Comprehensive simulation experiment system and method for engine front-end wheel train

A front-end gear train and simulation experiment technology, which is applied in engine testing, machine/structural component testing, measuring devices, etc., can solve the problem of not being able to determine components in time, unable to judge whether the matching parameters are within the qualified value range, or accurately obtain each component Problems such as performance parameters and coordination performance parameters, to achieve the effect of ensuring authenticity and reliability, changeable gear train speed, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

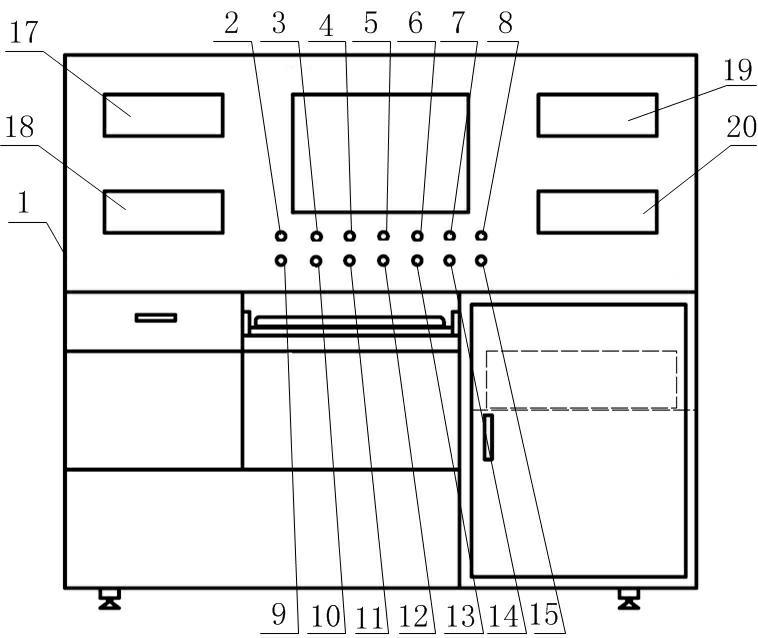

[0027] Engine front-end gear train comprehensive simulation experiment system, which includes engine front-end gear train comprehensive simulation experiment system test bench and engine front-end gear train comprehensive simulation experiment system console;

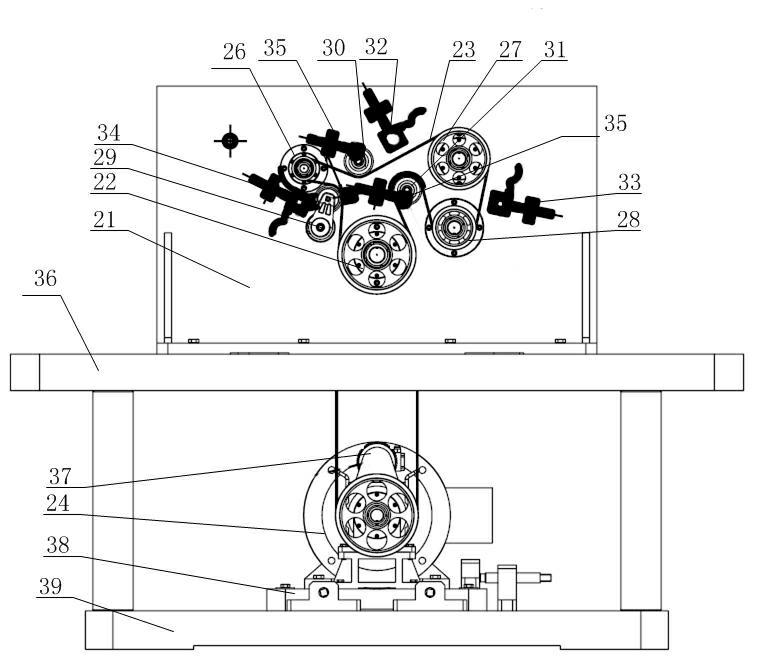

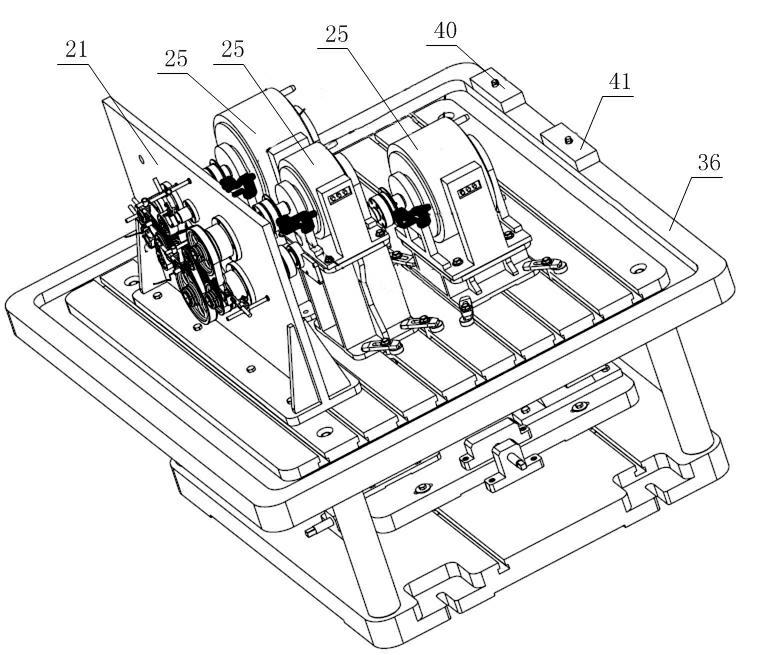

[0028] The test bench of the comprehensive simulation experiment system for the front end of the engine includes a fixed panel 21, on which the front end of the engine is installed, and the front end of the engine includes the engine pulley 22, the automatic tensioner 29, the load pulley And the idler gear, the distribution position of the engine front wheel train on the fixed panel 21 is the same as its actual installation position on the car, each pulley is installed on the fixed panel 21 through the pulley shaft, and is connected by a belt 23, and the rear end of the engine pulley shaft A main motor 24 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com