Patents

Literature

248 results about "Torque coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for calculating torque required by electric automobile driver

InactiveCN103935264AReduce economic downturnsMeet dynamic needsSpeed controllerData processing managementMaximum torqueDriver/operator

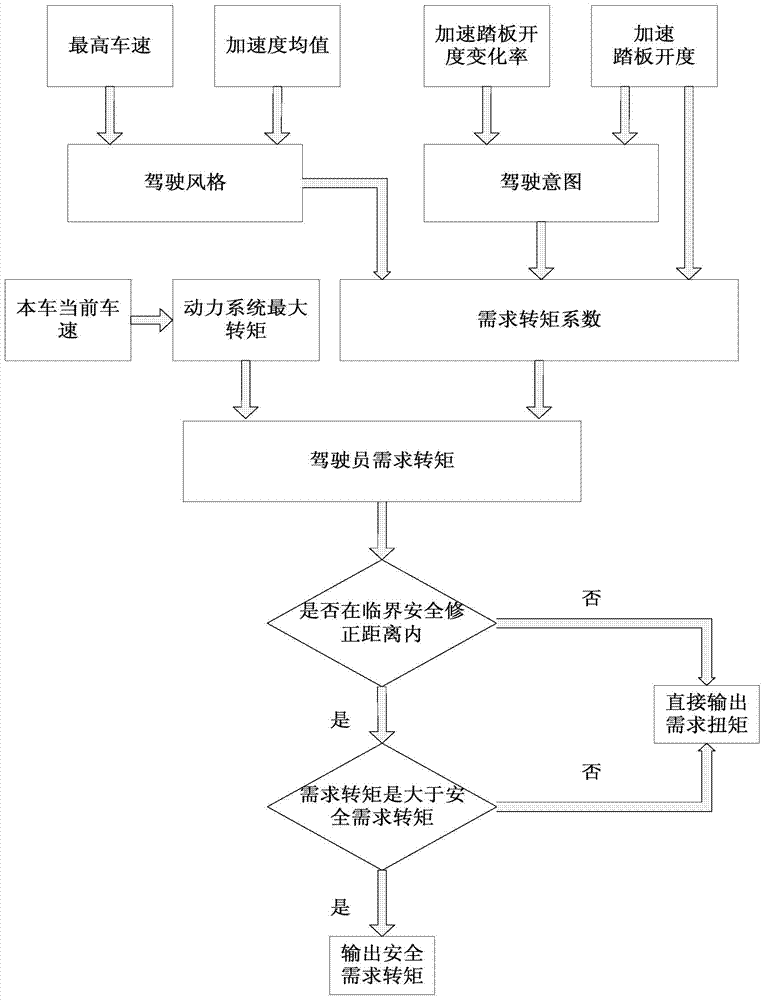

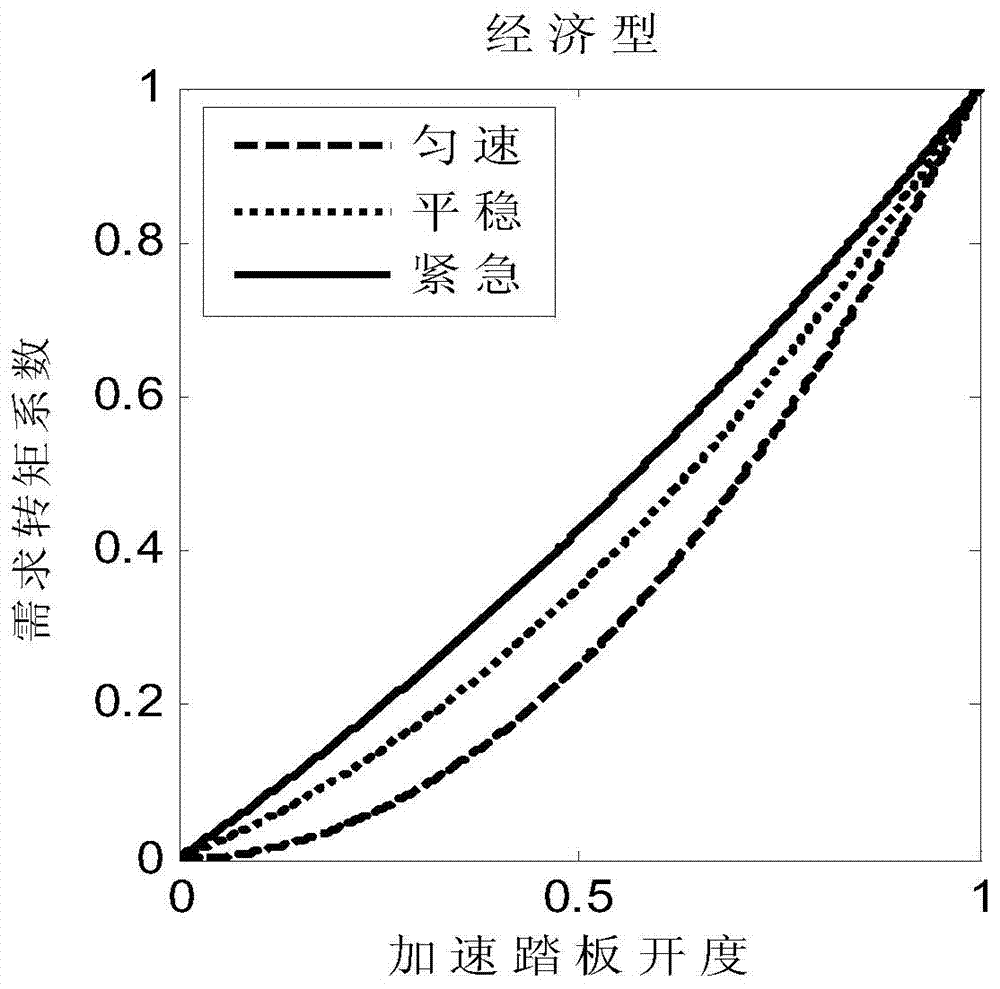

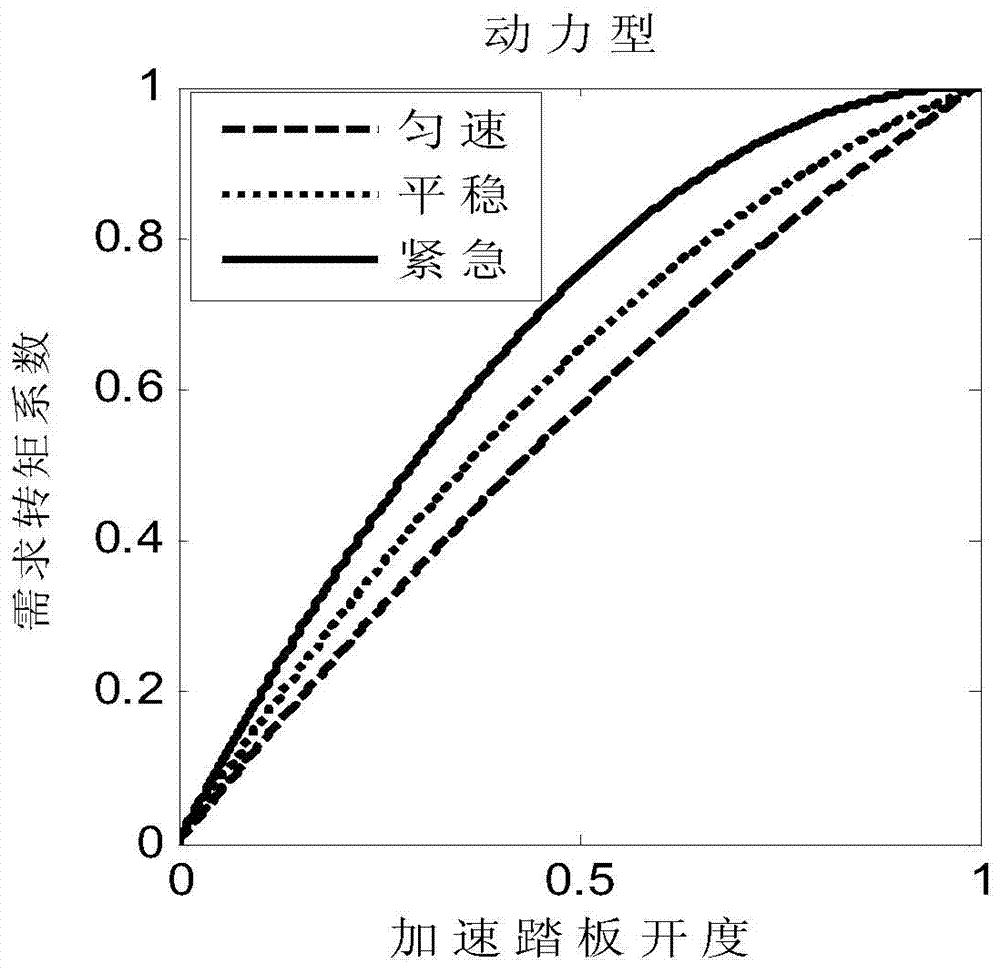

The invention discloses a method for calculating the torque required by an electric automobile driver. The method includes the following steps that the style of the driver and the driving intension of the driver are detected, and the required torque is calculated; the safe interval is detected, and safety modification is conducted on the required torque. According to the method, the driving style and the driving intention of the driver are recognized, torque coefficients required under different styles and different intentions are adjusted, and therefore power is obviously improved for a dynamical type driver under the situation the opening degree does not approach the opening degree of a saturated accelerator pedal, power changes are gentle for an economical type driver under the situation of the normal small pedal opening degree, the situation that economical efficiency is reduced when the load changes of a power system are overlarge is easily reduced, the required torque can be increased according to the emergency degree of acceleration, and the instant requirement of the driver for the dynamic property of the automobile is met. Due to the fact that the maximum torque required by the driver is limited within the critical safety modification distance, when the calculation result is smaller than zero, the torque required by automobile power is forced to reset; the automobile can safely run after other automobiles, and tailgating traffic accidents are avoided.

Owner:DALIAN UNIV OF TECH

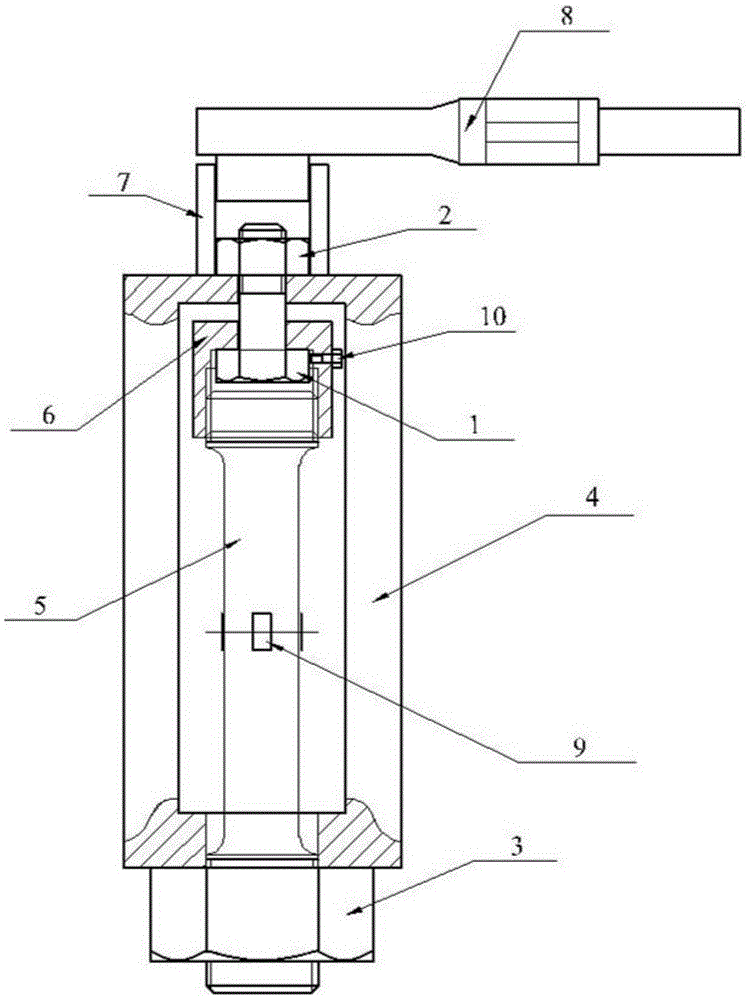

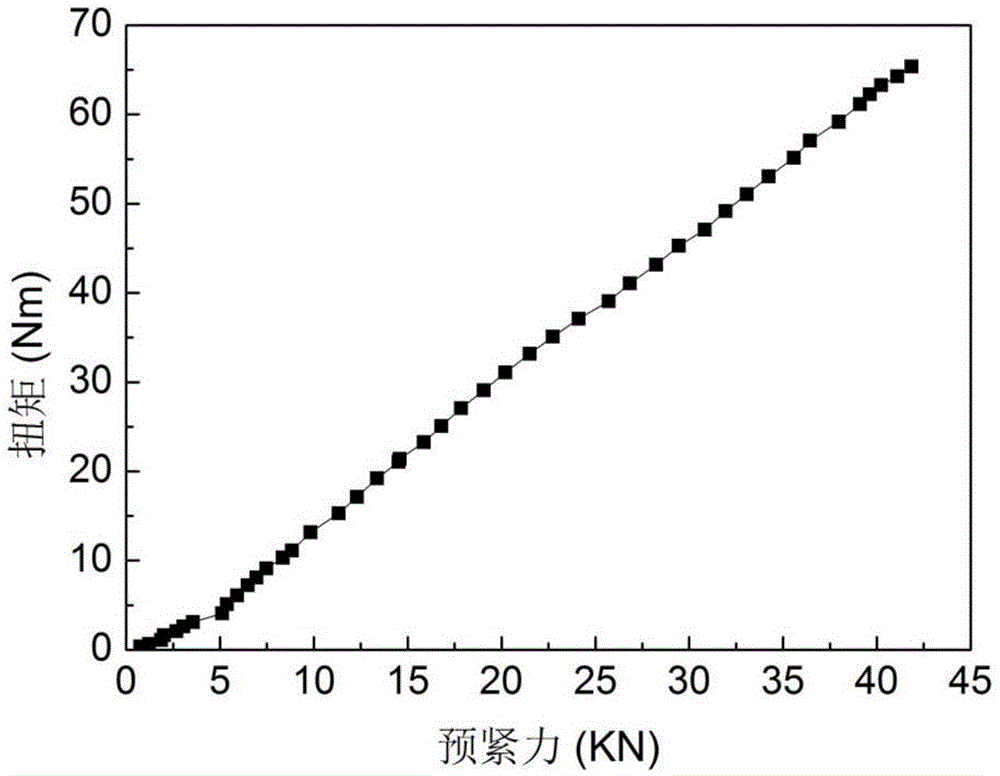

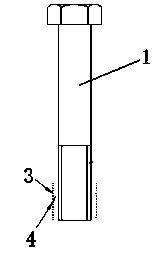

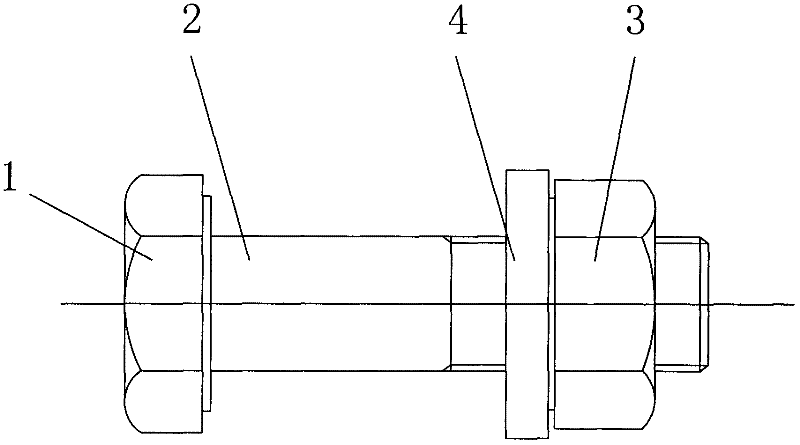

Bolt tightening torque coefficient measuring device

InactiveCN105606289AEasy to operateLow costMeasurement of torque/twisting force while tighteningTorque coefficientStrain gauge

The invention provides a bolt tightening torque coefficient measuring device. The bolt tightening torque coefficient measuring device includes a main body, a first sleeve, a second sleeve, a screw, a bolt to be measured, a nut, a stop screw, foil gauges and a torque spanner, wherein the internal of the main body is a hollow cavity; the hollow cavity sleeves the first sleeve coaxially; the main body is in clearance fit with the first sleeve; threaded holes are formed axially in both the main body and the first sleeve; one end of the bolt to be measured penetrates through the threaded holes in the main body and the first sleeve, and then is in threaded connection with the nut; the screw is in threaded connection with the first sleeve; the foil gauges are uniformly arranged on the screw in the circumferential direction; one end of the screw is connected with the bolt to be measured, and pre-tightens and fixes the bolt to be measured through the stop screw; and the other end of the screw is connected with an adjusting screw nut. The bolt tightening torque coefficient measuring device provides a simple and reliable measuring method for determination of a bolt tightening torque coefficient for engineering practice, and has guiding function for applying suitable pre-tightening force to the bolt.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

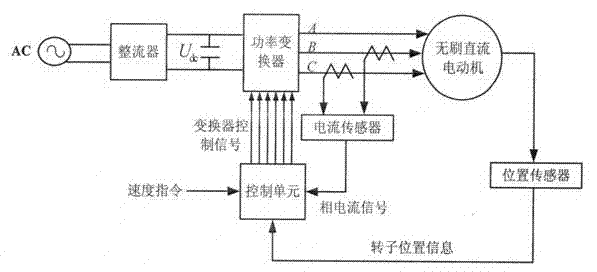

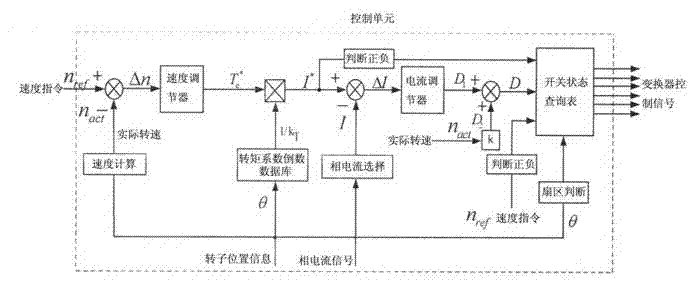

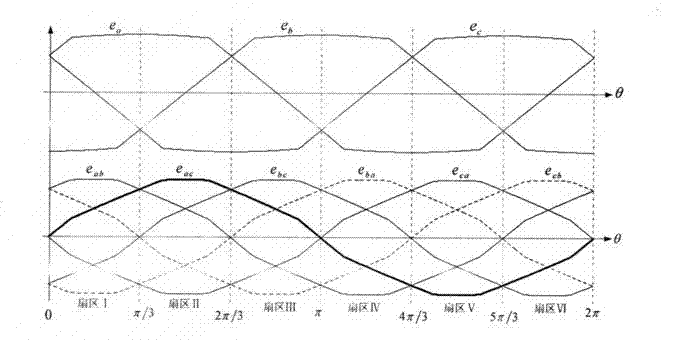

Instantaneous torque control method of brushless direct-current motor based on direct-current control

InactiveCN102780433AImprove rate of changeRealize four-quadrant operationTorque ripple controlPhase currentsReference current

The invention discloses an instantaneous torque control method of a brushless direct-current motor based on direct-current control. The control method comprises the following steps: a two-phase current value of the motor is detected by using a current sensor and a current value of another phase is calculated; a rotor position of the motor is detected by using a position sensor; the instantaneous torque required at present is obtained through calculation and comparison; an optimal reference current is obtained through a torque coefficient reciprocal database in combination with the rotor position; the optimal reference current is compared with a current obtained through the selection so as to obtain a duty ratio D1; the duty ratio D1 is added to a duty ratio D2 corresponding to a counter potential of which the rotate speed is in direct ratio so as to obtain a final duty ratio D; the final duty ratio D, a rotate speed instruction, the negative and positive of the optimal reference current and rotor position information are input into a switch state checking table together; a corresponding switch mode is selected to drive the brushless direct-current motor to operate, thus the four-quadrant operation of the brushless direct-current motor is realized, the control to the rotate speed of the motor and the instantaneous torque is realized, and the purpose of suppressing an electromagnetic torque pulsation of the brushless direct-current motor is achieved.

Owner:YANSHAN UNIV

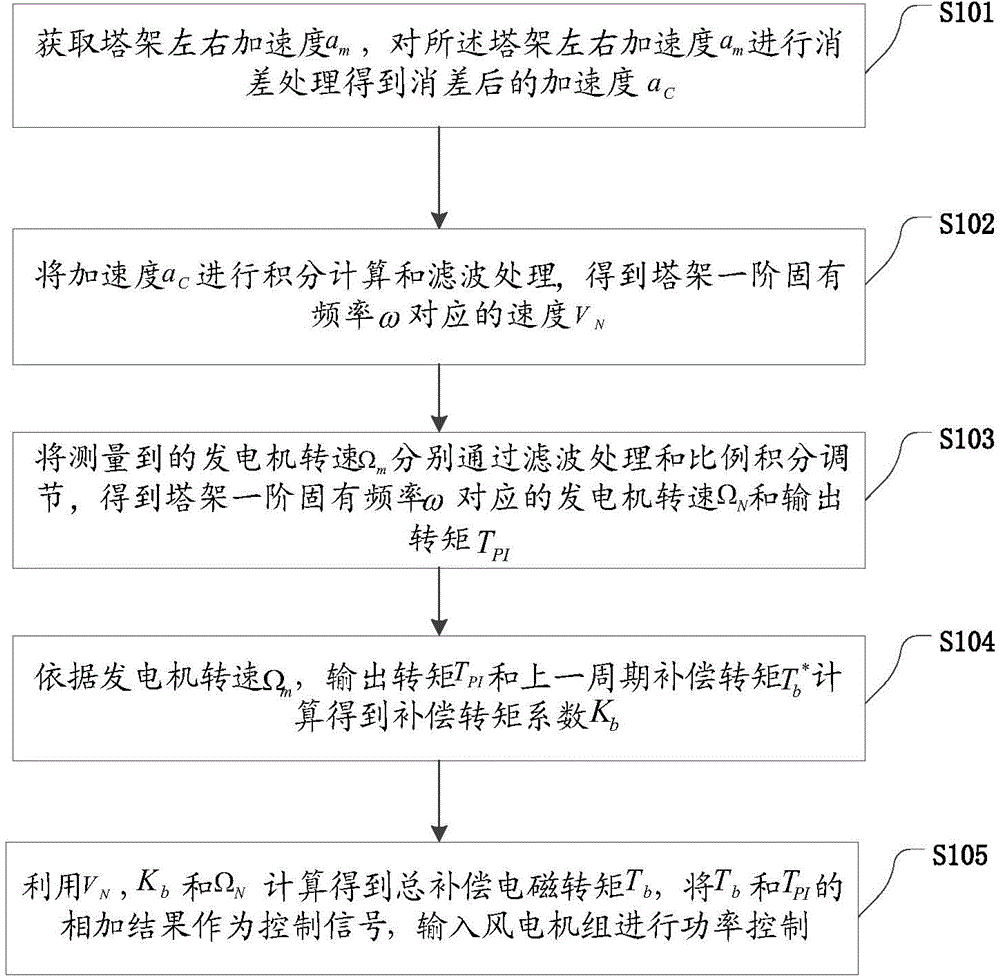

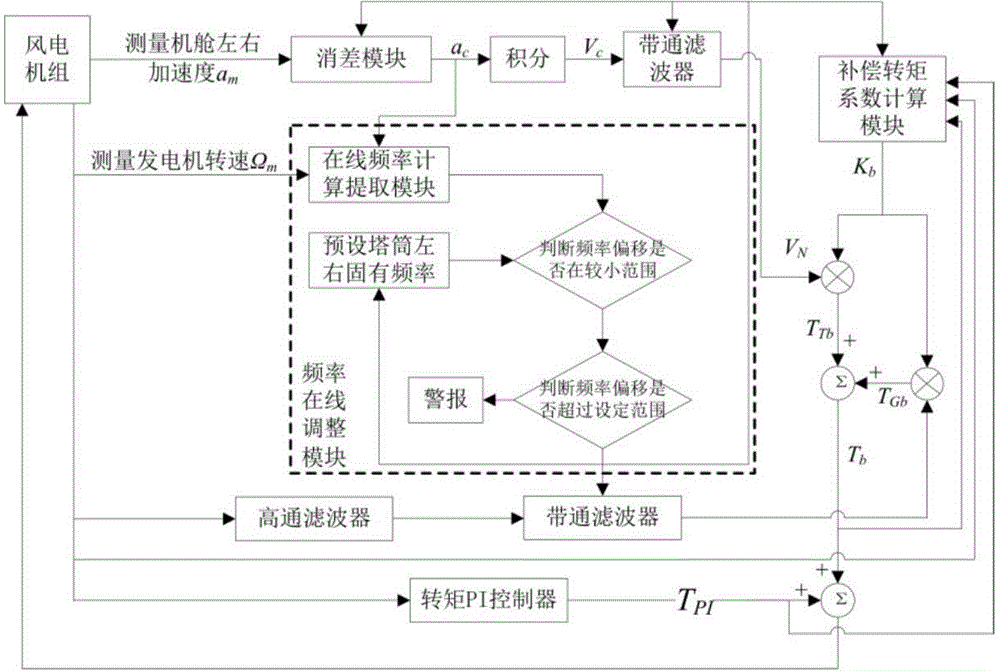

Control method and device for inhibiting side-to-side vibration of tower of wind generating set

ActiveCN104533732AMeet the needs of the control objectivesAvoid the influence of compensating torqueWind motor controlEngine fuctionsElectricityControl signal

The invention discloses a control method and device for inhibiting the side-to-side vibration of a tower of a wind generating set. The method comprises the following steps: obtaining a side-to-side acceleration am of the tower, and performing error elimination treatment on the side-to-side acceleration am of the tower to obtain an error-eliminated acceleration ac; performing integral computation and filtering treatment on the acceleration ac to obtain a speed VN corresponding to the first-order inherent frequency omega of the tower; performing filtering treatment on a measured generator speed Omegam, and then performing proportional-integral adjustment to obtain a generator speed OmegaN corresponding to the first-order inherent frequency omega of the tower, and an output torque TPI; calculating a compensation torque coefficient Kb from the output torque TPI and the previous-cycle compensation torque Tb* according to the generator speed Omegam; and calculating a total compensation electromagnetic torque Tb from the Kb and the OmegaN by use of the VN, and inputting the sum of the Tb and the TPI into the wind generating set as a control signal for power control. According to the method, the impact of the compensation torque on the output power is reduced, and the control effect on inhibiting the side-to-side vibration of the tower is improved.

