Hydrogen storage alloy performance integrated experimental appts

A technology for testing equipment and hydrogen storage alloys, applied in the field of material performance testing equipment, can solve the problems of small pressure application range, low degree of automation, poor system stability, etc., and achieve the effect of high safety, high degree of automation, and accident prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

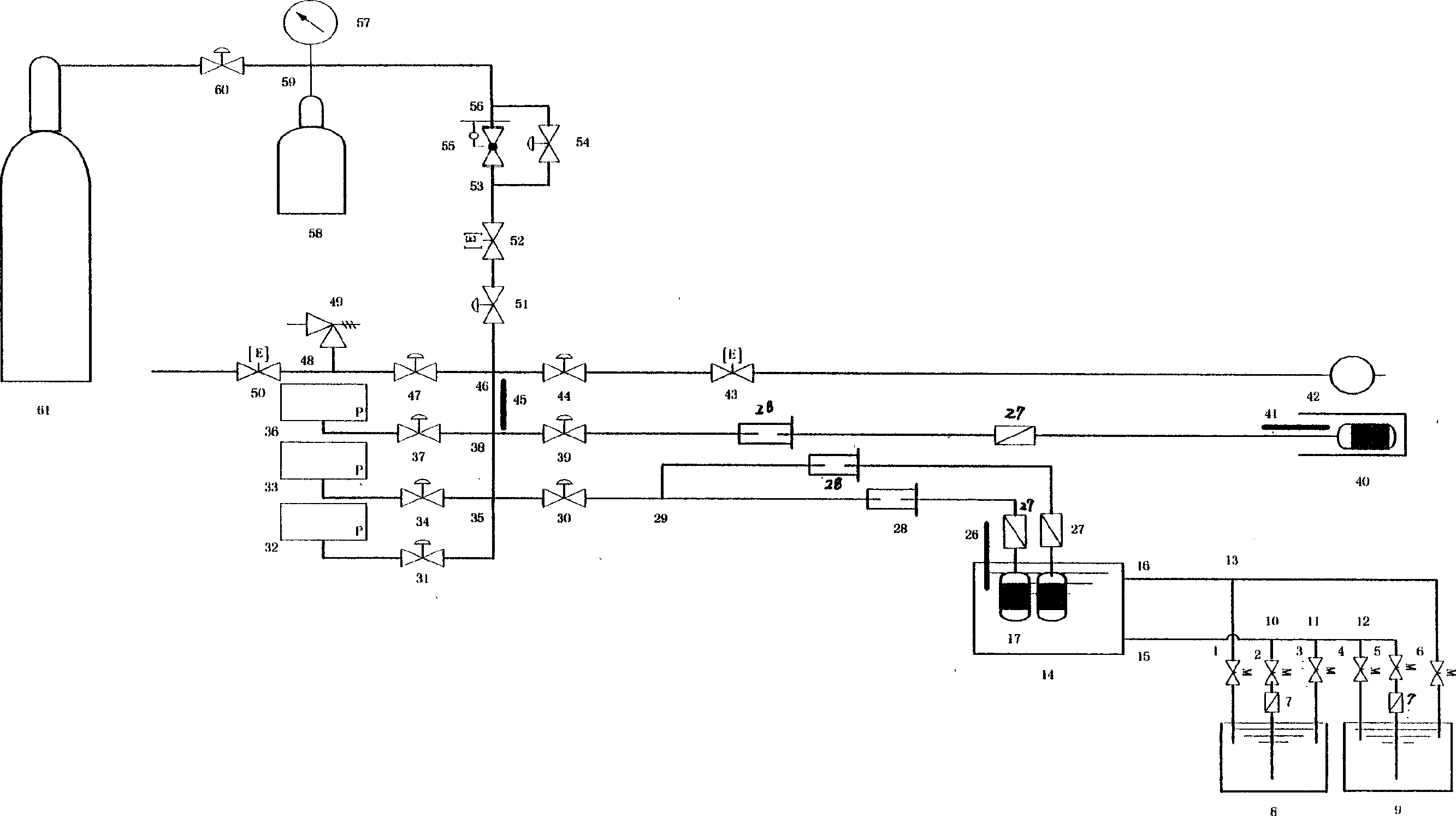

