Patents

Literature

43results about How to "Implement synchronous testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

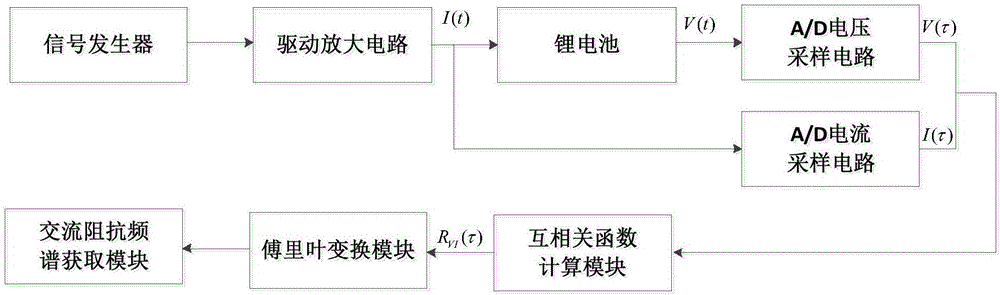

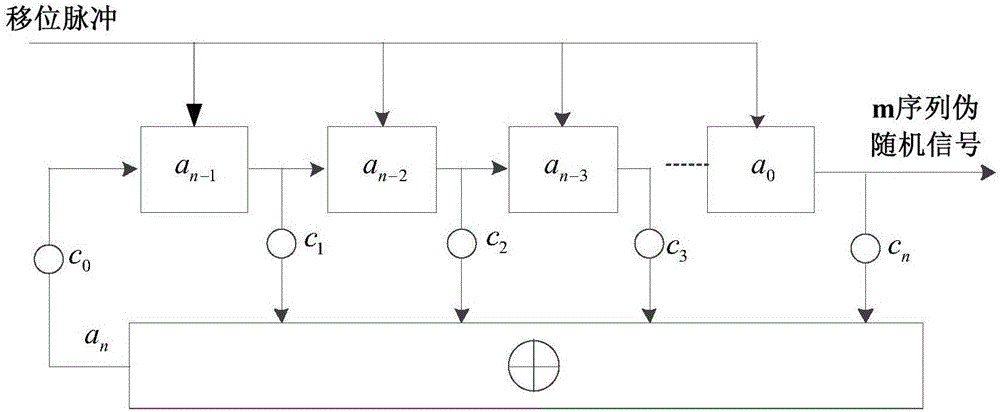

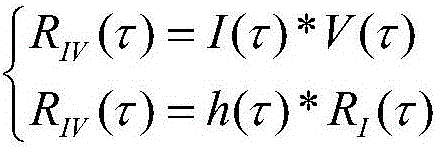

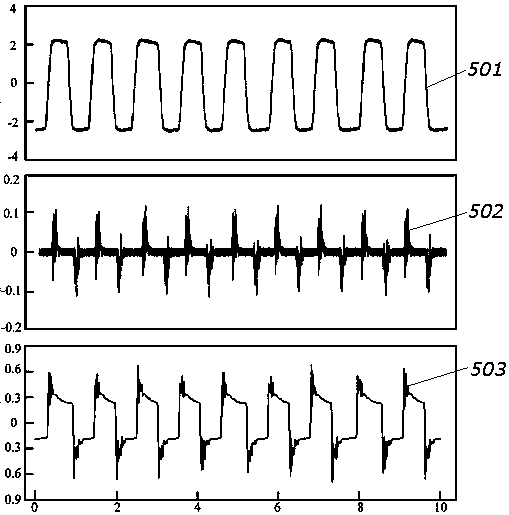

Lithium battery AC impedance spectrum online synchronous test method and device

InactiveCN106371029ALittle prior knowledgeEasy to identifyElectrical testingFrequency spectrumAnti jamming

The invention provides a lithium battery AC impedance spectrum online synchronous test method and device. The method is characterized by obtaining a current discrete sampling sequence and a voltage discrete sampling sequence through current excitation signals and voltage response signals of a lithium battery; then, calculating a cross-correlation function of the current discrete sampling sequence and the voltage discrete sampling sequence through a Wiener-Hopf equation, and serving the cross-correlation function as a time domain impulse response function of the lithium battery; then, carrying out Fourier transform on the time domain impulse response function to obtain frequency response of the lithium battery; and adjusting the order of a signal generator to obtain lithium battery AC impedance spectrum in different frequency bands. The method and device can realize synchronous test of a plurality of AC frequency impedance of the lithium battery; frequency response of the lithium battery can be obtained through the impulse response function; the required priori knowledge is less; identification can also be carried out very well under the condition that noise and signal-to-noise ratio are rather small; the correlation function can be obtained through the Wiener-Hopf equation; and the device and method have higher anti-jamming capability.

Owner:CHINA ELECTRIC POWER RES INST +2

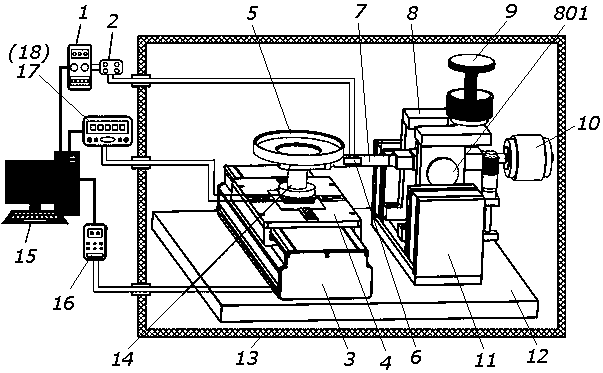

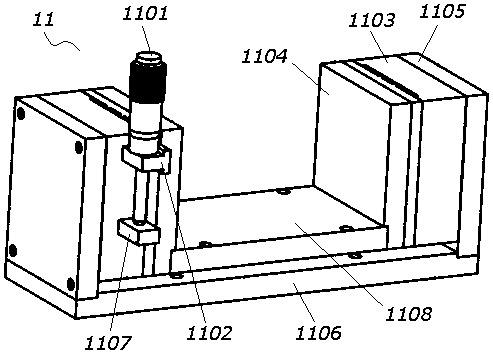

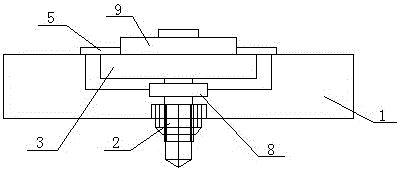

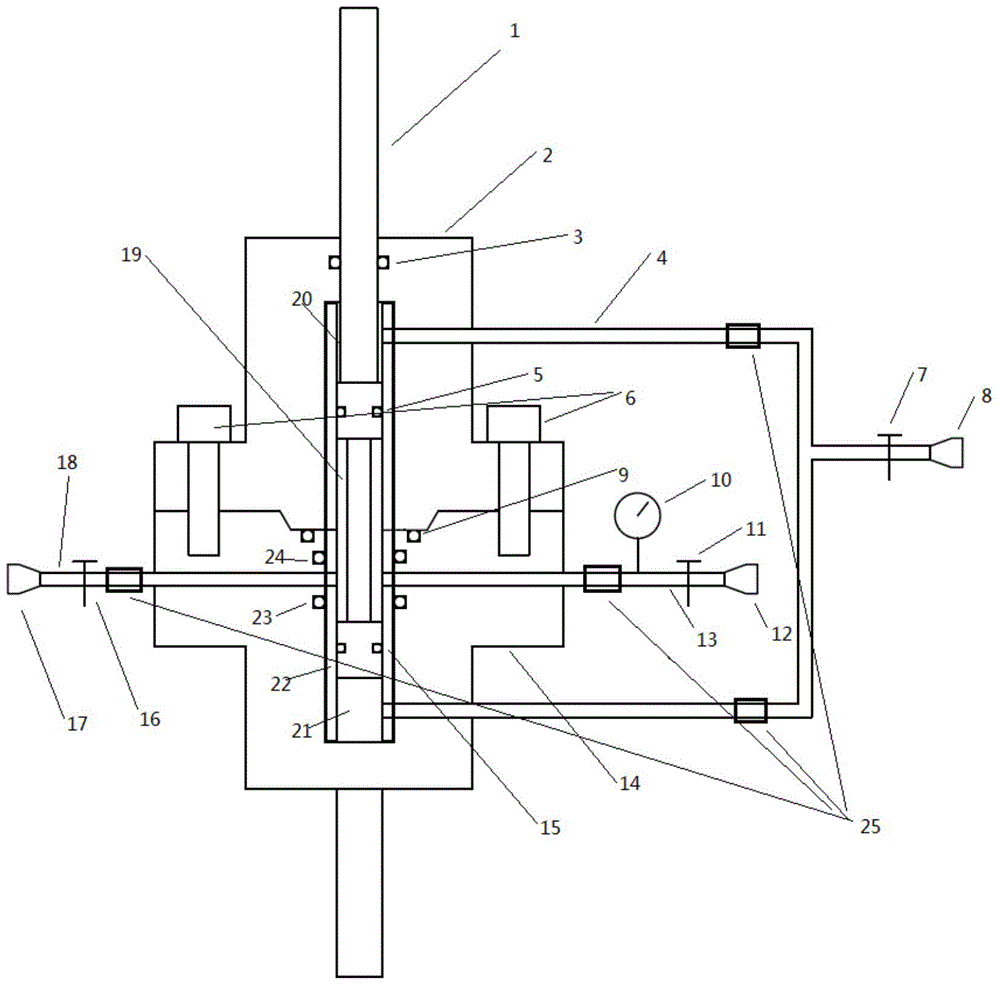

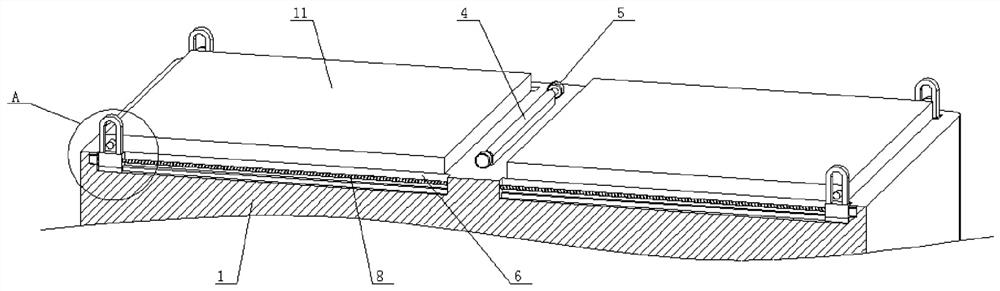

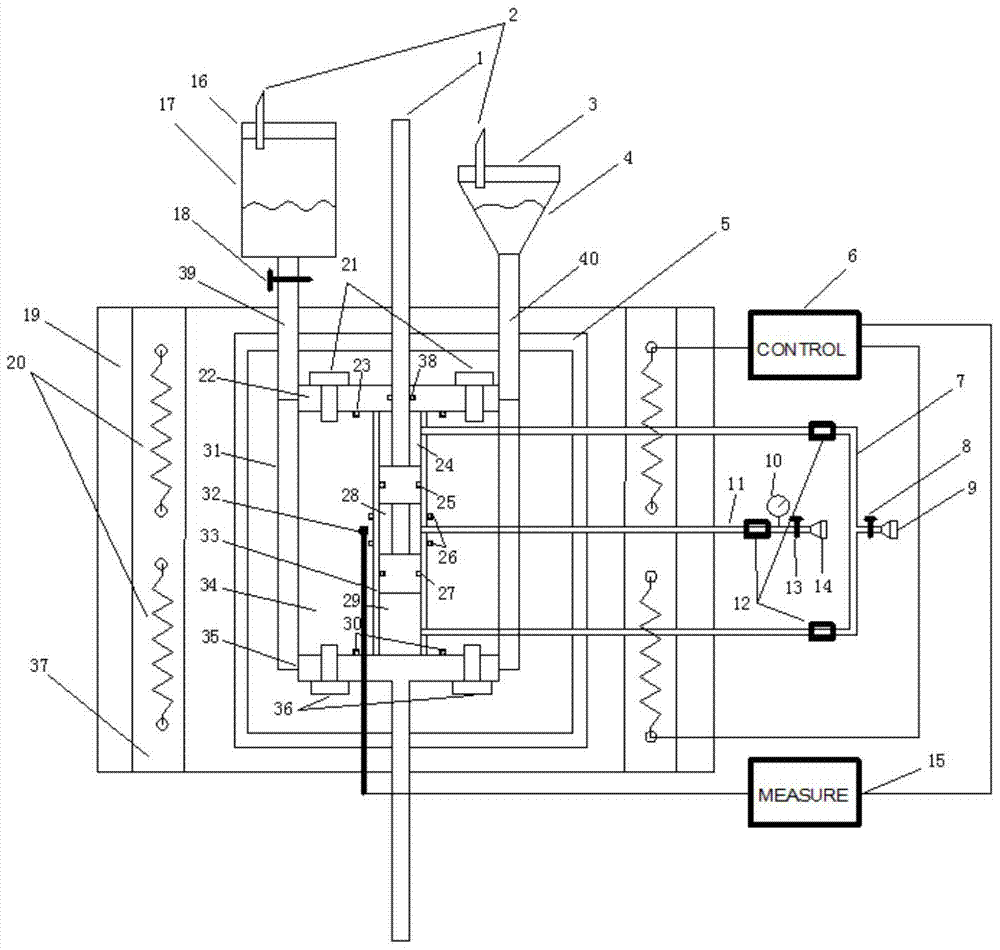

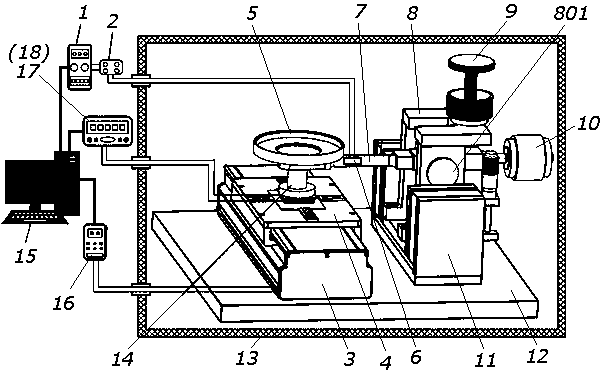

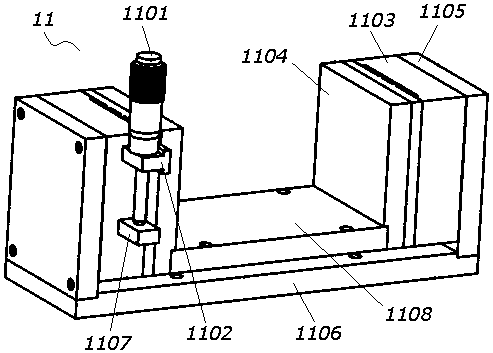

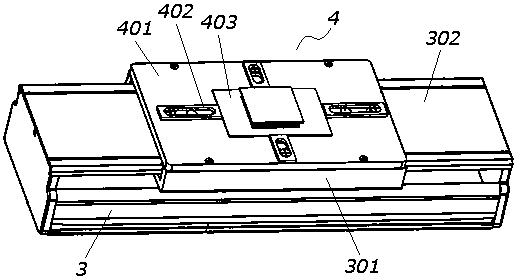

Device for synchronously testing reciprocating type friction power generation output property and friction coefficient

ActiveCN107655823AImplement synchronous testingMaterial analysis by electric/magnetic meansUsing mechanical meansStrain gaugeElectricity

The invention discloses a device for synchronously testing a reciprocating type friction power generation output property and a friction coefficient. A to-be-tested upper friction pair is arranged atthe front end, which is connected with a cantilever beam, of a cantilever beam supporting rack; a strain gage is arranged on the cantilever beam; a lower friction pair is arranged on a moving block ifa magnetic shaft linear motor and is positioned under the upper friction pair; the lower friction pair which is driven by the magnetic shaft linear motor to linearly move in a reciprocating manner relative to the static upper friction pair; current and voltage signals of friction power generation are output to a control and test computer; and meanwhile, the strain gage synchronously outputs the friction signals of the upper friction pair and the lower friction pair to the control and test computer. Because the control and test computer simultaneously acquires the current and voltage signals generated by friction power generation of the upper friction pair and the lower friction pair and friction signals, synchronous test on the friction power generation output property and the friction coefficient is realized; influence of interface friction behaviors to the friction power generation output property is discovered favorably; and the mechanism of action of the interface friction behaviors to an electric output property is facilitated.

Owner:SHENZHEN UNIV

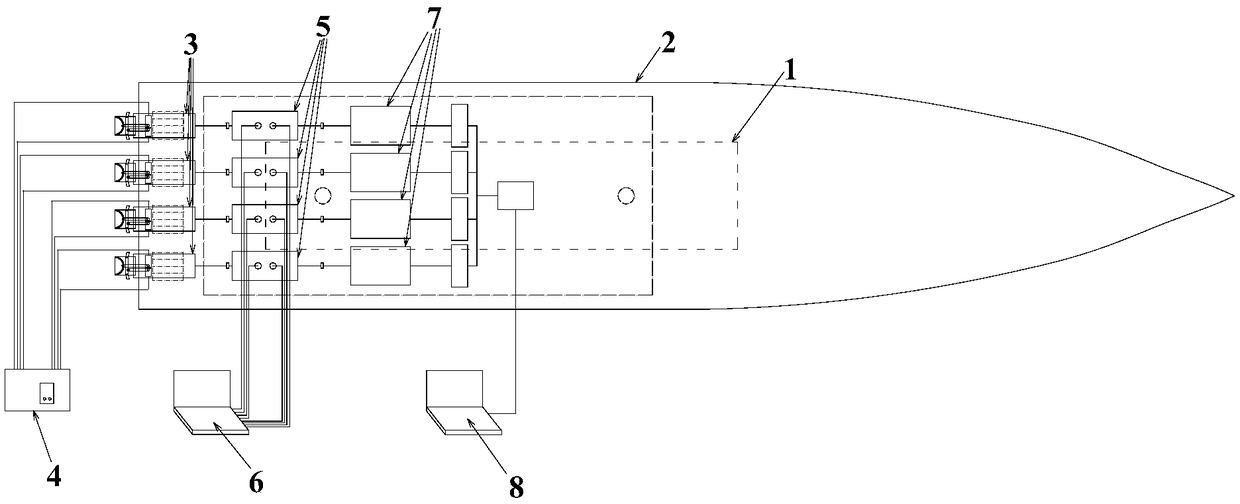

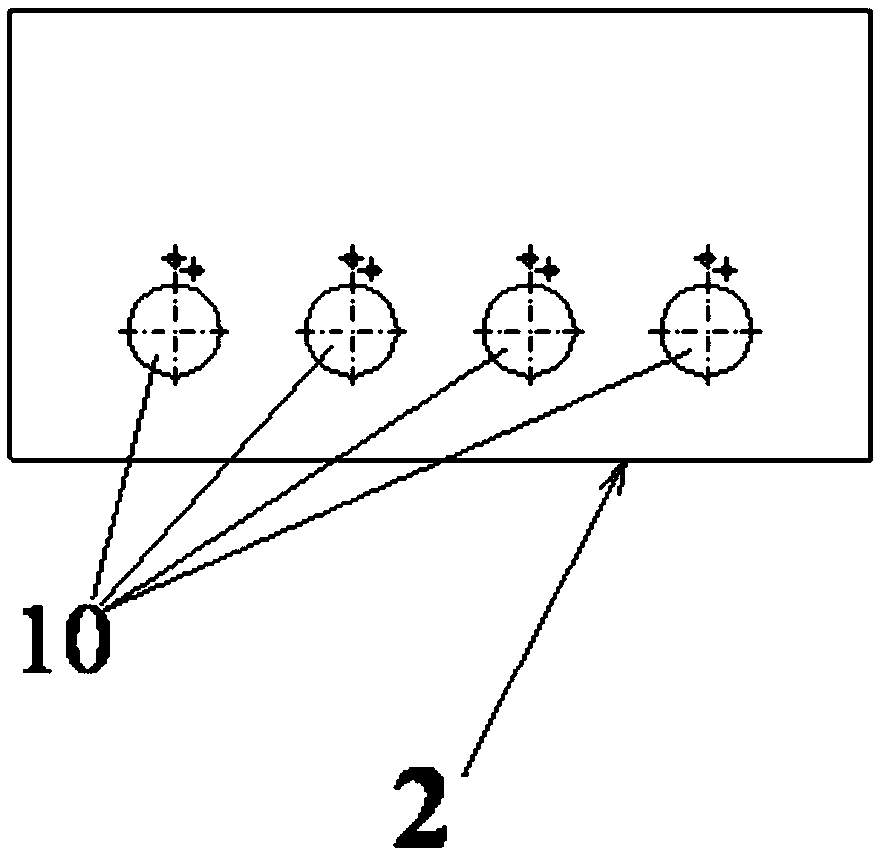

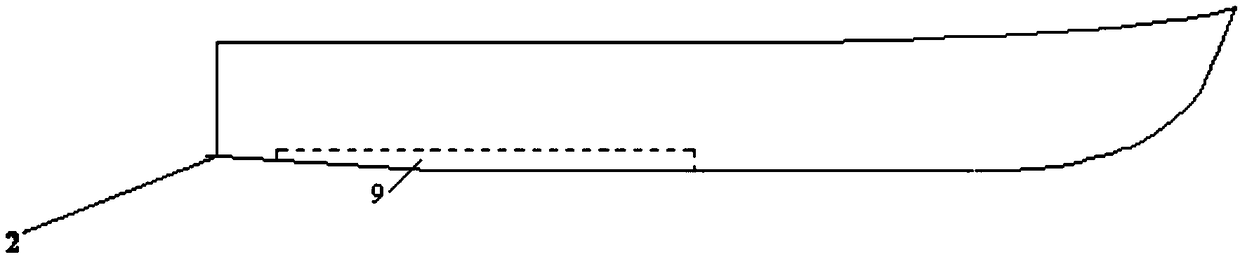

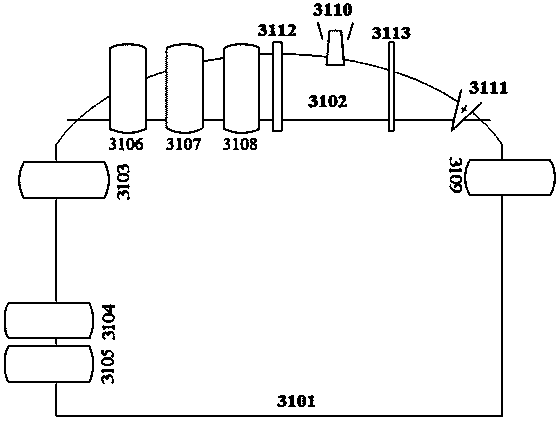

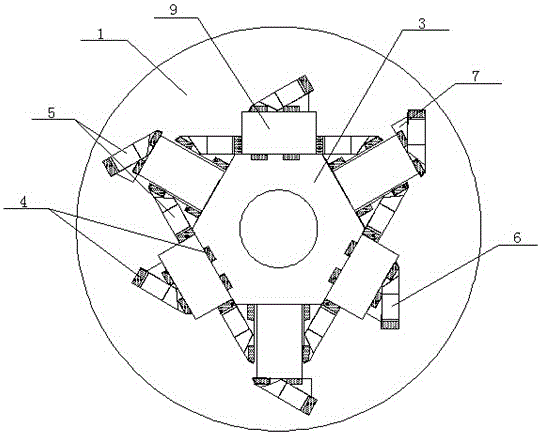

Maneuverability hydrodynamic testing device and testing method of hydrojet propelled ship model

InactiveCN109060299AClear division of laborSimple structureHydrodynamic testingControl systemPropeller

The invention discloses a maneuverability hydrodynamic testing device and a testing method of a hydrojet propelled ship model. The testing device comprises planar motion mechanism, wherein the planarmotion mechanism is fixed on a pool trailer and used for testing a hull hydrodynamic force of the hydrojet propelled ship model; the hydrojet propelled ship model comprises a bare hull model, hydrojetpropulsion devices, a hydrojet propulsion device control system, dynamic testers and a parallel acquisition system; the hydrojet propulsion devices are symmetrically arranged at the rear part of thebare hull model and used for providing a propulsion force to the bare hull model; the hydrojet propulsion device control system is connected with the hydrojet propulsion devices; the dynamic testers are arranged at the front parts of the hydrojet propulsion devices and used for measuring rotating speeds, propulsion forces and torques of propeller shafts of the hydrojet propulsion devices; and theparallel acquisition system is connected with the dynamic tester and used for acquiring the rotating speeds, the propulsion forces, the torques and the hull hydrodynamic force. The device is concise in structure; components are divided clearly; the testing method is reasonable; and a hydrodynamic derivative of the hydrojet propelled ship model by the action of certain water flow jet can be obtained accurately.

