Patents

Literature

68results about How to "Many measurement parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

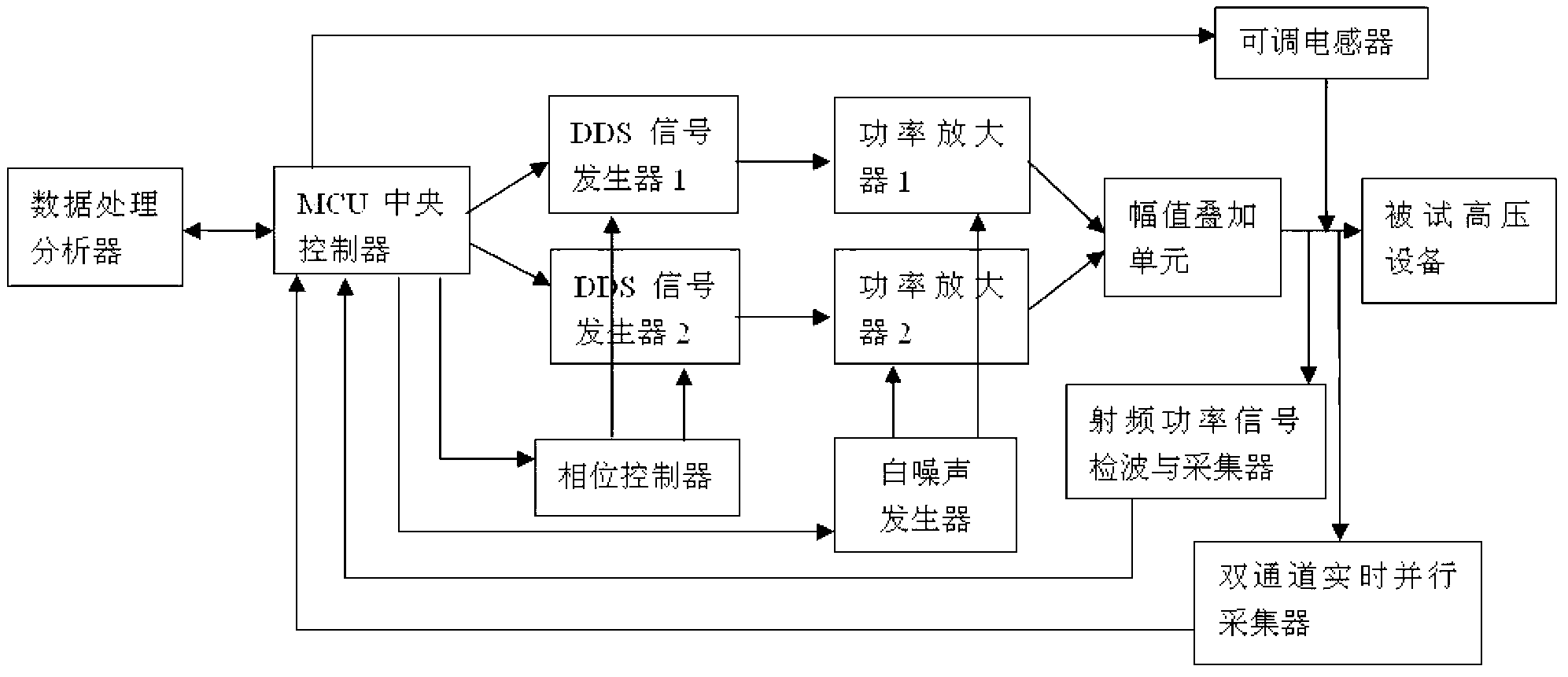

Capacitive high-voltage equipment insulation aging diagnostic test system and working method thereof

ActiveCN103323718ACause insulation damageGood test resultsTesting dielectric strengthInformation processingNoise control

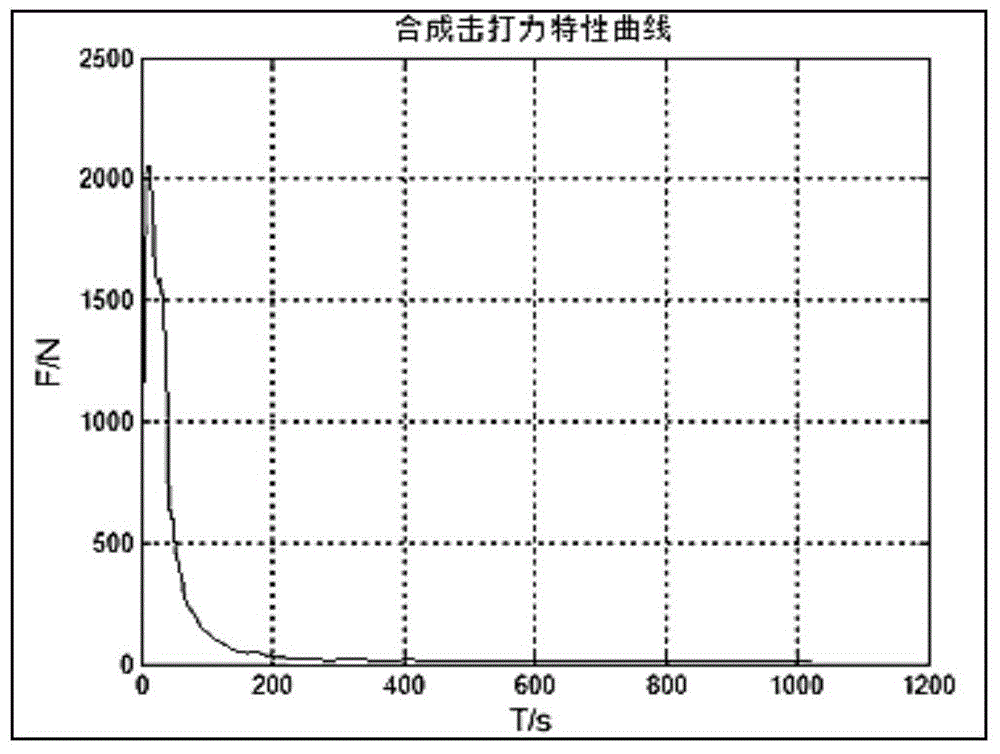

The invention discloses a capacitive high-voltage equipment insulation aging diagnostic test system and a working method thereof. Double-frequency time-varying signals are used in the system for carrying out an overlaying impact test, two independent DDS signal generators, a power amplifier with white noise control, an amplitude overlaying unit and a controllable inductive load which is in output connection with the amplitude overlaying unit in series or in parallel form a composite aliasing waveform output loop, a set of information processing analysis method is combined, and insulation aging of tested high-voltage equipment is subjected to test diagnosis. Compared with the prior art, the insulation aging diagnosis test can be completed by exerting a test signal which is lower than a nominal voltage on the tested high-voltage equipment, insulation damage cannot be caused on the high-voltage equipment, the test can be carried out at any time, on-site testing is convenient, testing efficiency is high, compared with an existing diagnosis test signal which is single in waveform, the overlaying impact test signals can obtain abundant testing parameters, and potential fault of the high-voltage equipment can be easily found.

Owner:GAUSS ELECTRONICS TECH

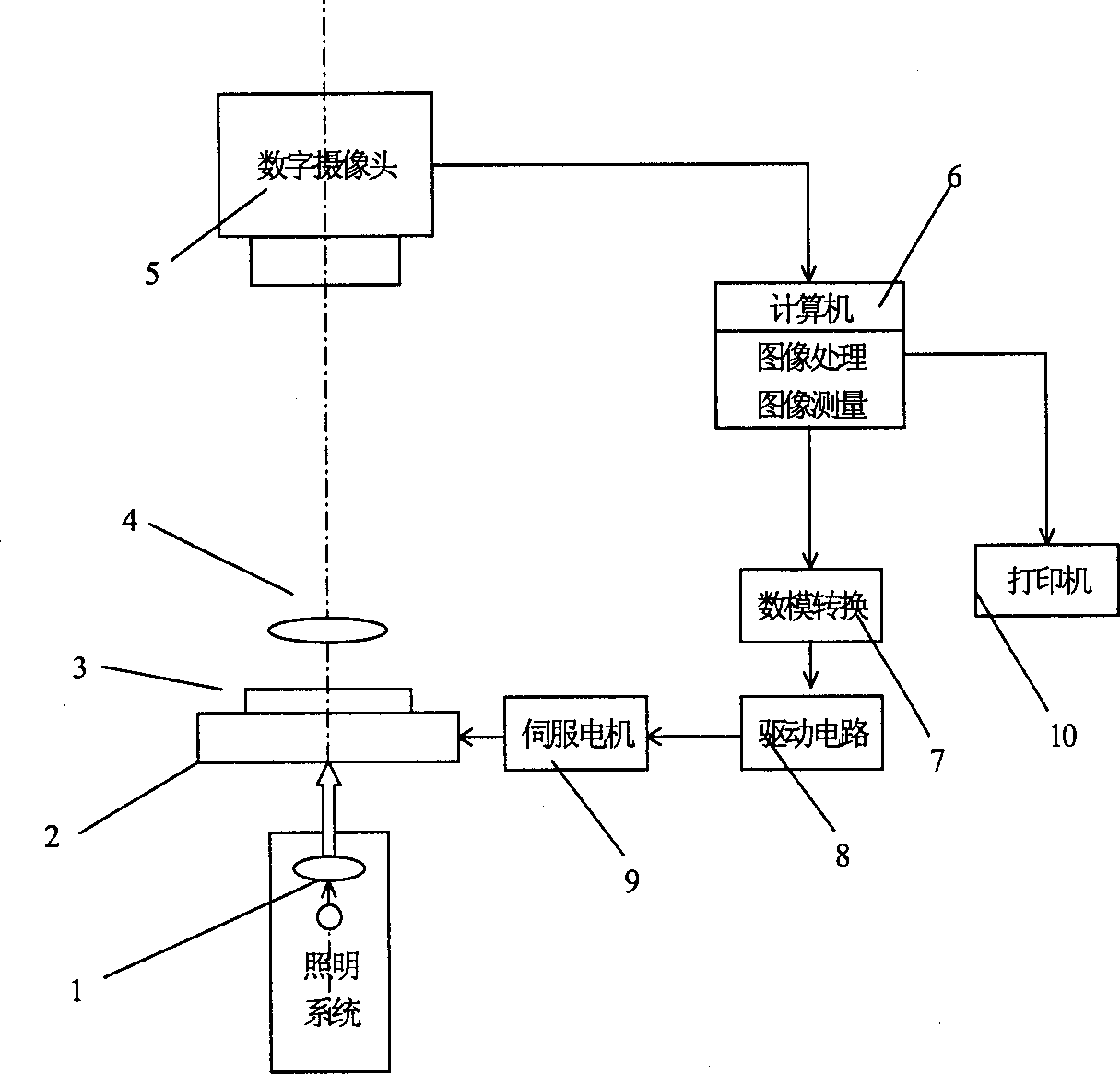

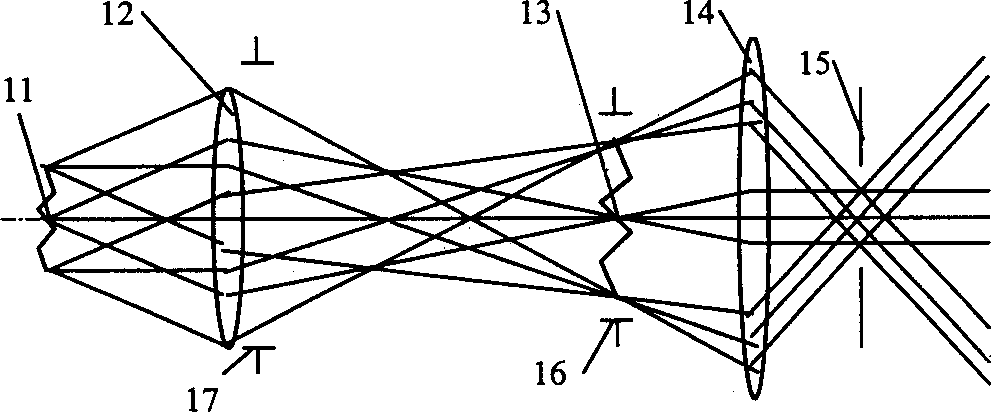

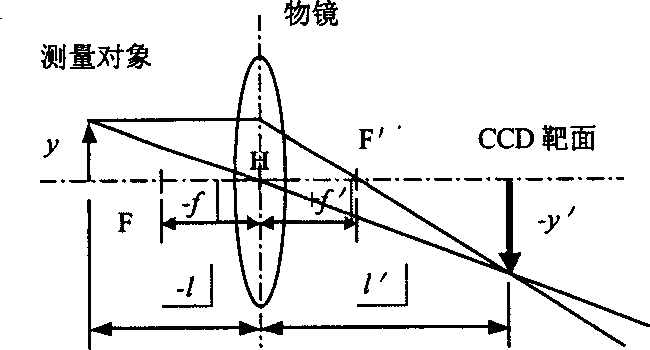

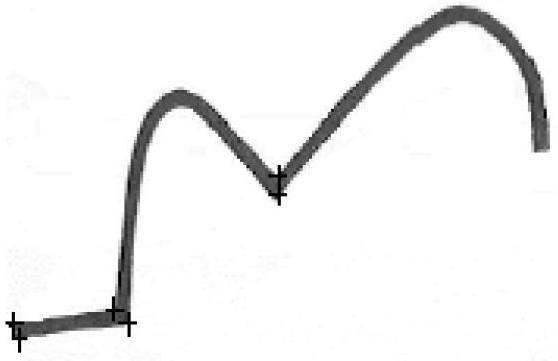

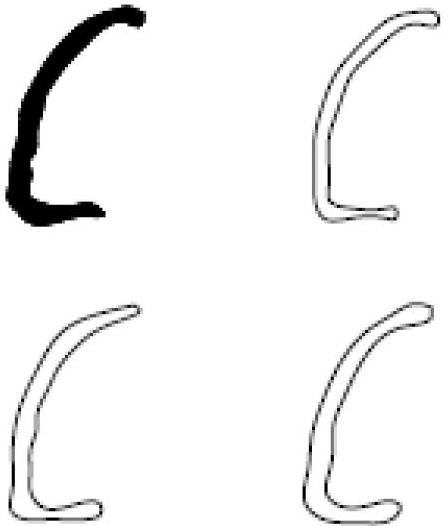

Method and system for measuring wool fiber fineness measurement

InactiveCN1359006AMany measurement parametersReliable resultsMaterial analysis by optical meansContinuous measurementSingle fibre

The present invention relates to a method for measuring wool fibre fineness and its system. Digital camera head (CCD) is adopted to convert the amplified fibre image into digital image, and transfer it into computer to mare real time processing to obtain fibre outline and calculate single fibre fineness, then it counts up the data of average fineness and fineness distribution of all the measured fibres. In said ivnention, general light source is used and the proper alogirhtm and software are designed with can measure animal fibre with the measurement range of 4-300 micrometers, and its measurement speed is 140 fibre / sec.

Owner:TSINGHUA UNIV

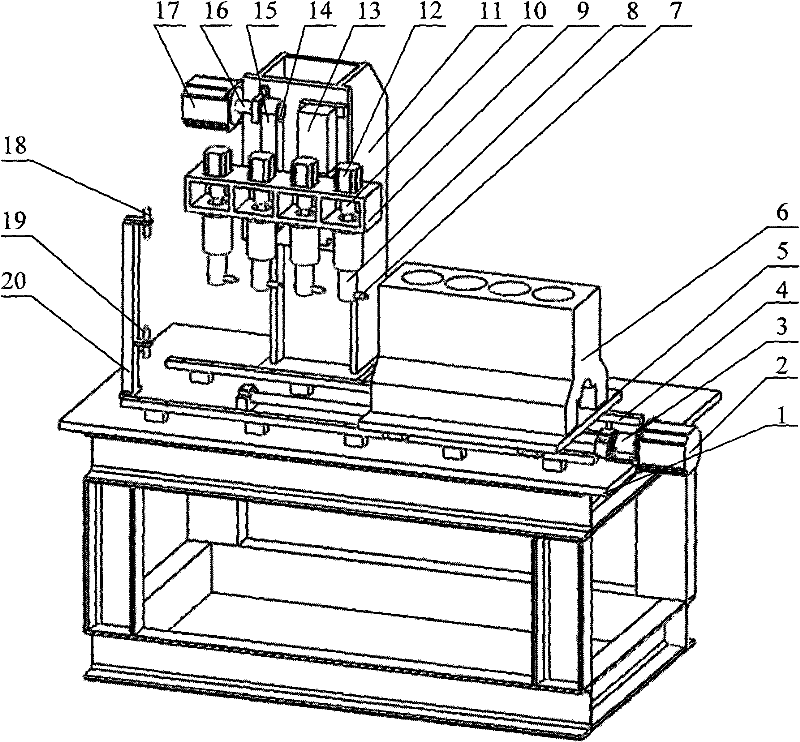

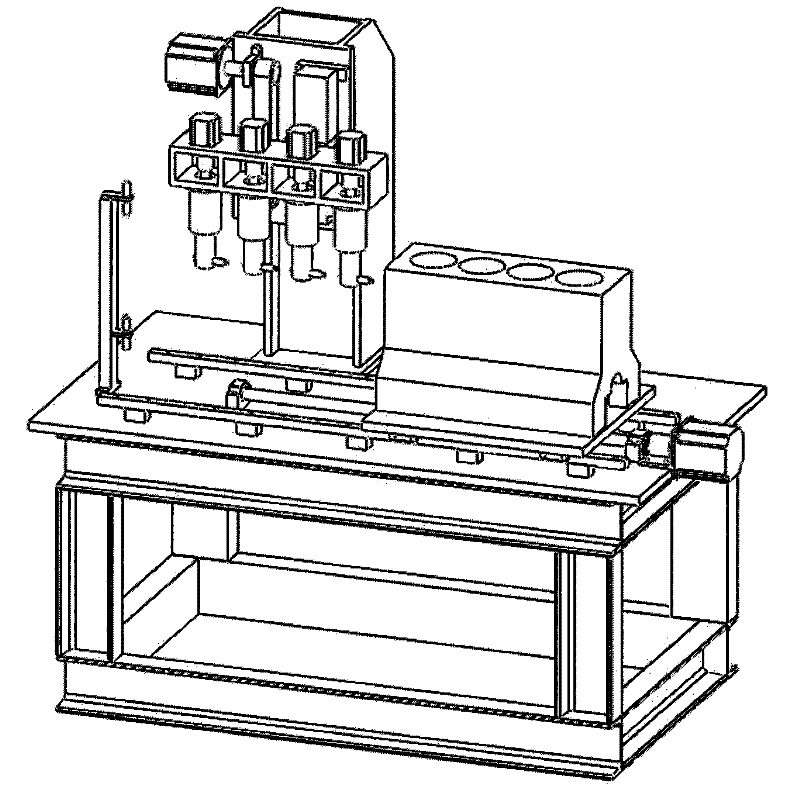

On -line detection equipment for automobile engine cylinder body

InactiveCN102192721ARealize automatic measurementRealize measurementMeasurement devicesAir bearingCoupling

The invention relates to on-line detection equipment for an automobile engine cylinder body and belongs to the technical field of on-line precision measurement. The equipment comprises a substrate platform; a motor fixed on the upper part of the substrate platform is connected with a lead screw guide rail through a coupler; an engine cylinder body detection workbench is arranged above the guide rail; and an engine cylinder body is placed on the detection workbench. A cylindricity measurement substrate is arranged on the substrate platform; a high-precision guide rail is arranged on the cylindricity measurement substrate; a cylindricity measurement adapter plate is connected with a guide rail sleeve; motors, high-precision air bearings and displacement sensors form four groups of cylindricity measurement mechanisms which are arranged on the adapter plate; and a cylindricity measurement motor drives the air bearings to rotate to drive the displacement sensors to rotate to perform measurement. A stepping motor drives the cylindricity measurement adapter plate to move up and down along the guide rail through a synchronous belt to realize the measurement of a cylinder hole of an engine. The substrate platform is fixedly provided with a cylinder height measurement substrate and is provided with the displacement sensor to realize the measurement of the cylinder body height of the engine.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

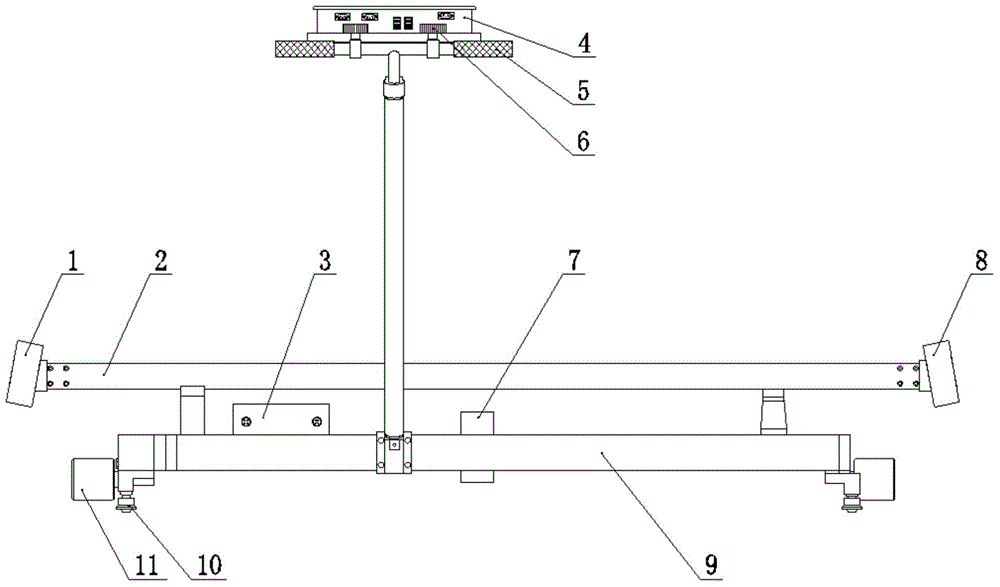

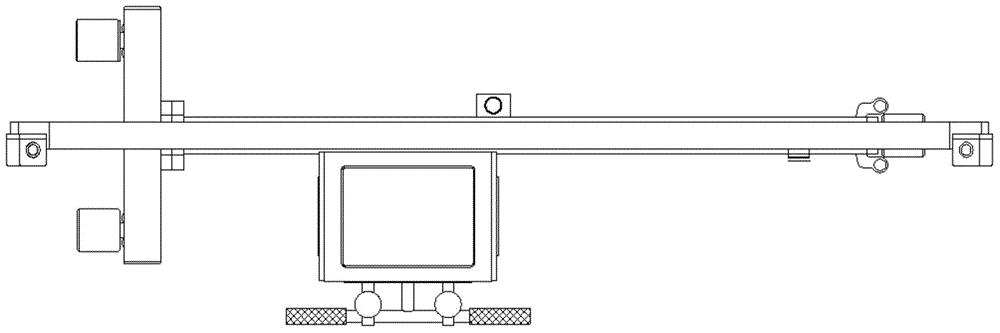

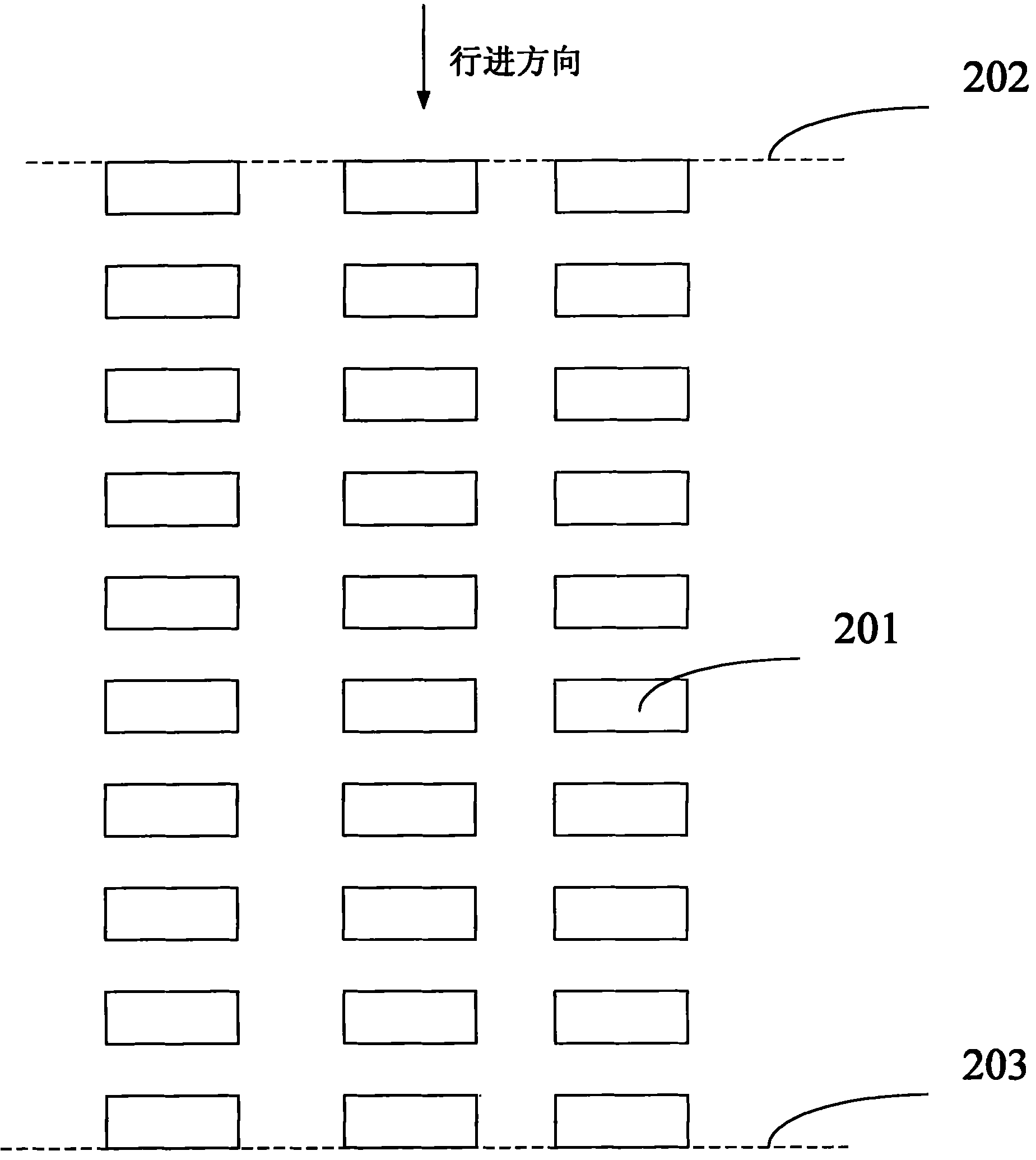

Vision measurement technology-based catenary geometric parameter measurement instrument and detection method

InactiveCN104406521AHigh precisionMany measurement parametersUsing optical meansEarly warning systemMeasuring instrument

The invention discloses a vision measurement technology-based catenary geometric parameter measurement instrument and a detection method. The measurement instrument comprises a measurement trolley, wherein a baseline connected with the measurement trolley is horizontally arranged on the measurement trolley; a camera for acquiring the information of a catenary is arranged at each of the two ends of the baseline, and is connected with the baseline; a vertical rod connected with the measurement trolley is perpendicularly arranged on the measurement trolley; an angle-adjustable industrial computer for being communicated with the cameras is arranged at the top of the vertical rod. According to the measurement instrument and the detection method, the precision measurement instrument which can be used in field is developed based on a precision mechanical design in combination with the requirements of an industrial field environment by taking computer vision measurement as a core; massive data acquired in field is analyzed to construct a railway catenary state model to deeply and precisely measure the state of the catenary so as to form a driving safety early-warning system of a catenary system.

