Rubber ring high pressure dynamic sealing test device under extreme conditions

A technology of extreme conditions and test equipment, applied in the field of aerospace technology and mechanical engineering, to achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

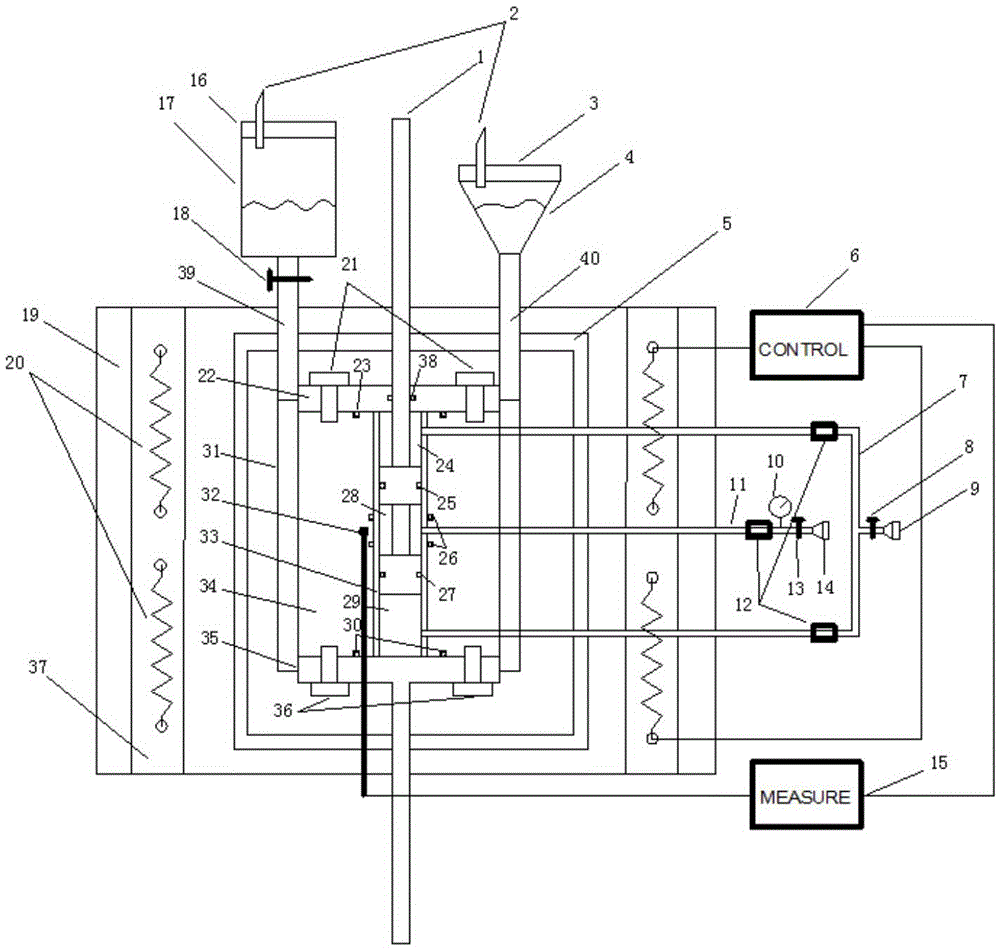

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] (1) Dynamic sealing test under low temperature and high pressure conditions

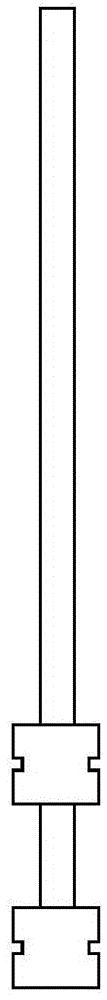

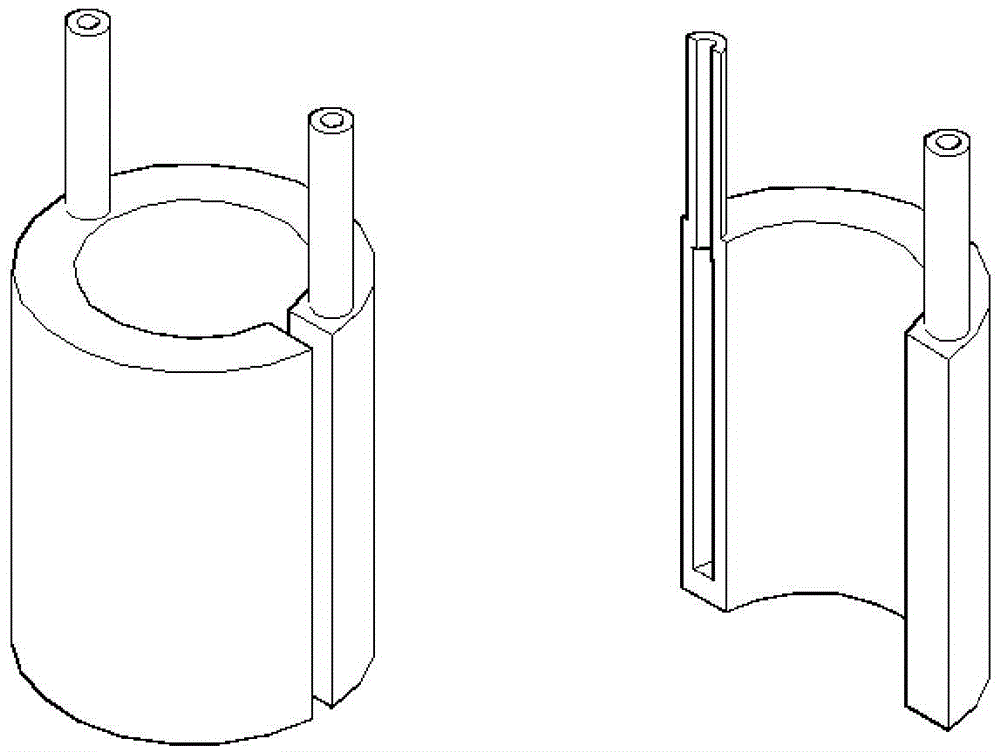

[0029]Step 1, test piece installation: place the upper and lower lining sealing rings 26 in the upper and lower position grooves of the middle hole of the cylinder 34, place the lower cover sealing ring 30 in the groove on the lower surface of the cylinder 34, and place the upper sealing cover 22 Place the upper cover sealing ring 38 in the upper groove of the cylindrical hole in the middle, fix the lower sealing cover 35 to the cylinder 34 through the lower fastening bolt 36, insert the inner lining 33 into the cylinder 34, the cylinder 34 and the inner lining 33 Align the corresponding upper, middle and lower three transparent holes, put the upper test rubber ring 25 in the groove of the cylinder whose outer diameter is slightly smaller than the inner diameter of the inner liner in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com