Hydrogen continuous transmission device

A kind of equipment and hydrogen transmission technology, which is applied in the direction of mechanical equipment, hydrogen separation, climate sustainability, etc., can solve the problems of oil content, wear of moving parts, and affecting the normal operation of fuel cells, etc., to achieve comprehensive measurement parameters, improve working life, and provide The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

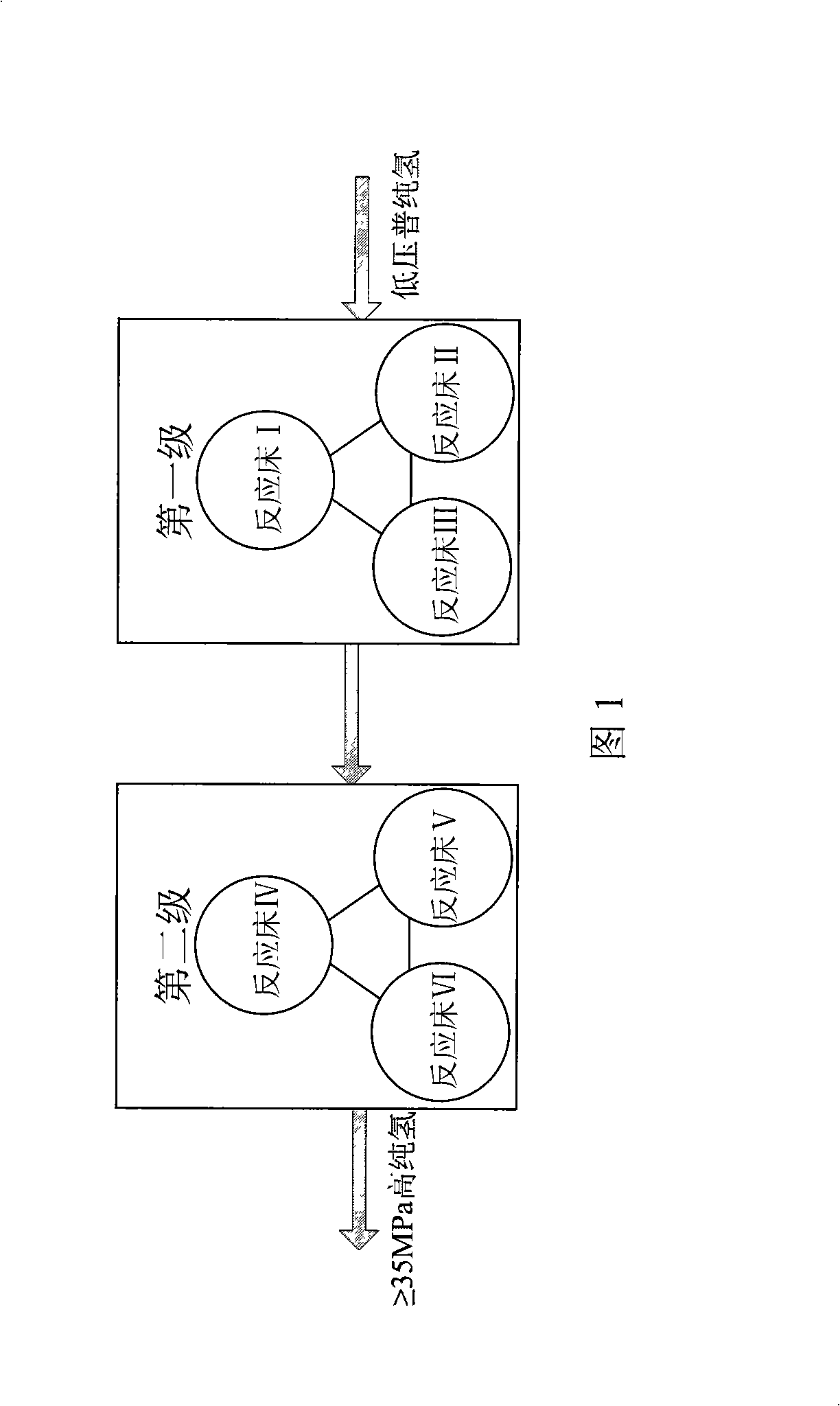

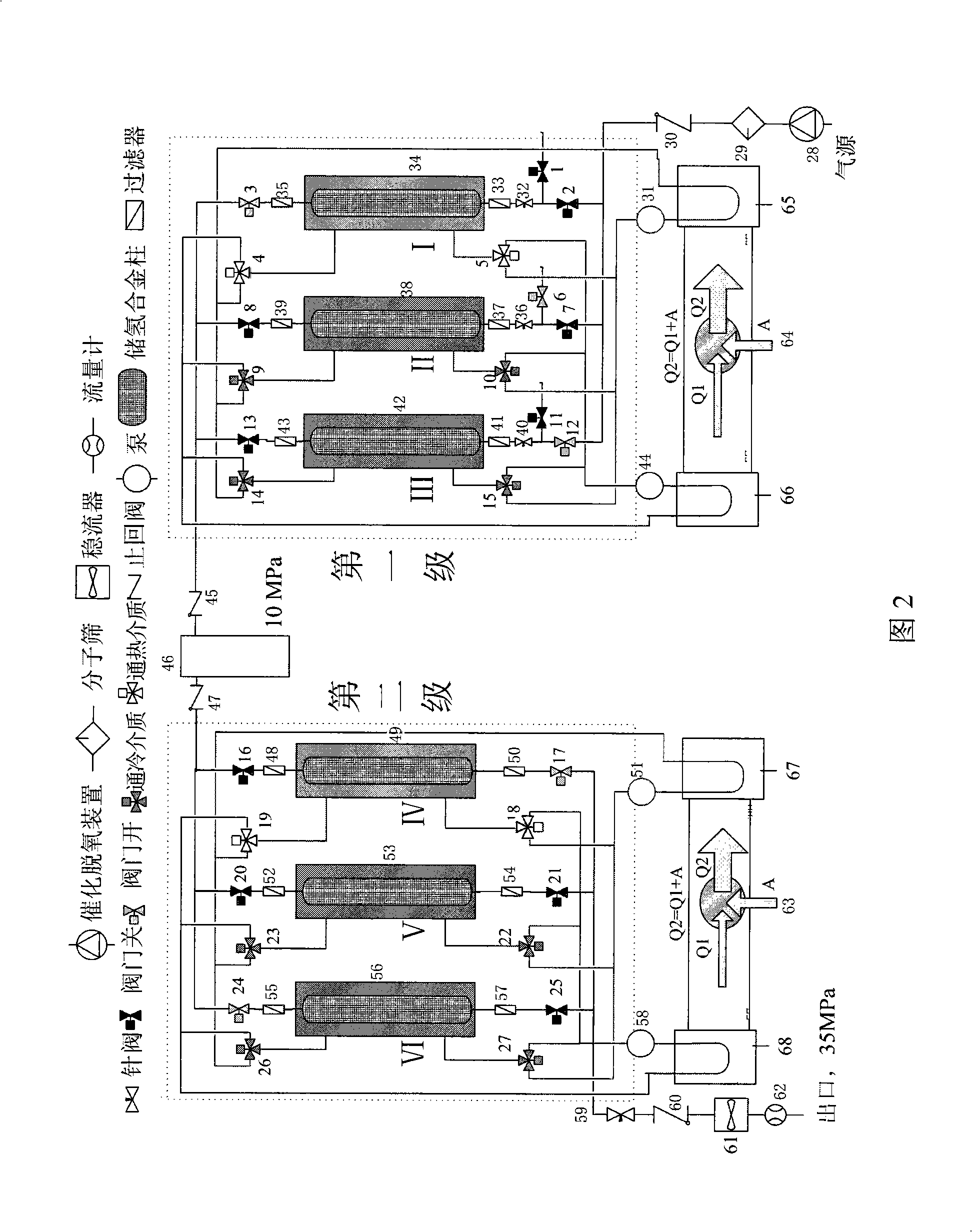

