Parameter measurement integration test system facing heat flow dynamics and test method thereof

A fluid dynamics and parameter measurement technology, applied in engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of no aero-engine measurement simulation and control simulation, high price, cumbersome operation, etc., and achieve compact structure , low cost, comprehensive effect of measurement parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

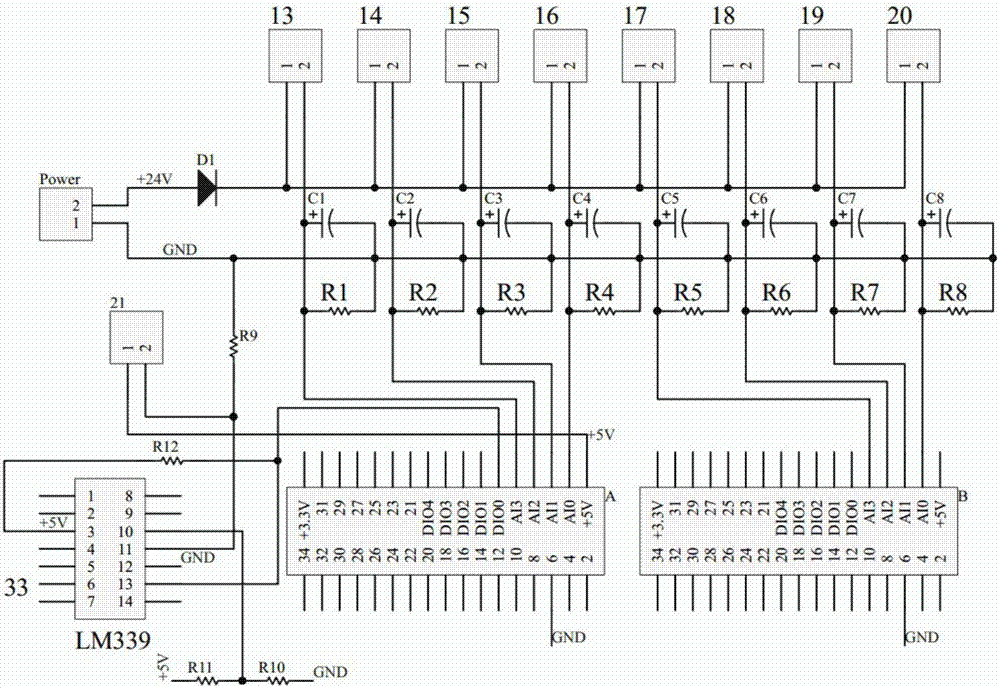

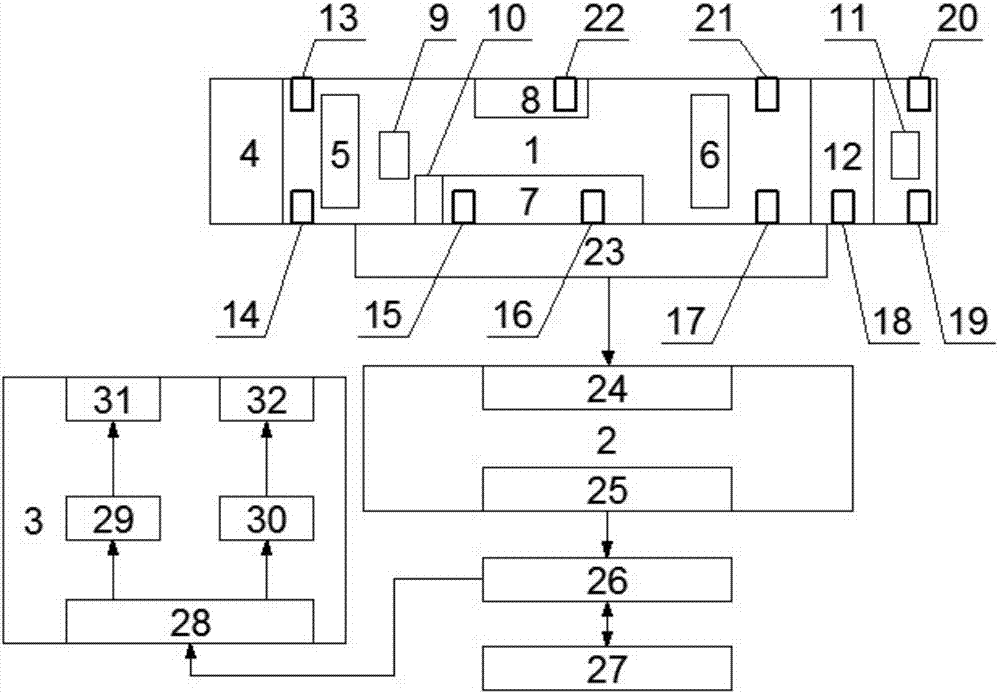

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0020] as attached figure 1 As shown, the thermodynamics-oriented parameter measurement comprehensive test system includes the system main module 1, the control module 3 and the measurement module 2. The main module of the system uses the ducted fan 4 as the air source, the turbine 12 as the power device, relies on the PTC heating ceramic 7 and the cylinder 8 as the heating system and the displacement system respectively, supplemented by differential pressure sensors 13 and 20, pressure sensors 14, 17 and 19, temperature sensors 15, 16 and 21, displacement sensor 22, rotational speed sensor 18 etc. are made up of ten different sensors altogether. When working, first use the relevant control program to provide a specific PWM signal to the electric regulator board 31 of the ducted fan 4 through the PC terminal, so that the ducted fan 4 starts to run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com