Owner:新疆海装风电设备有限公司

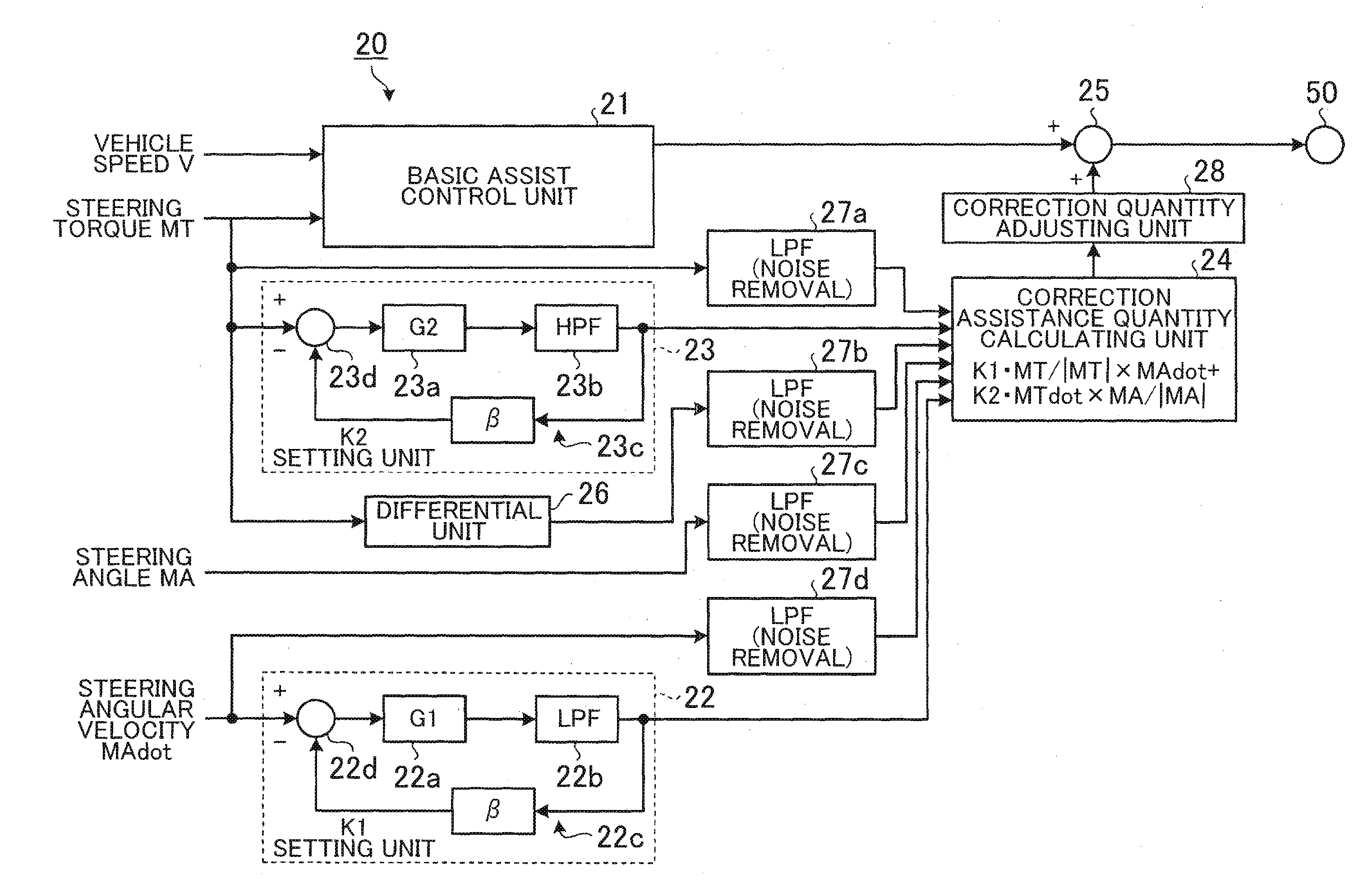

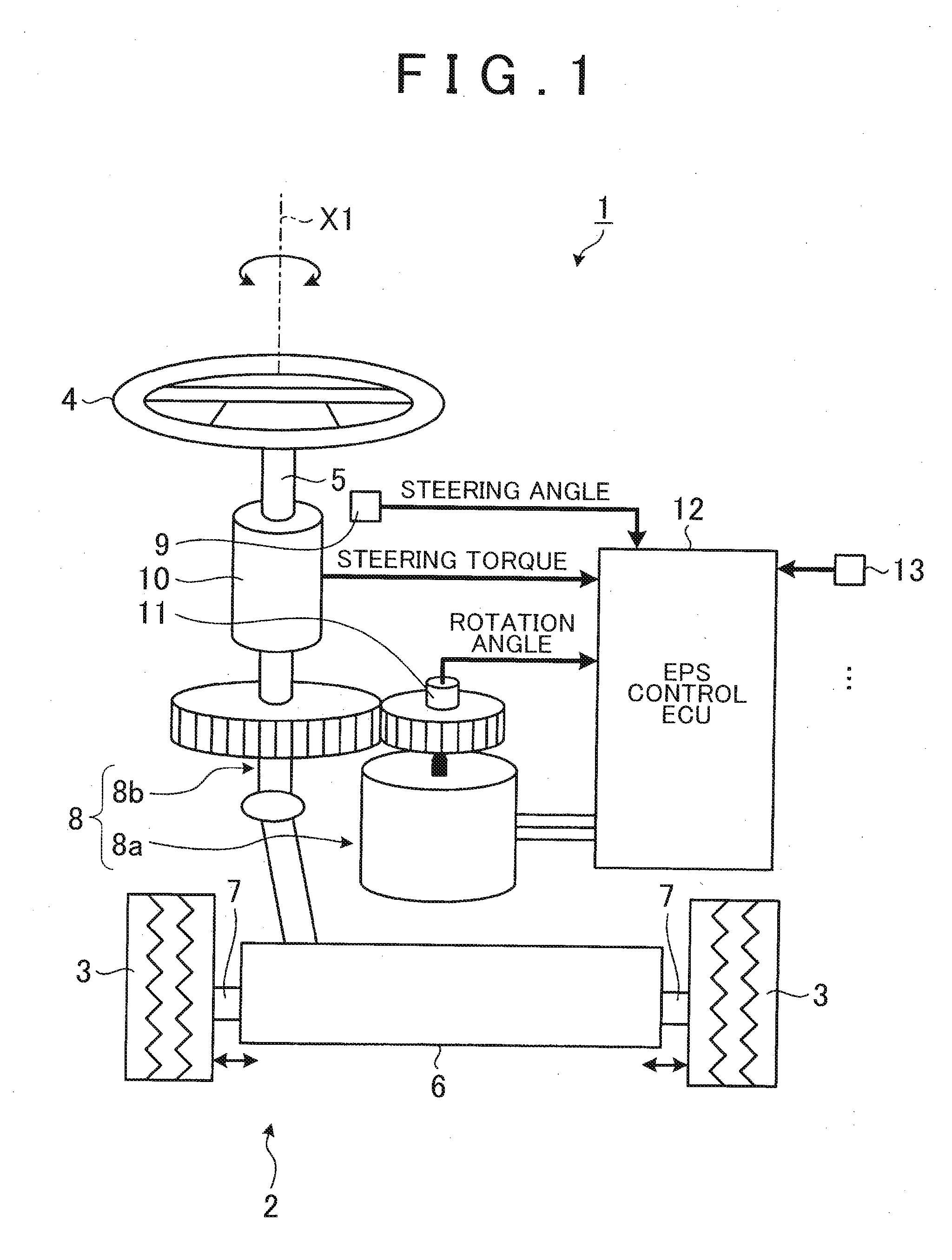

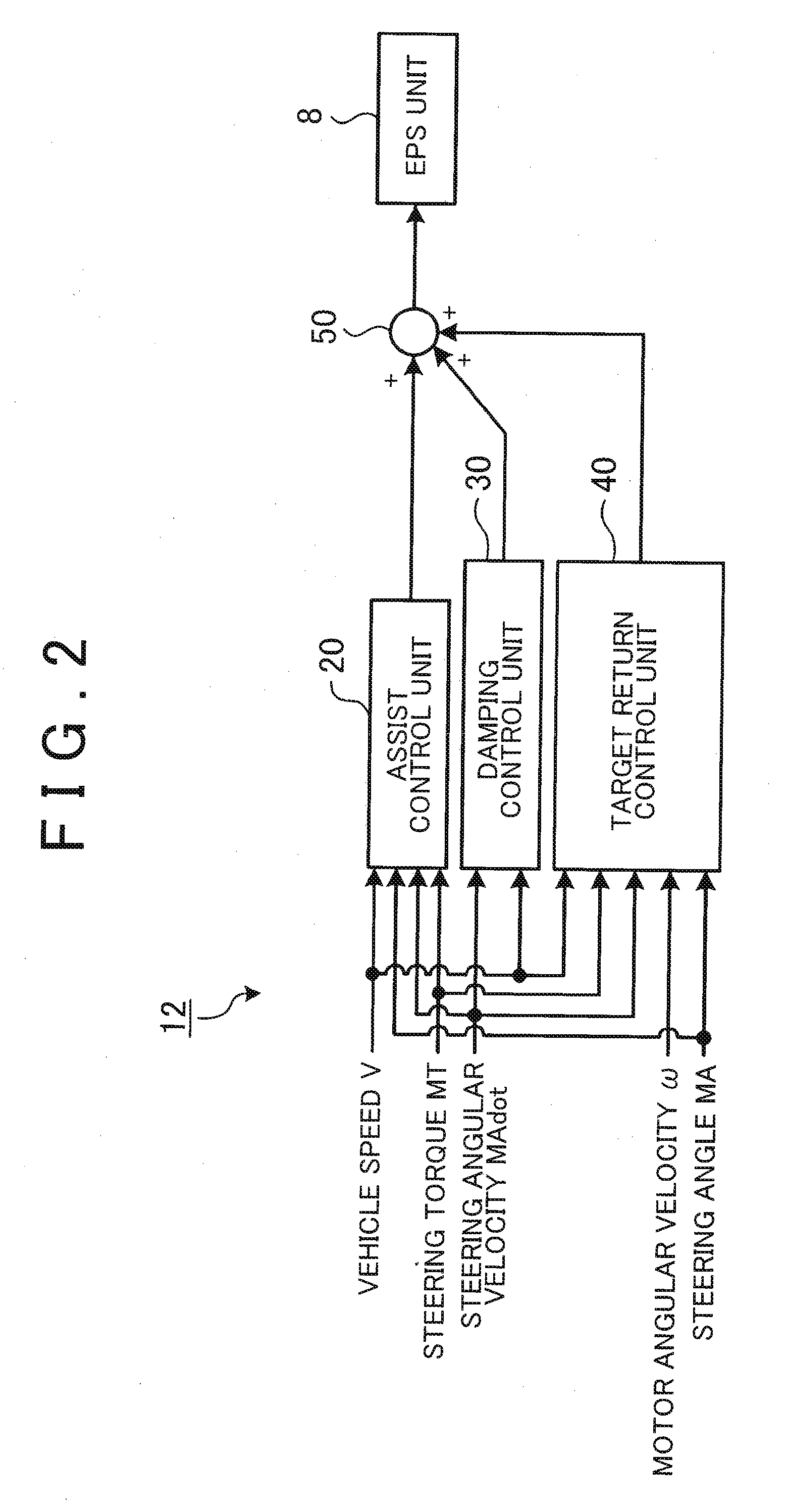

Steering apparatus and steering controller

ActiveUS20160200354A1Improve overall senseDigital data processing detailsSteering initiationsNegative feedbackAngular velocity

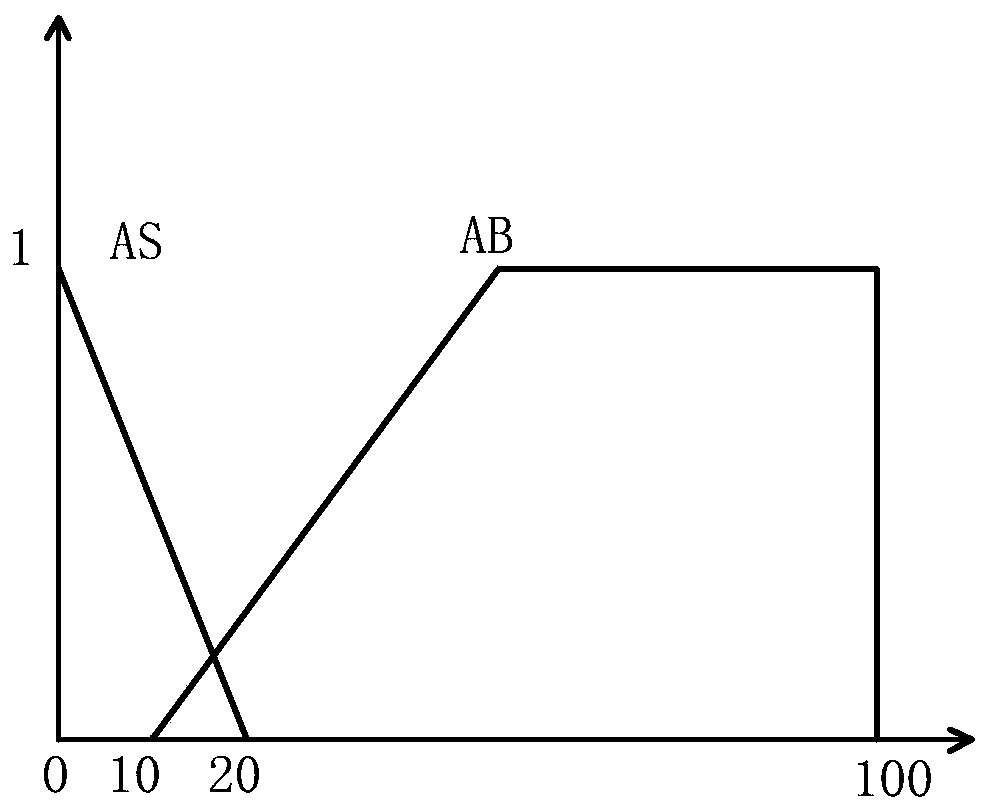

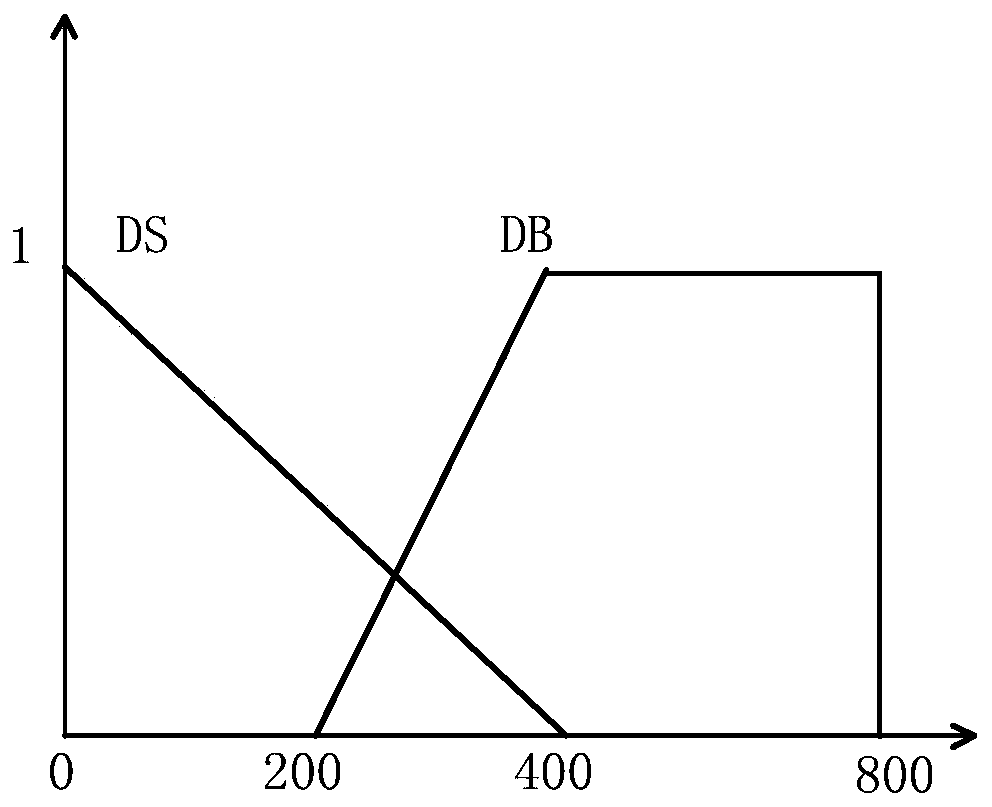

A controller of a steering apparatus includes a calculating unit that calculates a correction assistance quantity based on a steering angular velocity coefficient and a torque coefficient, a steering angular velocity coefficient setting unit that sets the steering angular velocity coefficient depending on a steering angular velocity and that sets the steering angular velocity coefficient to become larger as a feedback quantity of a negative feedback unit becomes larger, and a torque coefficient setting unit that sets the torque coefficient depending on a steering torque and that sets the torque coefficient to become larger as the feedback quantity of the negative feedback unit becomes larger. The feedback quantity of the torque coefficient setting unit when the steering torque is in a predetermined high-frequency range is larger than the feedback quantity of the steering angular velocity coefficient setting unit when the steering angular velocity is in a predetermined high-frequency range.

Owner:TOYOTA JIDOSHA KK

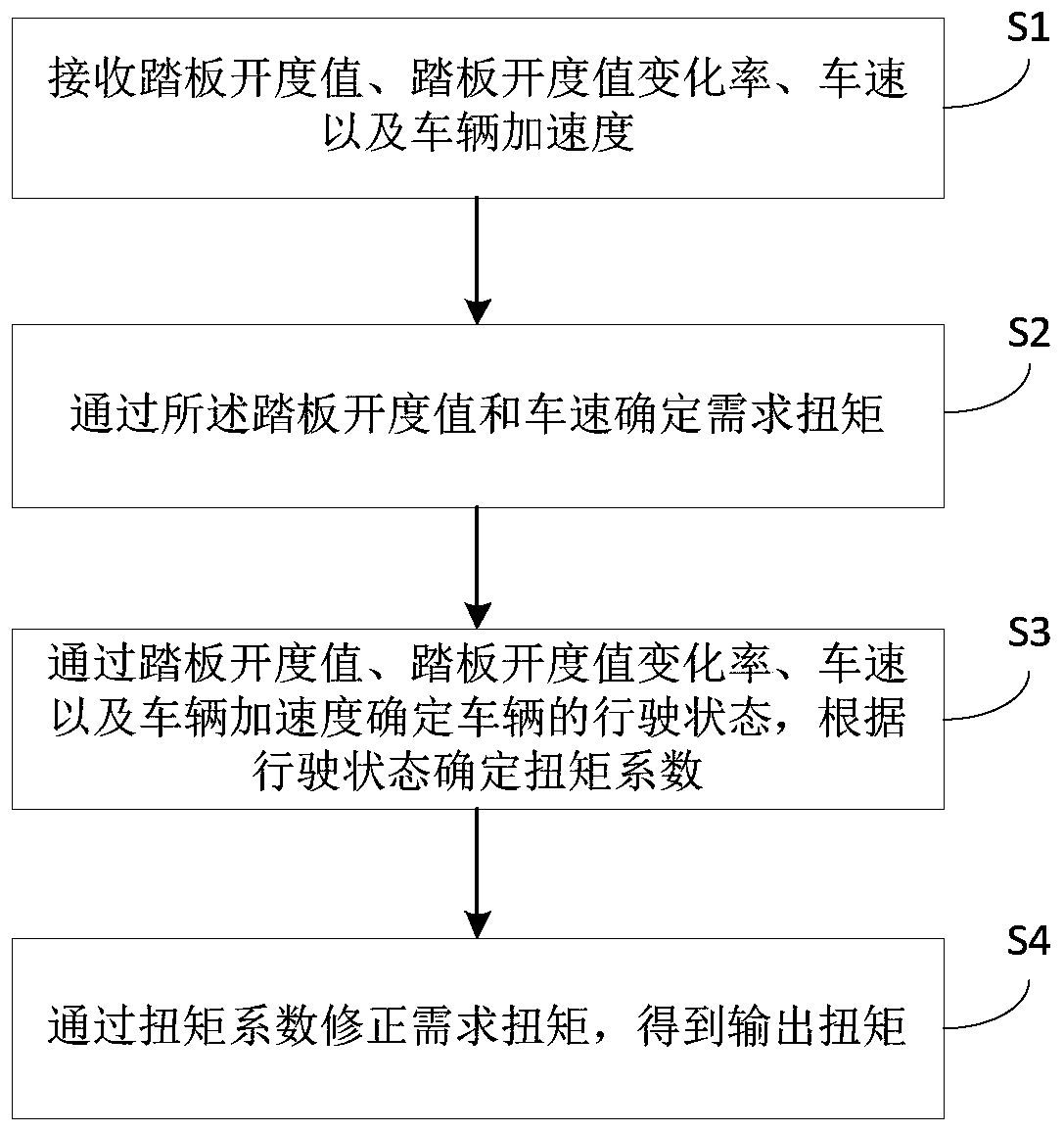

Single-pedal control method, device and system for electric automobile

ActiveCN111098717AIncrease redundancyAvoid introducingSpeed controllerElectric energy managementDriver/operatorControl system

The invention discloses a single-pedal control method, device and system of an electric automobile. The single-pedal control method comprises steps of receiving a pedal opening value, a pedal openingvalue change rate, a vehicle speed and a vehicle acceleration; determining a required torque according to the pedal opening value and the vehicle speed; determining a driving state of the vehicle according to the pedal opening value, the pedal opening value change rate, the vehicle speed and the vehicle acceleration, and determining a torque coefficient according to the driving state; and correcting the required torque through the torque coefficient to obtain an output torque. The single-pedal control method is advantaged in that two auxiliary input parameters, namely the pedal opening value change rate and the vehicle acceleration, are increased, redundancy of a control system is increased, the change rate of the pedal opening degree and the speed is considered, so the finally output torque is closer to the operation intention of a driver in a current vehicle driving state, and driving power performance of the electric vehicle is stable.

Owner:CHINA FIRST AUTOMOBILE

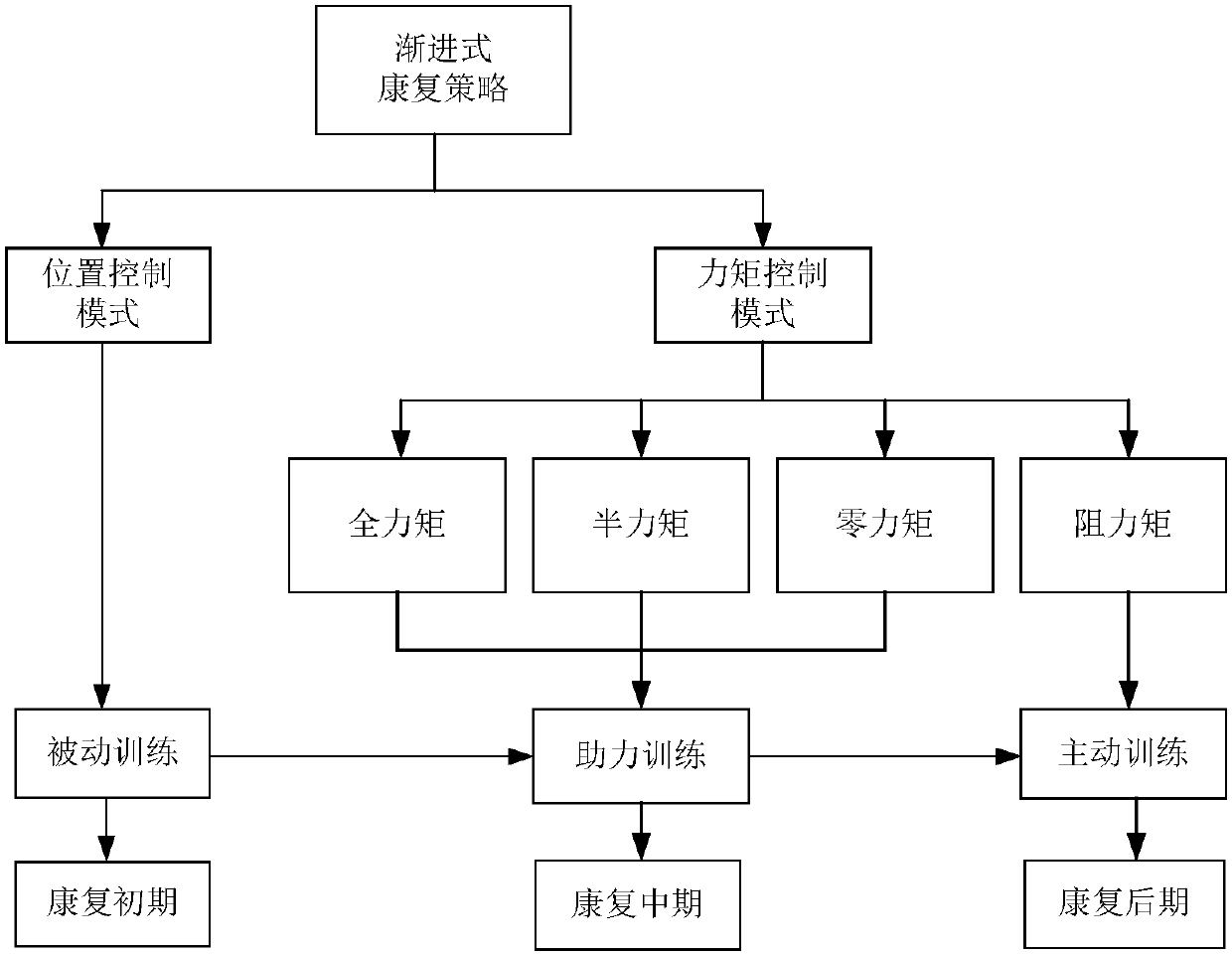

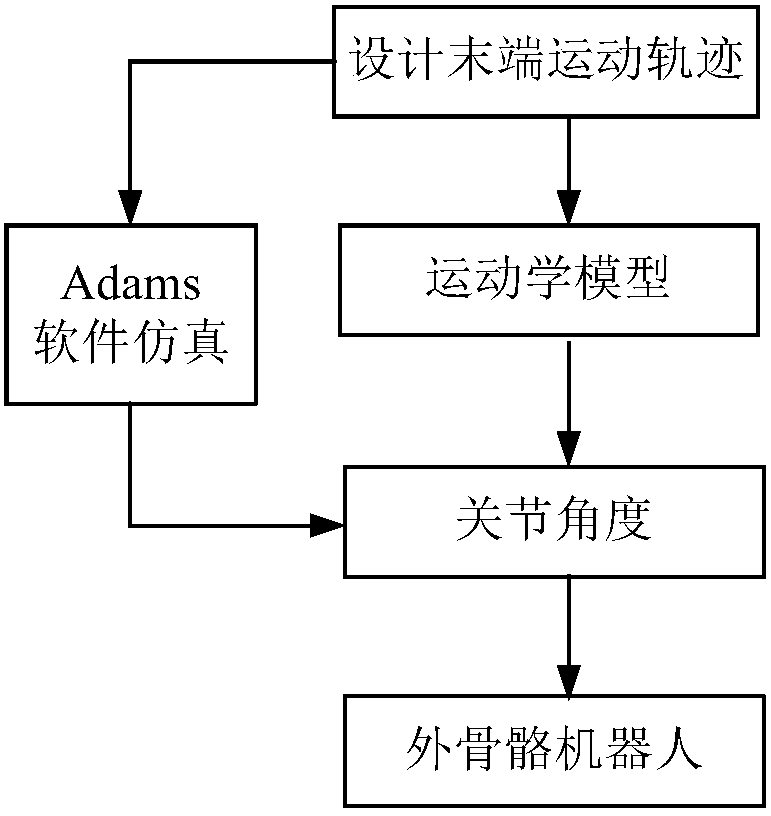

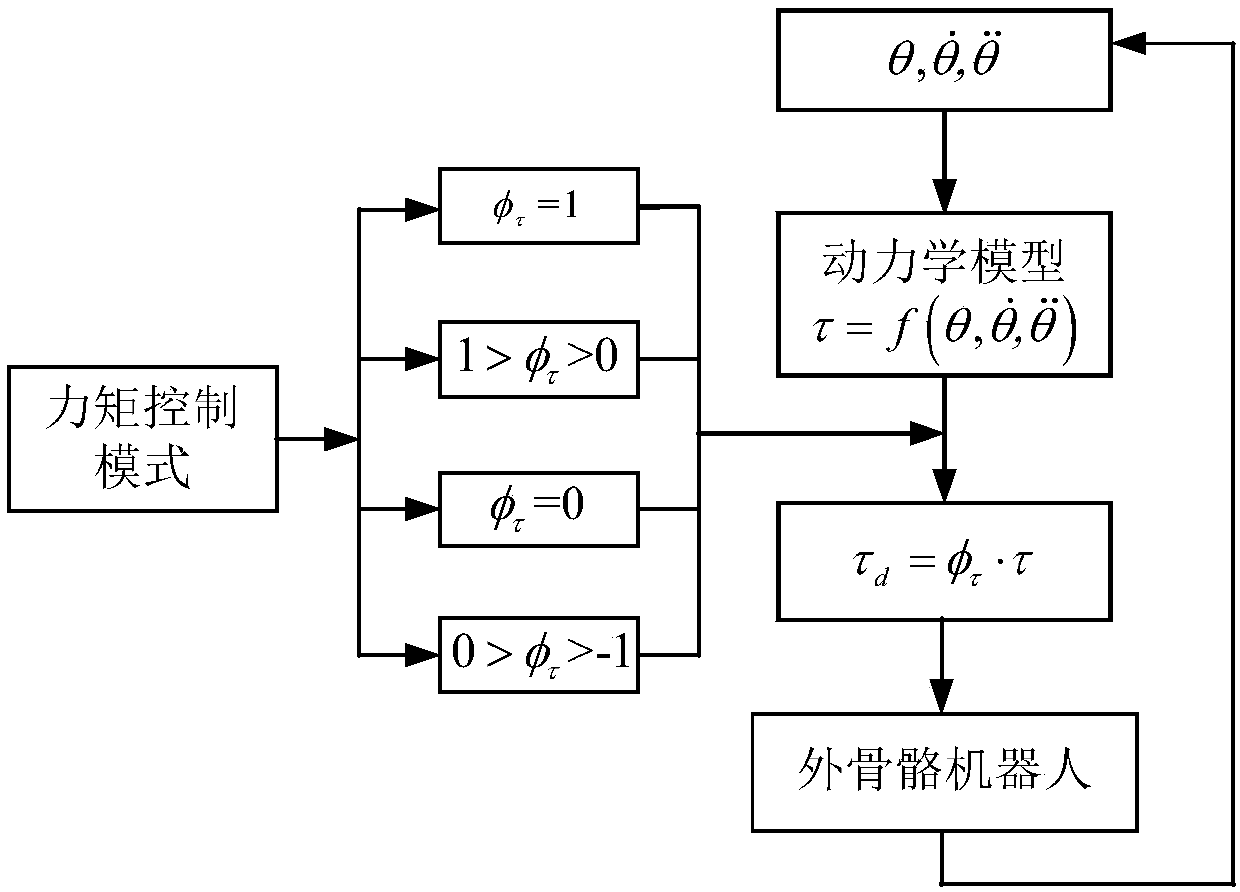

Progressive rehabilitation training method based on exoskeleton robot

ActiveCN108309689AIncrease mobilityPromote circulationChiropractic devicesMuscle exercising devicesExoskeleton robotPhysical medicine and rehabilitation

The invention provides a progressive rehabilitation training method based on an exoskeleton robot, and relates to a rehabilitation training method. In order to solve the problem that an existing training method cannot meet the different rehabilitation needs of patients with limb dysfunction in different periods, rehabilitation initial stage position control mode training and rehabilitation middle-late stage torque control mode training are divided according to different rehabilitation periods; the rehabilitation initial stage position control mode training is passive training based on trajectory traction, unilateral or bilateral limbs of a patient are tied to the exoskeleton robot, and the passive rehabilitation initial stage training is completely conducted under the traction of the exoskeleton robot; the rehabilitation middle-late stage torque control mode training utilizes a dynamic model for adjusting torque coefficients to obtain a torque value of a certain torque coefficient, andthe torque control mode training is gradually changed from full torque to half torque during the rehabilitation training period to further change into zero torque for assisted training of the patient; finally the resistance torque is obtained for active training of the patient. The method is used for patient rehabilitation training.

