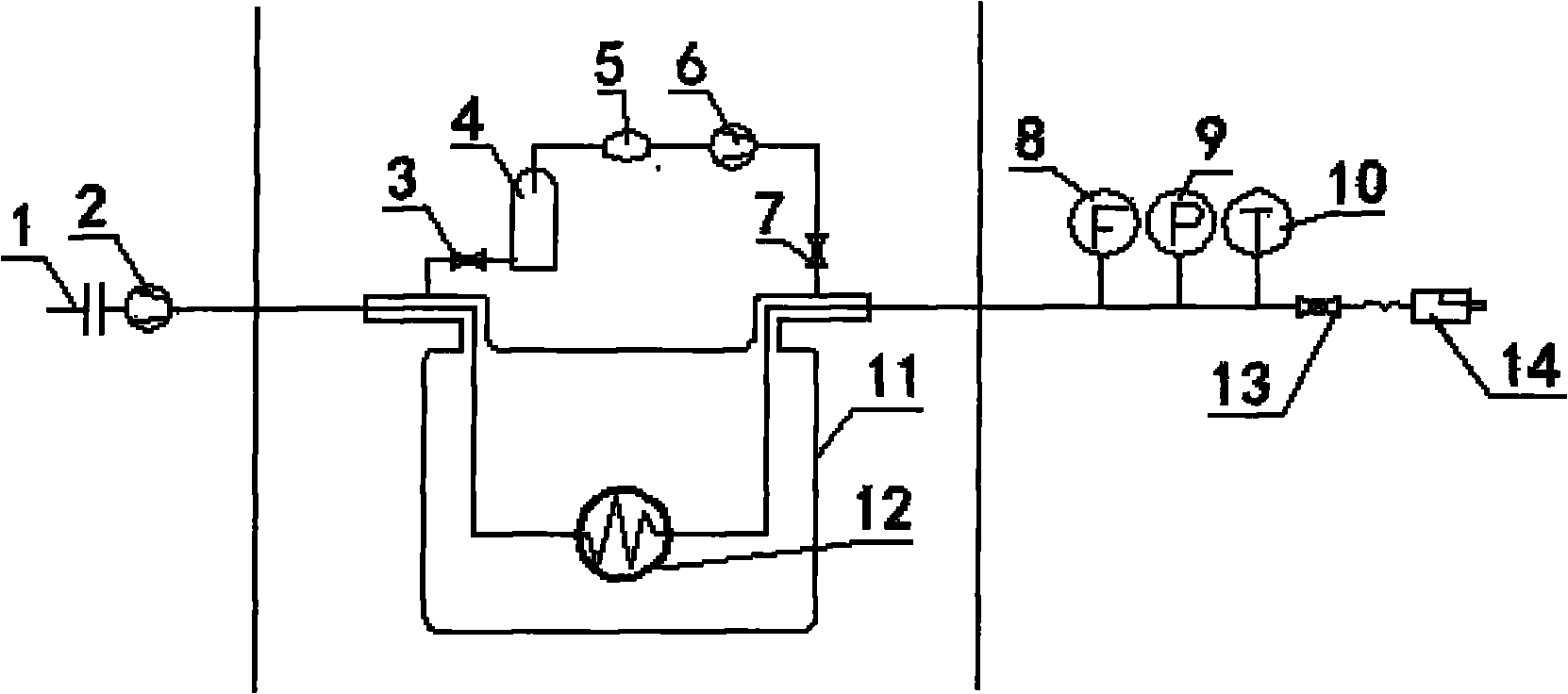

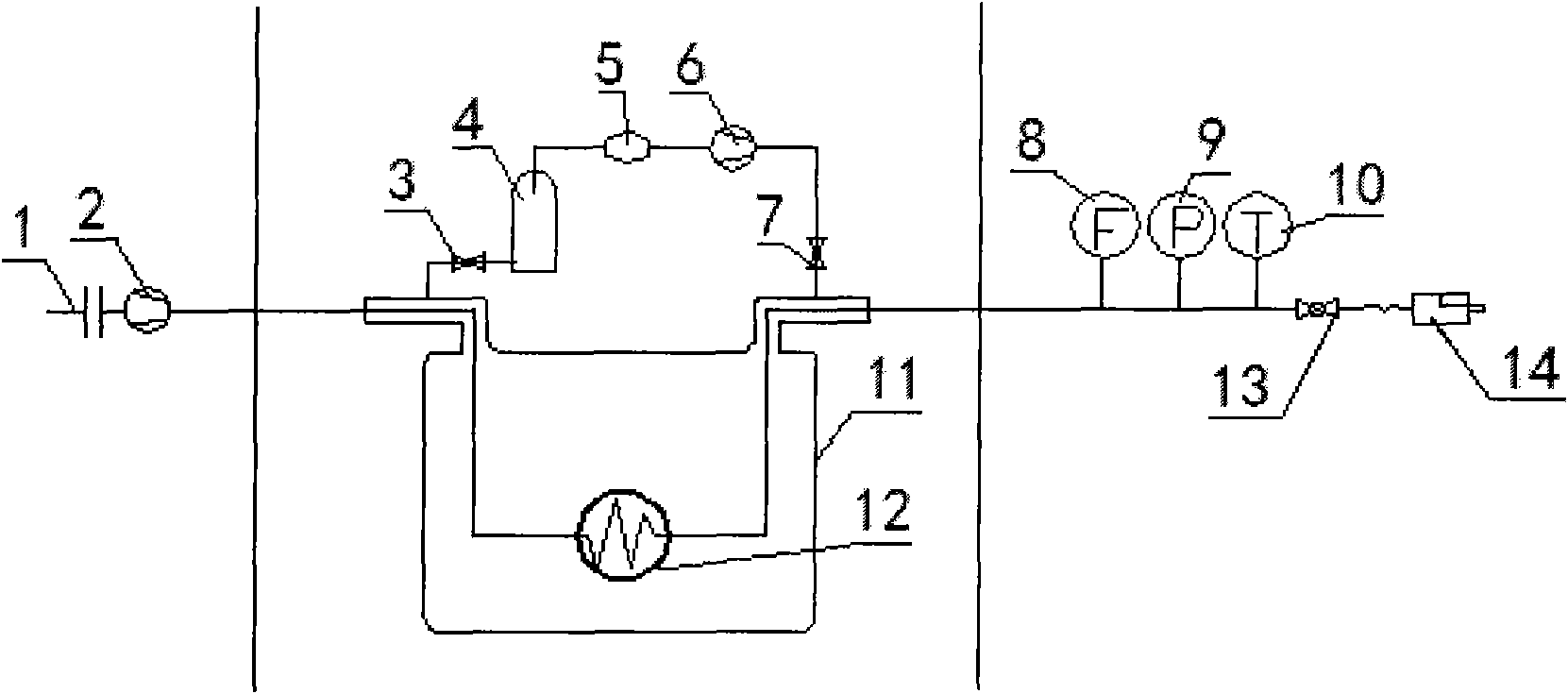

Hydrogeneration system of hydrogen compressor skid-mounted hydrogeneration equipment and hydrogeneration method thereof

ActiveCN108361546ACompact structureSmall footprintVessel geometry/arrangement/sizeSecondary cellsProcess engineeringSmall footprint

The invention provides a hydrogeneration system of hydrogen compressor skid-mounted hydrogeneration equipment and a hydrogenation method. The system comprises the following components arranged insidea skid-mounted shell: a pressurizing component, a hydrogen dispenser, a circulation loop and a controller, wherein a gas inlet of a diaphragm compressor in the pressurizing component is connected witha hydrogen inlet pipe, the end of the hydrogen inlet pipe is provided with an input end connected with a gas outlet of a hydrogen transporting truck, a gas outlet of the diaphragm compressor is connected with a hydrogen outlet pipe, and hydrogen in the hydrogen outlet pipe is cooled when flowing through a first cooling heat exchange element; a gas inlet pipeline of the hydrogen dispenser is connected with the hydrogen outlet pipe, and hydrogen in the gas inlet pipeline is cooled when flowing through a second cooling heat exchange element; one end of the circulation loop communicates with thehydrogen inlet pipe, and the other end of the circulation loop communicates with the hydrogen outlet pipe; and a first control valve, a second control valve and a third control valve which are used for controlling on and off of the pipelines are arranged on the hydrogen inlet pipe, the hydrogen outlet pipe and the circulation loop correspondingly, and are all connected with the controller. The whole hydrogeneration system is compact in structural arrangement, small in occupied area, and large in hydrogeneration capacity.

