Method of guaranteeing fan high-strength bolt pretightening force to be accurately exerted

A high-strength bolt, pre-tightening technology, applied in threaded fasteners, screws, mechanical equipment, etc., to ensure the effect of lubrication and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

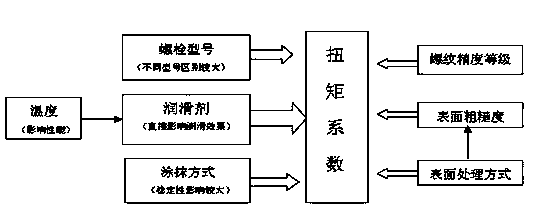

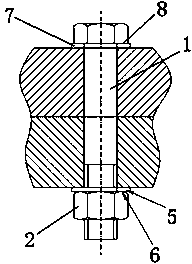

[0050] attached figure 1 A schematic block diagram of torque determination of the present invention is given, and it can be seen from the accompanying drawings that the present invention relates to a method for accurately applying the pretightening force of high-strength bolts of a wind power generating set. The accuracy grade, the surface roughness of the mating surface, the surface treatment method, the bolt model specification and the temperature influence factors on the torque coefficient. The grade, the roughness of the matching surface, the surface treatment method, the bolt type specification and the temperature control control the dispersion coefficient (maximum value of torque coefficient / minimum value of torque coefficient) of each batch of bolts of each specification when using the torque method. Within 1.25.

[0051] Further, the relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com