Bolt tightening torque coefficient measuring device

A technology of tightening torque and measuring device, which is used to measure torque/torsional force during tightening, which can solve the problems of high cost of sensors and unsuitable short bolts, and achieve the effect of strong operability, low cost, and simple and reliable measurement method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

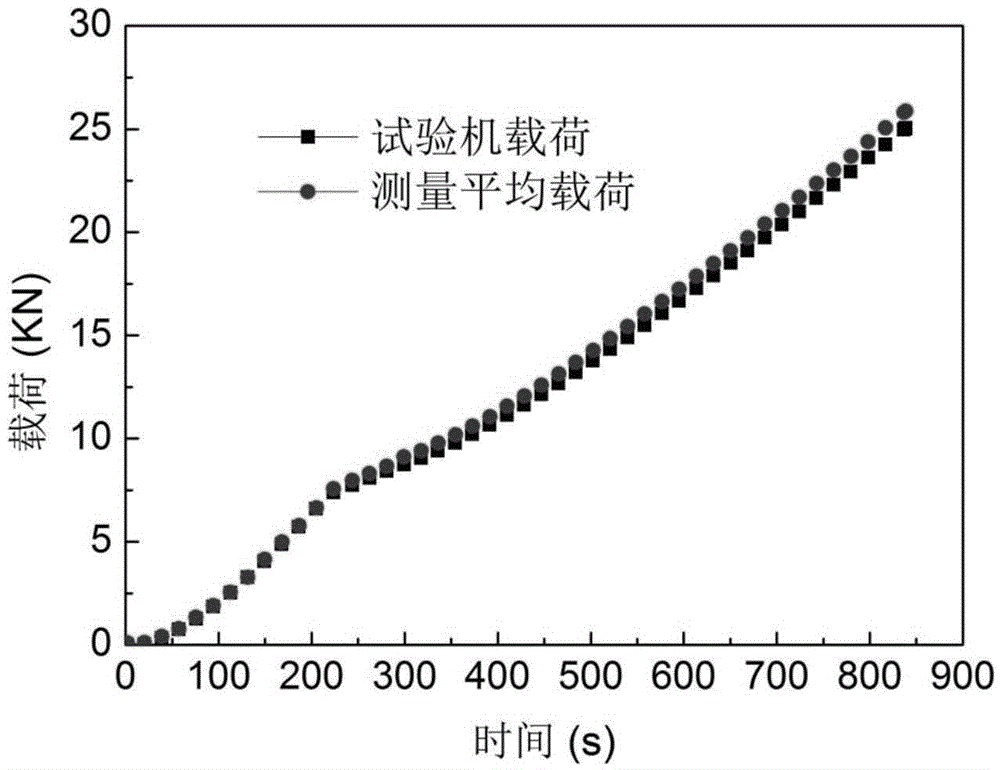

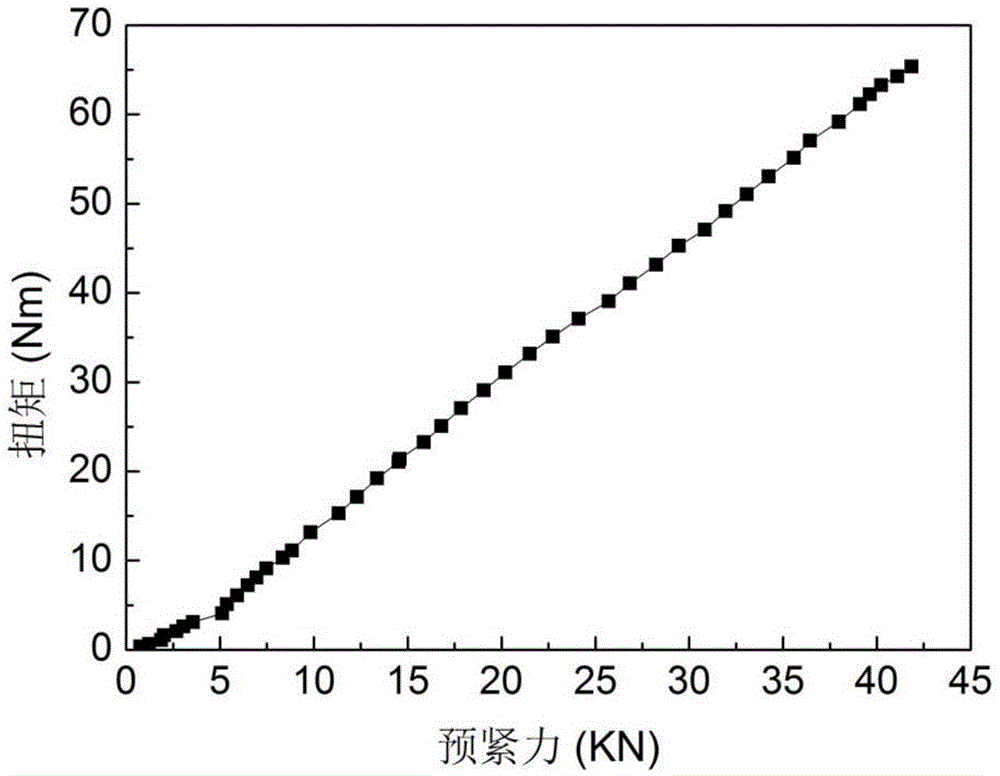

[0034] Implementation example: take the measurement of the tightening torque coefficient of the M10 bolt of GH4169 material as an example to describe the specific implementation steps in detail.

[0035] Refer to attached figure 1 , the specific steps of applying the present invention to measure the bolt tightening torque coefficient are:

