Stator core, motor and compressor

A stator core and stator technology is applied in the field of compressors, which can solve the problems of limited busbar voltage and the inability to increase the back EMF coefficient without limit, and achieve the effect of improving the torque and torque coefficient of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

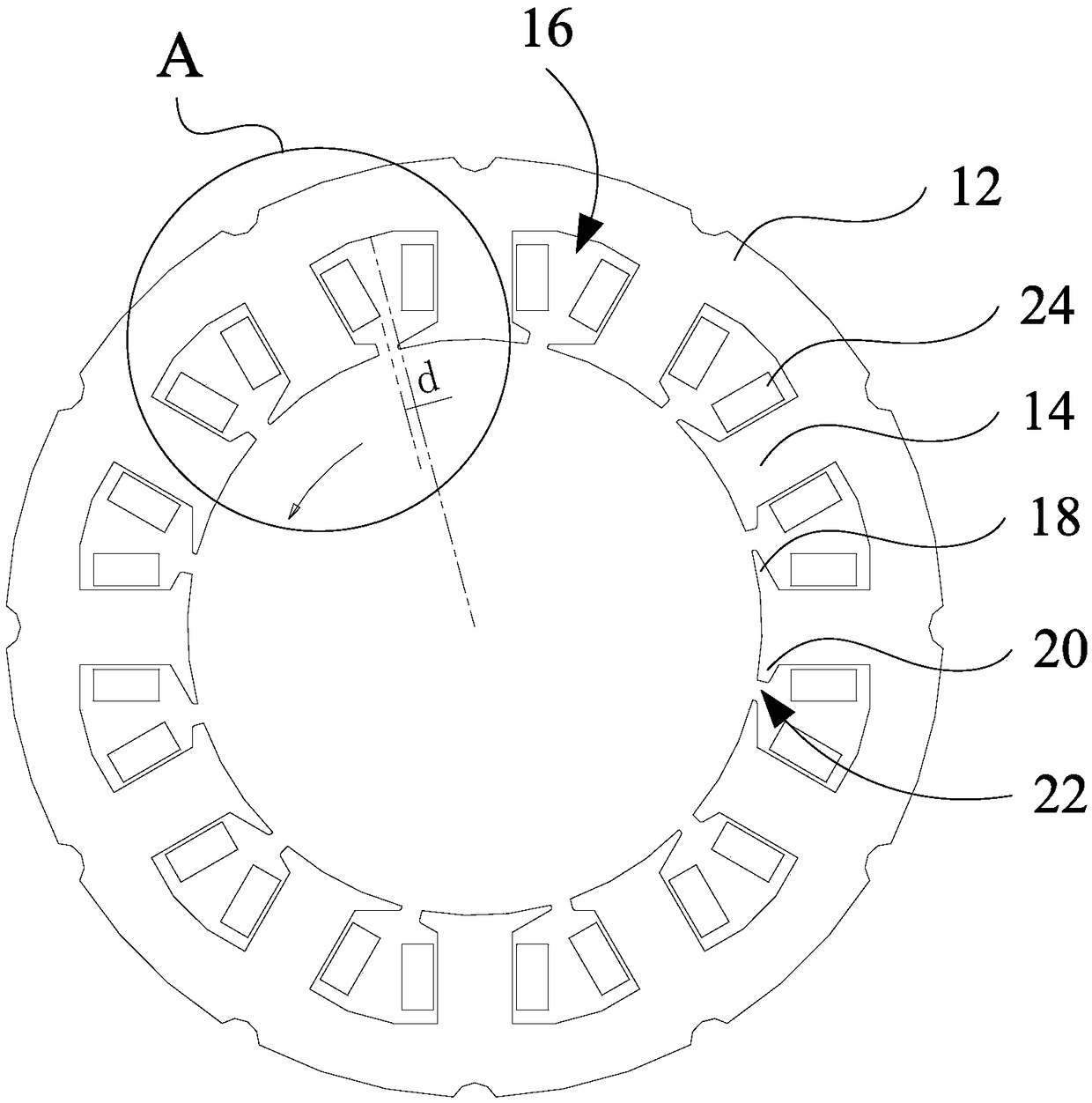

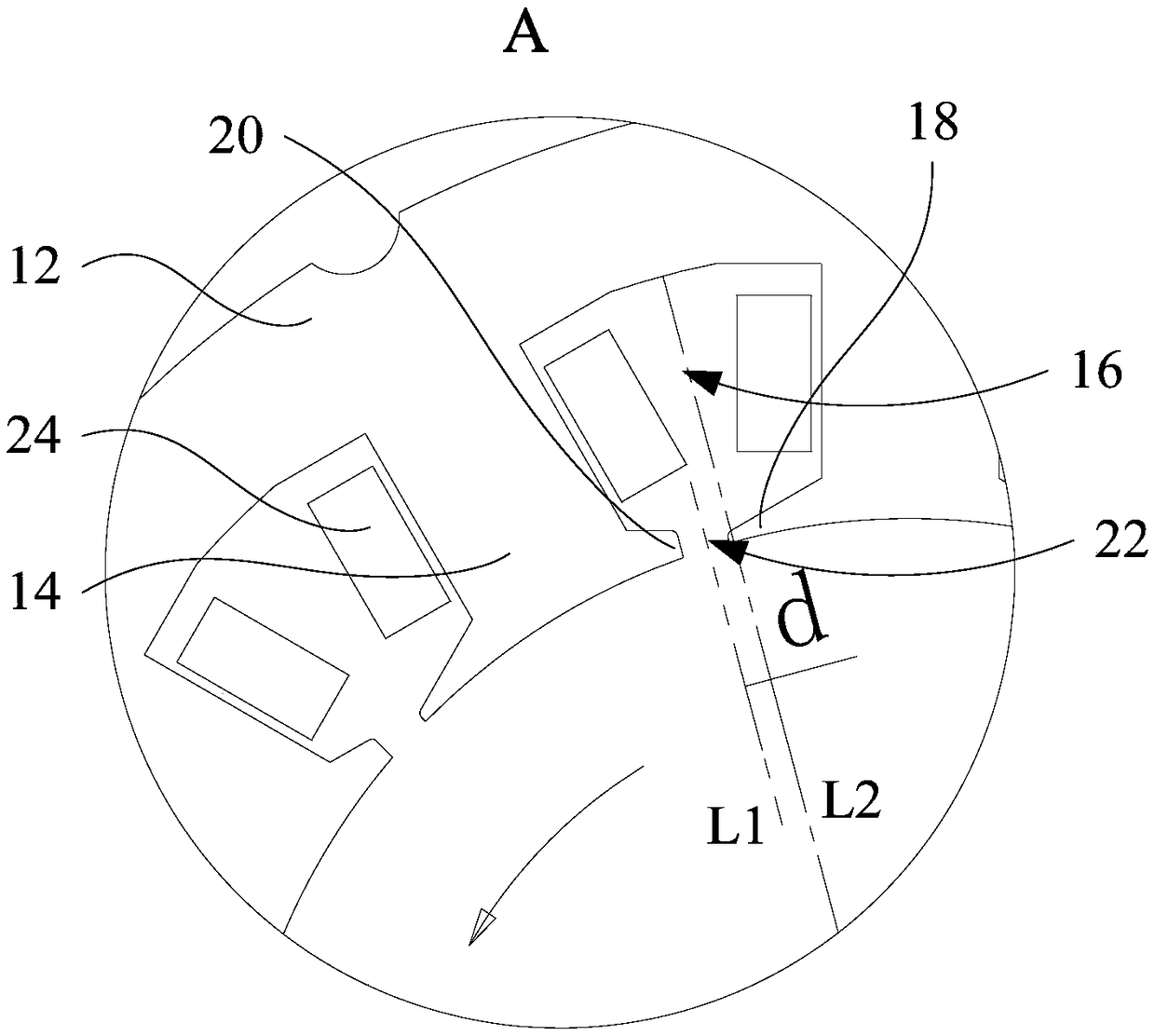

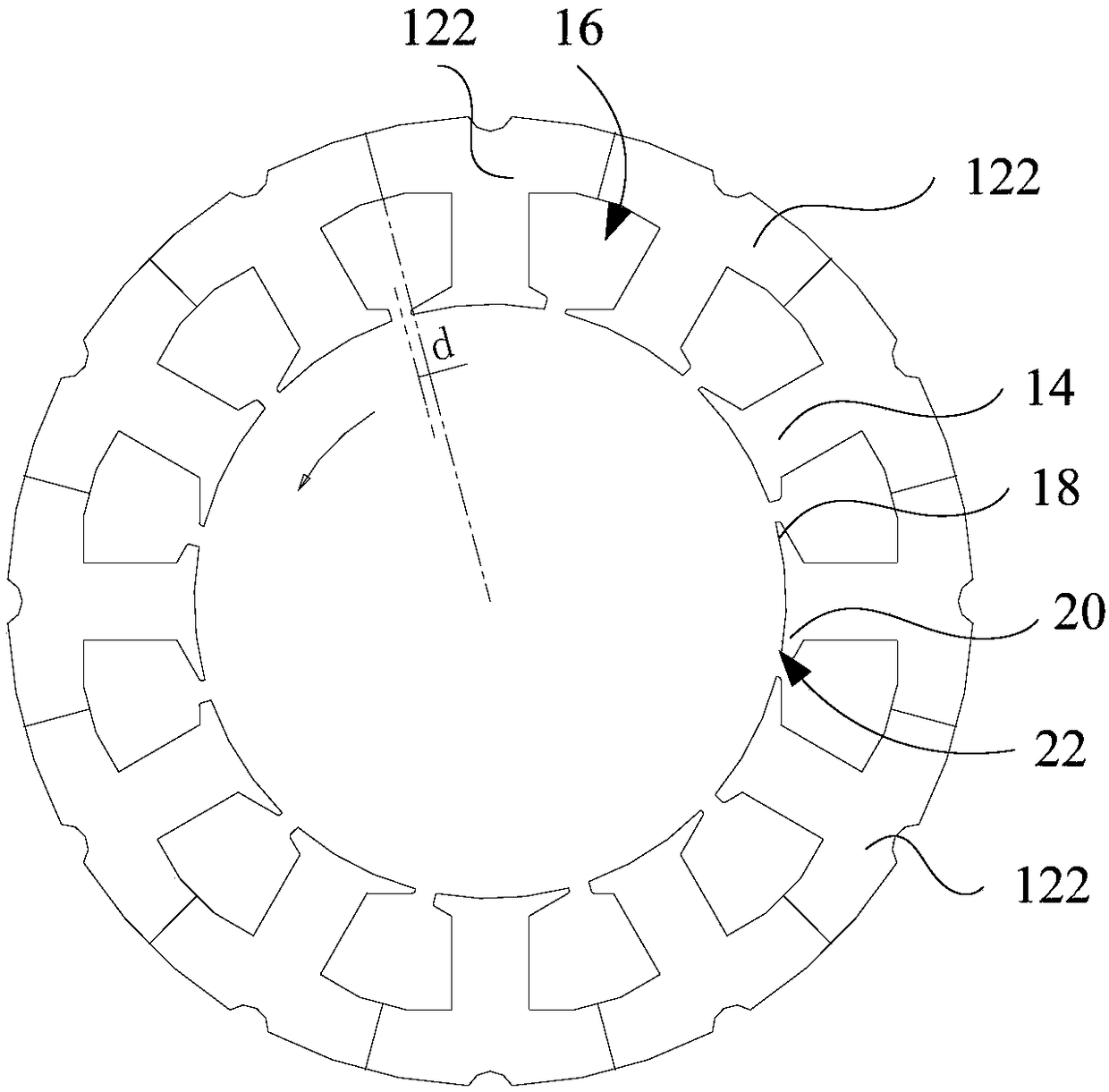

[0074] Figure 7 In the case of the same current, the output torque comparison chart of the motor. Specifically, the same eight-pole rotor is used to match the existing embodiment and the figure 1 With the stator core shown, calculate the output torque of the motor at different rotor positions. From Figure 7 It can be seen that whether it is the torque when the rotor position angle is 0°, or the maximum torque that changes with the torque position angle. Adopt the embodiment of the present invention, namely figure 1 Compared with the conventional example, the output torque of the stator core shown is significantly improved.

[0075] Figure 8 In the case of the same current, the iron loss comparison chart of the motor. Specifically, the same eight-pole rotor is used to match the existing embodiment and the figure 1 For the stator core shown, calculate the iron loss of the motor at different rotor positions. From Figure 8 It can be seen that whether it is the iron lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com