Synchronous measurement method for combustion rate and combustion wave of solid propellant

A solid propellant and synchronous testing technology, which is applied in fluid velocity measurement, fluid velocity measurement using thermal variables, velocity/acceleration/impact measurement, etc., can solve problems such as inaccurate timing, and achieve improved timing accuracy and burning rate test results Precise, short response time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

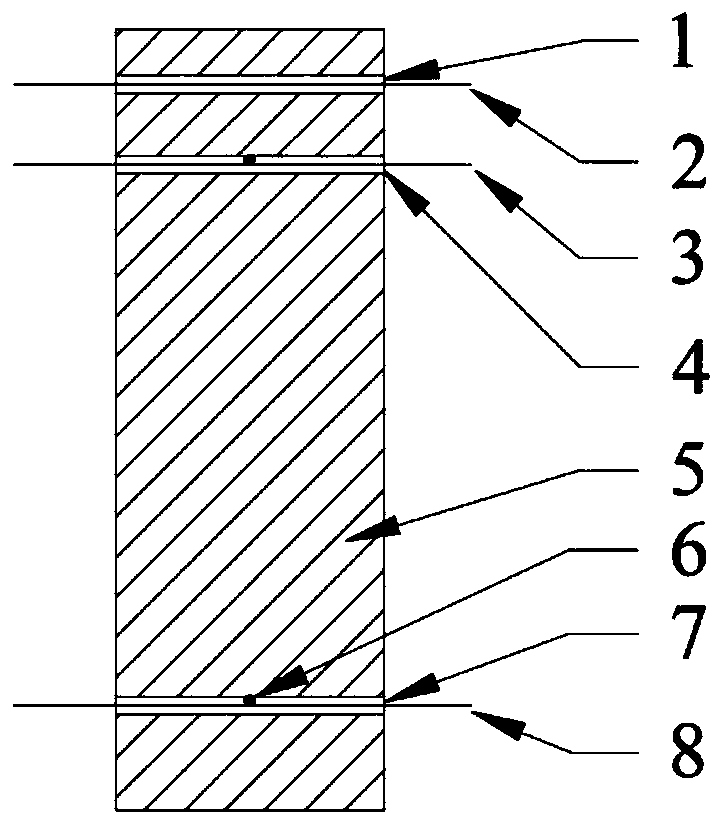

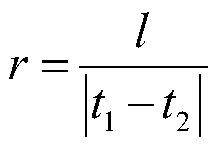

[0033] The boron-containing fuel-rich propellant was cut into 4×4×150mm rectangular medicinal strips, and the surface of the medicinal strips was coated with 8% polyvinyl butyral alcohol solution. A micro-drilling machine was used to perforate the coated propellant strips, the size of the drill bit was 0.4mm, and the distance between the two target line holes was 100.10mm. Punch a hole on one side of the propellant strip and insert a nickel-chromium ignition wire with a diameter of 1mm. The distance between the ignition wire and the thermocouple hole at the same end is 25mm. Two S-type platinum-rhodium thermocouples with a wire diameter of 13 μm were inserted into two target wire holes, and the diameters of the temperature measurement points of the two hot spot couples were 48 μm and 45 μm, respectively. Ignite the propellant strips in a constant pressure bomb, which is filled with nitrogen and the pressure is 1 MPa. The voltage-time curve measured by the thermocouple is conve...

Embodiment 2

[0035] The boron-containing fuel-rich propellant was cut into 4×4×150mm rectangular medicinal strips, and the surface of the medicinal strips was coated with 8% polyvinyl butyral alcohol solution. A micro-drilling machine was used to perforate the coated propellant strips, the size of the drill bit was 0.4mm, and the distance between the two target line holes was 99.35mm. Punch a hole on one side of the propellant strip and insert a nickel-chromium ignition wire with a diameter of 1mm. The distance between the ignition wire and the thermocouple hole at the same end is 28mm. Two R-type platinum-rhodium thermocouples with a wire diameter of 13 μm were inserted into two target wire holes respectively, and the diameters of the temperature measurement points of the two hot spot couples were 45 μm and 43 μm, respectively. The propellant strips are ignited in a constant pressure bomb, which is filled with nitrogen and the pressure is 10MPa. The voltage-time curve measured by the ther...

Embodiment 3

[0037] Use 8% polyvinyl butyral alcohol solution to coat the surface of a cylindrical double-base propellant strip with a size of Φ5×150mm, and use a micro drilling machine to beat the coated propellant strip The size of the drill bit is 0.4mm, and the distance between the two target line holes is 80.22mm. Punch a hole on one side of the propellant strip and insert a nickel-chromium ignition wire with a diameter of 1 mm. The distance between the ignition wire and the thermocouple hole at the same end is 22 mm. Two R-type platinum-rhodium thermocouples with a wire diameter of 13 μm were inserted into two target wire holes, and the diameters of the temperature measurement points of the two hot spot couples were 42 μm and 39 μm, respectively. The propellant strips are ignited in the constant pressure bomb, which is filled with nitrogen and the pressure is 3MPa. The voltage-time curve measured by the thermocouple is converted into a temperature-time curve to obtain the combustion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com