Owner:708TH RES INST OF CSSC

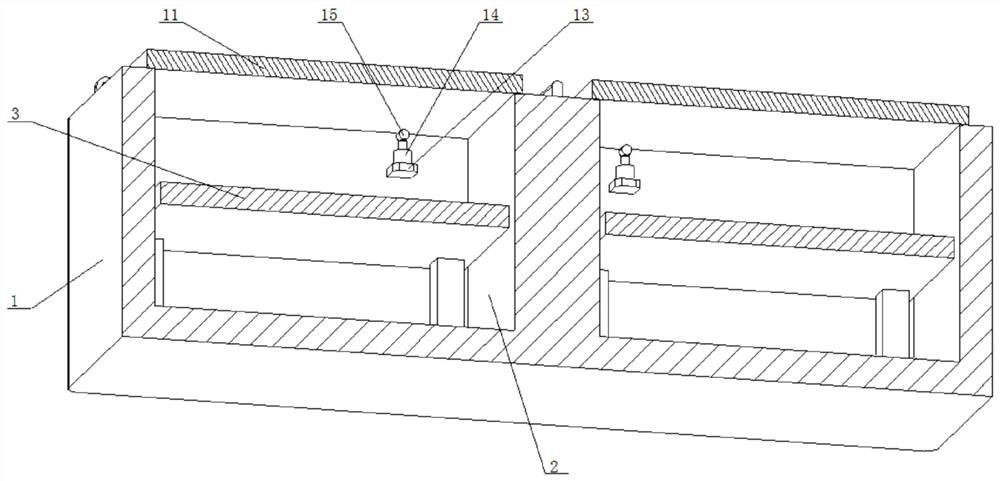

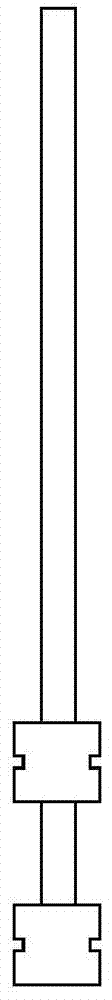

Rubber ring high pressure dynamic sealing test device under extreme conditions

ActiveCN105628309AImplement synchronous testingEasy to assembleMeasurement of fluid loss/gain rateRubber ringReciprocating motion

The invention provides a rubber ring high pressure dynamic sealing test device under extreme conditions, and belongs to the technical field of aerospace and mechanical engineering. The rubber ring high pressure dynamic sealing test device under the extreme conditions comprises a reciprocating movement test machine, a high pressure inflator, a gas flowmeter, a heating device, a refrigeration device and a test implementation body. Frictional force, displacement, temperature and gas leakage can be synchronously measured under sealed high pressure dynamic reciprocating movement of a rubber ring in the extreme conditions. The effects and the benefits of the rubber ring high pressure dynamic sealing test device under the extreme conditions are that dynamic sealing performance testing of the rubber ring under different extreme conditions (high pressure, high temperature and low temperature) can be realized. The device has the characteristics of being easy and convenient to assemble and flexible and easy to use.

Owner:DALIAN UNIV OF TECH

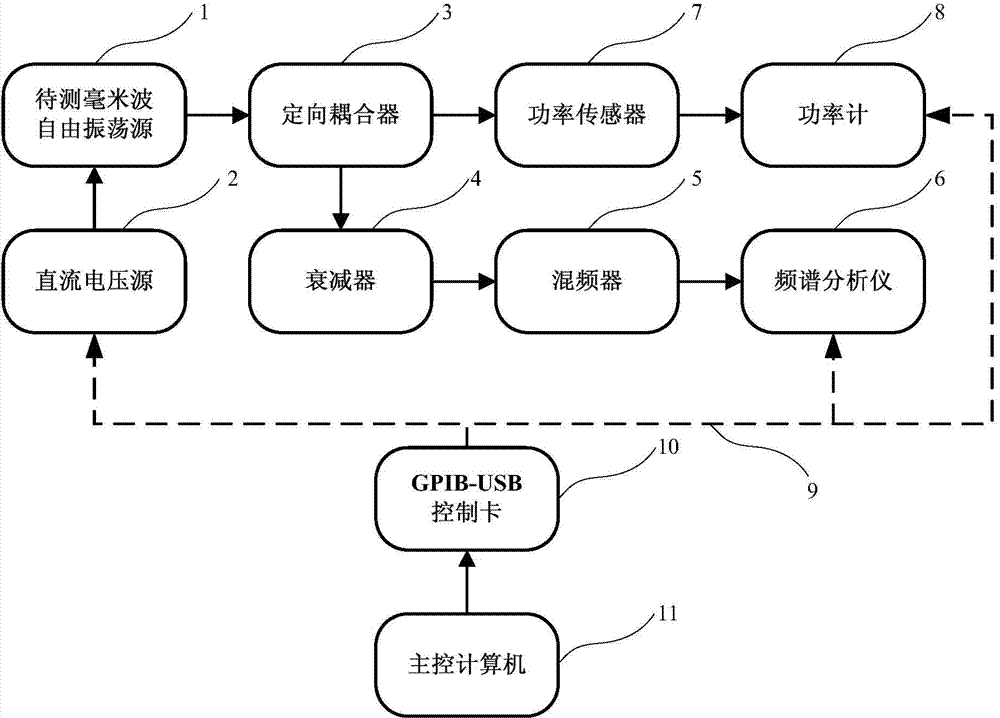

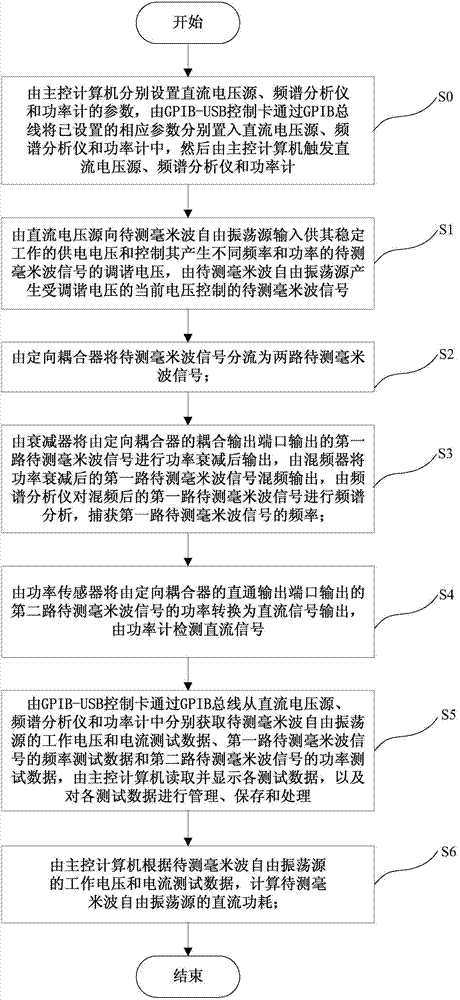

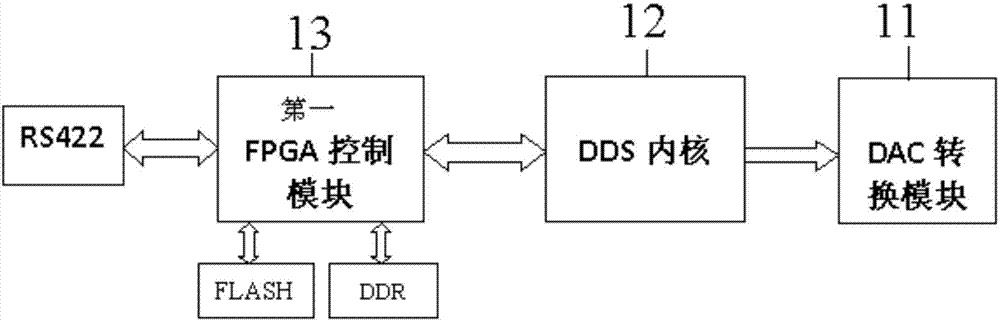

Millimeter wave free oscillation source automatic test system and method

InactiveCN104122442AOvercoming inefficiencyImplement automated testingSpectral/fourier analysisFrequency measurement arrangementPower sensorPhysics

The invention provides a millimeter wave free oscillation source automatic test system and method. The system at least comprises a millimeter wave free oscillation source to be tested, a direct current voltage source connected with the millimeter wave free oscillation source to be tested, a directional coupler with an input port connected onto the millimeter wave free oscillation source to be measured, an attenuator connected onto a coupling output port of the directional coupler, a mixer connected with the attenuator, a frequency analyzer connected onto the mixer, a power sensor connected onto a direct through output port of the directional coupler and a power meter connected onto the power sensor. Synchronous test of multiple performance parameters of the millimeter wave free oscillation source can be achieved through single connection, test data can be stored synchronously to facilitate follow-up processing, and automatic test of output frequency, output power and direct current power consumption of the millimeter wave free oscillation source in full band can be achieved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

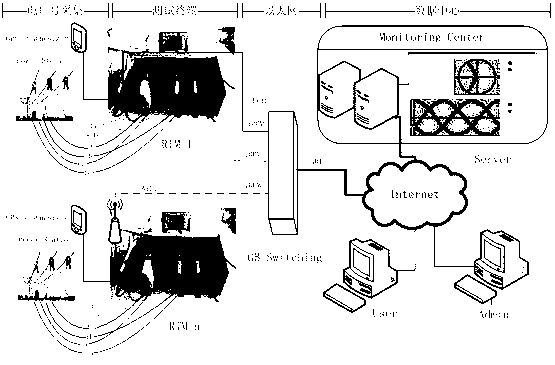

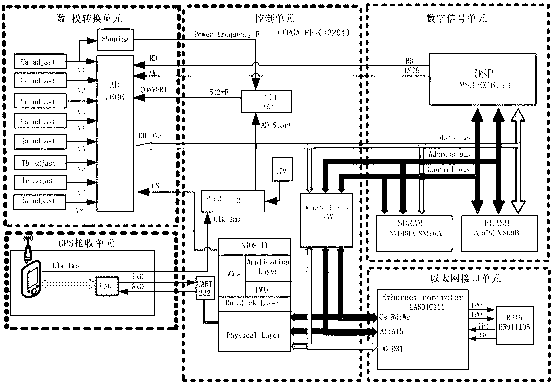

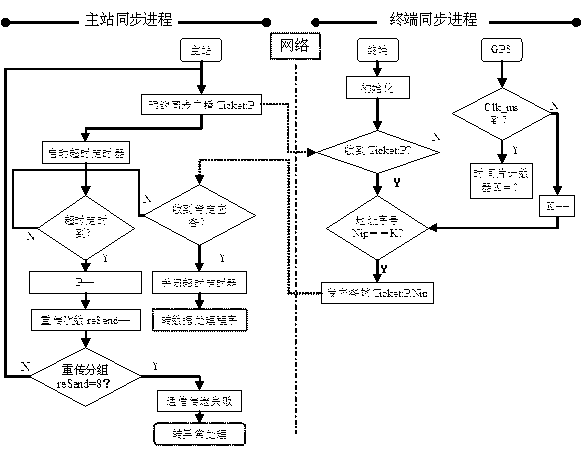

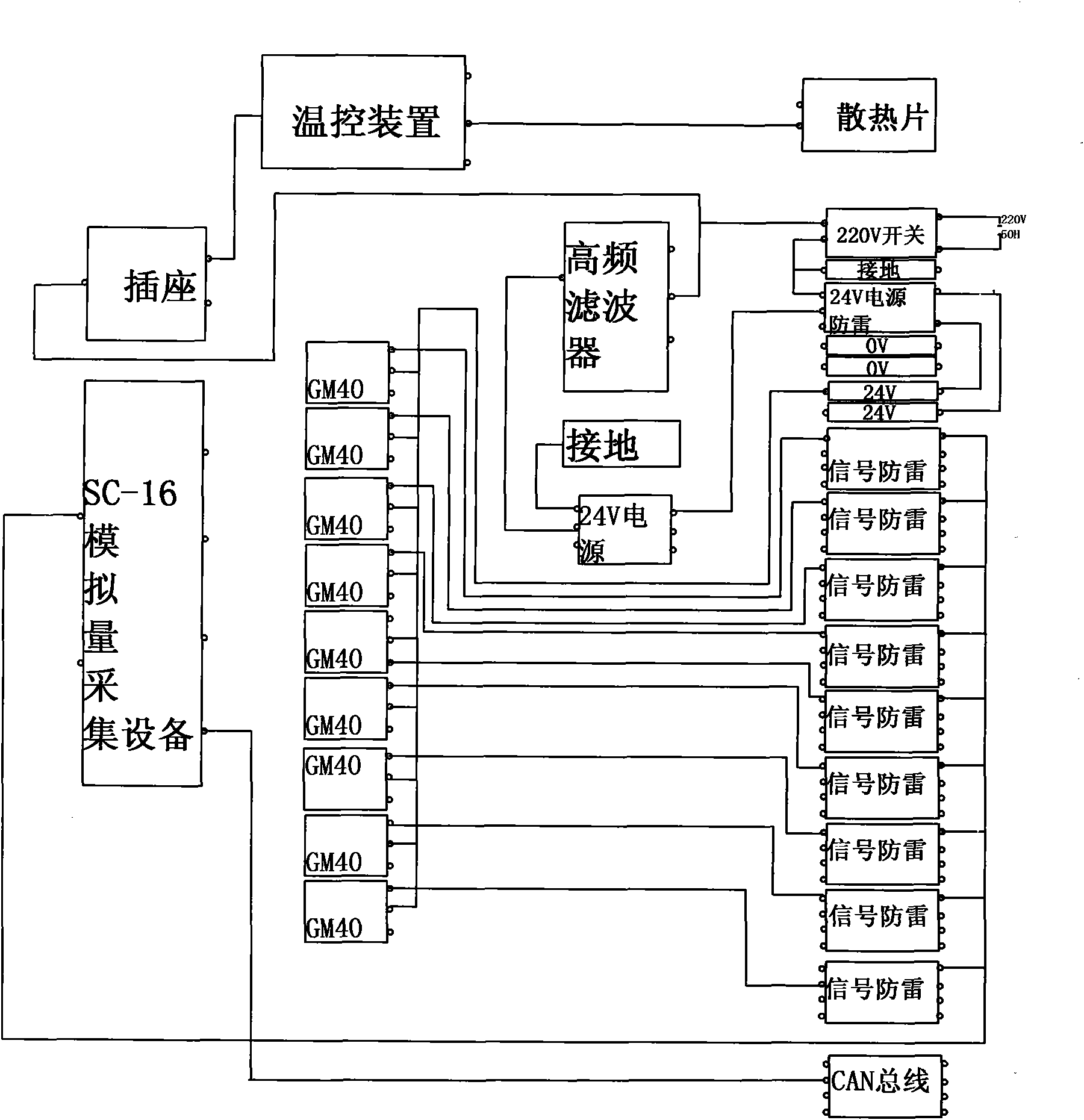

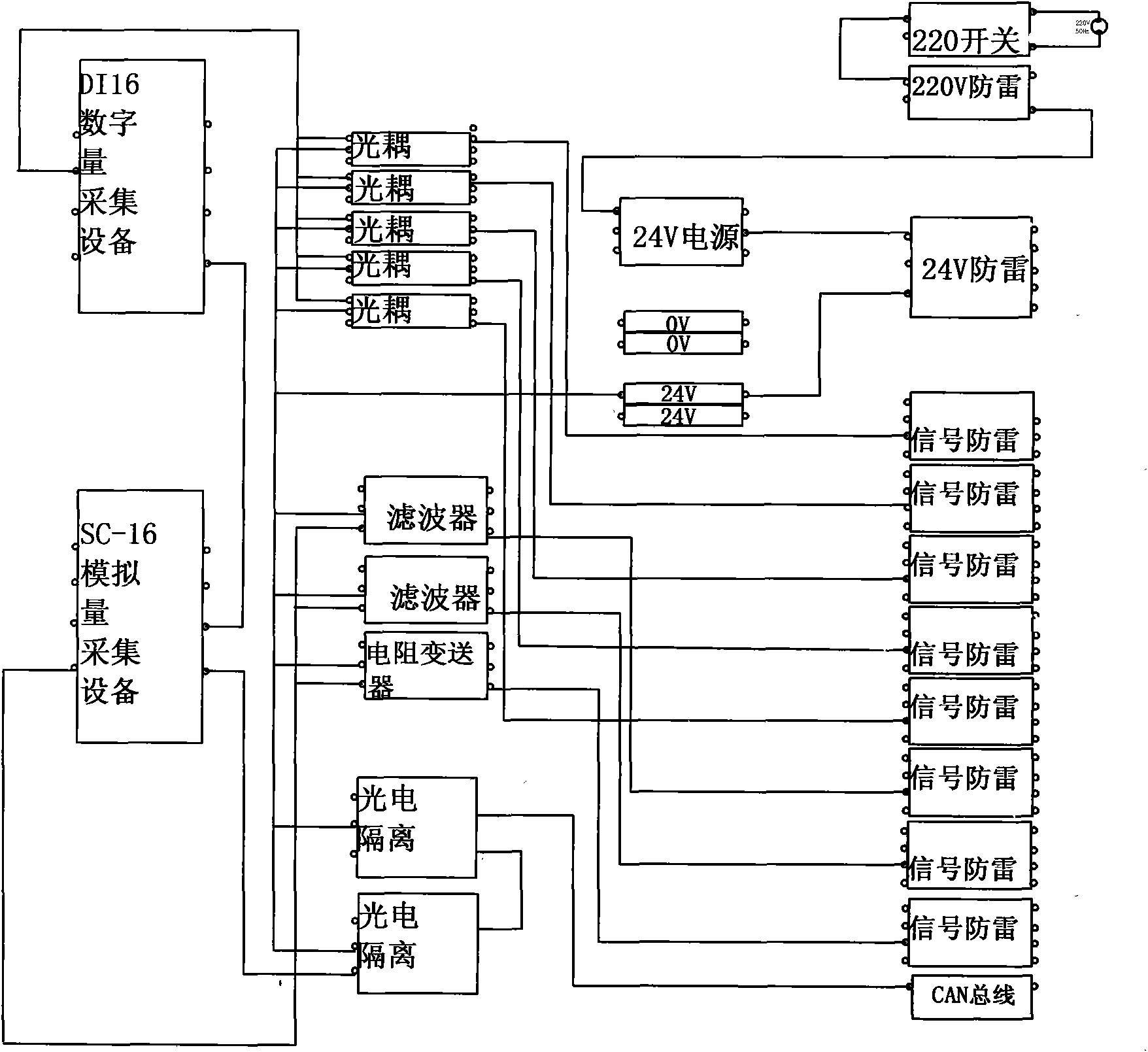

Smart power grid distribution type measurement and control synchronizing method

ActiveCN102710357AImplement synchronous testingEnsure safety monitoringTime-division multiplexTransmissionData acquisitionWorkstation

The invention discloses a smart power grid distribution type measurement and control synchronizing method. A test terminal with Ethernet networking and a GPS (Global Positioning System) synchronous sequence interface forms a hardware platform together with a server by a known rapid Ethernet exchanger, and the synchronous measurement and control of a distribution type power grid can be realized under the control of a synchronous acquisition and management program, wherein 128 terminals form a distribution type test system and are respectively connected at different parts of transformer substations or factories to complete the local data acquisition, control and processing, and meanwhile, each terminal is managed by a Workstation through a network so as to realize the synchronous control of the local test terminal and other terminals and the data processing by cooperation with the other terminals. According to the smart power grid distribution type measurement and control synchronizing method, the synchronous test between the remote test terminals of the power grid is realized, and the demands on the safety monitoring, grid-tied control and proper scheduling of each station by the distribution type power grid can be met.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

