Laser-high frequency induction composite welder and its method

A technology of laser welding and laser welding head, applied in laser-high frequency induction hybrid welding device and its fields, can solve the problems of formation of pores or voids, easy generation of cracks, adverse effects of base metal, etc., and eliminate the generation of pores and cracks. , to ensure stability and reliability, and to improve the overall performance of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to realize the laser-high frequency induction hybrid welding described in the present invention, a solid YAG or CO 2 A laser and an optical path capable of transmitting laser light, as well as a high-frequency induction heating device.

[0020] The implementation of laser-high frequency induction hybrid welding will be described below in conjunction with specific examples.

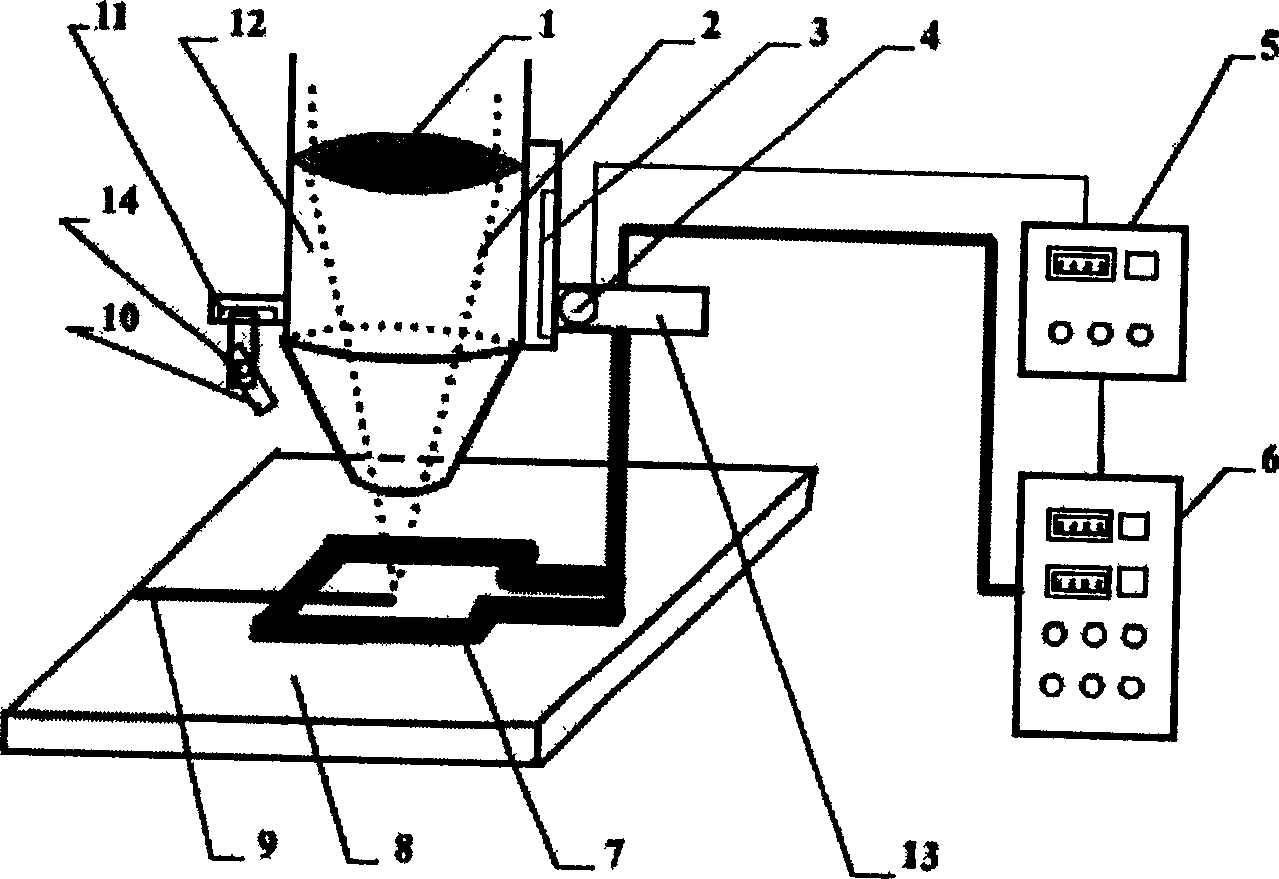

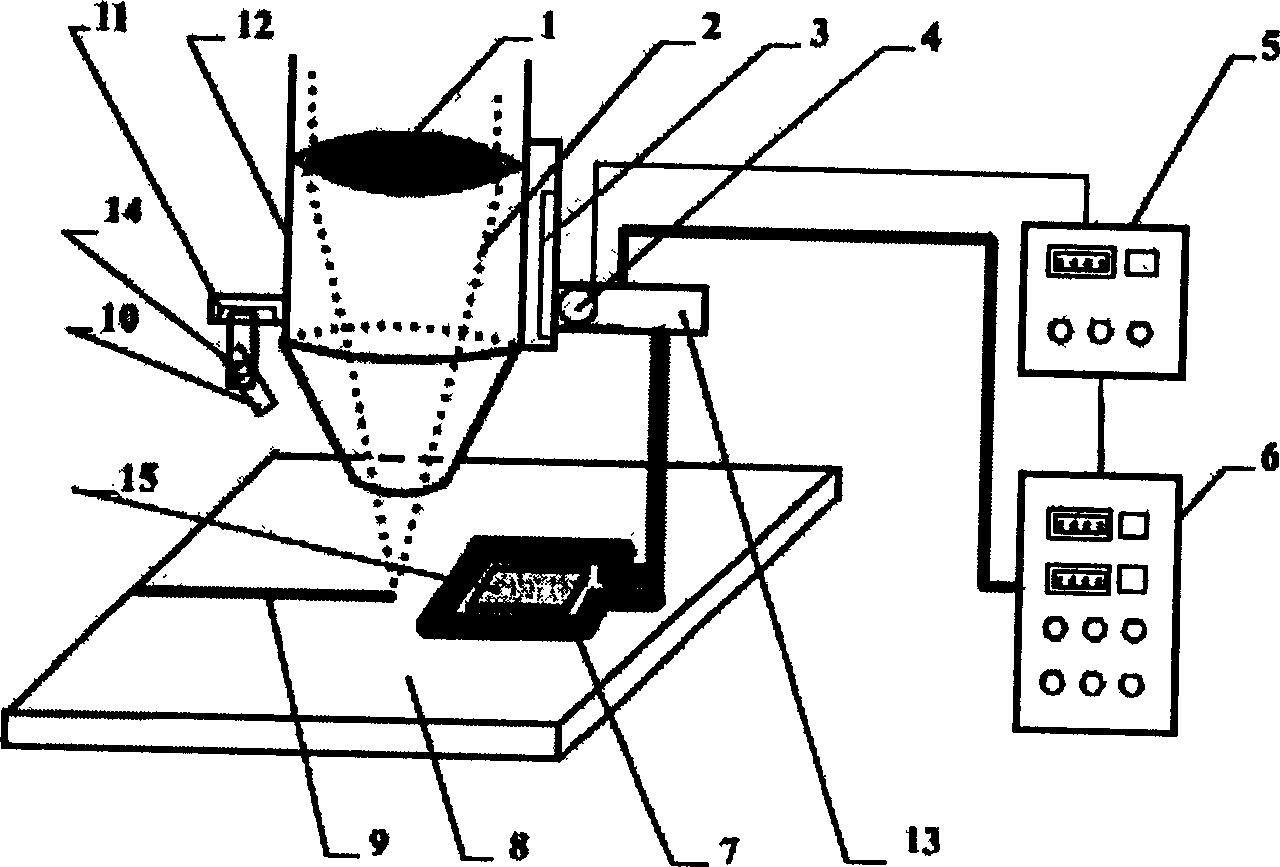

[0021] Option 1: If figure 1 As shown, the induction heating coil (7) and the laser beam (2) heat the workpiece welding area synchronously, and the focused laser beam (2) passes through the center of the induction heating coil and acts on the weld seam area to form deep penetration welding. The distance between the induction coil and the upper surface of the workpiece is 2mm, part of the energy of the induction heating coil directly heats the fusion zone to form the weld (9), and the other part is used to heat the surrounding area of the weld (9). The angle between the infrared temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com