Owner:HARBIN INST OF TECH

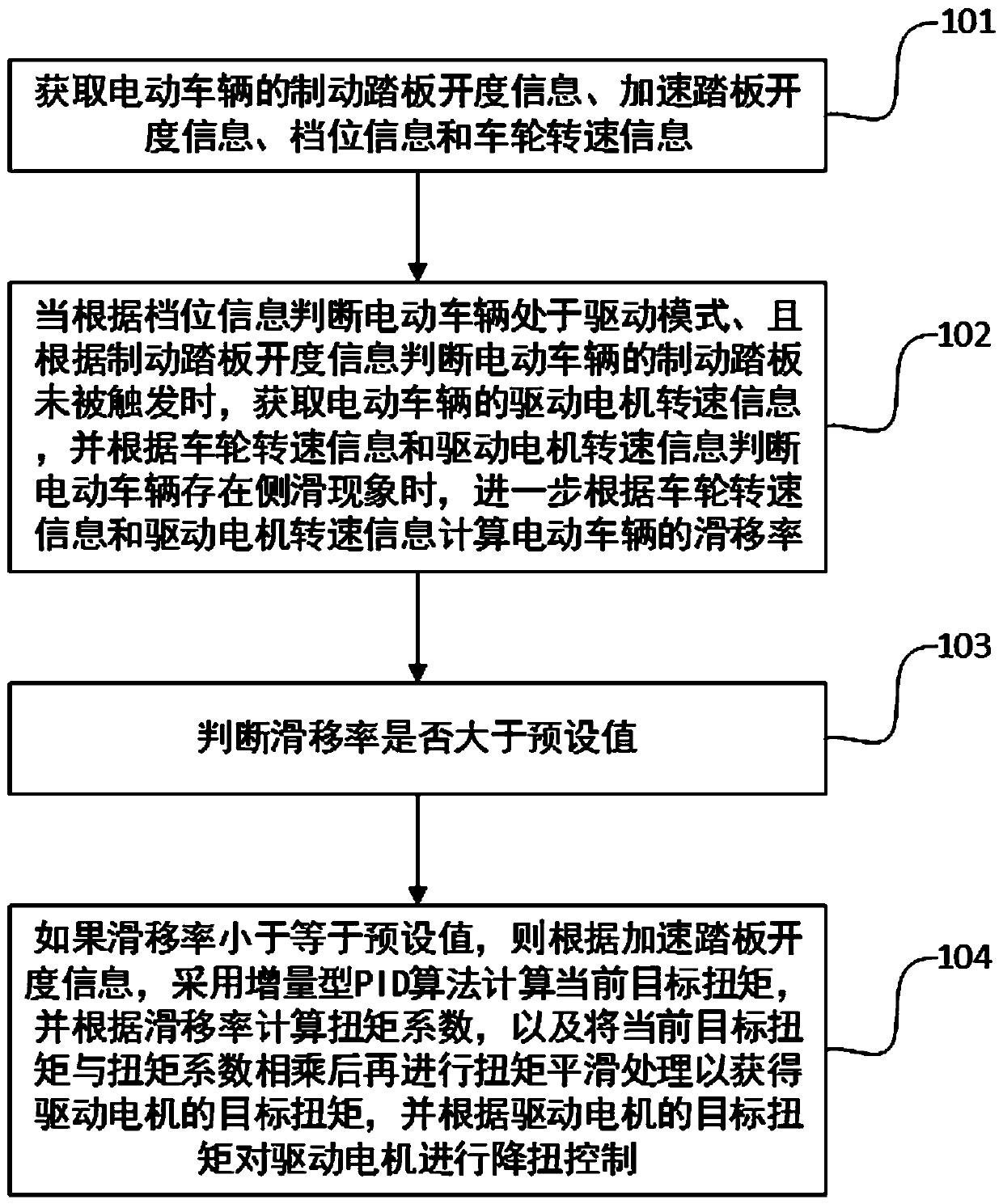

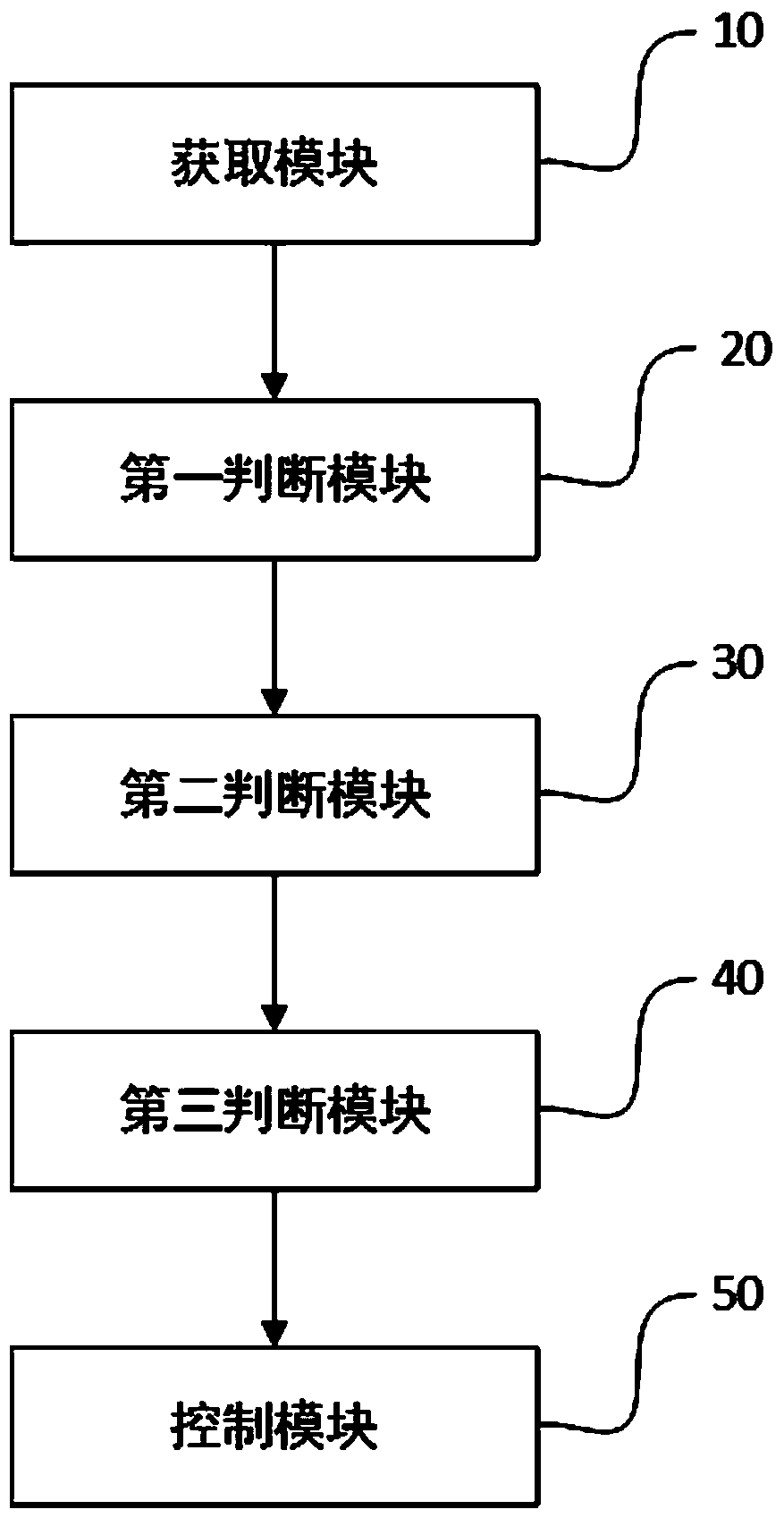

Driving anti-slip control method and control device for electric vehicle, medium and vehicle control unit

The invention discloses a driving anti-slip control method and control device of an electric vehicle, a medium, a vehicle control unit. The method comprises the following steps of acquiring vehicle information of an electric vehicle; when the electric vehicle is in a driving mode and a brake pedal is not triggered, acquiring the rotating speed information of the driving motor, and further calculating the slip rate when judging that the electric vehicle has a sideslip phenomenon; if the slip rate is smaller than or equal to the preset value, calculating a current target torque, calculating a torque coefficient according to the slip rate, carrying out torque smoothing processing to obtain a target torque of the driving motor, and carrying out torque reduction control on the driving motor according to the target torque of the driving motor. The motor torque can be intervened with through cooperation between the vehicle control unit and the motor controller, driving antislip control over the electric vehicle can be completed through the combination of a common PID algorithm and a torque smoothing algorithm, the process is simple and easy to implement, and it is possible that an ASR system can be widely applied to the electric vehicles.

Owner:厦门金龙汽车新能源科技有限公司

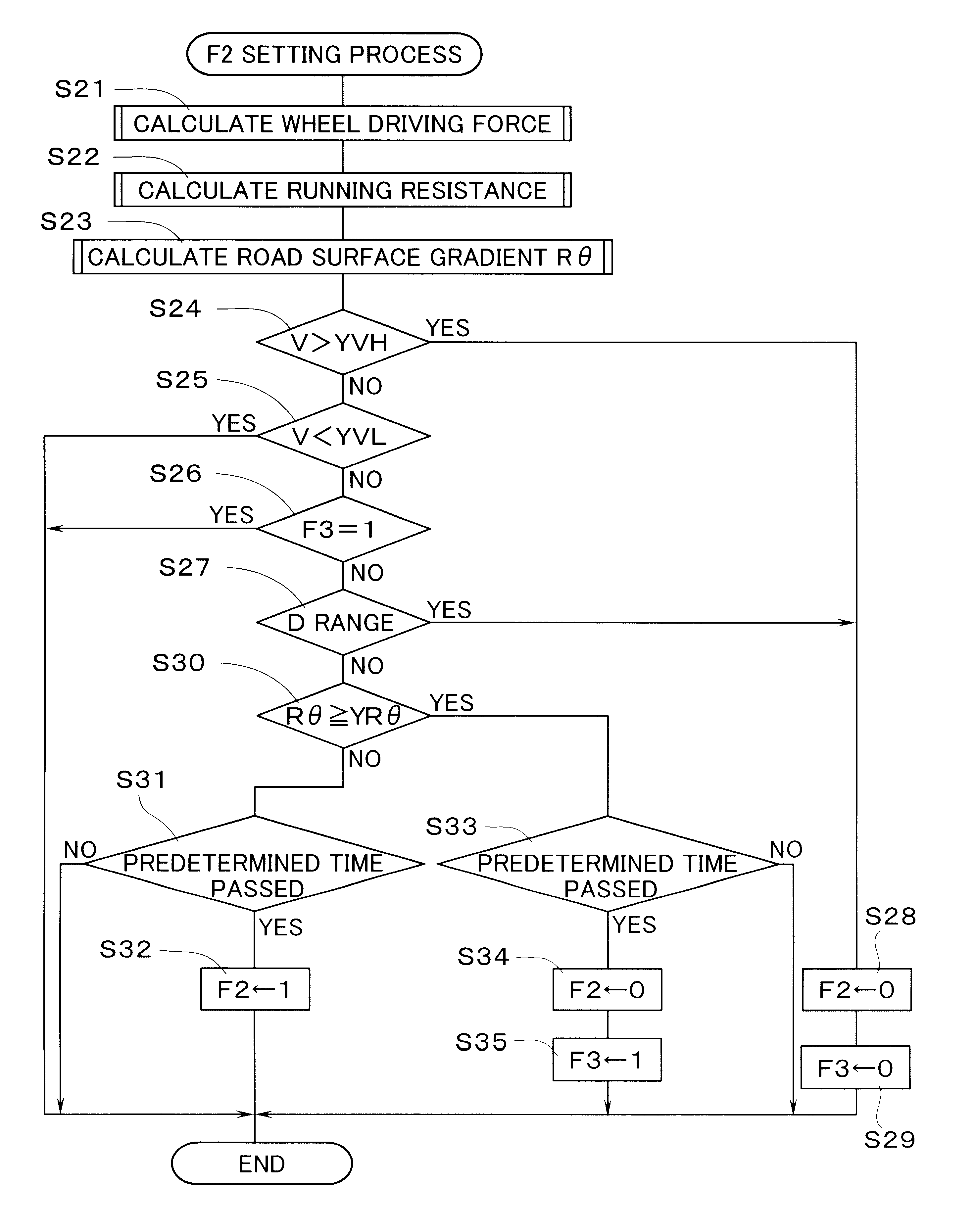

Road surface gradient detecting apparatus

When a road surface gradient is calculated by a wheel driving force and a vehicle acceleration, if the wheel driving force is calculated based on an output torque of an engine, the accuracy of calculating the wheel driving force, i.e., the road surface gradient becomes poor due to deterioration by aging of the engine or the like. In order to solve this kind of disadvantage, a fluid transmission torque of a torque converter is calculated by those torque ratio of the torque converter and an input shaft torque coefficient which correspond to a speed ratio of the torque converter, and an input rotational speed of the torque converter (=engine rotational speed (step S21-3). The road surface gradient is calculated by using a wheel driving force to be calculated by this torque.

Owner:HONDA MOTOR CO LTD

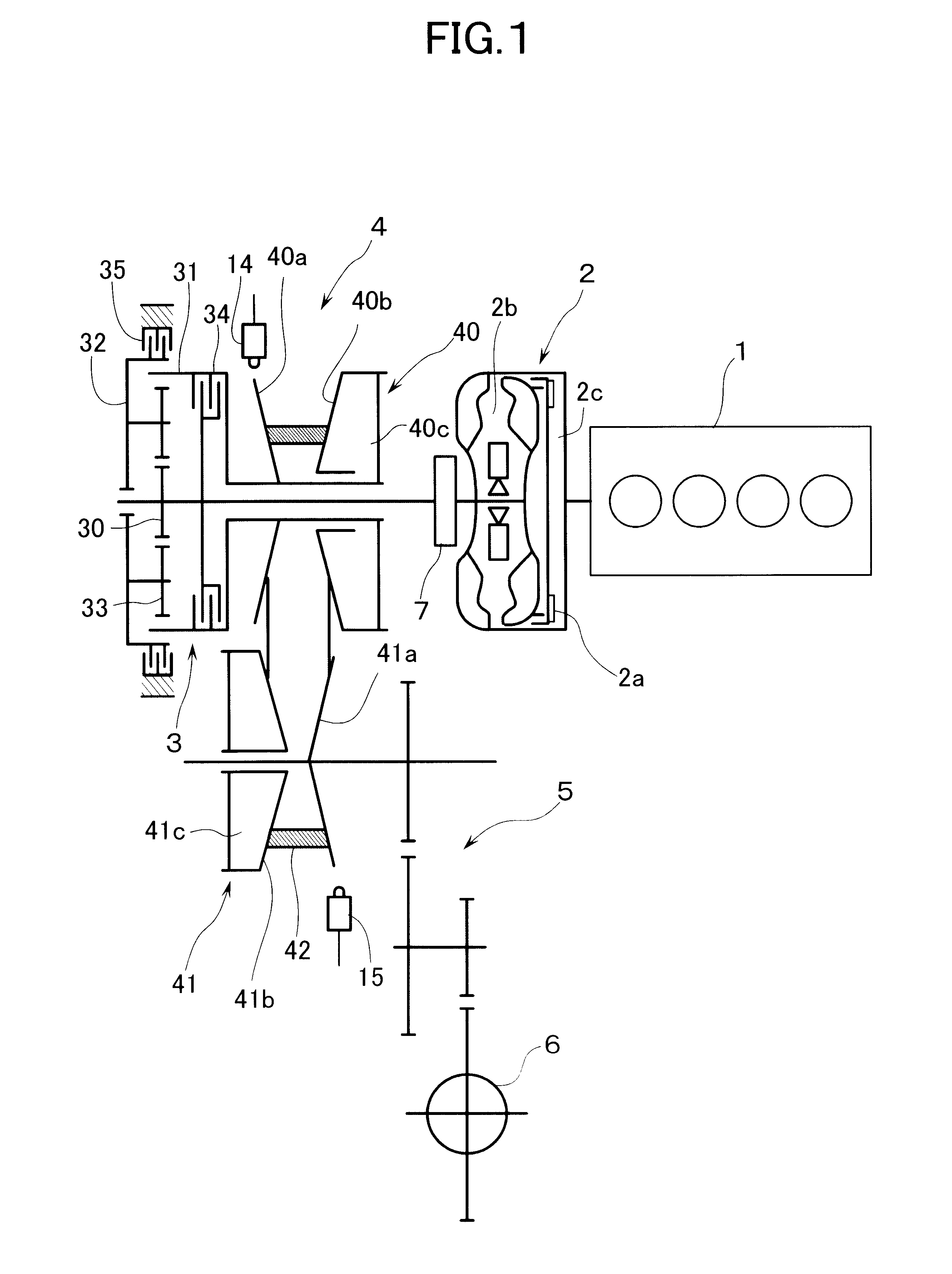

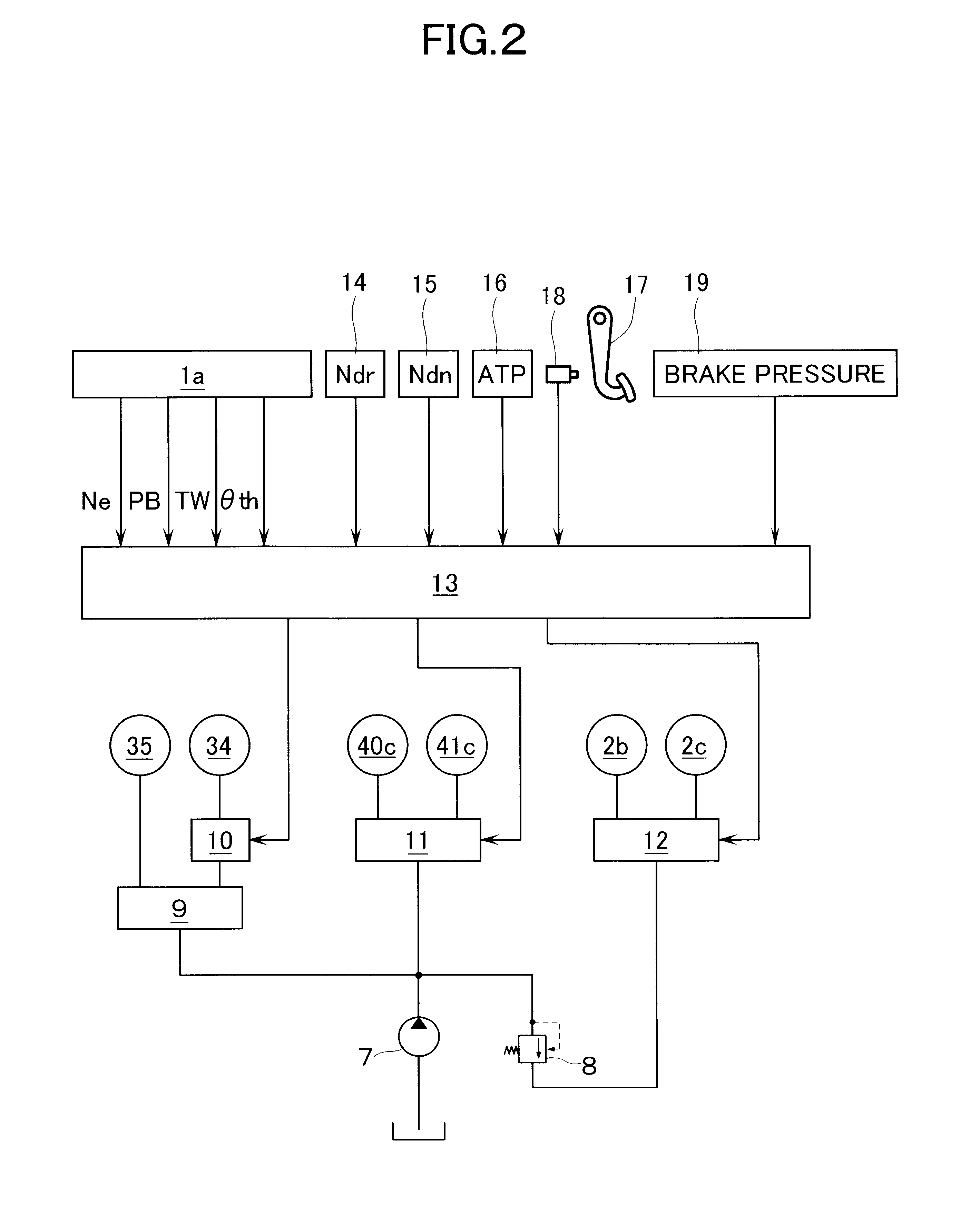

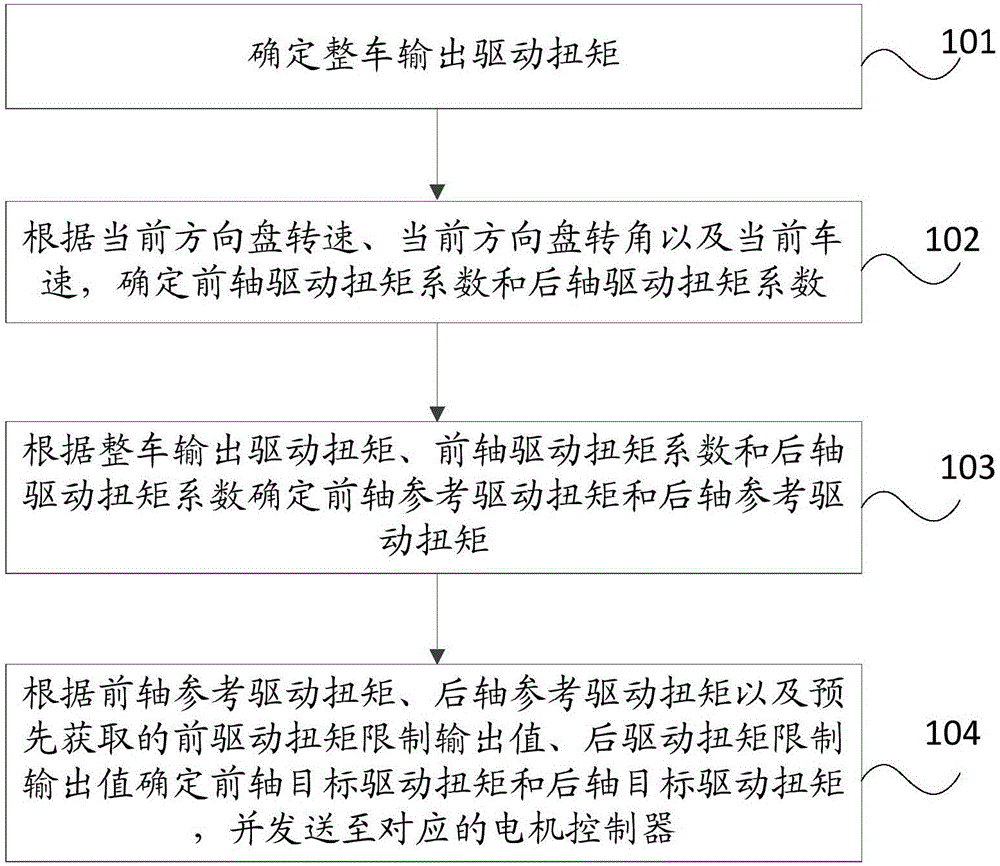

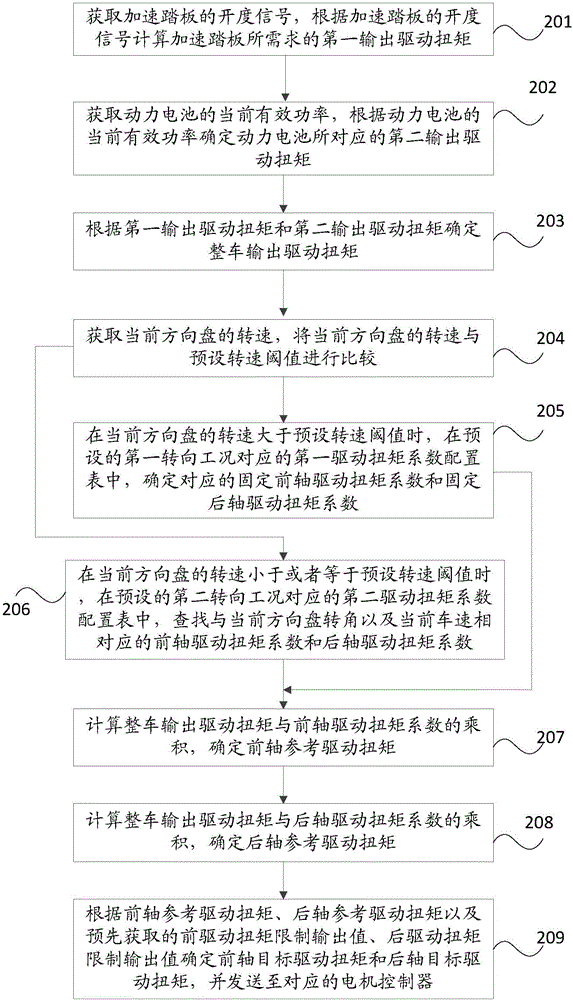

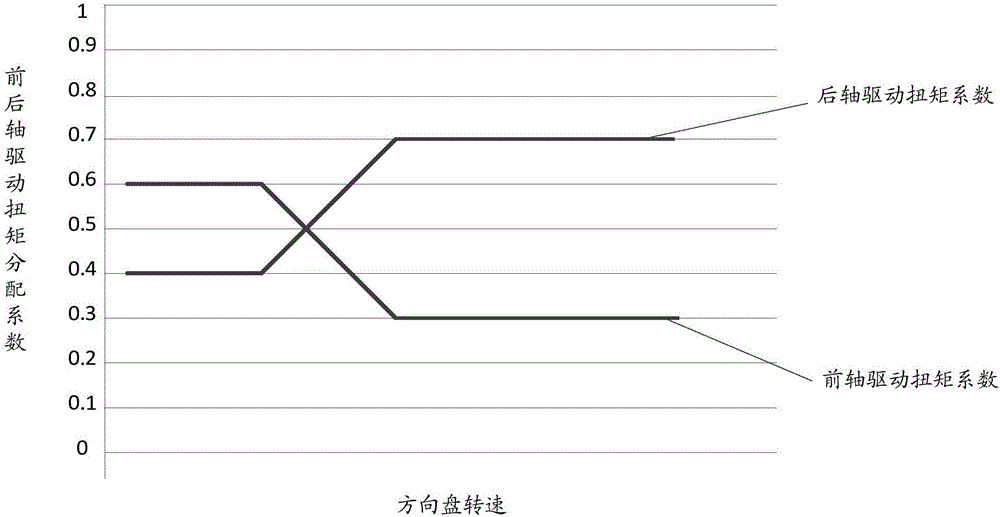

Drive torque distribution method, device and automobile

ActiveCN106379198AEnsure safetyAvoid oversteer characteristicsSpeed controllerElectric devicesSteering wheelMotor controller

The invention provides a drive torque distribution method, device and automobile. The method comprises the following steps: determining the whole output drive torque; determining the front-axle drive torque coefficient and the rear-axle drive torque coefficient according to the current steering wheel speed, current steering wheel angle and current speed; determining the front-axle reference drive torque and the rear-axle reference drive torque according to the whole output drive torque, the front-axle drive torque coefficient and the rear-axle drive torque coefficient; and determining the front-axle target drive torque and the rear-axle target drive torque according to the front-axle reference drive torque, the rear-axle reference drive torque and the front drive torque limit output value and rear drive torque limit output value obtained in advance, and sending to corresponding motor controllers. In the embodiment of the invention, the rear-axle drive torque can be increased in the case of vehicle emergency drive, the vehicle safety is guaranteed, and the phenomenon of drift or sideslip caused by the over-steering characteristic of the vehicle can be avoided.

Owner:BEIJING ELECTRIC VEHICLE

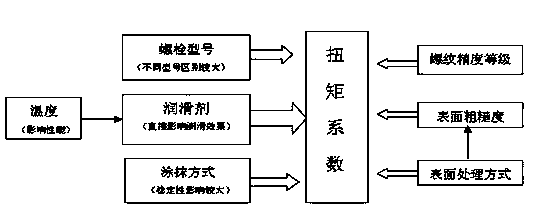

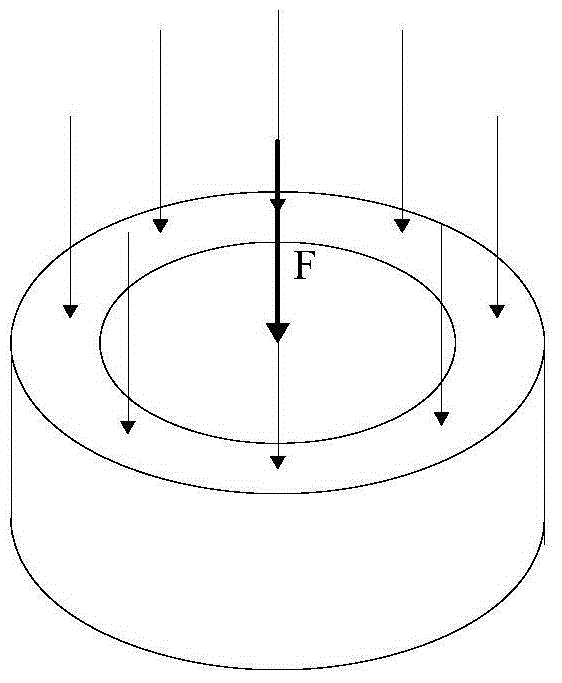

Method of guaranteeing fan high-strength bolt pretightening force to be accurately exerted

InactiveCN103423274AGuarantee stabilityAvoid the risk of mixingScrewsSpecial data processing applicationsSurface roughnessEngineering

The invention discloses a method of guaranteeing a wind generating set high-strength bolt pretightening force to be accurately exerted, which is characterized in that according to influence factors on a torque coefficient, such as lubricant which is used when a high-strength bolt is screwed down, a smearing mode, a thread precision grade, the surface roughness of a matched surface, a surface processing mode, a bolt model specification and temperature, the torque coefficient is confirmed on the basis of the theory of a torque method, and the range of dispersion coefficient of each specification of bolt in each batch when the torque method is adopted is controlled within 1.25 through controlling the lubricant, the smearing mode, the thread precision grade, the roughness of the matched surface, the surface processing mode, the bolt model specification and the temperature.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

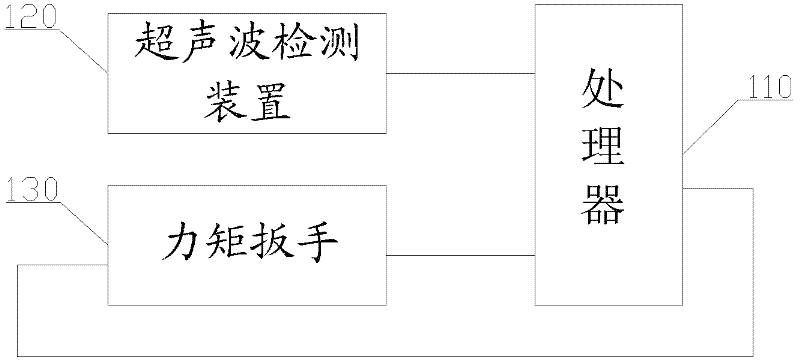

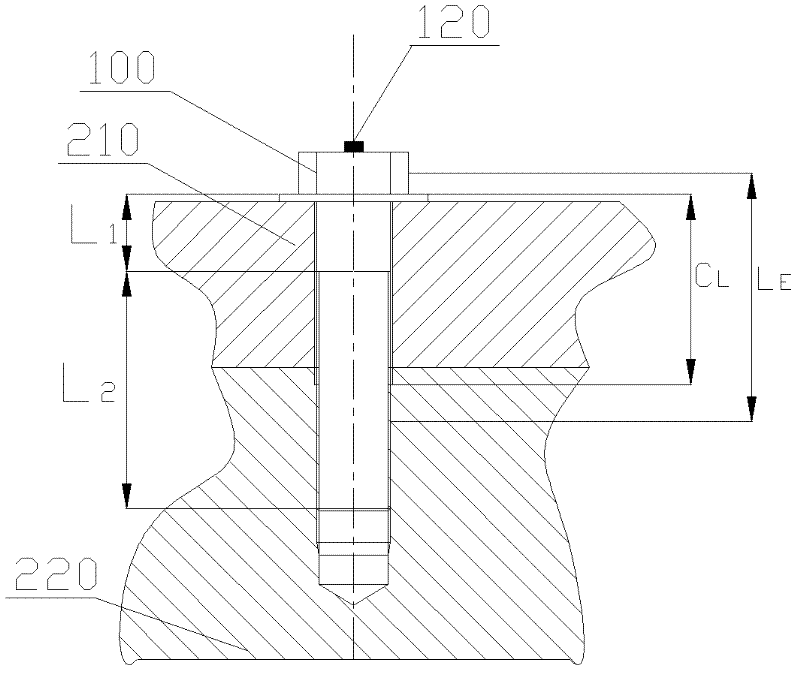

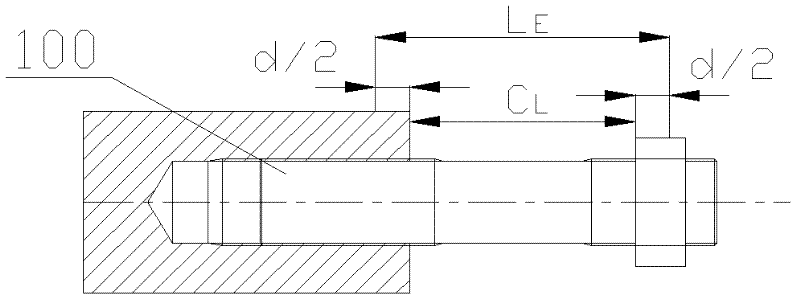

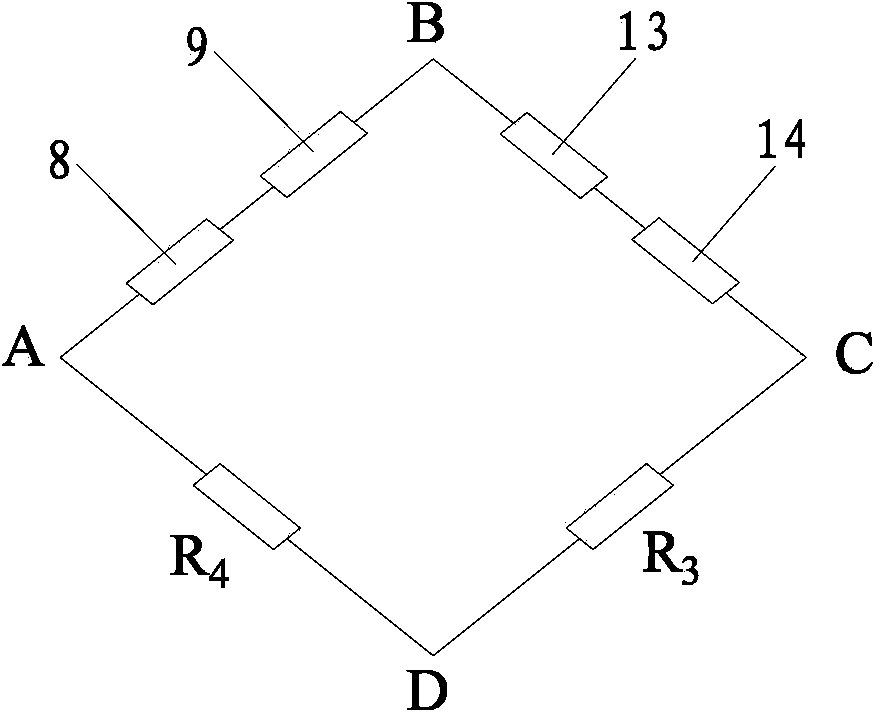

A method and device for measuring bolt torque coefficient

InactiveCN102288352AAvoid errorsImprove accuracyMeasurement of torque/twisting force while tighteningTorque coefficientControl theory

The invention discloses a method and a device for determining a torque coefficient of a bolt. By the method, a preset torque T which is applied to a screw fastener and the extension amount of the screw fastener are obtained; an axial load of the screw fastener is obtained according to the extension amount; and the torque coefficient of the screw fastener is obtained according to the preset torqueand the axial load. By the method, an error of the torque coefficient caused by difference between a detection scene and an actual installation scene can be avoided, the accuracy of the determined torque coefficient of the screw fastener is improved; meanwhile, when the screw fastener is in fit with a threaded hole which is formed in a connected piece, the torque coefficient of the screw fastenercan be determined by using the method. Therefore, the method is higher in adaptability. According to the torque coefficient, a tightening torque of the corresponding screw fastener can be corrected, so the difference between an applied actual tightening torque and a theoretical tightening torque is smaller, and the connection reliability of the screw fastener is guaranteed.

