Device and method for measuring torque coefficient of high-strength bolt connecting pair

A technology of high-strength bolts and torque coefficients, which is used to measure torque/torsion force and other directions during tightening, can solve the problems of manual work that is difficult to control accuracy, achieve accurate axial strain values, ensure measurement accuracy, and reduce stress The effect of uneven influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in further detail below in conjunction with accompanying drawing:

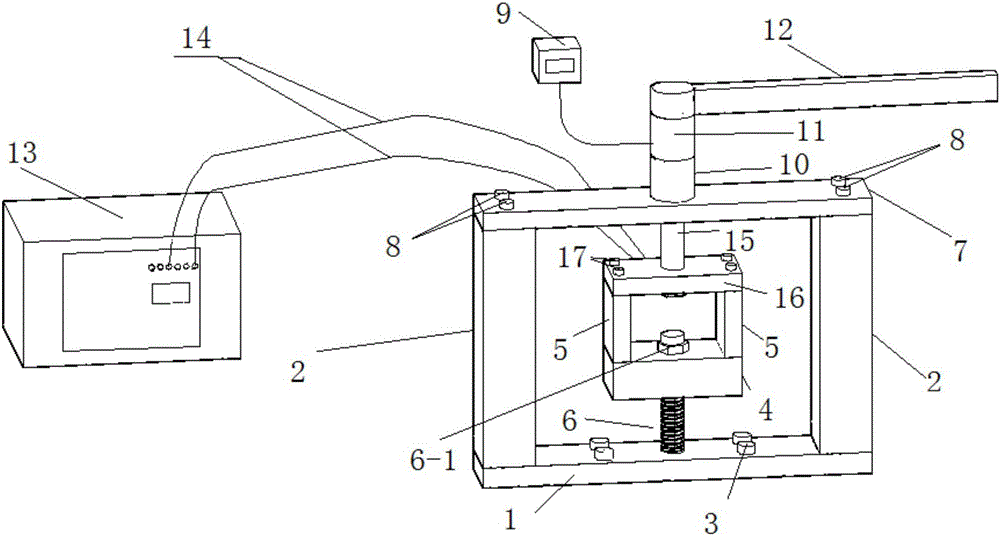

[0042] Such as Figure 1 to Figure 3 As shown, the device for measuring the torque coefficient of the bolt connection pair of the present invention includes a device to be tested, a test piece fixing device, a test piece loading device, and a data acquisition system:

[0043] The specimen fixing device includes an outer rectangular frame, an inner rectangular frame, a first high-strength bolt 3, an adjustable screw rod 6, a second high-strength bolt 8, and a third high-strength bolt 17, wherein the outer rectangular frame includes an outer bottom plate 1 and an outer baffle 2 , the outer top plate 7, the inner rectangular frame includes the inner bottom plate 4, the inner side baffle plate 5, and the inner side top plate 16;

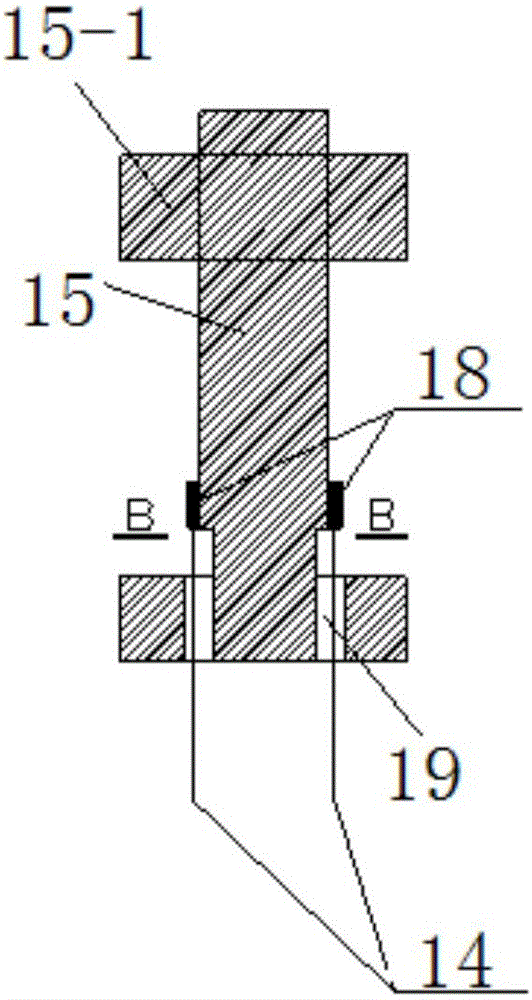

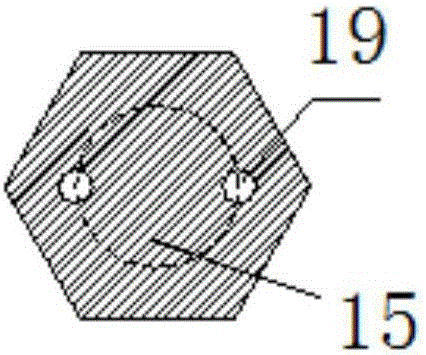

[0044] The device to be tested includes a one-way strain gauge 18 and a high-strength bolt connection pair 15 to be tested;

[0045] The speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com