Electric force application device of torque coefficient comparator

A technology of torque coefficient and force-applying device, which is applied to measure the direction of torque/torsional force during tightening, which can solve the problems of increasing unreliable factors, complex structure, inconvenient operation, etc., achieving easy operation, reducing labor intensity and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

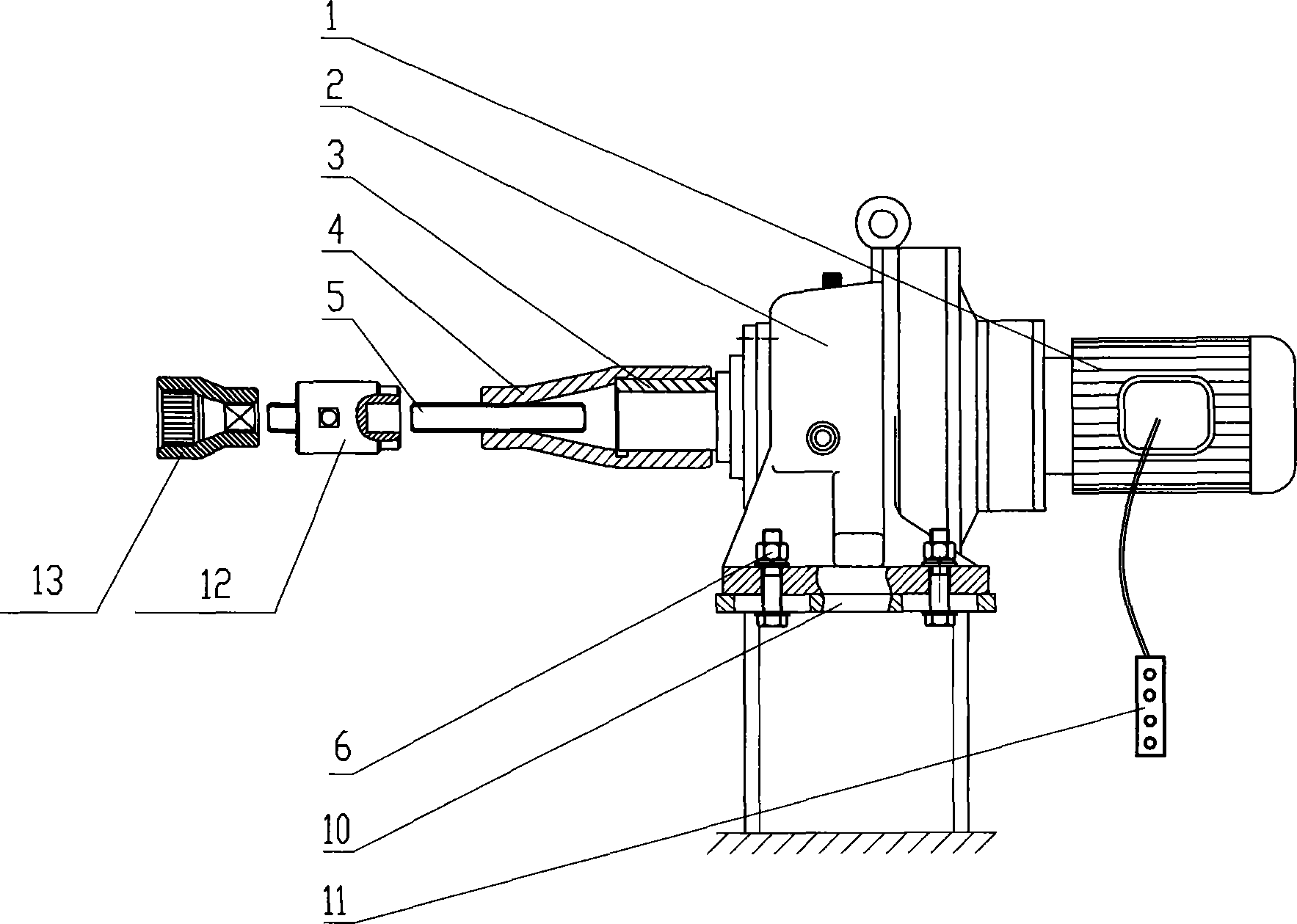

[0011] Such as figure 1 In the electric force applying device of the torque coefficient calibrator shown in the figure, the reducer 2 is a cycloidal pinwheel deceleration mechanism, the output shaft at one end of the reducer 2 is connected with the connecting shaft sleeve 4 with the fixed key 3, and the other end is connected with the motor 1, the reducer 2 is fixed on the fixed platform 10 with bolts 6. One end of the torque applying square roller 5 is matched with the square hole in the connecting shaft sleeve 4 and installed in the connecting shaft sleeve 4 to form a closed plane moving pair, and the other end of the torque applying square roller 5 is matched with the square hole of the torque sensor belonging to the torque coefficient calibrator . The output shaft of the reducer 2, the connecting bushing 4, the torque applying square roller 5 and the torque sensor 12 are located on the same central axis. The torque applying square roller 5 can slide along the axial direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com