Owner:SANY ELECTRIC CO LTD

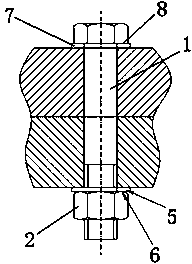

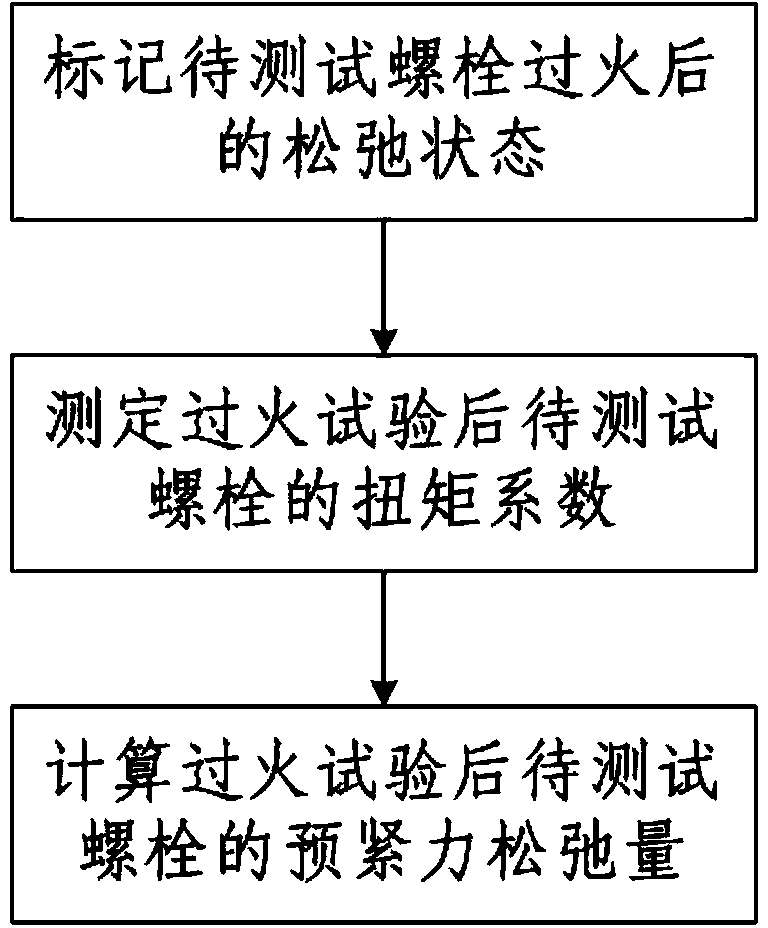

Device and method for testing amount of looseness of connecting pretightening force of after-fire high-strength bolt

InactiveCN103776579ASimple structureReasonable designMeasurement of torque/twisting force while tighteningAxial forceTorque coefficient

The invention discloses a device and method for testing the amount of looseness of connecting pretightening force of an after-fire high-strength bolt. The device comprises a strain tester, a computer, a base, a bolt axial-force bearing device and a torque loading device. The bolt axial-force bearing device is composed of a lower rigid cushion plate, an elastic steel sleeve and an upper rigid cushion plate, wherein the lower rigid cushion plate, the elastic steel sleeve and the upper rigid cushion plate are sequentially arranged from bottom to top, the bolt to be tested can penetrate through the lower rigid cushion plate, the elastic steel sleeve and the upper rigid cushion plate from bottom to top in sequence, a nut is connected to the end, penetrating through the upper rigid cushion plate, of the bolt to be tested in a threaded mode, and a first resistance strain gage and a second resistance strain gage are symmetrically bonded to the outer wall of the elastic steel sleeve. The method includes the following steps that firstly, the looseness state of the bolt, having suffered from fire, to be tested is marked; secondly, the torque coefficient of the bolt, having undergone a fire suffering test, to be tested; thirdly, the amount of looseness of connecting pretightening force of the bolt, having undergone the fire suffering test, to be tested is calculated. The device and method are high in testing precision, testing results can provide reference for after-fire safety performance assessment and reinforcement treatment of a steel structure, waste is avoided, potentially safety hazards are reduced, and the practicability is strong.

Owner:CHANGAN UNIV

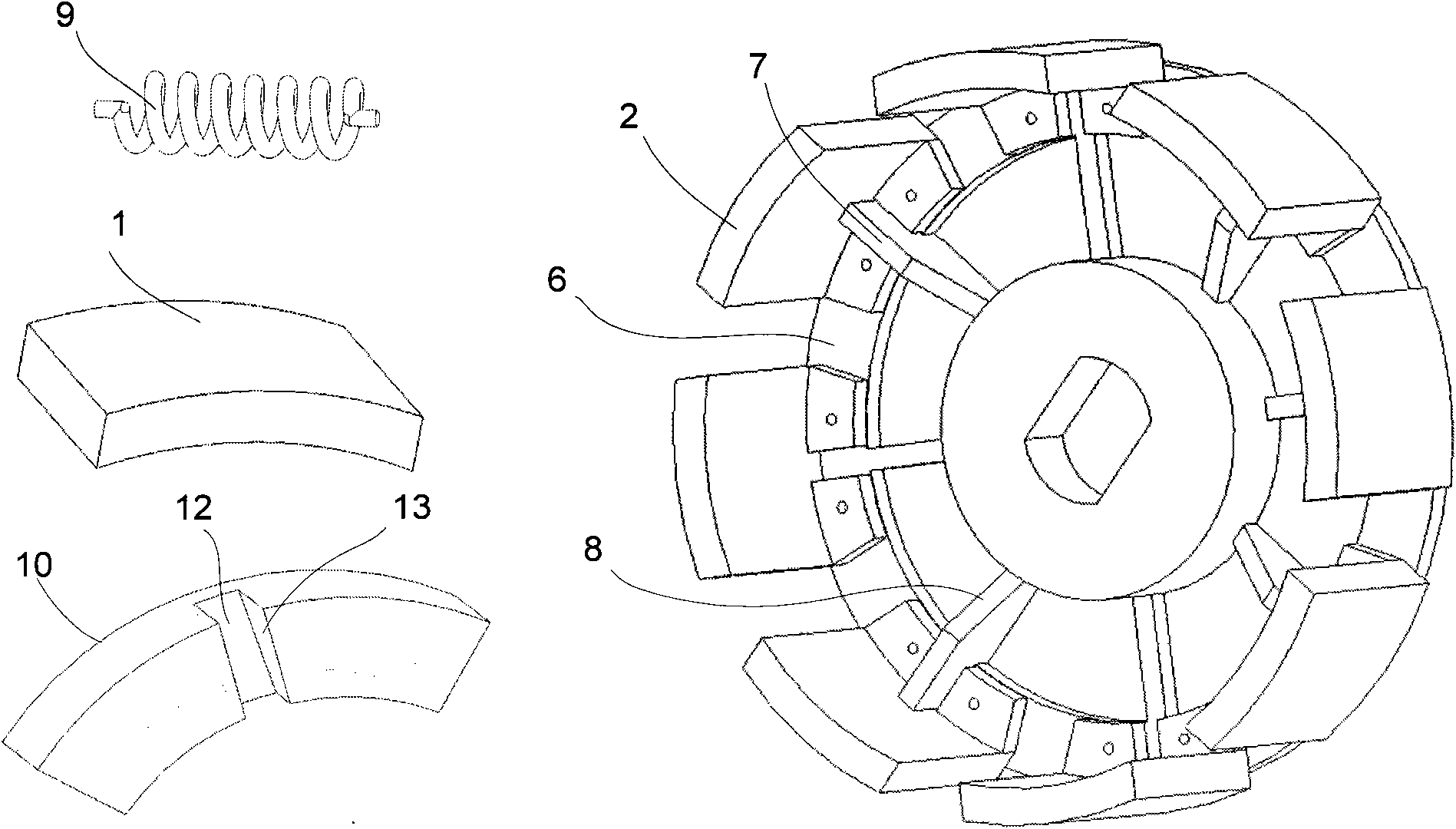

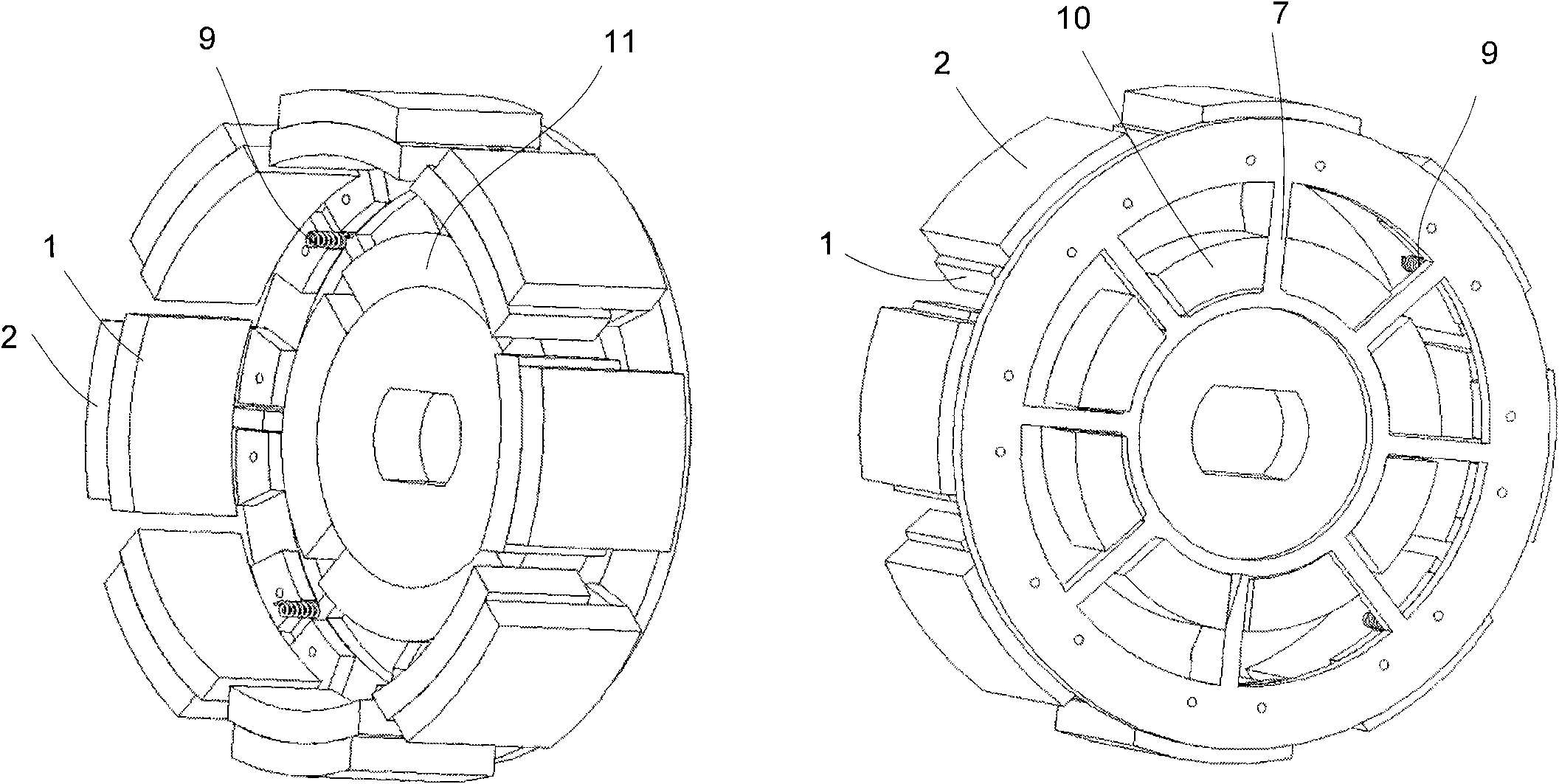

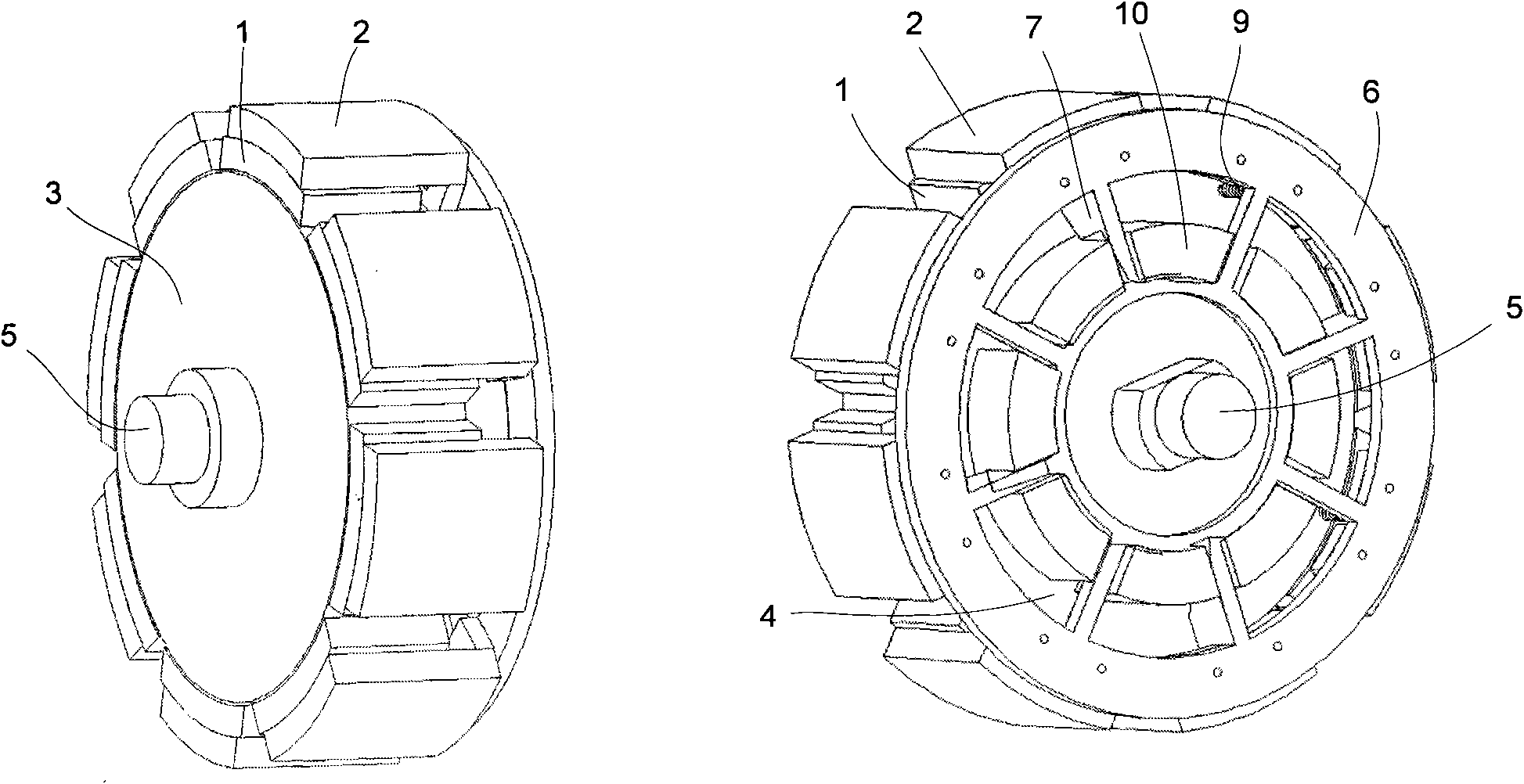

Permanent magnet motor capable of automatically adjusting magnetism

InactiveCN102111048AChange the effective axial lengthAdjust the back EMF coefficientSynchronous machine detailsMagnetic currentLow speed

Once a permanent magnet motor at present is manufactured, an electromagnetic structure of the permanent magnet motor is fixed and is not changed in operation, so when the motor is overloaded, the current is high, the cost of a controller is increased, the voltage is on the high side at a high speed, and the speed regulation range is influenced. The invention provides a speed regulation permanent magnet motor capable of automatically adjusting the magnetic flux of a stator winding of a linkage motor. The speed regulation permanent magnet motor is characterized by comprising a magnetism adjusting mechanism integrated in the motor, wherein the magnetism adjusting mechanism can change the magnetic flux of the stator winding of the linkage motor according to changes of the rotating speed of the motor, adjust torque coefficients and back electromotive force coefficients of the motor, reduce the current of the motor at a low speed, and reduce the cost of a motor controller; besides, the magnetism adjusting mechanism can reduce the motor voltage when the motor during high-speed operation, reduce weak magnetic current or leave out weak magnet control, and expand the speed regulation range of the motor.

Owner:刘行

Online compression amount measurement method for seal ring of small solid rocket

ActiveCN104792508AImprove test efficiencyLess assembly timesMachine part testingStress conditionsEngineering

An online compression amount measurement method for a seal ring of a small solid rocket includes: analyzing stress conditions of the seal ring; obtaining a relationship between a compression amount of the seal ring and a tightening torque by establishing a relationship between the compression amount of the seal ring and an axial stress and a relationship between the axial stress and tightening torque; further providing a technical test method for identifying a tightening torque coefficient according to a direct proportion relationship between the compression amount and the tightening torque; during technical test, writing reference values such as a reference value of the compression amount of the seal ring, a reference value of the tightening torque and the like besides the tightening torque coefficient into a database to provide a basis for judgment in online measurement; in a practical tightening process, calculating the compression amount of the seal ring by measurement of an angle and an output torque of a torque tightening motor, and writing data including a measured value of the compression amount of the seal ring, a measured value of the tightening torque and the like into the database for inquiring. By the online compression amount measurement method, real-time precision compression amount measurement of the seal ring of the small solid rocket can be realized.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

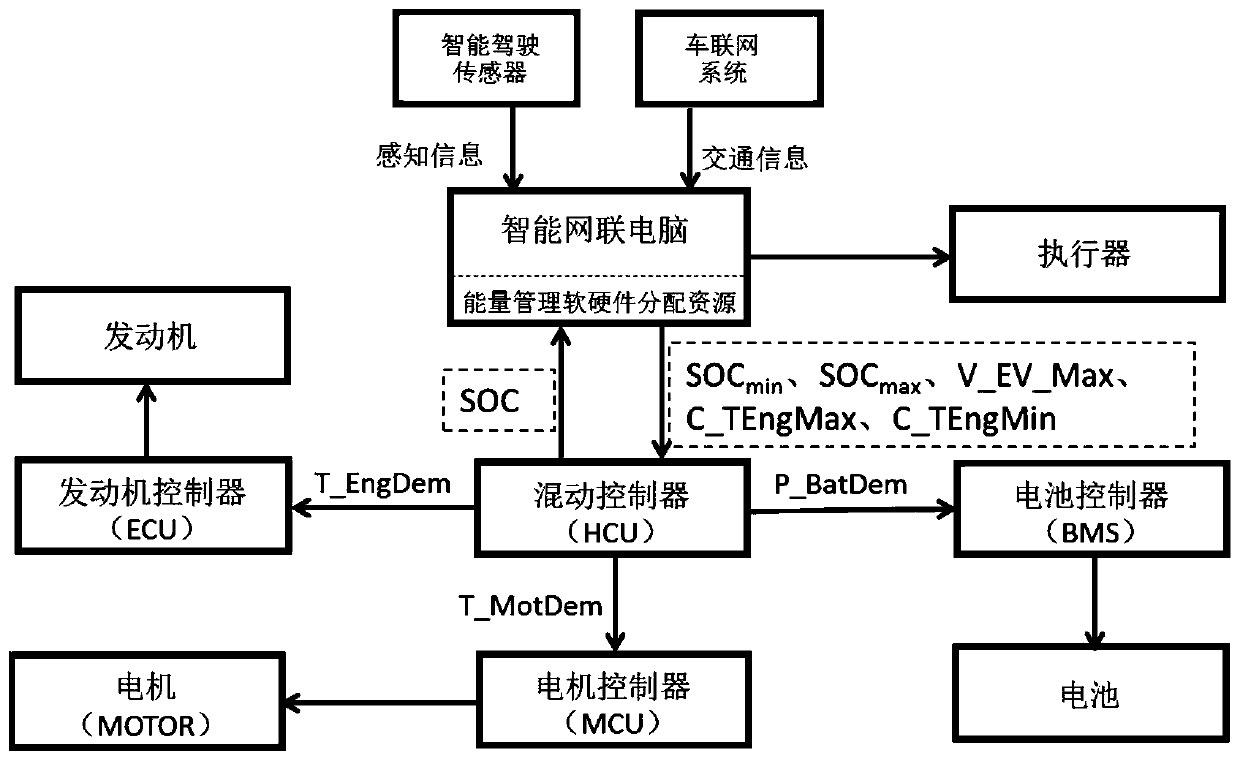

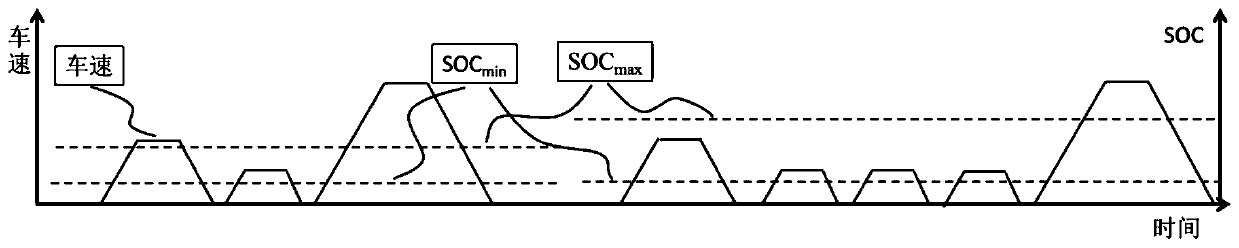

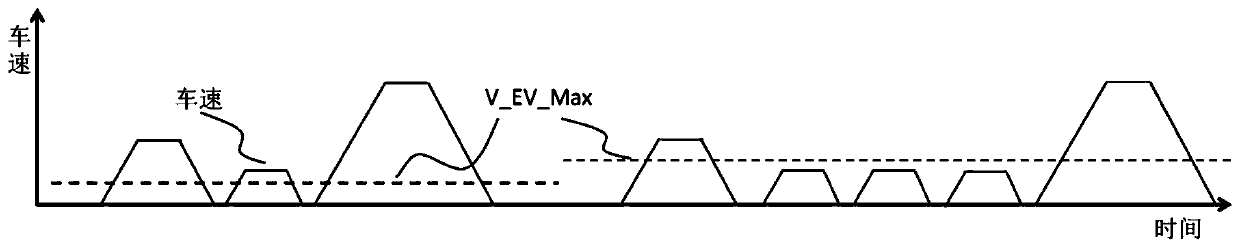

Hybrid electric vehicle energy management method and system based on road condition forecast

ActiveCN109910866AImprove fuel economyHybrid vehiclesInternal combustion piston enginesIntelligent NetworkTorque coefficient

The invention provides a hybrid electric vehicle energy management method based on road condition forecast. The method comprises the following steps: determining a key parameter threshold value of energy management on the basis of the planned route information, wherein the key parameter threshold value comprises a battery SOC minimum value, a battery SOC maximum, hybrid state pure electric drivinghighest vehicle speed, engine lowest torque coefficient and engine working condition point transfer torque coefficient; and obtaining motor torque, battery power and engine torque based on the key parameter threshold value and the preset control strategy for power system energy management. The invention also provides a hybrid electric vehicle energy management system based on road condition forecast. The original key parameter threshold value of the vehicle is adjusted on the basis of the forecast road condition information, so that in the actual use process, the fuel economy of an intelligent connected hybrid power automobile can be improved.

