Measurement task setting method for shaft detection instrument

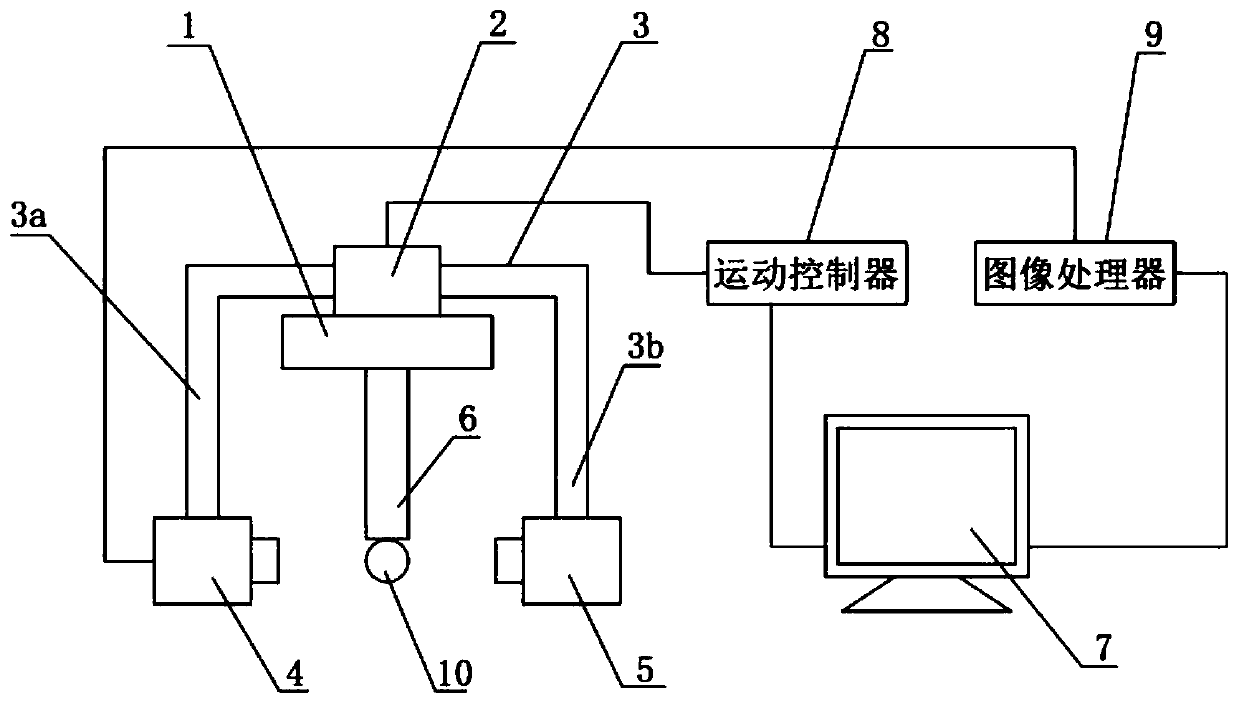

A technology for measuring tasks and setting methods, applied in measuring devices, instruments, and optical devices, etc., can solve the problems of high work intensity, low efficiency, and difficulty in online measurement, so as to improve the accuracy and stability of measurement, and improve the measurement accuracy. Fully parameterized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