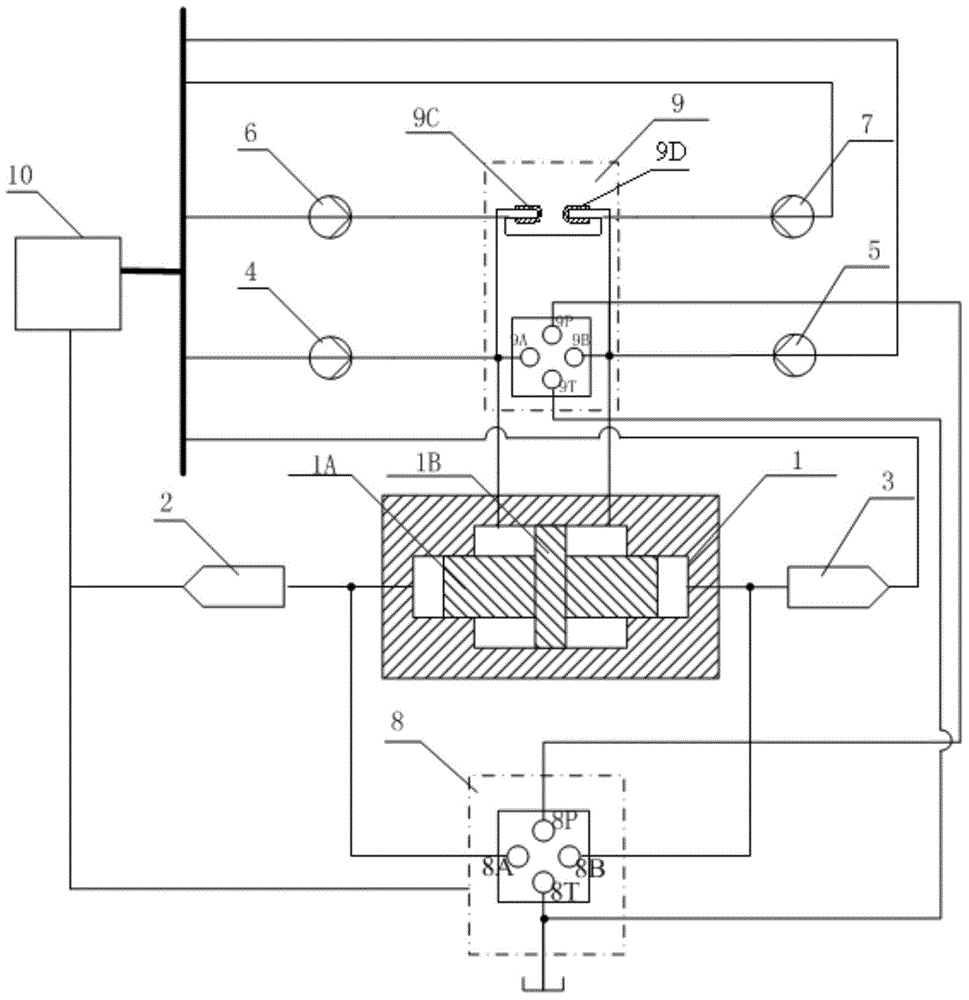

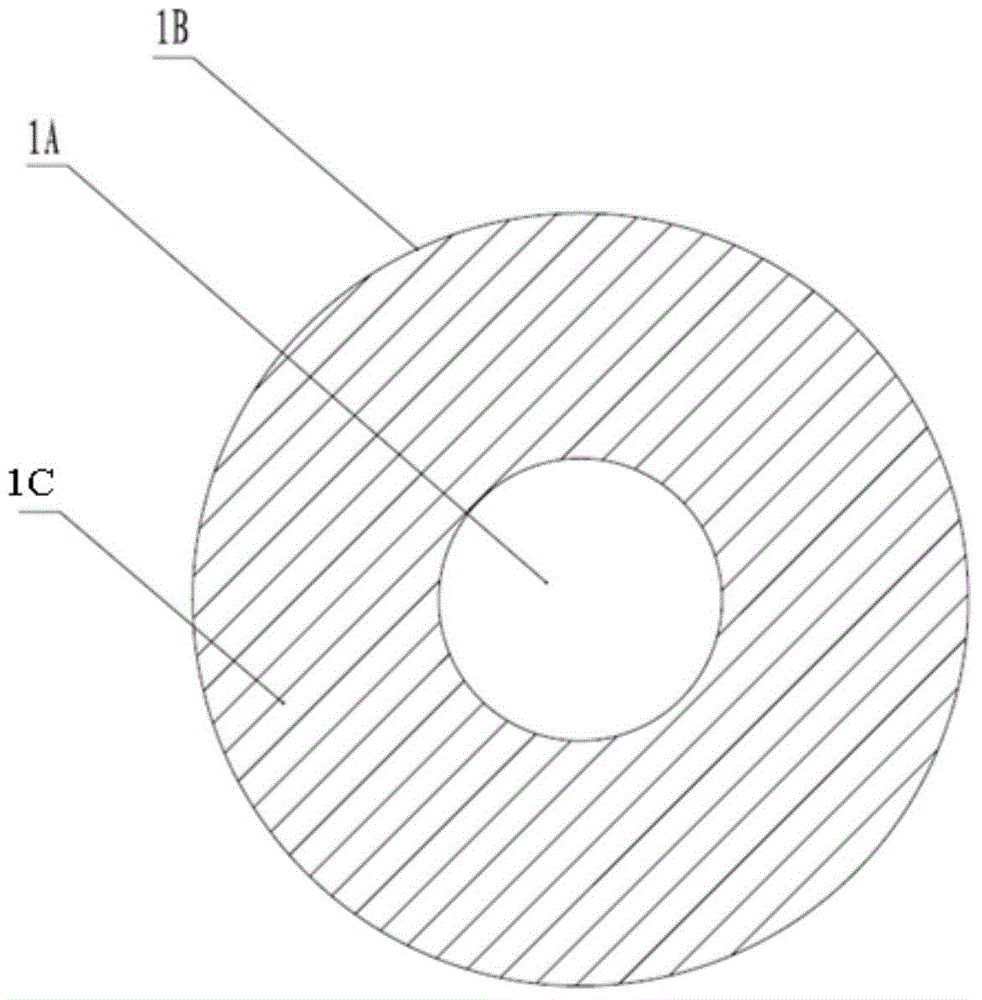

Dynamic loading device for dynamic pressure feedback test of servo valve

ActiveCN105605032ARealize the loadRealize functionFluid-pressure actuator testingHydraulic cylinderClosed loop

The invention belongs to the field of tests of an aerospace servo valve and specifically relates to a dynamic loading device for a dynamic pressure feedback test of a servo valve. The device comprises a dynamic loading cylinder, a displacement sensor, a speed sensor, a pressure sensor, a loading servo valve, the to-be-tested servo valve and a dynamic pressure feedback testing instrument, wherein a piston rod is disposed in the dynamic loading cylinder; a piston is disposed in the piston rod; and the piston rod, the piston and the inner wall of the dynamic loading cylinder form four chambers. The device provided by the invention is characterized in that the dynamic loading cylinder with the four chambers is designed; the speed sensor, the displacement sensor and the pressure sensor are separately installed on the four chambers of the cylinder body, so that a load pressure difference loading function and a state detection function can be realized simultaneously; and closed-loop control of servo loading of the dynamic hydraulic cylinder can be used to keep a load pressure difference stable, efficiency and accuracy of the dynamic pressure feedback test are increased, and production of the dynamic pressure feedback servo valve is guaranteed.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

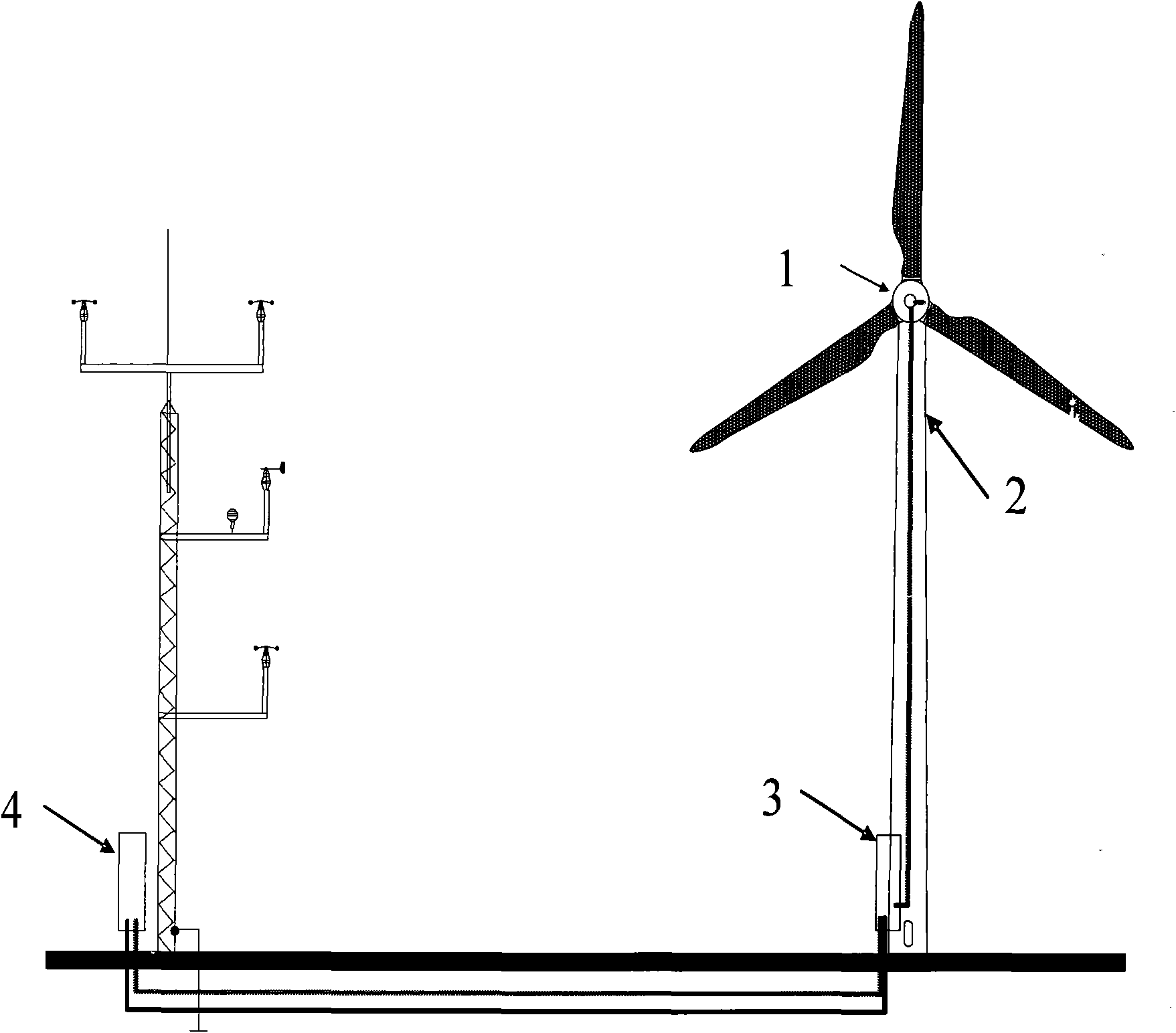

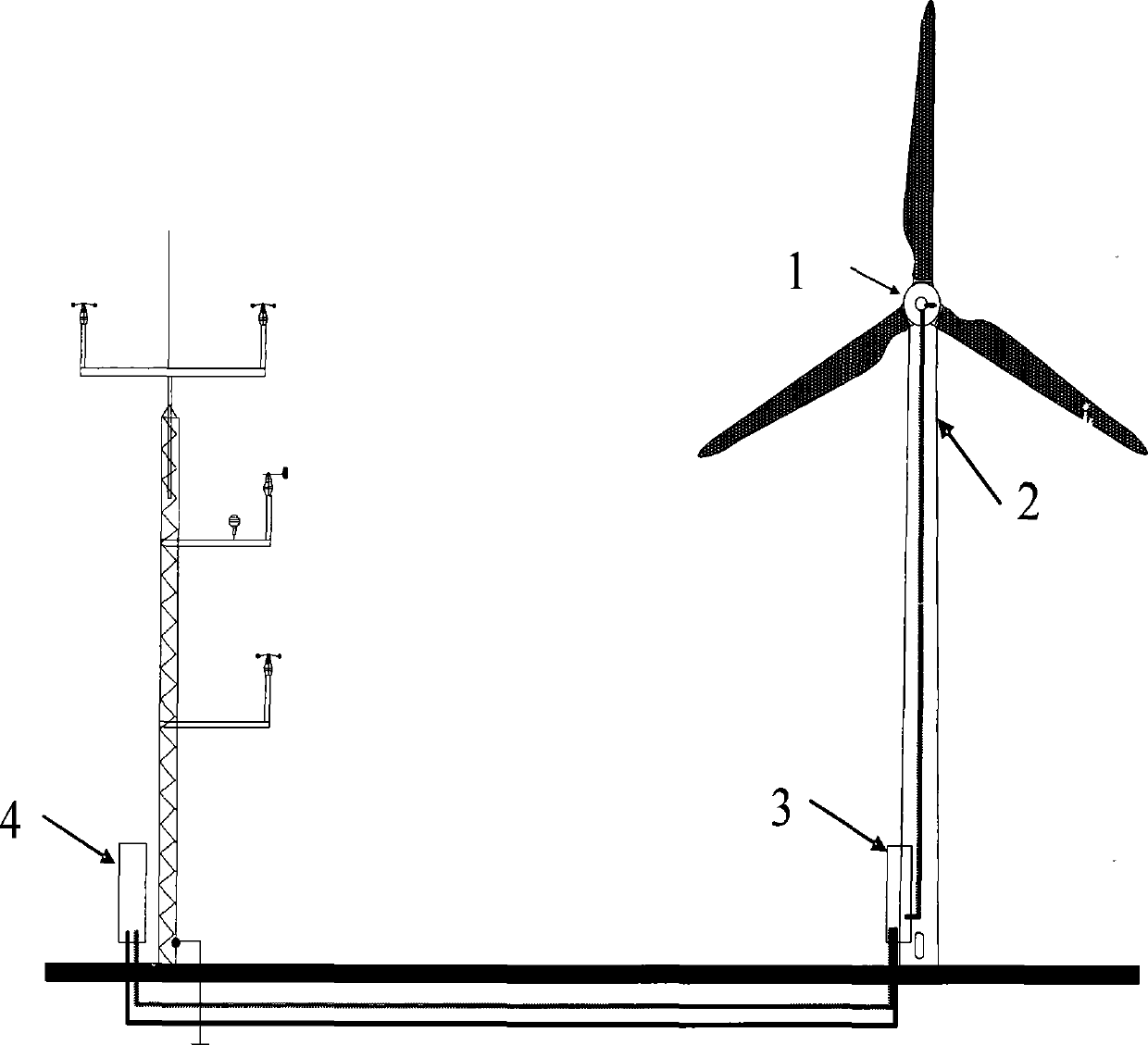

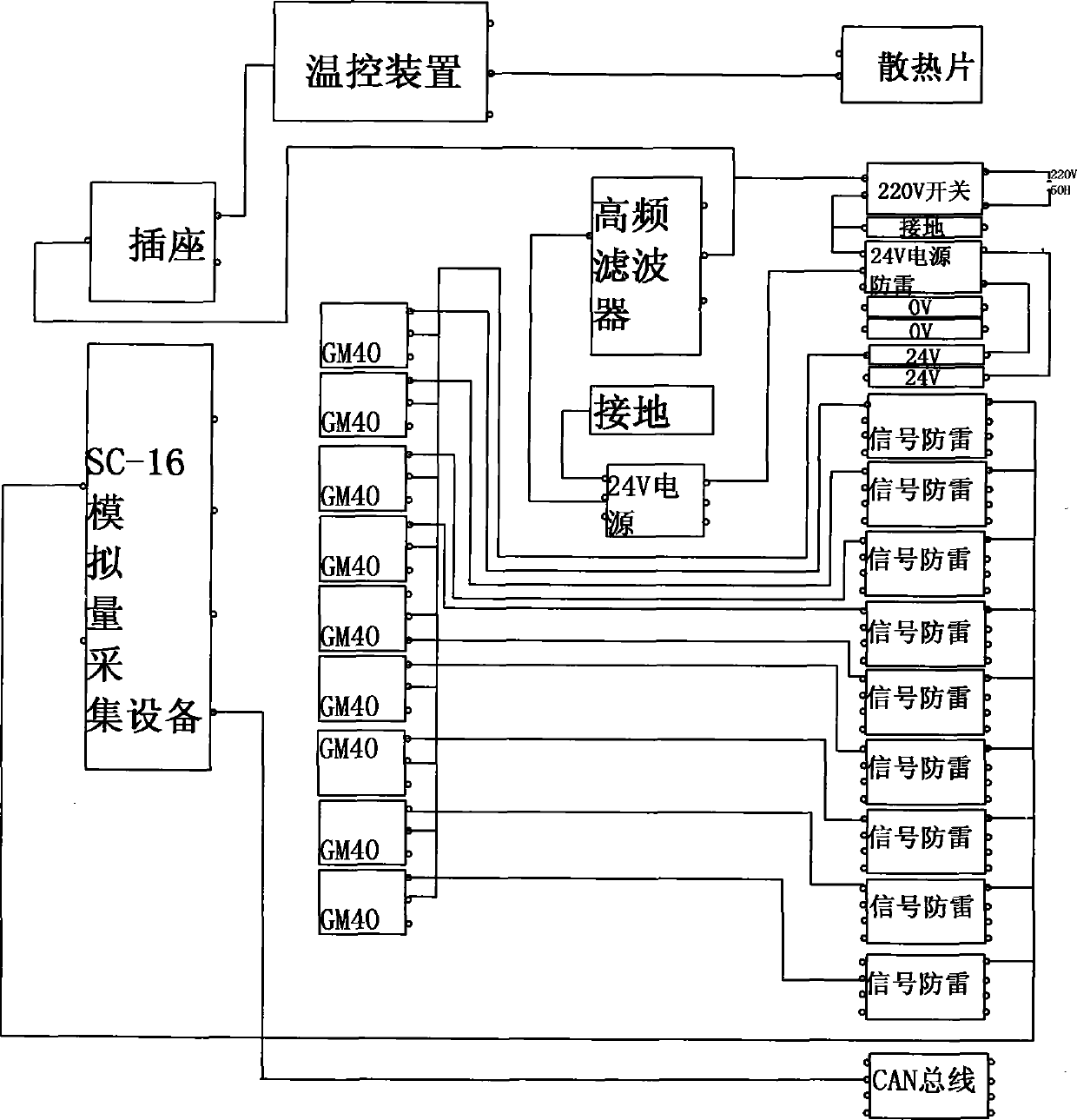

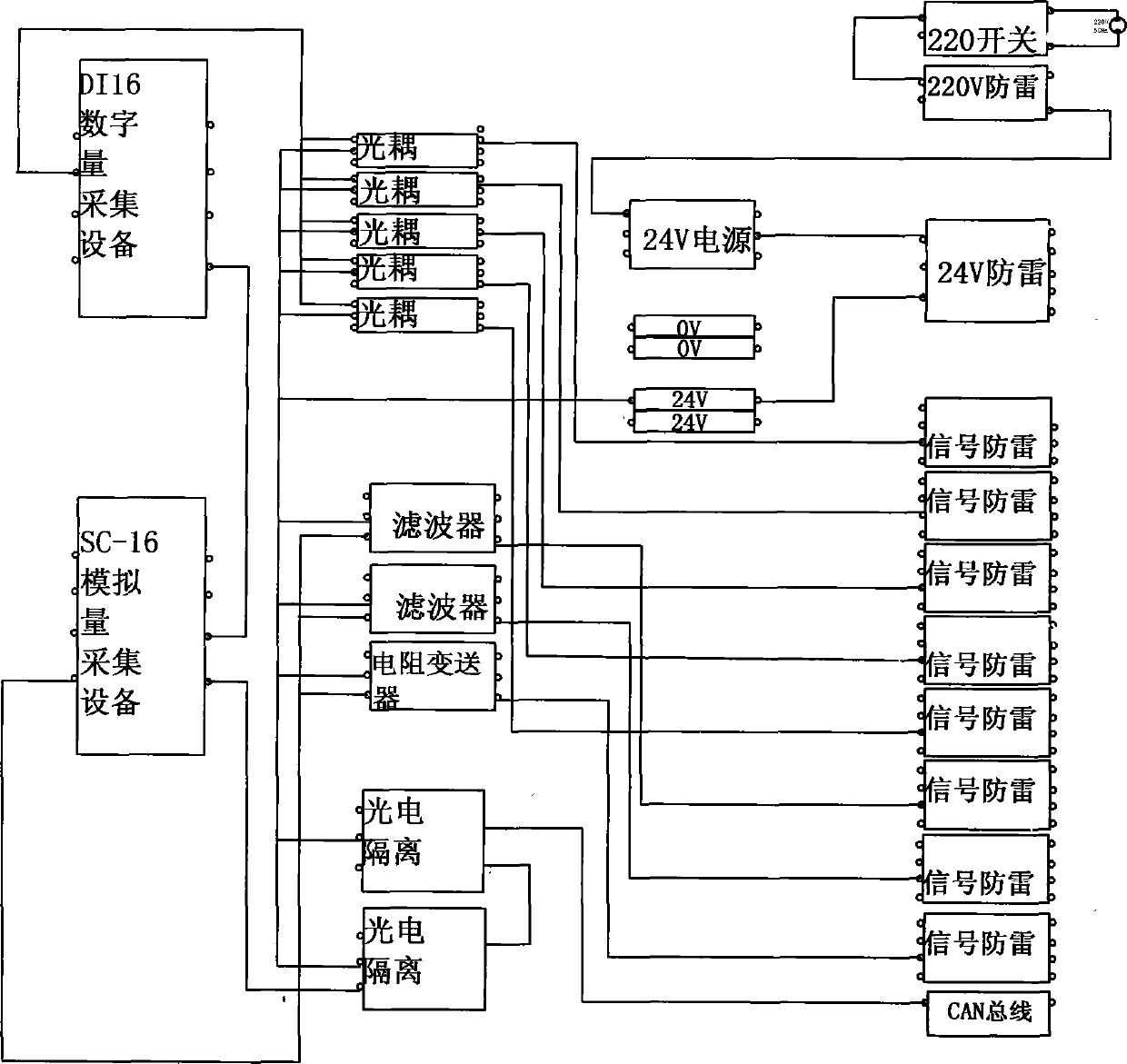

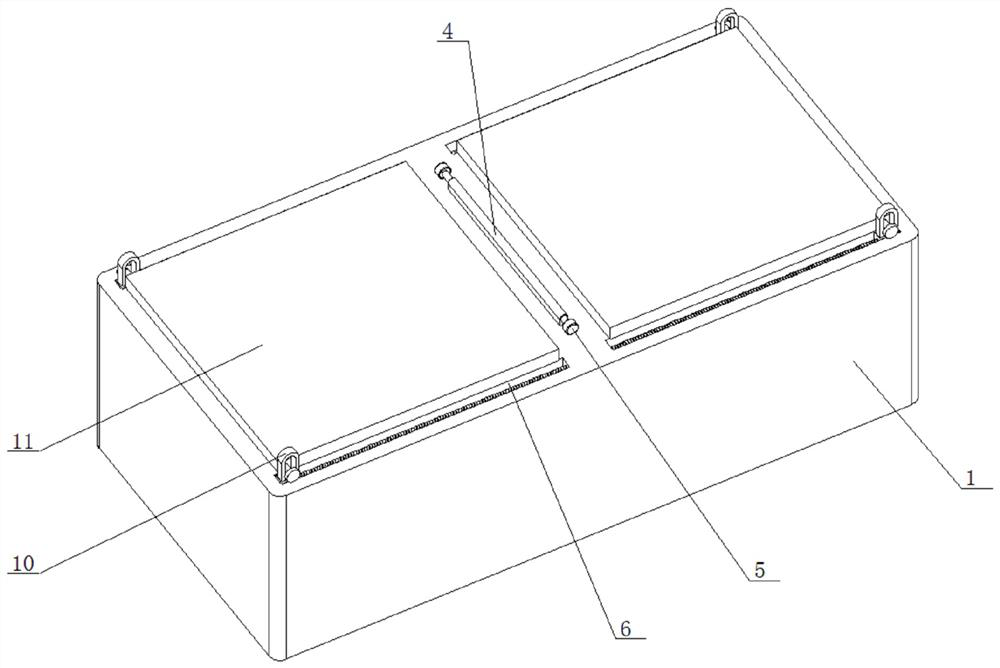

Wind generating set load testing system meeting IEC61400-13 standard

ActiveCN101975662AImplement synchronous testingHigh degree of standardizationEngine testingWork measurementElectricityControl system

The invention relates to a wind generating set load testing system meeting the international electrical committee IEC61400-13 standard. The wind generating set load testing system is characterized by comprising a subsystem and a master control system (3), wherein the subsystem comprises a wheel hub testing system (1), a tower top testing system (2) and a meteorological testing system (4); the meteorological testing system (4) is arranged at the bottom of a meteorological anemometer mast; the tower top testing system (2) is arranged on the top of a tower cylinder; the wheel hub testing system (1) is arranged in a wheel hub of the wind generating set and rotates with the wheel hub of the wind generating set when runs; and the master control system is arranged at the bottom of the tower cylinder. The wind generating set load testing system can be applied to verifying design load of the wind generating set, optimizing design scheme of the wind generating set, detecting quality of the wind generating set which leaves factory, avoiding safety accidents and the like and has high practicability.

