Surface treatment process of bolt connection pair

A technology of surface treatment and connection pair, which is applied in the direction of bolts, connection components, hot-dip plating process, etc., to achieve the effect of precisely controlling the torque coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

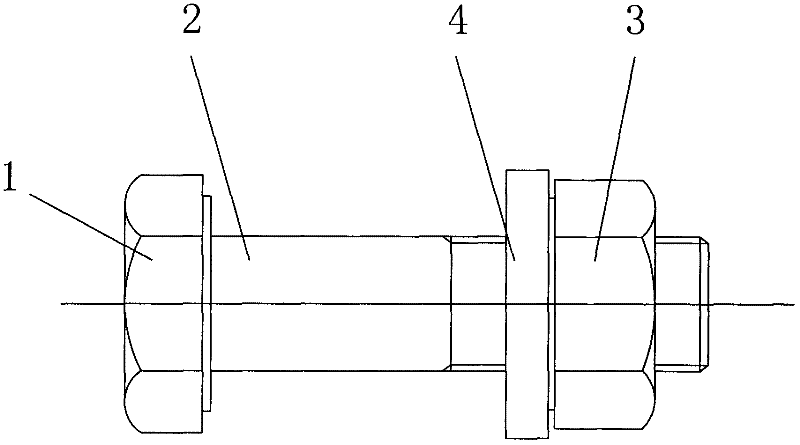

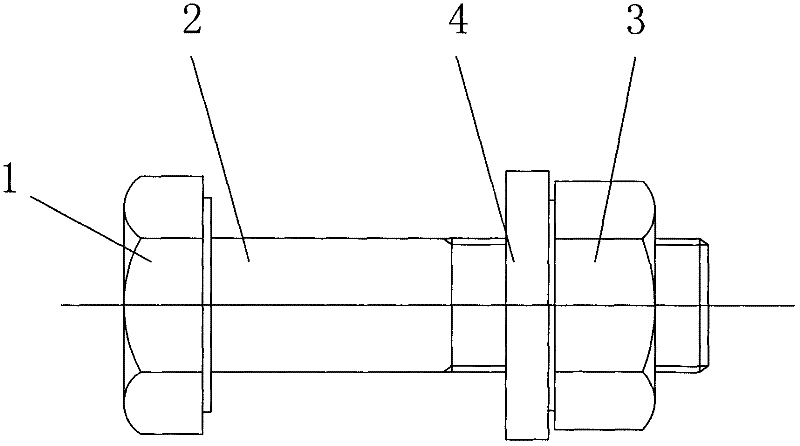

[0020] refer to figure 1 , The bolt connection pair includes a bolt with a screw head 1 and a screw rod 2 , and a nut 3 and a washer 4 screwed on the screw rod 2 . A surface treatment process for a bolt connection pair. First, galvanizing is performed on the surface of the bolt connection pair. The galvanizing method is Dacromet galvanizing. The steps are:

[0021] A: Prepare lubricant, which is composed of molybdenum disulfide, dry film lubricant and deionized water. The mass ratio of molybdenum disulfide: dry film lubricant: deionization is 1:15:100, and the dry film lubricant For the GLEITMO lubricant produced by German Fuchs Oil Group, the particle size of molybdenum disulfide is 2000 mesh, and the dry film lubricant and molybdenum disulfide are added to deionized water and stirred evenly;

[0022] B. Put the lubricant prepared in step A in the centrifuge, immerse the galvanized bolt connection pair into the lubricant prepared in step A, and turn on the centrifuge for ce...

Embodiment 2

[0026] refer to figure 1 , The bolt connection pair includes a bolt with a screw head 1 and a screw rod 2 , and a nut 3 and a washer 4 screwed on the screw rod 2 . A surface treatment process for a bolt connection pair. First, galvanizing is performed on the surface of the bolt connection pair. The galvanizing method is hot-dip galvanizing. After galvanizing, a secondary surface treatment is performed. The secondary surface treatment The steps are:

[0027] A: Prepare lubricant, which is composed of molybdenum disulfide, dry film lubricant and deionized water. The mass ratio of molybdenum disulfide: dry film lubricant: deionization is 1:15:50, and the dry film lubricant For the GLEITMO lubricant produced by German Fuchs Oil Group, the particle size of molybdenum disulfide is 2000 mesh, and the dry film lubricant and molybdenum disulfide are added to deionized water and stirred evenly;

[0028] B. Put the lubricant prepared in step A in the centrifuge, immerse the galvanized ...

Embodiment 3

[0032] refer to figure 1 , The bolt connection pair includes a bolt with a screw head 1 and a screw rod 2 , and a nut 3 and a washer 4 screwed on the screw rod 2 . A surface treatment process for a bolt connection pair. First, galvanizing is performed on the surface of the bolt connection pair. The galvanizing method is Dacromet galvanizing. The steps are:

[0033] A: Prepare lubricant, which is composed of molybdenum disulfide, dry film lubricant and deionized water. The mass ratio of molybdenum disulfide: dry film lubricant: deionization is 1:15:60, and the dry film lubricant For the GLEITMO lubricant produced by German Fuchs Oil Group, the particle size of molybdenum disulfide is 1980 mesh, and the dry film lubricant and molybdenum disulfide are added to deionized water and stirred evenly;

[0034] B. Put the lubricant prepared in step A in the centrifuge, immerse the galvanized bolt connection pair into the lubricant prepared in step A, and turn on the centrifuge for cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com