Distributed non-combustion type constant-temperature pressurized power generation system

A non-combustion type, power generation system technology, applied in the direction of fuel cell additives, fuel cell components, etc., can solve the problems of commercialization, fossil power pollution, and difficulty in stable control, and achieve system-wide stability Ease of operation, improved thermal efficiency, and stable operation of the entire system achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

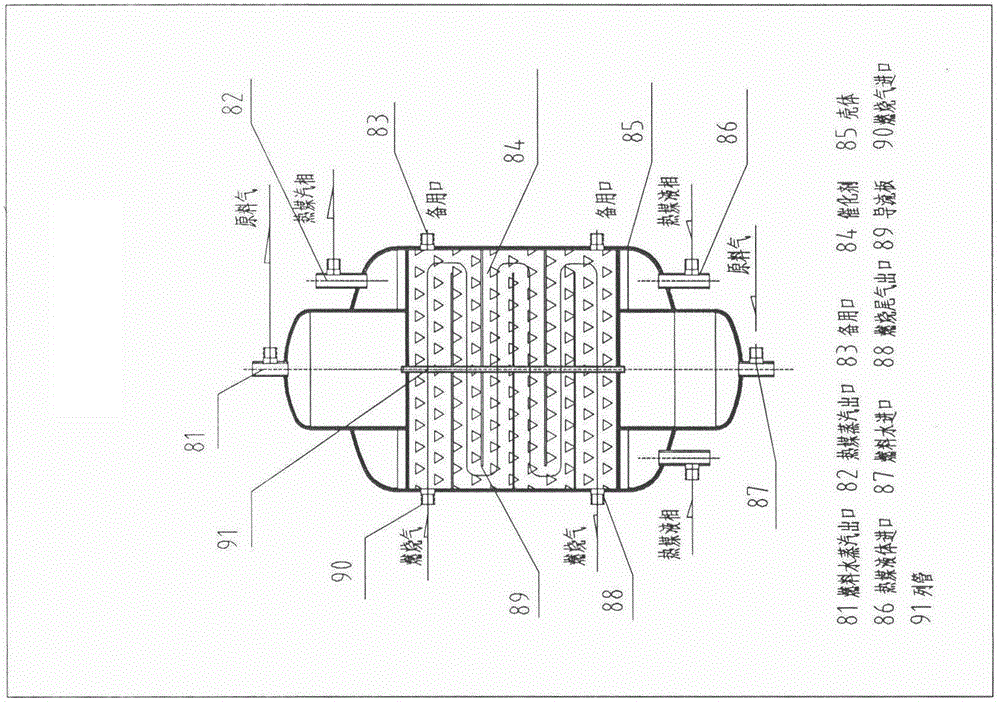

[0032] Example 1, such as figure 1 As shown, at system cold start:

[0033] When the system is cold booted:

[0034] All valves are controlled to be closed by a system controller (31). Open the valves (42, 43), start the expansion compressor (9), start the fuel atomizer (5) and control the fuel atomization into the mixer B (8) and the hot compressed air mixed into the catalytic combustion reactor (6) pre- Heat the whole system; the catalytic combustion tail gas is discharged from the catalytic combustion reactor (6) through the expansion compressor (9) to recover the heat work and reduce the power consumption of the compressed air before being emptied.

[0035] When the circulating heat medium in the catalytic combustion reactor (6) reaches the control pressure, the system controller (31) opens the valves (46, 49, 53), starts the fuel cell cooling circulation pump (15) and the fuel-water ratio pump (3 ), the fuel-water ratio pump (3) draws water and fuel in a certain ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com