A method and device for measuring bolt torque coefficient

A technology of torque coefficient and detection device, applied in the field of thread tightening, can solve the problems of excessive elastic deformation of connecting rods, different friction coefficients, and different torque coefficients are not considered, so as to ensure reliability, improve accuracy, and greatly adapt to sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not be regarded as limiting the technical content disclosed in the present invention.

[0035] For ease of understanding, this part first describes the device for measuring the bolt torque coefficient, and then describes the method for measuring the bolt torque coefficient provided by the invention.

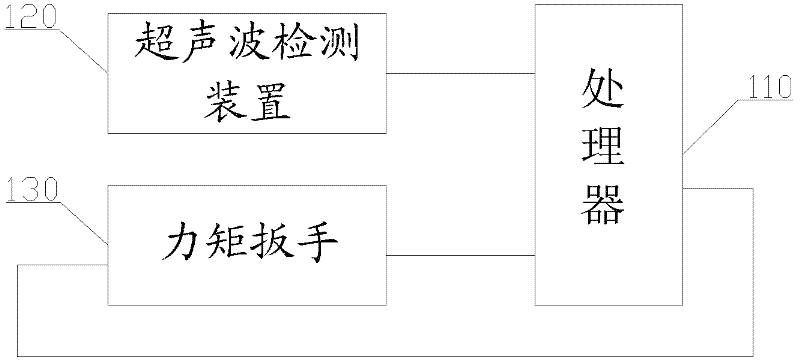

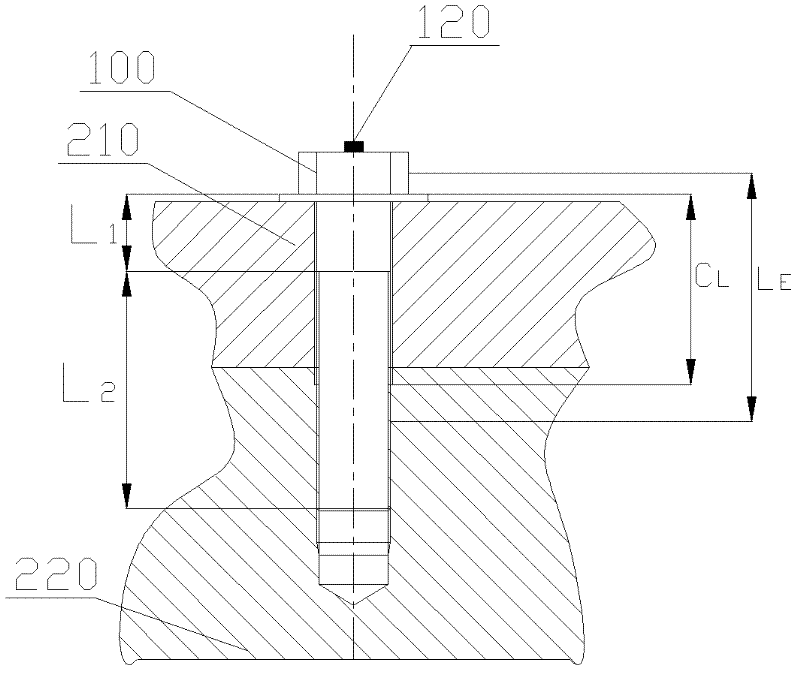

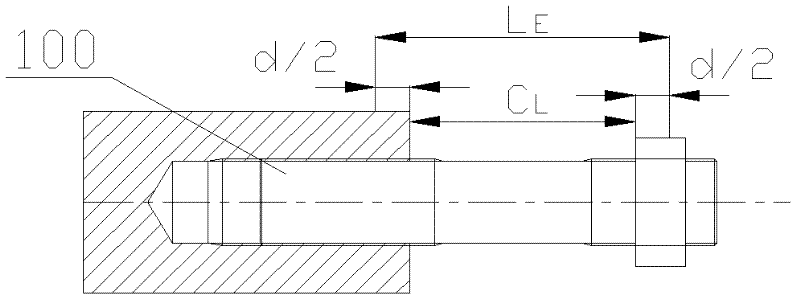

[0036] Please refer to figure 1 and figure 2 , figure 1 It is a structural block diagram of a device for measuring bolt torque coefficient provided by the present invention; figure 2 It is a schematic diagram of the working principle of the device for measuring the bolt torque coefficient provided by the present invention.

[0037] The device for measuring the bolt torque coefficient provided by the present invention includes a processor 110, an ultrasonic detection device 120 and a torque wre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com