Owner:STATE GRID CORP OF CHINA +2

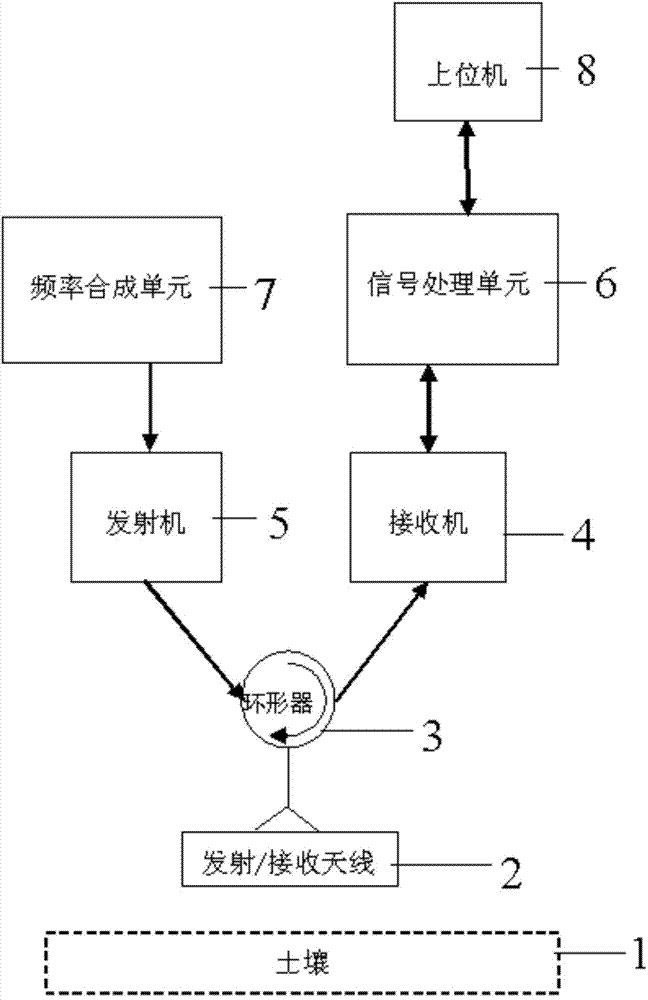

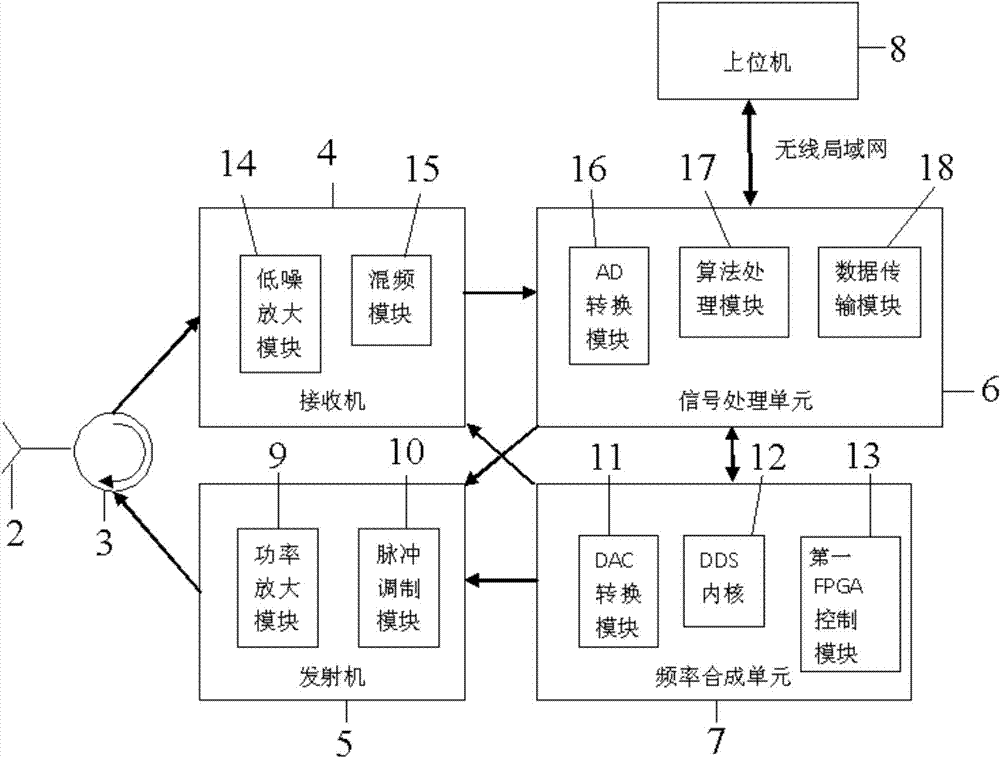

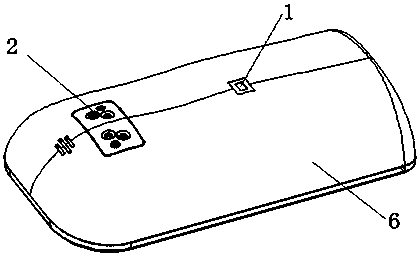

Portable ground penetrating radar capable of detecting soil water content in field

InactiveCN104749644AImprove network performanceImplement synchronous testingDetection using electromagnetic wavesMathematical modelTarget signal

The invention discloses a portable ground penetrating radar capable of detecting soil water content in a field. The portable ground penetrating radar comprises a transmission / receiving antenna which is connected with a circulator; a transmitter and a receiver are respectively connected with the circulator; a frequency synthesizing unit is connected with the transmitter, and while a signal processing unit is connected with the receiver; a host computer is connected with the signal processing unit. The portable ground penetrating radar has the beneficial effects that the preset code type can be processed by radar wave transmission, quick sampling of target echo, follow radar algorithm processing, and host computer data processing and displaying; all target signals exceeding threshold after detecting and determining can be uploaded to the host computer; the mathematical model obtained in test can be adopted; the host computer can be used for processing and displaying the water content rate data under different soil depth; in addition, the data are transmitted through WLAN, the networking capacity can be expanded in the future so as to achieve multi-point synchronous testing.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

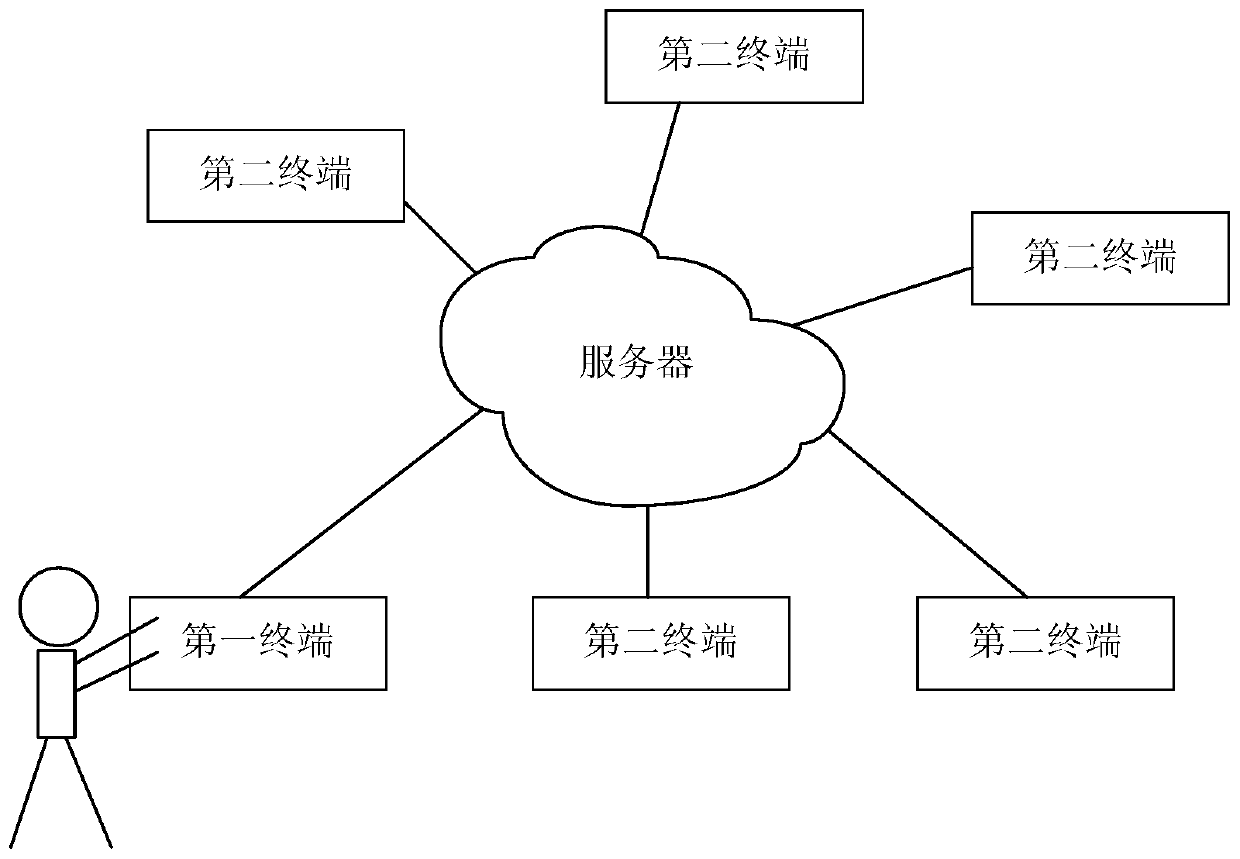

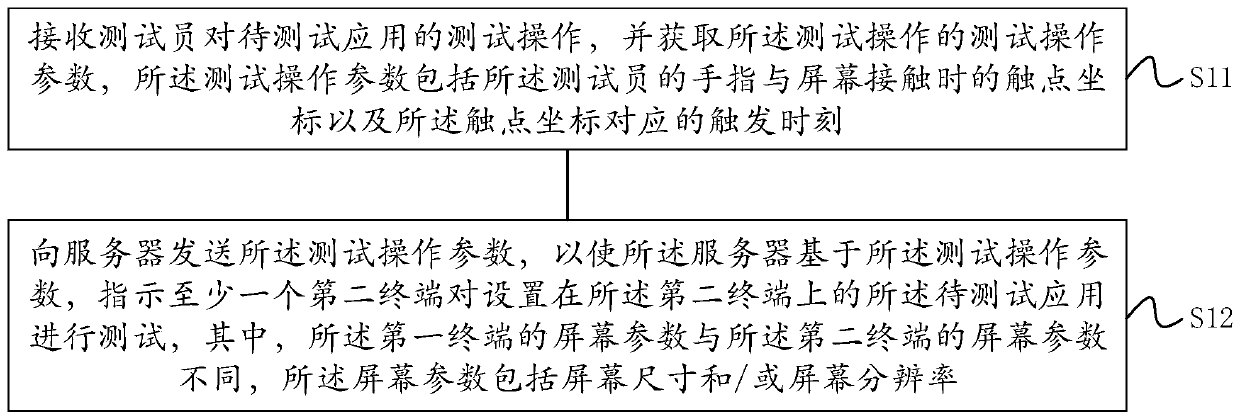

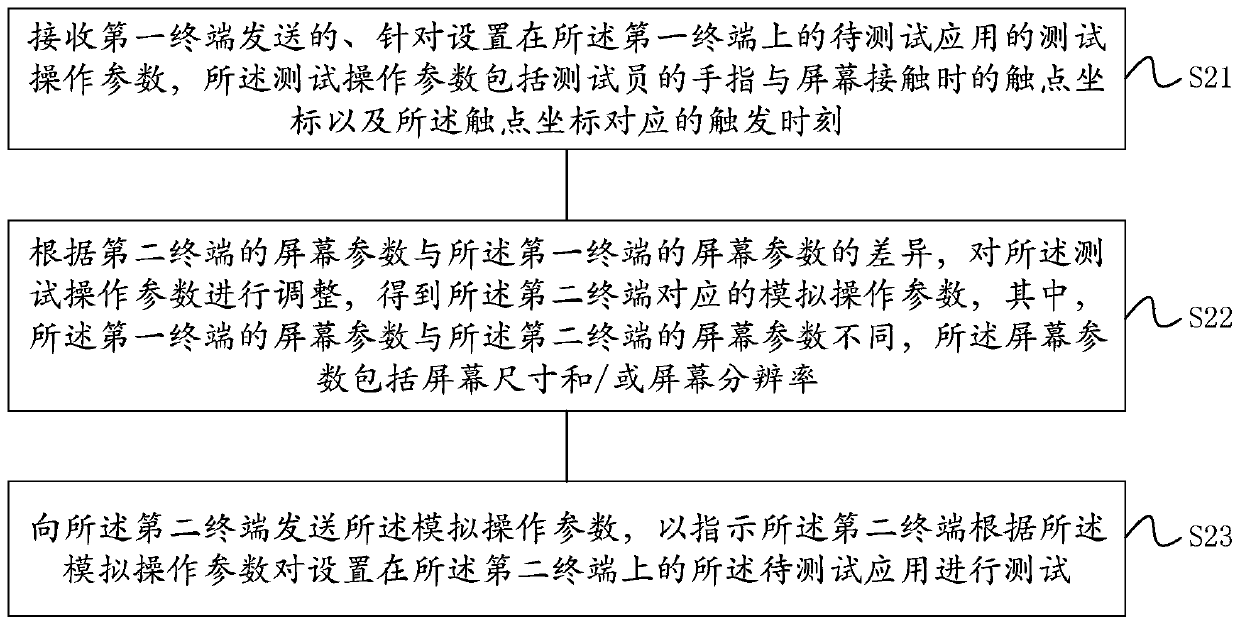

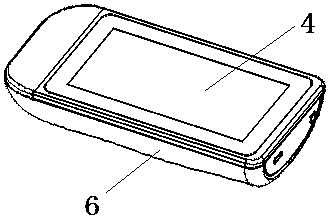

Application program testing method and device, electronic equipment and storage medium

PendingCN111324531AImprove test efficiencyImplement synchronous testingSoftware testing/debuggingTest efficiencyImage resolution

The embodiment of the invention discloses an application program test method and device, electronic equipment and a storage medium, relates to the technical field of computers, and can effectively improve the test efficiency of an application program. The method is based on a first terminal, and comprises the steps of receiving a test operation of a tester on a to-be-tested application, and obtaining test operation parameters of the test operation, the test operation parameters comprising a contact coordinate when a finger of the tester is in contact with a screen and a triggering moment corresponding to the contact coordinate; sending the test operation parameters to a server, , so that the server indicates at least one second terminal to test the to-be-tested application arranged on thesecond terminal based on the test operation parameter, the screen parameter of the first terminal being different from the screen parameter of the second terminal, and the screen parameter comprisinga screen size and / or a screen resolution. The method and the device are suitable for testing the application program.

Owner:JOYME PTE LTD

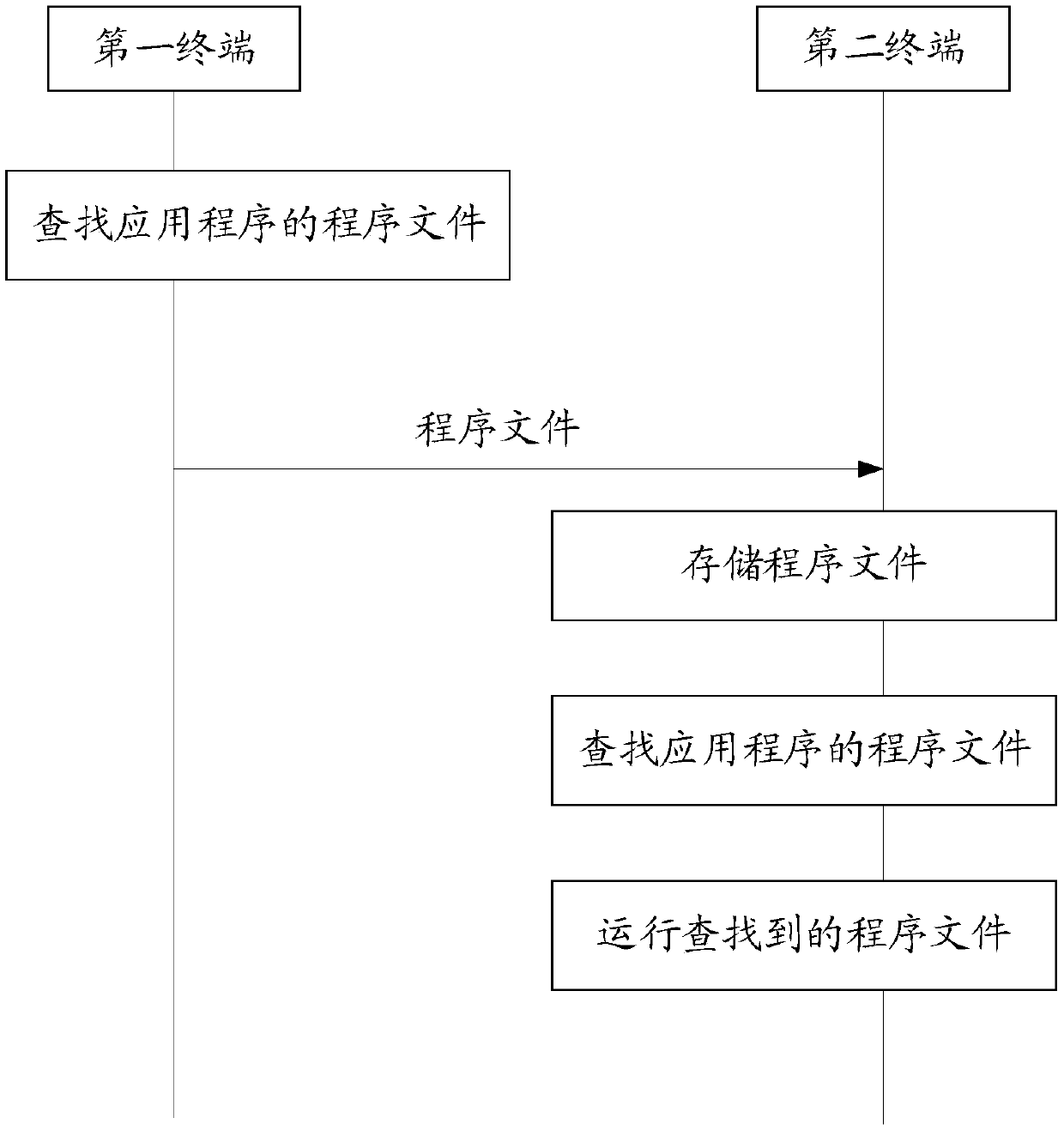

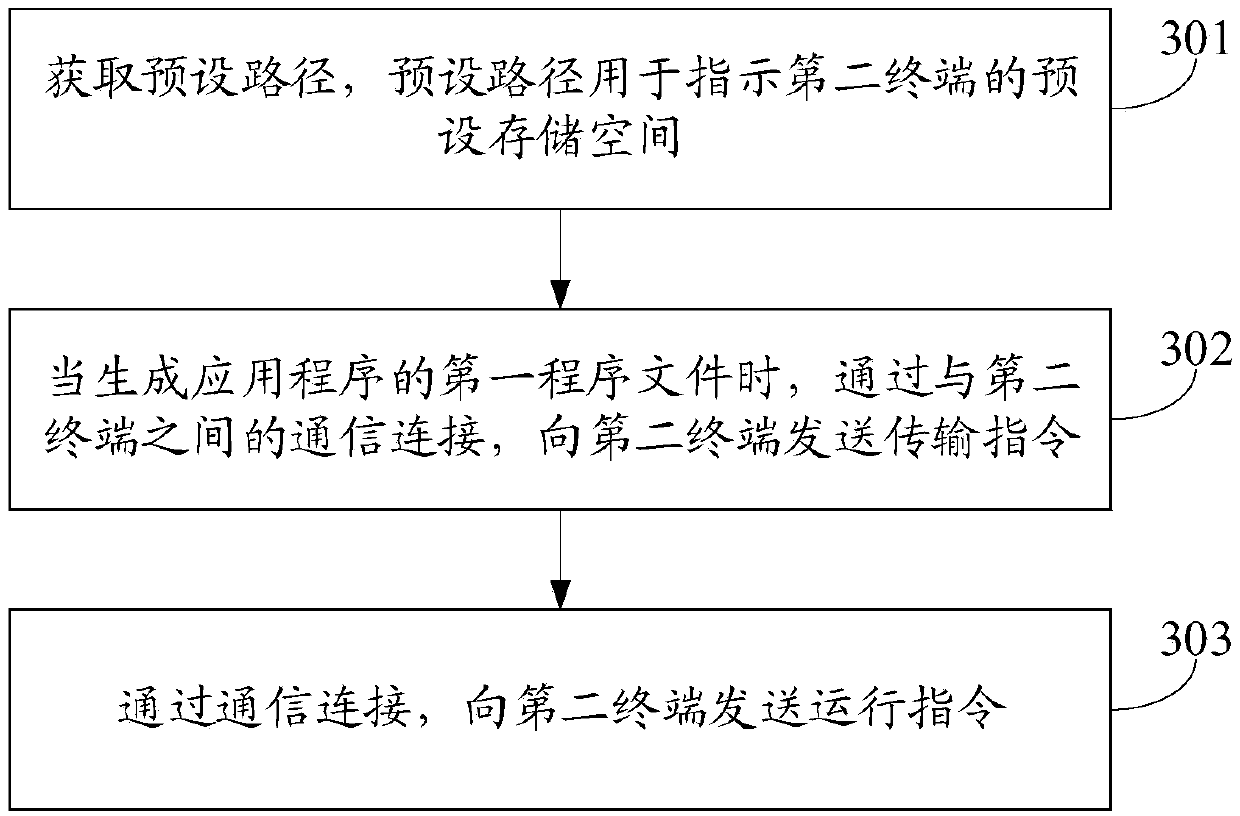

Program file running method and device, terminal and storage medium

ActiveCN109684112AEasy to operateSave human resourcesInterprogram communicationComputer hardwareApplication software