Owner:上海氢枫能源技术有限公司

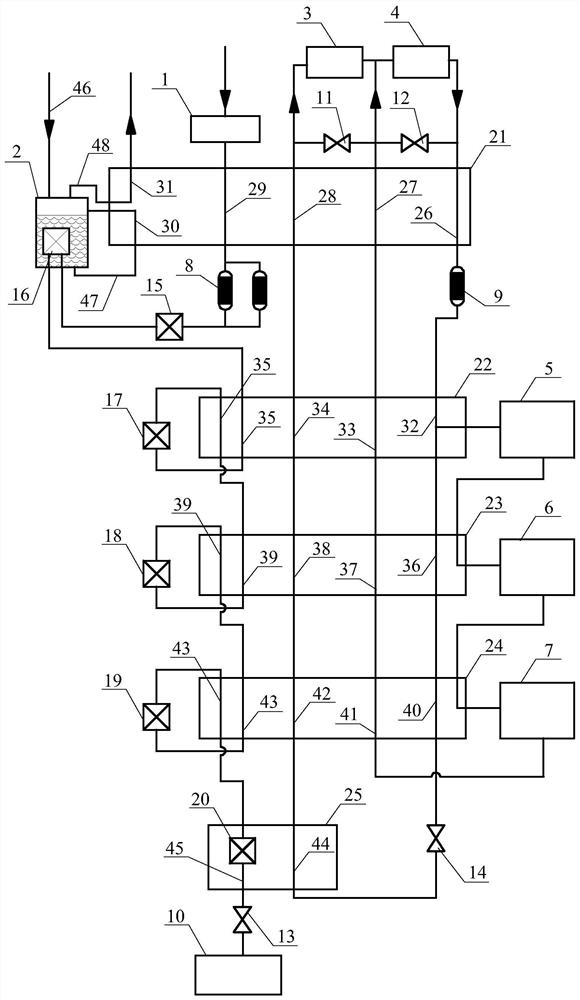

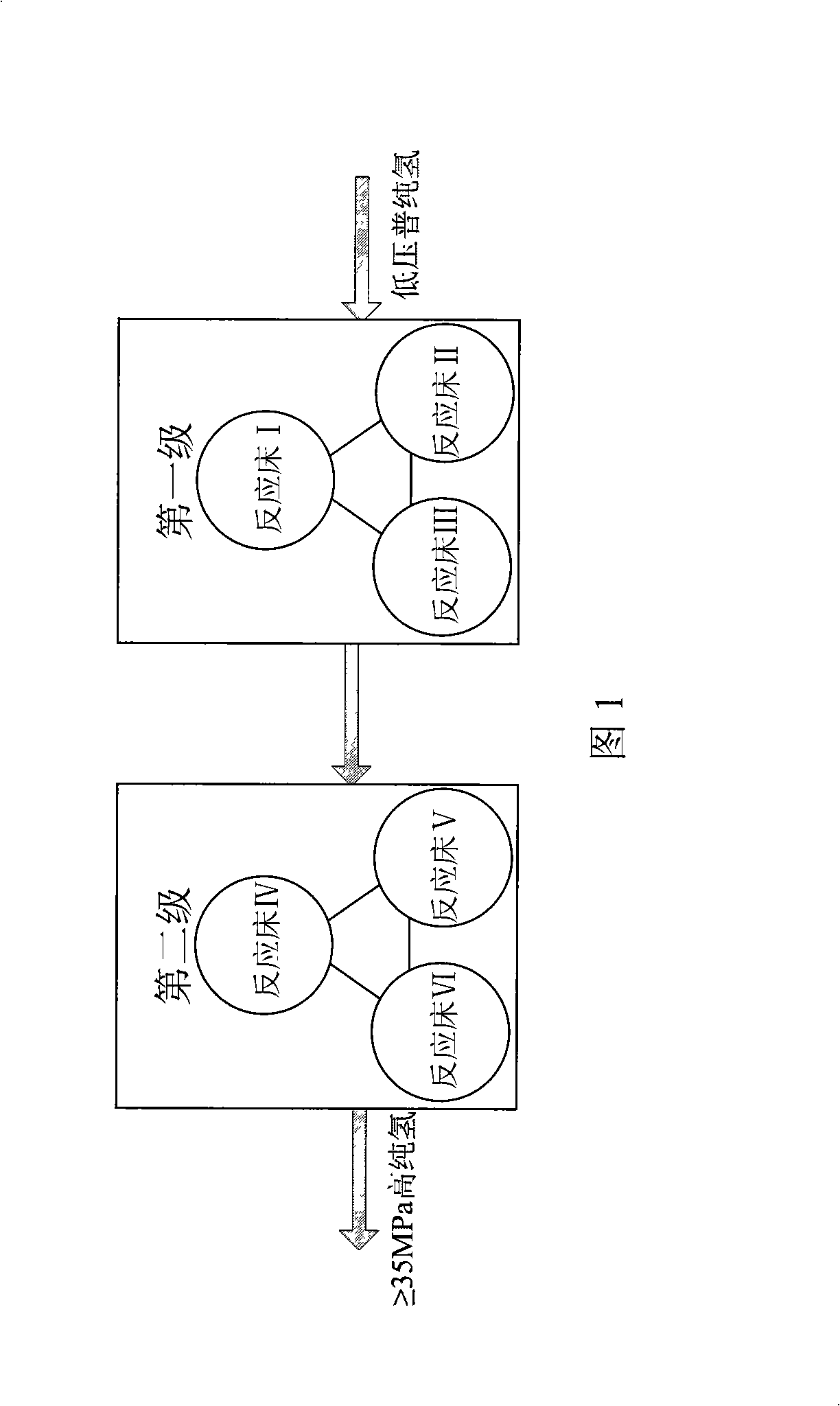

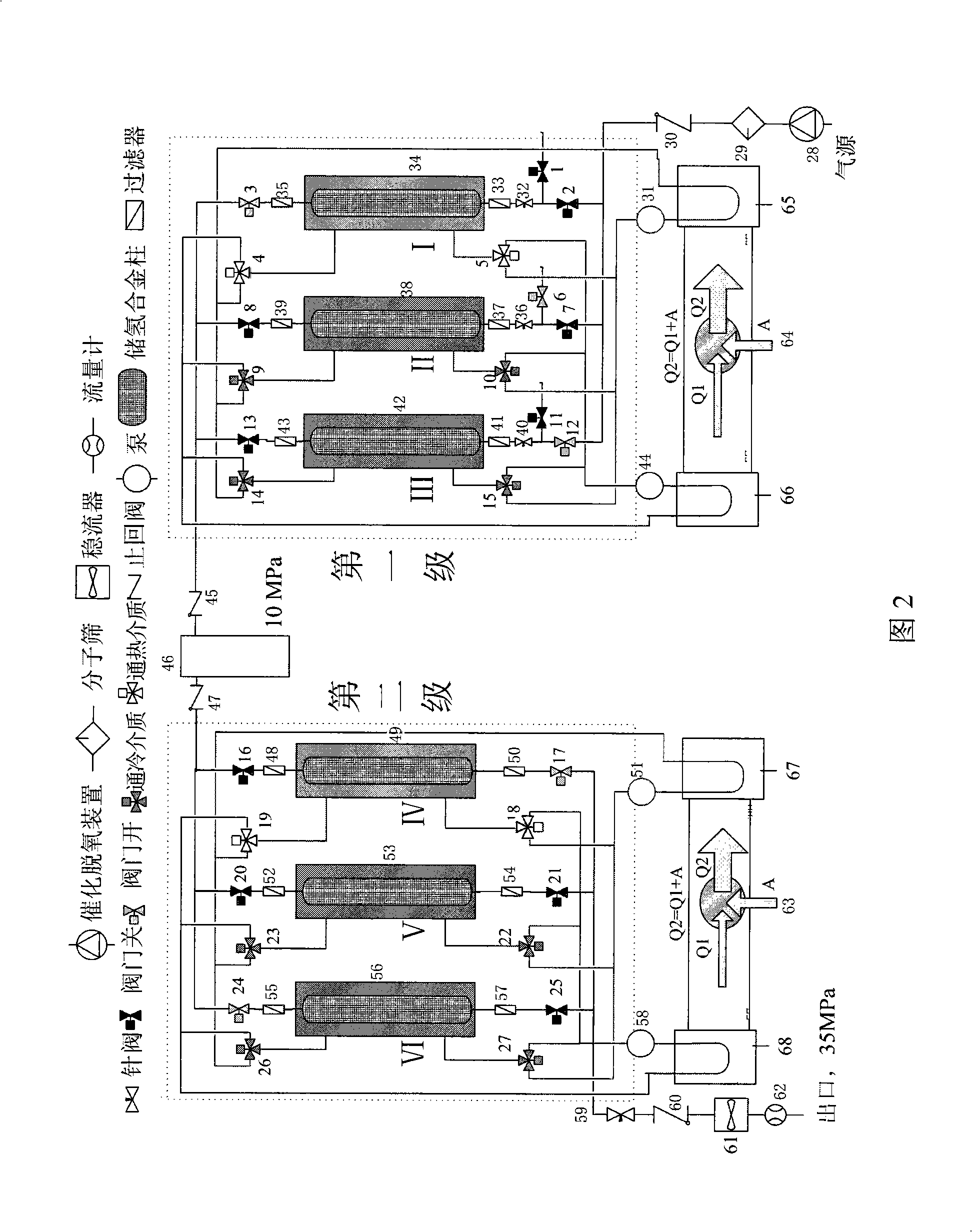

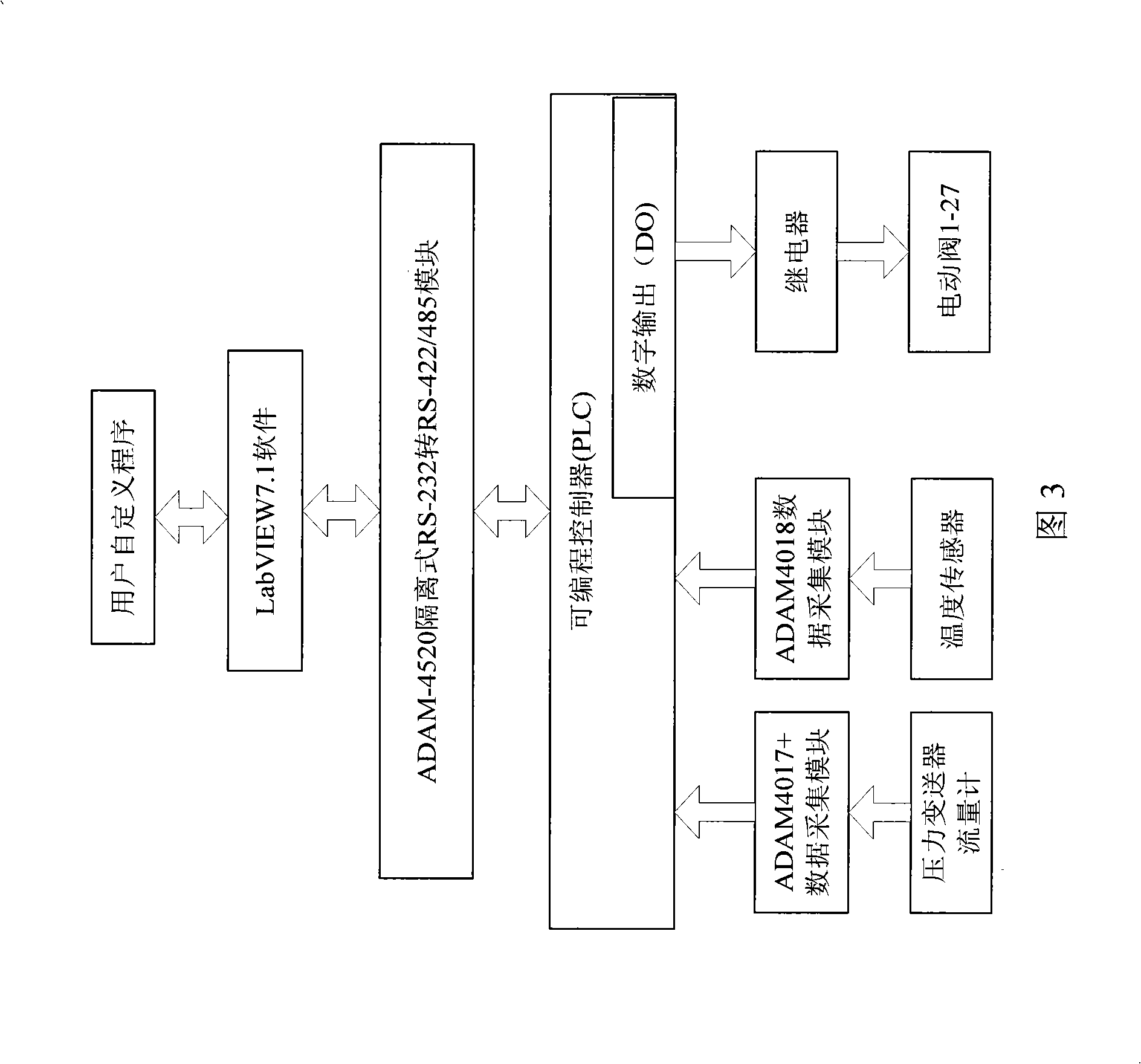

Hydrogen continuous transmission device

InactiveCN101335360AHigh degree of automationAutomatic Control RunabilityHydrogen separationChemical industryLow noiseHigh energy

The invention relates to gas supercharging purification equipment, in particular to a continuous hydrogen feeding device which is applicable to 35MPa hydrogen supercharging purification. The equipment solves the problems that gas emitted by a traditional mechanical hydrogen compressor with oil contains oil and affects the normal operation of a fuel cell and that abrasion occurs in the moving parts in a mechanical hydrogen compressor without oil. The equipment consists of a first level supercharging system, a second level supercharging system and a thermal exchange device. The pressure of hydrogen of general purity (purity is lower than 99 percent) is 1 to 2MPa and increases to 35MPa after passing through the first level supercharging system and the second supercharging system, and the purity of the hydrogen of general purity is higher than 99.999 percent. In the process of hydrogen supercharging and liquid circulation, a control and data collecting system collects and processes the data of temperature, pressure and flow rate, and controls the switching state of various valves in the system. The equipment has the advantages of high automation, all-around measurement parameters, high energy efficiency, convenient operation, high efficiency, safe operation, convenient maintenance, low investment and low noise, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

