Performance metering method of vehicle-mounted laser evenness instrument

A measurement method and flatness technology, applied in the field of performance measurement of vehicle-mounted laser flatness instrument, can solve problems affecting the quality of detection data, equipment verification or calibration work blank, unfavorable project quality evaluation, etc., to reduce the cost of measurement, measure The parameters are comprehensive and conducive to the effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

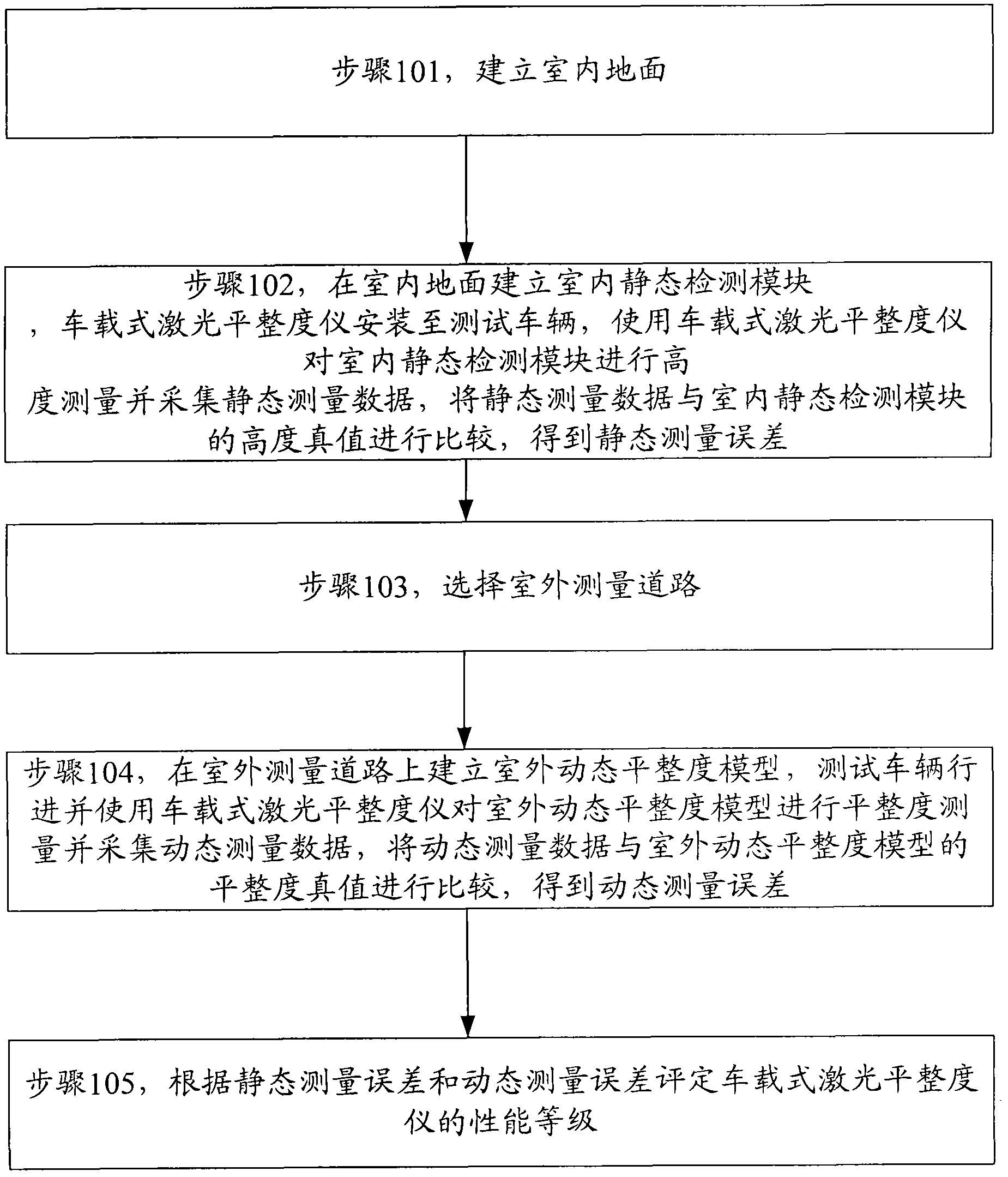

[0023] figure 1 It is a schematic flowchart of the performance measurement method of the vehicle-mounted laser flatness meter of the present invention. Such as figure 1 As shown, the performance measurement method of the vehicle-mounted structure flatness meter of the present invention includes

[0024] Step 101, establishing an indoor ground, the flatness of which is lower than 2.5mm / m;