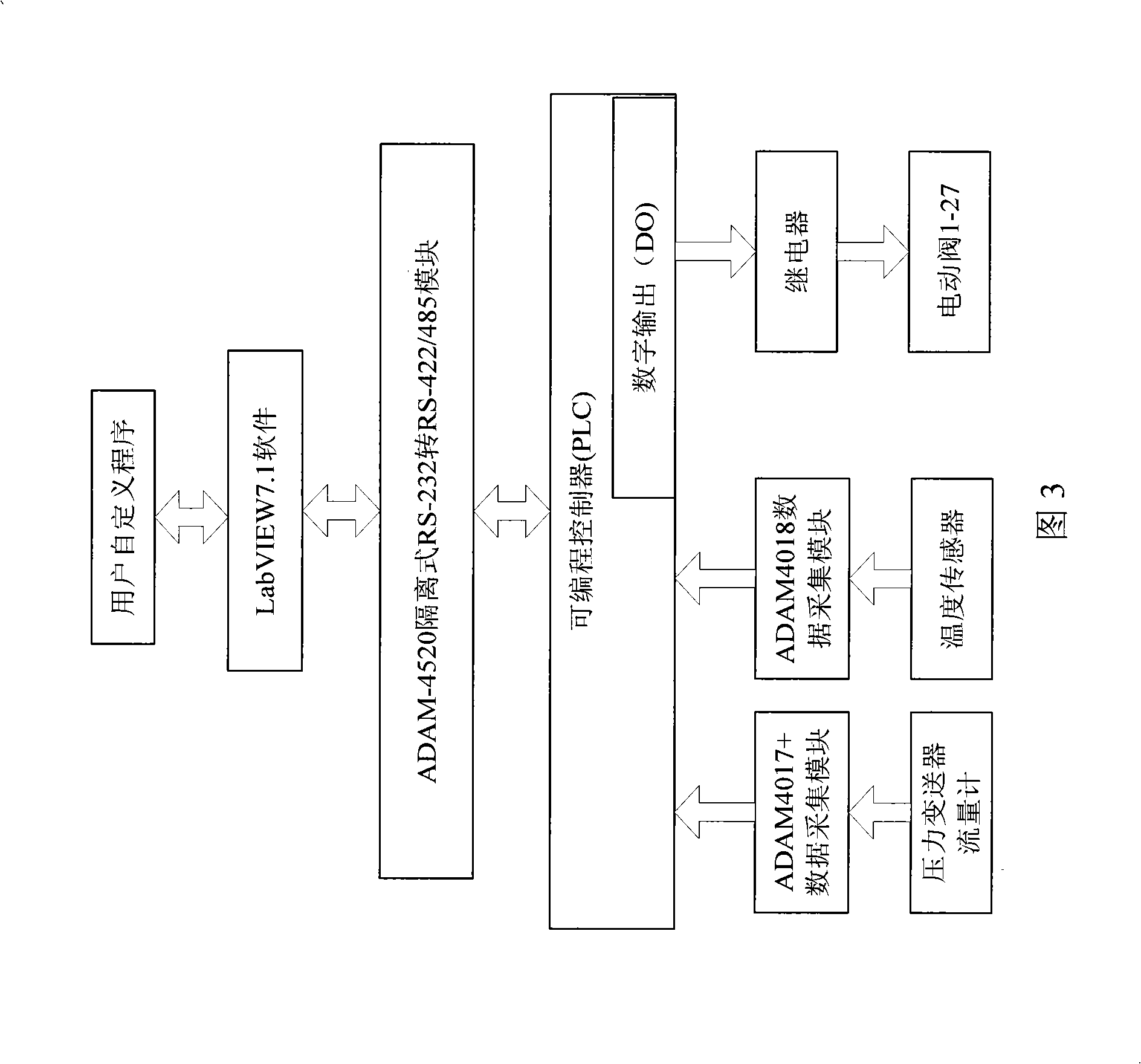

Method used

Image

Examples

Embodiment

[0058] The hydrogen gas with a pressure of 1 MPa and a hydrogen purity of 98% is connected to the entire device through the device inlet. In the first stage pressurized system, the alloy filled in the hydrogen storage alloy column is La-Y-Ni-Al alloy, and the heat transfer medium used in the liquid circulation heating pipeline and liquid circulation cooling pipeline in the first stage heat exchange system is water; in the second-stage pressurization system, the material filled in the hydrogen storage alloy column is LaNi 5 Ball-milling modified vanadium, the specific modification process is as follows: the electrolytic V is first washed with 50% HCl solution, then washed with water and absolute ethanol, and finally dried. Combine electrolytic V and LaNi 5 Mix according to the mass ratio of 12:1 and place it in a planetary ball mill, carry out controlled mechanical ball milling in Ar atmosphere, the ball-to-material ratio is 20:1, the ball milling time is 2 hours, and the ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com