Owner:CHINA FIRST AUTOMOBILE

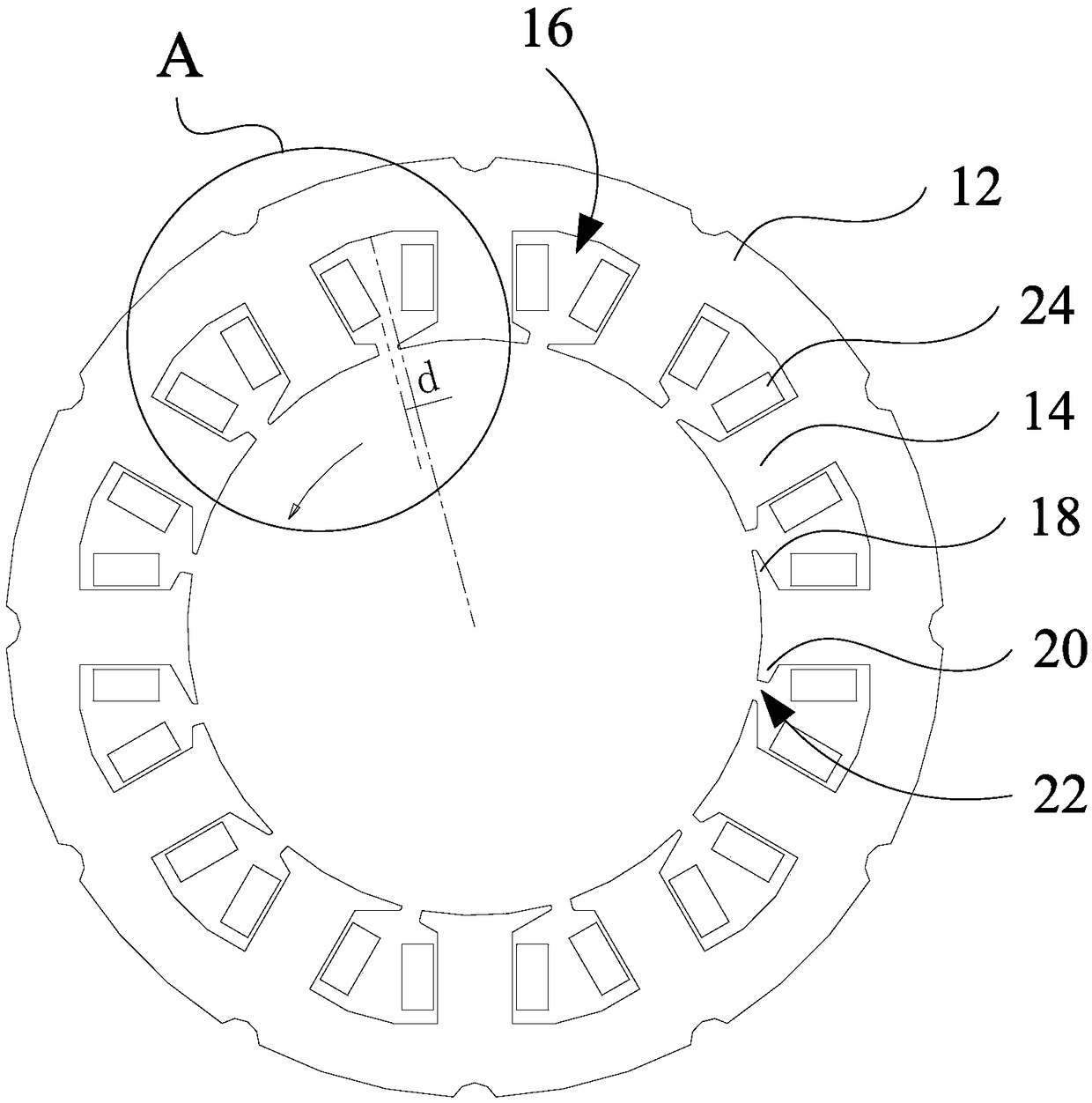

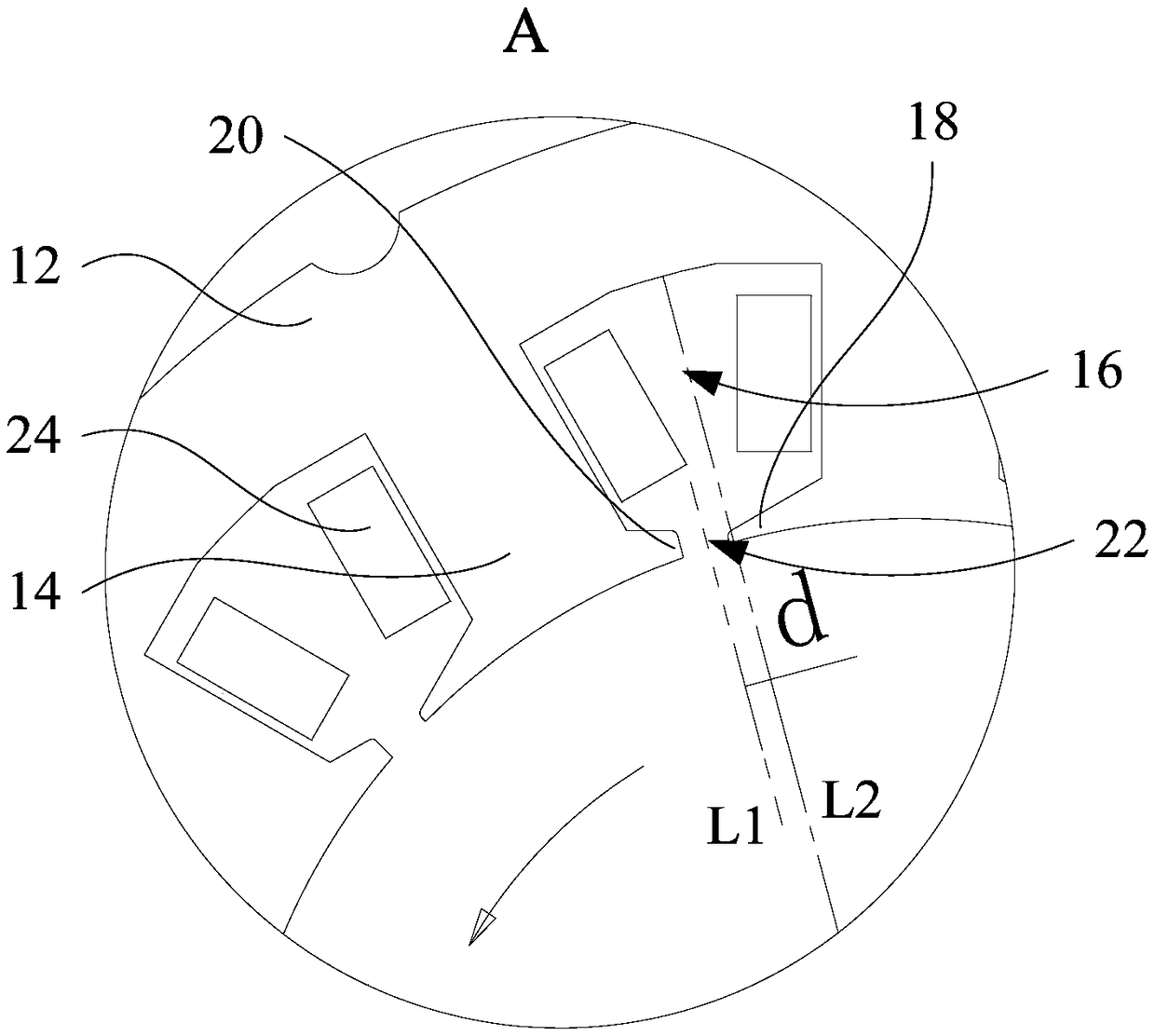

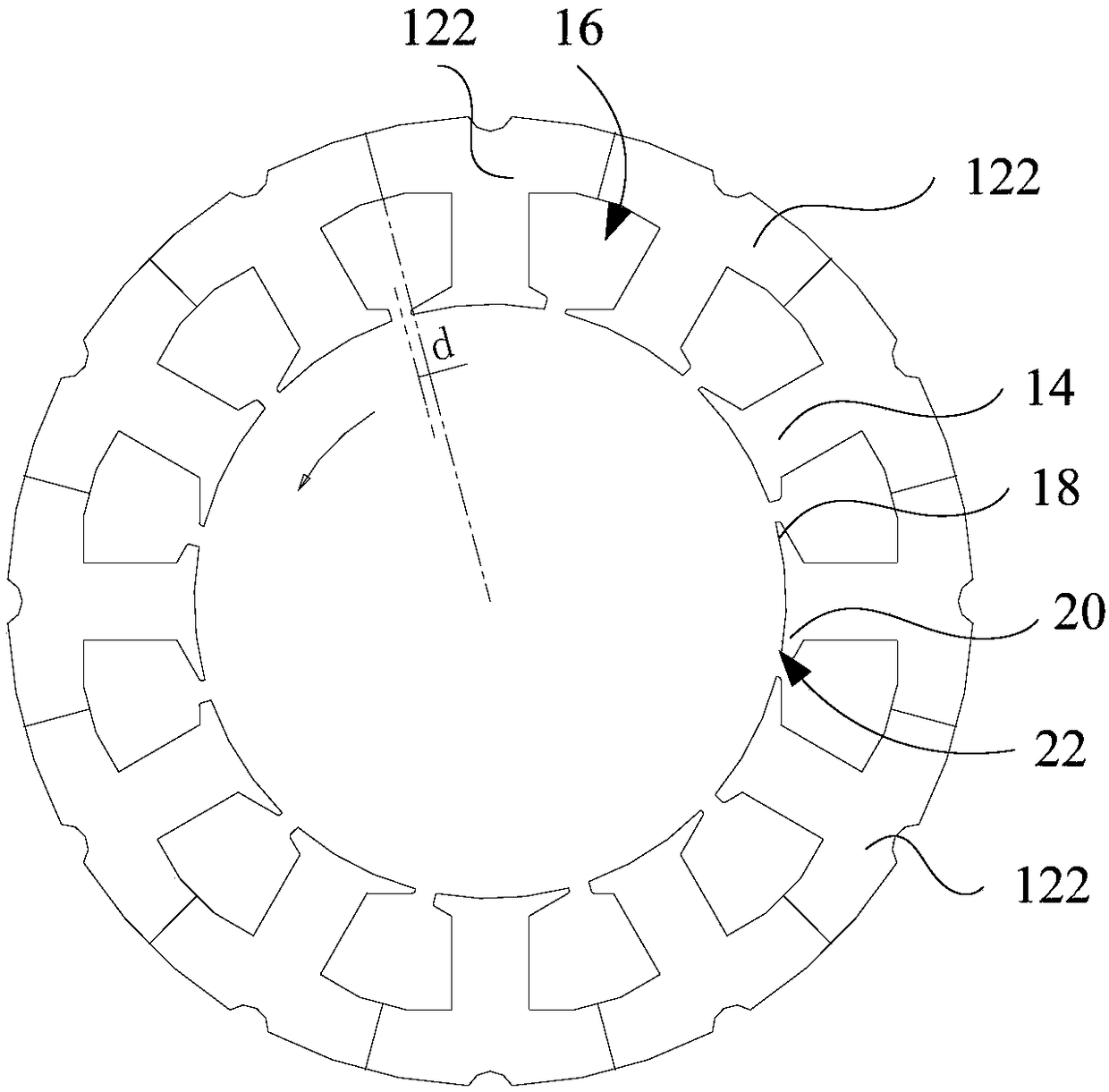

Stator core, motor and compressor

InactiveCN108768005AIncrease torqueImprove torque coefficientMagnetic circuit stationary partsTorque coefficientHigh torque

The invention provides a stator core, a motor and a compressor. A stator body is in a cylindrical shape, stator convex teeth are arranged at intervals along a circumferential direction of the stator body, a stator groove gap is limited by arbitrary two adjacent stator convex teeth, a first pole shoe and a second pole shoe both are arranged at one end, far away from the stator body, of each of theplurality of stator convex teeth and are respectively arranged at two sides of the stator convex pole teeth, the first pole shoe and the second pole shoe which are arranged at two sides of the statorgroove gap form a groove opening, a central line of adjacent stator groove gap is parallel to a central line of the groove opening, and preset distance is kept between the central line of adjacent stator groove gap and the central line of the groove opening. The preset distance is kept between the center of the groove opening and the central line of the stator groove gap, thus, reluctance torque caused by asymmetry of a rotor magnetic path structure is fully utilized, the torque and the torque coefficient of the motor can be improved by increasing the reluctance torque under the condition thata counter potential coefficient is not changed, and the motor is further enabled to have relatively high torque output capability during rotation.

Owner:GUANGDONG WELLING AUTO PARTS CO LTD

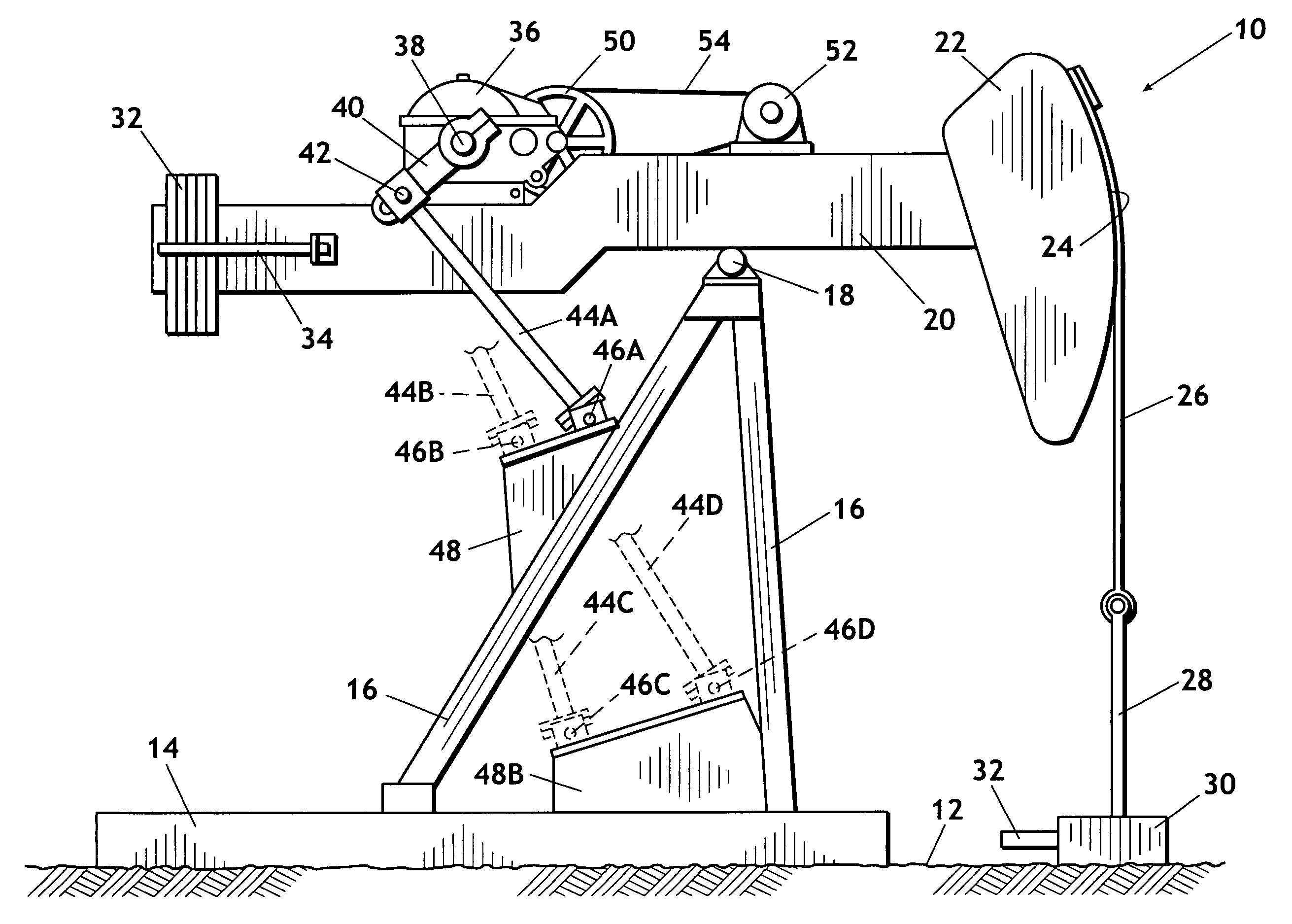

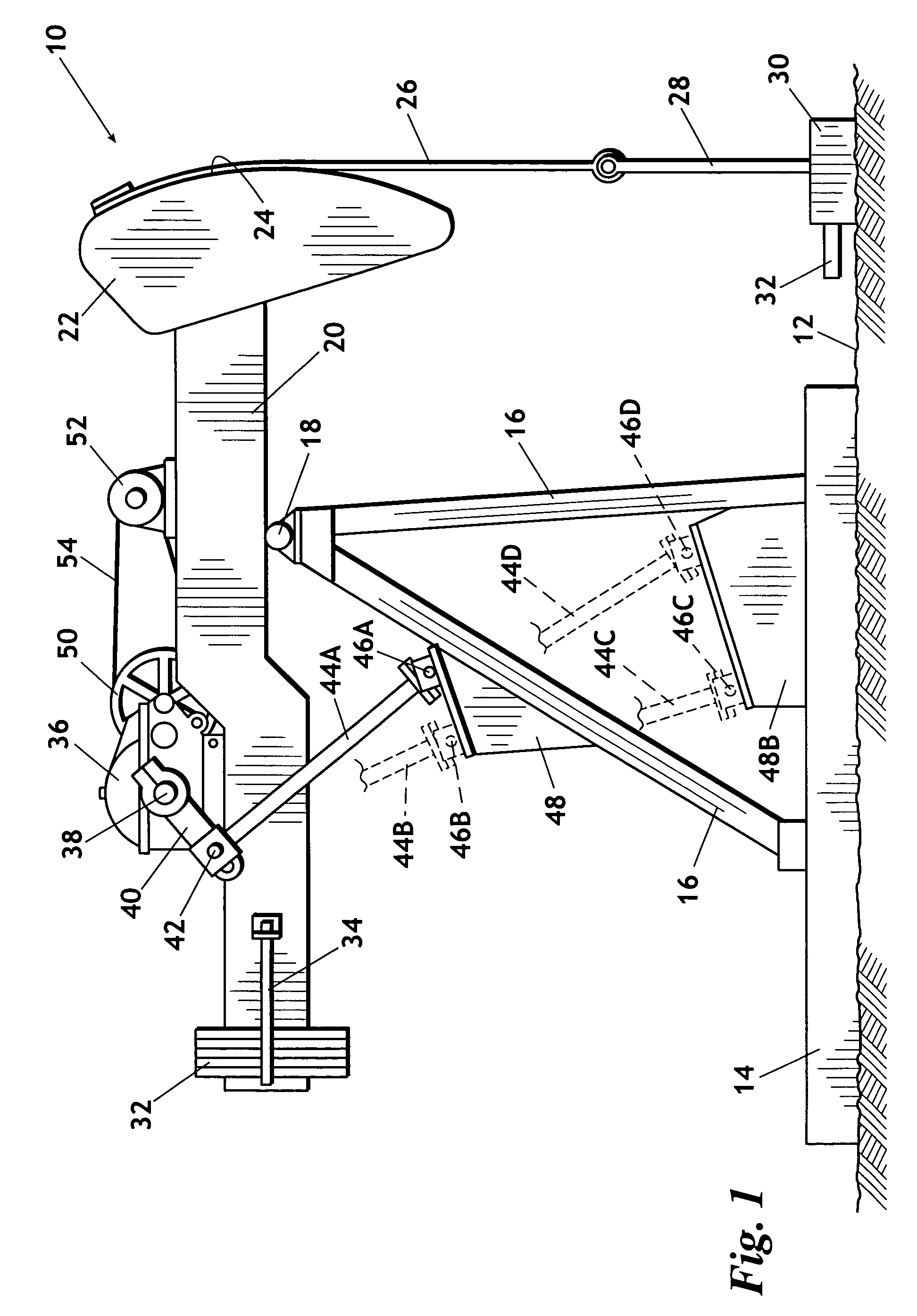

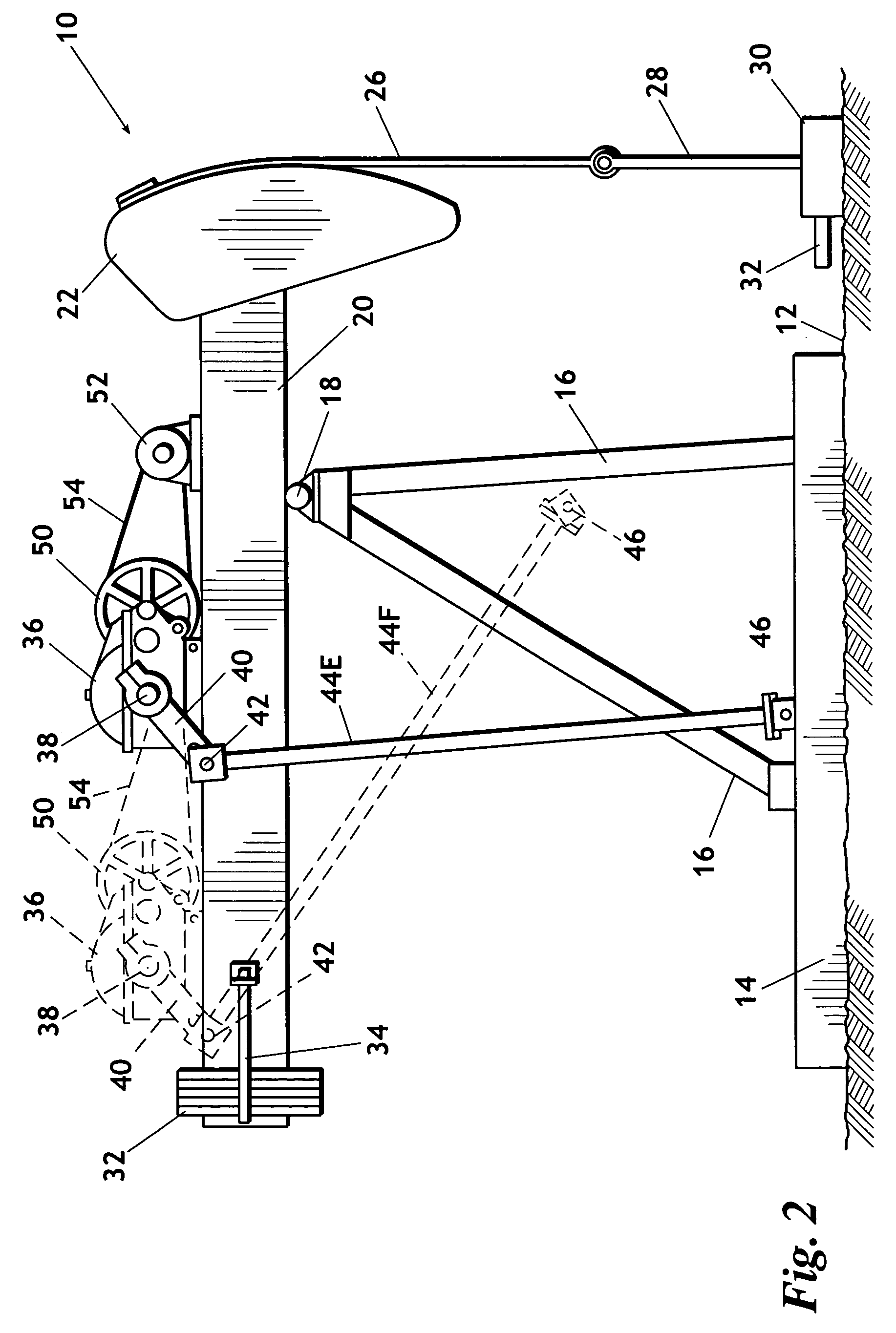

Pumping unit with variable work stroke and return stroke torque factor characteristics

InactiveUS7406887B2Motor coordinationReduce the amount requiredGearingFlexible member pumpsPrime moverPhysical medicine and rehabilitation

A pumping unit system having vertical sampson post, a walking beam pivotally supported at the upper end of the sampson post and a horsehead affixed at a forward end thereof that supports a reciprocated sucker rod string, including a gear reducer mounted at selectable positions on the walking beam and having a horizontally extending drive shaft, a crank arm affixed to the drive shaft the spacing between a selectable length pitman rod having a first end secured to said crank arm and a second end having a pitman bearing that is selectably mountable to a plurality of pitman bearing locations and a prime mover connected to the gear reducer and wherein the characteristics of the pumping unit are determined by the selectable position of the gear reducer, the selectable length of the crank arm, the selectable length of the pitman rod, and the selectable pitman bearing location.

Owner:JENSEN INT

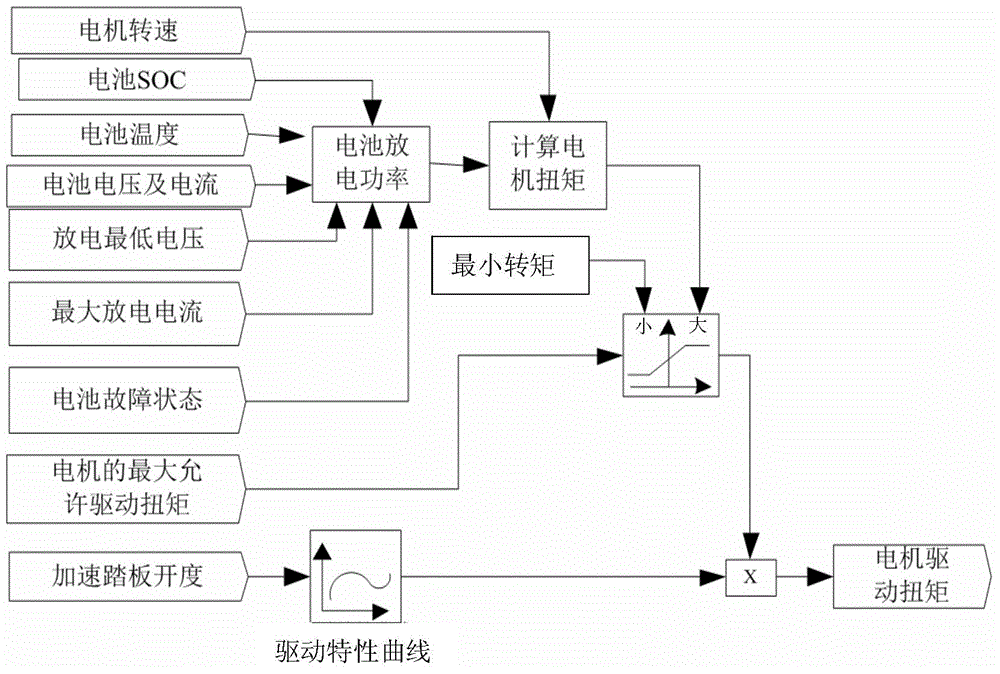

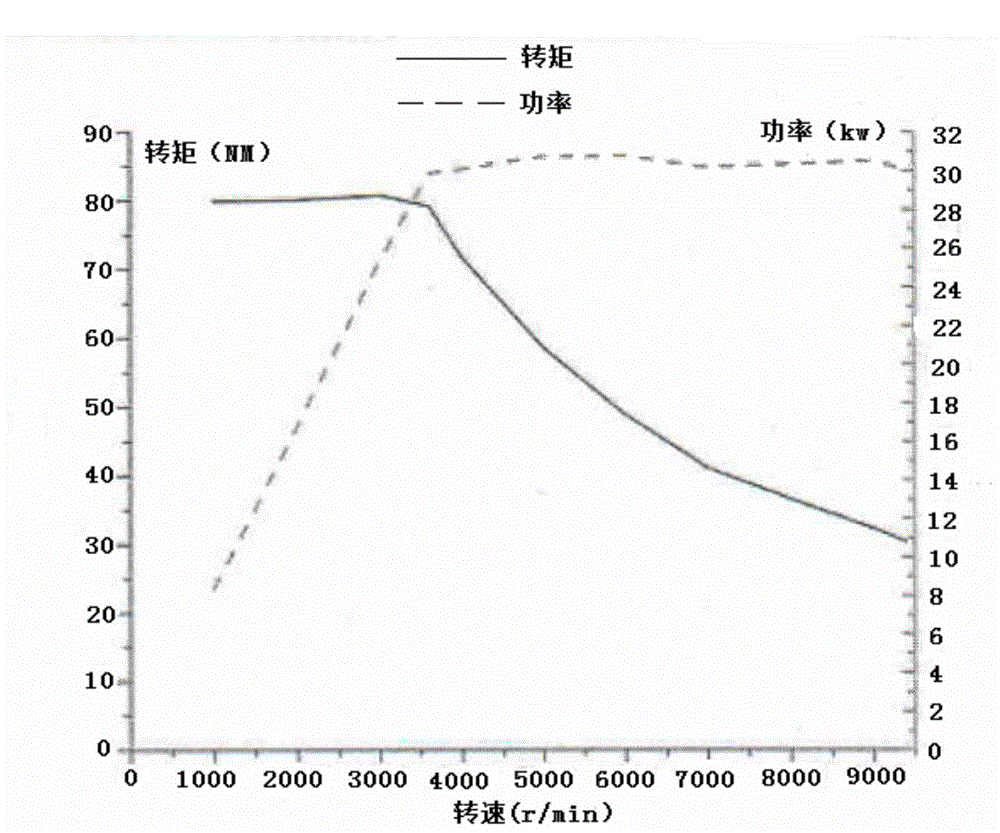

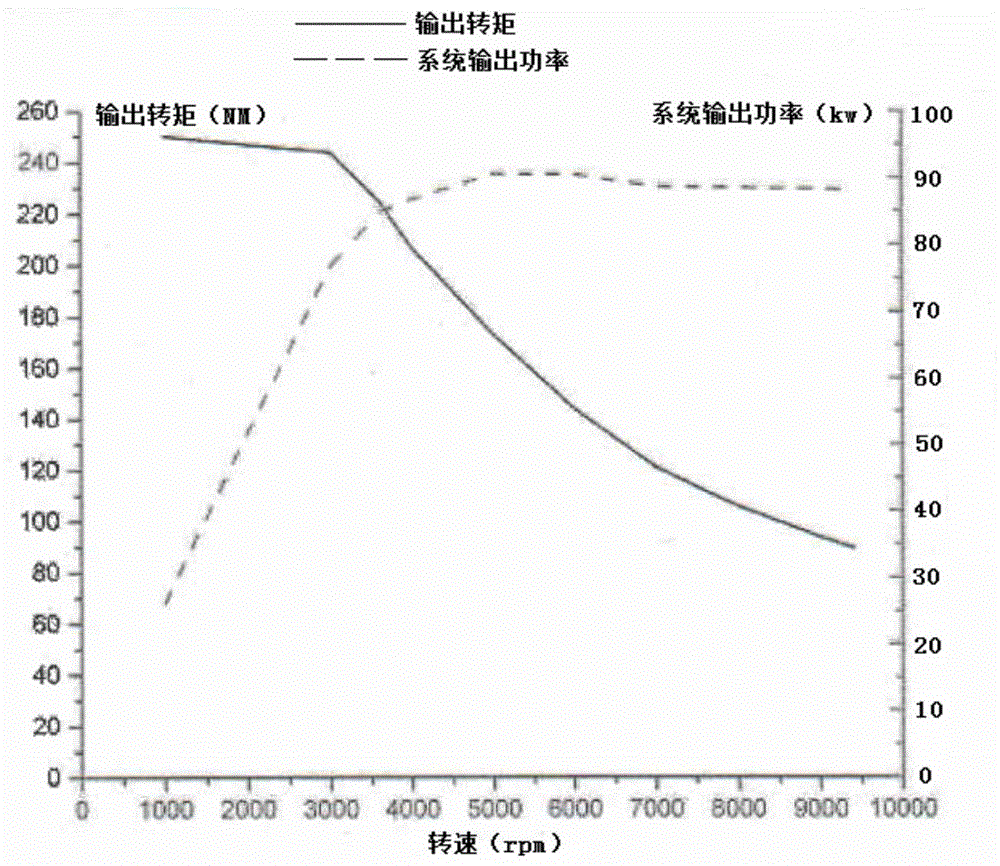

Control method for safety driving current of electric automobile

ActiveCN104648183AExtended service lifeImprove drivabilitySpeed controllerVehicular energy storageDriving currentPower battery

The invention discloses a control method for safety driving current of an electric automobile. The control method comprises the following steps of calculating energy discharging power P(energy discharging) of a current battery according to an SOC (state of charge) of the current battery and the battery temperature, and calculating a driving torque value T1 of the battery under the current automobile speed according to a formula P(energy charging) / V=T1 according to the current rotating speed V of a motor; calculating the maximum allowable driving torque T(max allowable) of the motor by the whole automobile controller according to an overload coefficient K1 under the current motor temperature and the optimal torque T(optimal torque) under the current rotating speed of the motor; comparing the driving torque value T1 with the maximum allowable driving torque T(max allowable) by the whole automobile controller, taking a smaller value as the maximum driving torque value for electric automobile driving, and multiplying the maximum driving torque value with a torque coefficient corresponding to the openness of an acceleration pedal to obtain the current safety driving current. According to the control method, the driving performance of the electric automobile is improved, and the service life of a power battery pack is prolonged; the current controllability and the safety during motor-operated running are guaranteed.

