Online compression amount measurement method for seal ring of small solid rocket

A measurement method and sealing ring technology, which can be used in measurement devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve problems such as low efficiency, improve measurement efficiency, improve test efficiency, reduce assembly times and The effect of measuring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

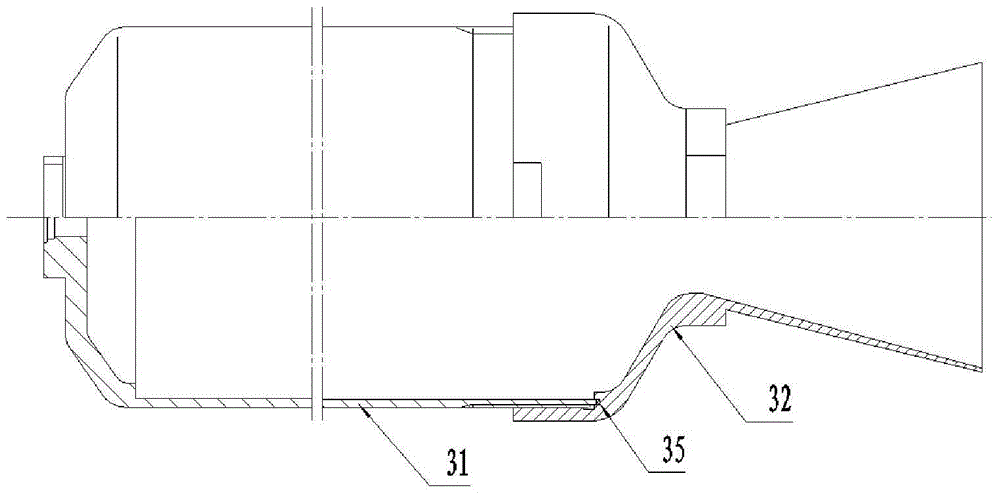

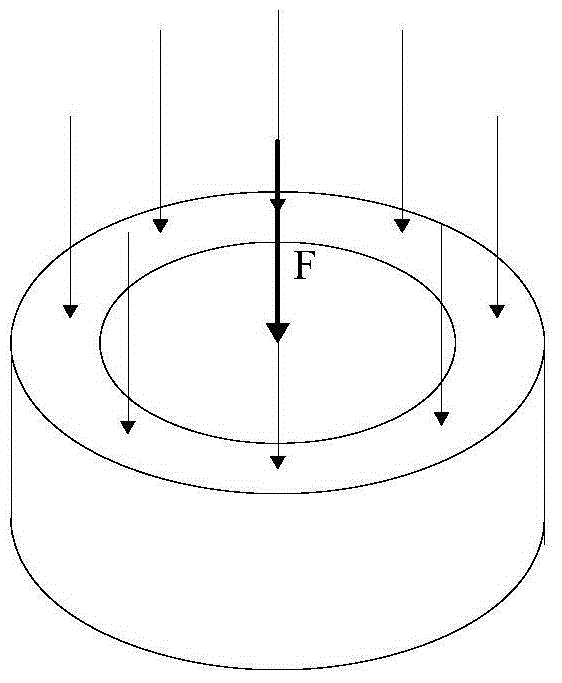

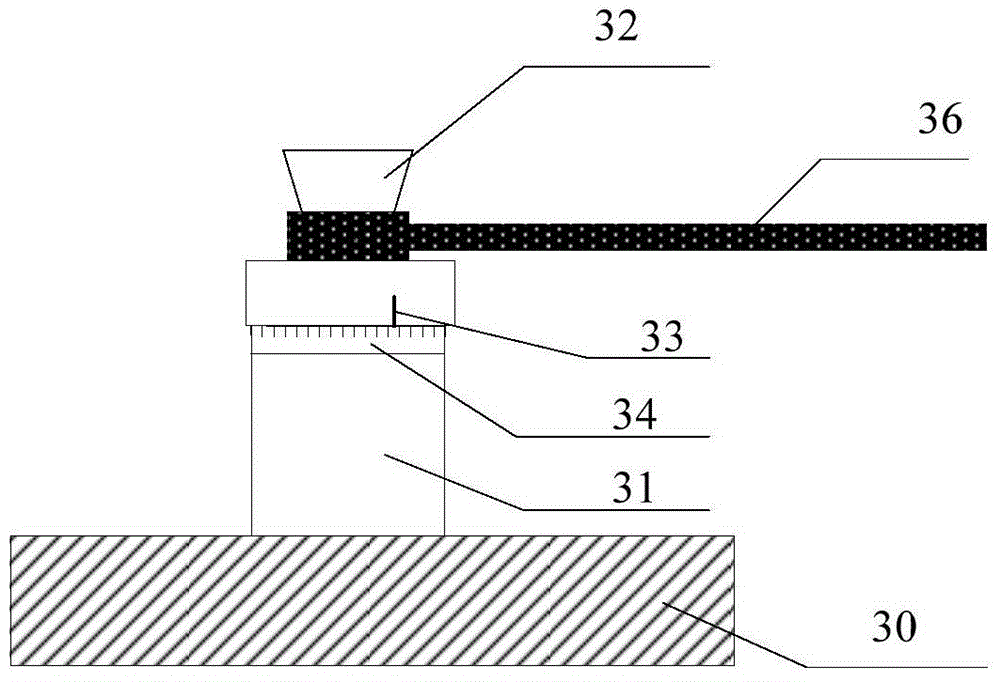

[0020] The present invention firstly analyzes the force condition of the sealing ring, and further obtains the relationship between the compression amount of the sealing ring and the tightening torque by establishing the relationship between the compression amount of the sealing ring and the axial force, and the relationship between the axial force and the tightening torque; The tightening torque is directly proportional to the tightening torque (this proportional coefficient is named as the tightening torque coefficient K), and the method of identifying the tightening torque coefficient through the process test is further proposed; in the process test, in addition to the tightening torque coefficient K, the sealing Circle compression reference value M, tightening torque reference value θ, etc., write these reference values into the database to provide a basis for online measurement judgment; in the actual tightening process, by measuring the angle and output torque of the tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com