Owner:济南蓝动激光技术有限公司

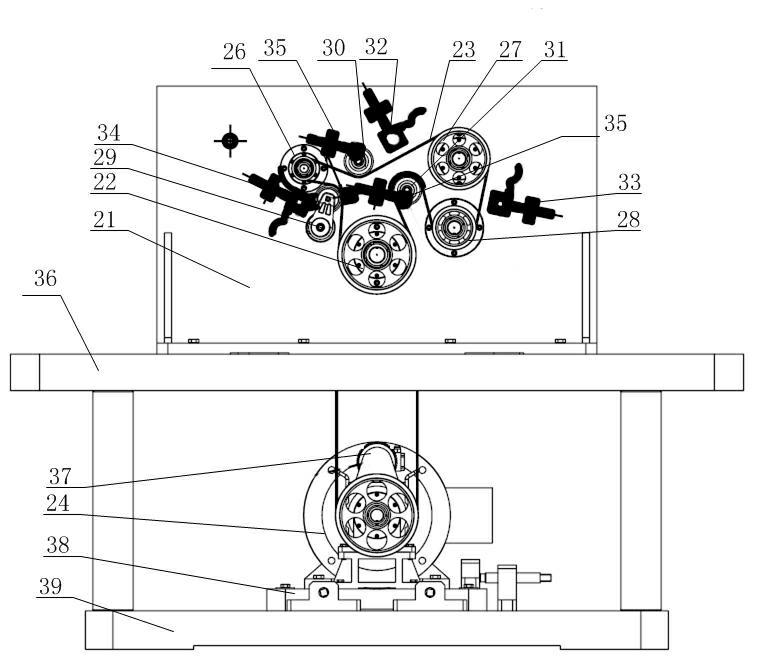

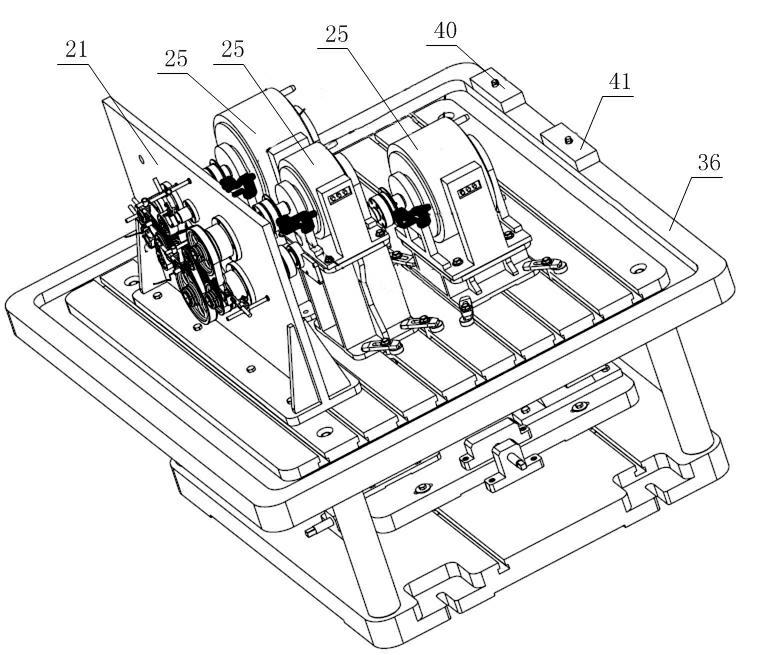

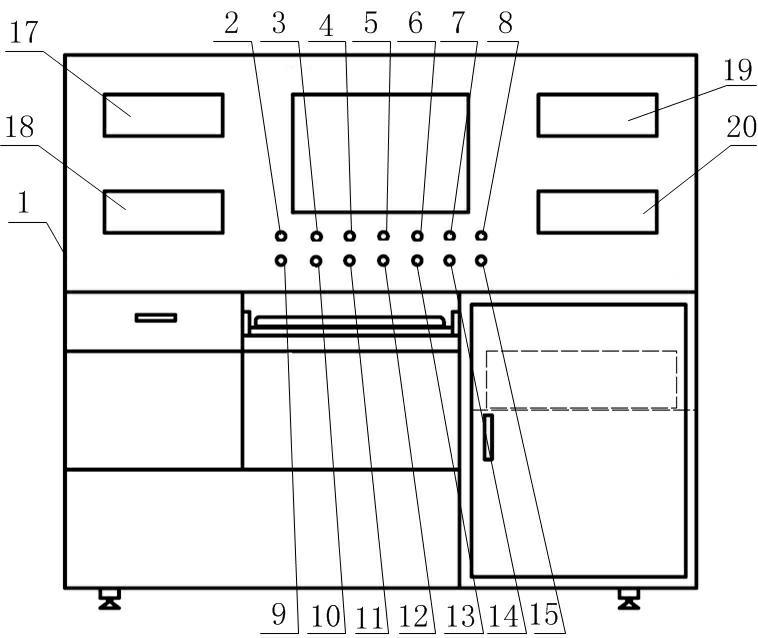

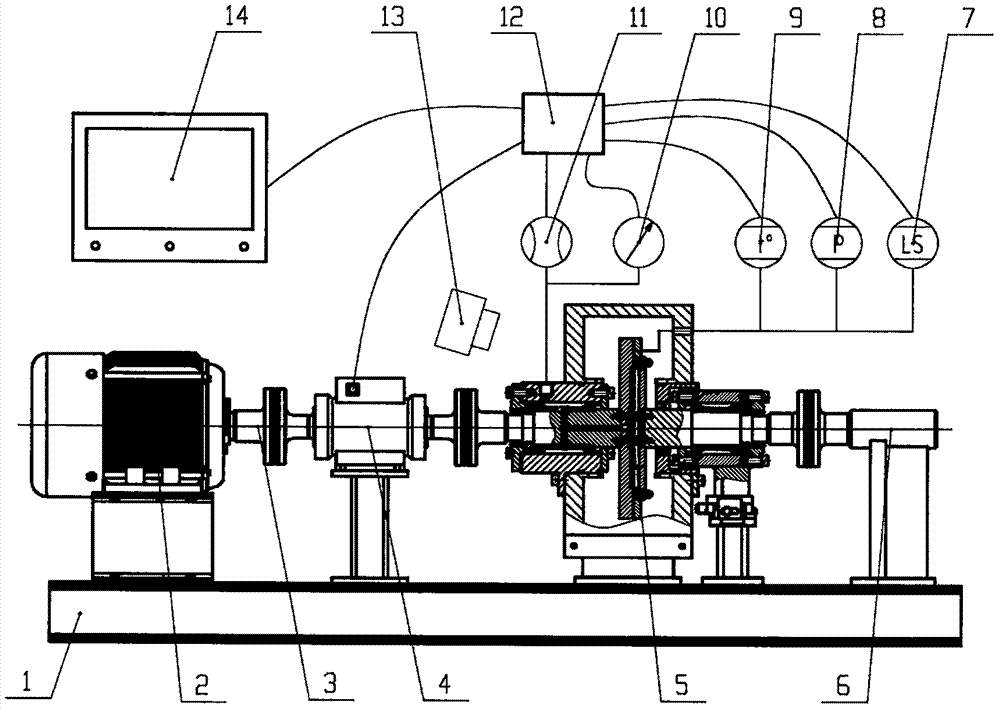

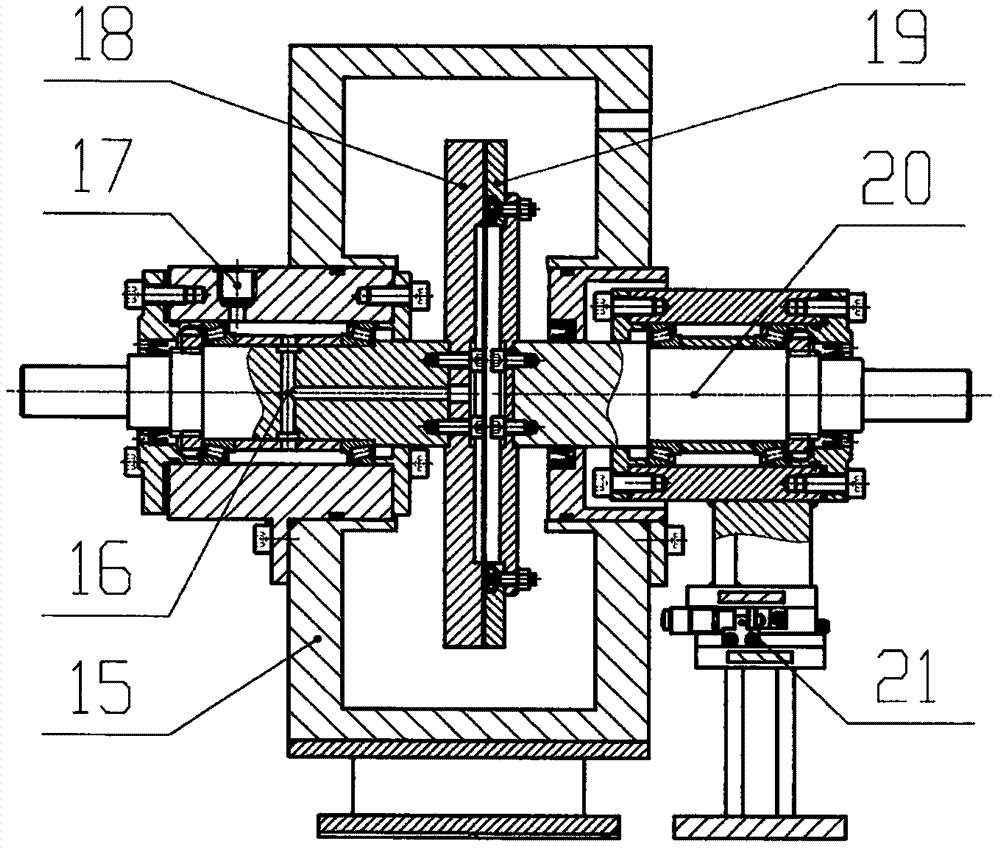

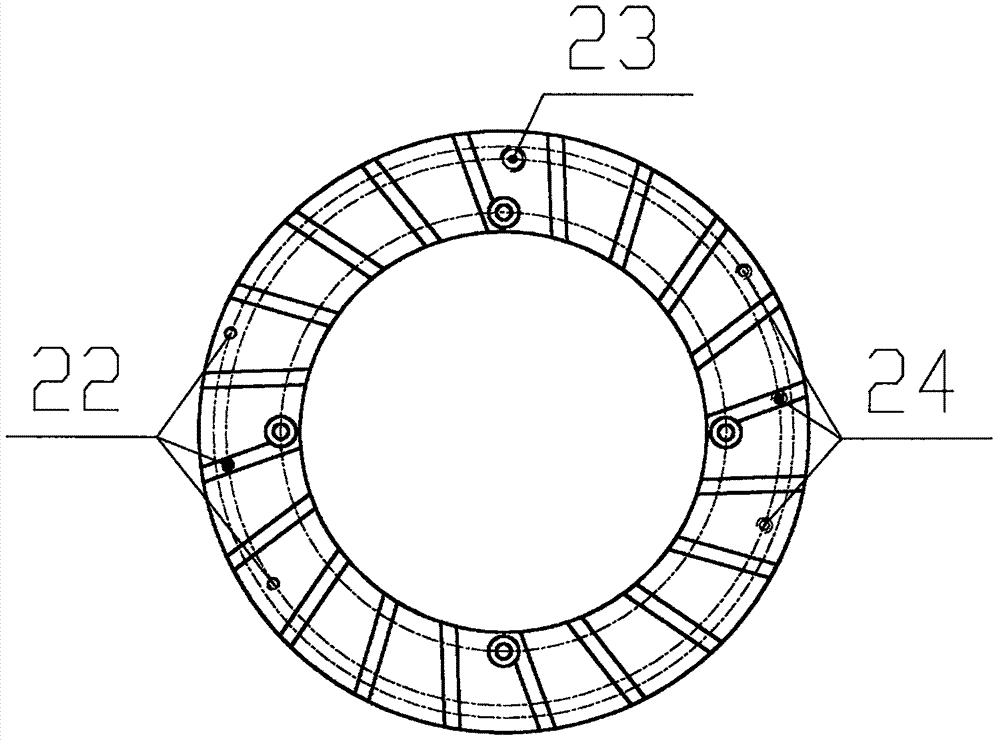

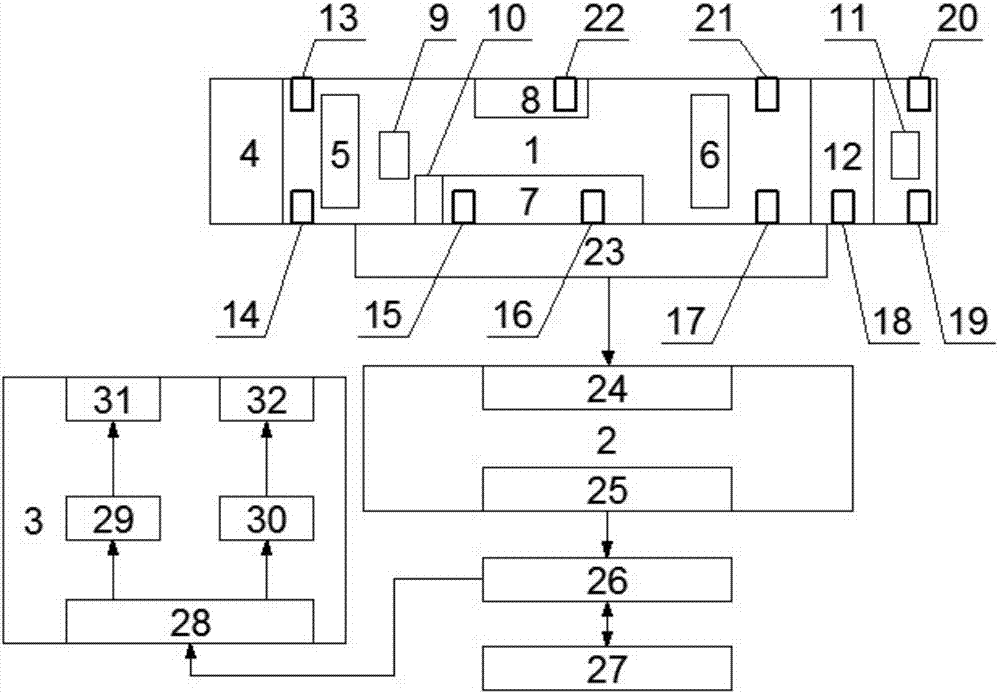

Comprehensive simulation experiment system and method for engine front-end wheel train

ActiveCN102494896AMany measurement parametersHigh measurement accuracyEngine testingControl systemElectric machinery

The invention discloses a comprehensive simulation experiment system and a comprehensive simulation experiment method for an engine front-end wheel train. The experiment system comprises an engine front-end wheel train comprehensive simulation experiment system test bed and an engine front-end wheel train comprehensive simulation experiment system control console, wherein the engine front-end wheel train comprehensive simulation experiment system test bed comprises a fixed panel (21); the engine front-end wheel train is arranged on the fixed panel (21); the rear end of an engine belt wheel shaft is connected with a main motor (24); the rear end of a load belt wheel shaft is connected with a power simulator (25); the engine front-end wheel train comprehensive simulation experiment system control console comprises a case (1) and a control system; the front of the case (1) comprises a control panel; and the control system comprises a personal computer (PC) host and a controller. The invention has the advantages that: various performance parameters of the engine front-end wheel train of an automobile under a working state can be obtained; the measured parameters are comprehensive, andthe measurement precision is high; furthermore, the test bed is high in integration property, and is convenient to mount and maintain.

Owner:CHENGDU JIALING HUAXI OPTICAL & PRECISION MACHINERY

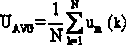

Alternating current and direct current voltage true virtual value measurement method capable of automatically identifying type of signal

ActiveCN103743944AAvoid enteringVersatileMeasurement using digital techniquesConvertersHemt circuits

The invention discloses an alternating current and direct current voltage true virtual value measurement method capable of automatically identifying the type of a signal. The method comprises the following steps that a measured alternating current and direct current signal is input to the input end of a voltage dividing buffer (1), and a low-impedance signal is output to a level translation circuit (2) and a zero-crossing synchronization circuit (4) after impedance conversion; an analogue signal output by the level translation circuit (2) enters the analogue input end of an A / D (analogue / digital) converter (3), and a digital signal obtained by conversion is transmitted into a microprocessor (5); the reference voltage output of the A / D converter (5) is connected to the reference voltage input end of the level translation circuit (2) for the determination of a new reference level point after the rising of reference zero level; the microprocessor (5) detects a synchronization pulse output by the zero-crossing synchronization circuit (4) through built-in measurement control software; a measurement result is output through a display interface and a communication interface. According to the method, alternating current, direct current and hybrid alternating current and direct current types are automatically identified, and an alternating current voltage true virtual value, a direct current voltage value and a hybrid alternating current and direct current true virtual value are automatically measured.