[0025] Step 102, establish an indoor static detection module on the indoor ground, install the vehicle-mounted laser levelness meter on the test vehicle, use the vehicle-mounted laser leveler to measure the height of the indoor static detection module and collect static measurement data, and compare the static measurement data with The height true value of the indoor static detection module is compared to obtain the static measurement error;

[0026] Step 103, select an outdoor measurement road;

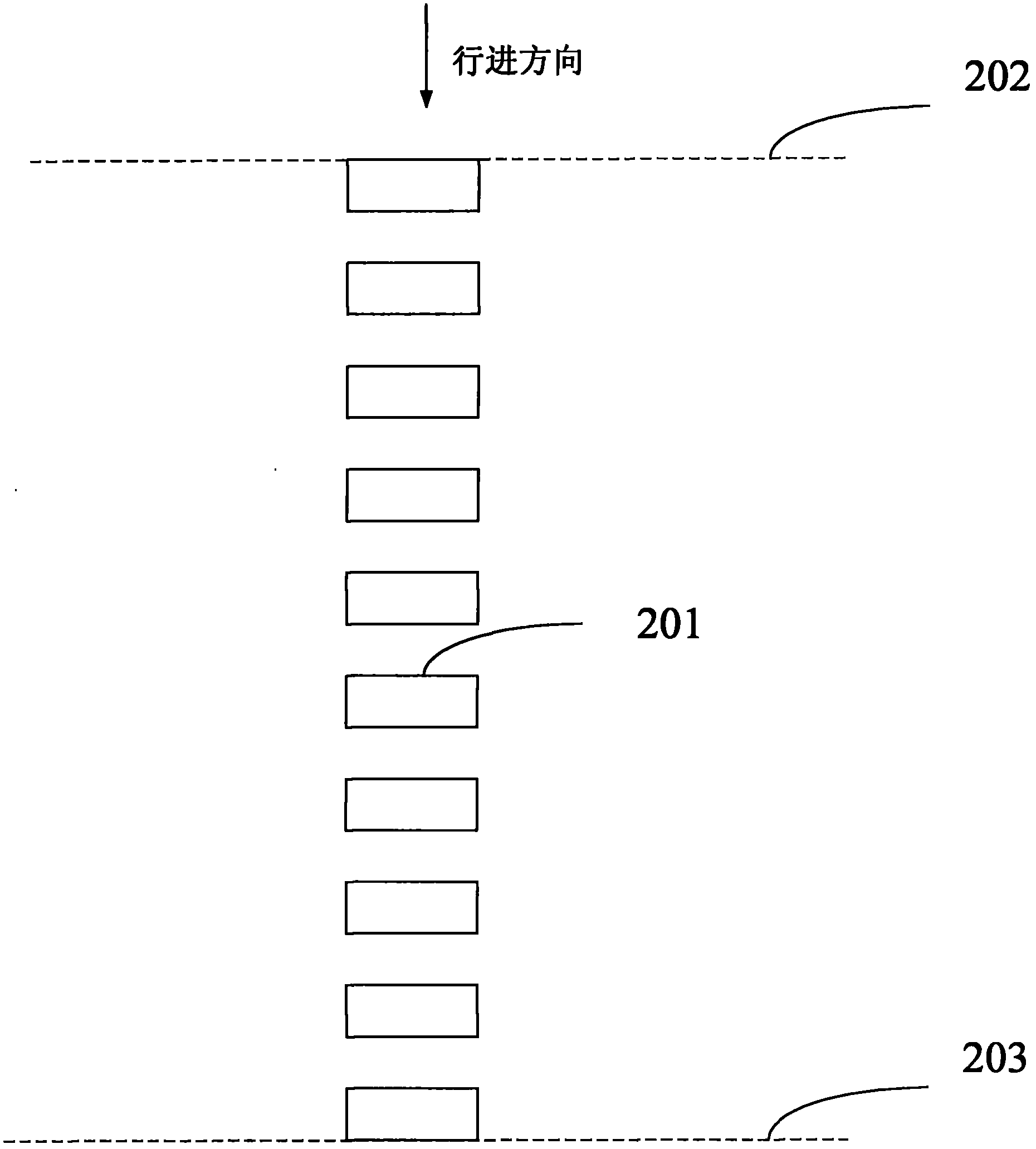

[0027] Step 104, establish an outdoor dynamic flatness model on the outdoor measurement roa...

Embodiment 2

[0077] The difference between this embodiment and the first embodiment lies in the establishment method of the flatness model. By increasing the number of modules and detection steps in this embodiment, the actual flatness model can be simulated more comprehensively and accurately, and the vehicle-mounted flatness model can be more accurately evaluated. Measuring performance of the meter.

