Permanent magnet motor characteristic quantity measuring device and torque coefficient measuring method

A technology for permanent magnet motors and measuring devices, applied in measuring devices, motor generator testing, force/torque/power measuring instruments, etc., can solve problems such as difficult to determine, cumbersome operations, and inability to detect back EMF coefficients, and achieve cost reduction , the effect of increasing versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

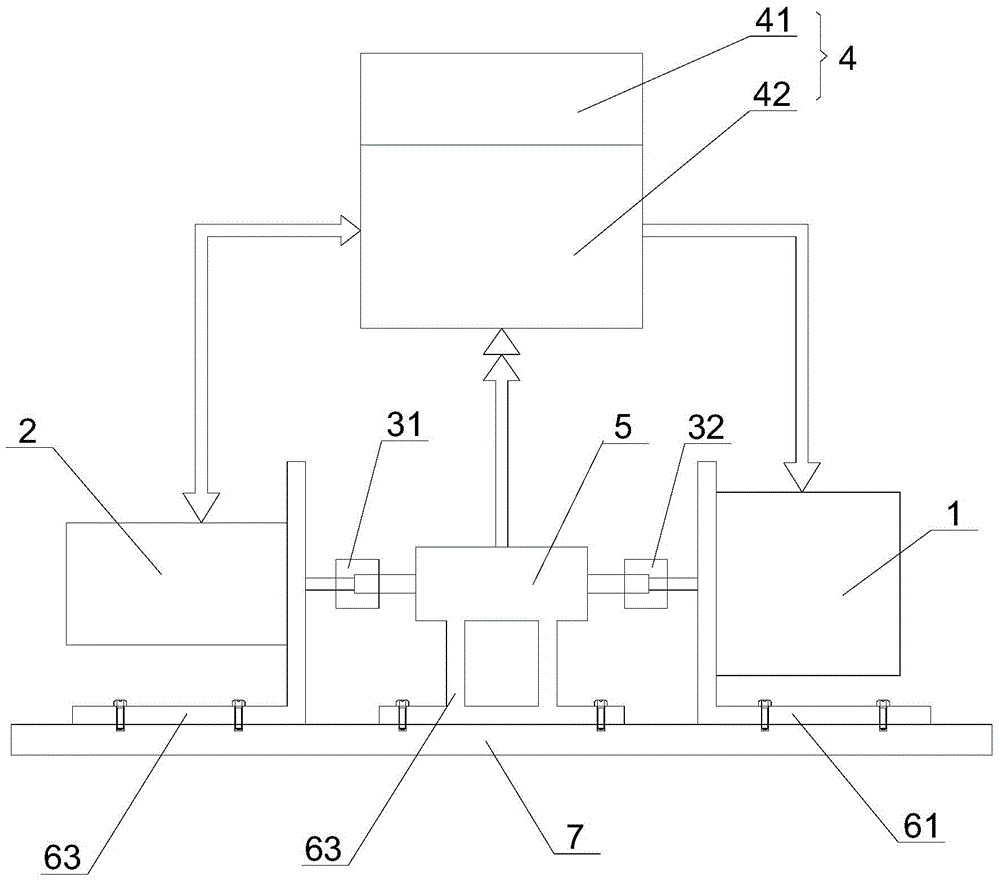

[0044] Such as figure 1 As shown, a measuring device for characteristic quantities of a permanent magnet motor provided in this embodiment includes a prime mover 1, a motor to be tested 2, a first coupling 31, a second coupling 32, a display controller 4, a rotary Torque speed sensor 5, support and test bench 7.

[0045] One end of the torque speed sensor 5 is rotatably connected to the motor 2 to be tested through a first coupling 31 , and the other end of the torque speed sensor 5 is rotatably connected to the prime mover 1 through a second coupling 32 . In addition to this connection method, two torque speed sensors 5 can also be used, and the two torque speed sensors 5 are respectively rotatably connected to the motor 2 to be tested and the prime mover 1 . Since the rotation of the prime mover 1 and the motor 2 to be tested is directly transmitted to the torque speed sensor 5 through the coupling, the accuracy of the torque signal and the detection value of the speed sign...