Owner:GUIZHOU METROLOGY & TESTING INST

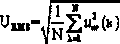

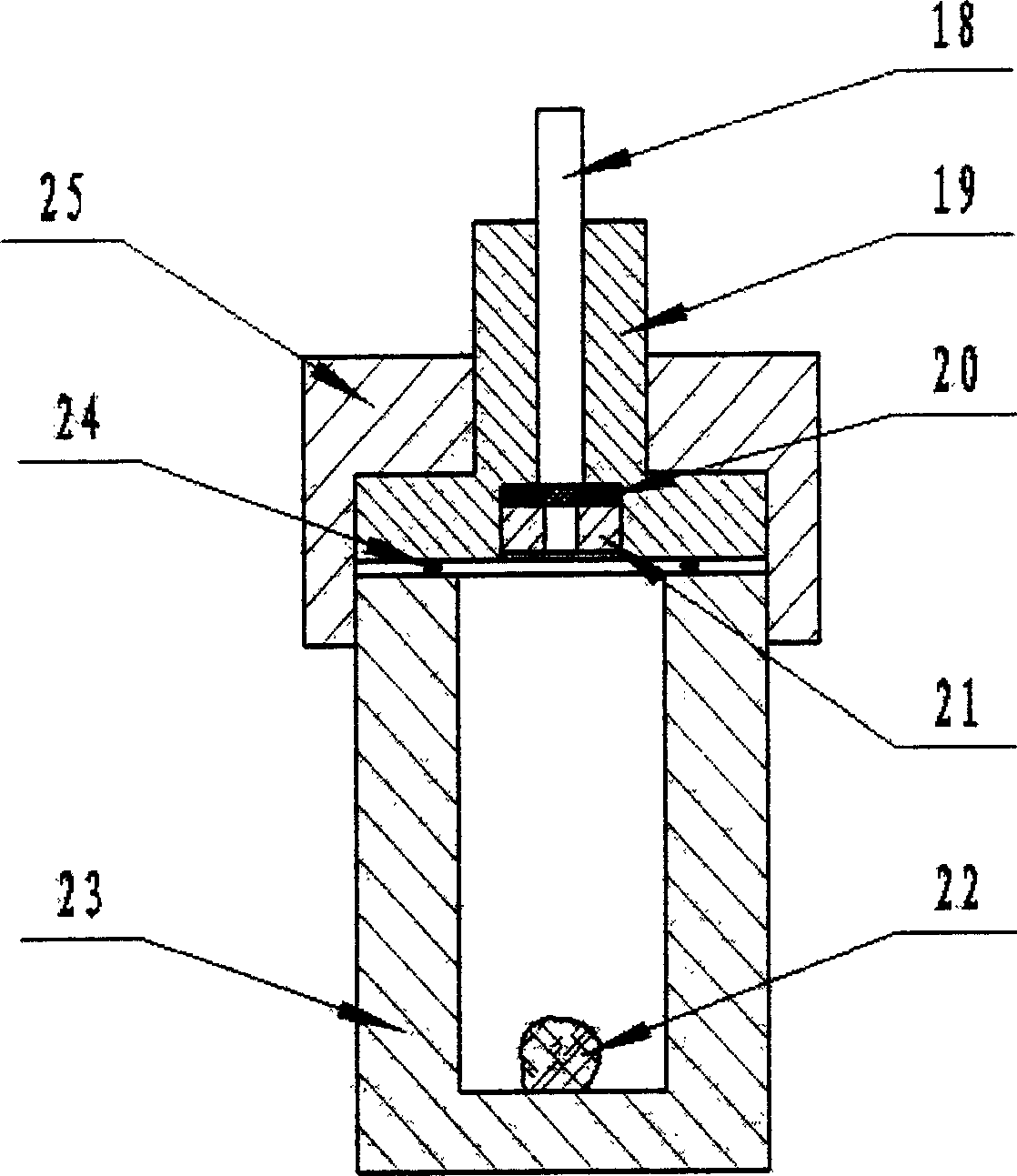

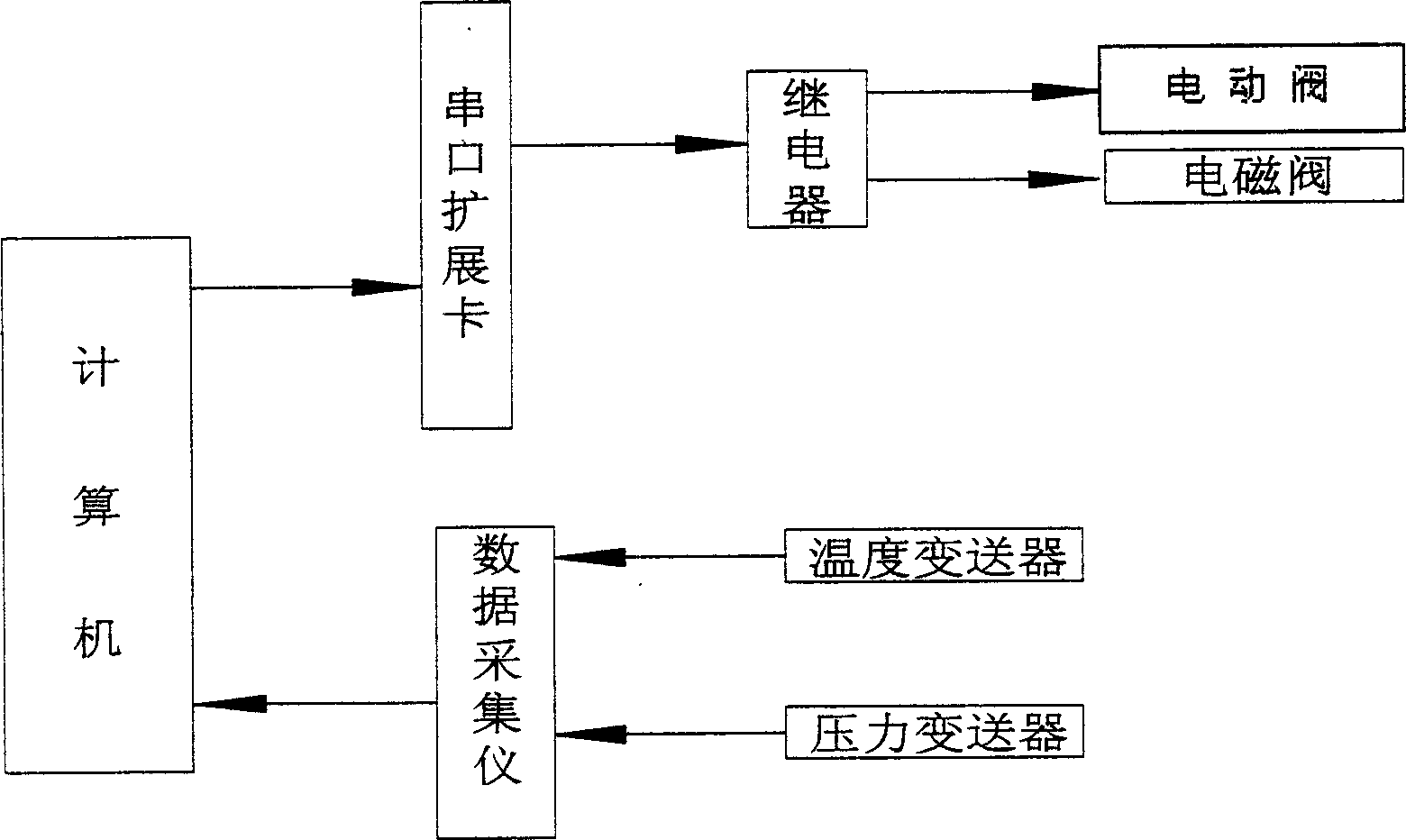

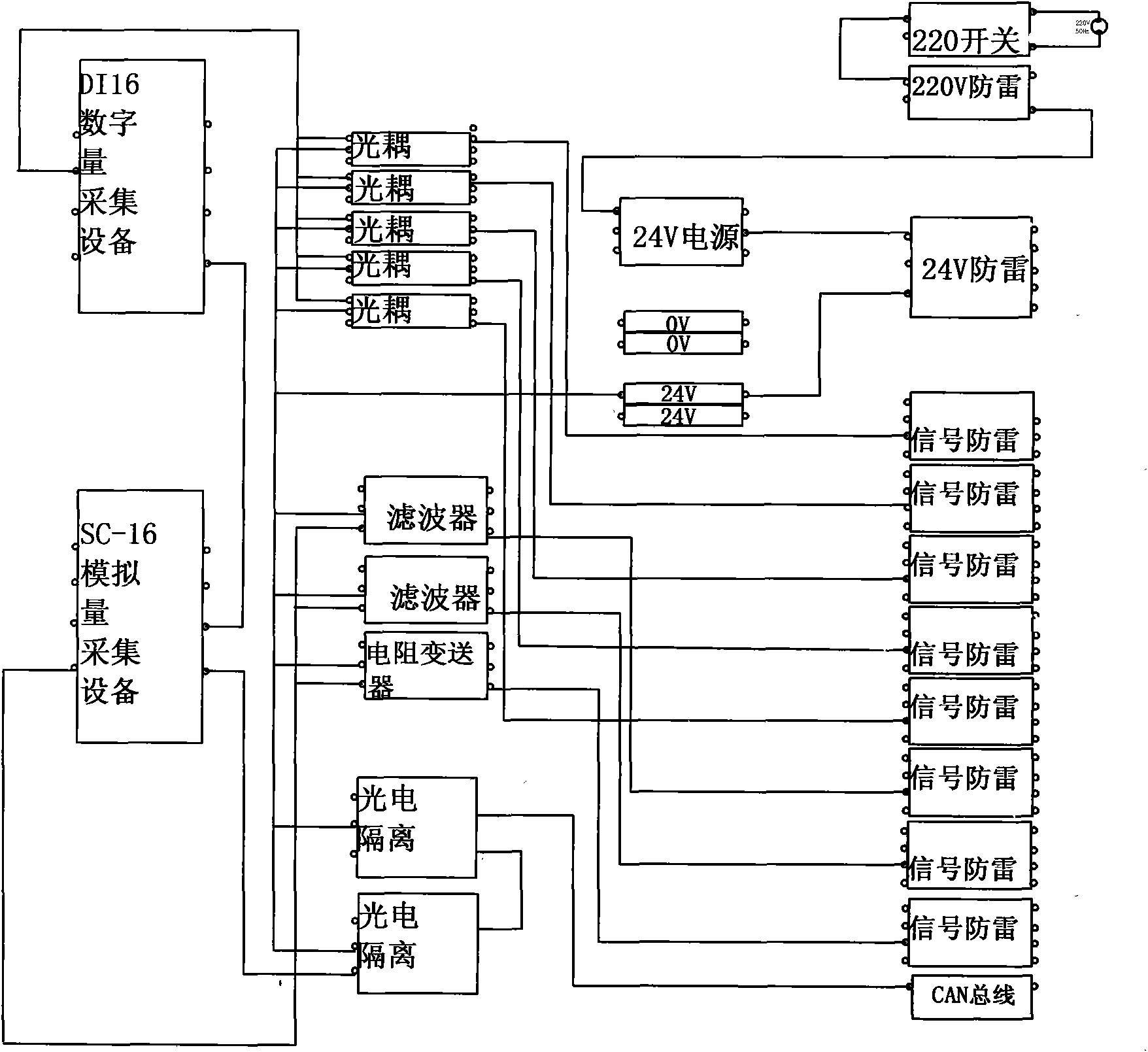

Hydrogen storage alloy performance integrated experimental appts

InactiveCN1601281AHigh degree of automationAutomatic Control RunabilityChemical methods analysisNuclear engineeringControl system

The invention relates to a material testing equipment, in particular, it relates to a hydrogen storage alloy testing equipment. It is formed from reaction chamber, hydrogen gas circulation system and liquor circulation system, in which between reaction chamber and hydrogen gas circulation system a quick joint is used to implement closed connection, the hydrogen gas circulation system can make the hydrogen gas be continuously circulated between the reaction chamber and hydrogen gas circulation system, and said liquid circulation system can make the constant temperature liquids with different temperatures be alternatively circulated between the opened container and oil bath so as to make the hydrogen storage alloy implement alternative circulation of absorbing and releasing hydrogen. In the course of hydrogen gas and liquid circulation the control and data acquisition system can be used for acquiring and processing data, and outputting signal to control system to make test.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

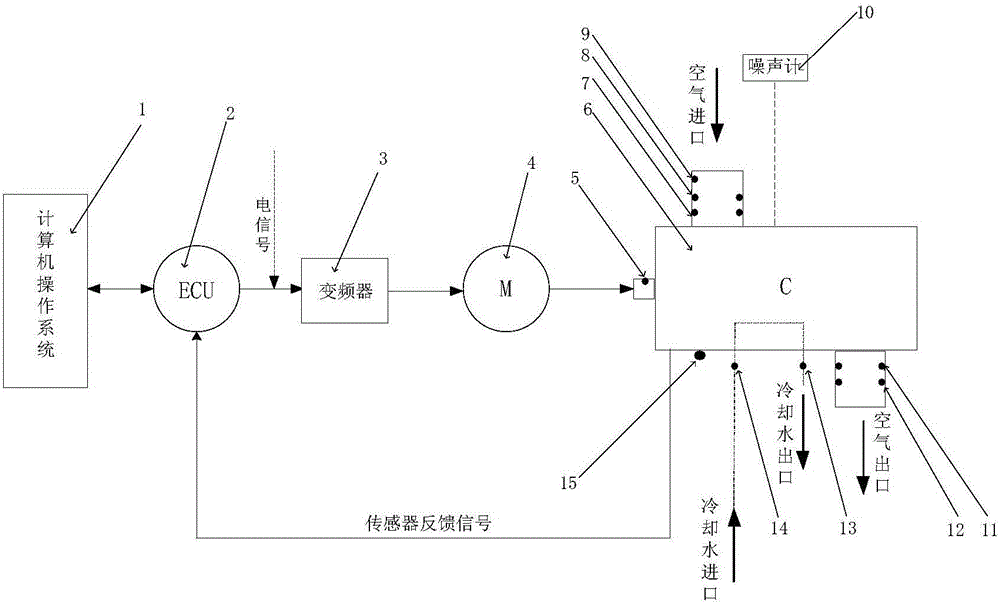

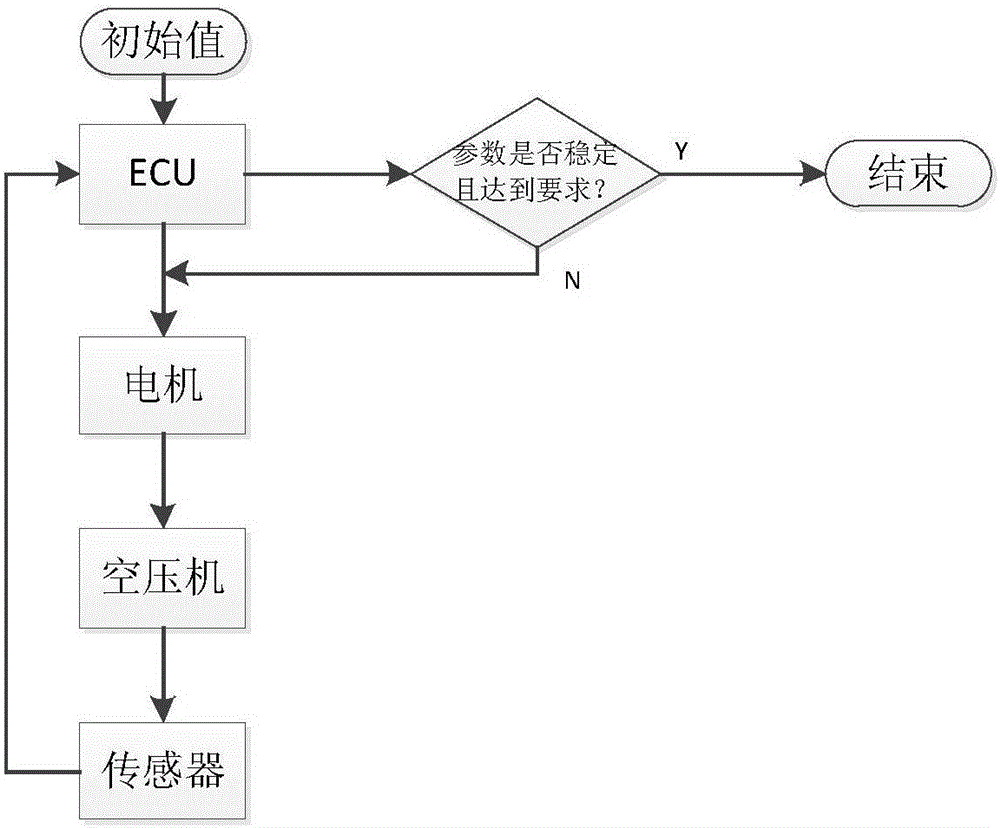

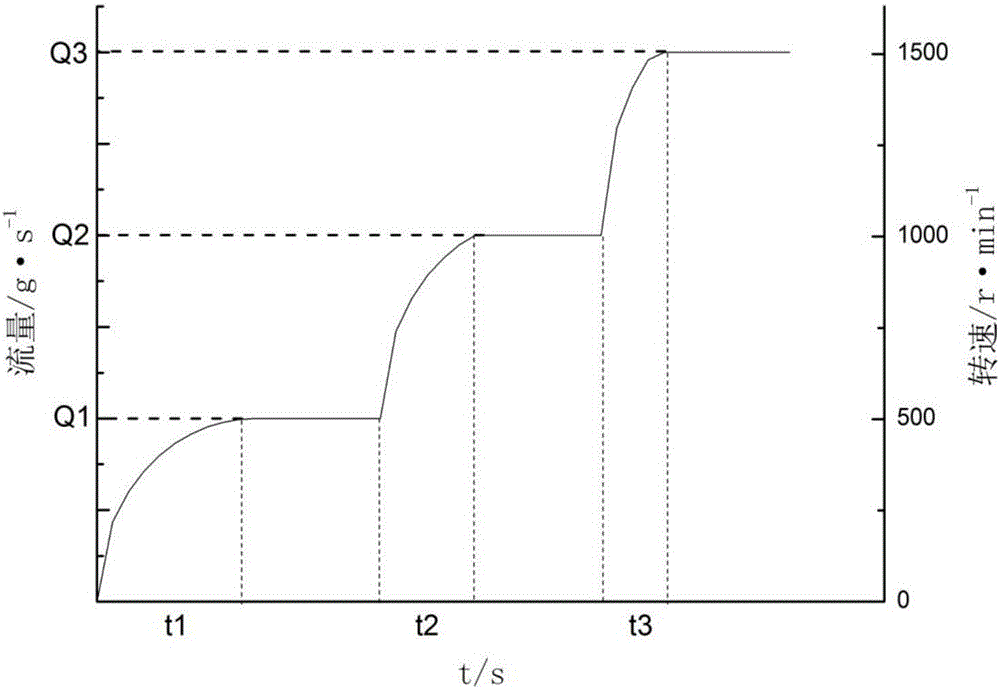

Vehicle fuel battery air compressor testing system controlled through ECU

InactiveCN106286259AChange speedHigh degree of intelligencePump testingPump controlFrequency changerFuel cells

The invention discloses a vehicle fuel battery air compressor testing system controlled through an ECU. The vehicle fuel battery air compressor testing system comprises a computer operation system, the ECU, a frequency converter, a motor, an air compressor and a sensor assembly. The ECU is connected with the frequency converter and the computer operation system. The frequency converter is connected with the motor. The motor is connected with the air compressor. The sensor assembly is connected with the ECU through a bus and is used for feeding back tested data signals to the ECU. The ECU analyses parameters fed back by the sensor assembly and judges whether the parameters are stable and meet the requirement or not, the rotating speed of the motor is changed, and therefore performance parameters of the air compressor under different working conditions are tested. The arrangement kinds of sensors of the vehicle fuel battery air compressor testing system are comprehensive, the arrangement positions of the sensors are reasonable, the rotating speed of the motor is increased through the ECU in a timing and staged manner, reference value is provided for model selection of the air compressor, the intelligence degree is high, model selection pertinence is high, safety is good, and measurement parameters are comprehensive.

Owner:WUHAN UNIV OF TECH

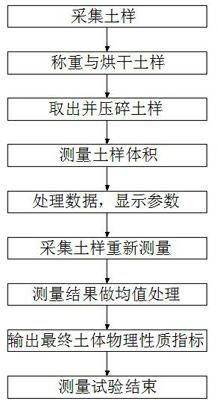

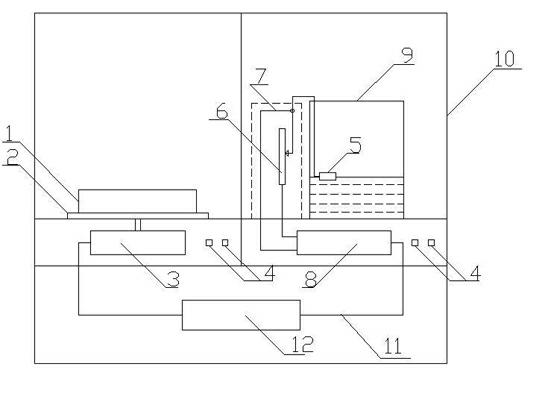

Method and device for measuring physical property indexes of soil body

InactiveCN102323178AEasy to measureQuick and easy measurement methodWeighing by removing componentPermeability/surface area analysisMeasurement deviceSoil science

The invention relates to a method and a device for measuring physical property indexes of a soil body. The method comprises the following steps of: measuring six basic parameters, namely corresponding masses and volumes of soil particles, water and gas in the soil body; and calculating to acquire nine conventional physical property indexes of the soil body through running relevant programs by virtue of data storage and processing equipment, and displaying the nine conventional physical property indexes once, wherein the conventional physical property indexes of the soil body can be measured quickly and comprehensively.

Owner:HOHAI UNIV

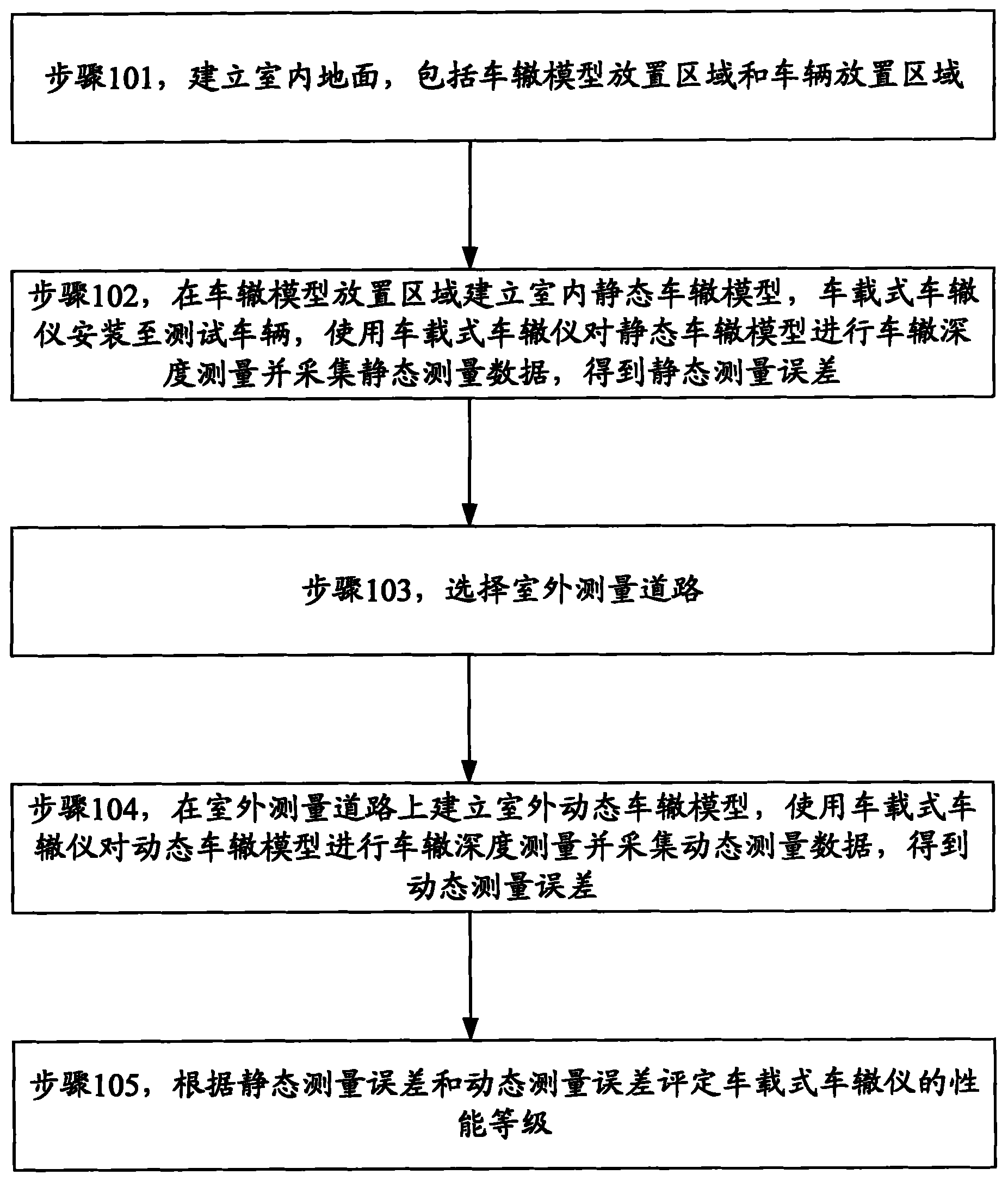

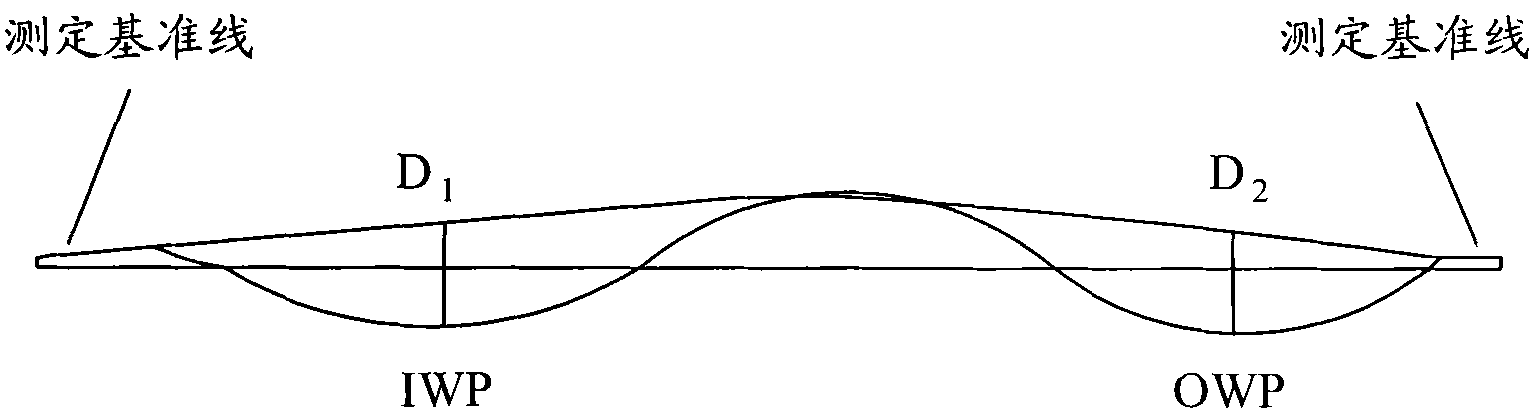

Performance metering method of vehicle-mounted laser evenness instrument

ActiveCN102011361AVibration Elimination PerformanceMany measurement parametersRoads maintainenceEngineeringLaser

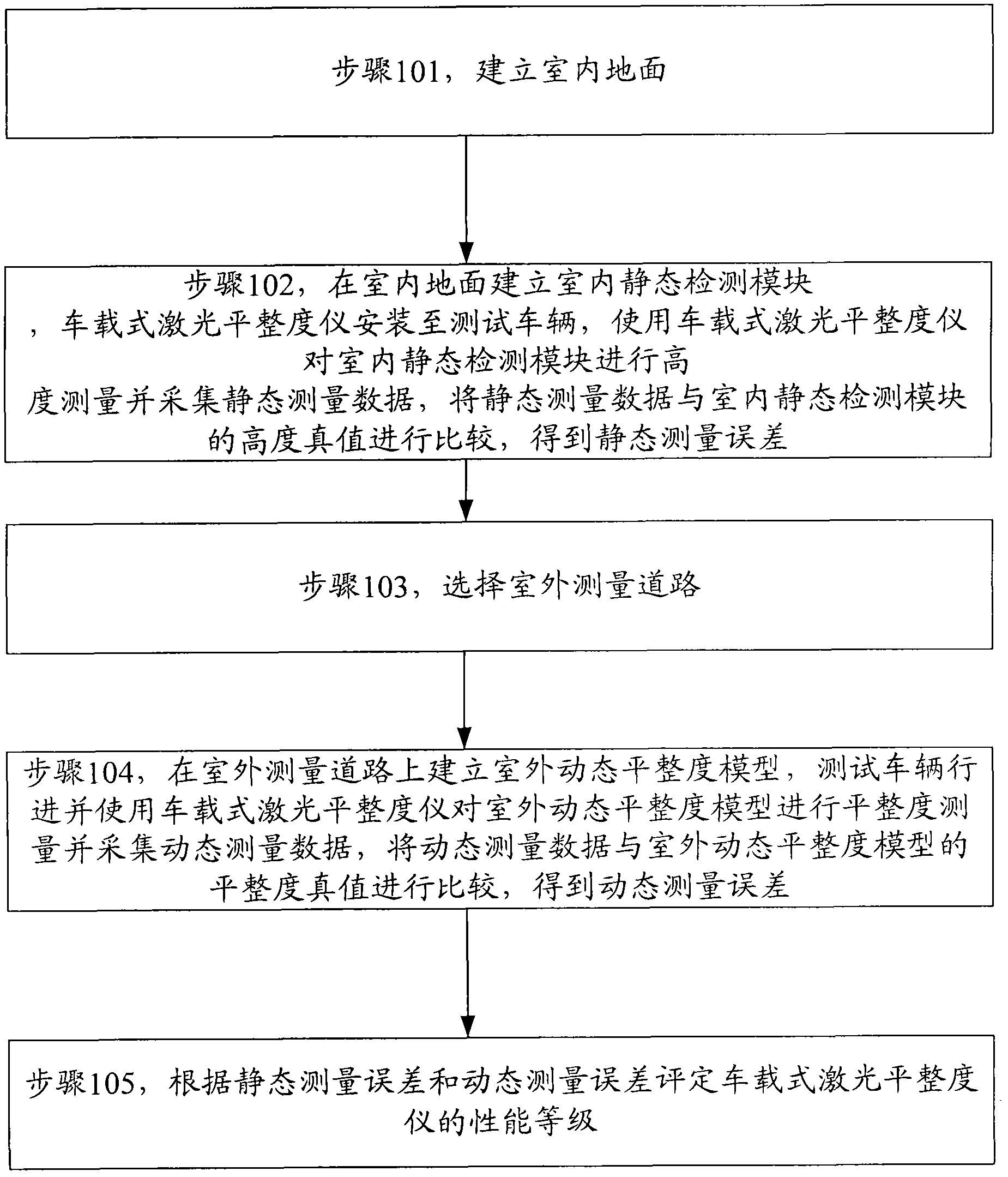

The invention provides a performance metering method of a vehicle-mounted laser evenness instrument, comprising the following steps of: step 101: establishing an indoor ground; step 102: establishing an indoor static detection model on the indoor ground, and measuring and acquiring static measured data to obtain the static measurement error; step 103: selecting an outdoor measuring road; step 104: establishing an outdoor dynamic evenness model on the outdoor measuring road, and measuring and acquiring dynamic measured data to obtain the dynamic measurement error; and step 105: evaluating the performance level of the vehicle-mounted laser evenness instrument according to the static measurement error and the dynamic measurement error. The performance metering method of the vehicle-mounted laser evenness instrument can scientifically, reasonably and accurately carry out metering and detection evaluation on the performances of various vehicle-mounted laser evenness instruments, is convenient for implement and is beneficial to popularizing, thereby reducing the metering cost.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