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

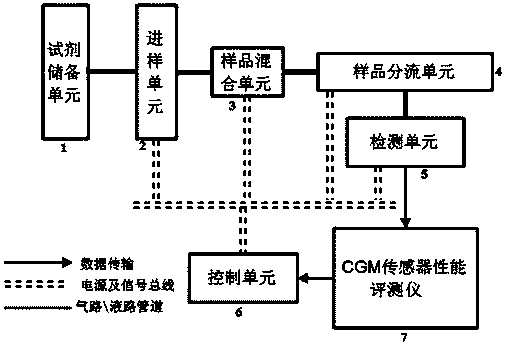

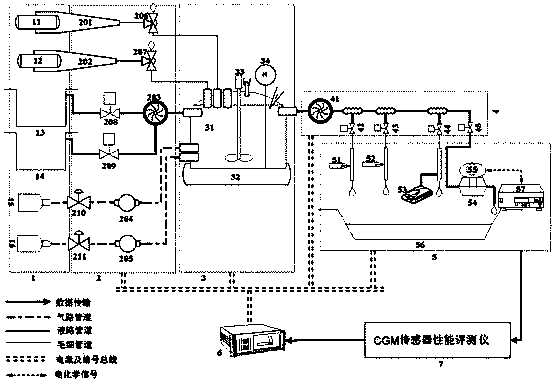

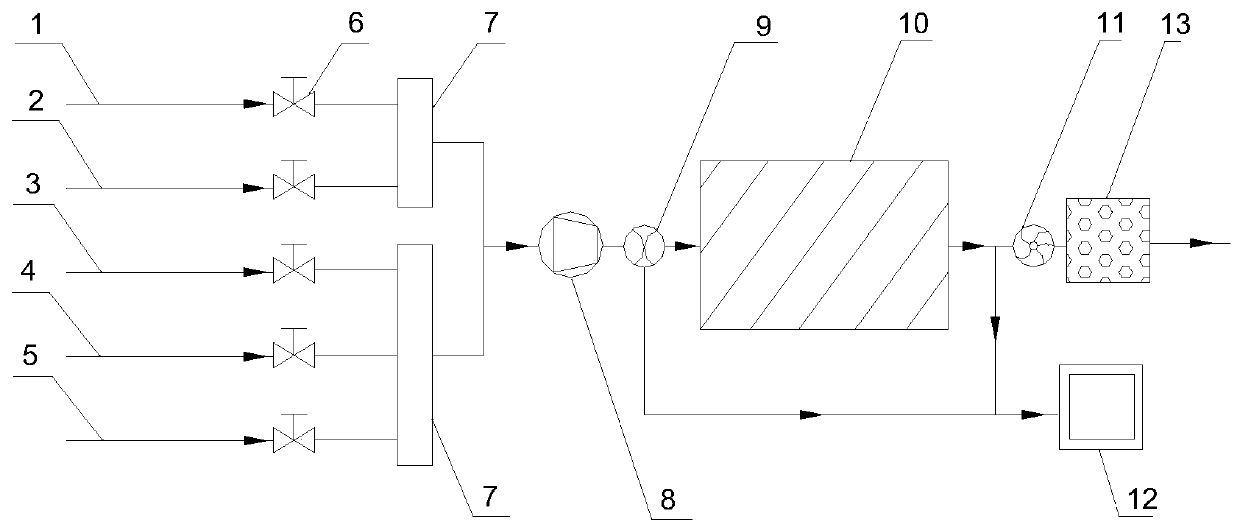

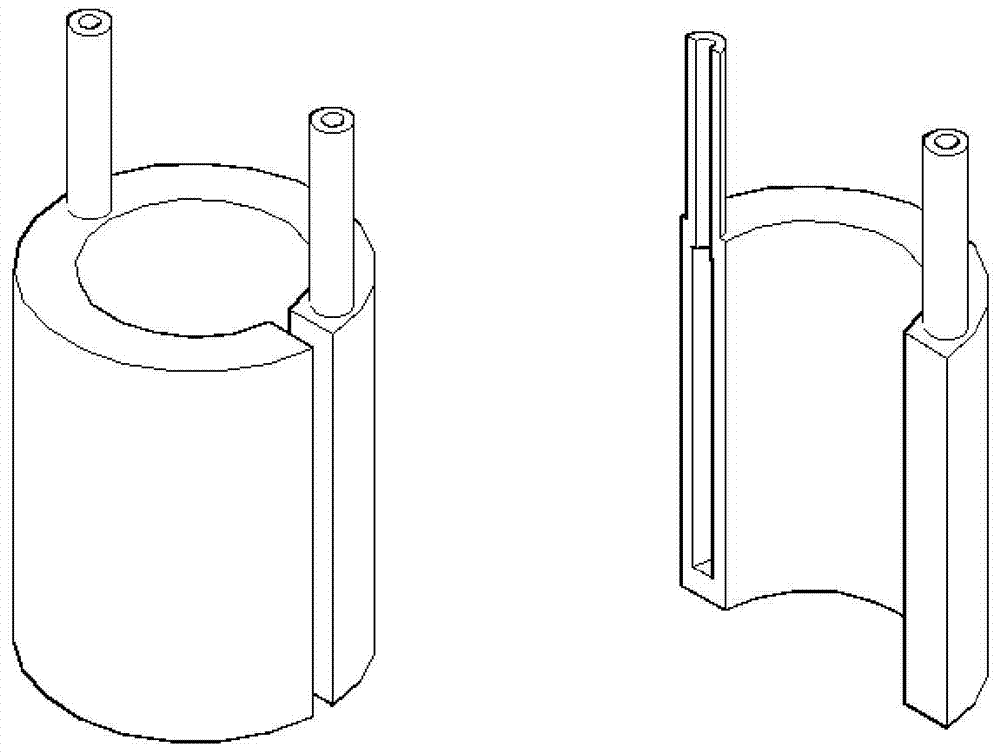

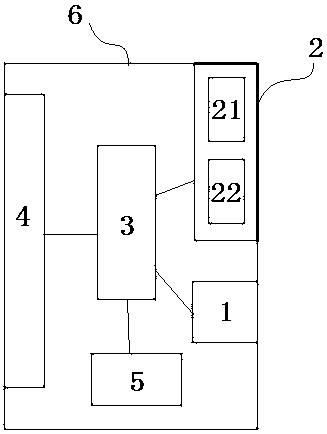

In vitro performance evaluating system of continuous blood sugar monitoring sensor

InactiveCN103995139APromote research and developmentAdjustable concentration changeBiological testingAssociation coefficientDetection performance

The invention discloses an in vitro performance evaluating system of a continuous blood sugar monitoring sensor. The in vitro performance evaluating system comprises a reagent storage unit (1), a sampling unit (2), a sample mixing unit (3), a sample distributing unit (4), a detecting unit (5), a control unit (6), and a CGM sensor evaluating instrument (7). The in vitro performance evaluating system is capable of analyzing and evaluating the in vitro performance including sensitivity, response speed, detection range, accuracy, continuous working service life, interference resistance, temperature association coefficient, oxygen dependence degree and other parameters of the continuous blood sugar monitoring sensor as well as the performance change of the to-be-monitored sensor in a continuous working state, and is capable of effectively detecting and evaluating the in vitro detection performance of the to-be-monitored sensor.

Owner:ZHEJIANG UNIV

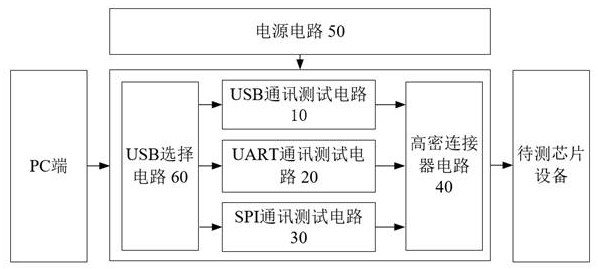

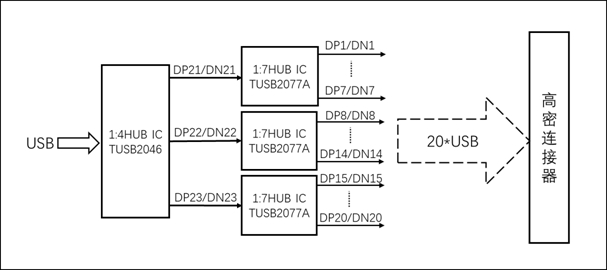

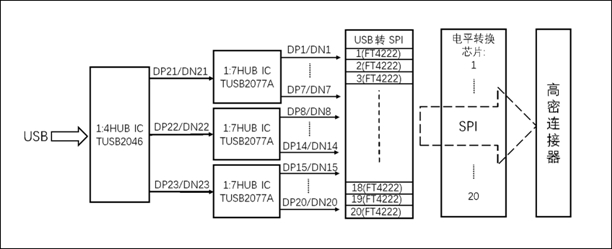

Chip synchronous testing device and chip synchronous testing method

PendingCN112130061AImplement synchronous testingEasy accessElectronic circuit testingCommunication interfaceHemt circuits

The invention provides a chip synchronous testing device and a chip synchronous testing method, and belongs to the field of chip testing. The chip synchronous testing device comprises communication testing circuits, a high-density connector circuit and a USB selection circuit; the communication testing circuits comprise a plurality of communication line ports and are used for synchronous testing of a plurality of chips; the high-density connector circuit is used for connecting the communication testing circuits and to-be-tested chip equipment; the USB selection circuit is used for switching ona corresponding chip testing interface based on the communication interface type of a to-be-tested chip; the USB selection circuit comprises a 1:3 protocol chip which is used for distinguishing chiptesting paths of different communication interface types. Through the arrangement of chip testing circuits of various interface types, diversity of chip testing types is realized; each type of communication test circuit comprises a plurality of port expansion chips, and a test path is expanded into a plurality of testing paths, so that the synchronous test of t plurality of chips is realized. Theproblem that a plurality of chips cannot be synchronously tested in the prior art is solved.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +1

Stress test jig for magnetic material

InactiveCN106768556AReasonable structural designImprove test accuracyApparatus for force/torque/work measurementEngineeringTest point

The invention discloses a stress test jig for a magnetic material. The stress test jig comprises a test base body, a test clamp and multiple test stop blocks, wherein the test clamp is mounted at the middle part of the test base body in a locking manner through a pin; at least one test point is arranged on each side of the test clamp; the multiple test stop blocks press against the magnetic material to fix the magnetic material on the test clamp; each test stop block is formed by stacking a trapezoid block and a triangular block, and test points are arranged on two sides of the trapezoid block and the sides of the triangular block; the test points on the test clamp and the test stop blocks are connected with the test base body through test lines. The stress test jig is reasonable in structural design; as the test points are arranged on the test clamp and the test stop blocks, synchronous test in multiple directions can be realized, and the test precision is high; furthermore, tests for multiple magnetic materials can be completed at one time; by distribution of multiple test stop block positions, the stress test jig can adapt to the test work for the the magnetic materials of different specifications, and is high in working efficiency and high in universality.

Owner:苏州沃诺斯精密机械有限公司

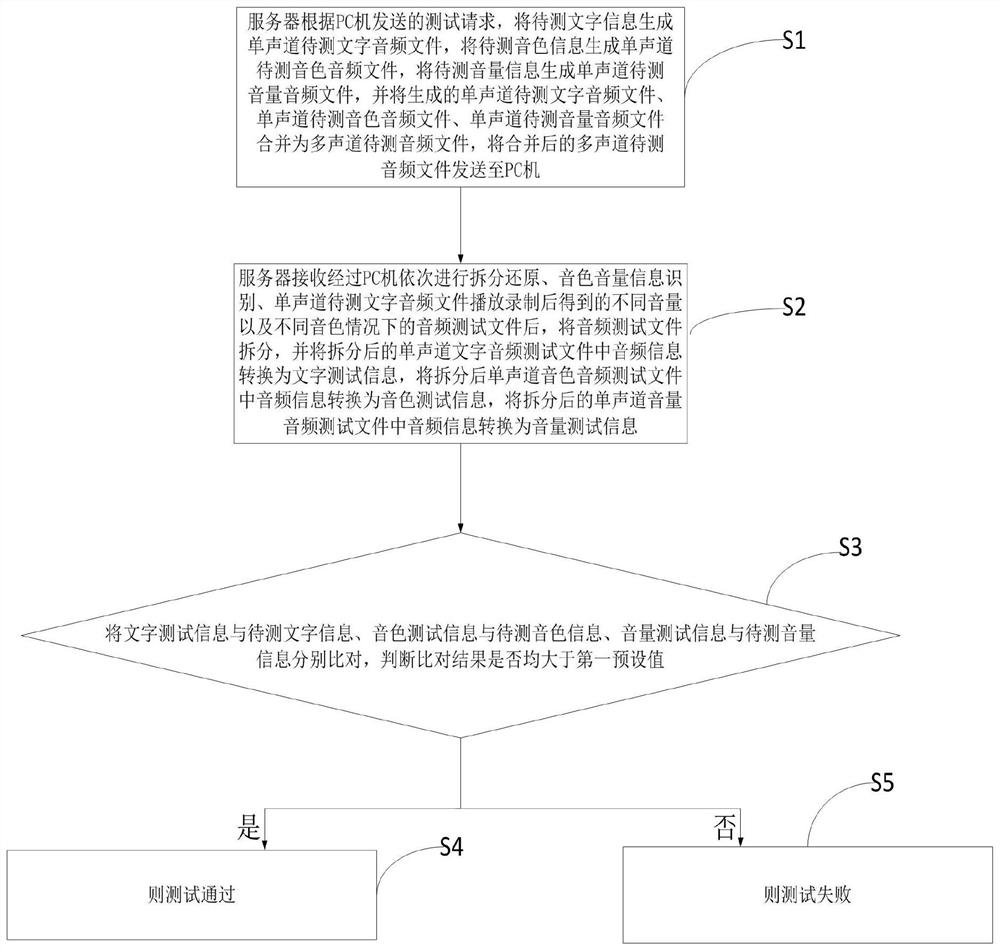

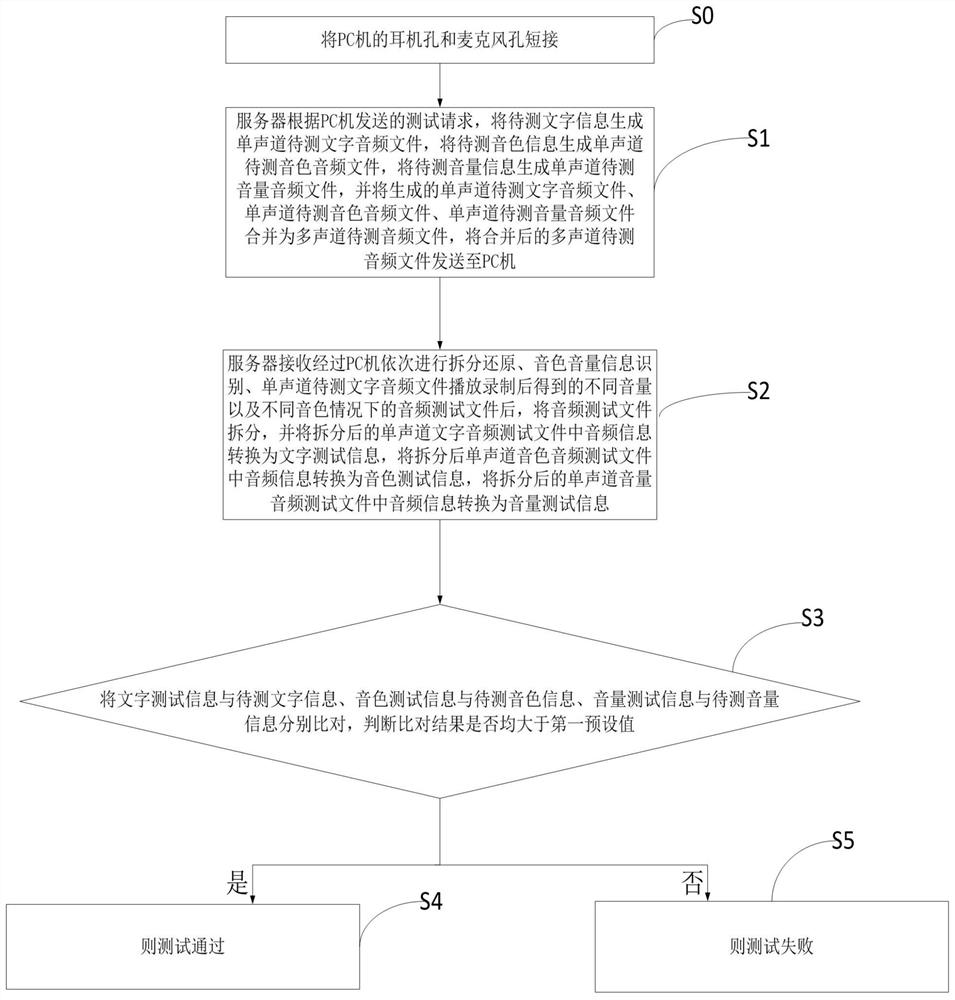

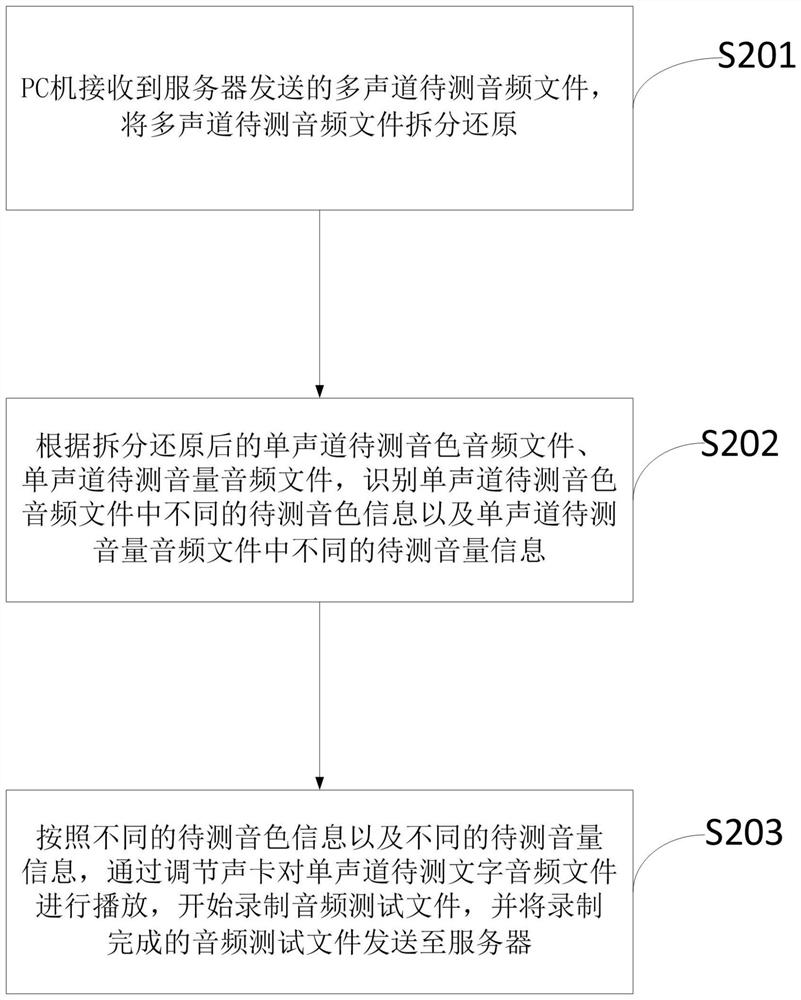

Method, device and system for testing sound card of PC (Personal Computer)

The invention provides a PC (Personal Computer) sound card testing method, which comprises the following steps: combining, by a server, a generated single-track to-be-tested character audio file, a single-track to-be-tested tone audio file and a single-track to-be-tested volume audio file into a multi-track to-be-tested audio file, and sending the multi-track to-be-tested audio file to a PC; receiving an audio test file under the conditions of different volumes and different timbres, which is obtained by sequentially carrying out splitting restoration, timbre volume information identification and single-track to-be-tested character audio file playing and recording through a PC (Personal Computer), and then splitting the audio test file; and comparing the character test information with the to-be-tested character information, the timbre test information with the to-be-tested timbre information and the volume test information with the to-be-tested volume information respectively. The invention further provides a PC sound card testing device and system; the accuracy and reliability of PC sound card testing can be improved, and the testing efficiency of the PC sound card under the conditions of different volumes and different timbres can be further improved.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