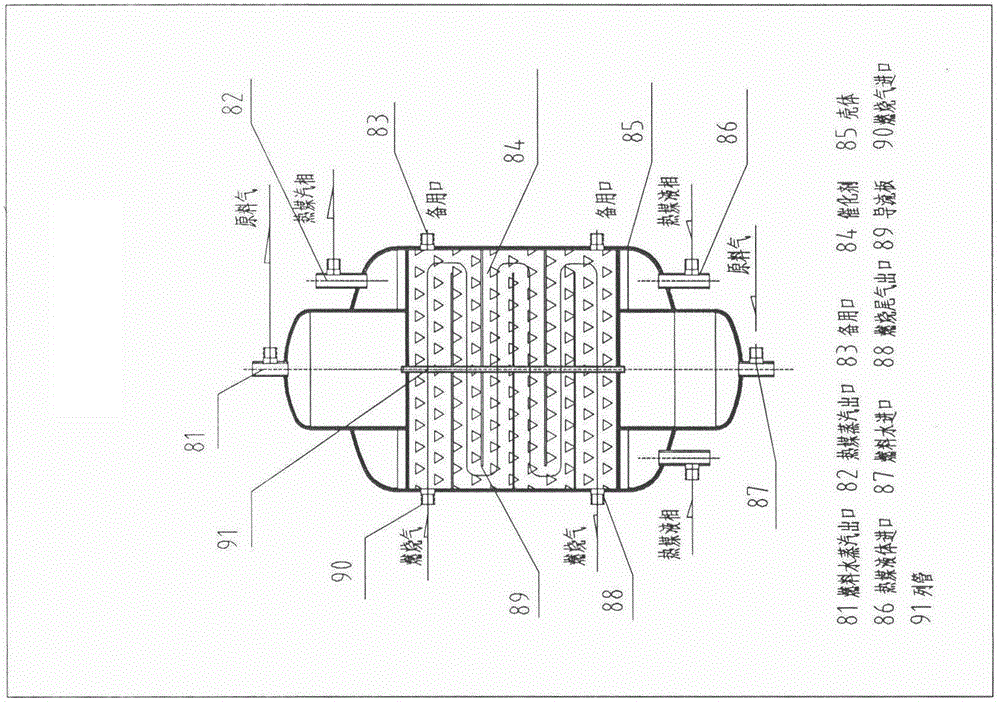

Composite coal hydrogenation oil refining reactor and oil refining method

ActiveCN104593037AGasification processes detailsLiquid hydrocarbon mixture productionCycloneHydrogen

The invention belongs to the technical field of pulverized coal pyrolysis oil refining device, and particularly relates to a composite coal hydrogenation oil refining reactor and an oil refining method, mainly aiming at solving the problems of high resource consumption, serious environmental pollution, high cost and the like of existing coal hydrogenation pyrolysis reaction. The composite coal hydrogenation oil refining reactor disclosed by the invention comprises a gasifier, a reactor, a high-temperature cyclone separator, an oil-gas separation tower and a carbon monoxide conversion system, wherein the top of the gasifier is communicated with a reactor; the top of the reactor is communicated with the high-temperature cyclone separator; a bottom outlet of the a high-temperature cyclone separator is communicated with a semicoke inlet of the gasifier through a semicoke pipeline; a top outlet of the high-temperature cyclone separator is connected with an oil-gas inlet of the oil-gas separation tower through a gas pipe; a gas outlet in the top of the oil-gas separation tower is connected with an inlet of the carbon monoxide conversion system; an outlet of the carbon monoxide conversion system is connected with a hydrogen compressor; and an outlet of the hydrogen compressor is connected with one section of hydrogen inlet and two sections of hydrogen outlets.

Owner:中美新能源技术研发(山西)有限公司

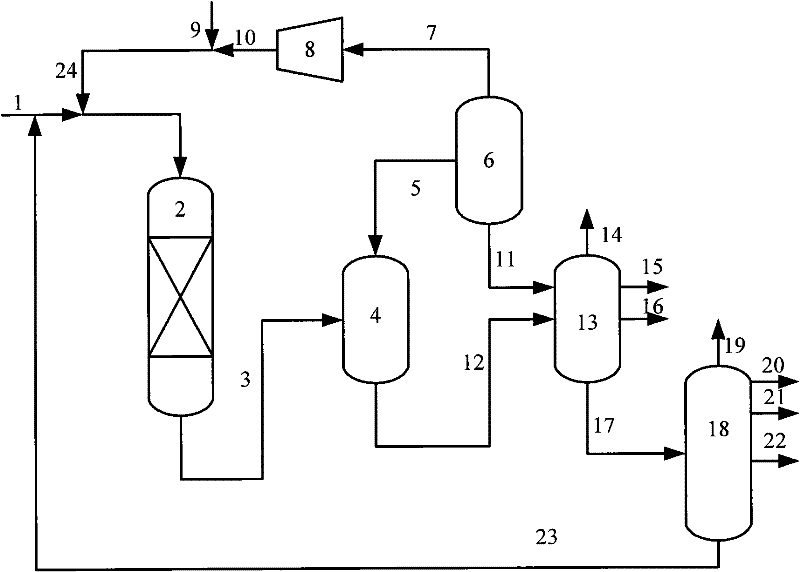

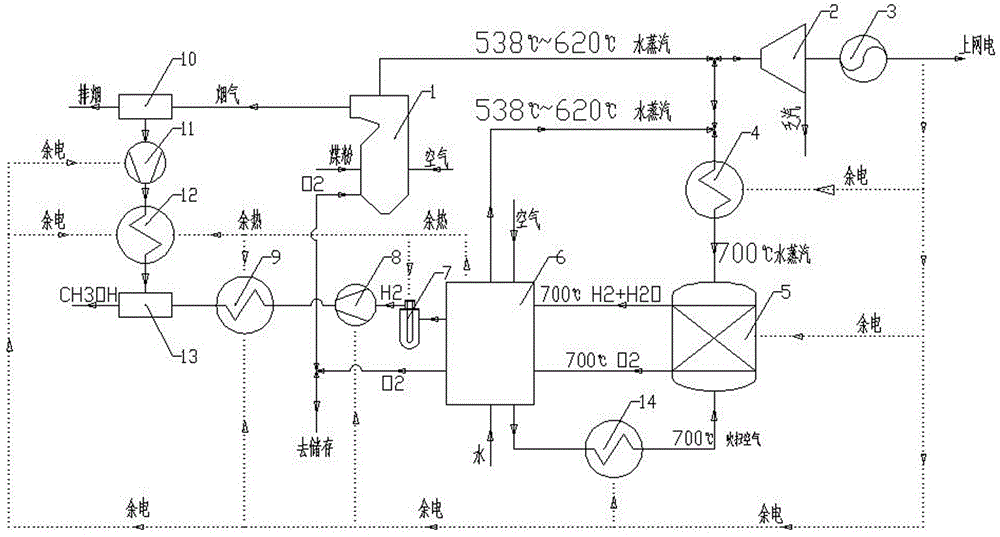

Combination method for residue hydrotreatment, catalytic cracking heavy oil hydrogenation and catalytic cracking

ActiveCN102344829AHigh yieldLow operating costTreatment with hydrotreatment processesGas phaseFuel oil