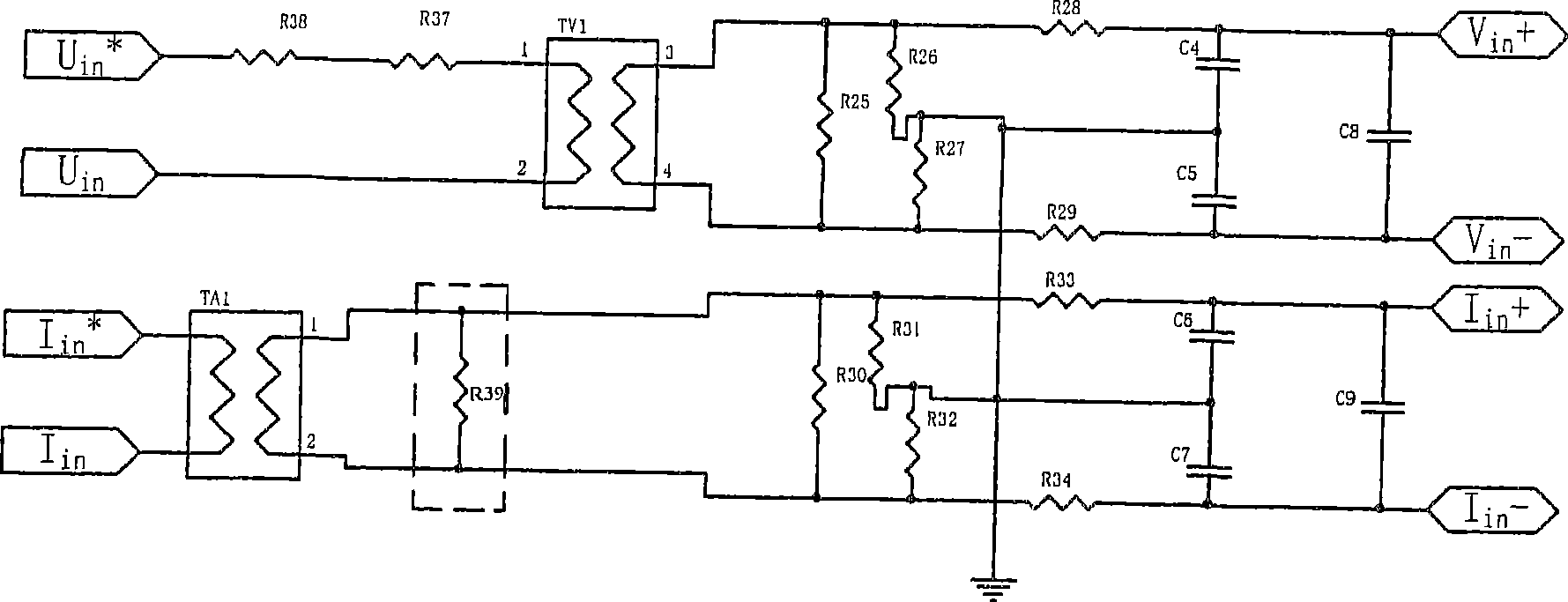

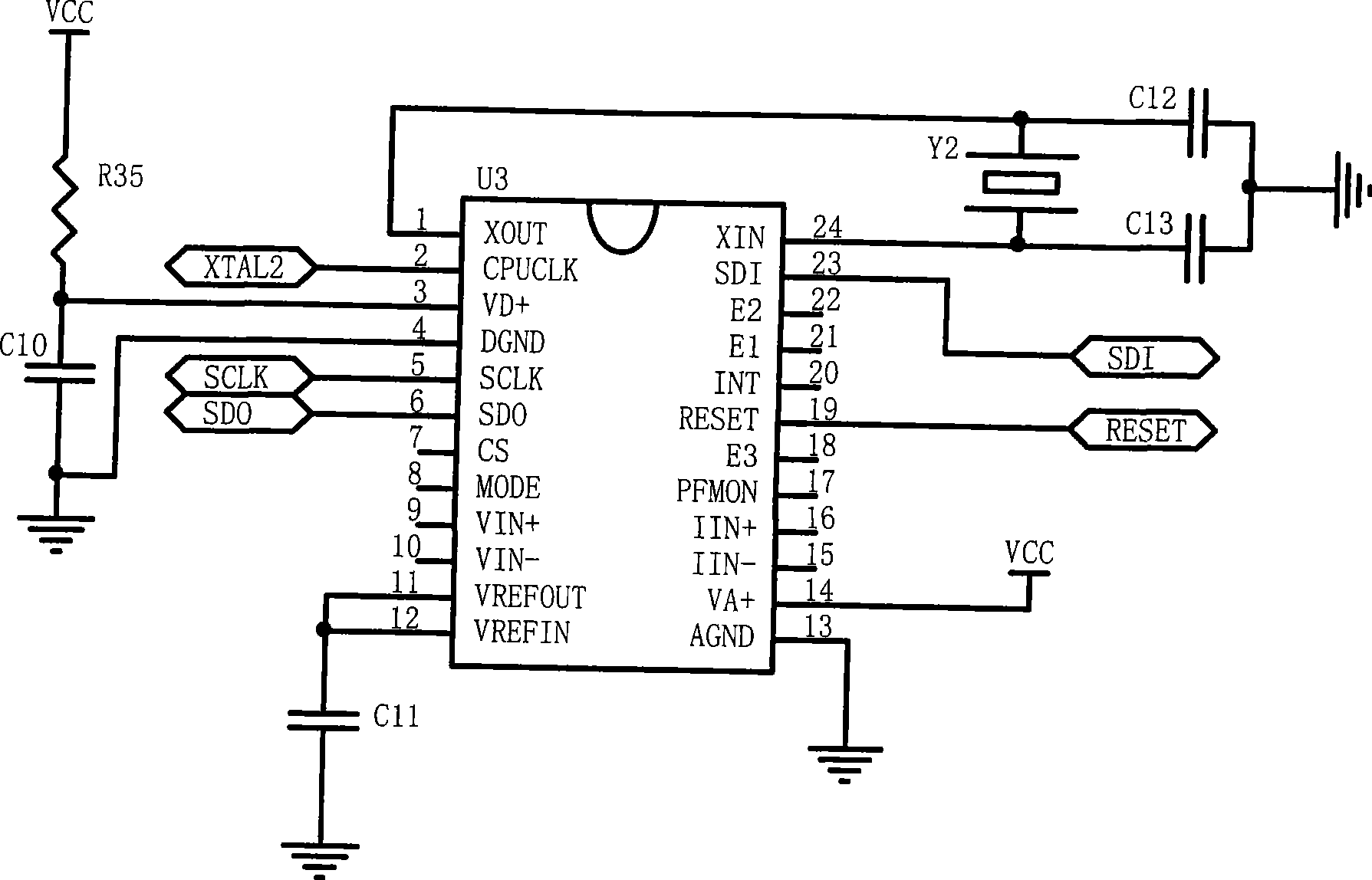

Single-phase multiple-parameter electric power instrument

InactiveCN101435833AImprove test accuracyMany measurement parametersMulti-tester circuitsMeasuring instrumentSingle-phase electric power

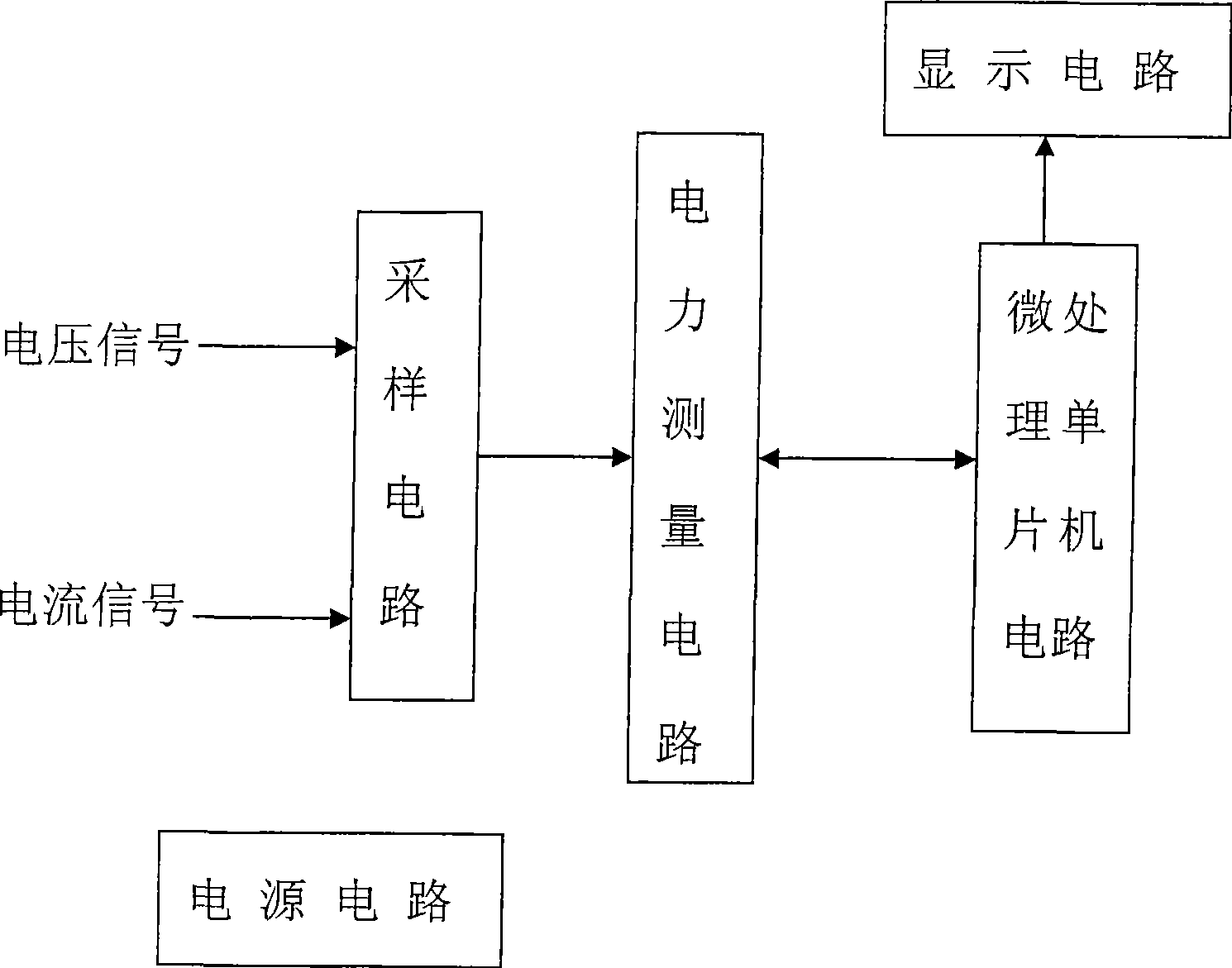

The invention relates to a single-phase multi-parameter electric power instrument which can provide a measuring instrument for a single-phase electric power parameter to realize the mensuration of a single parameter or multi-parameter of current, voltage, power factors, active power, reactive power and the like. The instrument comprises a sampling circuit, an electric power measuring circuit, a microprocessing singlechip circuit, a display circuit and a power supply circuit; the sampling circuit is connected with a voltage signal and a current signal; the electric power measuring circuit is connected with the sampling circuit and the microprocessing singlechip circuit; the display circuit is connected with the microprocessing singlechip circuit; and the power supply circuit provides power. The single-phase multi-parameter electric power instrument has the advantages that as the instrument adopts the electric power measuring circuit and the microprocessing singlechip circuit, the instrument has high testing precision and more measuring parameters; and the instrument adopts the mature chip in order to have small power consumption and be suitable for batch production.

Owner:SUZHOU WINFINE SMART ELECTRIC

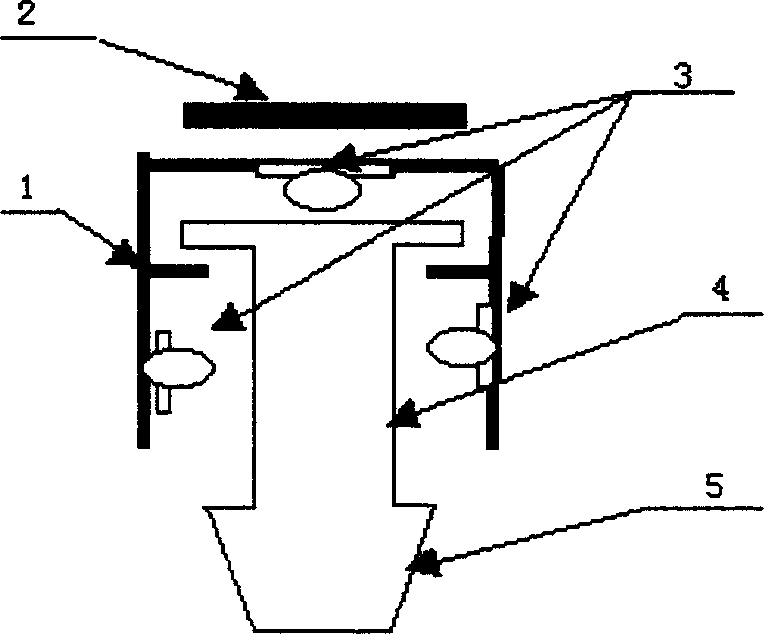

System and method for measuring a plurality of multi-dimensional motion parameters for fighting training

InactiveCN104596693AImprove anti-interference abilityImprove performanceNavigation by speed/acceleration measurementsApparatus for force/torque/work measurementMicrocomputerMicrocontroller

The invention discloses a system and method for measuring a plurality of multi-dimensional motion parameters for fighting training. The system mainly comprises a computer, a signal acquisition and processing device, a fixed boxing target (4) used for strength feature testing, and a boxing glove (6) used for track rebuilding testing, wherein a sensor of the fixed boxing target (4) and a sensor of the boxing glove (6) transmit measured data to the computer in a wired mode and a wireless mode respectively, and the signal acquisition and processing device mainly comprises a single-chip microcomputer and a digital sensor chip, and is connected with the computer through a serial port. According to the method, the parameters of fighting training are measured through the digital sensor chip. The method comprises the step of strength feature testing and the step of track rebuilding testing. The system and method can change a traditional training mode that fighting coaches and athletes in China only rely on hard training and diligent struggle, and the system has the advantages of being small in size, high in measuring accuracy, comprehensive in measuring parameter and good in stability.

Owner:WUHAN UNIV OF TECH

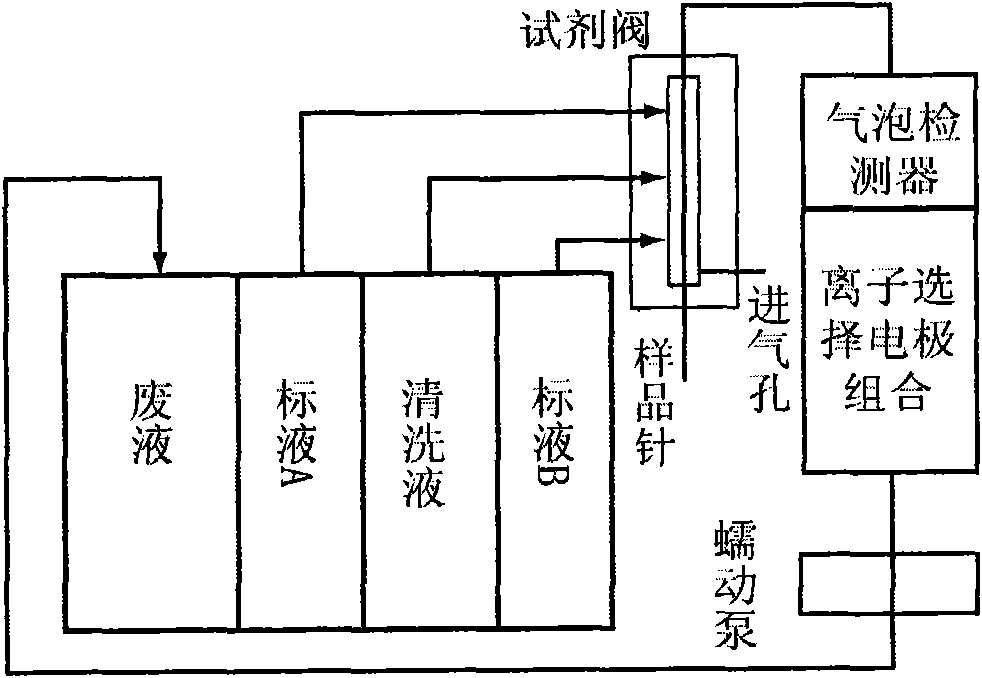

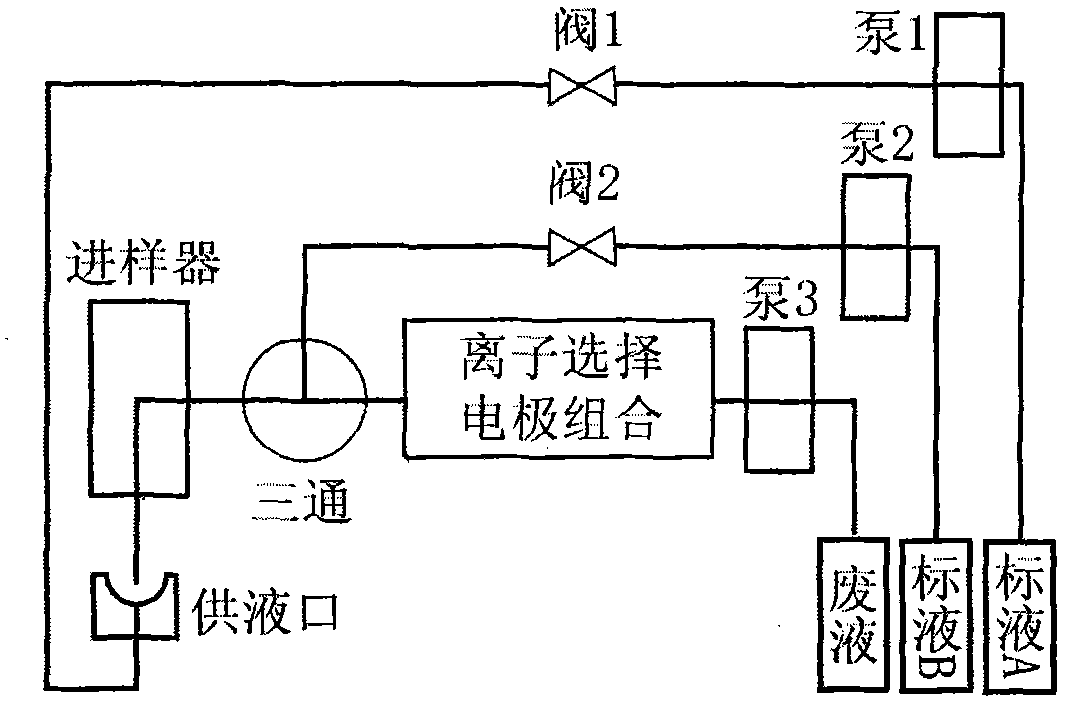

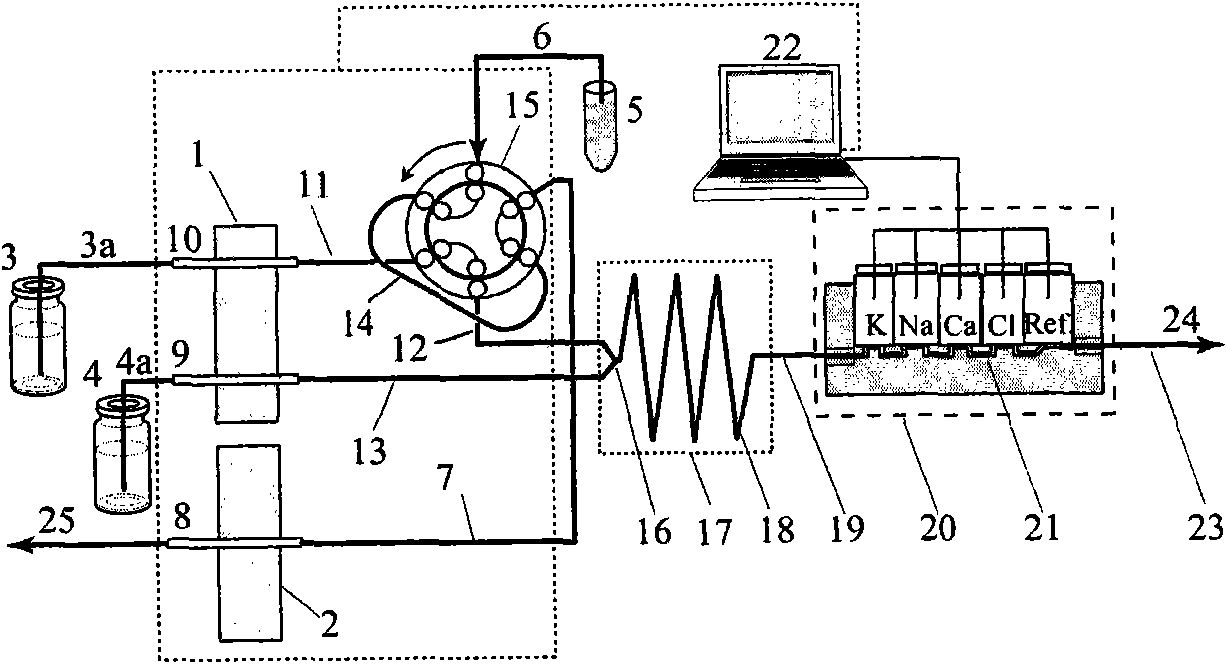

Flow injection serially connected microelectrode electrochemical automatic method and device for simultaneous measurement of various electrolytes in blood sample

InactiveCN102072930ASimple and efficient operationMany measurement parametersMaterial analysis by electric/magnetic meansMicroelectrodeEngineering

The invention discloses a flow injection serially connected microelectrode electrochemical automatic method and device for simultaneous measurement of various electrolytes in a blood sample, and belongs to the field of clinical examination. A multifunctional valve is arranged in a 'sampling' position, carrier flow is converged with an acidity regulator under the power action of a pump, continuously flows through a mixing coil and an electrochemical flow-through detector, and generates base line electrode potential signals; a blood sample simultaneously enters a sampling quantification ring for automatic precision quantification; a valve is switched to the 'injection' position, a quantified 'blood sample plug' is injected into the carrier flow in a high repetition manner, is mixed with the acidity regulator and flows into the electrochemical flow-through detector, respective potential signals can be obtained, and blood sample results can be obtained through a computer. Meanwhile, the carrier flow follows the 'blood sample plug' to automatically and timely clean an electrode sensitive membrane surface and a system. The invention has the advantages of high automation degree, fast measuring speed, good repeatability and less consumption of samples, and eliminates the system plugging caused by blood samples and the cross contamination.

Owner:SICHUAN UNIV

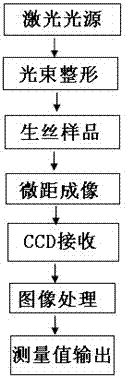

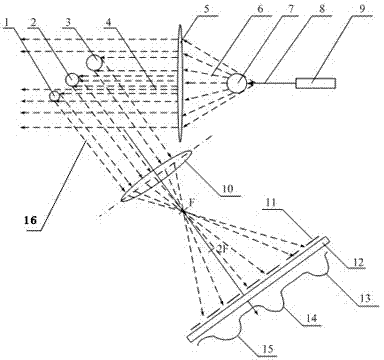

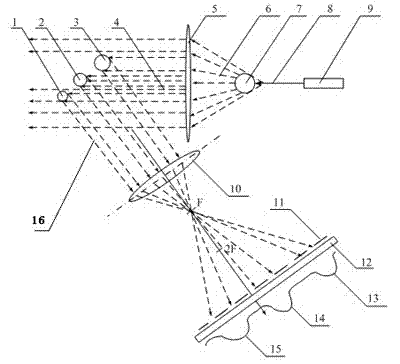

Method for measuring fineness of raw silks in real time and device of method

InactiveCN102519373ADoes not affect calculationDoes not affect measurement resultsUsing optical meansMicro imagingTextile fiber

The invention discloses a method for measuring fineness of raw silks in real time and a device of the method. The device comprises a parallel optical field, a microspur imaging system, a photoelectric sensor and an image processing system. During measurement, standard sample silks and raw silks to be measured are placed in the same parallel optical field, after reflecting light of the standard sample silks and the raw silks is in Fourier transform, the photoelectric sensor obtains a frame of image signals of the standard sample silks and the raw silks to be measured, and measurement results of the fineness of the raw silks to be measured are obtained via data processing. As the reflecting light of the raw silks is acquired during measurement, saturation of photosensitive elements of a CCD (charge coupled device) is avoided effectively, and distortion due to microscopy imaging is avoided by the aid of microspur imaging. Simultaneously, as the raw silks to be measured and the standard sample silks are located in the same optical field, measurement precision cannot be affected by environment factors, and accuracy and stability of measured values are effectively improved. The method and the device are applicable to measuring fineness of raw silks, wool, textile fibers and the like, and the device is an effective tool for realizing non-contact real-time dynamic fiber fineness detection.