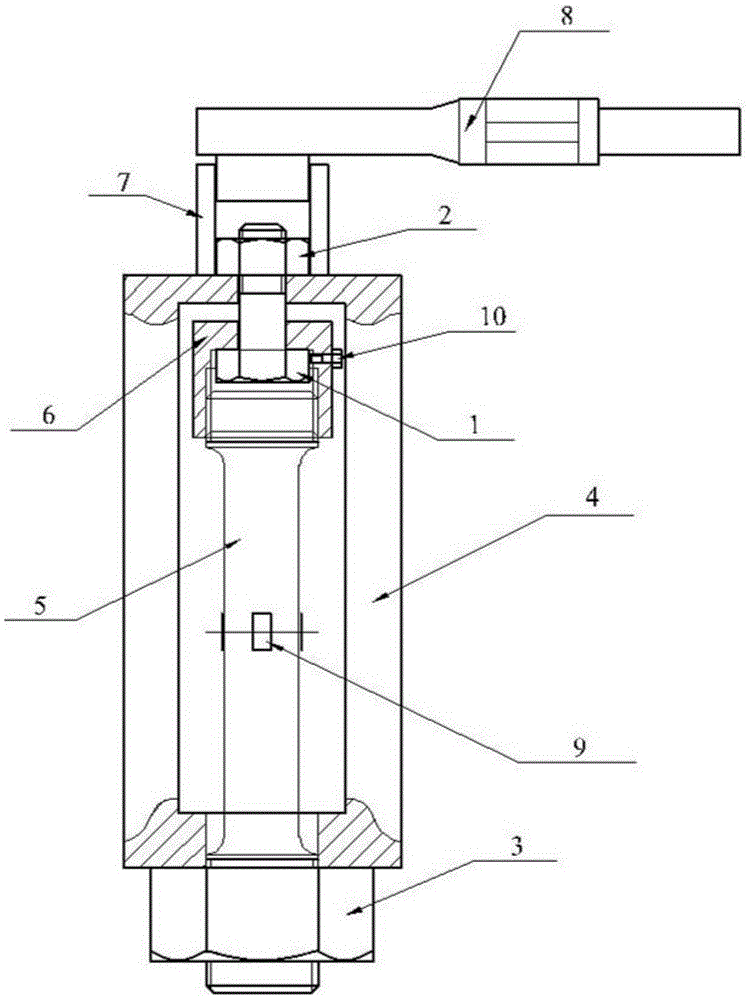

[0036] Step 1: Select the main body 4, and install the measuring screw 5 with the strain gauge attached into the main body 4. During the loading process, care should be taken to avoid damage to the strain gauge 9 and the connecting wires.

[0037] Step 2: Select the first sleeve 6 with M10 bolt holes, install the M10 test bolt 1 into the first sleeve 6 through the bolt holes, and install the bolts into the body 4 through the M10 bolt holes on the outer frame, Screw on the nut 2 to prevent the test bolt 1 from falling out.

[0038] Step 3: Connect the first sleeve 6 with the measuring screw 5 through threaded connection, then select the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com