Owner:SOUEAST

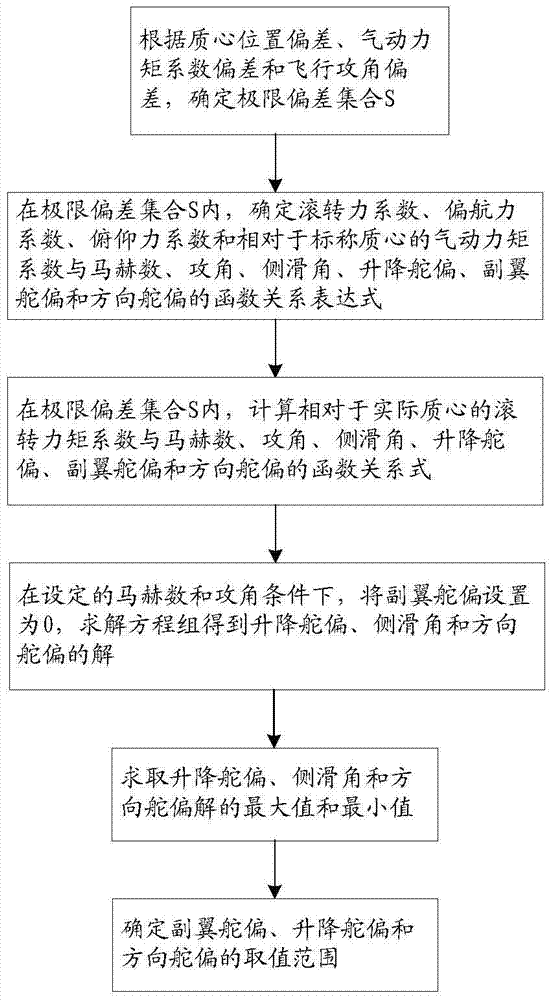

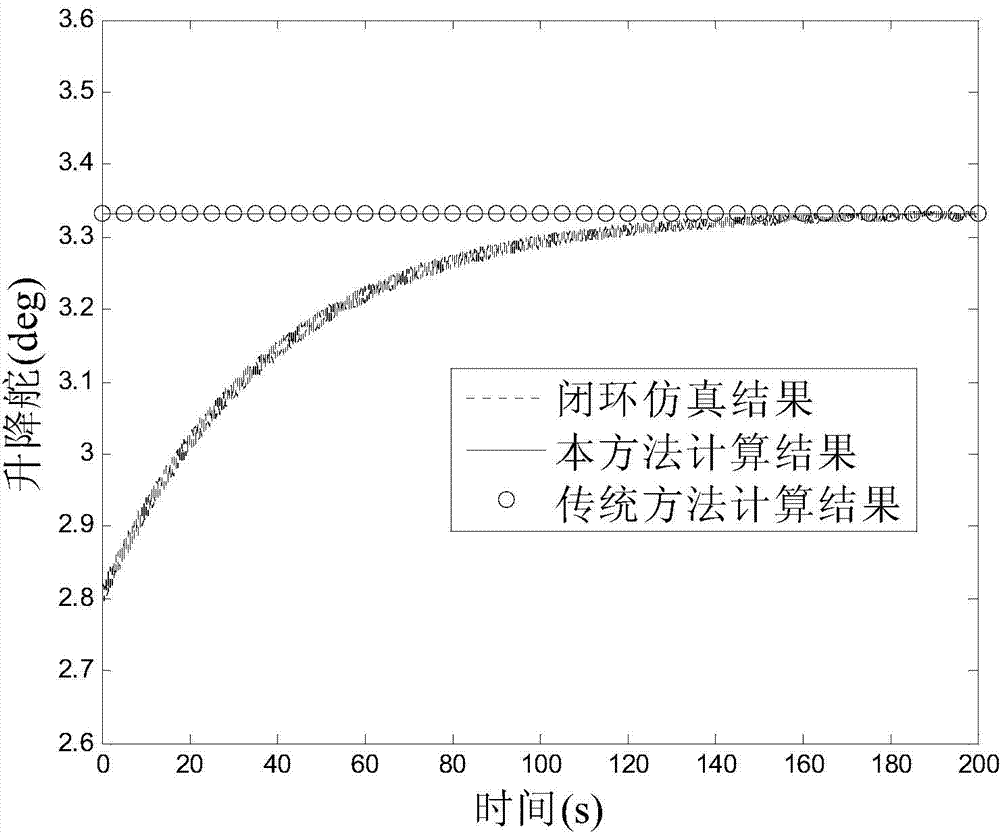

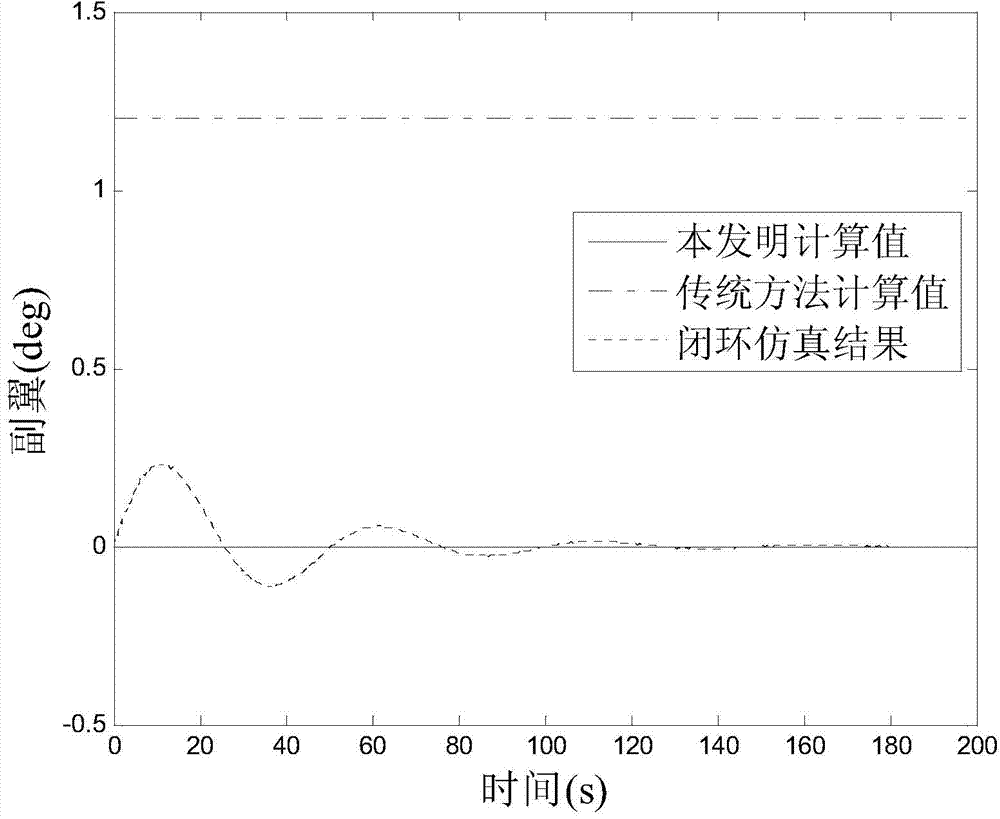

Pneumatic rudder deflection range calculation method based on direction rudder roll control strategy

ActiveCN104331084ADetermine the range of rudder deviationAccurately determineAdaptive controlPosition/course control in three dimensionsCalculation errorEngineering

The invention relates to a pneumatic rudder deflection range calculation method based on a direction rudder roll control strategy. The method comprises the steps that a limit deflection set is confirmed according center of mass position deflection of an aircraft, pneumatic torque coefficient deflection and attack angle deflection value range; then roll force coefficient, yaw force coefficient, pitching force coefficient and pneumatic torque coefficient relative to nominal center of mass and function expressions for mach number, an attack angle, a sideslip angle, elevating rudder deflection, aileron rudder deflection and direction rudder deflection are confirmed in the set; and a function relation expression of roll force coefficient relative to practical center of mass and the mach number, the attack angle, the sideslip angle, elevating rudder deflection, aileron rudder deflection and direction rudder deflection is calculated via the deflection values and the function expressions, an equation set is established and solved and rudder deflection and the sideslip angle are obtained under the condition of zero aileron rudder deflection and the set mach number and the attack angle, and value range of rudder deflection is confirmed according to the solution. Rudder deflection range of the aircraft based on the direction rudder roll control strategy can be accurately confirmed, and calculation error is small.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

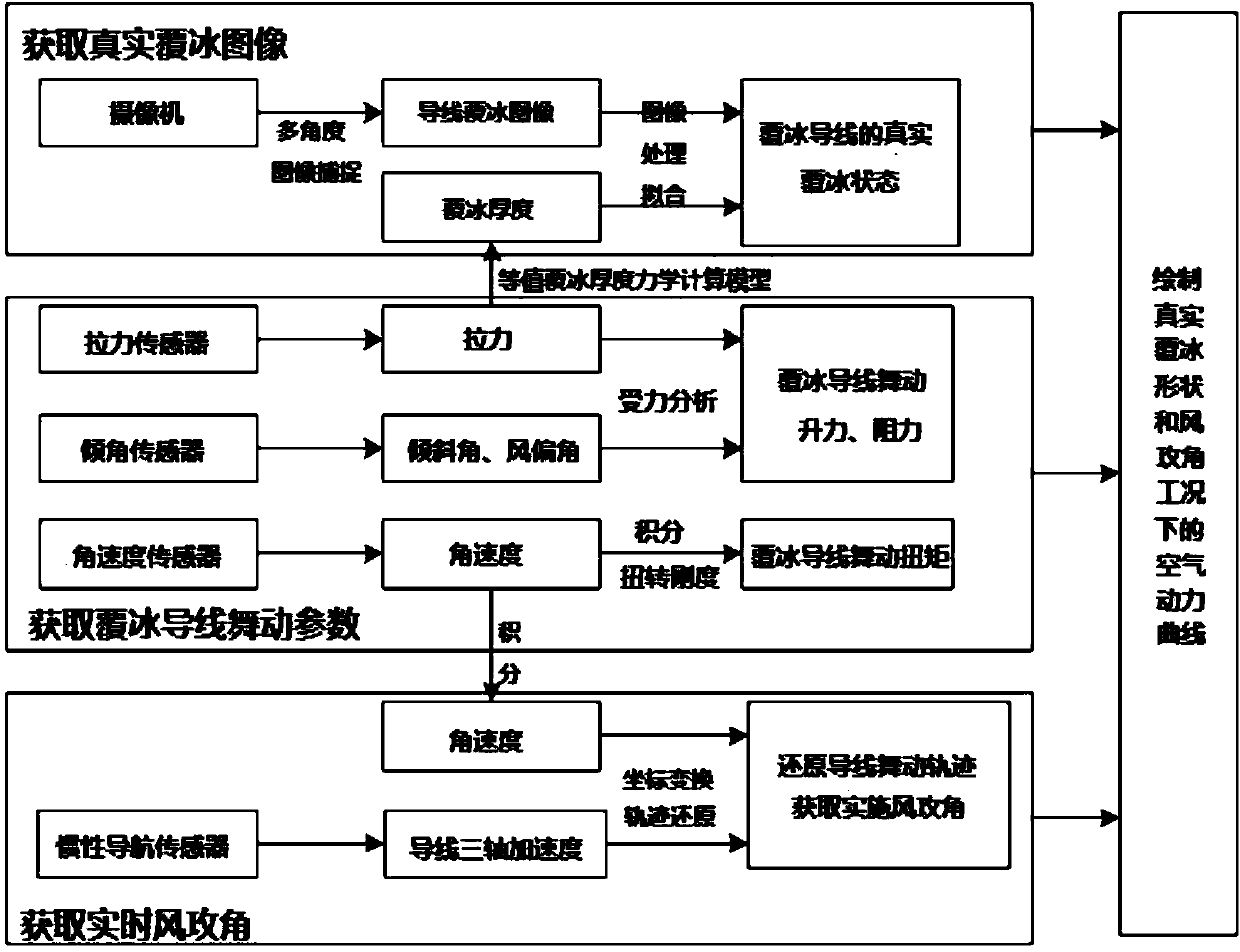

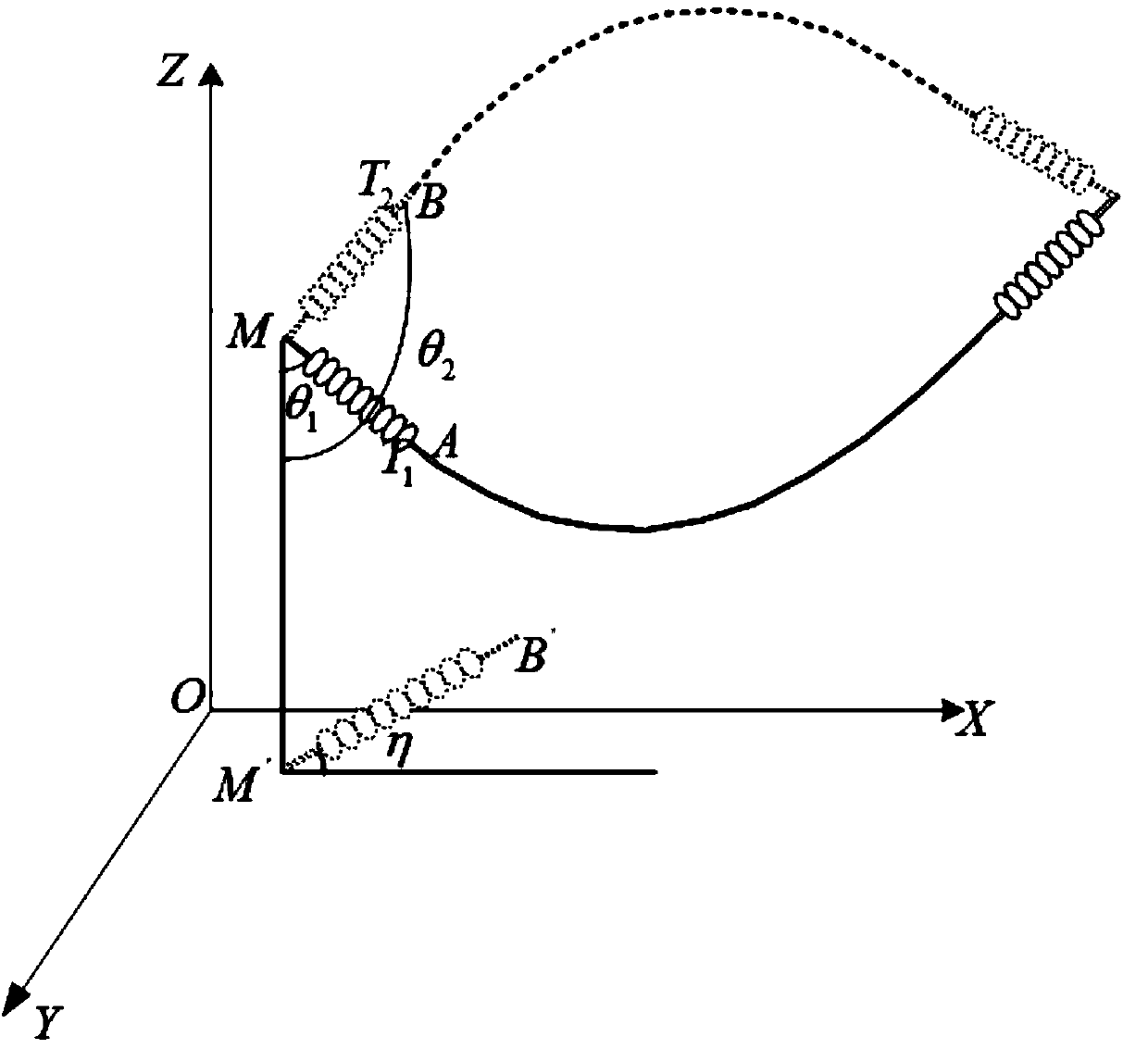

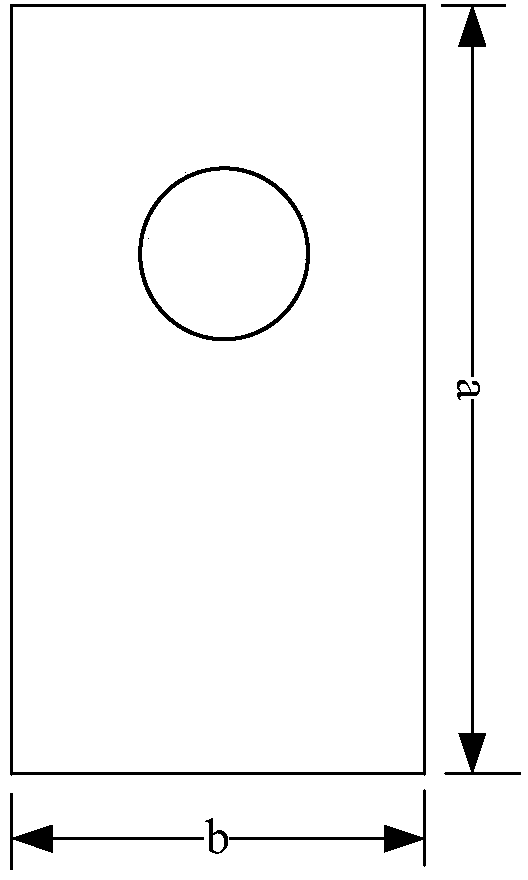

Measurement method of power transmission line iced conductor galloping aerodynamic parameters

ActiveCN104913900AGalloping aerodynamic parameters are favorableAerodynamic testingEngineeringTorque coefficient

The invention discloses a measurement method of power transmission line iced conductor galloping aerodynamic parameters. The measurement method includes the following steps that: the galloping lift coefficient, galloping drag coefficient and galloping torque coefficient of a power transmission line iced conductor are acquired; 2) a plurality of cameras are utilized to perform multi-angle image capture on the power transmission line iced conductor, and the icing outline of the power transmission line iced conductor is obtained through a "three-tower two-gear" equivalent icing thickness mechanical calculation model, and an icing shape is obtained through fitting, and therefore, an actual icing shape of the power transmission line iced conductor can be obtained; 3) an inertial navigation sensor is used in combination with power transmission line conductor galloping trajectory reduction technology, so that the real-time wind attack angle of the power transmission line iced conductor can be obtained; 4) all the obtained data are utilized to draw aerodynamic parameter curves under the actual icing shape and the wind attack angle, and as a result the measurement of the galloping aerodynamic parameters of the power transmission line iced conductor can be completed. With the measurement method of the invention adopted, the aerodynamic parameters in the galloping of the power transmission line iced conductor can be measured actually.

Owner:西安金源电气股份有限公司

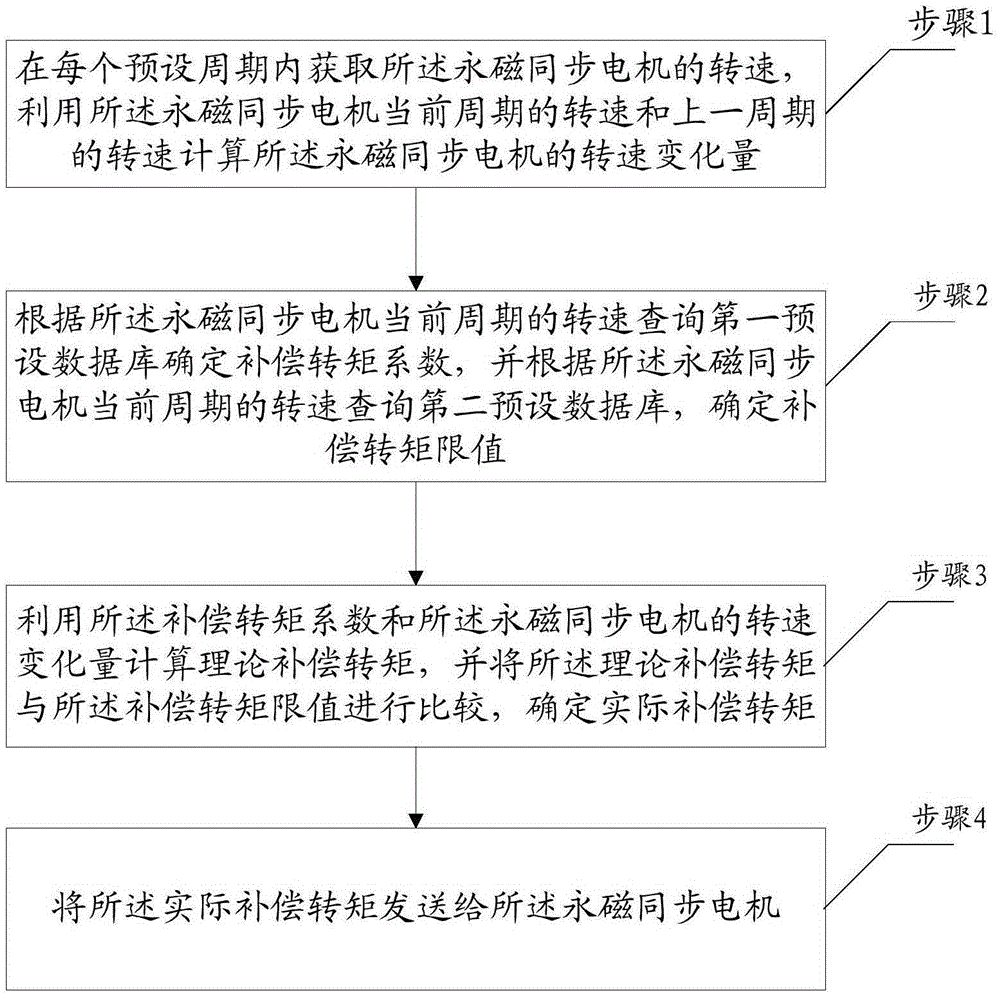

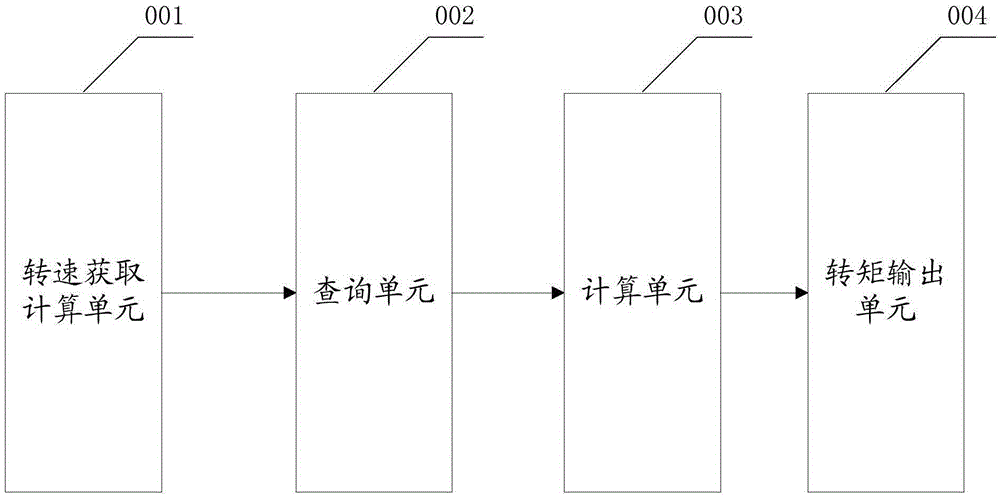

Electric vehicle, suppression method and suppression system of rotation speed fluctuation of permanent magnet synchronous motor

ActiveCN105305893AReduce jitterImprove comfortTorque ripple controlCar drivingPermanent magnet synchronous motor

The embodiment of the invention provides a suppression method and suppression system of the rotation speed fluctuation of a permanent magnet synchronous motor. The method includes the following steps that: the rotation speed of the permanent magnet synchronous motor is obtained in each preset period, and the variation quantity of the rotation speed of the permanent magnet synchronous motor is calculated through using the rotation speed of the permanent magnet synchronous motor in the current period and the rotation speed of the permanent magnet synchronous motor in the last period; a first preset database is queried according to the rotation speed in the current period, so that a compensation torque coefficient can be determined, and a second preset database is queried according to the rotation speed in the current period, so that a compensation torque limit value can be determined; theoretical compensating torque is calculated through utilizing the compensation torque coefficient and the variation quantity of the rotation speed of the permanent magnet synchronous motor, and the theoretical compensating torque is compared with the compensation torque limit value, so that actual torque compensation torque can be determined; and the actual compensation torque is transmitted to the permanent magnet synchronous motor. With the method adopted, jigger generated when the permanent magnet synchronous motor is applied to an electric vehicle can be reduced, and the driving comfort of the electric vehicle can be improved.

