Stress test jig for magnetic material

A magnetic material and stress testing technology, applied in the direction of force/torque/power measuring instruments, measuring devices, instruments, etc., can solve the problems of low work efficiency, high cost, time-consuming and laborious, etc., and achieve reasonable structural design and high work efficiency , the effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

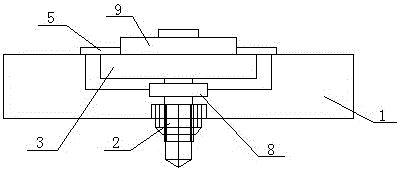

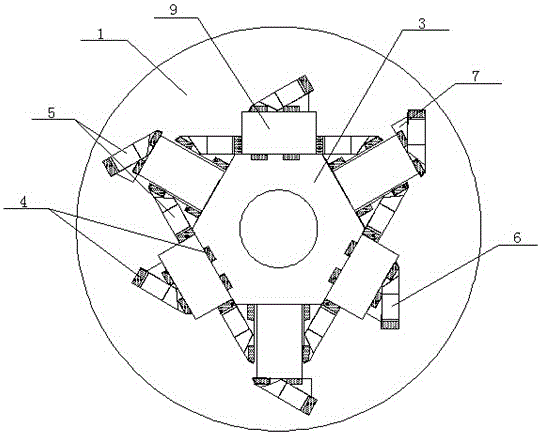

[0016] Such as figure 1 and figure 2 A magnetic material stress test fixture shown includes a test base 1, a test fixture 3 and a plurality of test blocks 5. The middle part of the test base 1 is locked with a pin 2 to install a test fixture 3. The test fixture 3 is a regular polygon. structure, each side of the regular polygon test fixture 3 is provided with at least one test point 4, a plurality of test stoppers 5 are pressed against the magnetic material 9 and fixed on the test fixture 3, and a single test stopper 5 is composed of a trapezoidal block 6 and a triangular block 7 are superimposed, and the two sides of the trapezoidal block 6 and the side of the triangular block 7 are provided with test points 4, and the test fixture 3 and the test points 4 on the test block 4 are connected to the test substrate 1 through the test line.

[0017] In the present embodiment, the opposite surfaces between a plurality of magnetic materials 9 share a test block 5. When the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com