Fuel assembly deformation detection system based on underwater binocular vision

A fuel assembly and detection system technology, applied to measurement devices, instruments, optical devices, etc., can solve the problems of sensitive placement angle, inability to accurately measure key parameters of spent fuel assemblies, time-consuming and labor-intensive, etc., to achieve convenient use and measurement parameters. Rich, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

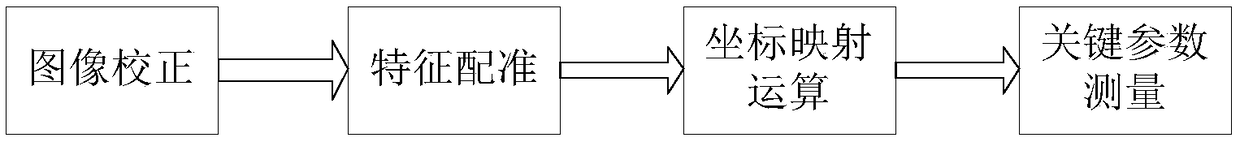

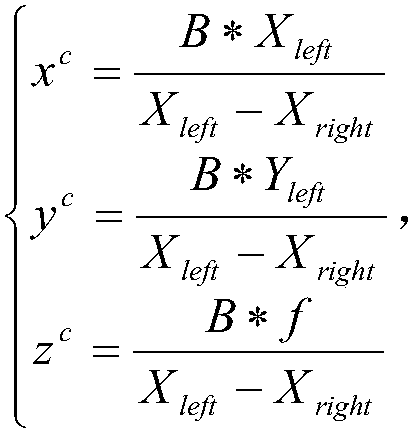

[0022] Based on 16 groups of underwater camera units, the present invention realizes synchronous imaging of the overall appearance of the spent fuel assembly through hardware external triggering. The three-dimensional coordinate values of the key parameters, and then according to the characteristics of the key parameters, the parameter measurement data and the overall deformation state of the component can be obtained.

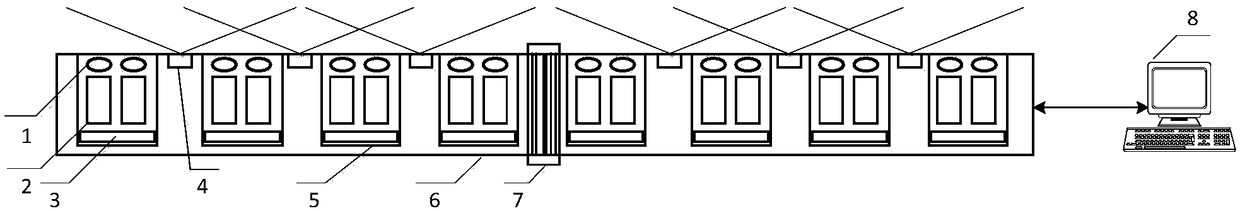

[0023] like figure 1 As shown, the present invention is composed of a high-definition optical lens 1, a CMOS camera 2, a hardware trigger module 3, a uniform light source 4, a water-sealed casing 5, a segment reference module 6, a threaded buckle 7 and a computer 8.

[0024] The working process of the fuel assembly deformation detection system based on underwater binocular vision in this embodiment is as follows:

[0025] U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com