Owner:深蓝汽车科技有限公司

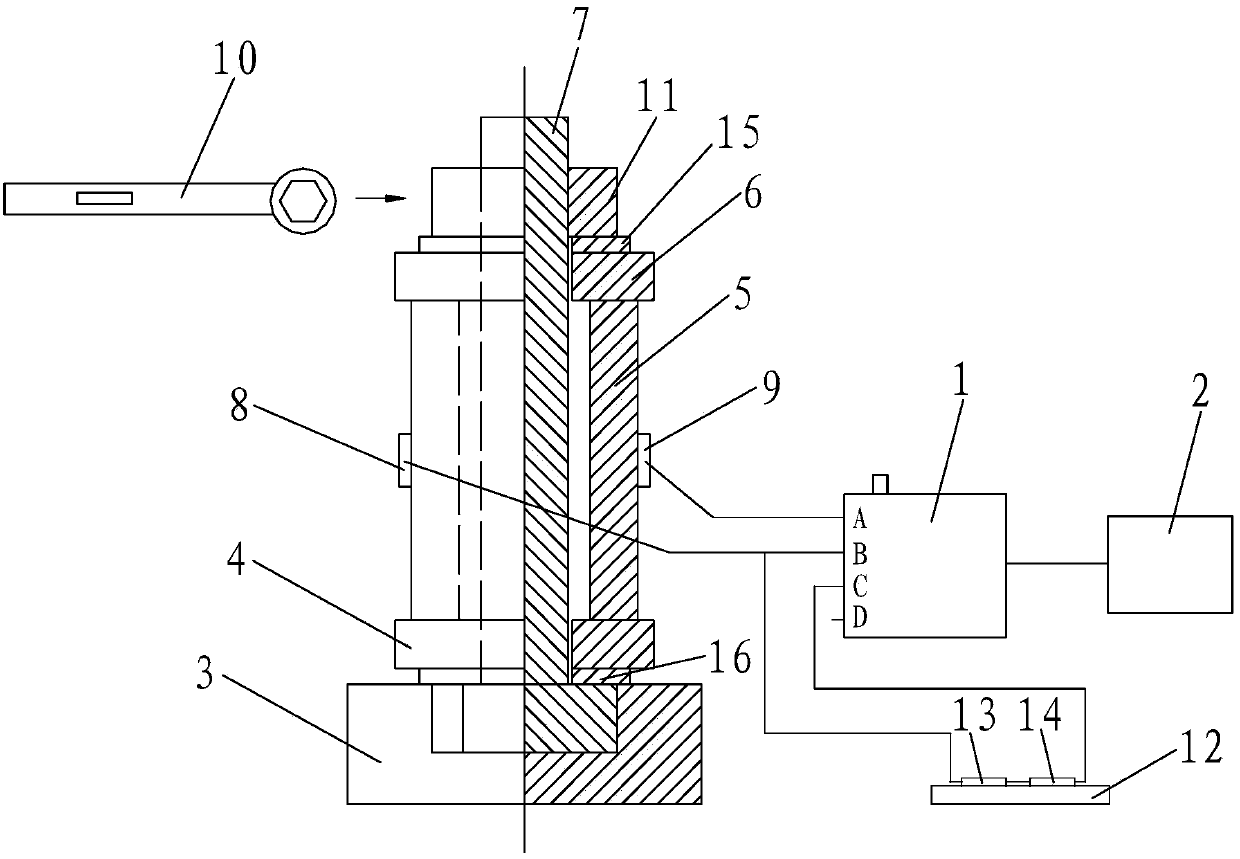

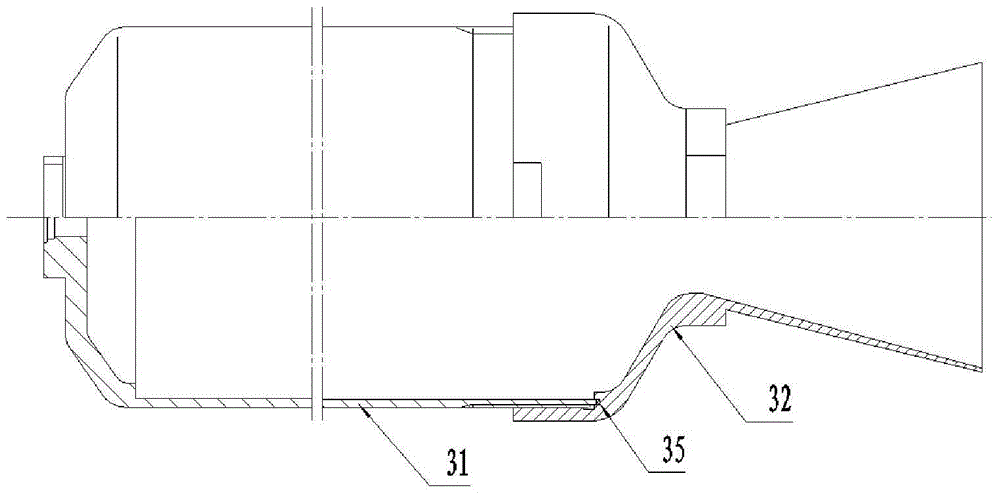

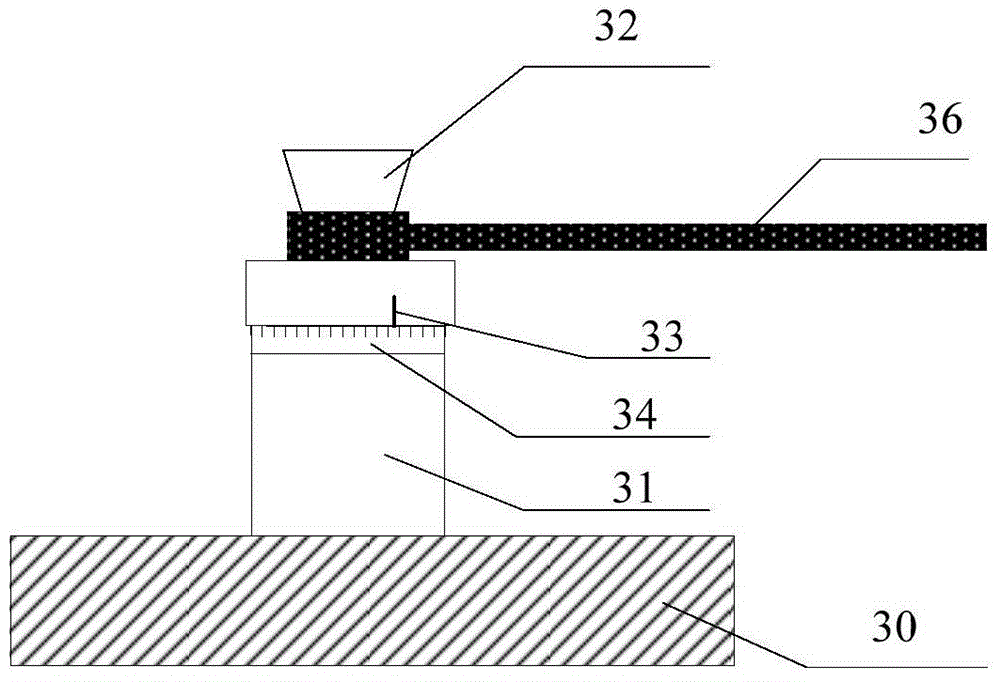

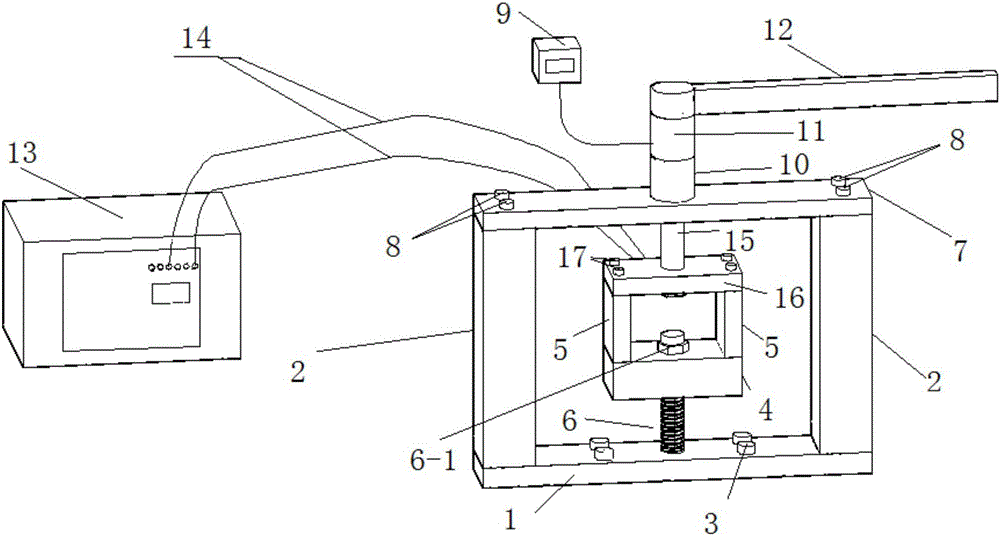

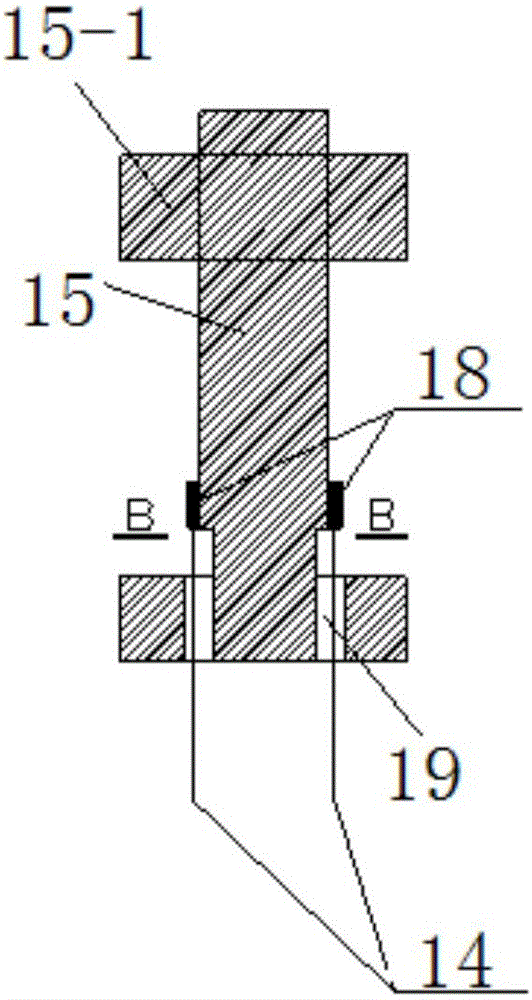

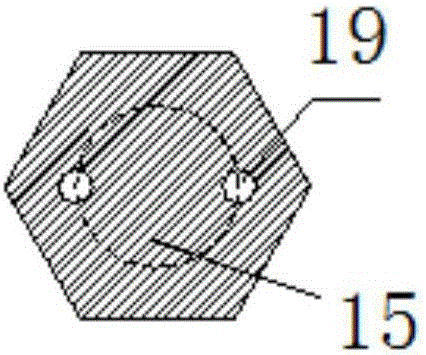

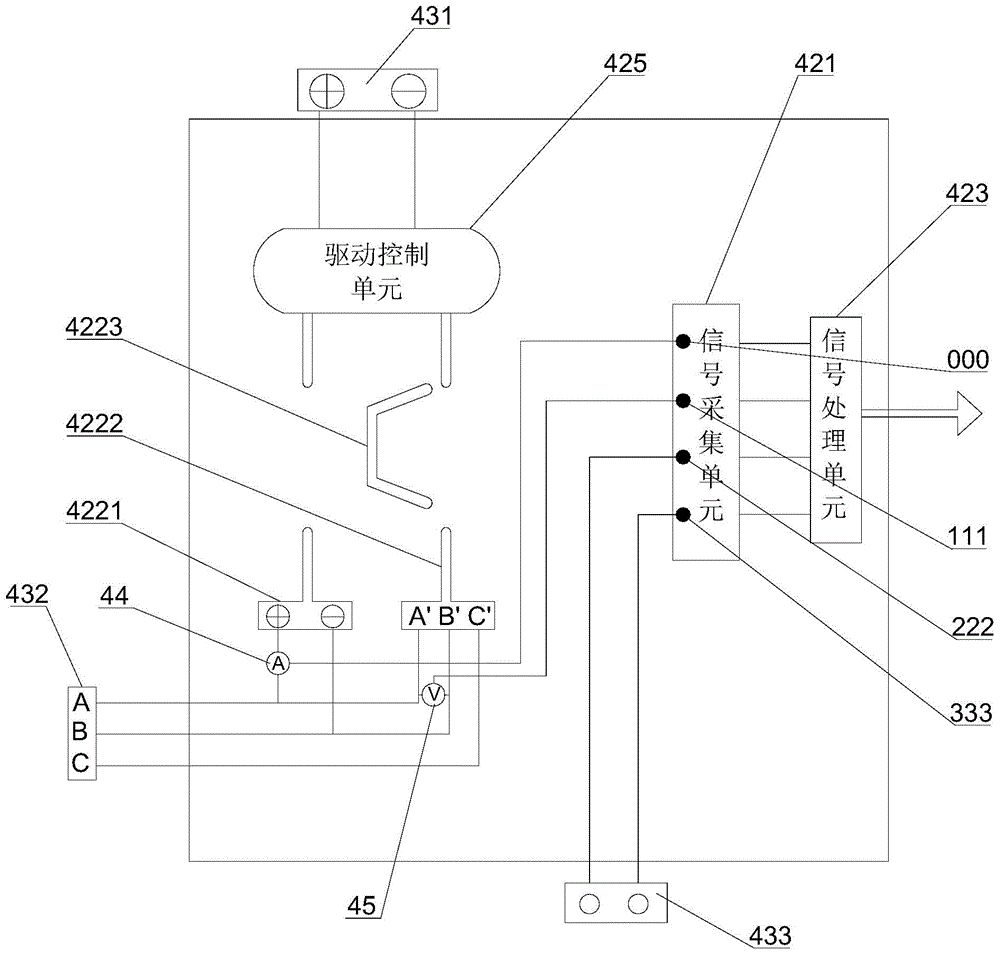

Device and method for measuring torque coefficient of high-strength bolt connecting pair

PendingCN106289622AAccurate dataAccurateMeasurement of torque/twisting force while tighteningElectrical resistance and conductanceMeasuring instrument

The invention belongs to the technical field of mechanical measuring instruments and equipment, and relates to a device and a method for measuring a torque coefficient of a high-strength bolt connecting pair. The device comprises a fixing device fixedly connected with a high-strength bolt connecting pair to be measured, and a torque spanner arranged at a nut matched with the high-strength bolt connecting pair to be measured and used for applying a torque to the nut, wherein the torque spanner is connected with the nut through a sleeve; a torque sensor is arranged between the torque spanner and the sleeve; the torque sensor is connected with a torque display; unidirectional strain sheets for measuring the axial strain of a screw of the high-strength bolt connecting pair to be measured are arranged on the screw between the nut and the head of the high-strength bolt connecting pair to be measured; the unidirectional strain sheets are connected with a resistance strain gauge. The device is simple in assembly, fast in operation, and accurate and reliable in measurement result, and is especially applicable to detection on the torque coefficients of the high-strength bolt connecting pairs in small batches.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

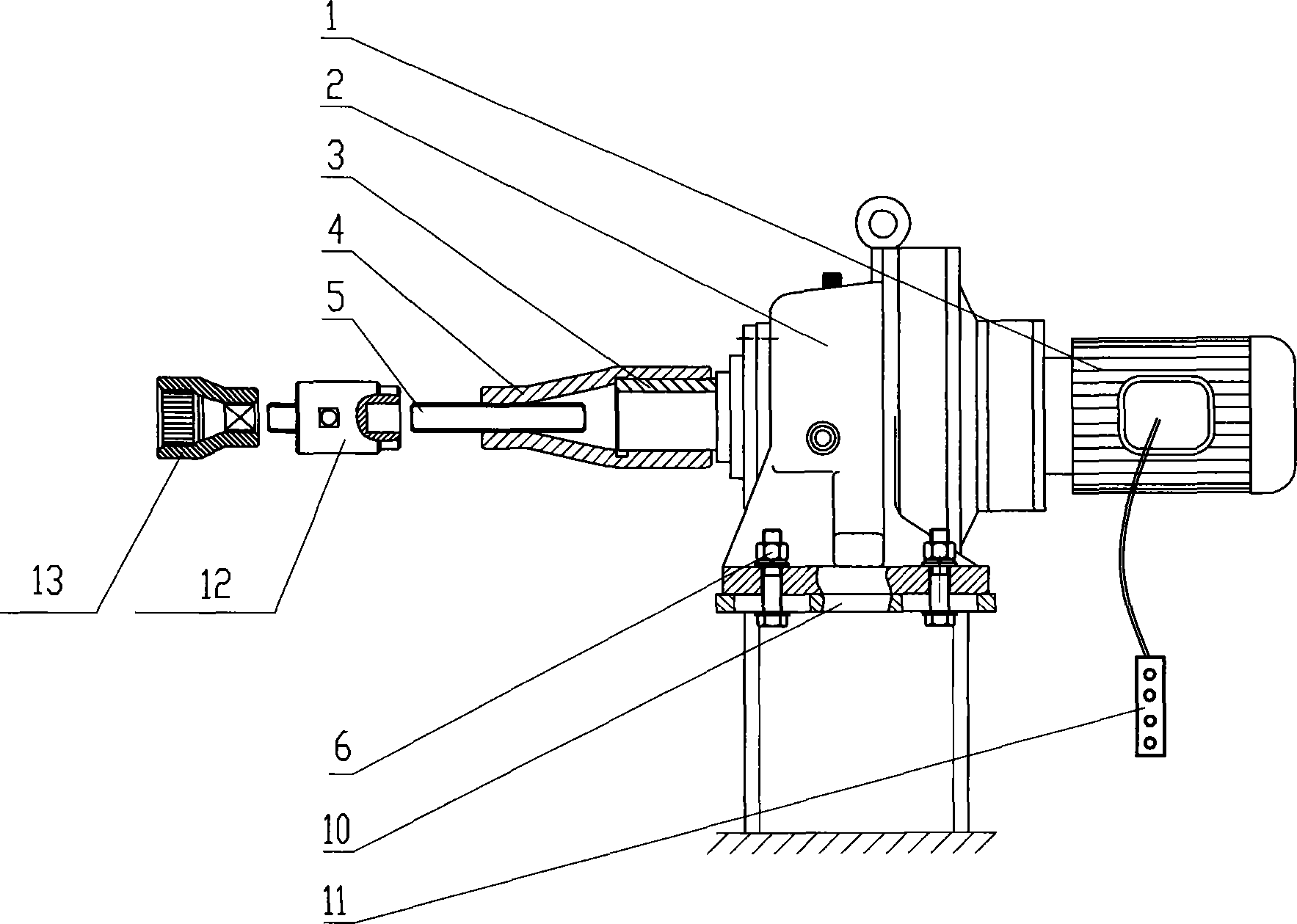

Electric force application device of torque coefficient comparator

InactiveCN101246069AGood realization of electric force application functionRealize the function of electric force applicationMeasurement of torque/twisting force while tighteningElectric forceReduction drive

The present invention relates to a torque coefficient detecting device electric force applying device in the high-strength bolt torque coefficient detecting field, and the device comprises a fixed platform, an electric motor, a speed reducer, a connecting axle sleeve, a torque force applying square roller and a control switch, the output axis of the speed reducer is connected with the connecting axle sleeve with a dead key, the torque force applying square roller is installed in the connecting axle sleeve and can slide along the axis direction of the connecting axle sleeve in the connecting axle sleeve. The torque coefficient detecting device electric force applying device provided by the invention has a fixed installing position, in the using process the high-strength bolt torque coefficient detecting device can be excellent applied with force, at the same time the free advancing and retreating of the torque sensor which is affiliated with the detecting device in the detecting process is set aside with a space, the experiment requirement to various standard bolts is adapted thereby facilitating the more portability and flexibility of the operation. Besides, the invention realizes the uniform-speed load applying and accuracy control to the experiment torque and helps to increase the experiment precision; the experiment procedure can be completed with one man, the labor intensity is reduced greatly and the operating efficiency is increased.

Owner:WUCHUAN HEAVY ENG

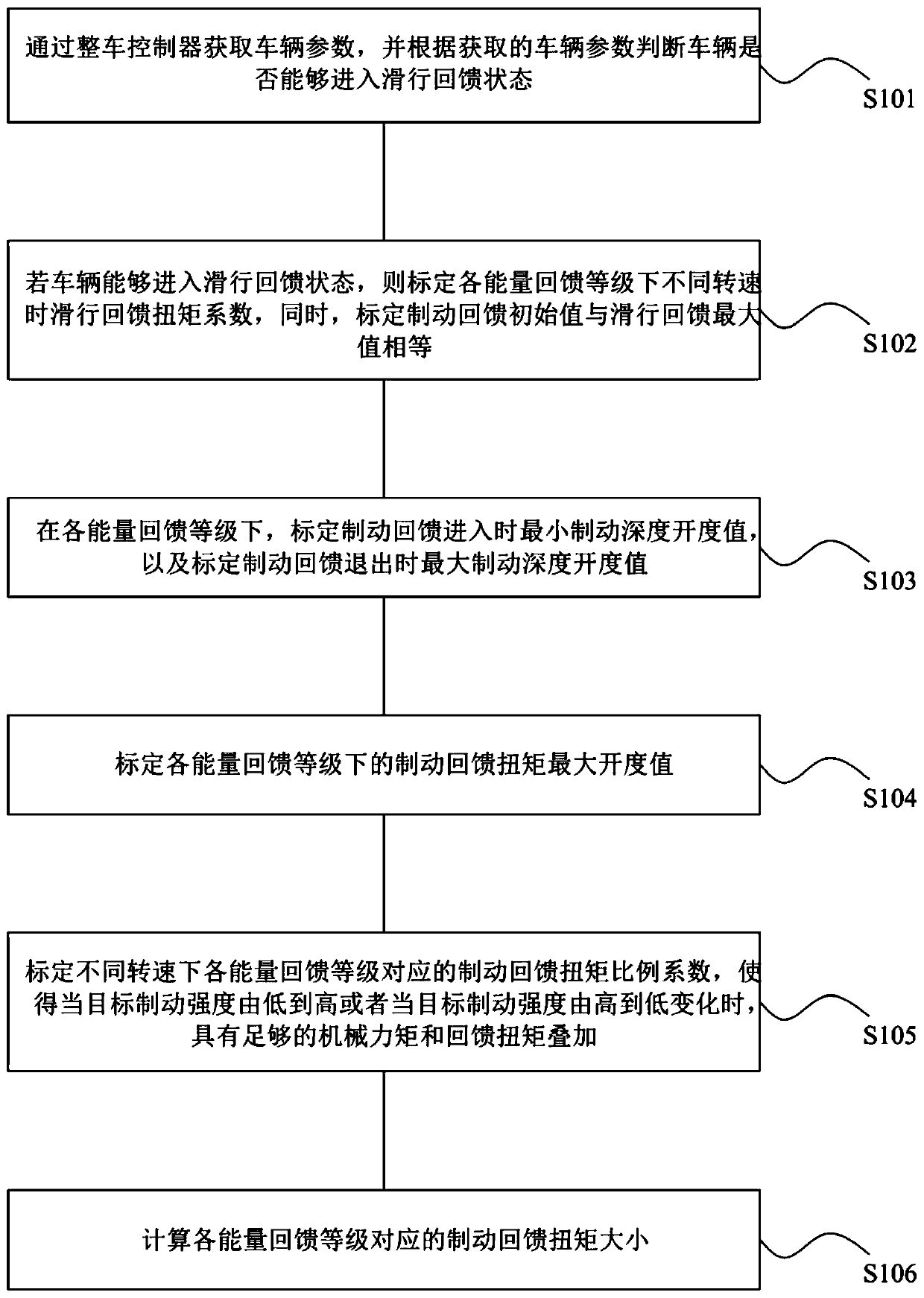

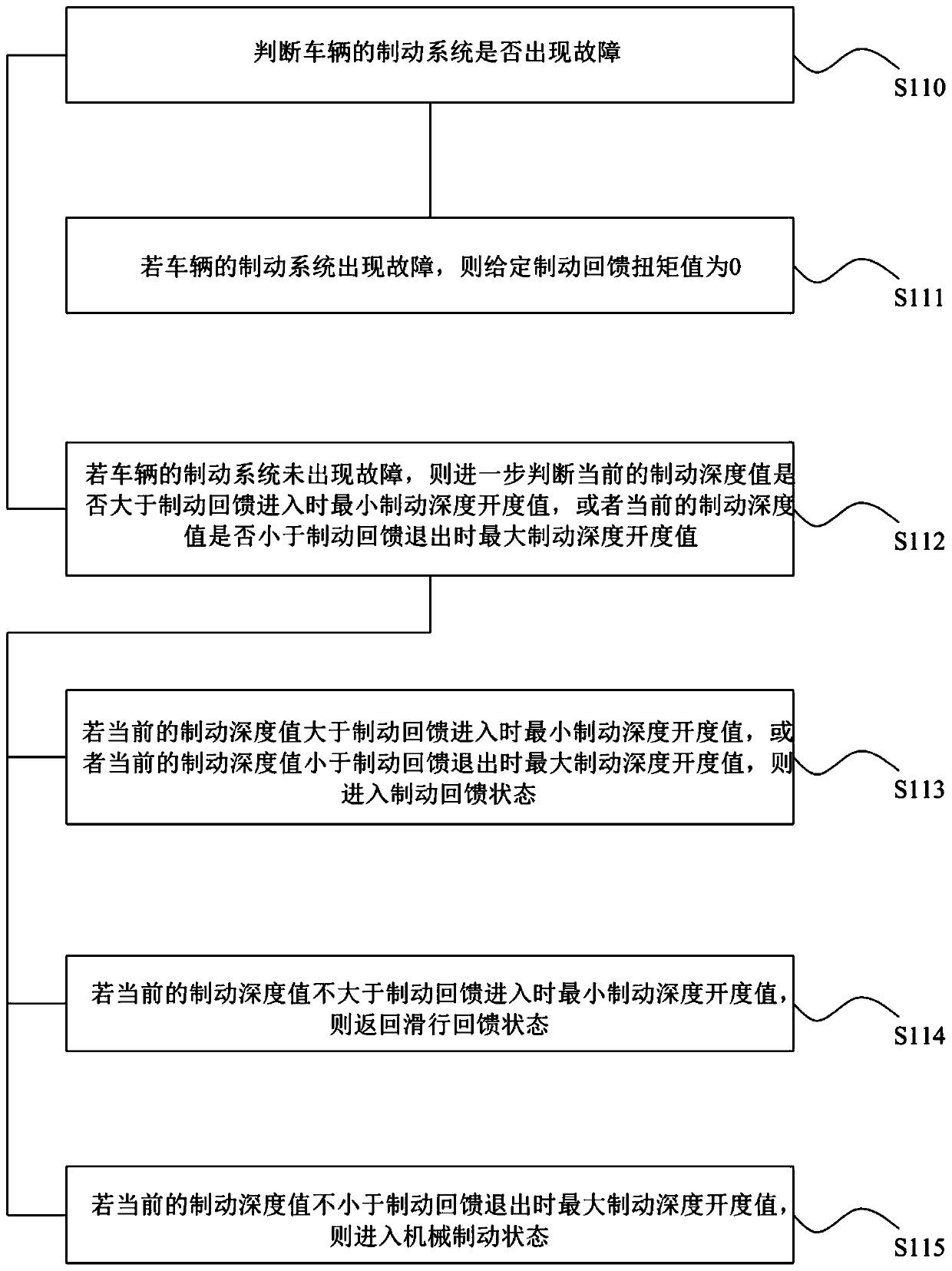

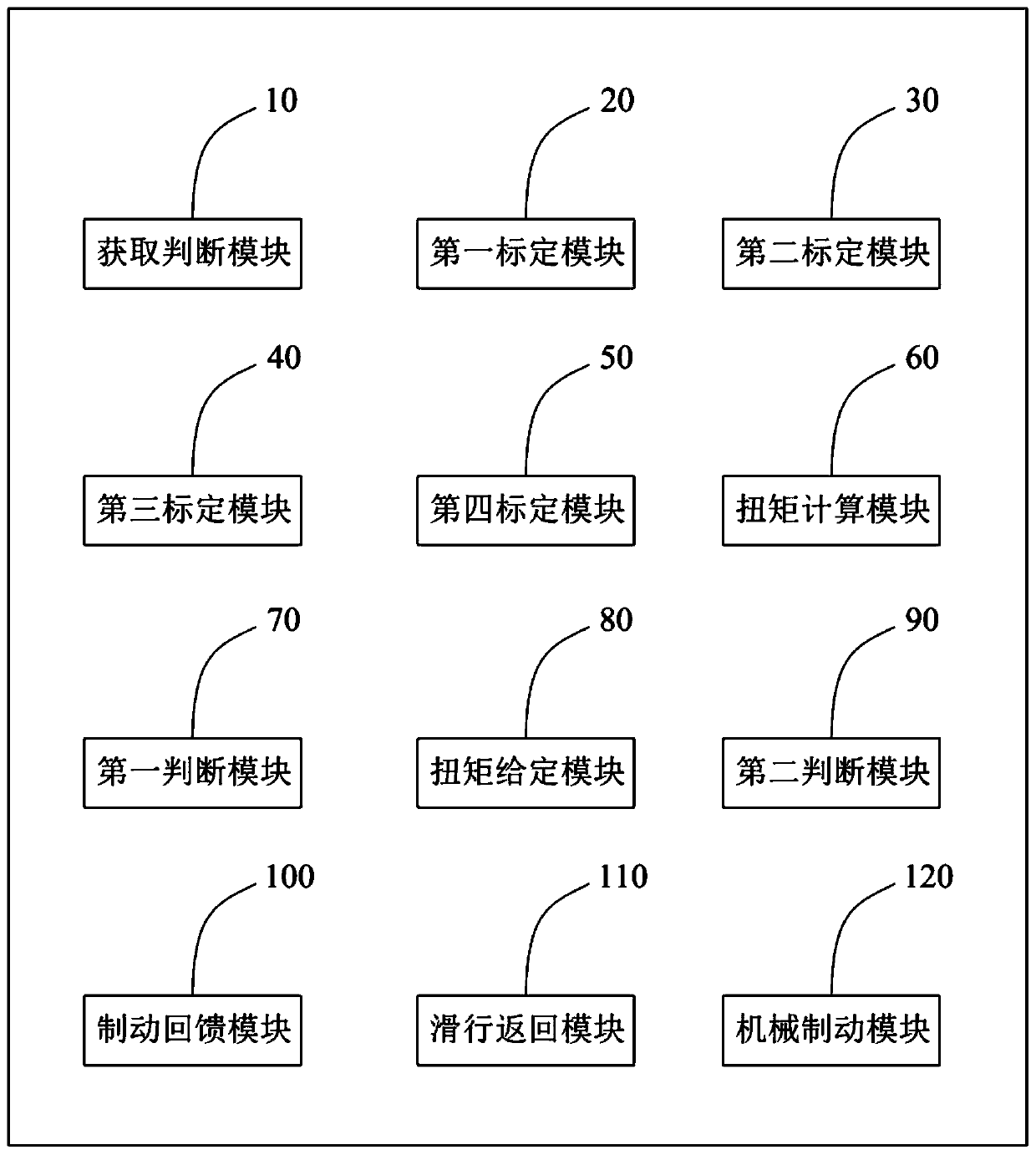

Brake linear calibration method and system for electric vehicle

ActiveCN109827782AMaximum braking feedback energyMaximum braking line sexinessVehicle testingApparatus for force/torque/work measurementEnergy recoveryTorque coefficient

The invention discloses a brake linear calibration method and system for an electric vehicle. The method comprises: acquiring a vehicle parameter by a vehicle controller and determining whether the vehicle enters a sliding feedback state based on the obtained vehicle parameter; if so, calibrating sliding feedback torque coefficients at different rotating speeds under all energy feedback levels andcalibrating the equivalence between an initial brake feedback value and a maximum sliding feedback value; under all energy feedback levels, calibrating a minimum braking depth opening value at entrance of brake feedback and calibrating a maximum braking depth opening value at exit of brake feedback; calibrating a maximum brake feedback torque opening value under all energy feedback levels; calibrating braking feedback torque proportional coefficients corresponding to all energy feedback levels at different rotating speeds; and calculating brake feedback torque corresponding to all energy feedback levels. Therefore, a technical problem of low linearity of electric vehicle braking is solved on the premise that the energy recovery is met; and thus the driving comfort is improved.

Owner:JIANGXI JIANGLING GRP NEW ENERGY AUTOMOBILE CO LTD

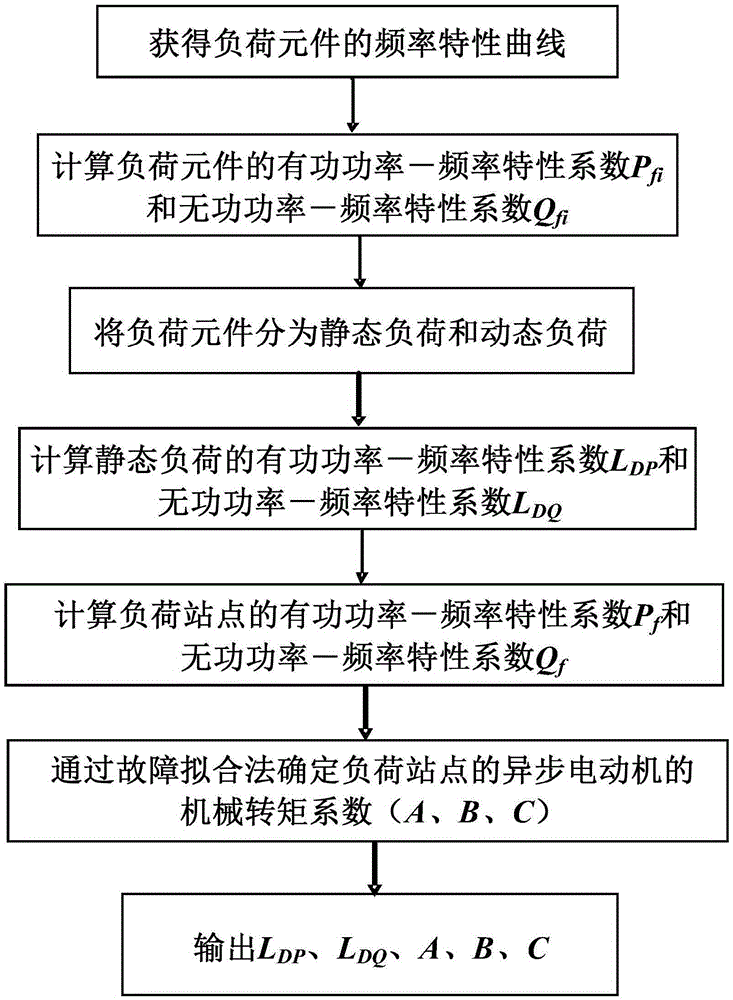

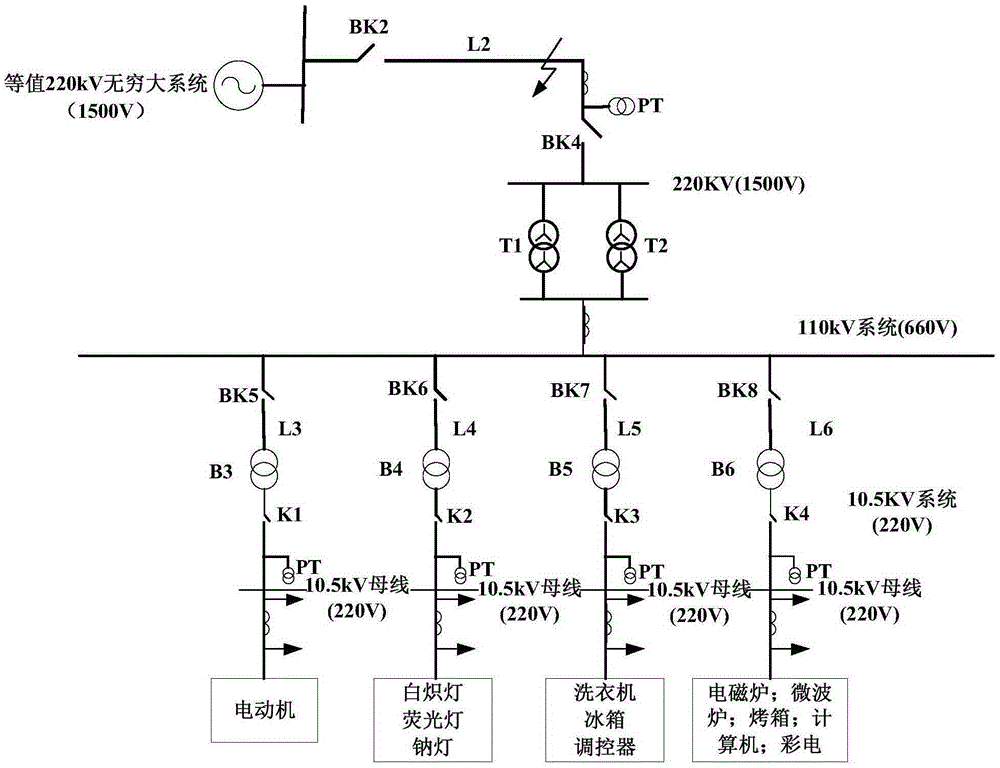

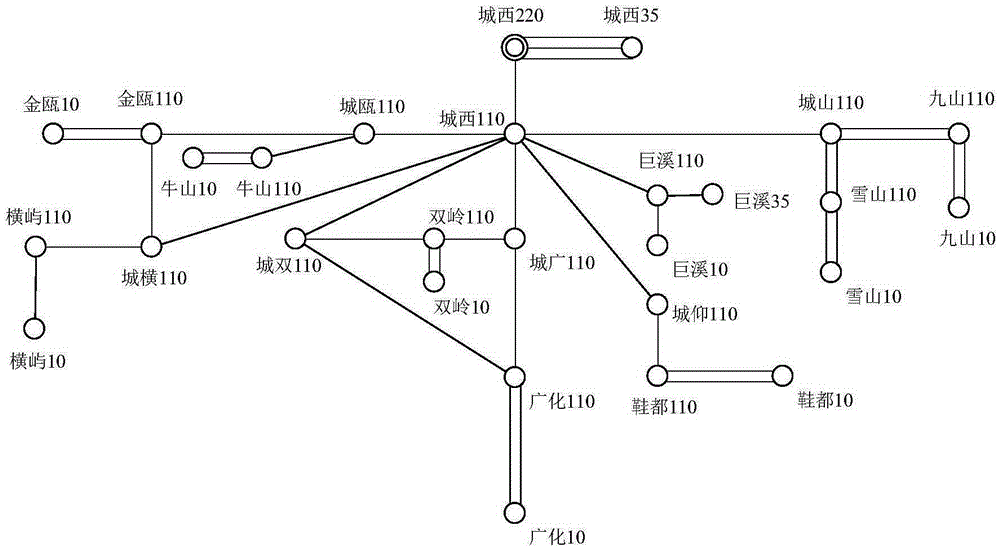

Load model building method of considering load frequency characteristics

ActiveCN105429131AEnsure safetyGuaranteed uptimeSpecial data processing applicationsAc network circuit arrangementsNODALInduction motor

The invention provides a load model building method of considering load frequency characteristics. The method comprises the following steps: obtaining a frequency characteristic curve of a load component; calculating an active power-frequency characteristic coefficient and a reactive power-frequency characteristic coefficient of the load component; dividing the load component into a static load and a dynamic load according to the load characteristic; calculating the active power-frequency characteristic coefficient and the reactive power-frequency characteristic coefficient of the static load; calculating the active power-frequency characteristic coefficient and the reactive power-frequency characteristic coefficient of a load node; and determining a mechanical torque coefficient of an asynchronous motor of the load node. According to the load model building method, the defect that a traditional load model cannot accurately describe the load frequency characteristics is overcome; the simulating calculation credibility of a power system is improved; and a forceful guarantee is provided for scientific planning and safe and stable operation of the power system.