The invention relates to a combination method for residue hydrotreatment, catalytic cracking heavy oil hydrogenation and catalytic cracking. A reaction product obtained by a residue hydrotreatment reactor is separated into gas phase material flow and liquid phase material flow, residue hydrogenation tail oil obtained by fractionating the liquid phase material flow is taken as a catalytic cracking raw material to enter into a catalytic cracking device, catalytic cracking heavy oil in the catalytic cracking product is mixed with the gas phase material flow of the residue hydrogenation reaction product to enter into a catalytic cracking heavy oil hydrogenation reactor, the hydrogenated catalytic cracking heavy oil is circularly returned into the catalytic cracking device. According to the invention, a residue hydrogenation device and the catalytic cracking device are organically combined for conversing the residual oil into light oil to maximum limit and raising the yield of gasoline and diesel oil. In addition, a hydrogen source and a hydrogen system of the existing residue hydrogenation device are fully used, the separated hydrogen source and a circular hydrogen compressor are not required to the catalytic cracking heavy oil hydrogenation which substantially saves the investment cost and operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

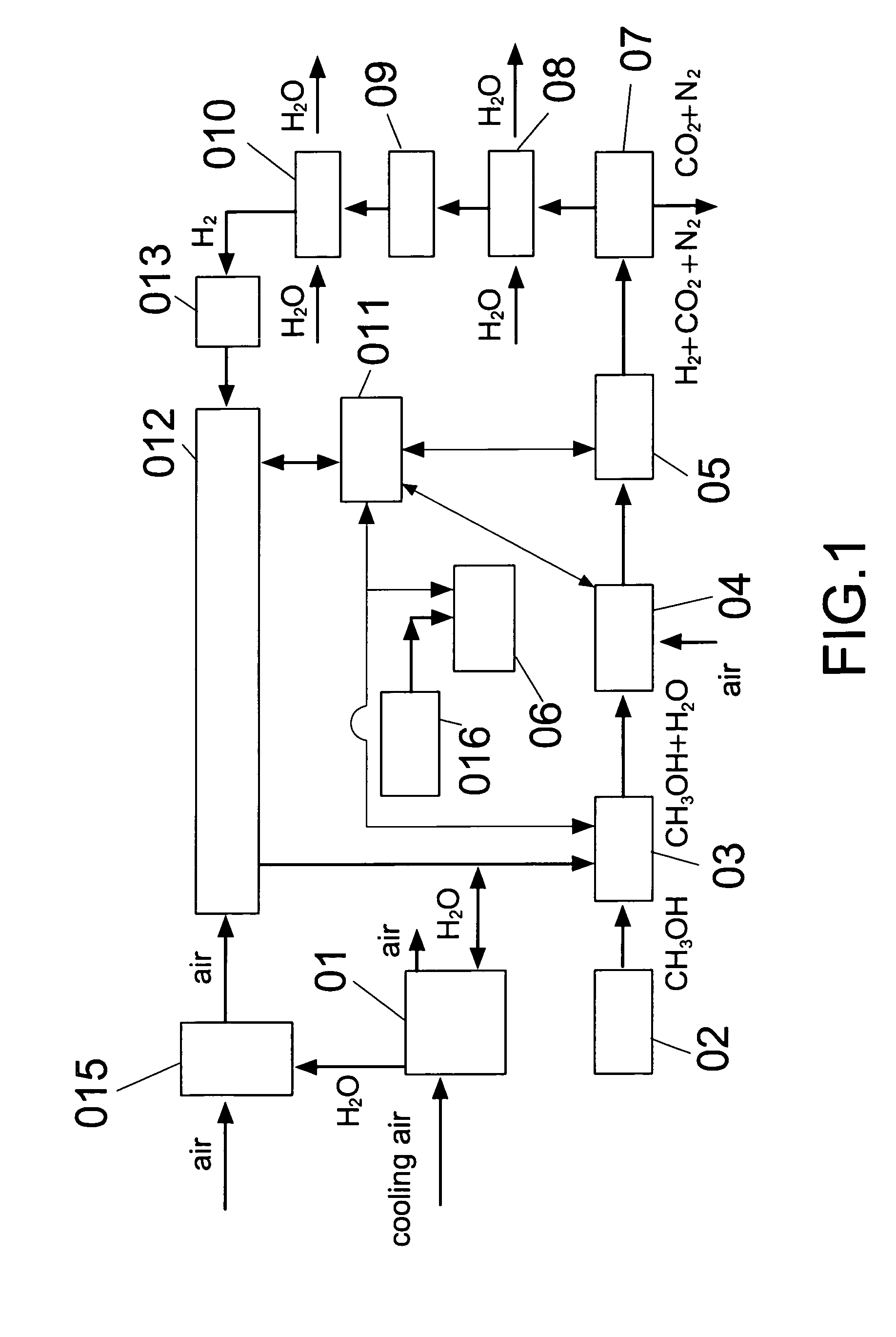

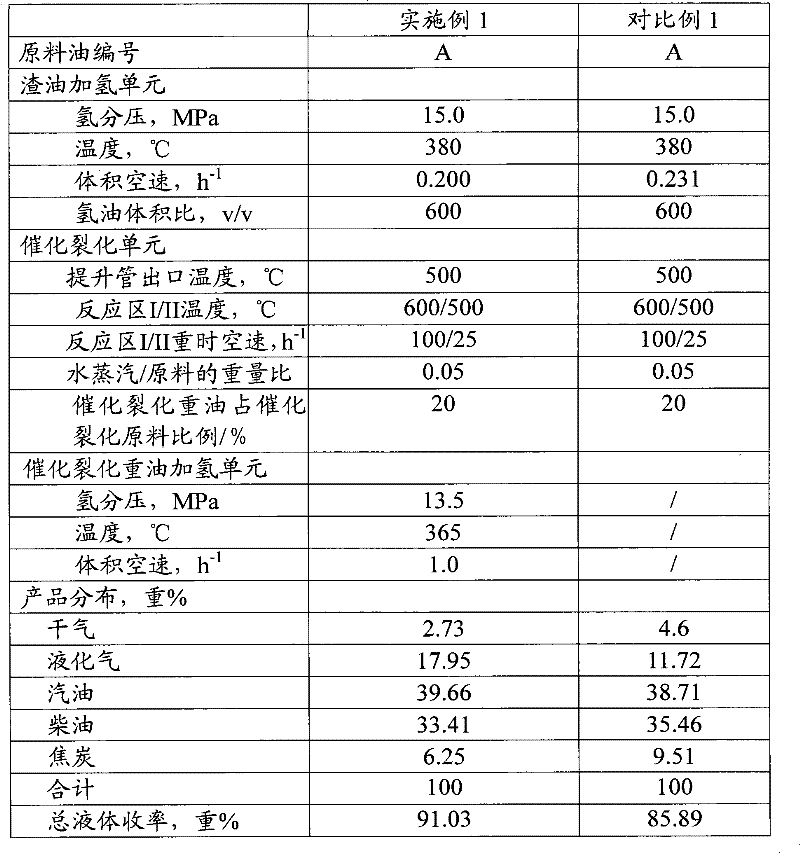

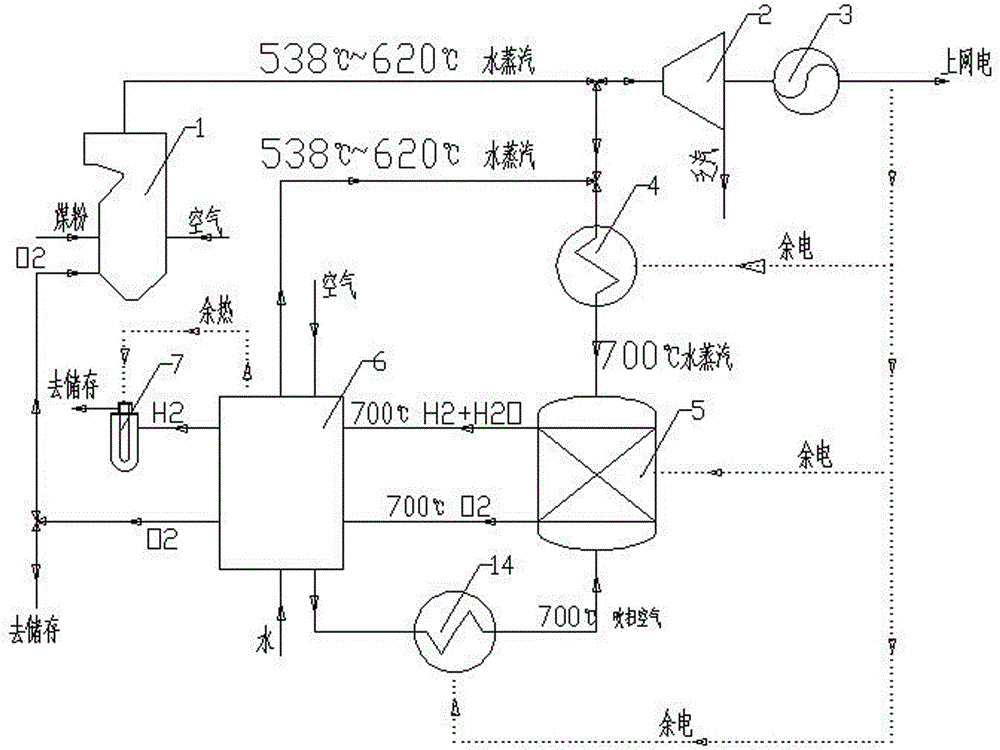

System and method for producing hydrogen and methyl alcohol by utilizing residual electricity and residual heat of coal-fired generating unit

The invention relates to a system and a method for producing hydrogen and methyl alcohol by utilizing residual electricity and residual heat of a coal-fired generating unit. The system comprises a boiler, a steam turbine and an electric generator, wherein the boiler produces water steam to drive the electric generator through the steam turbine to generate electricity. The system also comprises a water steam auxiliary electric heater, a high-temperature water steam electrolytic bath, a residual heat recovery device, a scavenging air auxiliary electric heater, a hydrogen compressor, a hydrogen heating device, a carbon dioxide collecting device, a carbon dioxide compressor, a carbon dioxide heating device and a methanol synthesis device. According to the method, a boiler main steam