Embodiment 2

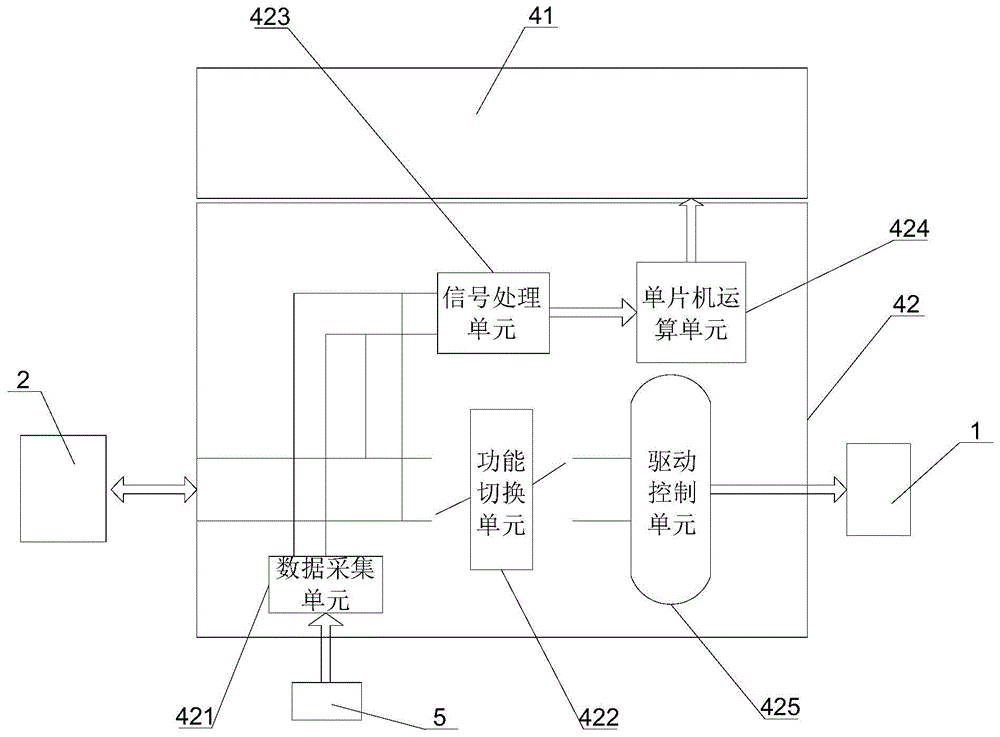

[0050] Such as figure 2 As shown, on the basis of Embodiment 1, further, a display controller 4 provided in Embodiment 2 includes a display 41 and a controller 42, the controller 42 is electrically connected to the display 41, and the controller 42 will The calculation result is sent to the monitor for display.

[0051] Further, the controller 42 includes a data acquisition unit 421 , a function switching unit 422 , a signal processing unit 423 , a single-chip computing unit 424 and a drive control unit 425 .

[0052] The single-chip computing unit 424 is used for calculating and storing the data of the characteristic quantity of the permanent magnet motor, and delivering the calculation result to the display 41 for display, and it is electrically connected with the signal processing unit 423, and can carry out data interaction with the signal processing unit 423, And perform operations on the data provided by the signal processing unit 423 . The single-chip computer operat...

Embodiment 3

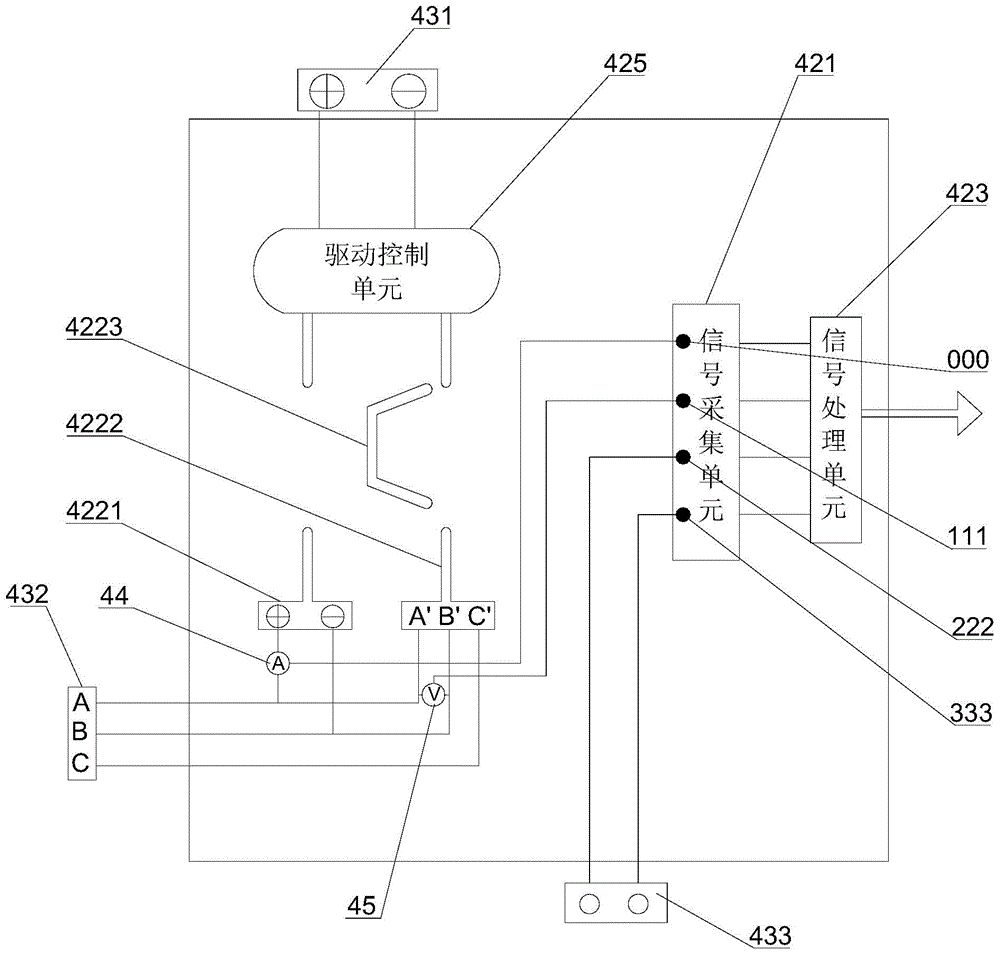

[0058] Such as image 3 As shown, on the basis of Embodiment 1 and Embodiment 2, further, the display controller 4 provided in Embodiment 3 is provided with an electrical interface to facilitate the prime mover 1, the motor to be tested 2 and the torque speed sensor 5 The connection with the display controller 4 also facilitates the replacement of the prime mover 1 , the motor to be tested 2 and the torque speed sensor 5 , especially the replacement of the motor to be tested 2 .

[0059] The electrical interface includes a prime mover interface 431, a machine to be tested interface 432, and a sensor interface 433. The prime mover interface 431 is used to connect the prime mover 1, and it is electrically connected with the drive control unit 425, so that the prime mover 1 can be easily connected with the drive control unit 425. electrical connection.

[0060] The DUT interface 432 is used to connect the DUT motor 2 , the sensor interface 433 is used to connect the torque speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com