Image collecting system of shaft detecting device and image collecting method of image collecting system

An image acquisition system and image acquisition technology, applied in the direction of instruments, optical devices, and optical testing of defects/defects, can solve the problems of accuracy and efficiency not reaching the expected effect, fewer types of measurement tasks, and difficulty in online measurement. Achieve the effect of reducing manual operation, high degree of automation, and complete measurement parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

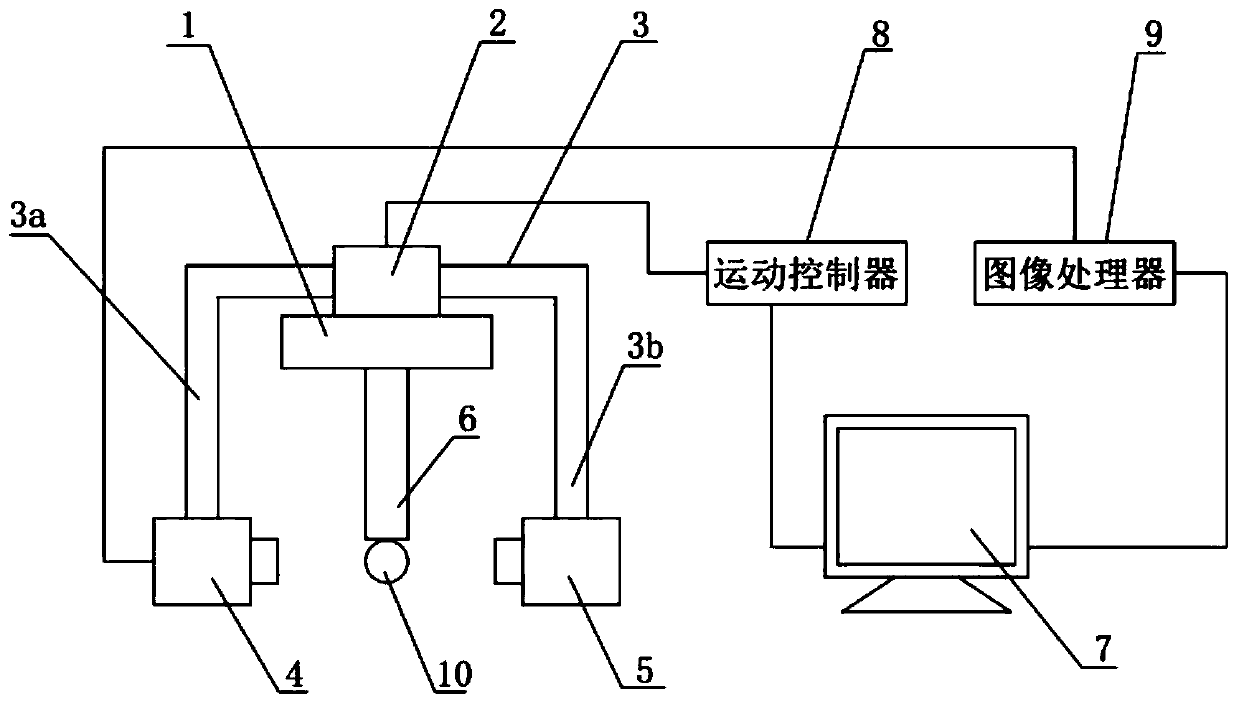

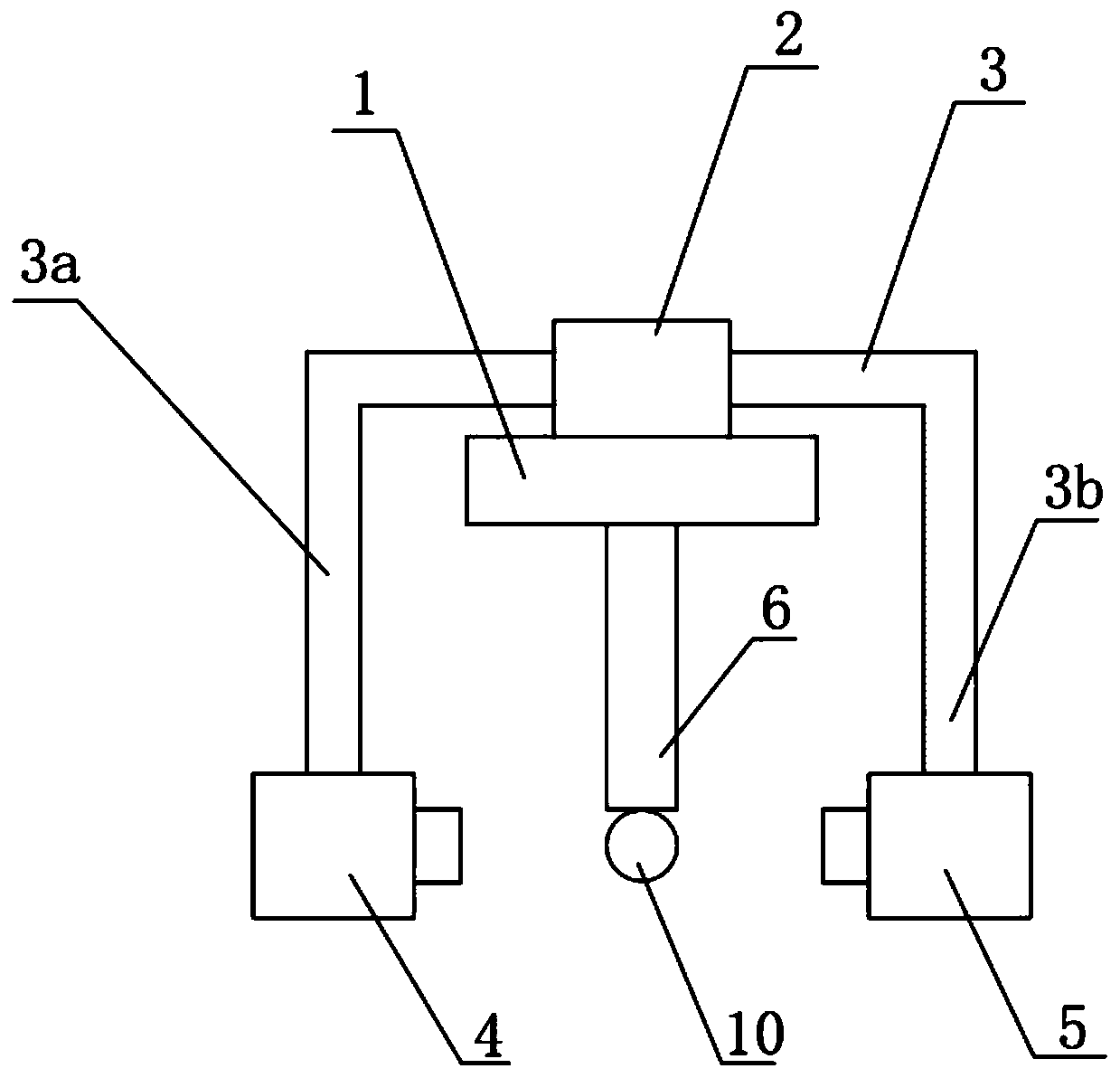

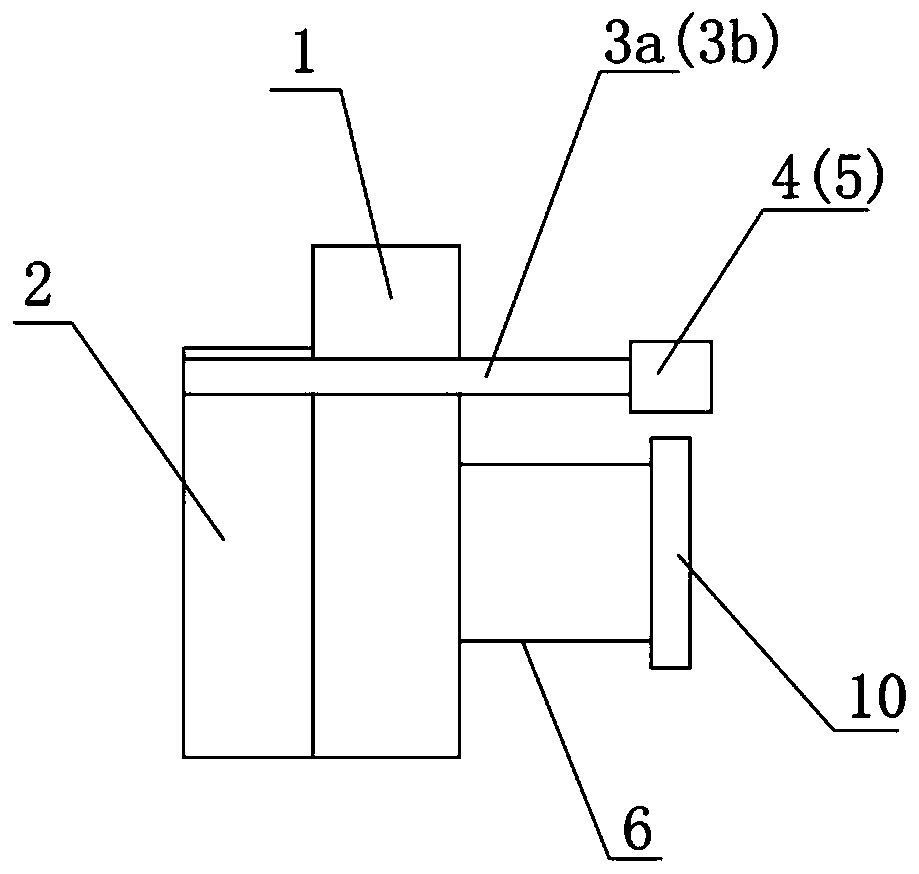

[0027] see as figure 1 and figure 2 As shown, it is a specific embodiment of the image acquisition system of the axis inspection instrument of the present invention, which includes a base 1, a moving translation platform 2 and a workpiece fixing frame 6, the moving translation platform 2 is arranged on the back of the base 1, and the workpiece to be tested The fixed frame 6 is arranged on the front of the base 1, the moving translation platform 2 is connected with the support frame 3, the left end of the support frame 3 is provided with the lens support frame 3a, the right end is provided with the light source support frame 3b, the lens support frame 3a and the light source support frame 3b is symmetrical to the base 1, a camera 4 is fixed on the lens support frame 3a, a light source 5 is fixed on the light source support frame 3b, and the lens of the camera 4 is coaxially opposite to the light source 5;

[0028] Also include PC 7, motion controller 8 and image processor 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com