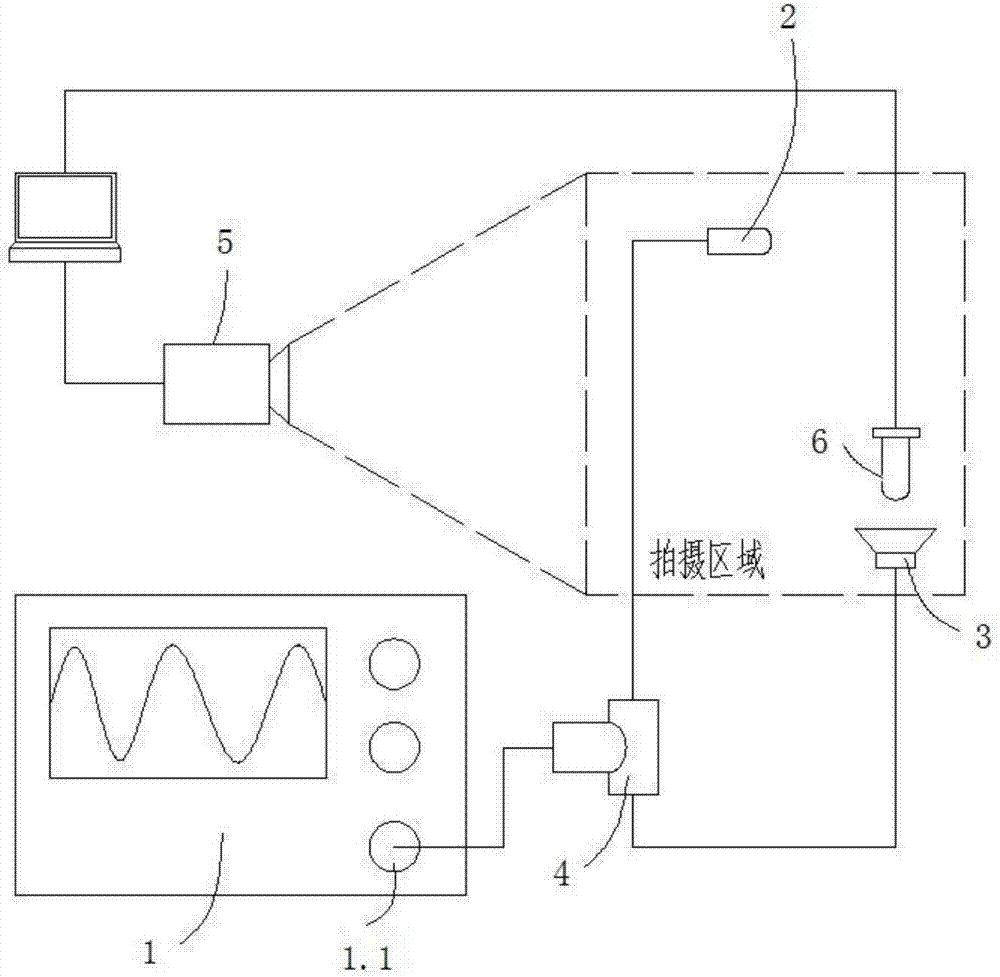

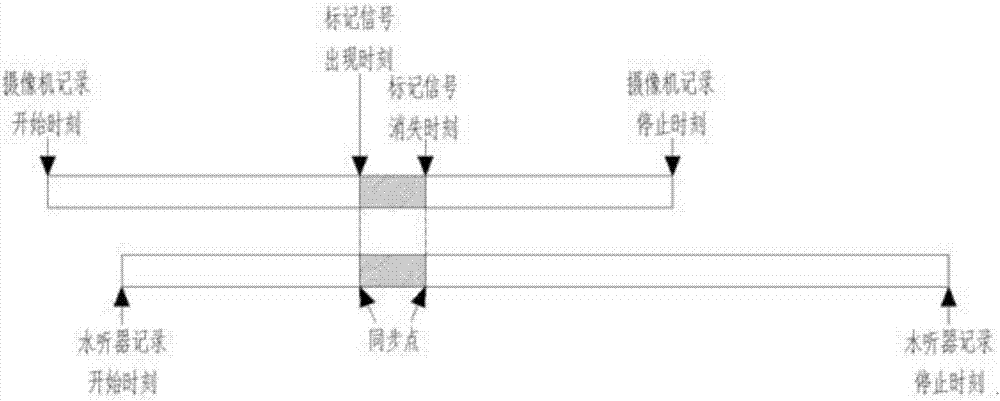

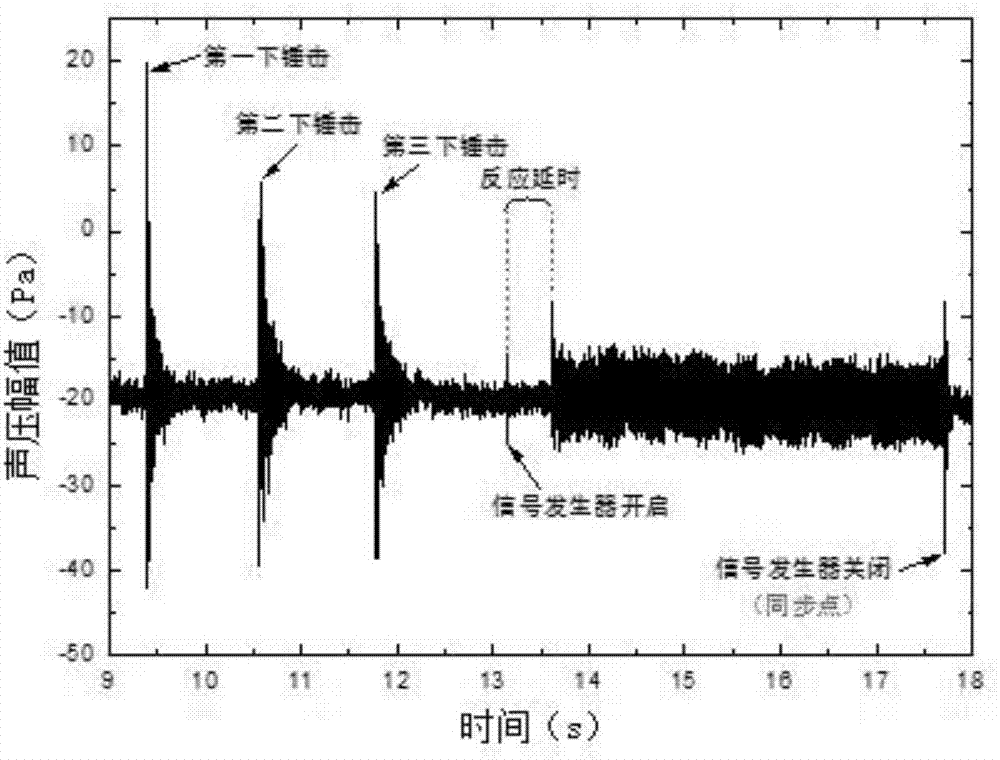

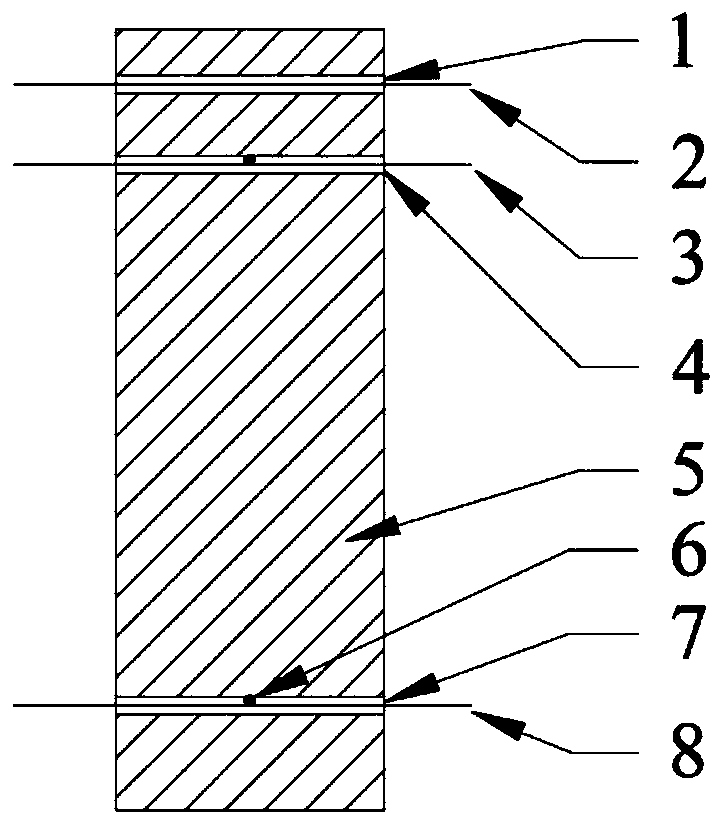

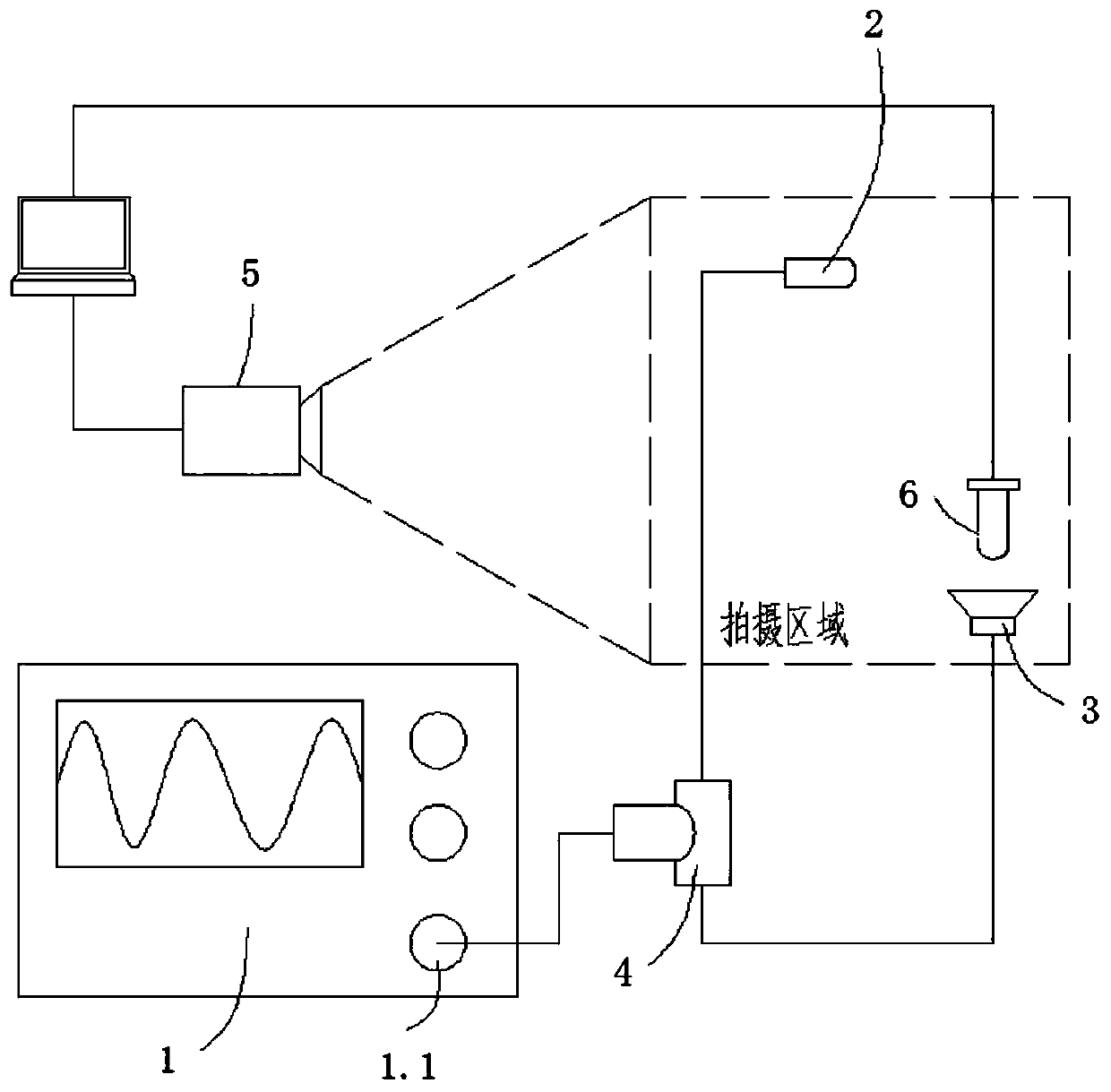

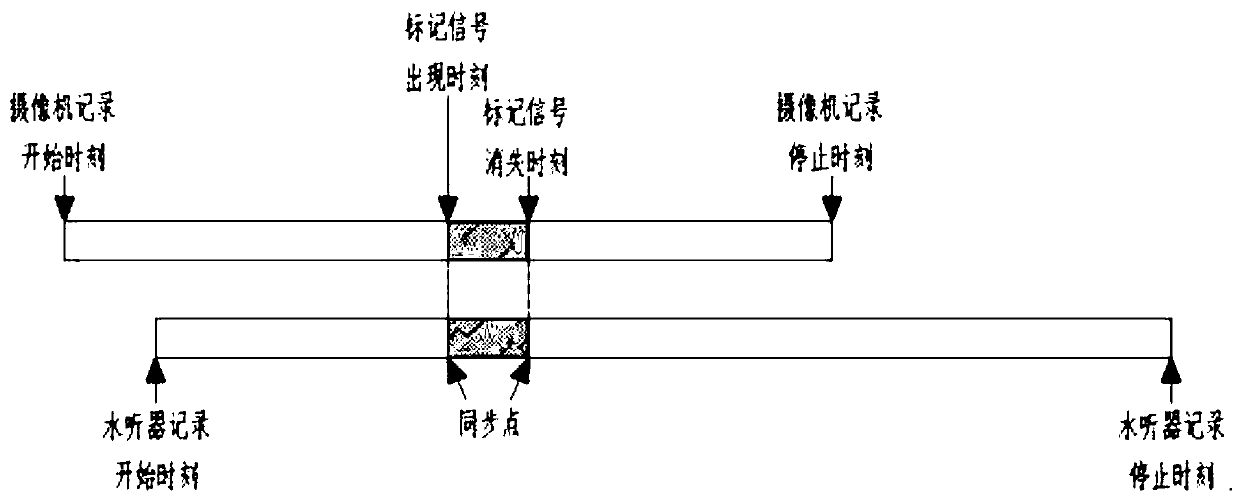

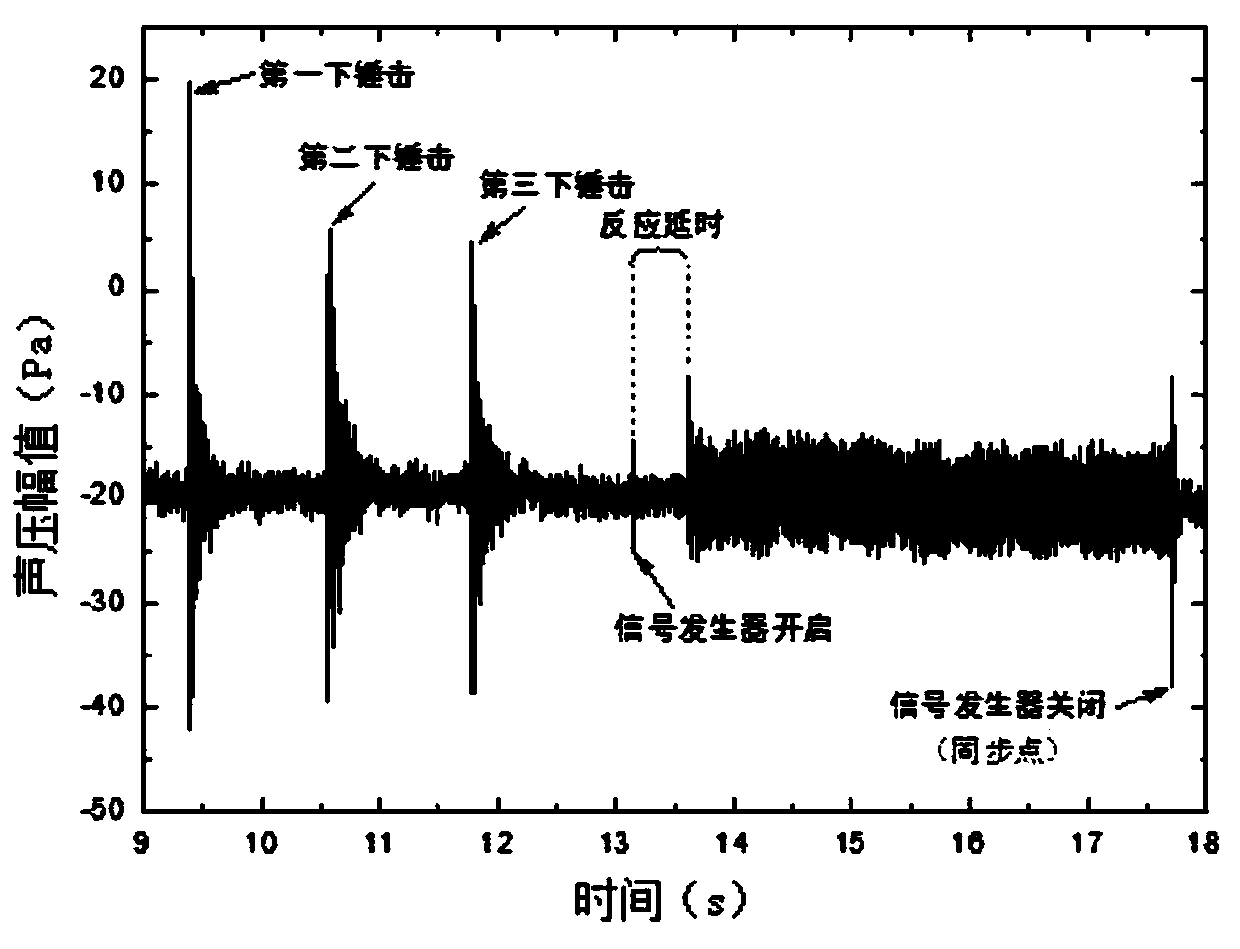

Audio and video signal synchronization device and method applicable to bubble acoustic research

ActiveCN107277296AImplement synchronous testingLess investment in additional testingTelevision system detailsSpeech analysisHydrophoneSignal generator

The invention discloses an audio and video signal synchronization device applicable to bubble acoustic research, which comprises a signal generator, a light emitting diode and a loudspeaker. The output end of the signal generator is connected with a three-way joint; the three-way joint is connected with the light emitting diode and the loudspeaker; the light emitting diode is arranged in a shooting range of a camera; and the loudspeaker is arranged beside a hydrophone. The invention further provides an audio and video signal synchronization method applicable to bubble acoustic research. According to the audio and video signal synchronization device and method applicable to bubble acoustic research, which are disclosed by the invention, when sound and video acquisition equipment does not have a trigger function, high-accuracy synchronous testing of audio and video signals can still be implemented.

Owner:CHINA SHIP DEV & DESIGN CENT

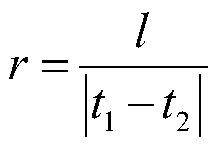

Synchronous measurement method for combustion rate and combustion wave of solid propellant

InactiveCN110455861AHigh time accuracySolve the problem of not easy to fuseMaterial heat developmentThermometers using electric/magnetic elementsIridiumPlatinum

The invention discloses a synchronous measurement method for a combustion rate and a combustion wave of a solid propellant. The method comprises the following steps: drilling holes in a radial direction at both axial ends of a cuboid-shaped or cylindrical propellant strip, and measuring a spacing between the two holes; drilling holes on one side of the propellant strip in an axial direction and inserting ignition wires into the holes; inserting two micro platinum-iridium thermocouples into the holes respectively; putting the propellant strip in a constant pressure bomb for ignition, recordinga time t1 at which the first thermocouple shows a maximum voltage when the burned solid propellant is close to a temperature measuring head of the first thermocouple and recording a time t2 at which the second thermocouple shows a maximum voltage when the burned solid propellant is close to a temperature measuring head of the second thermocouple, calculating a combustion rate of the propellant andthen obtaining two combustion wave curves of the propellant strip. The synchronous measurement method of the invention adopts micro thermocouples with a small wire diameter and has a short response time. The synchronous measurement method uses micro thermocouples instead of traditional target line methods to effectively improve a timing accuracy of the target line and realize synchronous test forthe combustion rate and the combustion wave of the solid propellant.