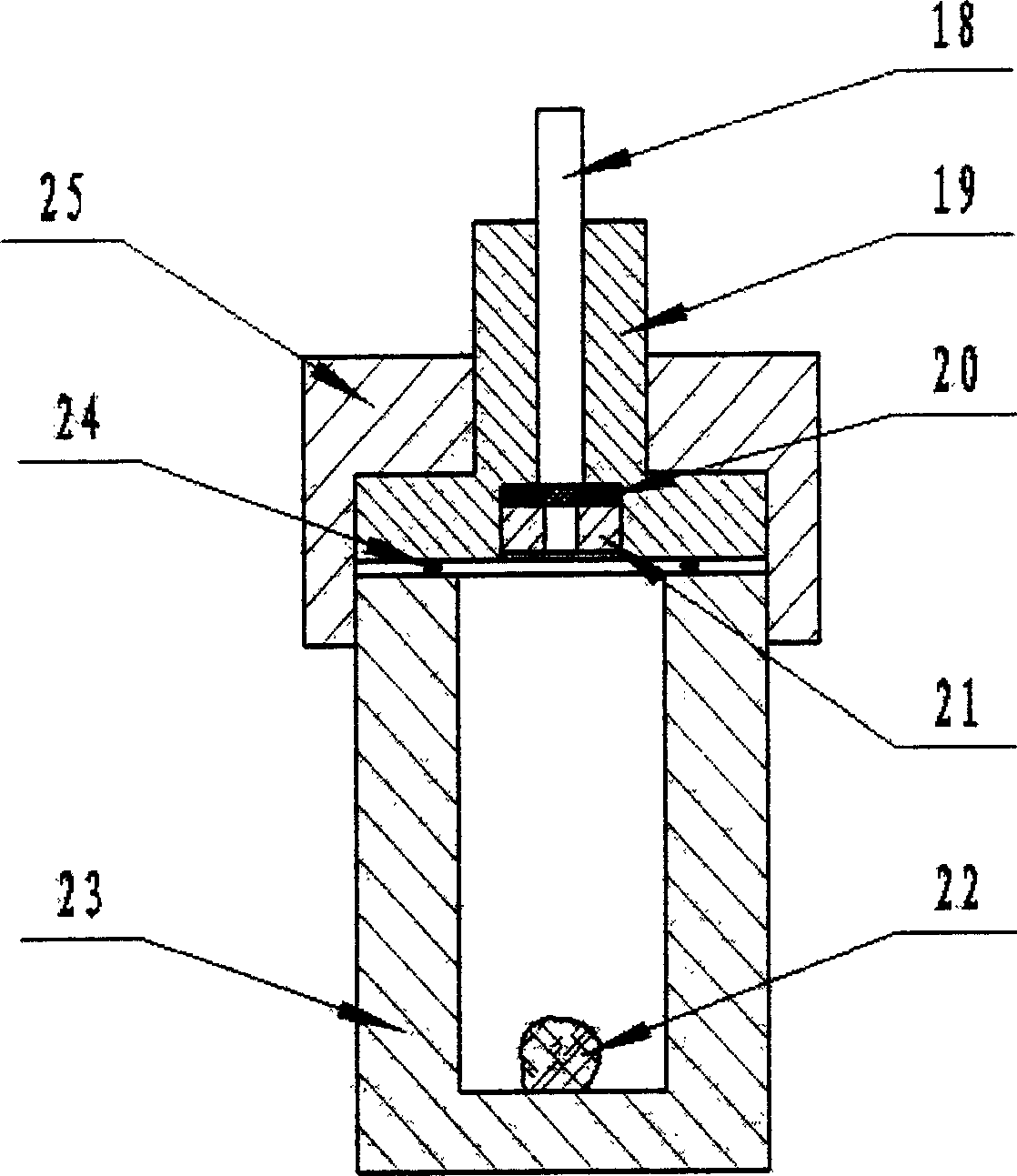

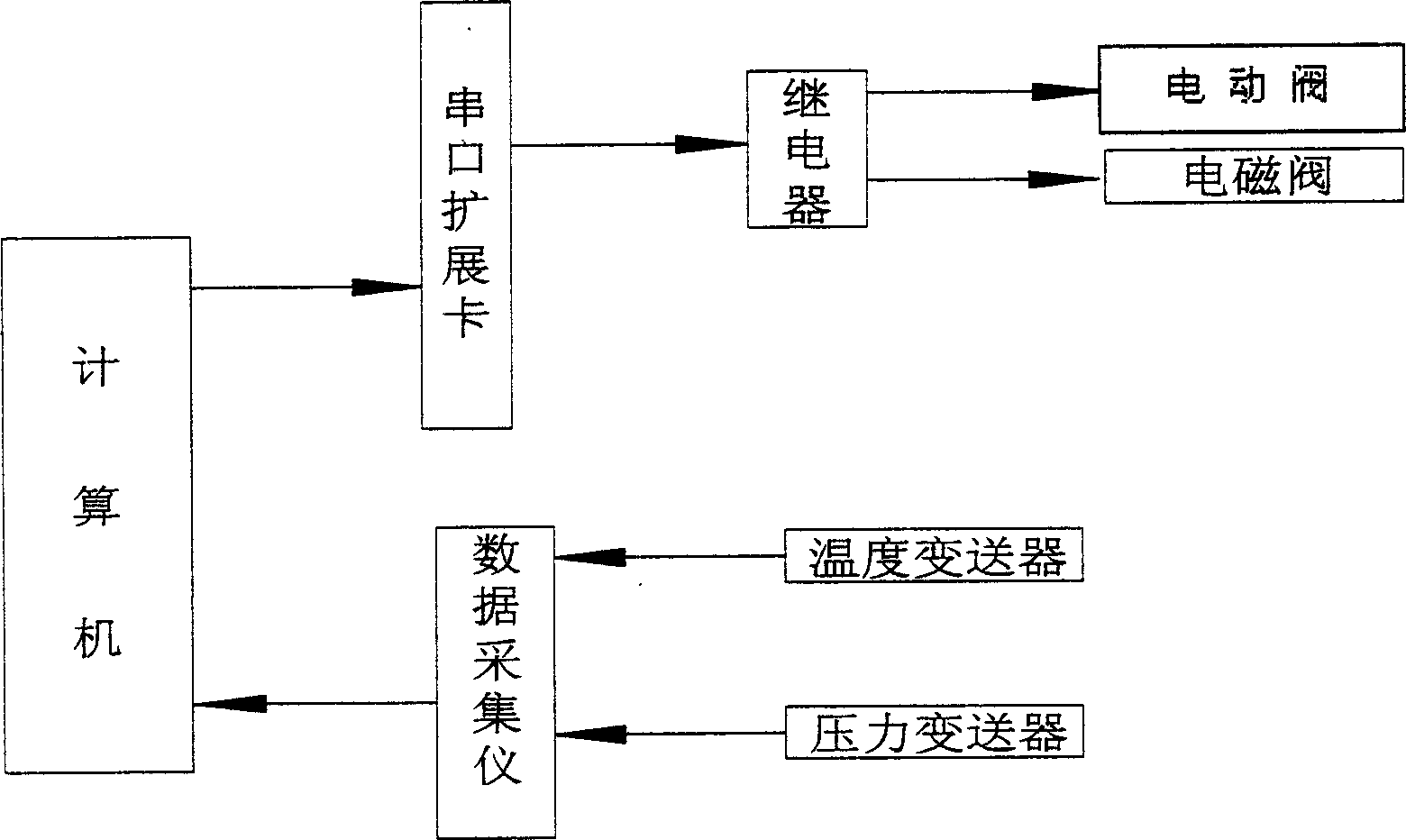

[0025] like figure 1As shown, the present invention is made up of reaction chamber 17 and hydrogen circulation system, liquid circulation system; The inlet and outlet 18 of reaction chamber 17 is connected with hydrogen circulation system by quick joint 28, and reaction chamber 17 is immersed in the open container 14 that fills constant temperature liquid simultaneously in, or placed in a temperature-controlled electric furnace 40. The copper tube 23 of the reaction chamber 17 is equipped with a hydrogen storage alloy 22; the inlet and outlet 18 of the two reaction chambers 17 immersed in the constant temperature liquid are connected to one end of the filter 27; the other end of the filter 27 is connected to one end of the quick connector 28; The other end of the quick joint 28 is connected with two ports of the first three-way 29 ; the first three-way 29 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com