Owner:SUZHOU UNIV +1

High-precision transparent hydro-viscous transmission experimental test device

PendingCN107421737AEasy to adjustHigh precisionMachine gearing/transmission testingMaterial testing goodsExperimental testingMeasuring instrument

The invention discloses a high-precision transparent hydro-viscous transmission experimental test device which mainly includes a base, a motor, a coupling, a torque and speed measuring instrument, a host, a locking device, a displacement sensor, a pressure sensor, a temperature sensor, a pressure gauge, a flow meter, a data acquisition card, a high-speed camera, a computer, and the like. The motor, the torque and speed measuring instrument, the host and the locking device are fixed to the base by bolts, and are driven by the coupling. The displacement sensor, the pressure sensor and the temperature sensor are installed on a passive film through threaded connection. The pressure gauge and the flow meter are connected with an oil inlet through a pipeline. The data acquisition card is connected with the detection sensors and the computer, and is used for collecting, processing and outputting signals. The high-speed camera is installed outside a transparent box, and is used for photographing an oil layer between active and passive films. The device has the advantages of fast and convenient adjustment, comprehensive measurement parameters, high test precision, multi-angle observation, and dynamic real-time test.

Owner:苏州方德锐精密机电科技有限公司

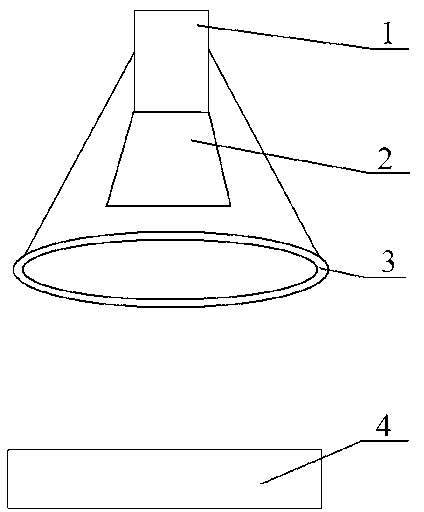

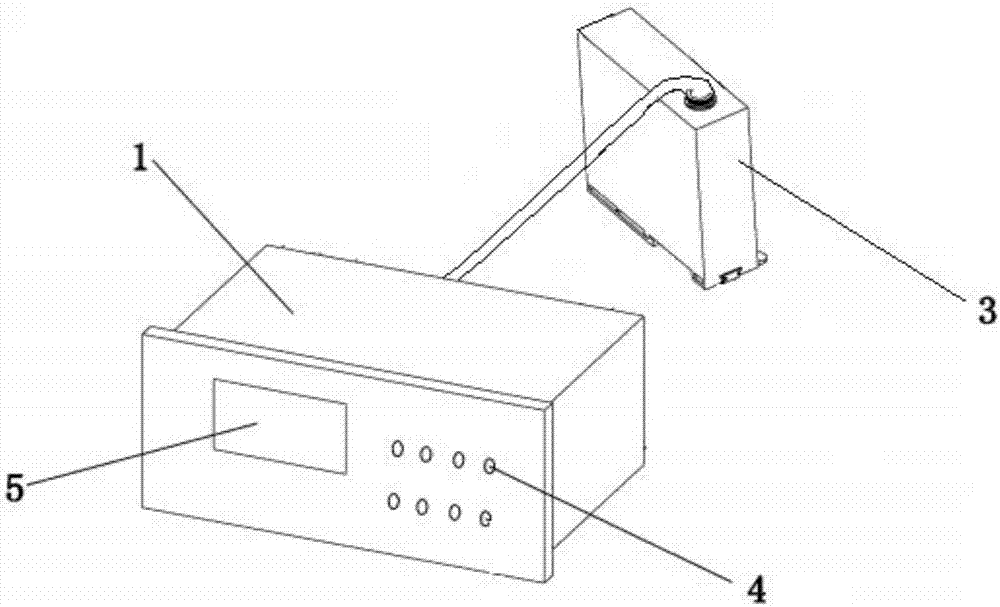

Method for evaluating and judging hydrophobicity grade of composite insulator of annular light tube

InactiveCN103175758AIncrease contrastContaminated Area SuppressionSurface/boundary effectComposite insulatorsSoftware system

The invention discloses a method for evaluating and judging hydrophobicity grade of a composite insulator of an annular light tube. The method comprises an evaluating and judging device and a hydrophobicity grading software system, wherein the evaluating and judging device consists of a visualized image pickup system, a water spraying system and the annular light tube, and the hydrophobicity grading software system is used for digital image water drop boundary extraction based on a water drop boundary digital image. The method has the advantages of simple structure, convenience in operation, good stability, multiple measurement parameters, easiness in popularization and application, and the like.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

Performance measurement method of vehicle-carried rut meter

ActiveCN101929124AMany measurement parametersThe measurement parameters are reasonableRoads maintainenceMeasurement costEngineering

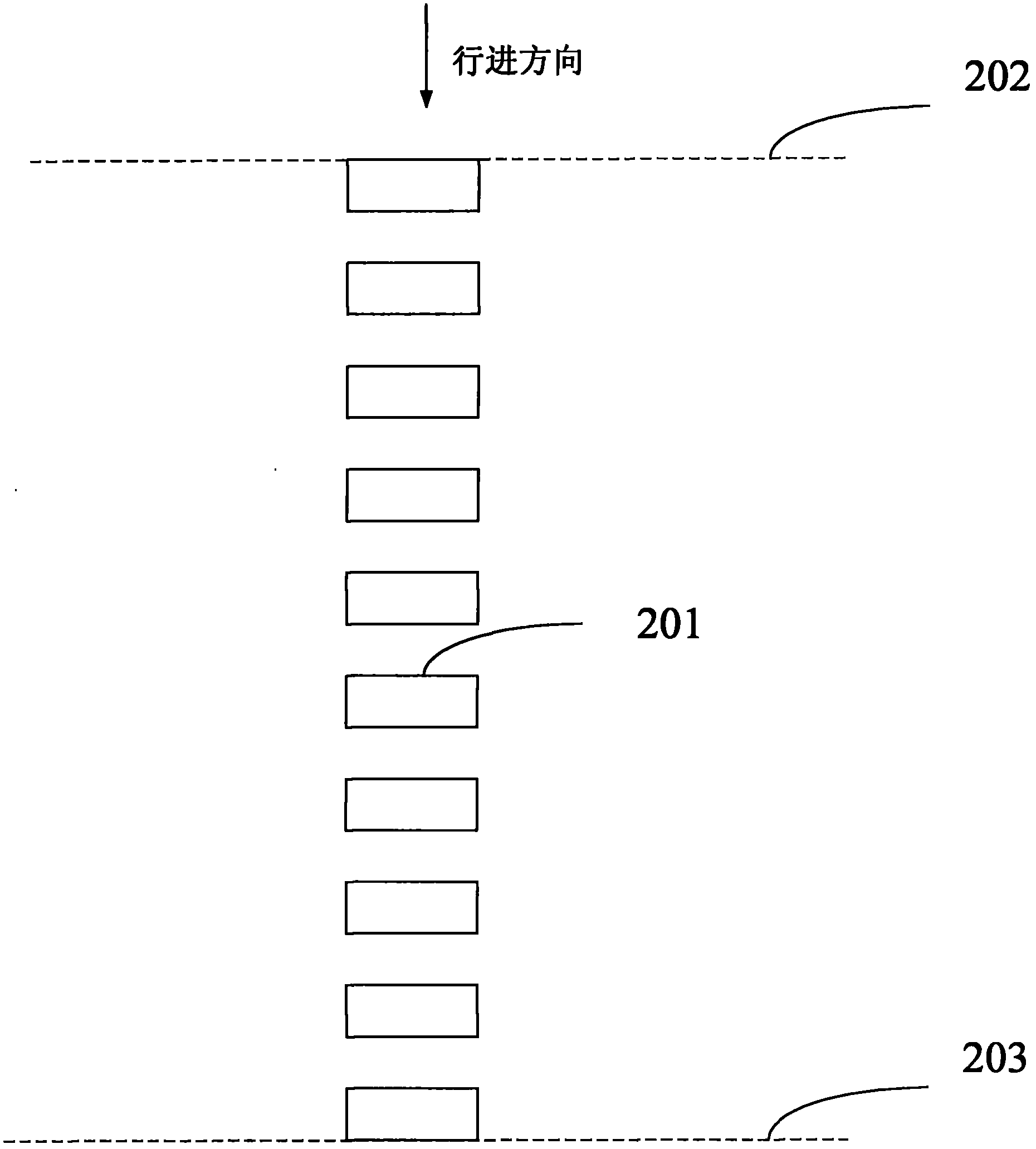

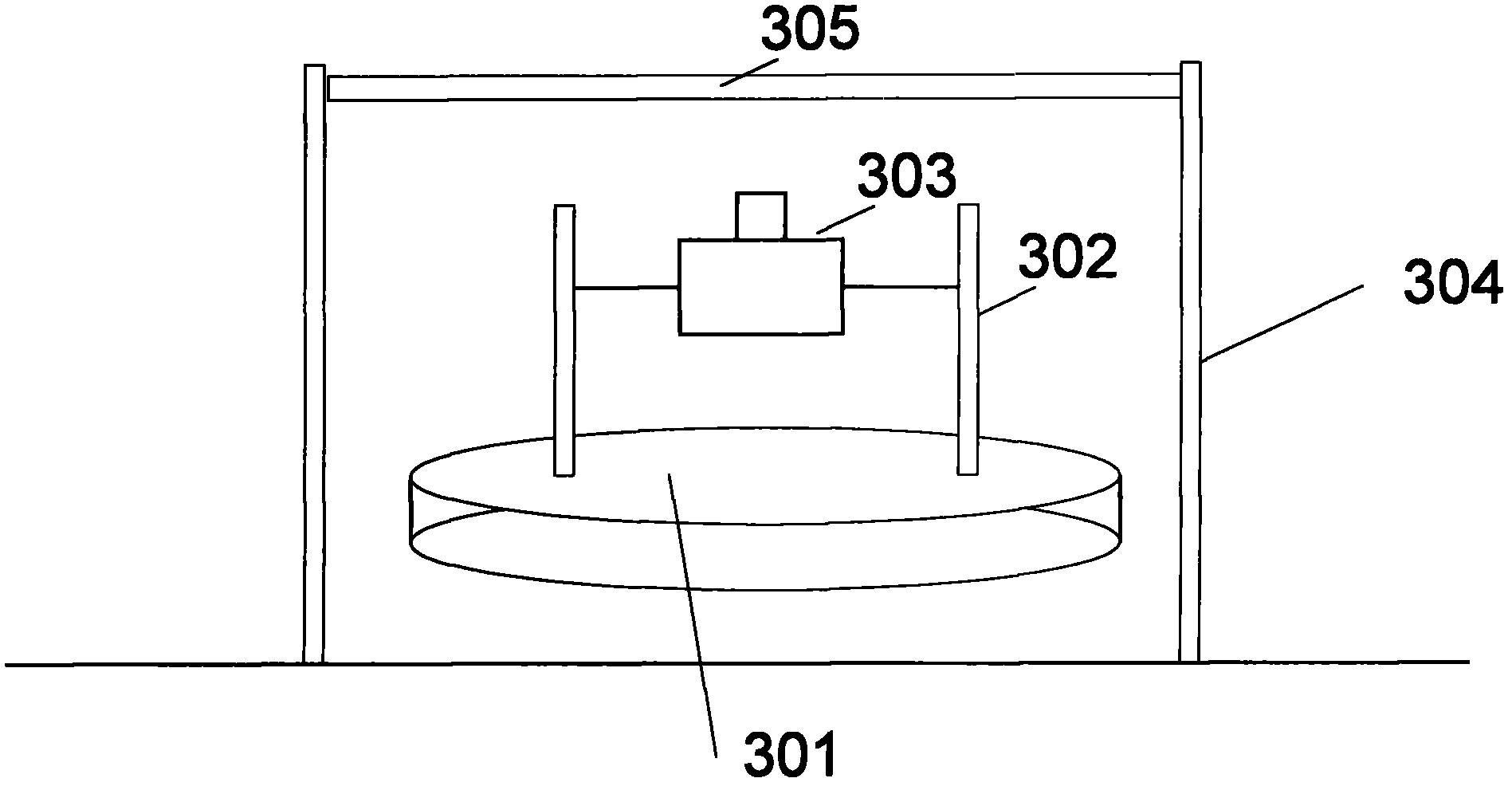

The invention provides a performance measurement method of a vehicle-carried rut meter, comprising the steps of: 101, establishing an indoor ground comprising a rut model placing area and a vehicle placing area; 102, establishing an indoor static rut model in the rut model placing area, carrying out rut depth measurement on the static rut model by the vehicle-carried rut meter and acquiring the static measurement data so as to obtain a static measurement error; 103, selecting an outdoor measurement road; 104, establishing an outdoor dynamic rut model on the outdoor measurement road, carrying out rut depth measurement on the dynamic rut model by the vehicle-carried rut meter and acquiring the dynamic measurement data so as to obtain a dynamic measurement error; and 105, evaluating the performance level of the vehicle-carried rut meter according to the static measurement error and the dynamic measurement error. The performance measurement method of the vehicle-carried rut meter of the invention can scientifically, rationally and correctly measure, detect and evaluate the performances of various vehicle-carried rut meters, and is convenient to implement and beneficial for popularization; therefore, the measurement cost is reduced.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

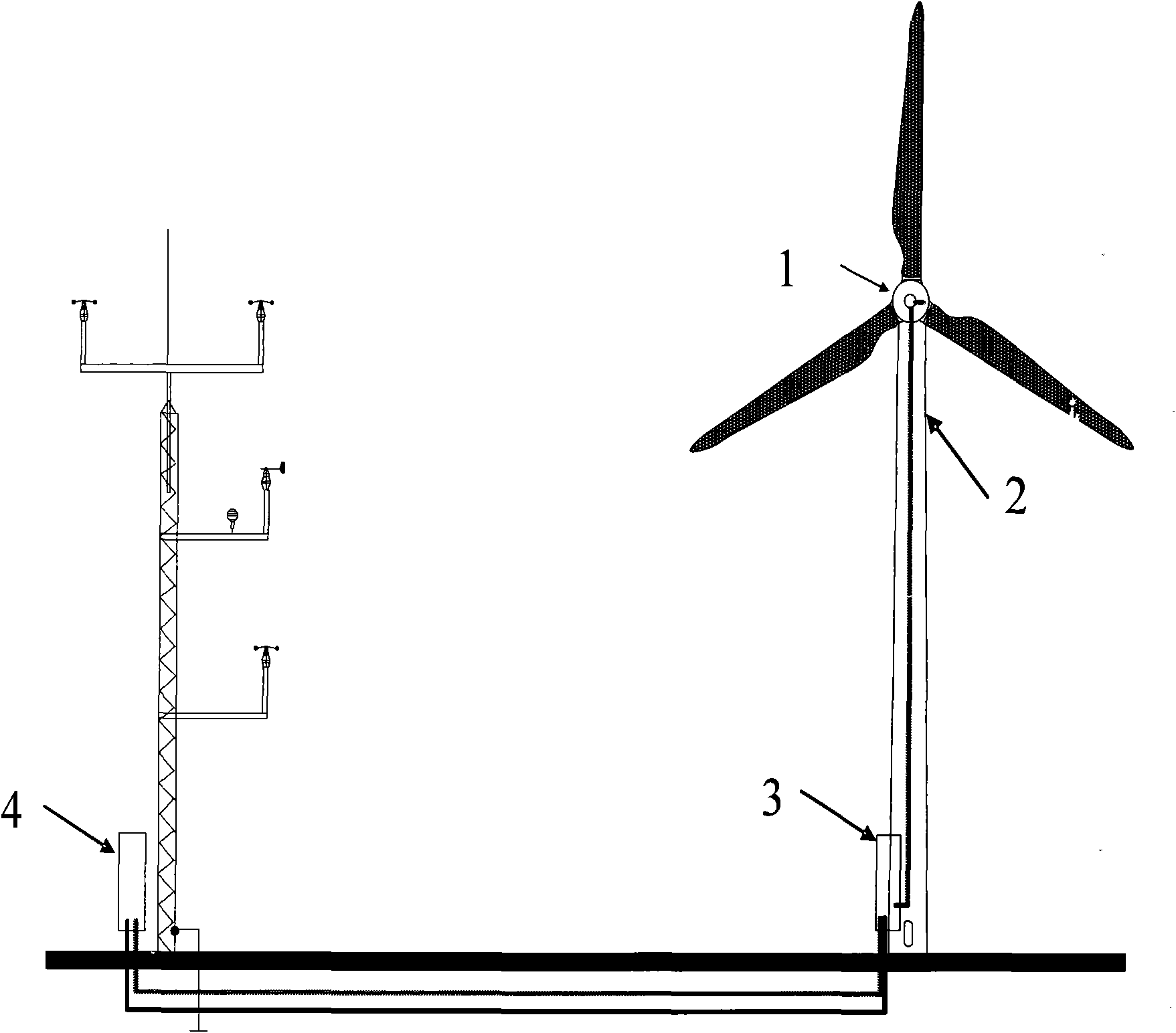

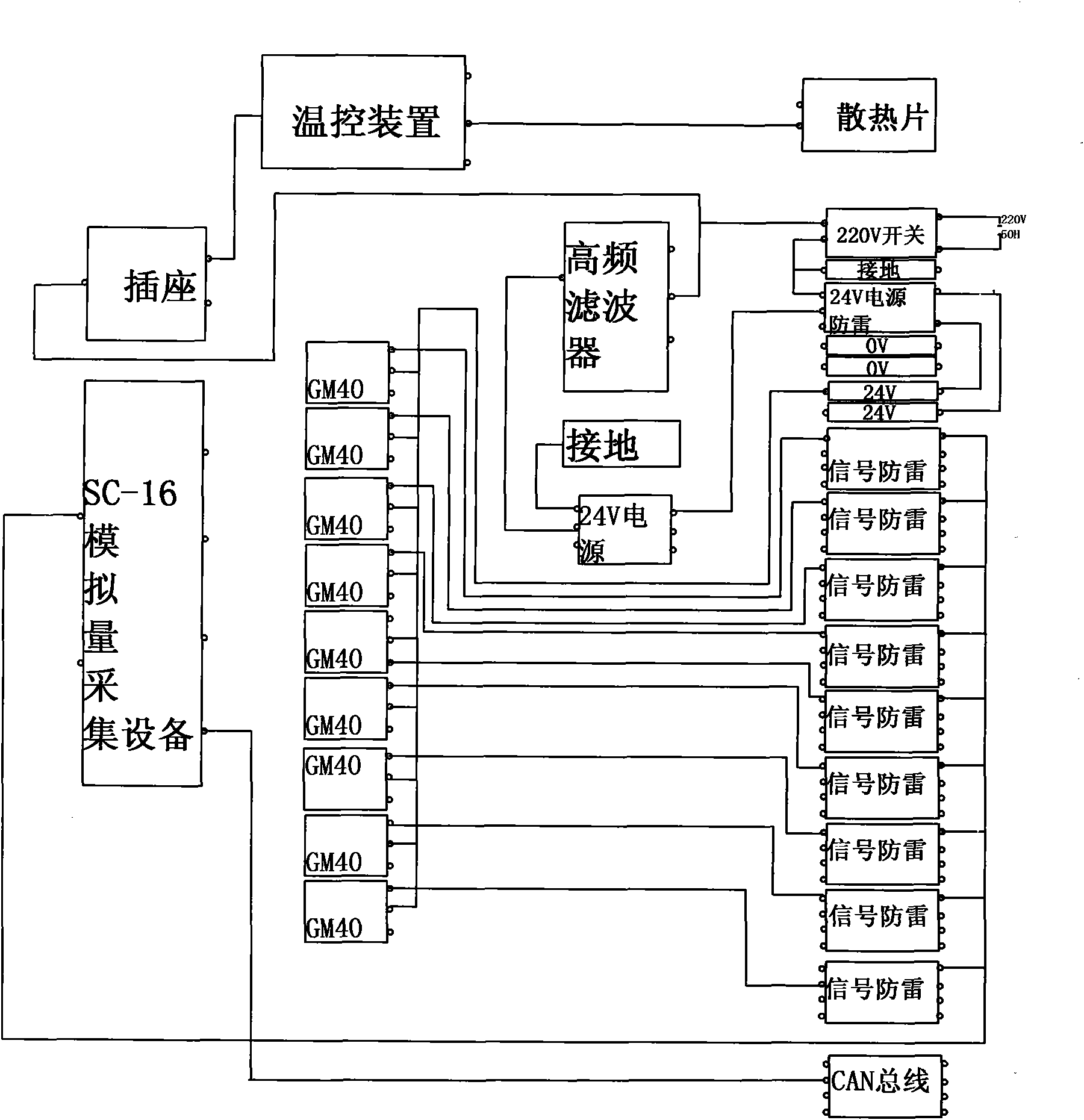

Wind generating set load testing system meeting IEC61400-13 standard

ActiveCN101975662AImplement synchronous testingHigh degree of standardizationEngine testingWork measurementElectricityControl system

The invention relates to a wind generating set load testing system meeting the international electrical committee IEC61400-13 standard. The wind generating set load testing system is characterized by comprising a subsystem and a master control system (3), wherein the subsystem comprises a wheel hub testing system (1), a tower top testing system (2) and a meteorological testing system (4); the meteorological testing system (4) is arranged at the bottom of a meteorological anemometer mast; the tower top testing system (2) is arranged on the top of a tower cylinder; the wheel hub testing system (1) is arranged in a wheel hub of the wind generating set and rotates with the wheel hub of the wind generating set when runs; and the master control system is arranged at the bottom of the tower cylinder. The wind generating set load testing system can be applied to verifying design load of the wind generating set, optimizing design scheme of the wind generating set, detecting quality of the wind generating set which leaves factory, avoiding safety accidents and the like and has high practicability.