outlet is divided into two paths, wherein one path of steam enters the steam turbine for work to drive the electric generator to generate electricity; the other path of steam enters the water steam auxiliary electric heater so as to be heated to achieve the water steam electrolysis working temperature, and then enters the high-temperature water steam electrolytic bath to electrolyse; and a high-temperature hydrogen / water steam mixture is formed on an outlet at the cathode side of the electrolytic bath. The system and the method provided by the invention are reasonable in procedure, and efficiently utilize the residual electricity / the residual heat of the coal-fired generating unit to produce fuels such as the hydrogen and the methyl alcohol.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Distributed non-combustion type constant-temperature pressurized power generation system

InactiveCN105895936ASmall fluctuations in heat recoveryExtend your lifeFuel cell auxillariesFuel cell detailsCarbon monoxideVapor–liquid separator

The invention provides a distributed non-combustion type constant-temperature pressurized power generation system. The system comprises a water tank (1), a fuel storage tank (2), a fuel water proportioning pump (3), a mixer A (4), a fuel atomizer (5), a second heat exchanger (26), a first heat exchanger (25), dehydration tanks (27, 28 and 12), a carbon monoxide removal reactor (11), a catalytic combustion reactor (6), a fuel water reforming reactor (29), a composite air-cooling heat sink (22), a hydrogen-air pressure balancer (14), a fuel cell cooling liquid tank (13), a compressed air heat exchanger (23), a fuel cell cooling circulation pump (15), a recycled hydrogen compressor (21), a hydrogen-rich storage tank (19), a hydrogen recycle membrane separator (17), a hydrogen fuel cell pack (16), an exhaust purifier (7), an expansion compressor (9), a control valve (18), a (normal-pressure fuel water) vapor-liquid separator (20), a mixer B (8), a mixer C (10), a mixer D (24), a steam trap (30), a system controller (31), a one-way valve (41) and valves (42-54). By applying an energy state theory, a vapor-liquid two-phase coexistence constant-temperature condensation or evaporation principle and phase-change heat-transfer highest efficiency principle, hydrogen production by reforming and constant-temperature control on a hydrogen fuel battery are achieved.