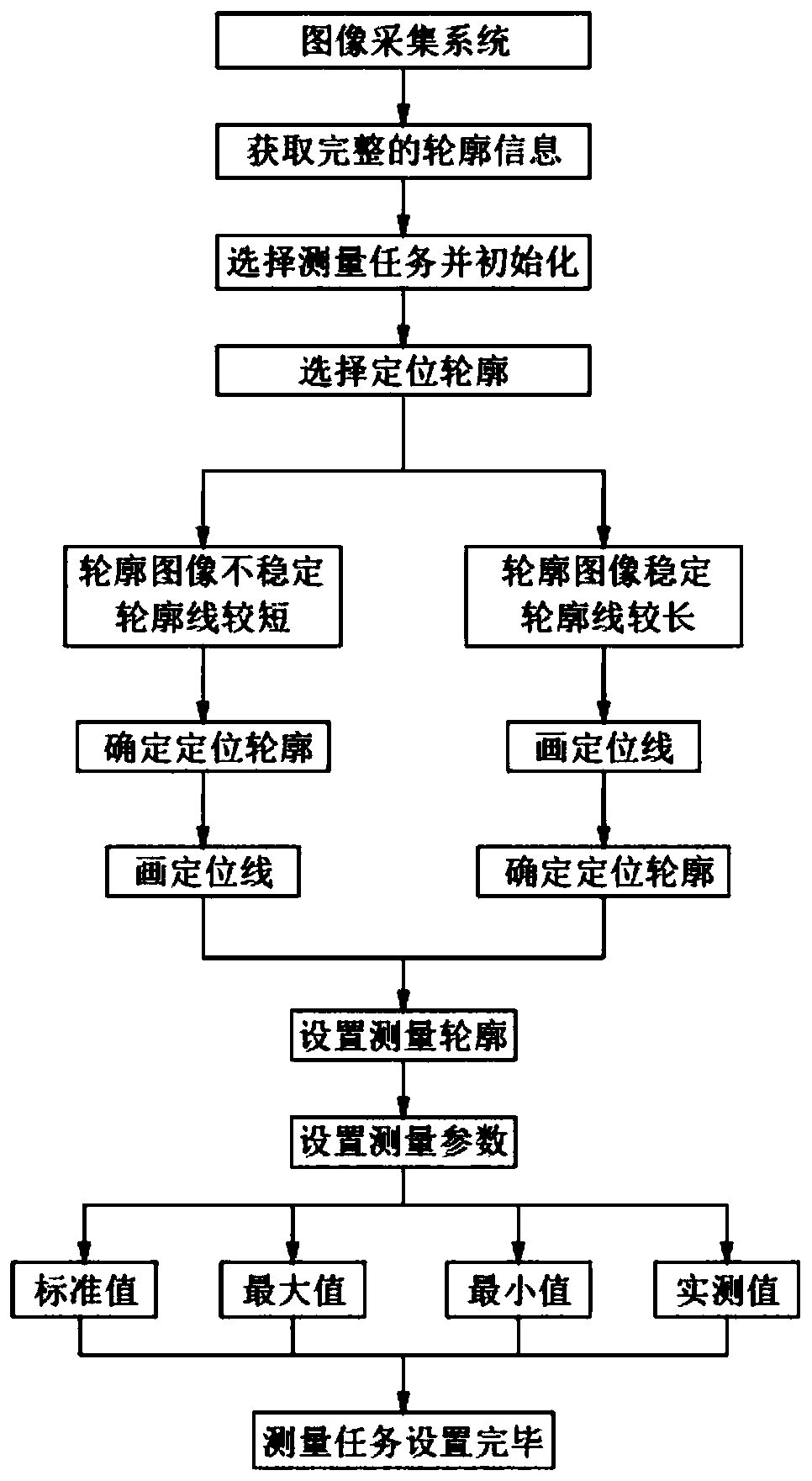

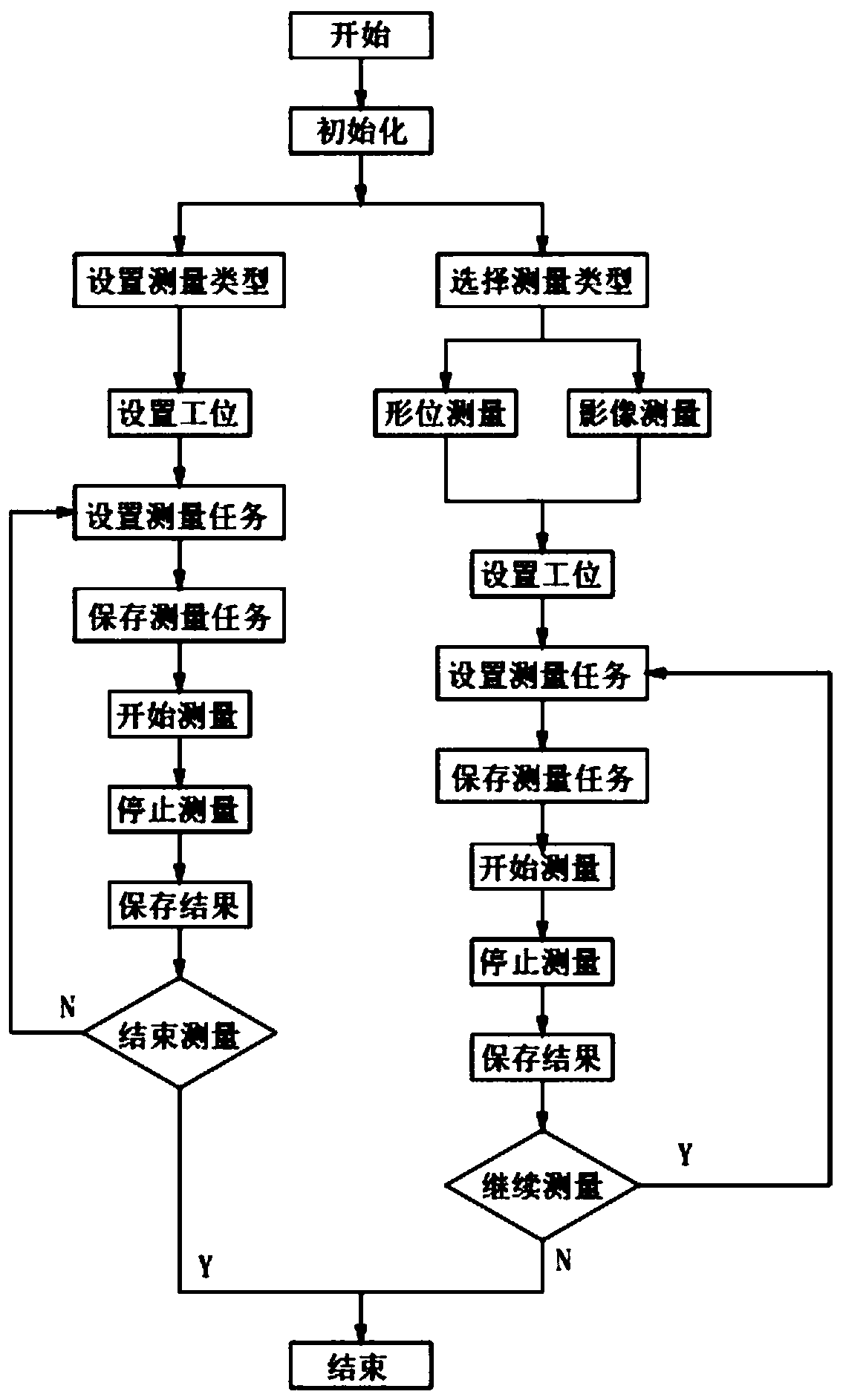

[0060] Embodiment 1, taking setting the diameter of the measurement shaft as an example, explains the specific task setting process. In this embodiment of the shaft diameter measurement task setting embodiment, the contour image information of the part to be measured is stable and the contour line is long, such as Figure 4 ~ Figure 6 As shown, the specific setting process of the measurement task is as follows:

[0061] (1) Obtain the complete contour image of the workpiece to be measured;

[0062] (2) Select the relatively stable contour of the contour image information of the part to be measured as the positioning contour, because in this embodiment, the upper contour edge information of the shaft part to be measured is stable, so the upper contour is selected as the positioning contour, so a short straight line is drawn Intersect with the upper contour of the shaft part to be measured (eg Figure 4 shown), this short straight line is the positioning line, and the upper con...

Embodiment 2

[0065] Embodiment 2, take setting the distance between the measuring line and the line as an example, that is, Figure 7 with Figure 8 As shown, the distance between the left and right vertical lines is measured, and the specific task setting process is described: in this measurement task setting example, because the left and right vertical lines are too short to be easily positioned, it is necessary to select The contour image information near the part to be measured is stable and the longer contour is used as the positioning contour. The specific setting process of the measurement task is as follows:

[0066] (1) Obtain the complete contour image of the workpiece to be measured;

[0067] (2) Select the longer contour line near the contour line of the part to be measured as the positioning contour, and then draw a short straight line to intersect with the longer contour line (such as Figure 7 shown), this short straight line is the positioning line, and the longer contour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com