Owner:STATE GRID CORP OF CHINA +2

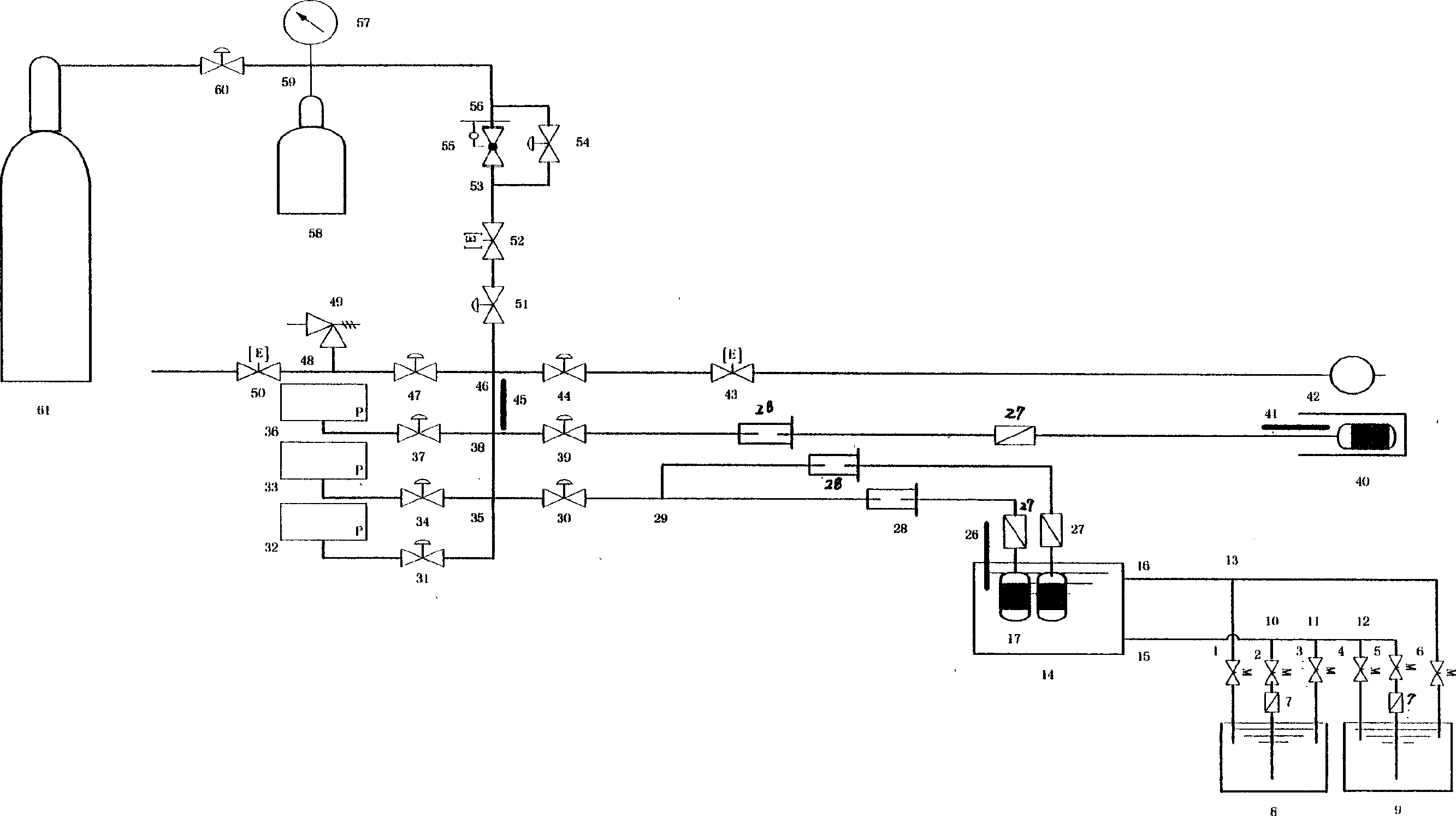

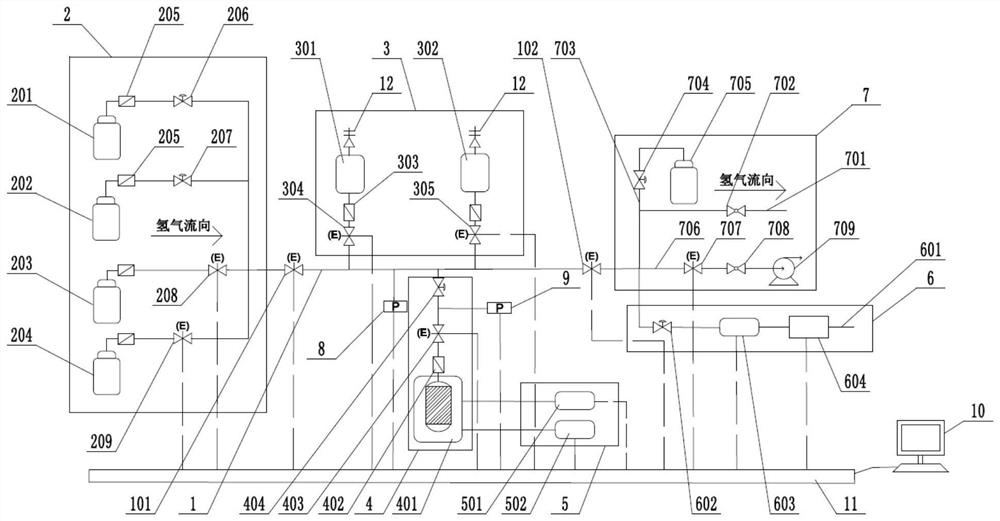

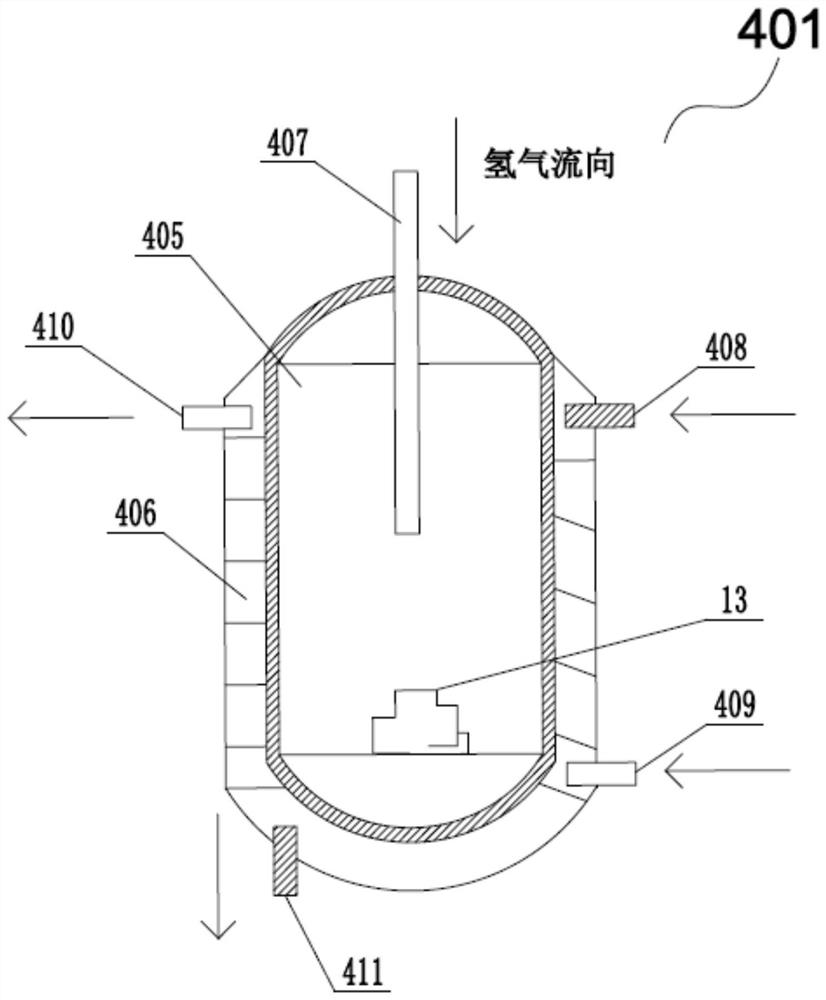

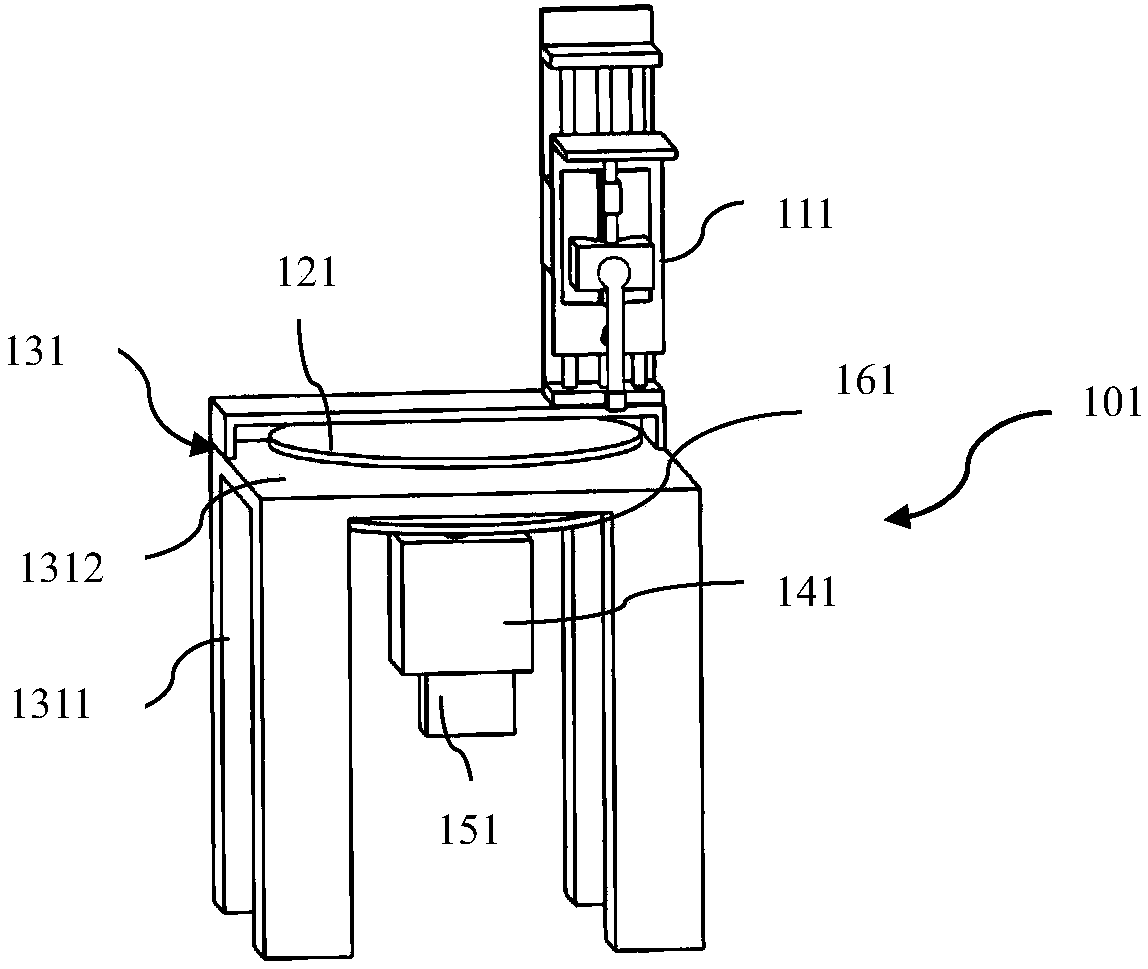

System and method for testing multiple properties of hydrogen storage material

PendingCN112326501AEasy to useThe monitoring parameters are comprehensive and sufficientMaterial heat developmentHydrogen purityTemperature control

The invention relates to the technical field of hydrogen storage material performance testing, and discloses a system for testing multiple properties of a hydrogen storage material. The system comprises a main pipeline, a high-pressure gas source subsystem, a gas storage subsystem, a reaction subsystem, a temperature control subsystem, a thermal conductivity monitoring subsystem, an exhaust subsystem, a data acquisition and processing subsystem, a first pressure sensor and a second pressure sensor. The system can complete calibration of the volume of the reaction chamber, measurement of the leakage rate of the reaction chamber, performance test of the hydrogen storage material under different hydrogen purities, measurement of the hydrogen purities before and after hydrogen storage / release,test of the cycle life of the hydrogen storage material under different initial hydrogen purities and the like. The invention also discloses a test method of the system for testing the multiple properties of the hydrogen storage material. The system and method are controlled by a computer, convenient to operate, complete in measurement parameters and high in accuracy, so that the performance of the hydrogen storage material under different hydrogen filling purities can be better obtained.

Owner:HUIZHOU HUA DA TONG GAS MFG CO LTD

Measurement system and method for dynamic sliding friction coefficients

InactiveCN108037070AAchieving vertical loadImprove continuityUsing mechanical meansMaterial analysisData processing systemEngineering

The invention provides a measurement system and method for dynamic sliding friction coefficients. The system comprises a parameter loading system, a power supply device connected with the input terminal of the parameter loading system, a sensor signal reading system connected with the output terminal of the parameter loading system, and a data processing system connected with the sensor signal reading system 3. The system and the method solve the technical problems of strict experiment requirements, less measured coefficients and narrow sliding velocity load range in the existing measurement system and method for sliding friction coefficients. The system and the method have the advantages that the change rule of sliding friction coefficients along with load, sliding velocity, rough pavement, rubber property and temperature can be tested, and the continuous loading and keeping of vertical load, sliding velocity and temperature are realized.

Owner:BEIJING INFORMATION SCI & TECH UNIV

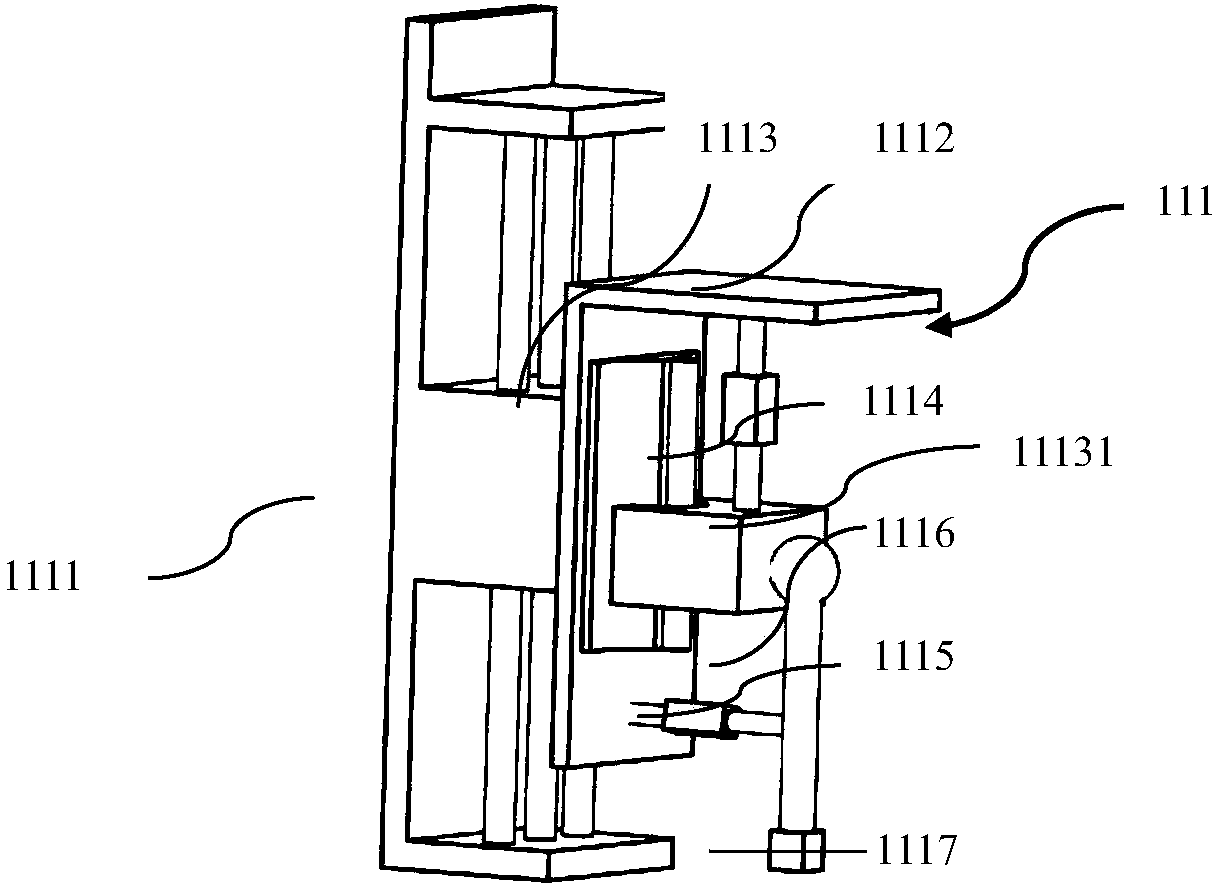

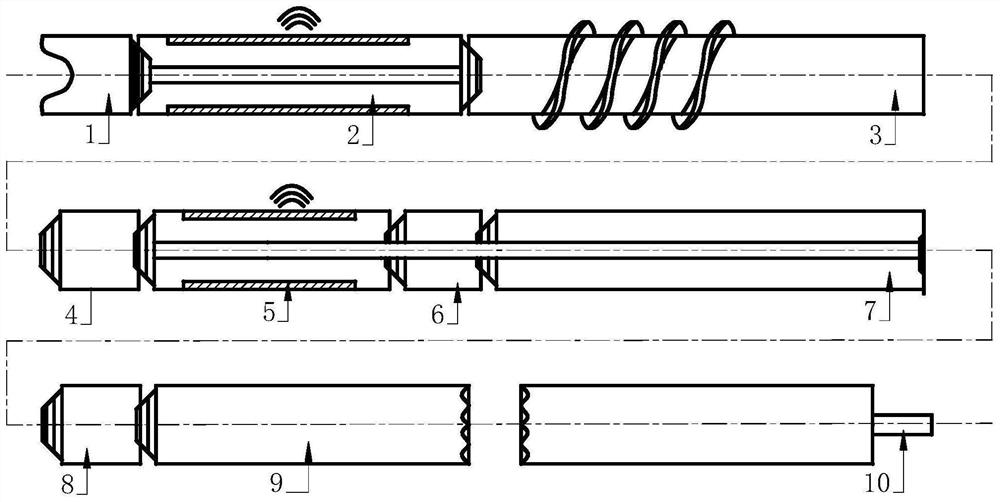

Near-bit multi-parameter underground while-drilling measurement and control system

PendingCN114033361AReal-time monitoring of real-time changesMany measurement parametersSurveyConstructionsDrilling systemData processing

The invention discloses a near-bit multi-parameter underground measurement and control while drilling system and is composed of ground equipment and an underground assembly, wherein the underground assembly sequentially comprises a drill bit, a multi-parameter collecting, measuring and transmitting short section, a power drilling tool, a receiving and transmitting short section, a wireless communication short section, a non-magnetic drill collar and the like, wherein the measuring and transmitting short section is used for collecting data according to a preset time interval, storing the collected data to the storage module and transmitting the collected data to the signal receiving antenna, and transmitting a received signal to the receiving and transmitting short section through a communication medium formed between the screw power drilling tool and drilling fluid; the receiving and transmitting short section conducts wireless transmission in an electromagnetic coupling mode and transmits signals to the wireless communication short section, the wireless communication short section transmits the received signals to ground equipment through the mud pulse generator in a pulse signal mode, and a ground system conducts data processing and analysis. According to the real-time measurement and control system, the real-time change of underground engineering parameters can be monitored in real time and adjusted in real time, and drilling time efficiency is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

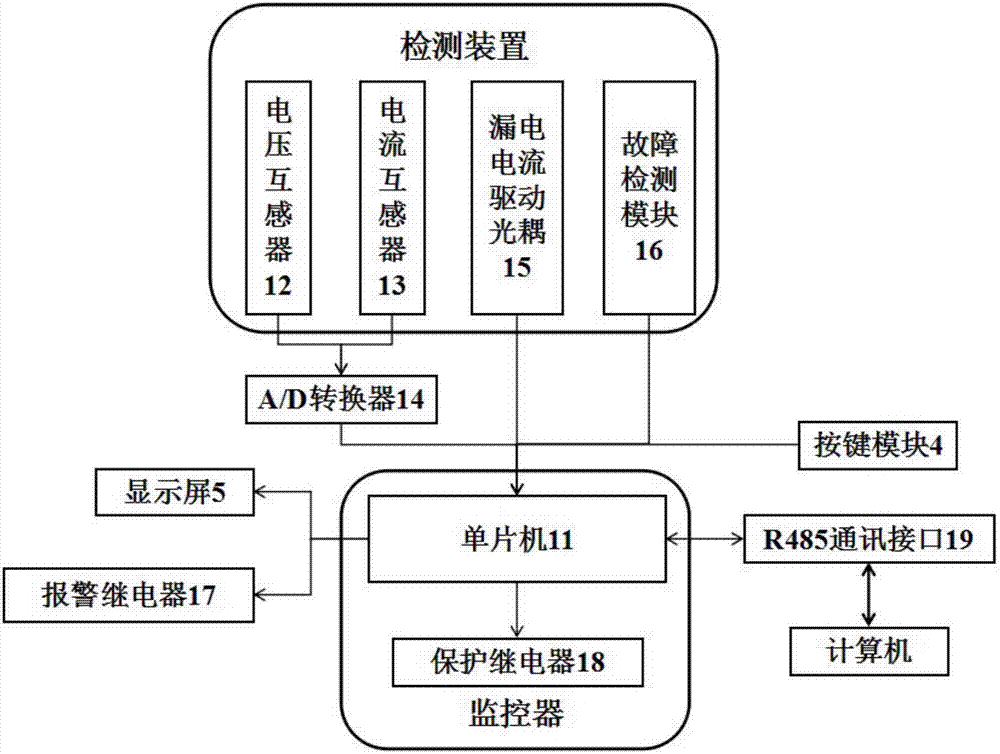

Motor intelligent monitoring system

InactiveCN107508259AFix damageEasy to useEmergency protective circuit arrangementsMicrocontrollerMicrocomputer

The invention discloses a motor intelligent monitoring system, and relates to the motor technical field; the motor intelligent monitoring system comprises a monitor and a detection device; the detection device outputs data information to the monitor; the monitor comprises a single-chip microcomputer and a protection relay; the detection device outputs data information to the single-chip microcomputer; the single-chip microcomputer outputs a circuit break order to the protection relay; the single-chip microcomputer outputs the data information to a display screen; the detection device comprises a voltage transformer, a current transformer, an electric leakage current driving optical coupler and a fault detection module; the voltage transformer and the current transformer output data information to the single-chip microcomputer through an A / D converter; the electric leakage current driving optical coupler and the fault detection module output fault information to the single-chip microcomputer. The single-chip microcomputer and the protection relay can solve the motor damage problems caused by abnormal states; the motor intelligent monitoring system is convenient to install, accurate in monitoring control, and complete in protection functions.

Owner:ANHUI SANHE ELECTRIC POWER TECH

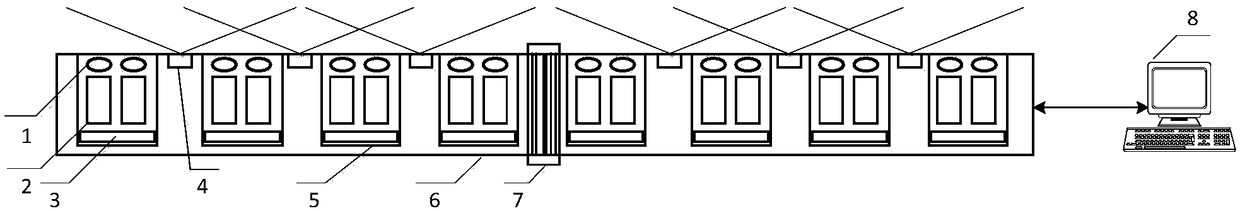

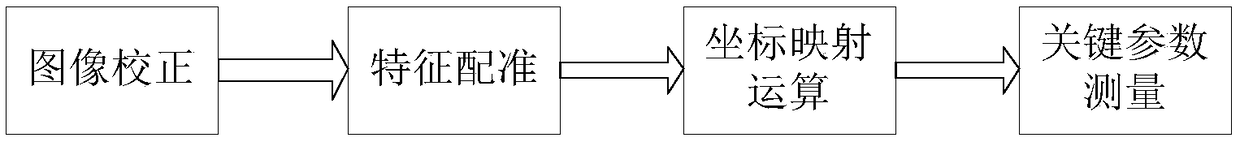

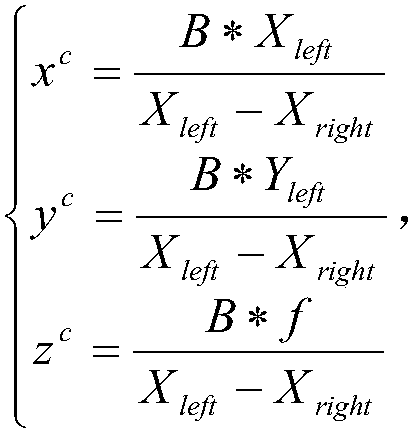

Fuel assembly deformation detection system based on underwater binocular vision

InactiveCN108917633AMany measurement parametersEasy to useUsing optical meansCMOS sensorThree dimensional measurement

The invention discloses a fuel assembly deformation detection system based on underwater binocular vision. The system is composed of two parts including an underwater binocular array acquisition sub-system and a parameter three-dimensional measurement sub-system; the underwater binocular array acquisition sub-system includes two sections; the sections are connected through a threaded clamping buckle; global data acquisition of a large assembly is realized; each section includes four sets of binocular acquisition modules; a uniform light source module is configured between adjacent modules; sufficient illumination is provided for assembly imaging in a corresponding view field; the critical area of the assembly is imaged on a corresponding CMOS sensor through an optical lens; the system realizes synchronous acquisition of eight sets of binocular acquisition modules through a hardware triggering module; and thus, three-dimensional measurement of various key parameters of a fuel assembly can be realized. According to the fuel assembly deformation detection system based on underwater binocular vision in the invention, three-dimensional sizes of the key parameters of the fuel assembly can be obtained; furthermore, the overall outline of the assembly can be measured; and thus, a powerful tool is provided for parameter measurement of high-temperature and high-radiation underwater spentfuel assemblies, such as local deformation and overall bending.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