[0078] Wherein, in step 101, the flatness of the indoor ground is lower than 2.5 mm / m.

[0079] Step 102 includes:

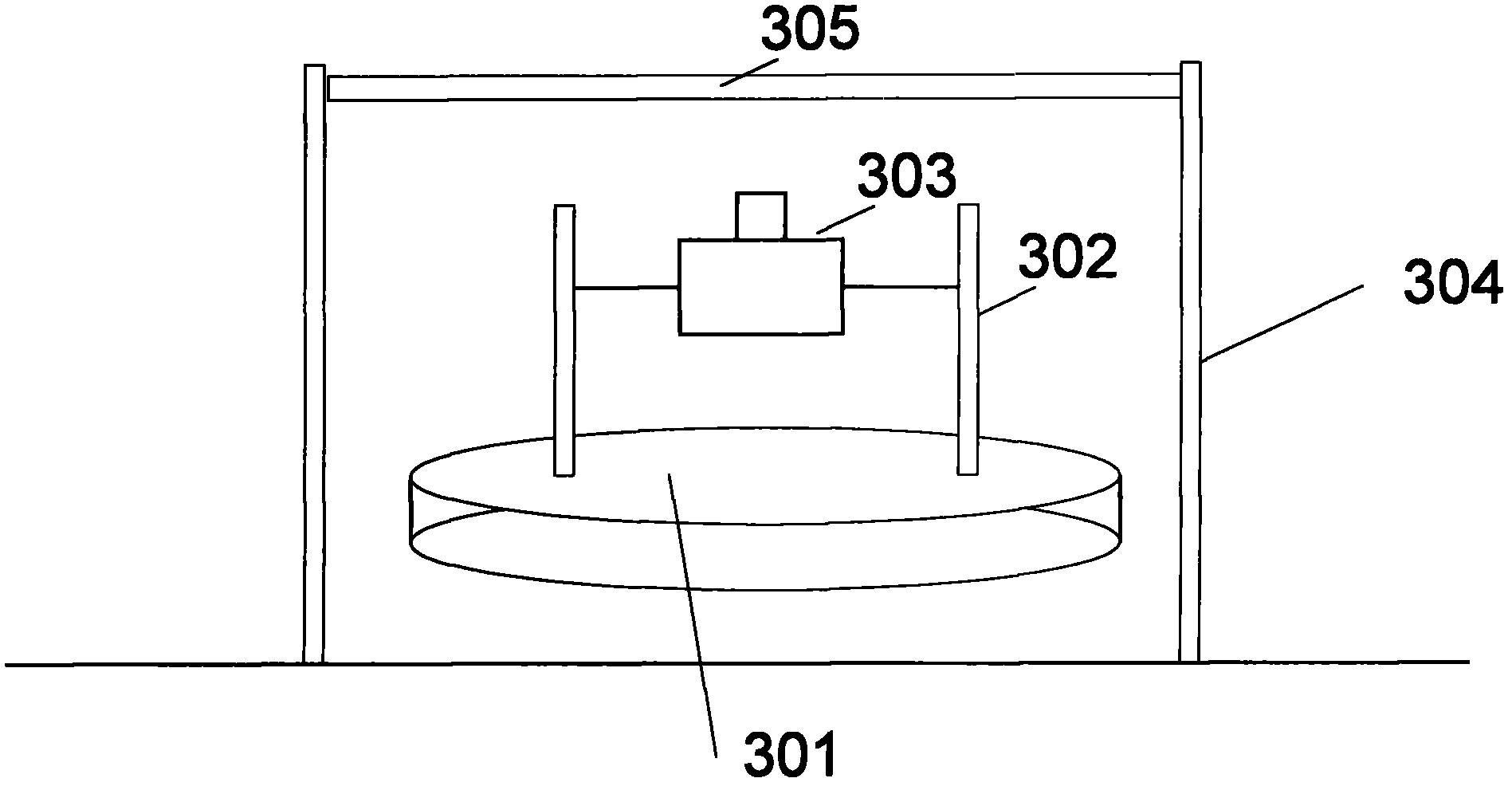

[0080] Step 102c, place a metal strip with a size of 400cm×10cm×3cm directly under the laser sensor of the vehicle-mounted laser levelness meter and level it, and use the vehicle-mounted laser levelness instrument to measure the distance between the laser sensor and the metal strip The distance is checked by the laser distance measurement of the flatness meter.

[0081] Step 102d, change the distance between the laser sensor and the metal slat by changing the height of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com