Torsional vibration damper

A technology for torsional shock absorbers, accumulators, applied in spring/shock absorber, vibration damping adjustment, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

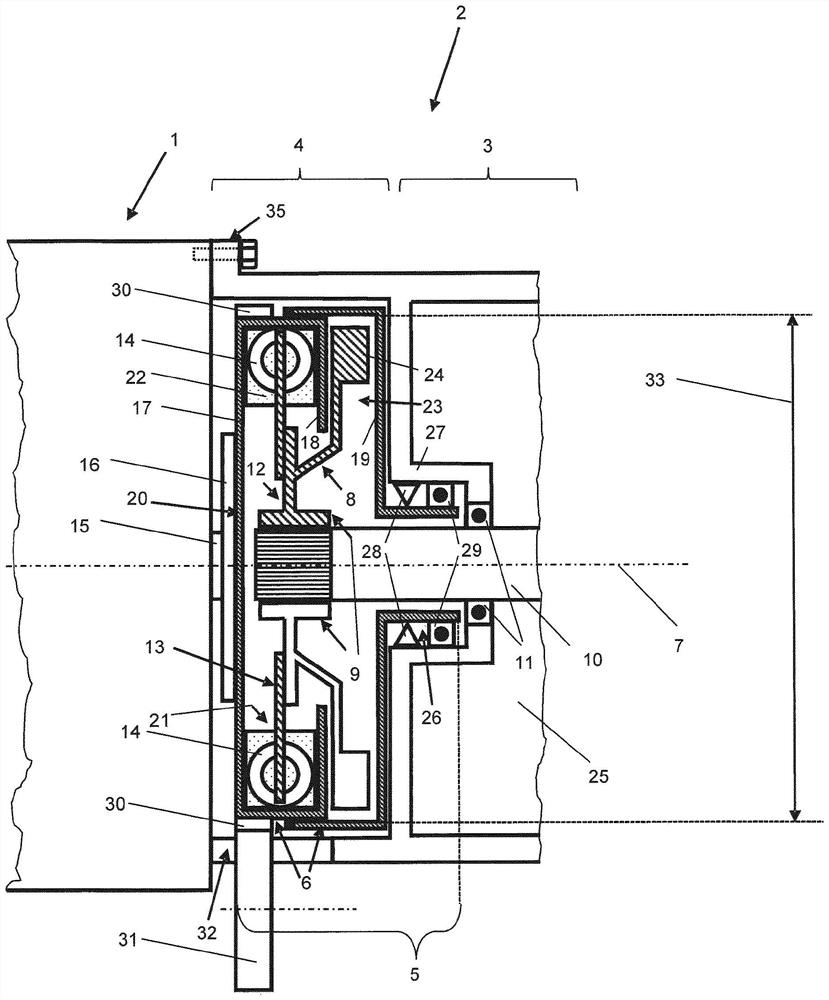

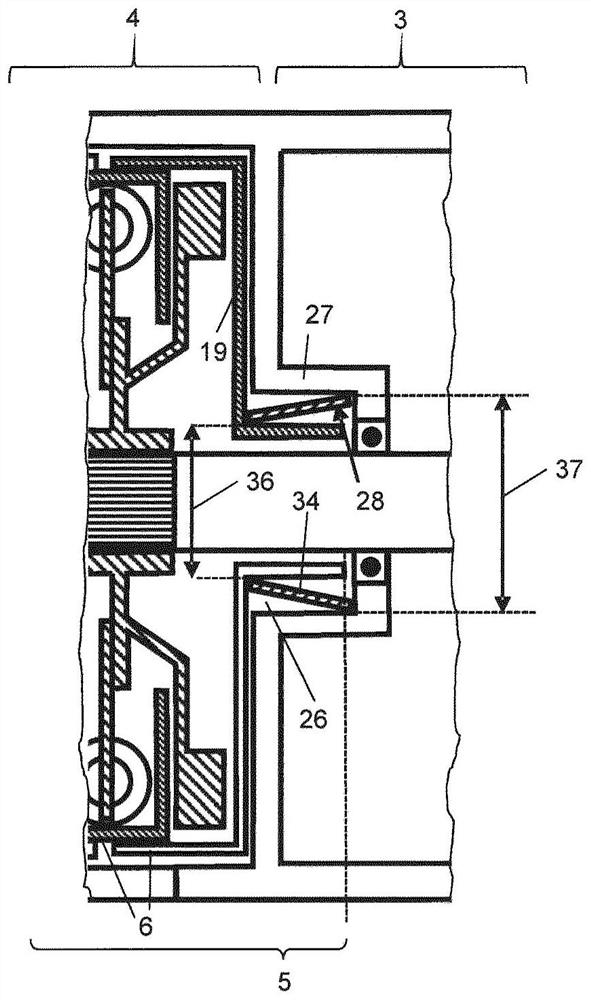

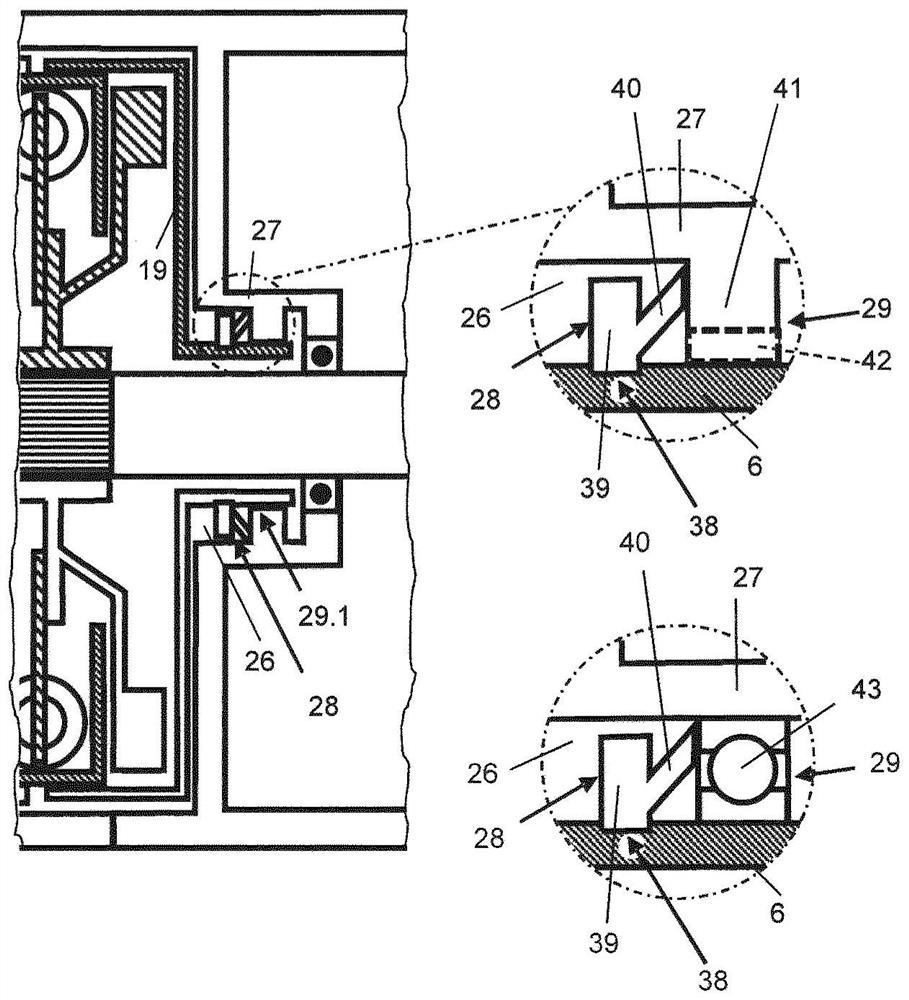

[0025] figure 1 A drive train (not shown) of a motor vehicle is shown in a simplified partial view, consisting of a drive motor 1 (partial view) and a transmission 2 (partial view). The transmission 2 is shown in section and consists on the housing side of the (actual) transmission housing 3 and a bell-shaped attachment 4 , which is usually referred to as the transmission bell. The bell-shaped appendage 4 of the transmission bell housing 3 is fastened fixedly to the drive motor by means of corresponding screw connections 35 . The transmission 2 can be both a conventional shift transmission and an automatically engaged dual-clutch transmission. The illustration of the clutches and transmission stages arranged in the transmission housing 3 is omitted, since this is not relevant in the context considered here. In the bell-shaped attachment 4 , a torsional vibration damper 5 , shown in section along the axis of rotation 7 of the attachment, is arranged between the drive motor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com