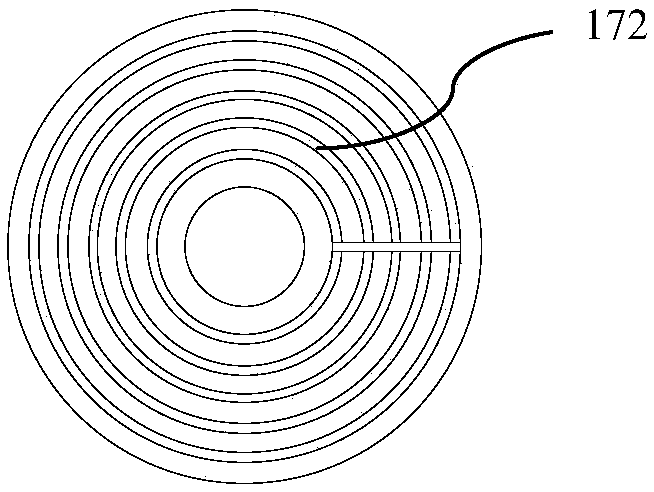

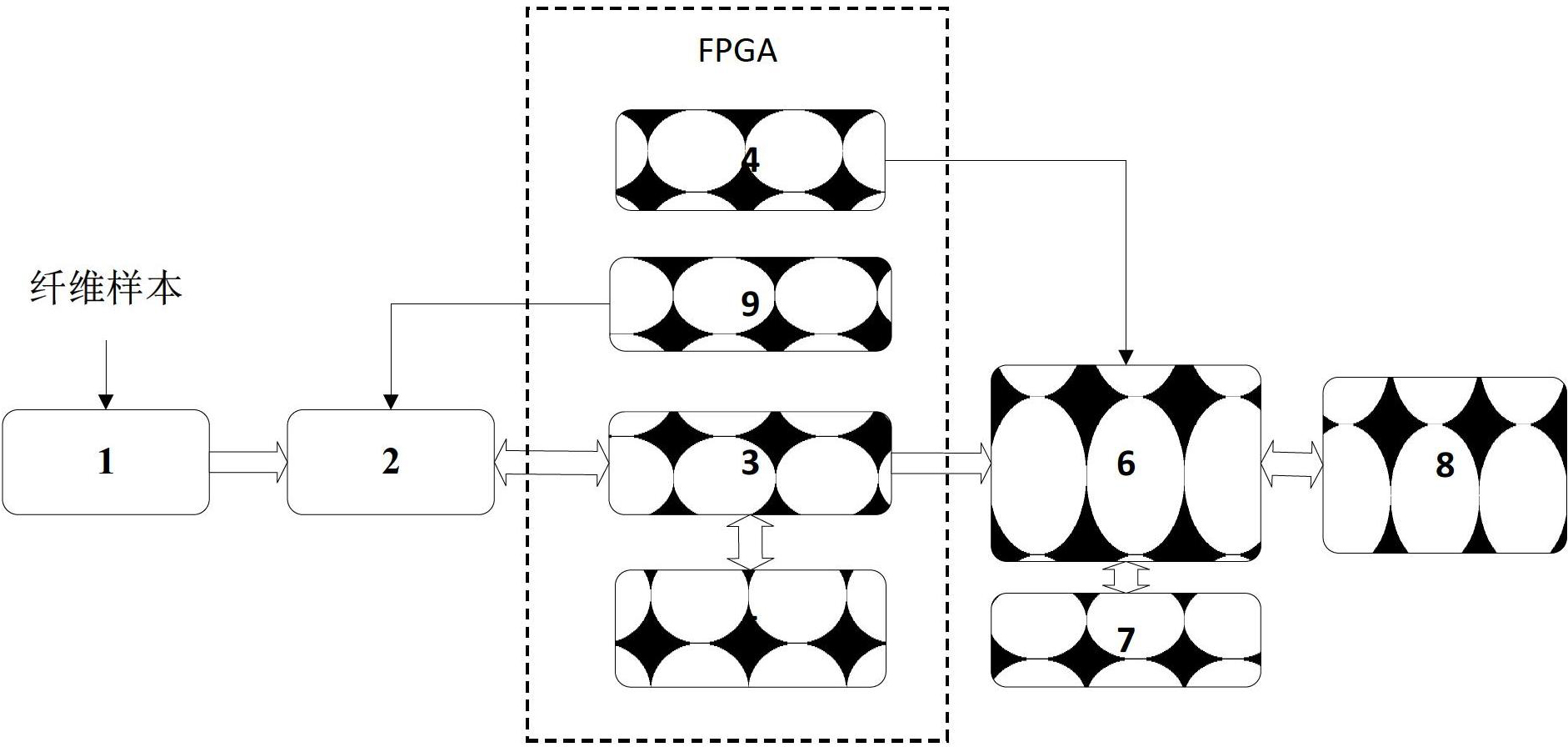

FPGA (Field Programmable Gate Array) and DSP (Digital Signal Processor) based system and method for rapidly measuring embedded pulp fiber morphological parameters

The invention relates to a small-sized, rapid and accurate FPGA (Field Programmable Gate Array) and DSP (Digital Signal Processor) based system and a method for rapidly measuring embedded pulp fiber morphological parameters. The system comprises a CCD (Charge Coupled Device) camera which is connected with an ADC (Analog-to-Digital Conversion) chip; the ADC chip is connected with an SDRAM (Synchronous Dynamic Random Access Memory) module in an FPGA module; the SDRAM module is connected with a fiber image preprocessing module; the FPGA module is also provided with an DSP data reading control module and an ADC sequential control module, wherein the ADC sequential control module is connected with the ADC chip, the DSP data reading control module is communicated with a DSP module, and the DSP module also communicates with the SDRAM module, an LCD (Liquid Crystal Display) and a fiber image and morphological parameter storage FLASH module. The system and the method can be used for accurately measuring multiple morphological parameters of pulp fiber in real time and has the characteristics of high automation degree, low cost, small size and the like.

Owner:QILU UNIV OF TECH

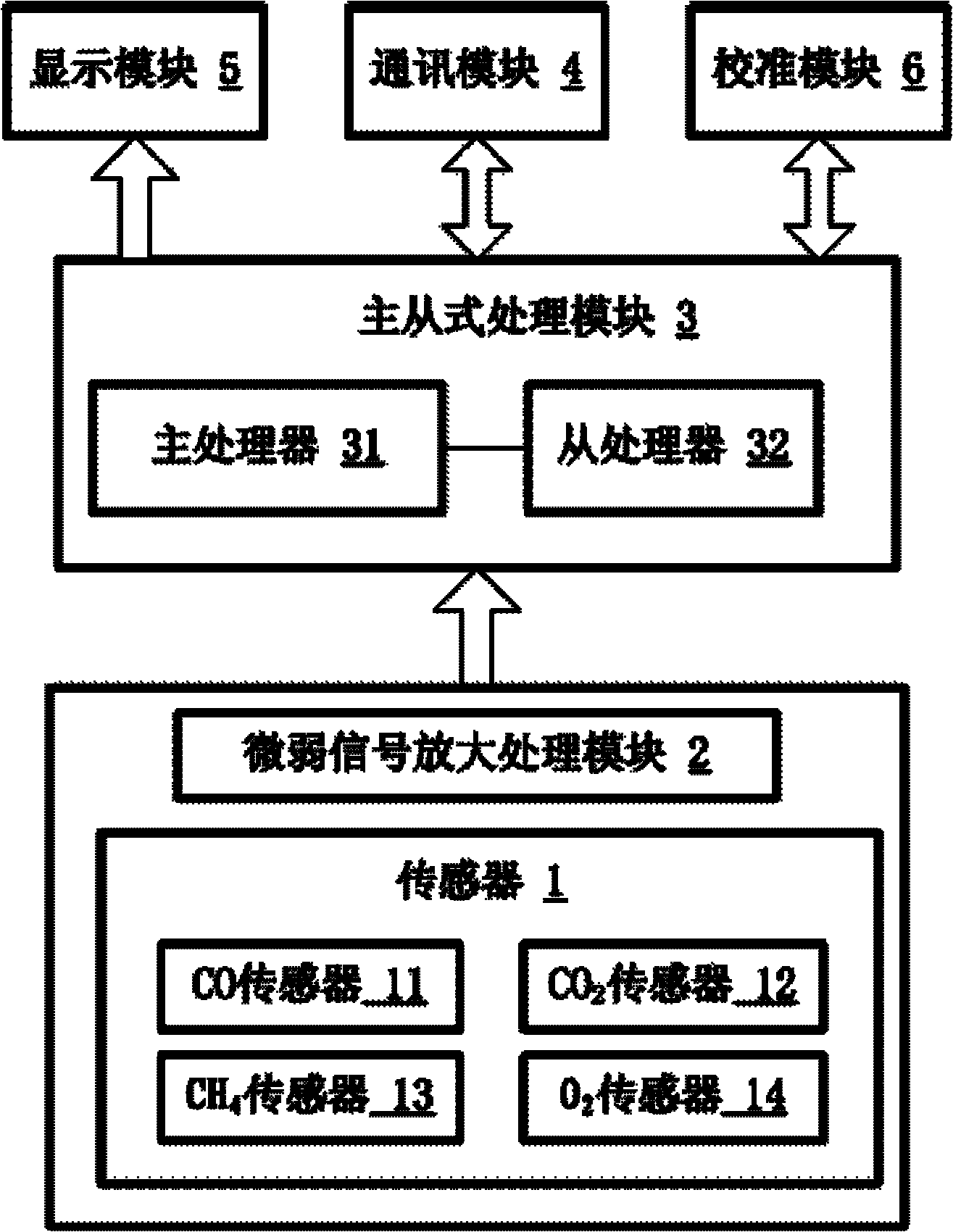

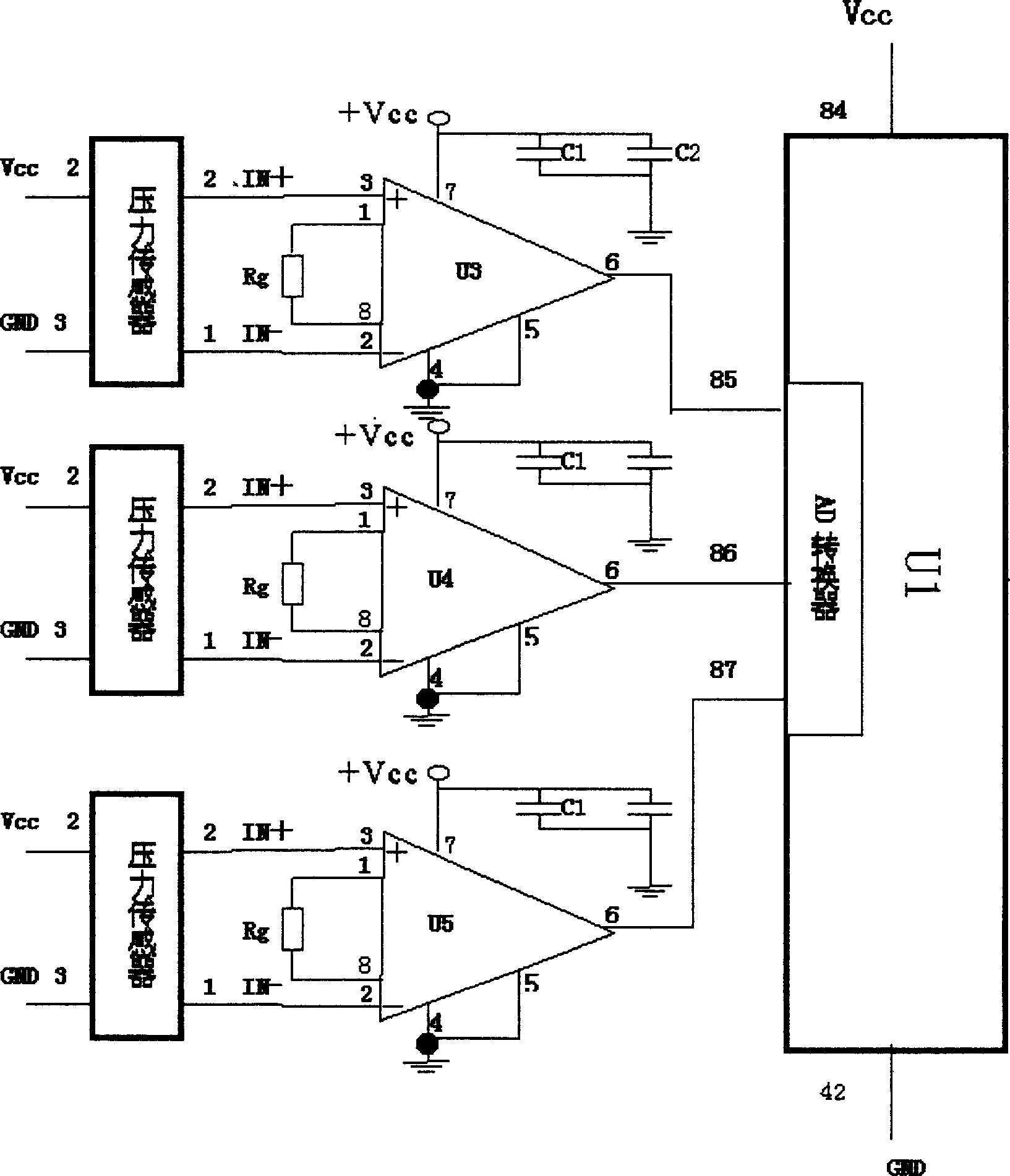

Transition chamber multi-parameter sensor

InactiveCN102279244AAccurate and stable measurement accuracyImprove reliabilityMaterial analysisAntechamberEngineering

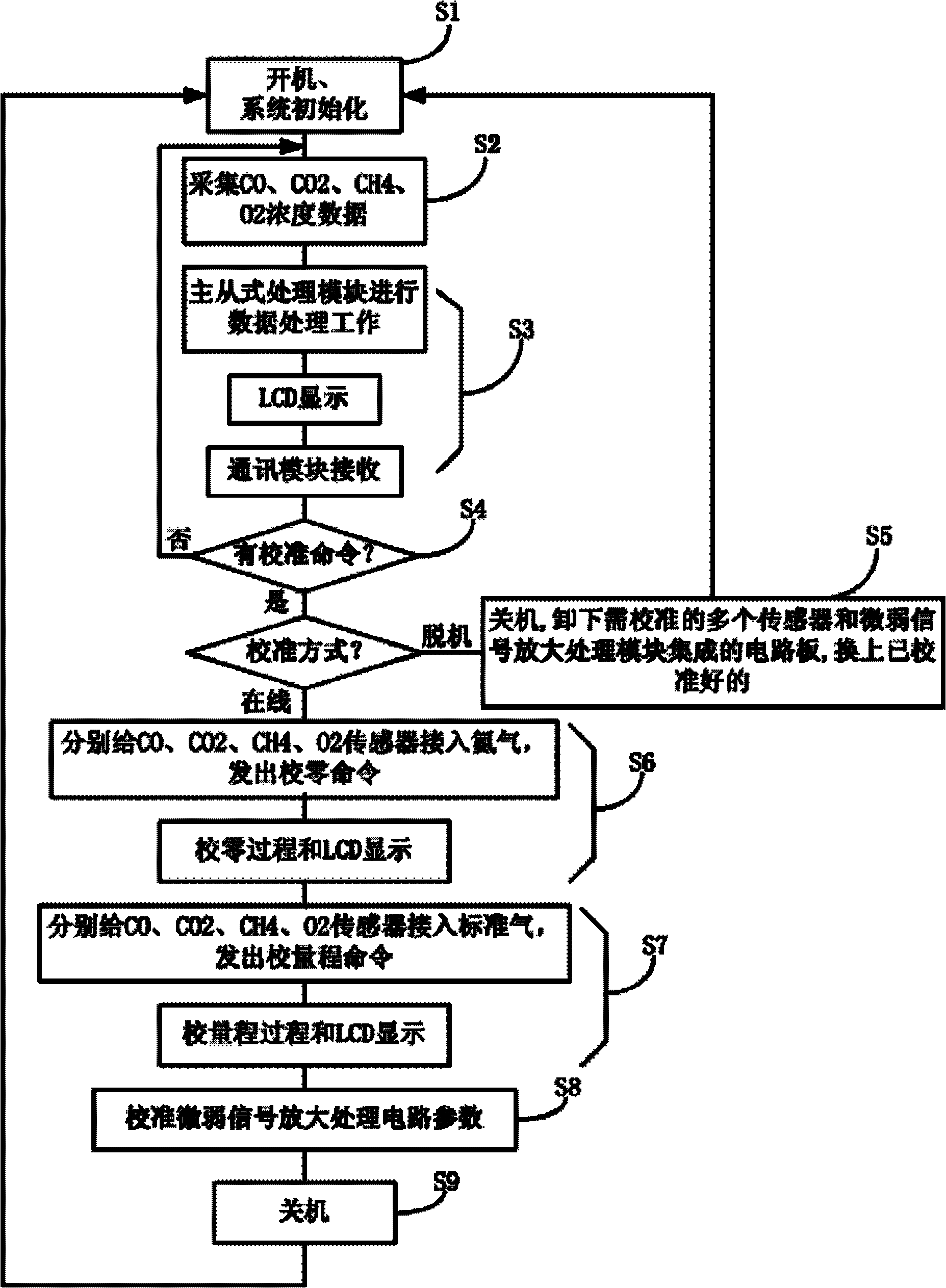

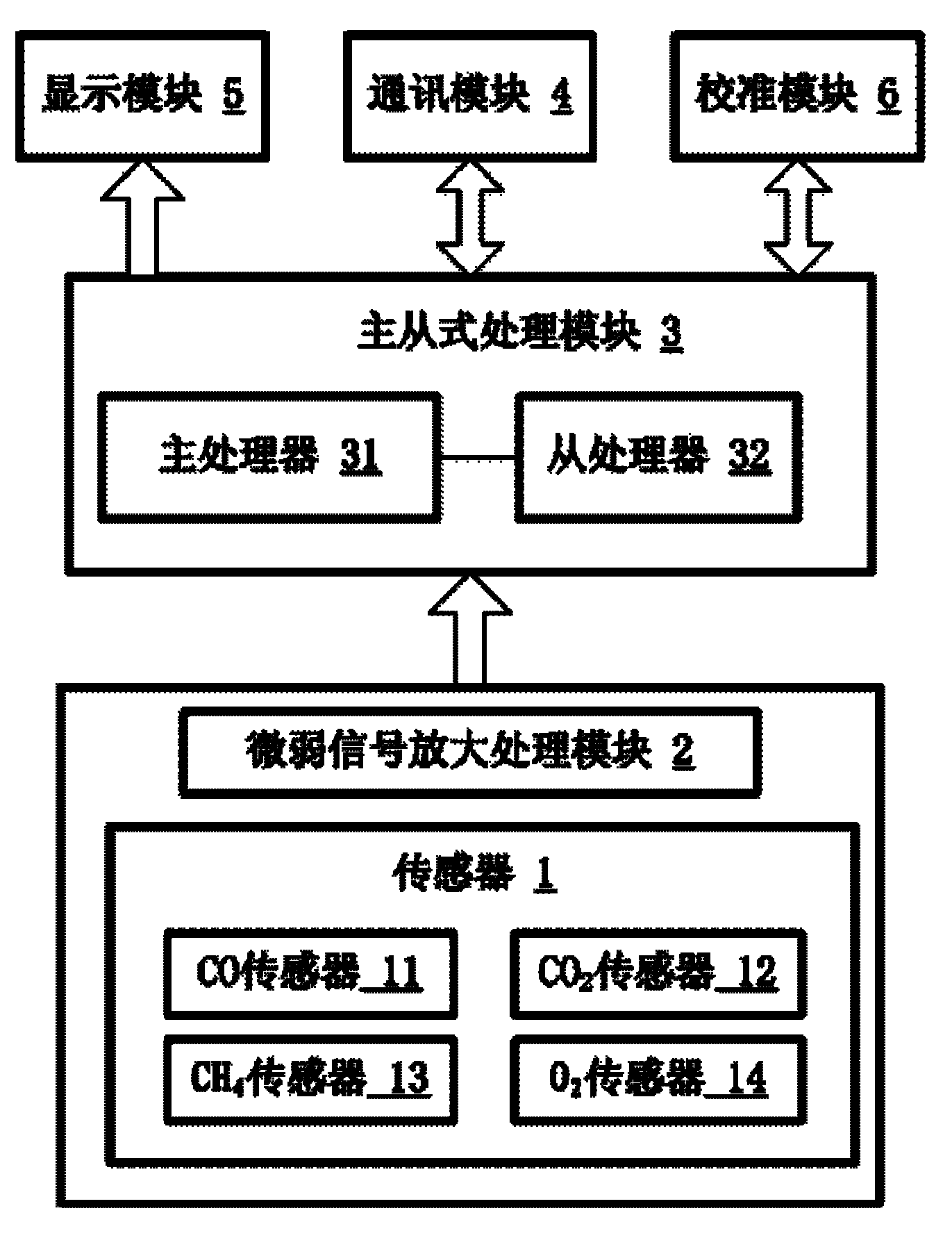

The invention relates to a multi-parameter sensor for a transition chamber, which includes a plurality of sensors, a weak signal amplification processing module, a master-slave processing module, a communication module, a display module, a calibration module and a shell structure. The present invention can be installed in the transition cabin, collect CO, CO2, CH4, O2 gas concentration data in the cabin in real time, and transmit them to the monitoring and control system of the mobile rescue cabin and the fixed refuge chamber through the RS232 / RS485 serial port and the CAN bus interface. The calibration of each sensor has two ways: online calibration and offline calibration. The zero point and range of CO, CO2, CH4, O2 can be calibrated at one time, and the parameters of the weak signal amplification processing circuit can also be calibrated. The master-slave processing module ensures the stability of the present invention. High performance and reliability, the display module and the explosion-proof structure shell make the operation convenient and safe. It solves the problem of installing multiple sensors and data transmission interfaces in the limited space of the transition cabin in the underground mobile rescue cabin of the mine.

Owner:中安金力(北京)安全生产技术研究院

Pit parameter measuring method

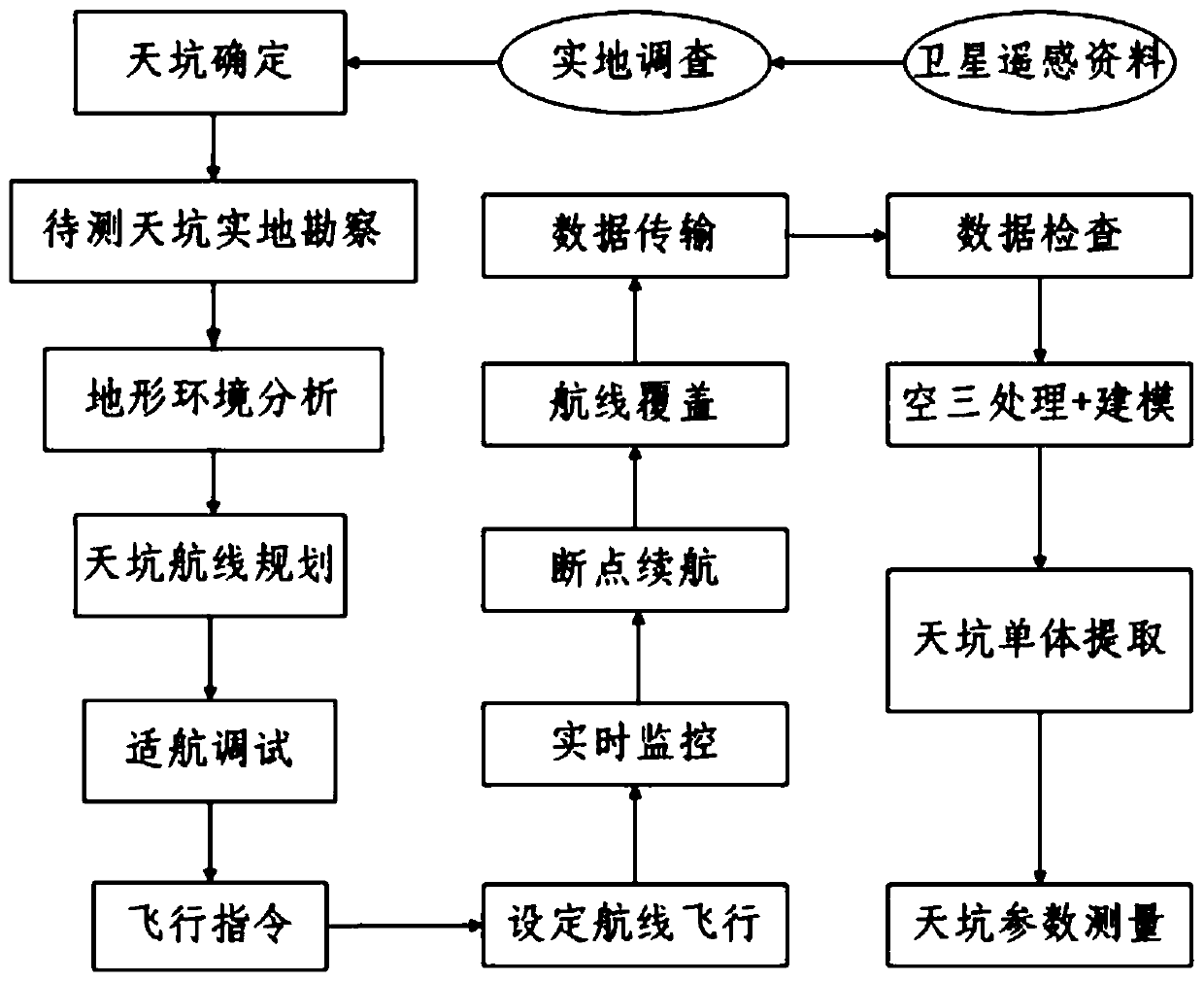

PendingCN110836661ASimple and efficient operationMany measurement parametersPicture interpretationData transmissionThree dimensional model

The invention discloses a pit parameter measurement method and belongs to a landform measurement method. The method comprises the following steps of carrying out satellite remote sensing interpretation on pit landform; performing on-site investigation and determining a data acquisition area; performing airworthiness condition analysis and route planning; allowing an unmanned aerial vehicle carrying an optical sensor to perform data acquisition; transmitting a flight instruction and performing real-time monitoring, performing breakpoint endurance, performing course coverage, ending the data acquisition of the optical sensor, and transmitting acquired data; checking and processing the acquired data, processing the acquired data through aerial triangulation software, and establishing a three-dimensional model; performing pit monomer extraction; and measuring and analyzing various typical parameters of the pit three-dimensional landform model. According to the method, the pit full view including a pit opening, a pit wall and a pit bottom can be obtained, the problem that manual measurement cannot be conducted comprehensively is solved, full-coverage, high-precision and multi-view pit appearance data are obtained, the measurement parameters are comprehensive, the accuracy is high, and permanent measurement data are provided for protection, development and utilization of the pit appearance.