Owner:CHINA ELECTRIC POWER RES INST +1

Surface treatment process of bolt connection pair

ActiveCN102212767APrecise control of torque coefficientEasy to operateHot-dipping/immersion processesNutsMolybdenum disulfideControl torque

The invention discloses a surface treatment process of a bolt connection pair, comprising the following steps of: galvanizing on the surface of the bolt connection pair; and then performing secondary surface treatment by the steps of: A, preparing lubricant, wherein the lubricant is composed of molybdenum disulfide, dry film lubricant and de-ionized water; and the mass ratio of the molybdenum disulfide to the dry film lubricant to the de-ionized water is 1:15:(50-100); adding the dry film lubricant and the molybdenum disulfide into the de-ionized water and uniformly stirring; B, immersing thegalvanized bolt connection pair in the lubricant prepared in the step A to perform centrifugal rotation, wherein the rotation speed is 300 rpm and the centrifugal rotation time is 30 s; and C, after the centrifugal rotation, taking out the bolt connection pair; and drying at 200-250 degrees centigrade for 30 min. The bolt connection pair can be applicable to application occasions with requirementon higher rust protection capability through the secondary surface treatment so as to achieve the purpose of precisely controlling torque coefficients.

Owner:宁波中京电气科技有限公司

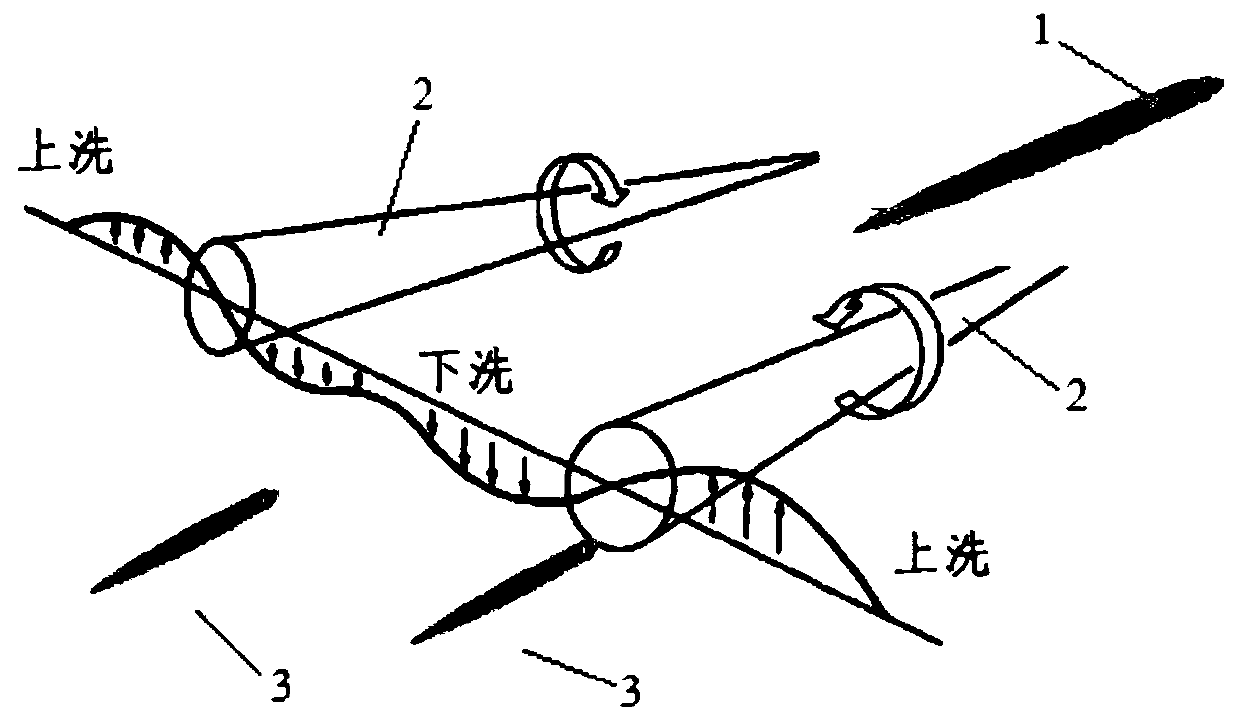

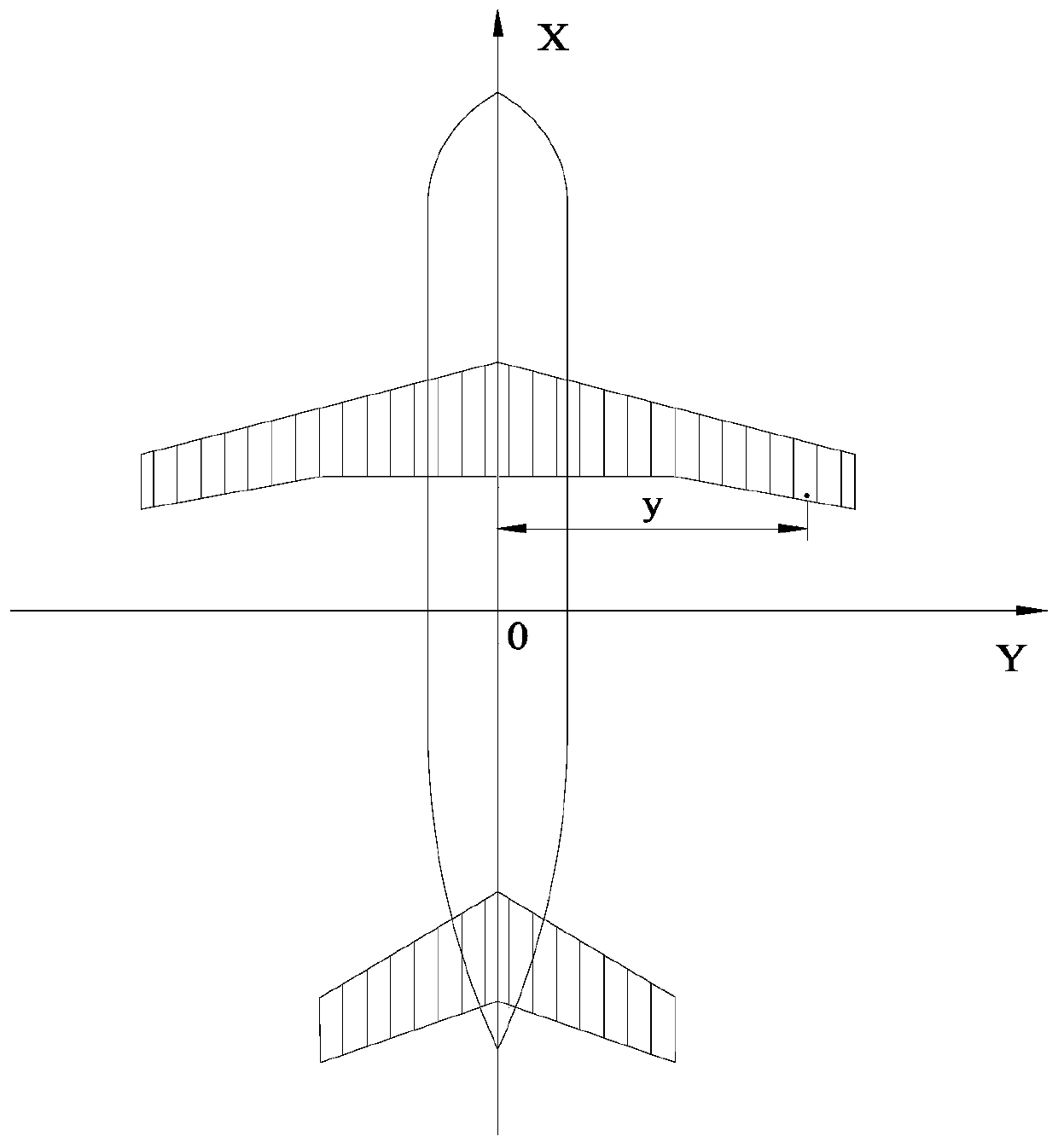

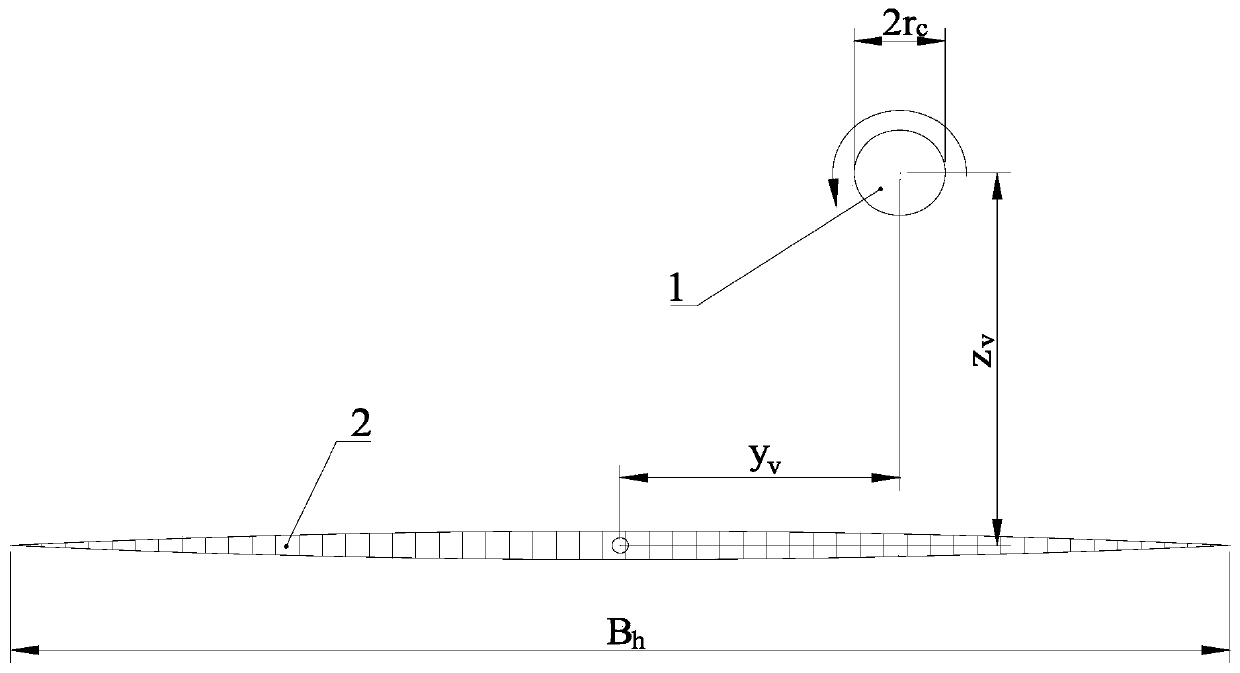

A method for measuring the rolling risk degree of an aircraft after the aircraft encounters a trailing vortex

ActiveCN109918764AVerify suitabilityFit closelySpecial data processing applicationsJet aeroplaneTorque coefficient

The invention discloses a method for measuring the rolling risk degree of an airplane after the aircraft encounters a tail vortex. The method comprises the following steps that the initial vortex ringquantity Gamma 0 and the tangential speed V Theta (r) of the front tail vortex are calculated; Based on a strip-shaped band method, simplifying the aircraft into wings, and calculating a trailing vortex induced moment M borne by a rear aircraft; And adopting the rolling torque coefficient RMC to measure the rolling risk degree of the aircraft encountering the tail vortex, and calculating the rolling torque coefficient RMC according to the induced torque M of the tail vortex. According to the method, a strip-shaped band method is used for researching and analyzing wake flow induction torque, an RMC model for measuring the encountering severity degree is established, the RMC value obtained through calculation and the RMC value under the ICAO interval standard have the good fitting degree, the applicability of the model is verified, and the method can be used for safety analysis of an airplane encountering wake flow; The RMC model can provide research basis for wake flow safety intervalstandard reduction between specific aircrafts in operation, so that the safety distance when the aircrafts approach is better provided.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA +1

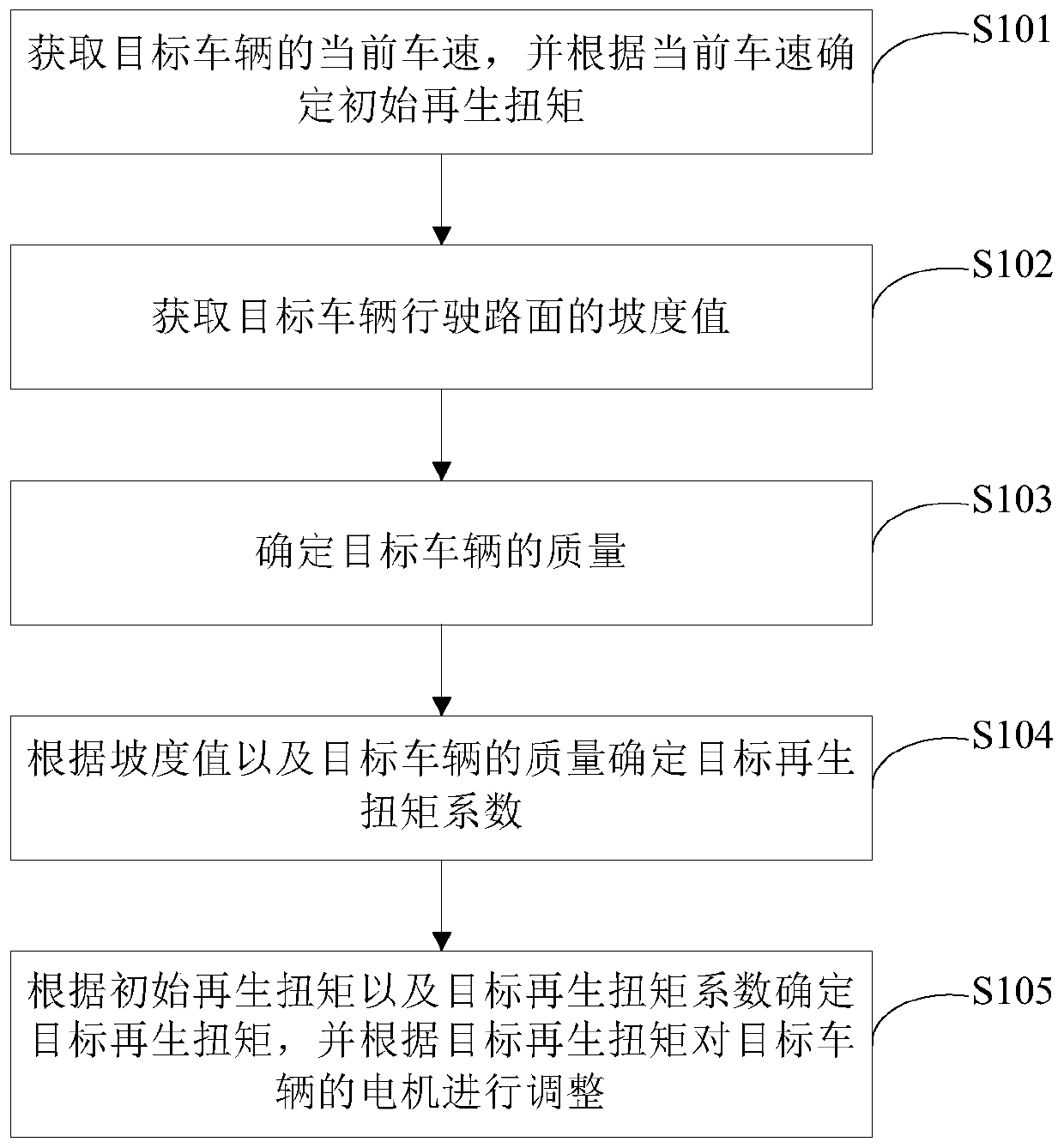

Vehicle regeneration torque adjusting method and vehicle

ActiveCN111361544AEfficient recyclingAvoid wastingElectrodynamic brake systemsElectric machineryRoad surface

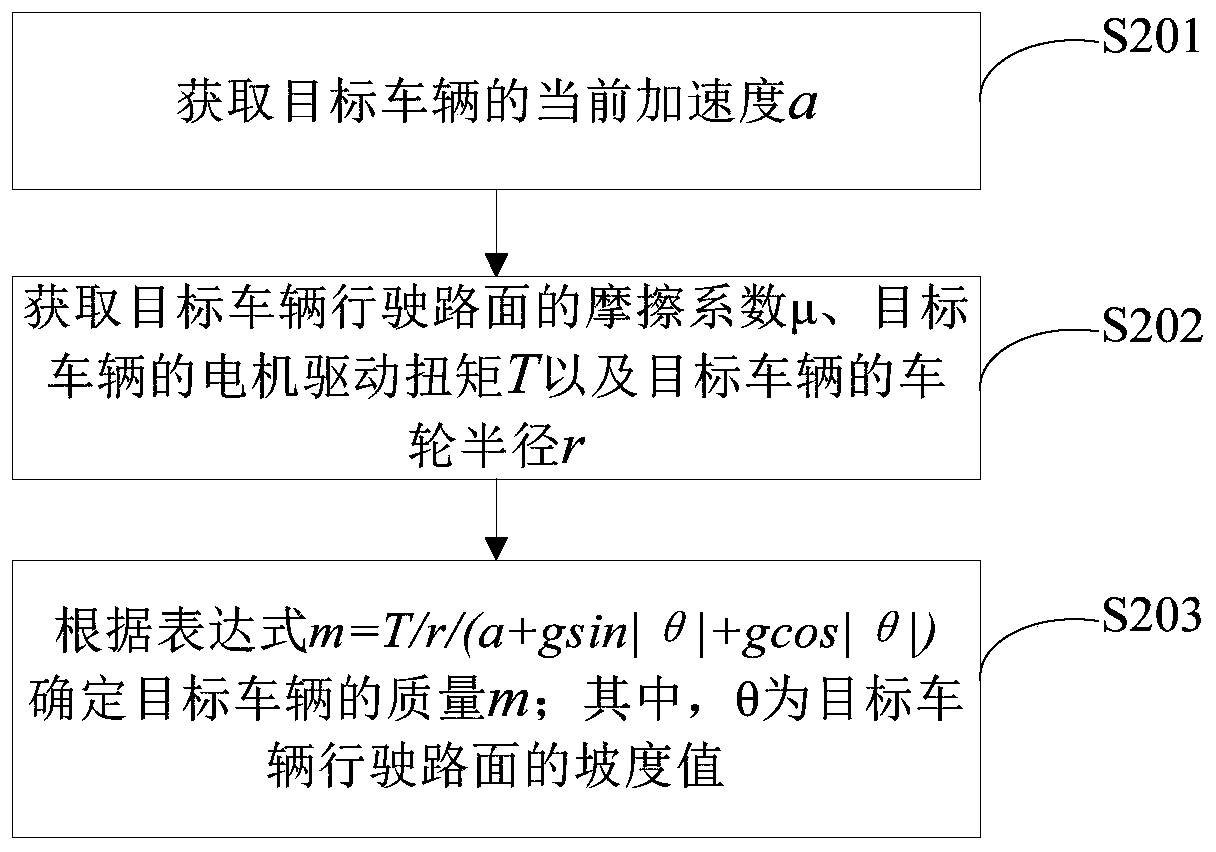

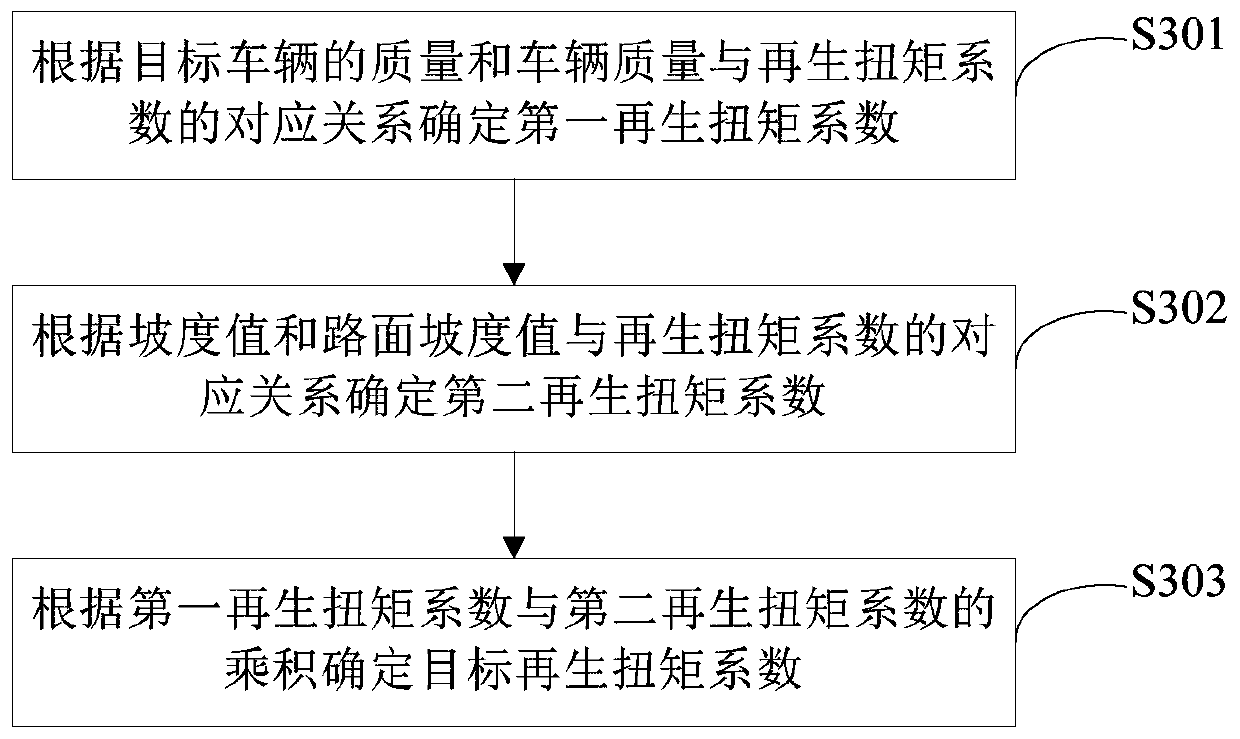

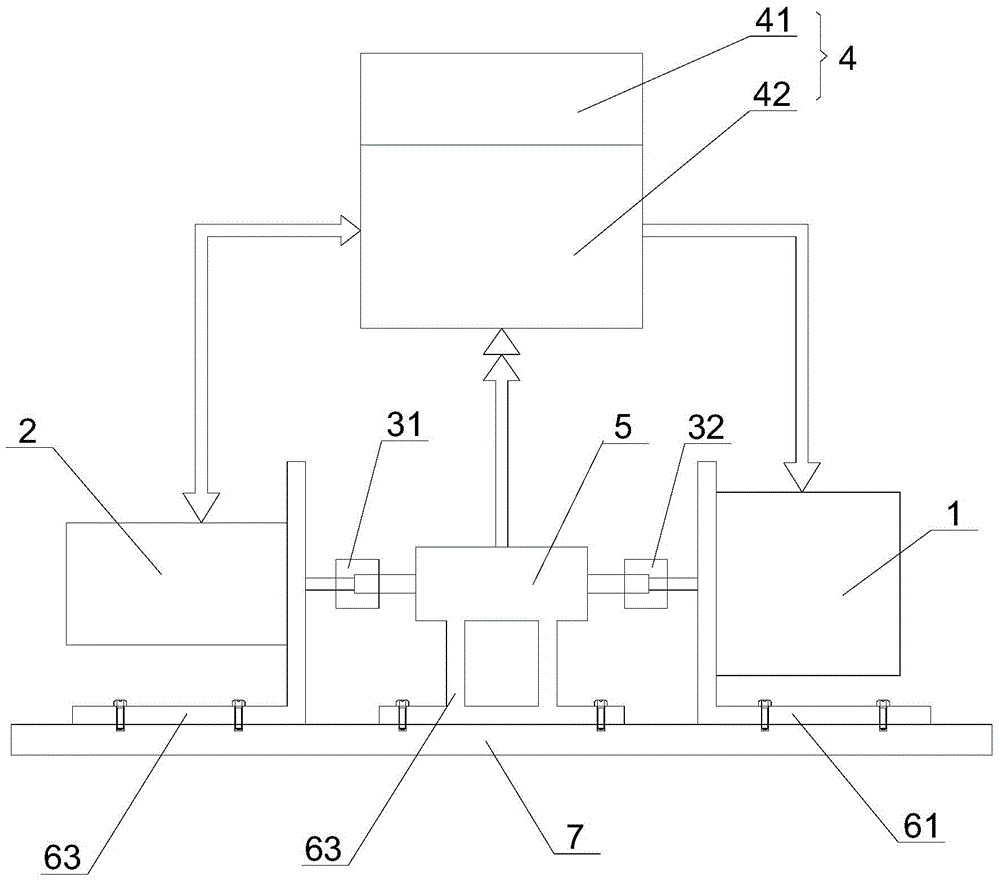

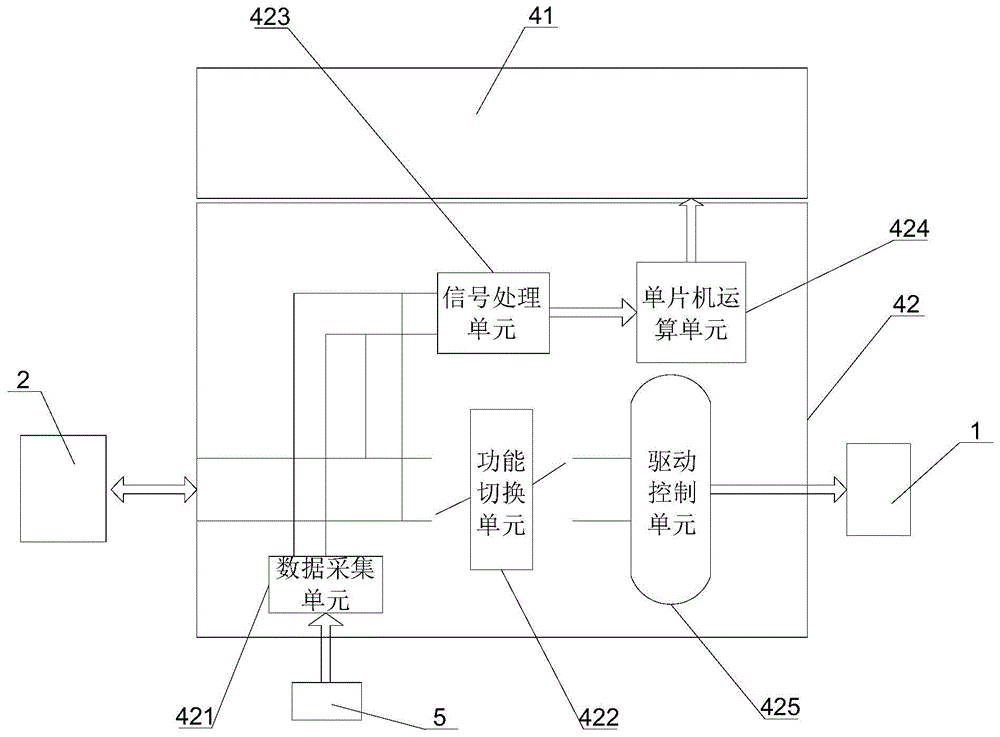

The embodiment of the invention provides a vehicle regeneration torque adjusting method and a vehicle. The method comprises the following steps: obtaining the current speed of a target vehicle, and determining an initial regeneration torque according to the current speed; obtaining a gradient value of the driving road surface of the target vehicle; determining the mass of the target vehicle; determining a target regeneration torque coefficient according to the gradient value and the mass of the target vehicle; and determining a target regeneration torque according to the initial regeneration torque and the target regeneration torque coefficient, and adjusting a motor of the target vehicle according to the target regeneration torque. According to the embodiment of the invention, the brake energy can be more efficiently recycled, and energy waste is avoided.

Owner:WEICHAI POWER CO LTD

Permanent magnet motor characteristic quantity measuring device and torque coefficient measuring method

InactiveCN104635158AGuaranteed accuracyImprove versatilityApparatus for force/torque/work measurementDynamo-electric machine testingCouplingElectric machine

The invention discloses a permanent magnet motor characteristic quantity measuring device, and belongs to the field of a permanent magnet motor measuring device. The measuring device comprises a prime mover, a motor to be measured and a shaft coupler, wherein the prime mover is connected with the motor to be measured through the shaft coupler, the permanent magnet motor characteristic quantity measuring device also comprises a display control instrument and a torque and rotating speed sensor, the display control instrument is used for measuring a torque coefficient and a back electromotive force coefficient, the torque and rotating speed sensor is respectively and rotatablely connected with the prime mover and the motor to be measured through the shaft coupler, the display control instrument is respectively and electrically connected with the prime mover, the motor to be measured and the torque and rotating speed sensor. The measuring device has the switching function, the torque coefficient detection can be carried out, and the back electromotive force coefficient detection can also be realized. The invention also discloses a torque coefficient measuring method used for the measuring device of the permanent magnet motor to be measured. In the torque coefficient measuring mode, the torque inflection point of the permanent magnet motor due to magnetic field saturation is precisely measured.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com