Owner:XIAN MODERN CHEM RES INST

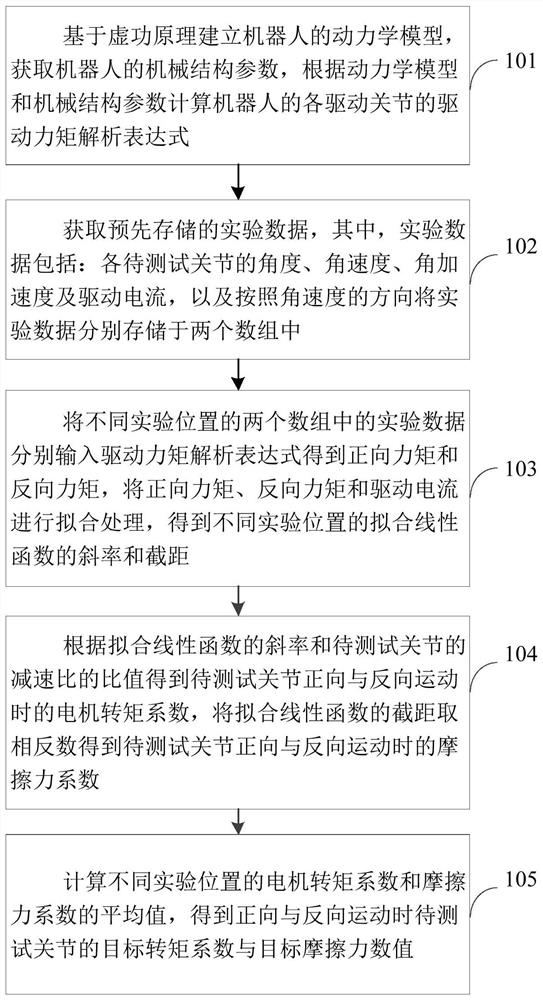

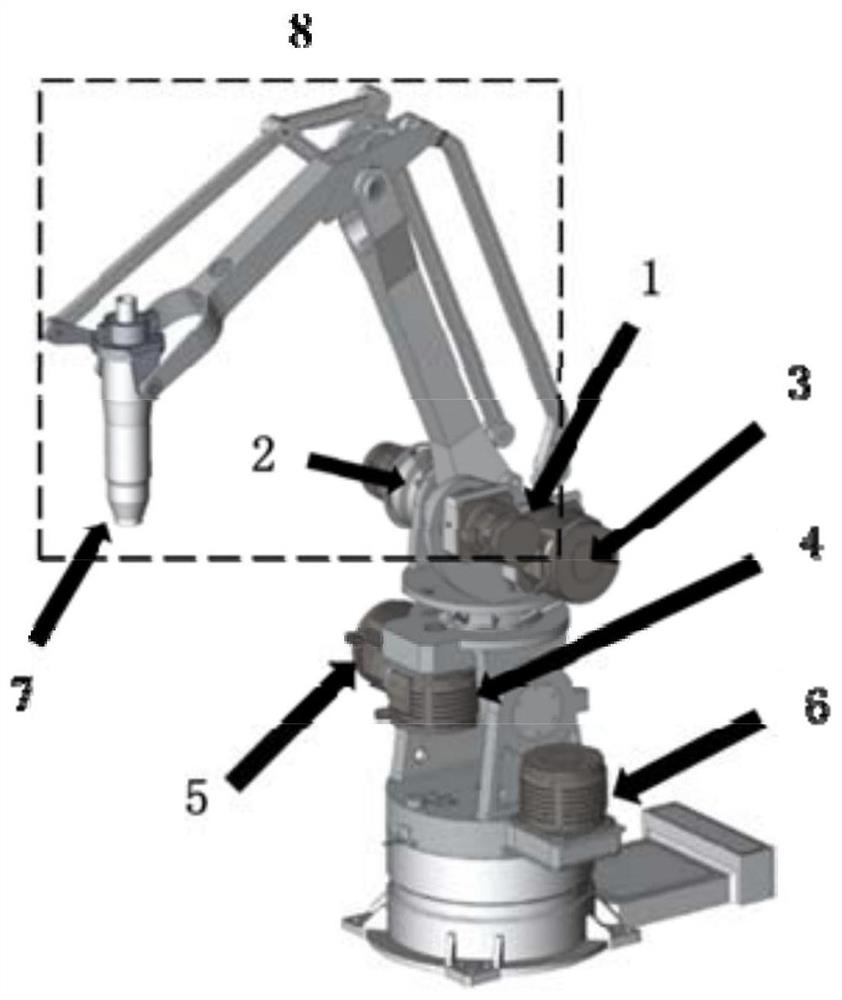

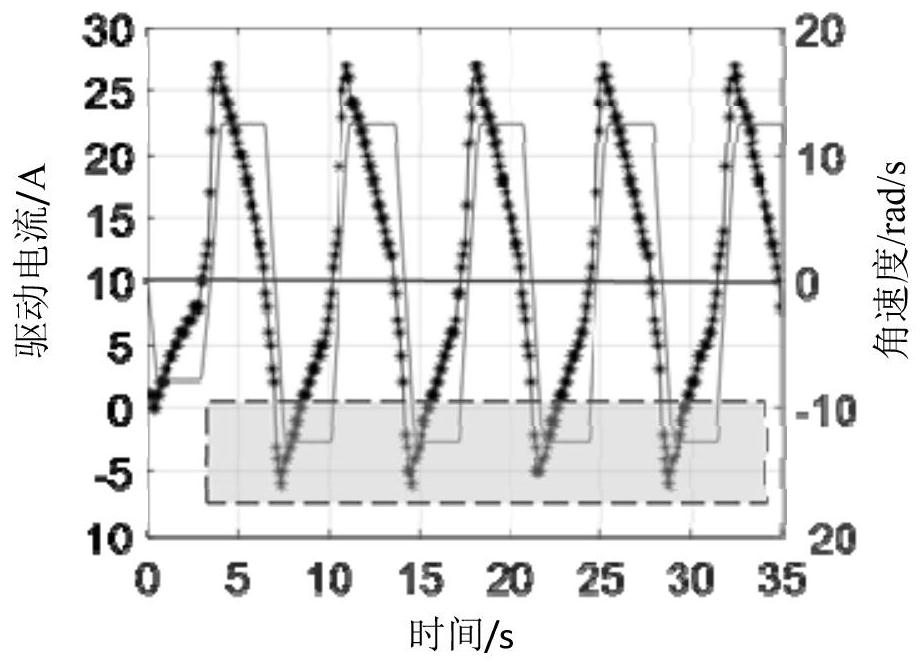

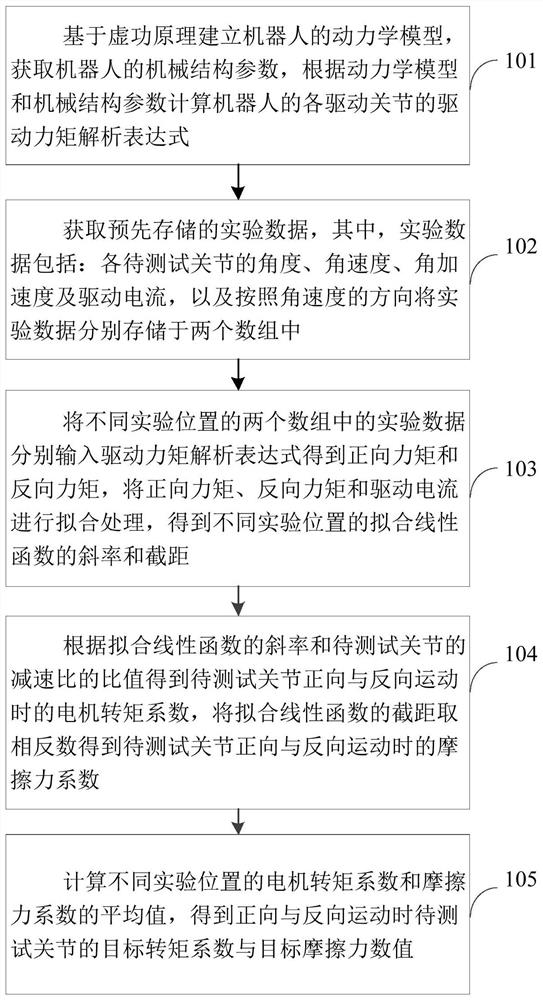

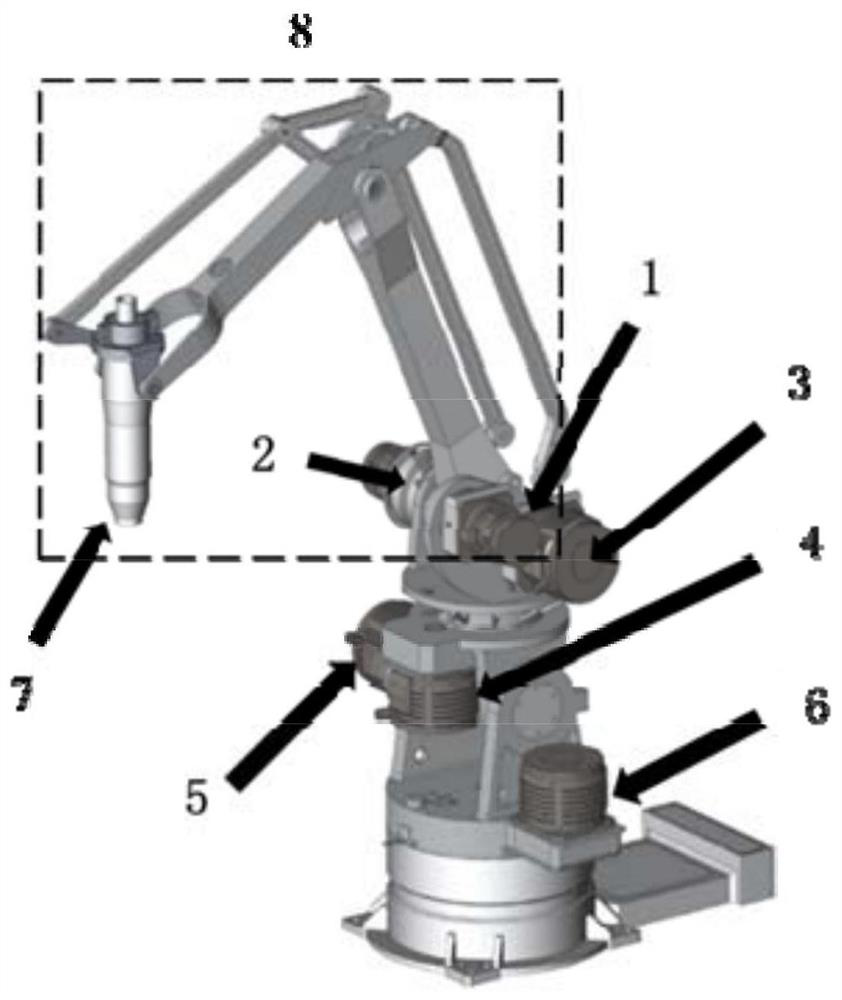

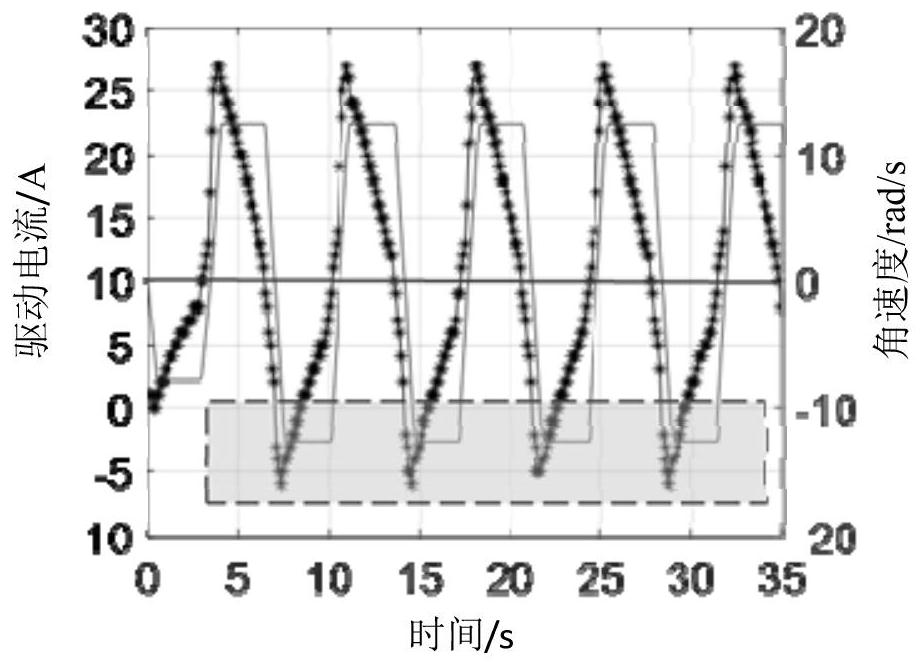

Joint motor torque coefficient and friction force synchronous test method and device for robot

ActiveCN112179551AImplement synchronous testingImprove test accuracyManipulatorMeasurement of force applied to control membersElectric machineryTorque coefficient

The invention provides a joint motor torque coefficient and friction force synchronous test method and device for a robot. The method comprises the steps of calculating a driving torque analytical expression of a driving joint of the robot according to a kinetic model of the robot and structural parameters of the robot; inputting the stored experimental data into a driving moment analytical expression to obtain a forward moment and a reverse moment, and fitting the forward moment and the reverse moment with the driving current to obtain slopes and intercept of fitting linear functions at different experimental positions; obtaining a motor torque coefficient of a joint to be tested during forward and reverse movement by combining the reduction ratio of the joint to be tested, and obtaininga friction coefficient of the joint to be tested during forward and reverse movement by taking the intercept as a reverse number; and calculating the average value of the motor torque coefficients andthe friction coefficients at different experimental positions to obtain the target torque coefficient and the target friction coefficient of the joint to be tested during forward and reverse movement. Therefore, synchronous testing of the joint motor torque coefficient and the forward and reverse friction coefficient is realized, and the testing precision is improved.

Owner:TSINGHUA UNIV

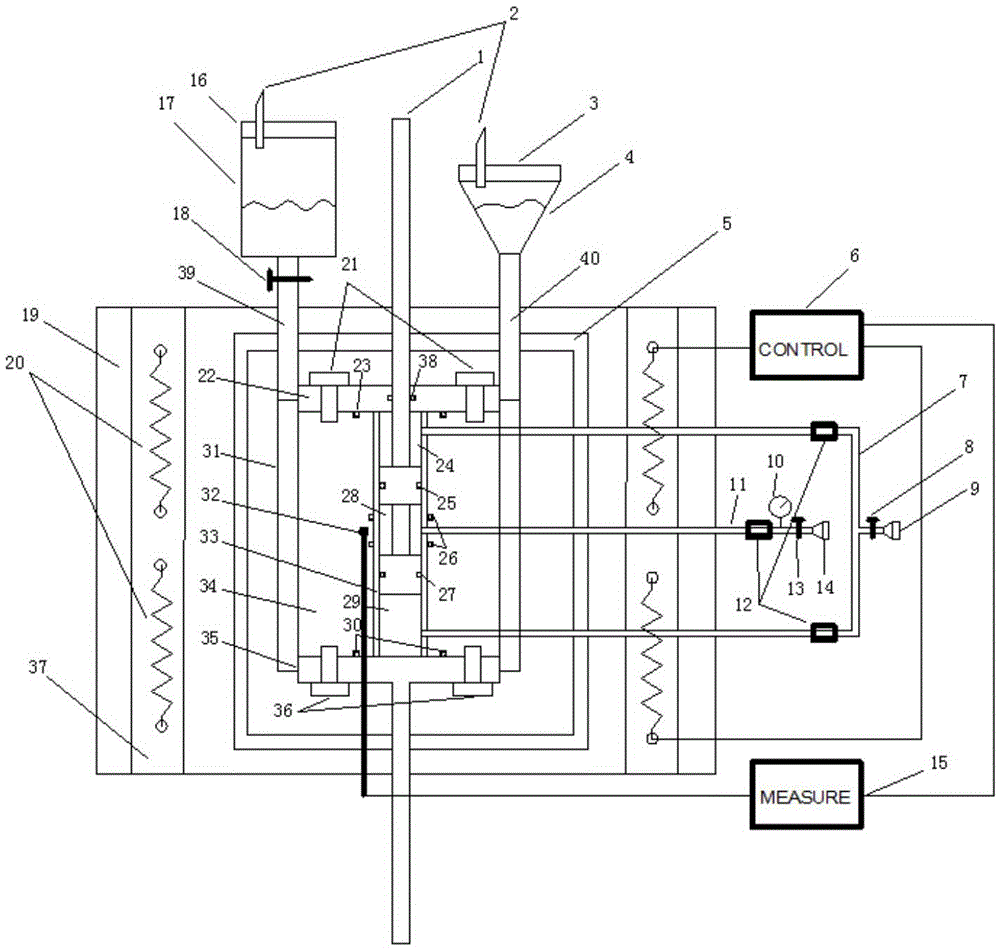

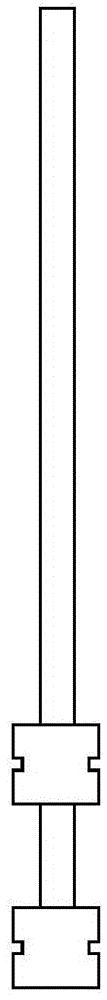

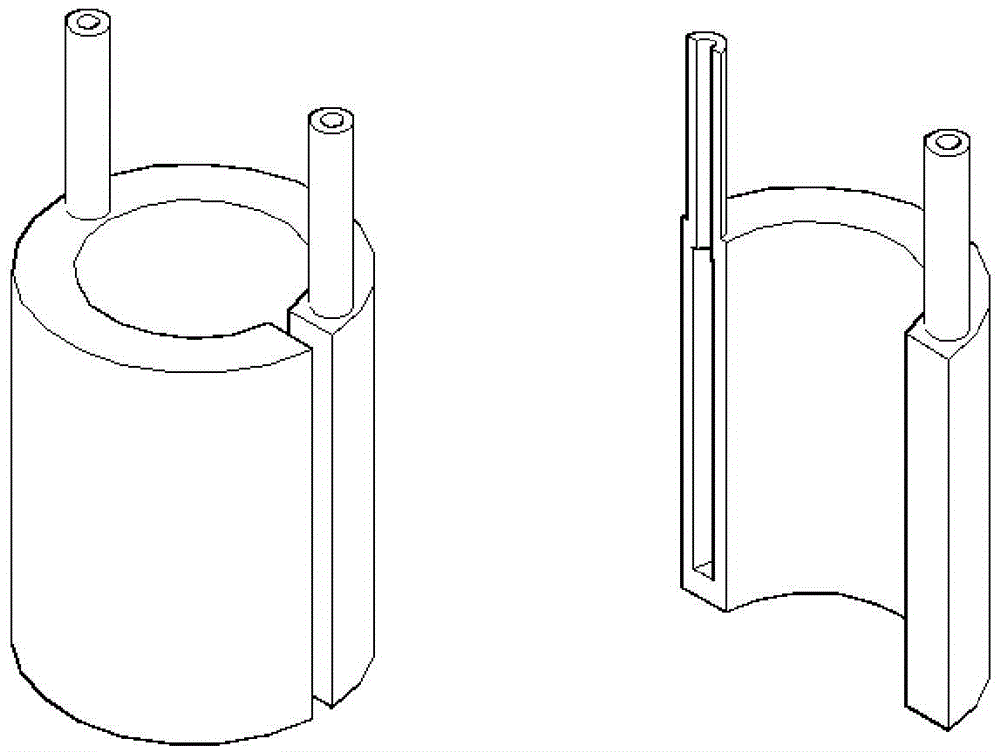

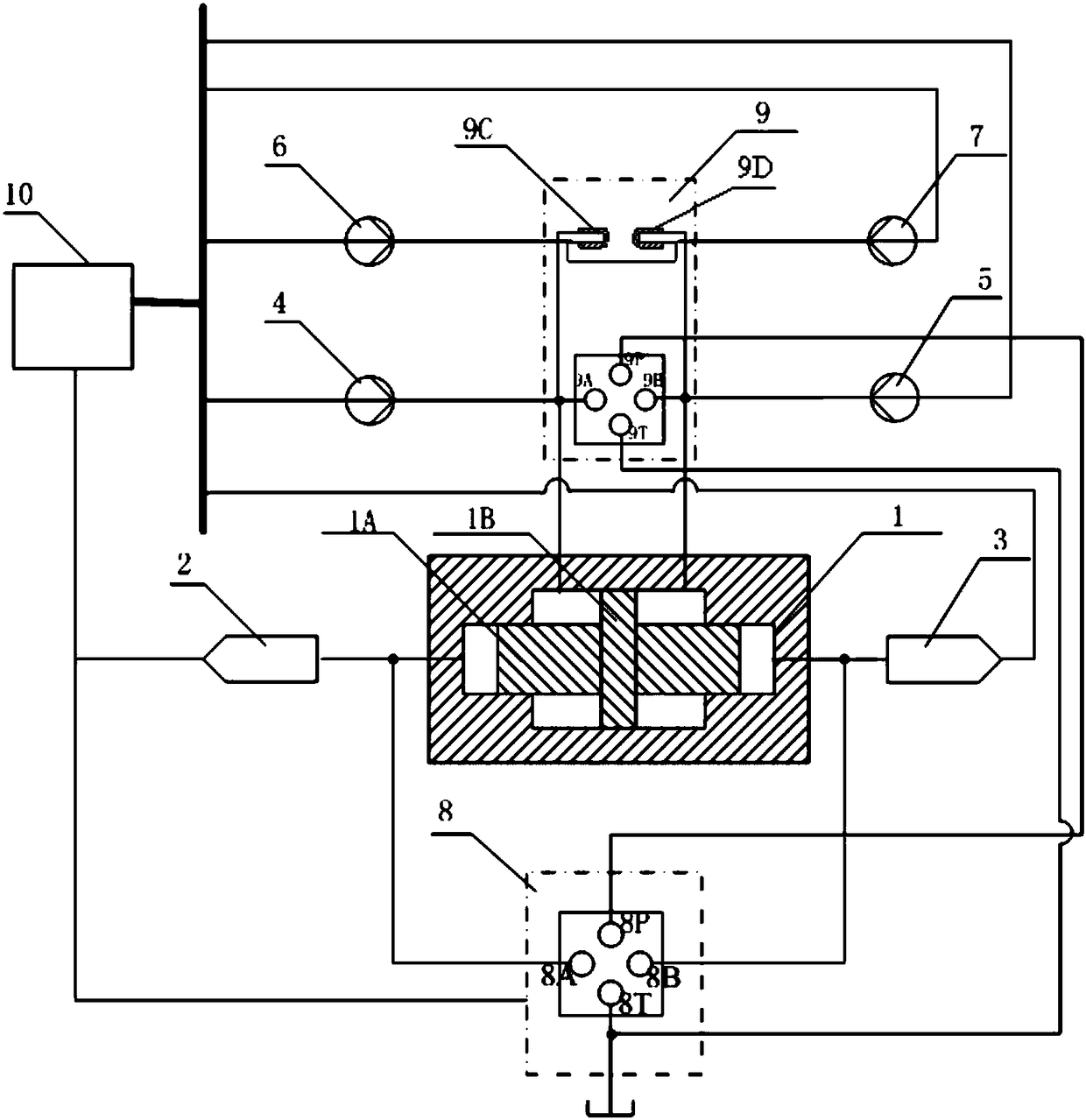

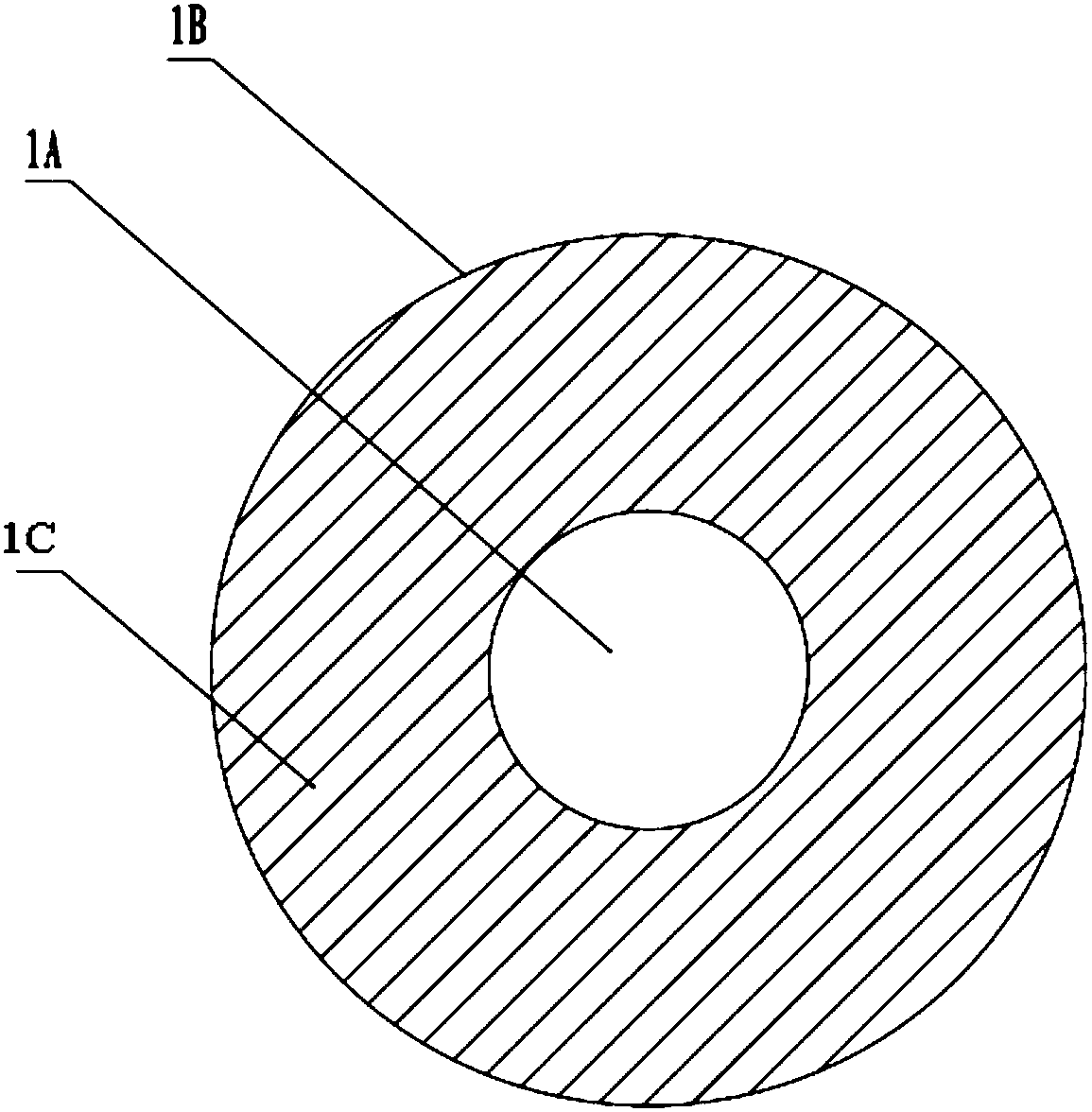

A rubber ring high pressure dynamic sealing test device

ActiveCN104390749BImplement synchronous testingEasy to assembleMeasurement of fluid loss/gain rateApparatus for force/torque/work measurementRubber ringMechanical engineering technology

The invention provides a high-pressure dynamic sealing testing device for a rubber ring, and belongs to the technical field of aerospace and mechanical engineering. The device comprises a reciprocating moving testing machine, a high pressure aerator, a gas flow meter and a test implementing body; the reciprocating moving testing machine moves by a reciprocating manner to enable the frictional movement between a sealing rubber ring on a connecting rod in the test implementing body and a replaceable lining testing material, and the reciprocating moving testing machine is able to synchronously measure the force and displacement; the gas leakage quantity can be synchronously measured through a designed pipeline system. The device has the effect and benefit that the high pressure dynamic sealing of the rubber ring can be tested under different design parameters; the device has the characteristics of being simple and convenient to assemble, flexible and easy to be used.

Owner:DALIAN UNIV OF TECH

Wind generating set load testing system meeting IEC61400-13 standard

ActiveCN101975662BImplement synchronous testingHigh degree of standardizationEngine testingWork measurementElectricityControl system

The invention relates to a wind generating set load testing system meeting the international electrical committee IEC61400-13 standard. The wind generating set load testing system is characterized by comprising a subsystem and a master control system (3), wherein the subsystem comprises a wheel hub testing system (1), a tower top testing system (2) and a meteorological testing system (4); the meteorological testing system (4) is arranged at the bottom of a meteorological anemometer mast; the tower top testing system (2) is arranged on the top of a tower cylinder; the wheel hub testing system (1) is arranged in a wheel hub of the wind generating set and rotates with the wheel hub of the wind generating set when runs; and the master control system is arranged at the bottom of the tower cylinder. The wind generating set load testing system can be applied to verifying design load of the wind generating set, optimizing design scheme of the wind generating set, detecting quality of the wind generating set which leaves factory, avoiding safety accidents and the like and has high practicability.