Owner:INST OF KARST GEOLOGY CAGS

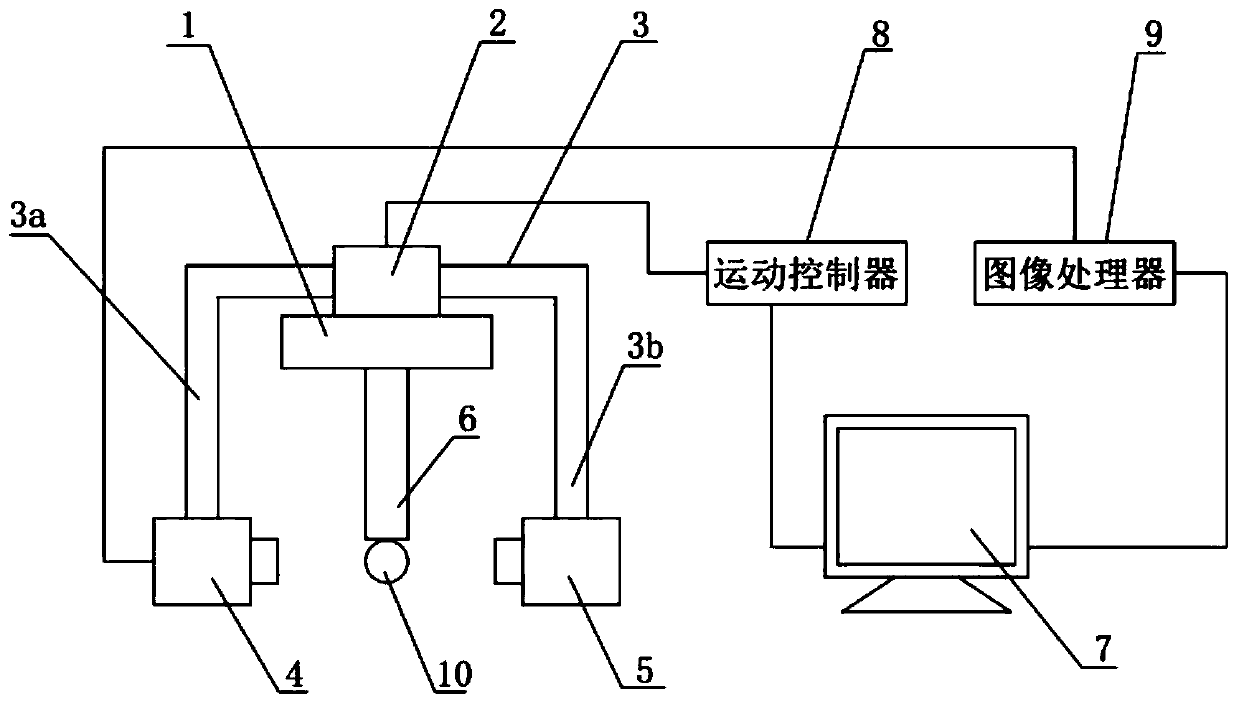

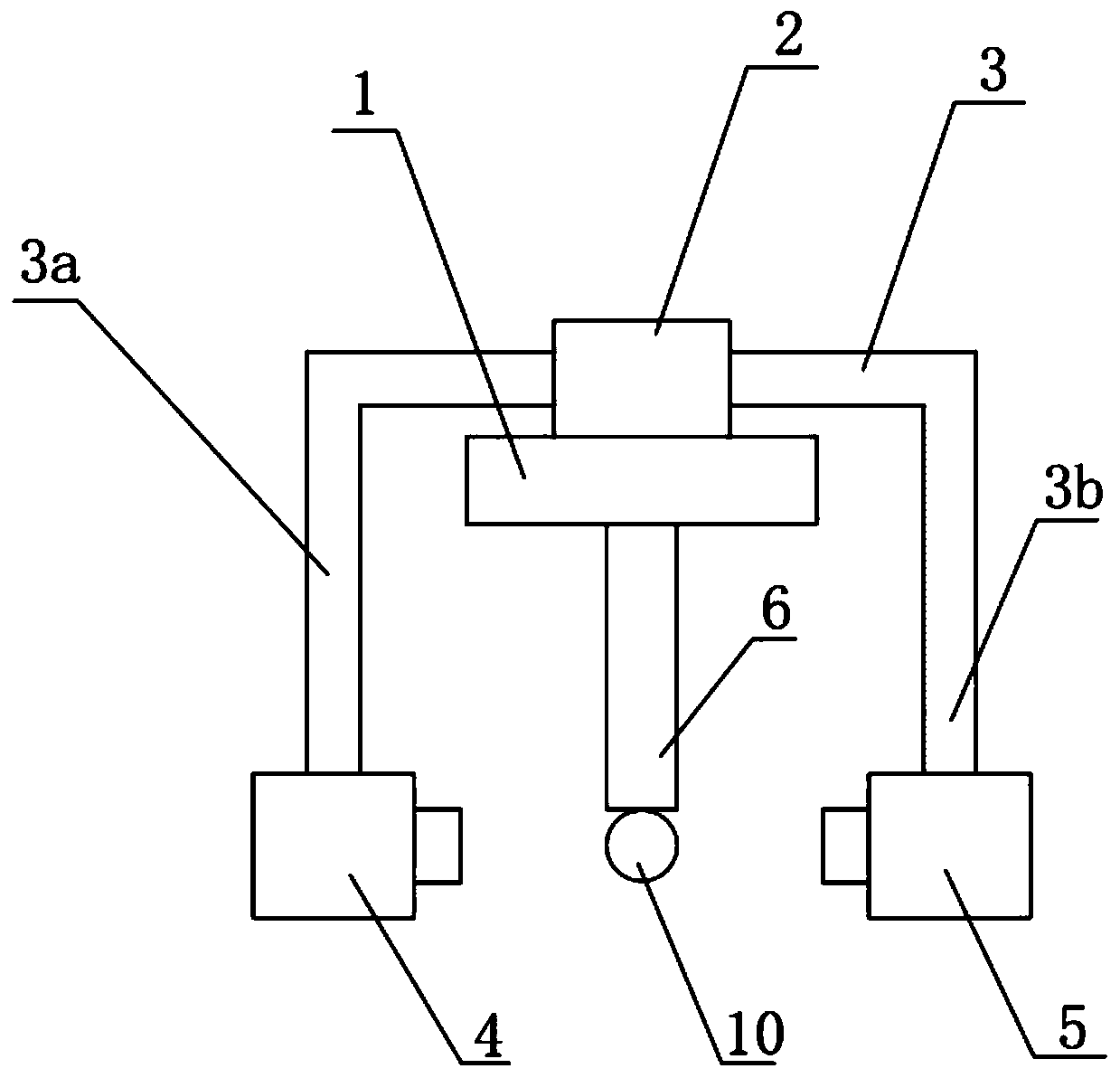

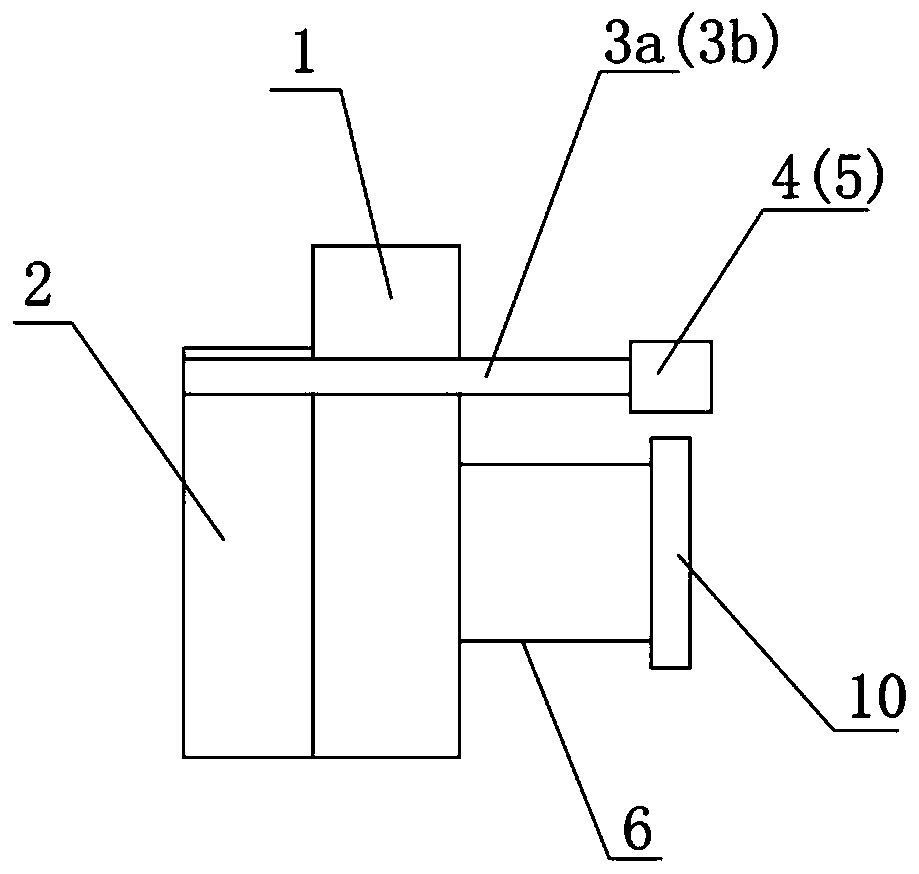

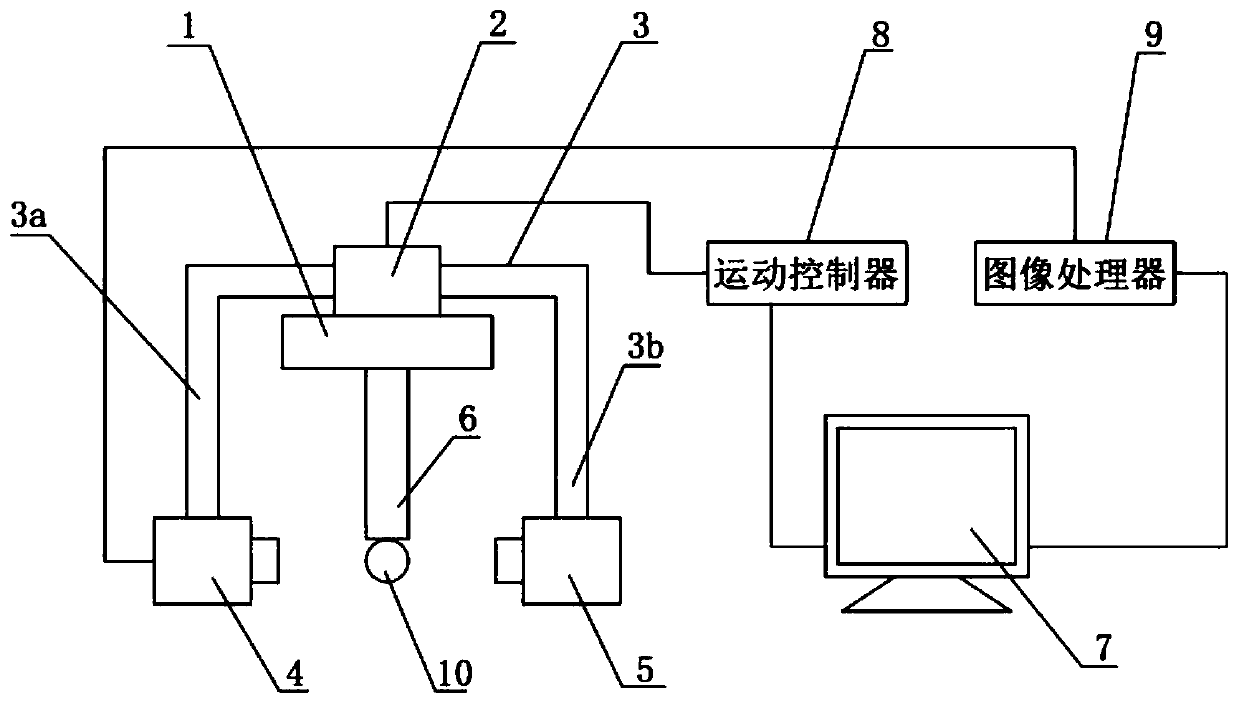

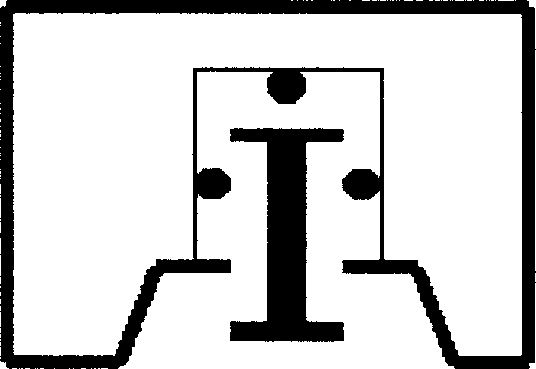

Image collecting system of shaft detecting device and image collecting method of image collecting system

InactiveCN109883322AMany measurement parametersAvoid damageOptically investigating flaws/contaminationUsing optical meansElectricityLight source

The invention discloses an image collecting system of a shaft detecting device and an image collecting method of the image collecting system. The image collecting system of the shaft detecting devicecomprises a base, a moving translation stage and a to-be-tested fixing tool rack. The moving translation stage is arranged on the back surface of the base, the to-be-tested fixing rack is arranged onthe front surface of the base, the moving translation stage is connected with a supporting rack, a lens supporting rack and a light source supporting rack are arranged at the two ends of the supporting rack, the lens supporting rack and the light source supporting rack are symmetrically arranged, a camera is fixed to the lens supporting rack, a light source is fixed to the light source supportingrack, and a lens of the camera is opposite to the light source in a center parallel mode. The image collecting system of the shaft detecting device further comprises a PC machine, a moving controllerand an image processor, the PC machine is electrically connected with the moving controller and the image processor, the moving controller is electrically connected with the moving translation stage,and the image processor is electrically connected with the camera. According to the image collecting system of the shaft detecting device and the image collecting method of the image collecting system, measurable parameters are complete, the automation degree is high, the shaft-like parts are subjected to parameter measuring by using an image processing technology, the measuring precision is high,and the situation of damaging due to part contacting is avoided.

Owner:WUHAN TEXTILE UNIV

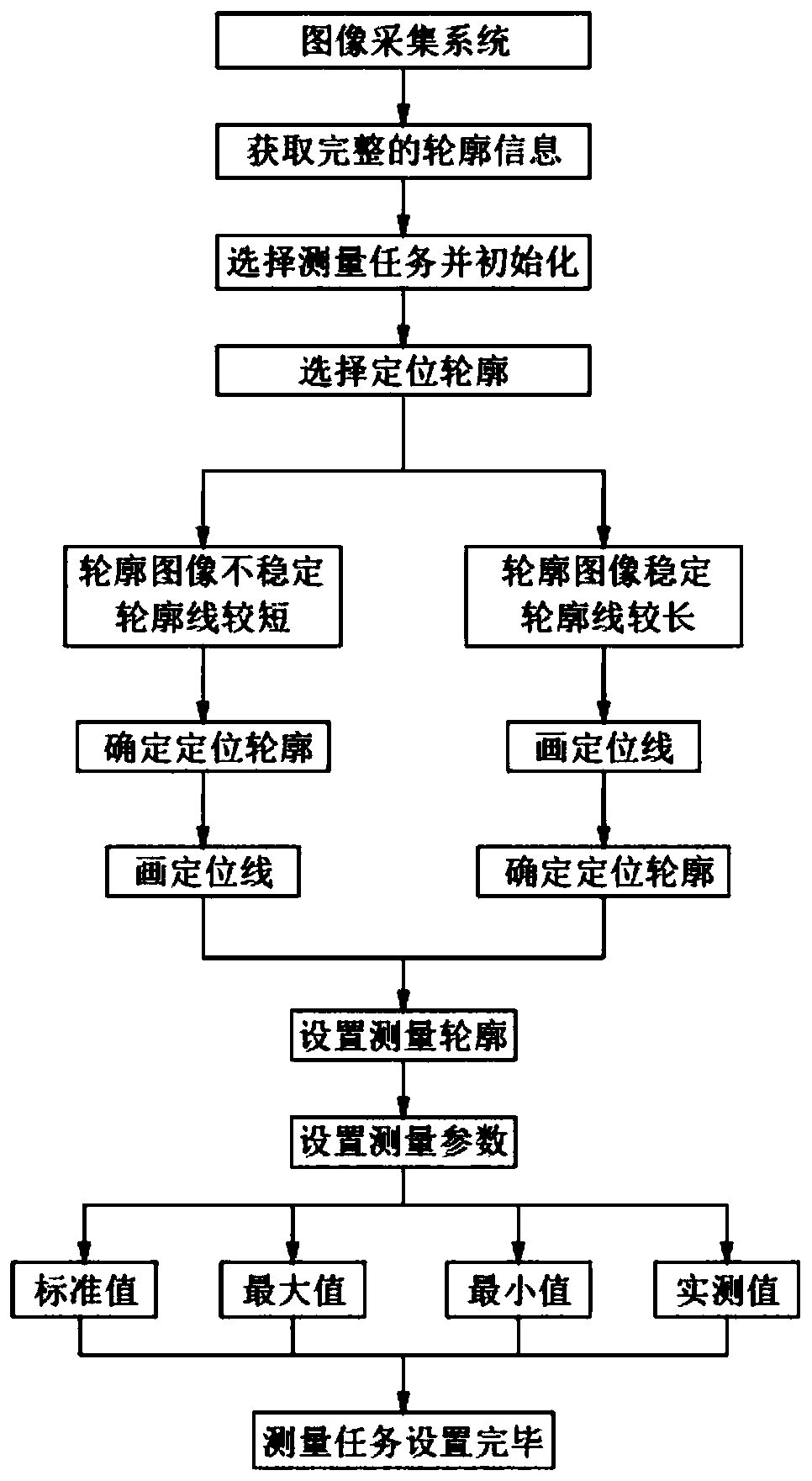

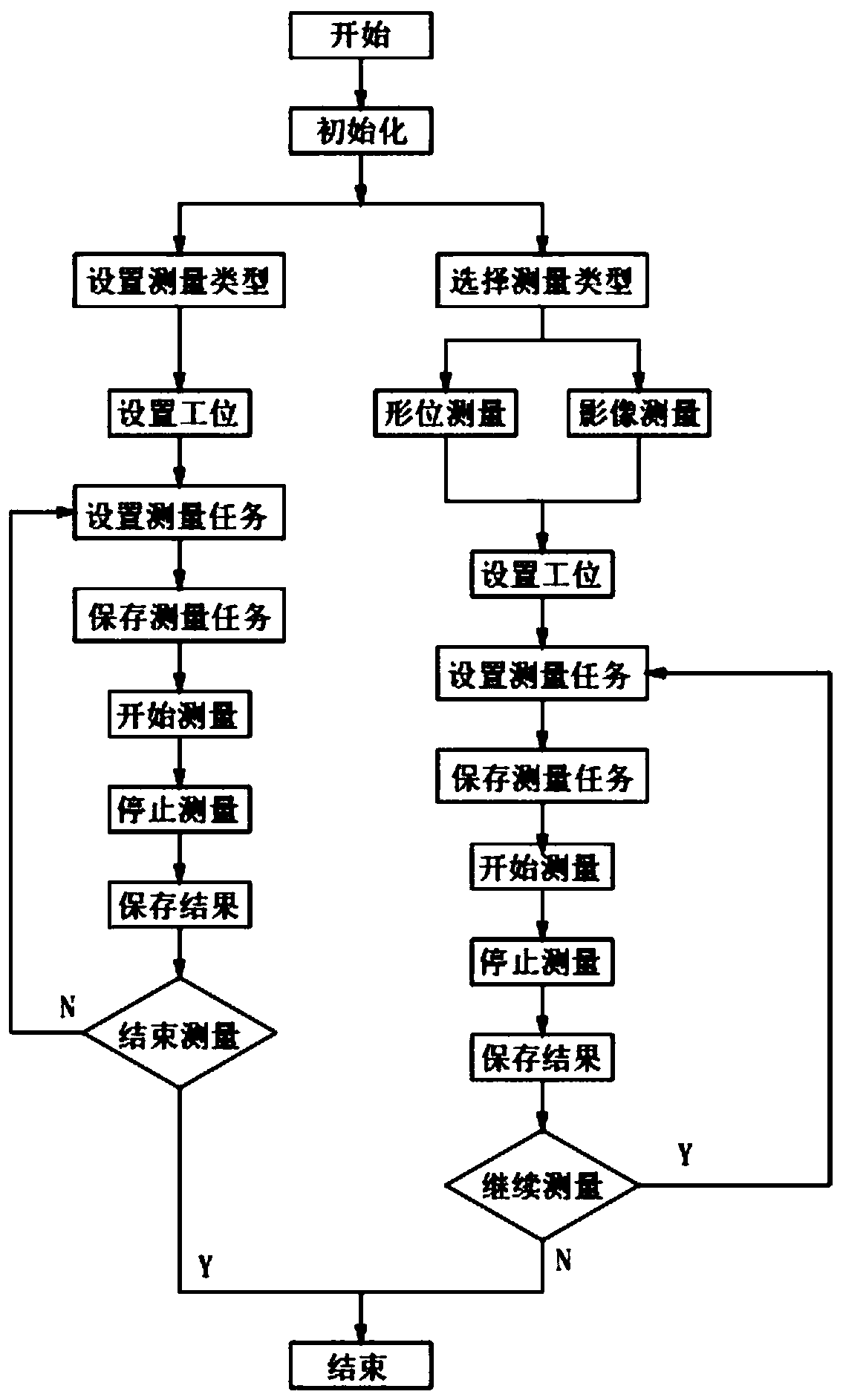

Measurement task setting method for shaft detection instrument

ActiveCN109813248AMeet different needsHigh precisionUsing optical meansCollection systemComputer vision

The invention discloses a measurement task setting method for a shaft detection instrument. The method comprises the following steps that integral outline image information is acquired through an image collection system; a measurement task is selected, and initialization is conducted; a locating outline is selected; a measurement outline is set; measurement parameters are set; after being set, themeasurement task is stored. According to the method, firstly, a shaft part is located, the accuracy of outline selection is improved, stability and accuracy of subsequent measurement are improved, parameters used for measurement are complete, and different requirements of users are met.

Owner:武汉联扬科技有限公司

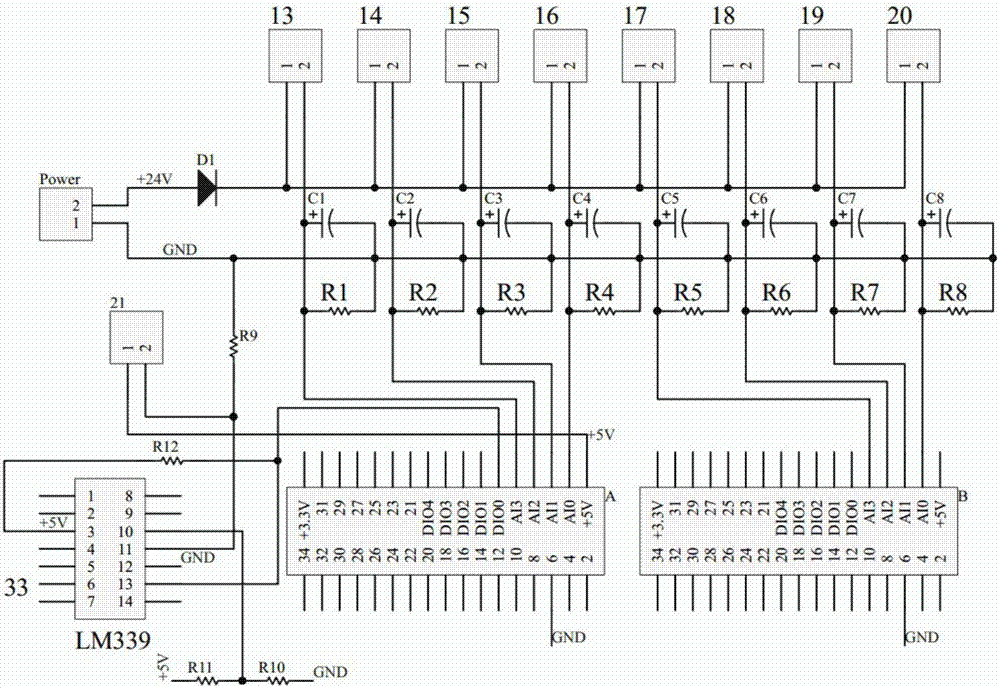

Ground characteristics detecting device used for snake shaped robot

A ground characteristics detector of snake-shaped robot is installed in head module and is composed of casing, pressure sensor, pressing rods and contacts.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Parameter measurement integration test system facing heat flow dynamics and test method thereof

InactiveCN107515119AMany measurement parametersCompact structureEngine testingHeat flowDifferential pressure

The invention relates to a parameter measurement integration test system facing heat flow dynamics and a test method thereof. The system comprises a system main body module, a measurement module and a control module. The test system takes a ducted fan as a gas source and a turbine as a power apparatus. PTC heating ceramic and an air cylinder are served as a heating system and a displacement system respectively. A differential pressure sensor, a pressure sensor, a temperature sensor, a displacement sensor and a rotating speed sensor are used to assist to simulate measurement of some important parameters (a flow, pressure, a temperature, a displacement, a rotating speed and the like) during aircraft engine operation. Through adjusting a valve opening degree and controlling an input signal, parameter adjusting is realized. The system can visually display a heat flow dynamics basic principle, covers comprehensive measurement parameters and possesses characteristics of a compact structure, low cost, high operability and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com