Owner:YANGZHOU SANYE NEW ENERGY SCI & TECH CO LTD

Ultrahigh pressure hydrogen pressure test system

PendingCN110702528AHigh test pressureImprove the efficiency of inflation experimentsMachine part testingMaterial strength using tensile/compressive forcesUltra high pressureGas cylinder

The invention discloses an ultrahigh pressure hydrogen pressure test system. The system comprises a hydrogen input port, wherein the hydrogen input port is connected with a gas inlet of a first gas cylinder group through a first pipeline provided with a first stop valve, a gas outlet of the first gas cylinder group is connected with a gas inlet of a second gas cylinder group through a second pipeline provided with a pressure reducing valve, a gas outlet of the second gas cylinder group is connected with a gas inlet of a 120MPa hydrogen compressor through a third pipeline, a gas outlet of the 120 MPa hydrogen compressor is connected with a gas inlet of a high pressure gas cylinder group through a fourth pipeline, a gas outlet of the high pressure gas cylinder group is connected with a hydrogen inlet and a hydrogen outlet of a test gas cylinder through a fifth pipeline, and the fifth pipeline is also connected with the first pipeline through a sixth pipeline provided with a fifth pneumatic ball valve and a second one-way valve. The ultrahigh pressure hydrogen pressure test system is high in test pressure, and adopts a combined pressurization mode of a diaphragm compressor and a high-pressure liquid-driven oil-free piston machine, and the pressurization pressure can reach 120MPa.

Owner:北京海德利森科技有限公司

Cooling and filling method for hydrogen fuel used for vehicle

InactiveCN102104162AImprove high temperature conditionMeet fast filling needsFuel cell heat exchangeGas cylinderProcess engineering

The invention discloses a cooling and filling method for a hydrogen fuel used for a vehicle, and belongs to the technical field of gas fuel filling. The method is characterized by comprising the following steps of: (1) compressing and heating hydrogen from a hydrogen source by using a hydrogen compressor; (2) exchanging heat with a cooling pipeline through a heat exchange pipeline in a cooling heat exchange device to cool the compressed hydrogen in the heat exchange pipeline; and (3) connecting a filling gun of a filling and metering device with an on-vehicle hydrogen cylinder, and filling the compressed and cooled hydrogen into the on-vehicle hydrogen cylinder to finish filling. The method has the advantages that: not only the temperature of a gas cylinder can be controlled in a safety loading condition, but also the requirement on rapid filing of the vehicle can be met to ensure the safety of a filling process of the vehicle. The hydrogen filling time is short; and the safety and stability effects are very good. The method is not only suitable for the hydrogen filling of an on-vehicle gas cylinder under the pressure of 35 MPa, but also suitable for the hydrogen filling of the on-vehicle gas cylinder under the pressure of 70 MPa.

Owner:上海昆仑新奥清洁能源股份有限公司

Combined hydrogenation method

ActiveCN1952069AGood for deep saturationReduce loadTreatment with hydrotreatment processesNaphthaProduct gas

The invention disclosed an associated hydrogenating technology. The invention is about deep hydrogenationg refinement of poor quality ship-coal by neo-hydrogen (such as cyclane radical or cyclane intermediate radical). The gas which is rich in hydrogen is used as the supplementary gas in hydrocracking process of diesel oil; the invention adopts hydrocracking method to treat poor quality diesel oil; the gas which is rich in hydrogen can be recycled. In the invention, the poor quality ship-coal contacts the neo-hydrogen first so as to get the high-quality ship-coal products; by hydrocracking the diesel oil, the producer can produce high quality diesel oil directly, as well as some high quality ship-coal and high arene naphtha. The invention can save the investment of devices and equipments; it also has the advantage of less hydrogen consumption, less energy expenditure, and small circulated hydrogen compressor volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for preparing ethanol through acetic acid or acetic ester catalytic hydrogenation reaction

ActiveCN103373899AReduced hydrogen-acid ratioSolve the problem of high operating costsOrganic compound preparationHydroxy compound preparationAcetic acidAcetic acid ear

The invention relates to a device and method for preparing ethanol through acetic acid or acetic ester catalytic hydrogenation reaction. According to the device and method, acetic acid or acetic ester and hydrogen are used as raw materials, at least two reaction sections are connected in series, the acetic acid or acetic ester raw material is divided into two or more sections which enter each hydrogenation reaction section, liquid acetic acid or acetic ester or partially-liquid acetic acid or acetic ester feeds among the reaction sections to play a role in direct heat exchange and cooling and raw material supplementation, and a reaction system is provided with one recycle hydrogen compressor, so that the hydrogen acid ratio of the whole acetic acid or acetic ester hydrogenation reaction system is greatly reduced under the condition that the hydrogen acid ratio of each reaction area is higher. Compared with the prior art, by adopting the device and the method, industrial amplification of a process for producing ethanol through acetic acid or acetic ester hydrogenation is well realized, so that the device and the method can be widely applied to industrial production of ethanol.

Owner:PUJING CHEM IND SHA +1

Liquid-solid two-phase hydrogenation method

ActiveCN101381623AReduce dosageReduce lossesRefining to eliminate hetero atomsSolubilityLiquid product

The invention discloses a solid-liquid two phase hydrogenation method. In the method, the circulating hydrogen and a circulating hydrogen compressor are not used, hydrogen is mixed with fresh raw oil and circulating oil to form mixing material current in the presence of a solvent or a diluent, the mixing material current enters a reactor, a part of or all the circulating oil is mixed with the hydrogen, and enters the reactor from the catalyst bed interlayers through one path or a plurality of branch paths, a part of the reaction effluent is used as the circulating oil, and another part of the reaction effluent is separated to be the solvent or the diluent, the liquid product is the finished product, the gas with the volume percentage of between 0.1 and 15 percent is contained in the reactor according to the total volume of the reactor, and the solubility of the hydrogen in the solvent or the diluent is larger than that in the mixture of fresh raw oil and the solvent or the diluent.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com