A reciprocating friction power generation output performance and friction coefficient synchronous testing device

A technology of friction power generation and output performance, which is applied in the direction of measuring devices, mechanical devices, and material analysis through electromagnetic means. It can solve the problems of inability to measure electrical output performance synchronously, hindering the practical process of high-efficiency friction power generation, and unclear friction power generation. Issues such as the law of output performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

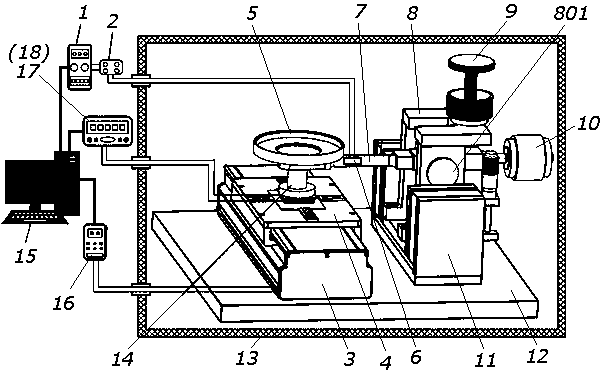

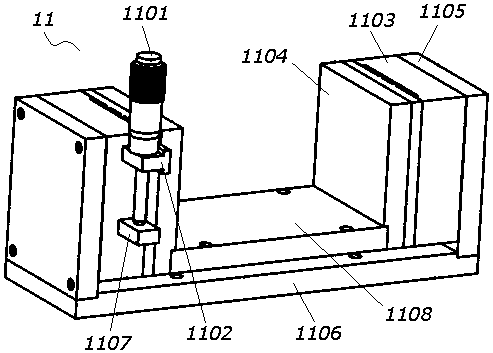

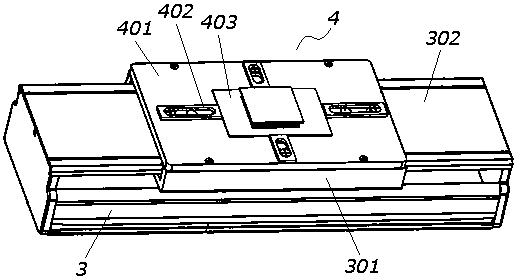

[0027] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an embodiment of the reciprocating friction power generation output performance and friction coefficient synchronous testing device of the present invention; the reciprocating friction power generation output performance and friction coefficient synchronous testing device includes a magnetic axis linear motor 3 and a friction pair clamping platform 4 under friction power generation , a pair of strain gauges 6, a cantilever beam 7, a cantilever beam support frame 8, a friction pair clamping platform 14 on friction power generation, a control and test computer 15; wherein, the friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com