Device and method for testing amount of looseness of connecting pretightening force of after-fire high-strength bolt

A technology of high-strength bolts and measuring devices, which can be used to measure the direction of torque/torsion during tightening, which can solve problems such as axial force meter measurement, and achieve the effects of avoiding waste, convenient operation and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

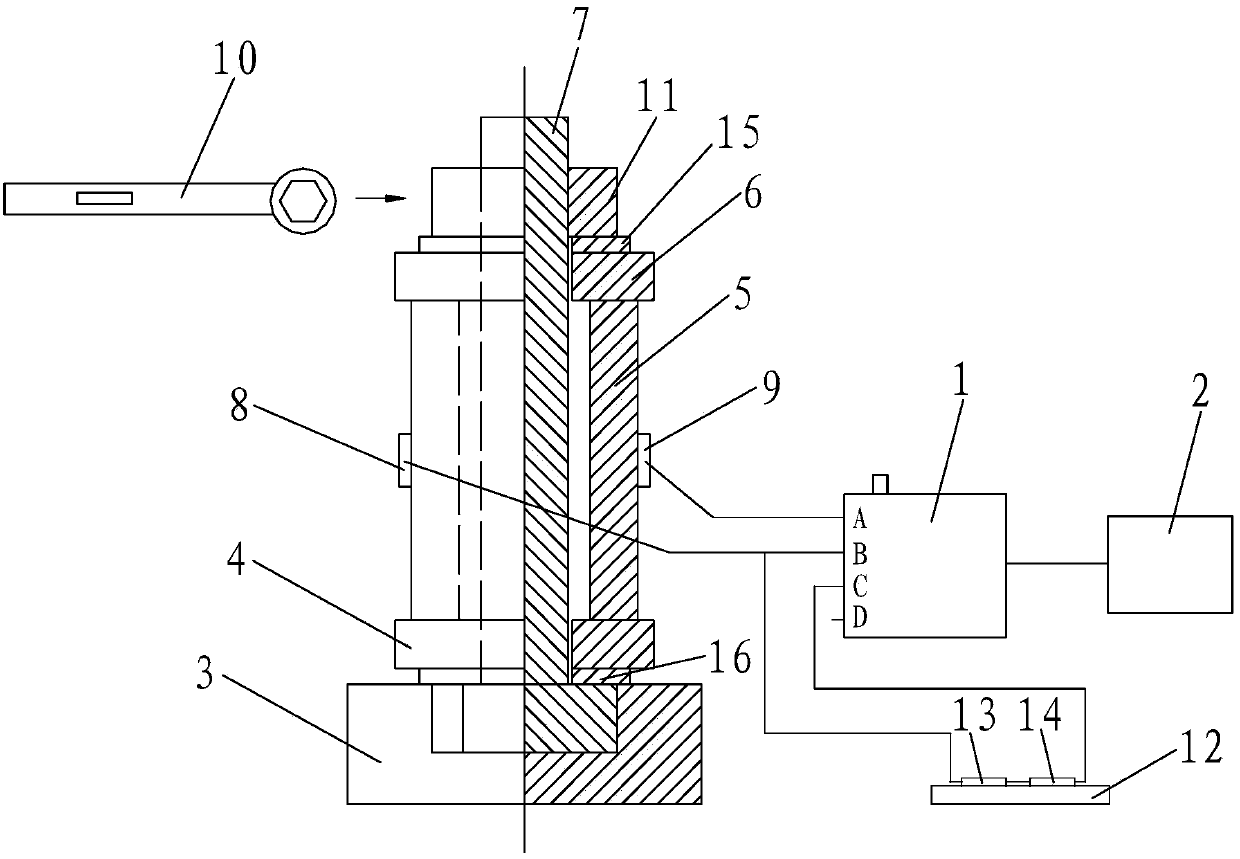

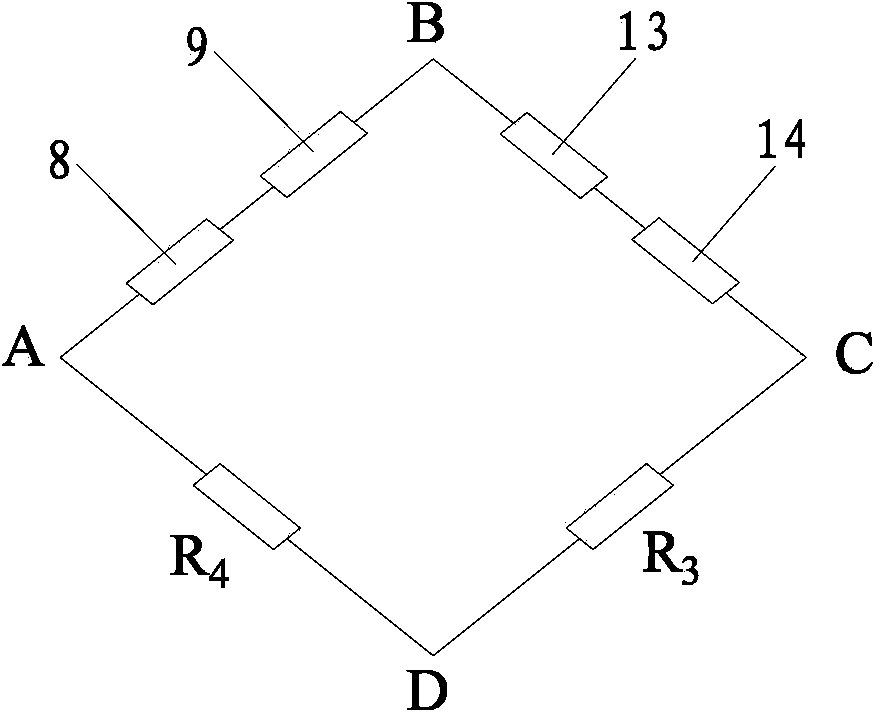

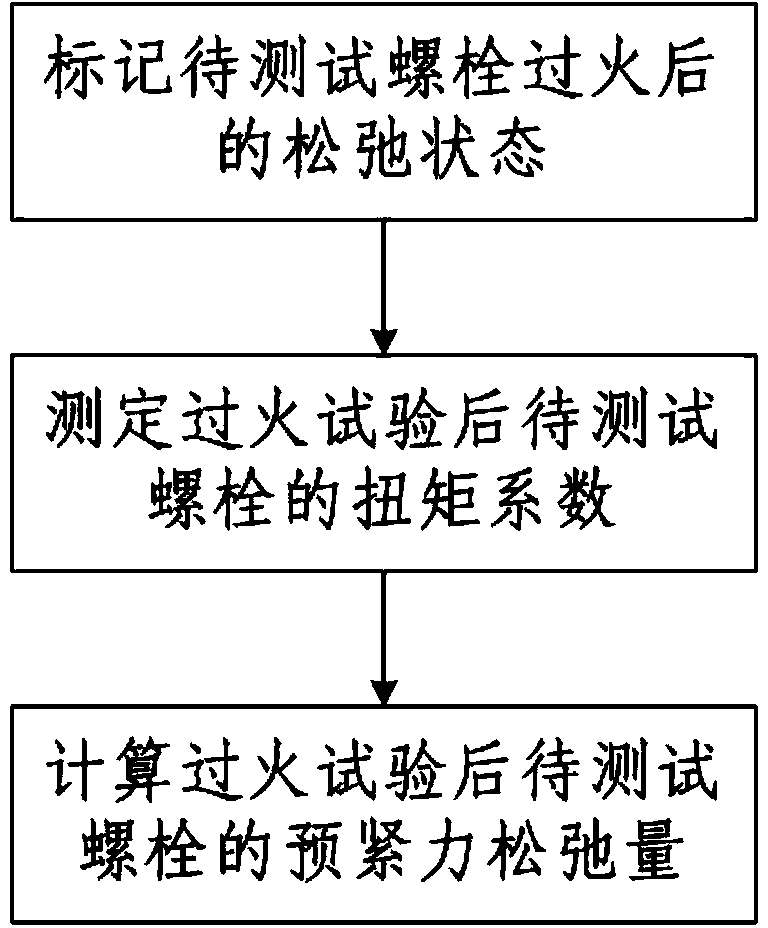

[0052] Such as figure 1 As shown, the high-strength bolt connection pretightening force slack measuring device after a fire of the present invention includes a strain tester 1, a computer 2 connected with the strain tester 1, a base 3 for fixing the bolt 7 to be tested and a bearing for bearing The bolt axial force receiving device for receiving the axial force of the test bolt 7, and the torque loading device 10 for applying torque to the bolt pair composed of the bolt 7 to be tested, the nut 11, the upper gasket 15 and the lower gasket 16; The base 3 is provided with a hole for engaging and connecting the bolt heads of the bolts 7 to be tested, and the bolt axial force bearing device is arranged in sequence from bottom to top and the bottom for the bolts to be tested 7 to pass through in sequence from bottom to top. Rigid backing plate 4, elastic steel sleeve 5 and upper rigid backing plate 6 are made up of, and described nut 11 is threadedly connected on one end of to-be-te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com