Owner:STATE GRID CORP OF CHINA +2

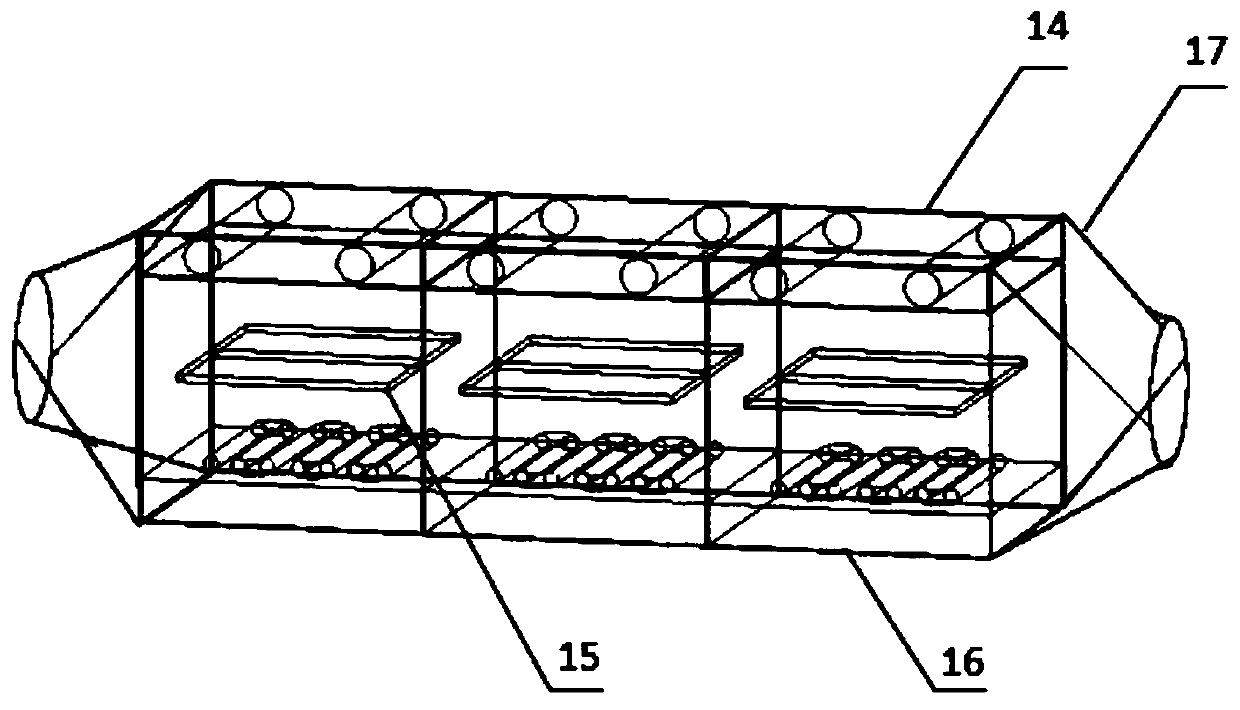

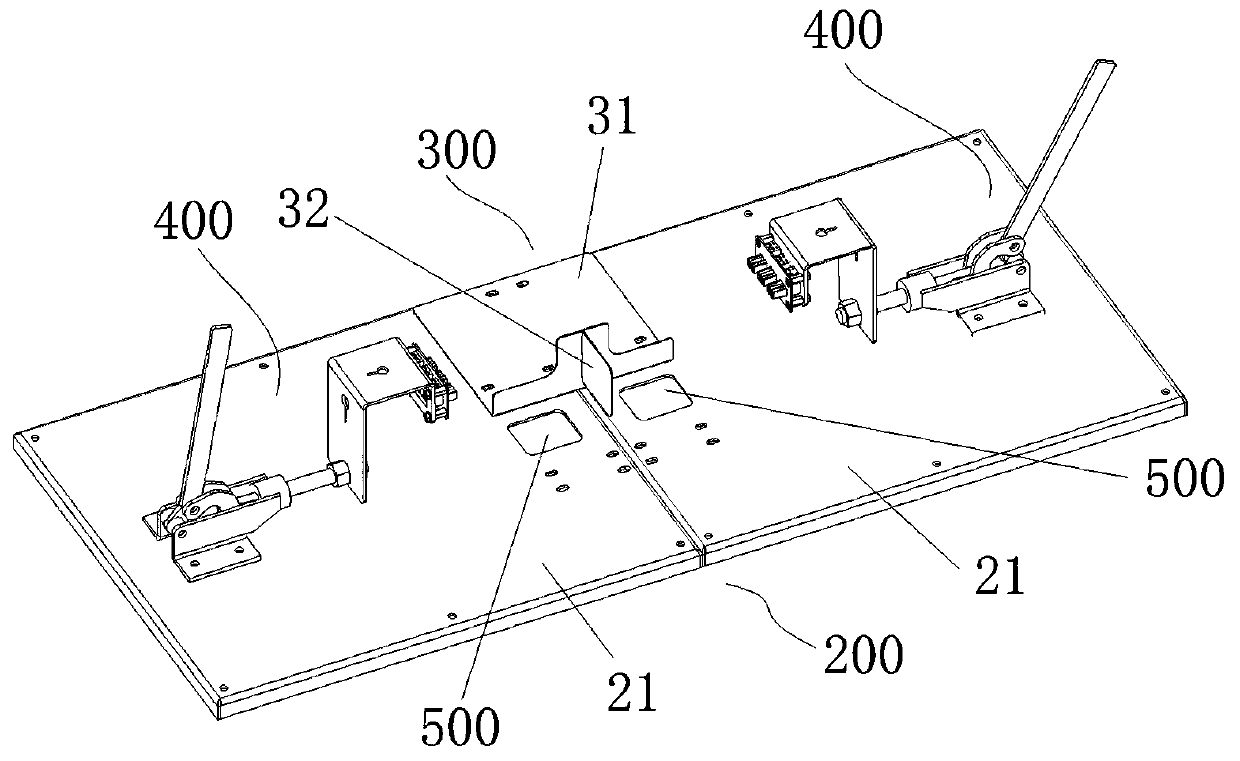

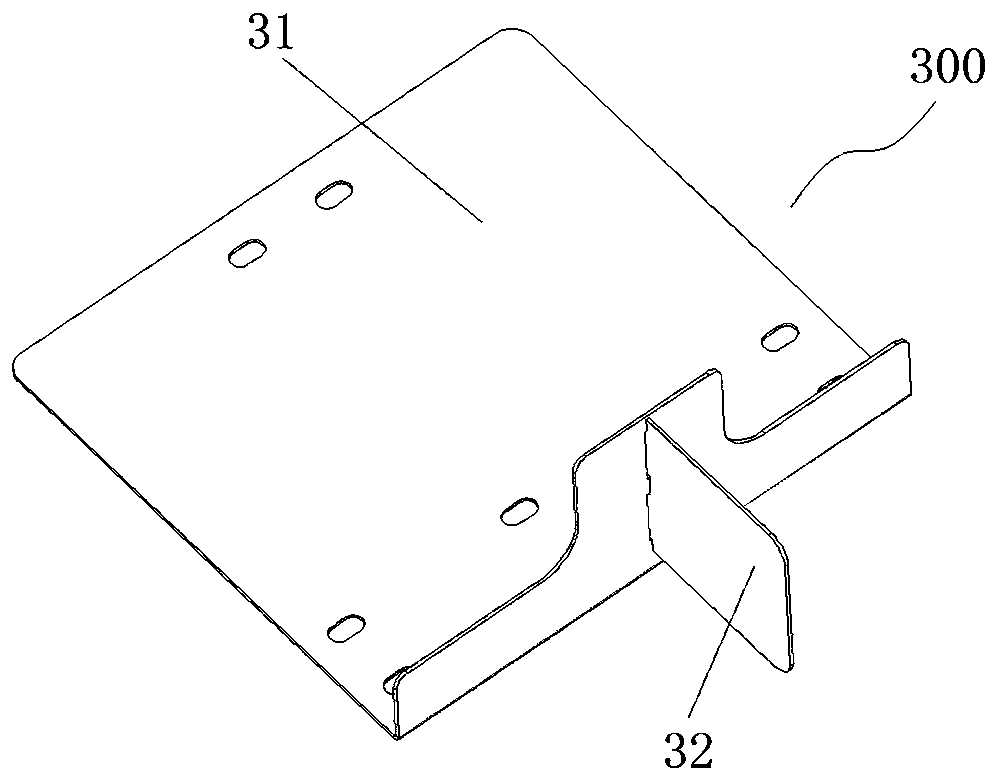

Electronic product aging automatic test platform and test method thereof

ActiveCN113777475AAchieve closureImplement synchronous testingElectronic circuit testingMeasurement instrument housingEngineeringStructural engineering

The invention discloses an electronic product aging automatic test platform and method, and the test platform comprises a test box body, the interior of the test box body is provided with at least two test cavities, each test cavity is internally provided with a test plate, the top of each test cavity is provided with a box door, and the top of the test box body is provided with grooves at the two sides of the box door. Mother plates are slidably installed in the grooves, sliding seats are fixedly connected to the tops of the mother plates, shaft rods fixedly connected to the two sides of the box door are embedded into the sliding seat and are in limiting movable fit connection with the sliding seats, two fixing plates are fixedly connected to the inner wall of each testing cavity, and a second air cylinder is fixedly connected to the top end of each fixing plate in the vertical direction; the top ends of the second cylinders are provided with magnetic rollers for supporting the box door, the top of the test box body is fixedly provided with a mounting seat between the two test cavities, and two ends of the mounting seat are rotatably provided with rollers in rolling connection with the lower end face of the box door. The electronic product aging automatic test platform can realize automatic opening and closing of the box door.

Owner:山东博蓝建筑工程有限公司

Audio and video signal synchronization device and method suitable for bubble acoustic research

ActiveCN107277296BImplement synchronous testingLess investment in additional testingTelevision system detailsSpeech analysisHydrophoneAcquisition apparatus

The invention discloses an audio and video signal synchronization device applicable to bubble acoustic research, which comprises a signal generator, a light emitting diode and a loudspeaker. The output end of the signal generator is connected with a three-way joint; the three-way joint is connected with the light emitting diode and the loudspeaker; the light emitting diode is arranged in a shooting range of a camera; and the loudspeaker is arranged beside a hydrophone. The invention further provides an audio and video signal synchronization method applicable to bubble acoustic research. According to the audio and video signal synchronization device and method applicable to bubble acoustic research, which are disclosed by the invention, when sound and video acquisition equipment does not have a trigger function, high-accuracy synchronous testing of audio and video signals can still be implemented.

Owner:CHINA SHIP DEV & DESIGN CENT

Multifunctional photocatalytic material performance testing device and testing method

PendingCN110426340ASolve the problem of photocatalytic performance testingFlexible structureChemical analysis using catalysisWeather/light/corrosion resistancePhotocatalytic reactionDistribution system

The invention relates to the technical field of photocatalytic testing analysis, in particular to a multifunctional photocatalytic material performance testing device and testing method. The multifunctional photocatalytic material performance testing device comprises a gas distribution system, a photocatalytic reaction system, an analytical testing system and a gas treatment system; the gas distribution system comprises two or more gas paths, all the gas paths are connected with a constant flow pump, and the constant flow pump is connected with the photocatalytic reaction system and the analytical testing system separately through a conversion valve; the output end of the photocatalytic reaction system is connected with the analytical testing system and the gas treatment system separately.The multifunctional photocatalytic material performance testing device is flexible in structure, easy to manufacture and capable of achieving testing and evaluation of photocatalytic performance andageing-resistance performance of homogeneous materials, multi-type materials, engineering application materials and the like in a complicated pollution environment, the comprehensive performance of the photocatalytic materials are accurately and quickly represented, and thus research and application of the photocatalytic materials are boosted.

Owner:国合通用(青岛)测试评价有限公司

Method and device for synchronous testing of joint motor torque coefficient and friction force of robot

ActiveCN112179551BImplement synchronous testingImprove test accuracyManipulatorMeasurement of force applied to control membersClassical mechanicsElectric machinery

Owner:TSINGHUA UNIV

A dynamic loading device for servo valve dynamic pressure feedback test

ActiveCN105605032BRealize the loadRealize functionFluid-pressure actuator testingHydraulic cylinderDifferential pressure

The invention belongs to the field of aerospace servo valve testing, in particular to a dynamic loading device for servo valve dynamic pressure feedback testing, which includes a dynamic loading cylinder, a displacement sensor, a speed sensor, a pressure sensor, a loading servo valve, a servo valve to be tested and a dynamic loading device. Pressure feedback tester; there is a piston rod in the dynamic loading cylinder, a piston is arranged in the middle of the piston rod, and four cavities are formed by the piston rod, the piston and the inner wall of the dynamic loading cylinder. The present invention adopts a dynamic loading cylinder designed with four cavities, and installs speed sensors, displacement sensors and pressure sensors on the four cavities of the cylinder respectively, so that the load pressure difference loading and state detection functions can be realized at the same time; at the same time, the servo loading dynamic The closed-loop control of the hydraulic cylinder maintains the stability of the load pressure difference, improves the efficiency and accuracy of the dynamic pressure feedback test, and provides guarantee for the production of the dynamic pressure feedback servo valve.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

A high-pressure dynamic sealing test device for rubber rings under extreme conditions

ActiveCN105628309BImplement synchronous testingEasy to assembleMeasurement of fluid loss/gain rateRubber ringReciprocating motion

The invention provides a rubber ring high pressure dynamic sealing test device under extreme conditions, and belongs to the technical field of aerospace and mechanical engineering. The rubber ring high pressure dynamic sealing test device under the extreme conditions comprises a reciprocating movement test machine, a high pressure inflator, a gas flowmeter, a heating device, a refrigeration device and a test implementation body. Frictional force, displacement, temperature and gas leakage can be synchronously measured under sealed high pressure dynamic reciprocating movement of a rubber ring in the extreme conditions. The effects and the benefits of the rubber ring high pressure dynamic sealing test device under the extreme conditions are that dynamic sealing performance testing of the rubber ring under different extreme conditions (high pressure, high temperature and low temperature) can be realized. The device has the characteristics of being easy and convenient to assemble and flexible and easy to use.

Owner:DALIAN UNIV OF TECH

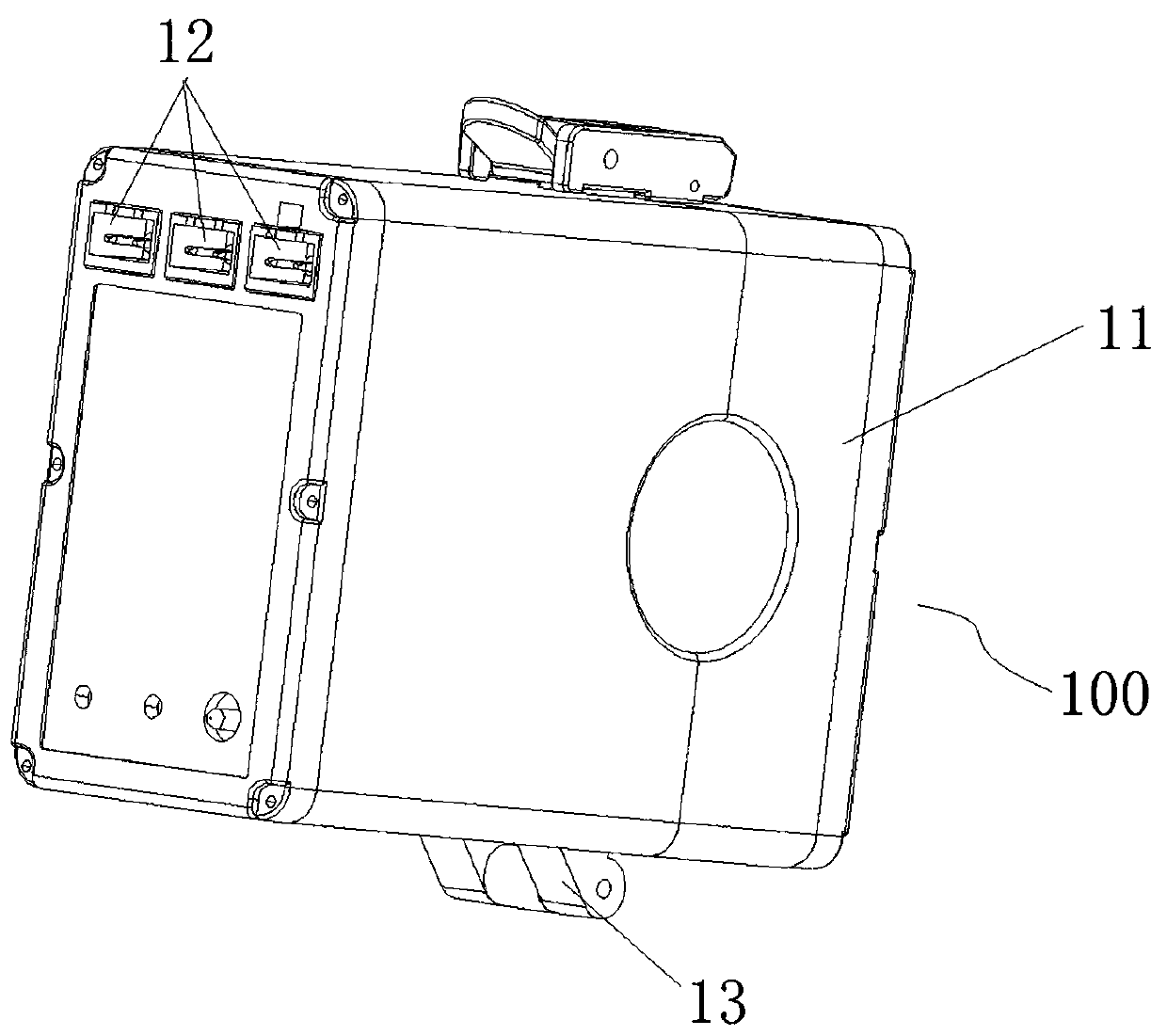

Test tool for low-voltage branch monitoring unit

PendingCN110824403AAvoid accidental injuryImprove test efficiencyElectrical measurementsEngineeringStructural engineering

The invention relates to the technical field of finished product detection, in particular to a test tool for a low-voltage branch monitoring unit. The test tool comprises a base which is provided witha supporting plane; a linear driving member; a mounting base which is fixedly arranged at the linear output end of the linear driving part, wherein test terminals are fixedly arranged on the mountingbase, and the number and the arrangement mode of the test terminals are consistent with the number and the arrangement mode of terminal bases in the low-voltage branch monitoring unit; a back surfacelimiting part which is fixedly arranged on the base, is positioned beside the supporting plane, is spaced from the linear output end in the moving direction of the linear output end, and is used forbeing matched with the back surface, back to the terminal bases, in the low-voltage branch monitoring unit in a stopping manner; a side surface limiting part which is arranged beside the supporting plane and is used for being matched with the side surface, adjacent to the back surface, in the low-voltage branch monitoring unit in a stopping manner; wherein the back limiting part, the side limitingpart and the supporting plane are matched to position and place the low-voltage branch monitoring unit on the base.

Owner:HENAN HUASHENGLONGYUAN ELECTRICAL CO LTD

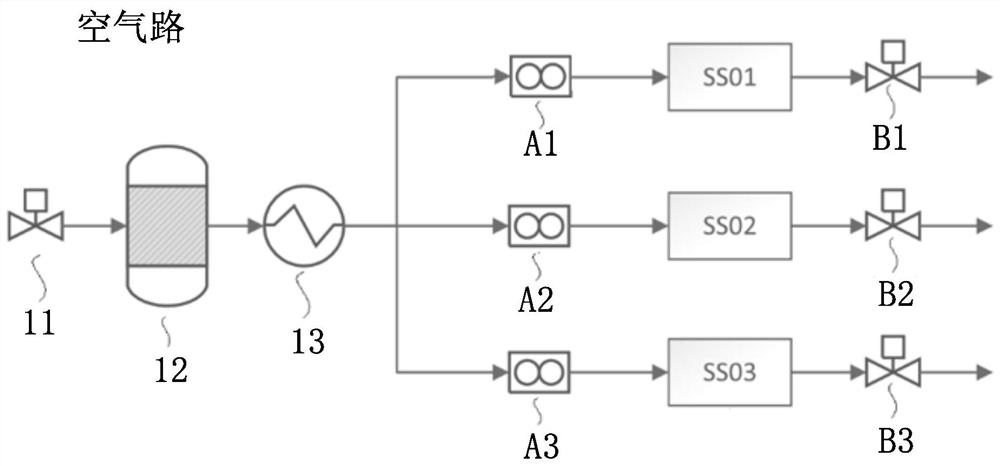

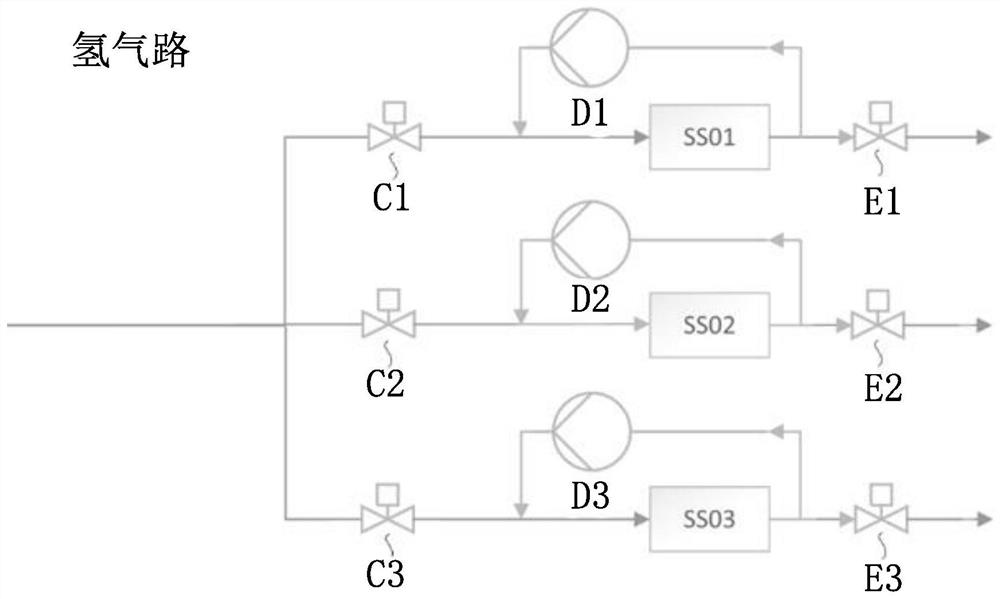

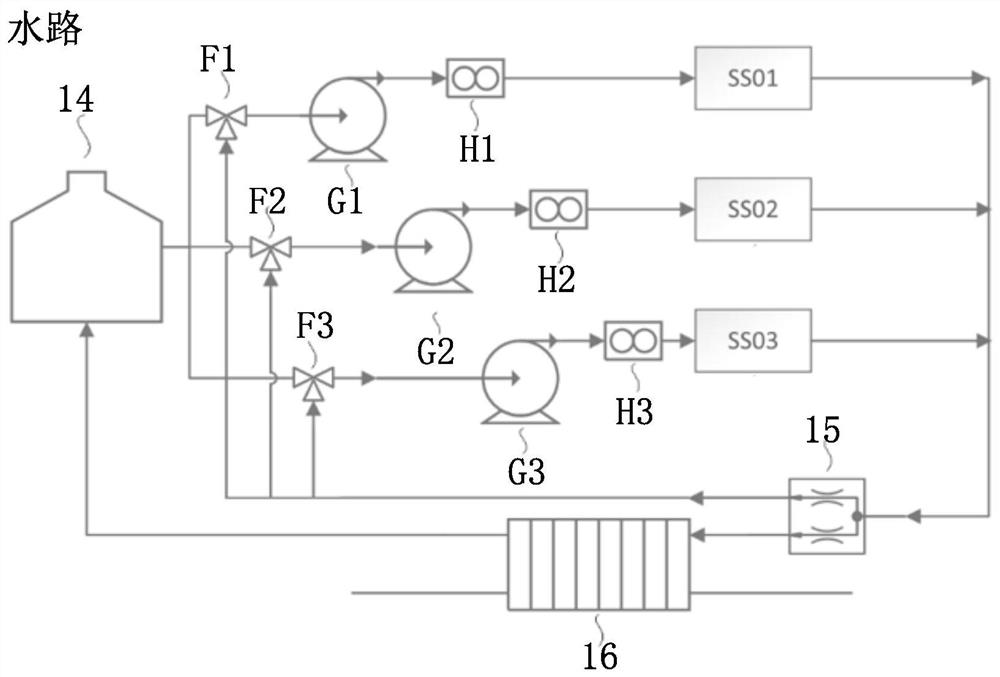

A multi-working-condition multi-sample fuel cell stack testing system and its control method

ActiveCN111916791BImplement synchronous testingAvoid interactionReactant parameters controlElectrical testingFuel cellsControl engineering

Owner:SHANGHAI HYDROGEN PROPULSION TECH CO LTD

A reciprocating friction power generation output performance and friction coefficient synchronous testing device

ActiveCN107655823BImplement synchronous testingMaterial analysis by electric/magnetic meansUsing mechanical meansCantilevered beamElectricity

The invention discloses a device for synchronously testing a reciprocating type friction power generation output property and a friction coefficient. A to-be-tested upper friction pair is arranged atthe front end, which is connected with a cantilever beam, of a cantilever beam supporting rack; a strain gage is arranged on the cantilever beam; a lower friction pair is arranged on a moving block ifa magnetic shaft linear motor and is positioned under the upper friction pair; the lower friction pair which is driven by the magnetic shaft linear motor to linearly move in a reciprocating manner relative to the static upper friction pair; current and voltage signals of friction power generation are output to a control and test computer; and meanwhile, the strain gage synchronously outputs the friction signals of the upper friction pair and the lower friction pair to the control and test computer. Because the control and test computer simultaneously acquires the current and voltage signals generated by friction power generation of the upper friction pair and the lower friction pair and friction signals, synchronous test on the friction power generation output property and the friction coefficient is realized; influence of interface friction behaviors to the friction power generation output property is discovered favorably; and the mechanism of action of the interface friction behaviors to an electric output property is facilitated.

Owner:SHENZHEN UNIV

Portable cardiopulmonary detection training instrument

InactiveCN109770876AEasy to carryEasy to transportDiagnostic recording/measuringSensorsWireless transmissionRate parameter

The invention discloses a portable cardiopulmonary detection training instrument. The training instrument comprises a heat rate collector, a breath collector, a data analyzer and a wireless transmission module. The data analyzer is in signal connection with the heart rate collector, the breath collector and the wireless transmission module. The heart rate collector collects heart rate parameters and outputs the heat rate parameters to the data analyzer; the breath collector collects breath parameters and outputs the breath parameters to the data analyzer; a calculation unit, a storage unit anda drawing unit are arranged in the data analyzer. The calculation unit analyzes the heart rate parameters and the breath parameters and outputs heart rate analyzing data and breath analyzing data; the drawing unit reads the heart rate analyzing data and the breath analyzing data which are output by the calculation unit to generate a breath parameter curve graph and a heart rate curve graph. The wireless transmission module is used for data sharing and remote analyzing management. The instrument can synchronously detect the heart rate and the breath. Through real-time signal interaction, reference advice is provided for cardiopulmonary training. Telemedicine is achieved.

Owner:苏州康予德生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com